Evaluation of Thermal Conductivity of Sustainable Concrete Having Supplementary Cementitious Materials (SCMs) and Recycled Aggregate (RCA) Using Needle Probe Test

Abstract

:1. Introduction

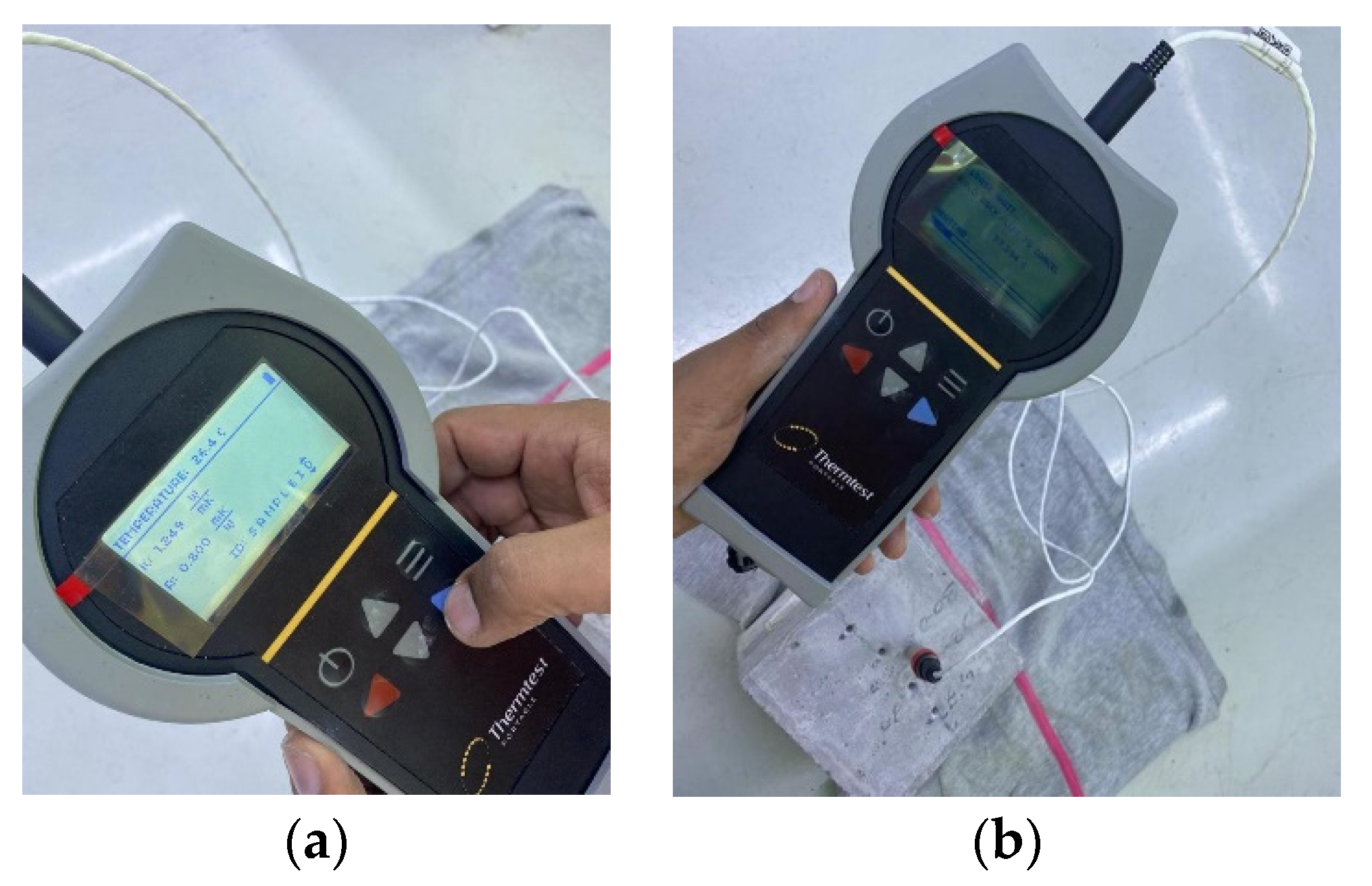

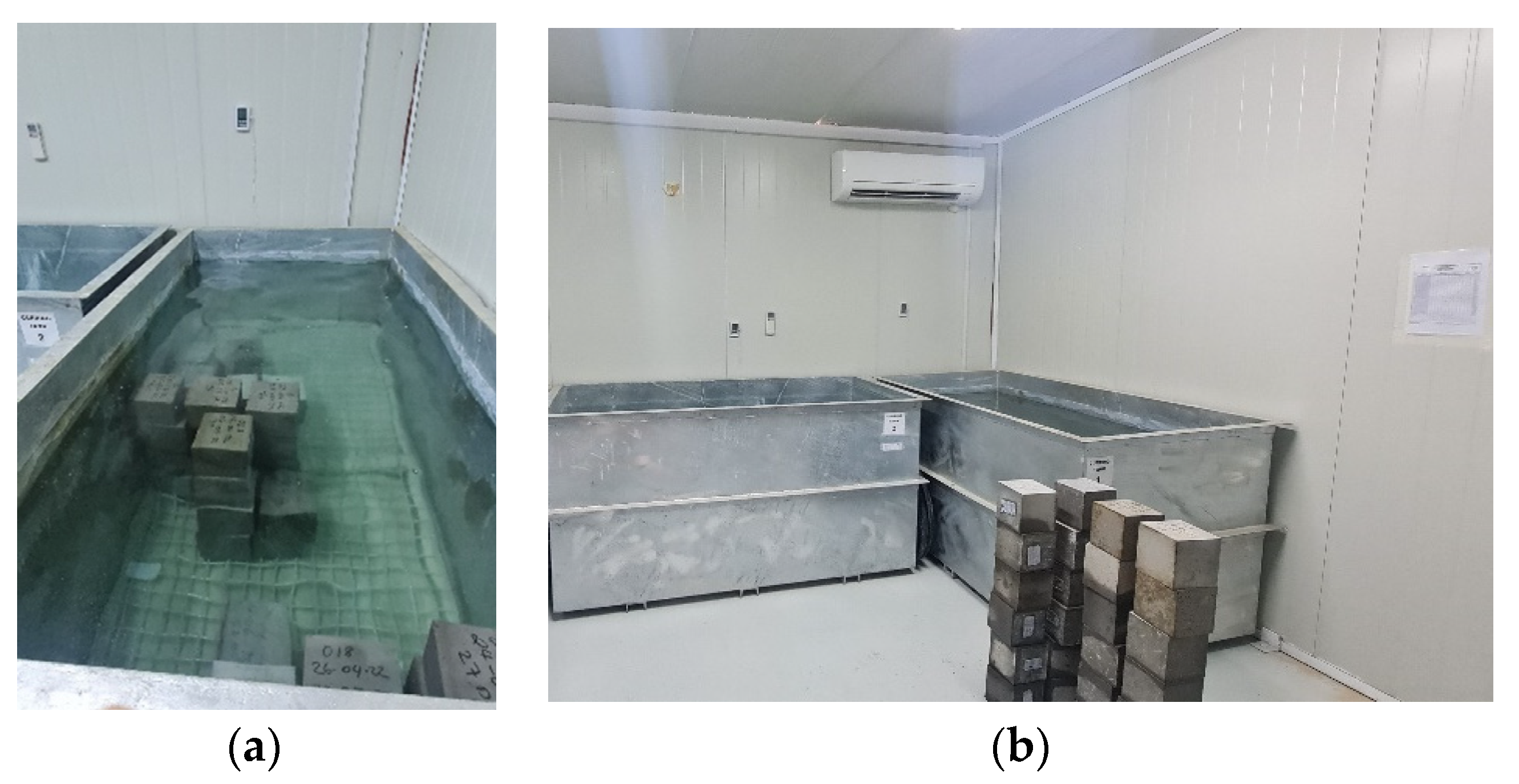

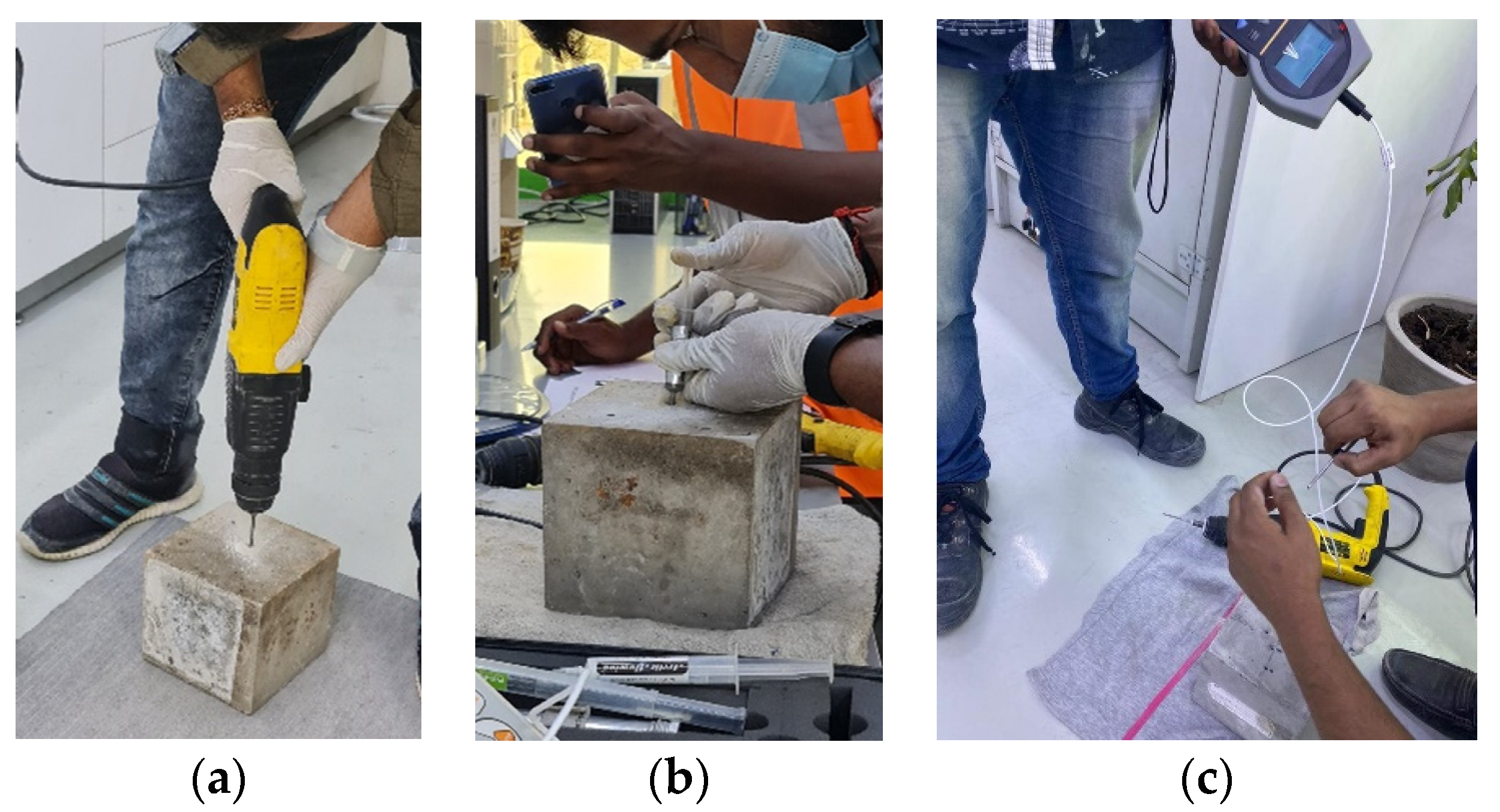

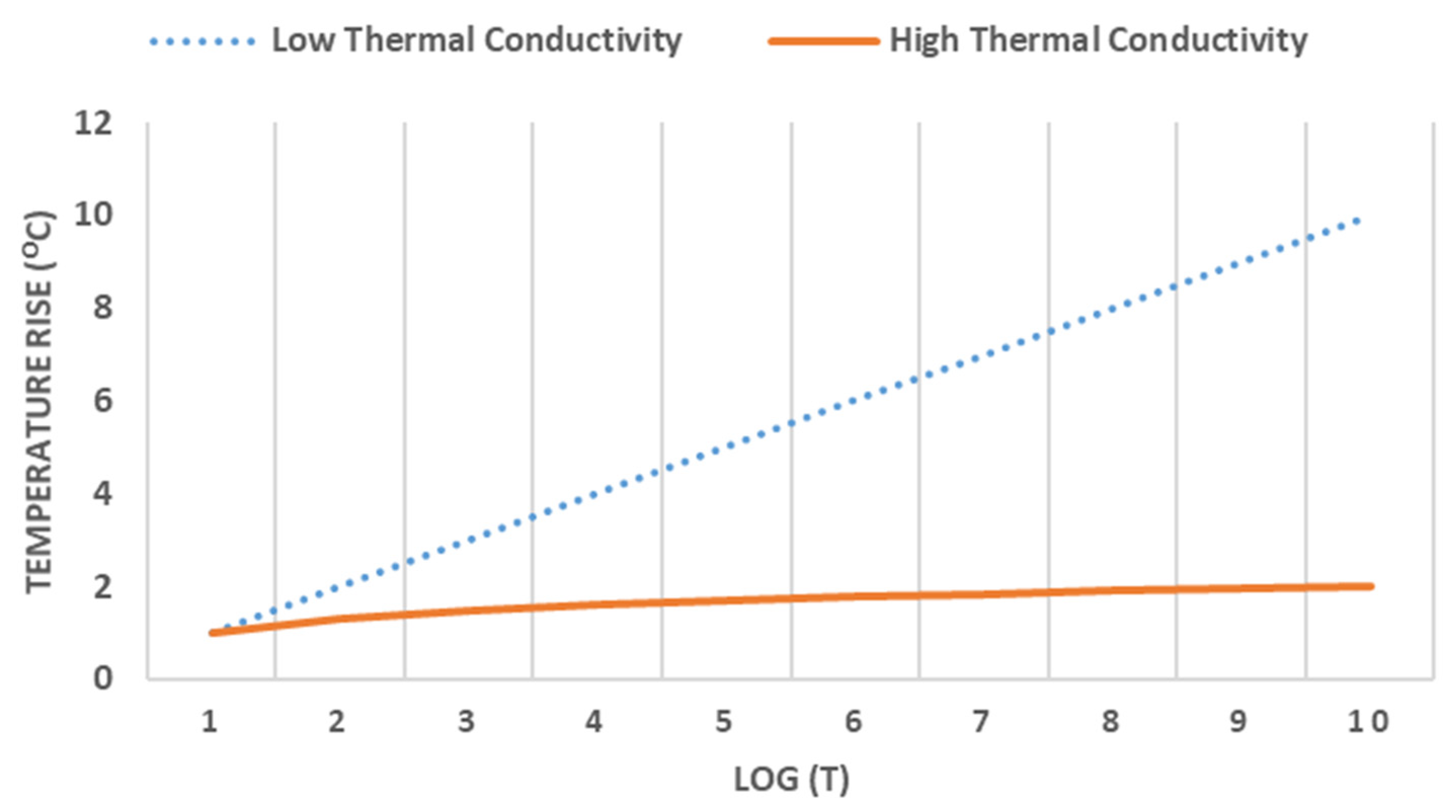

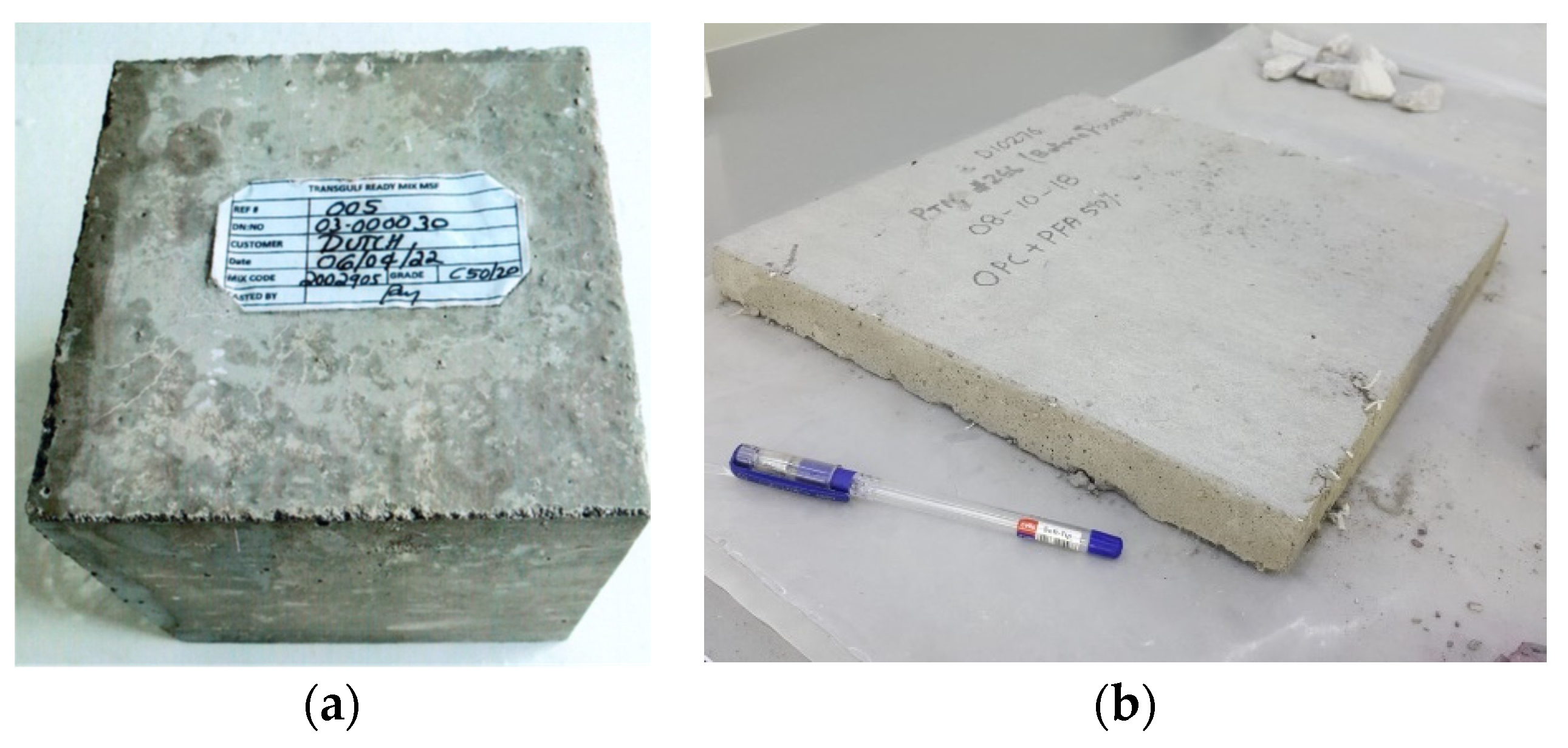

2. Materials and Methods

3. Results and Discussion

3.1. Thermal Properties of the Studied Structural Concrete Mixes

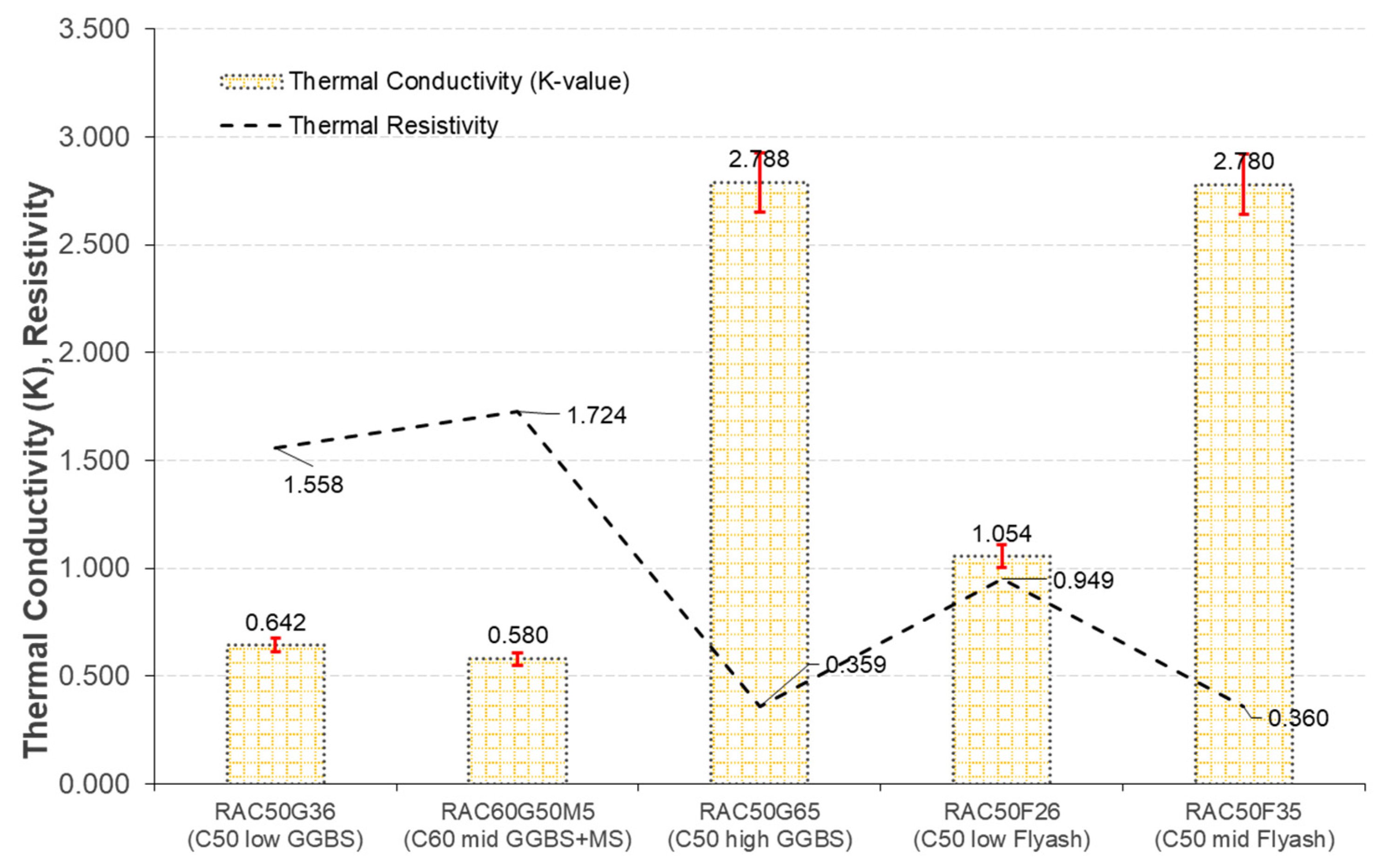

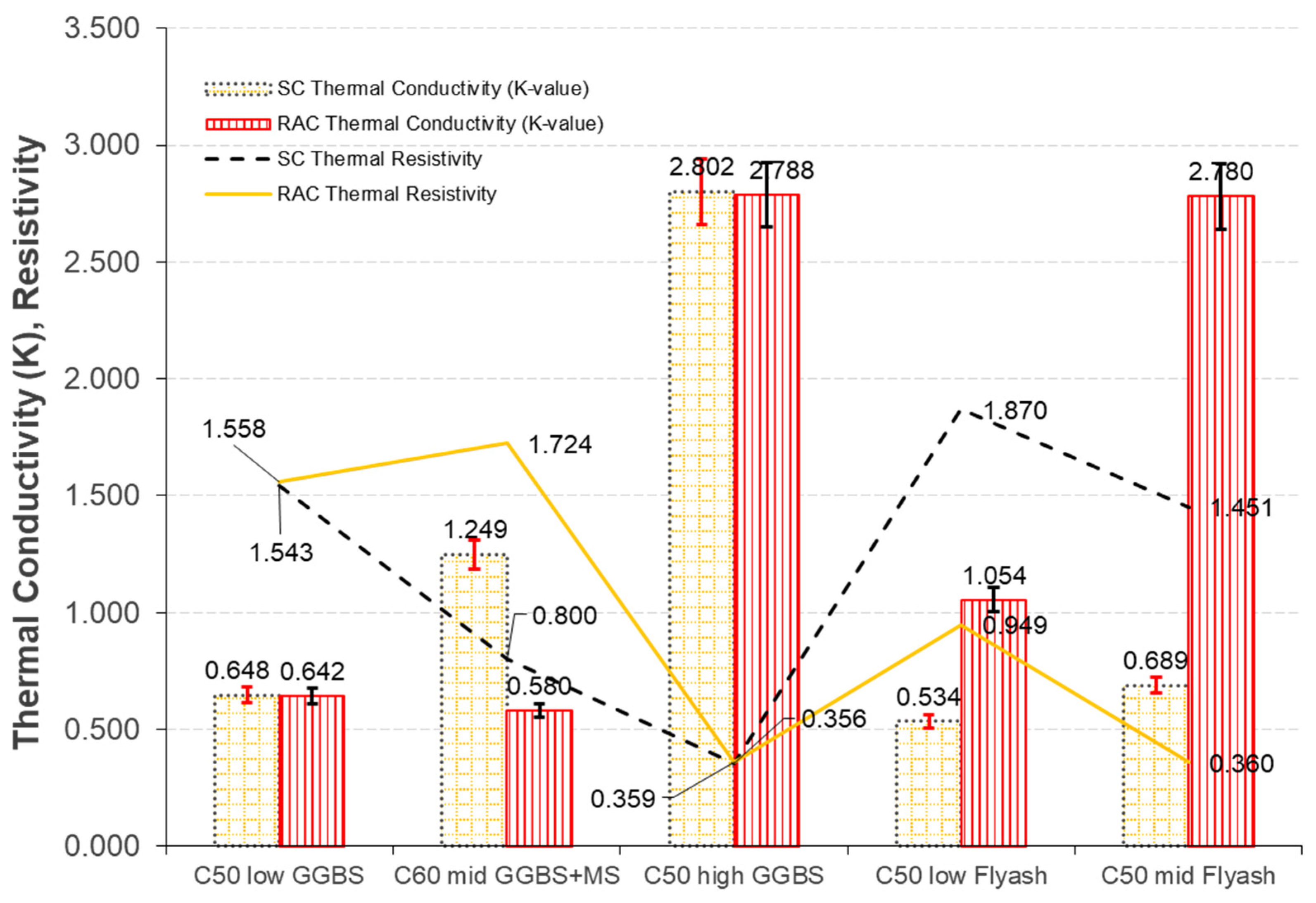

3.2. Thermal Properties of the Studied Recycled Aggregate Concrete Mixes

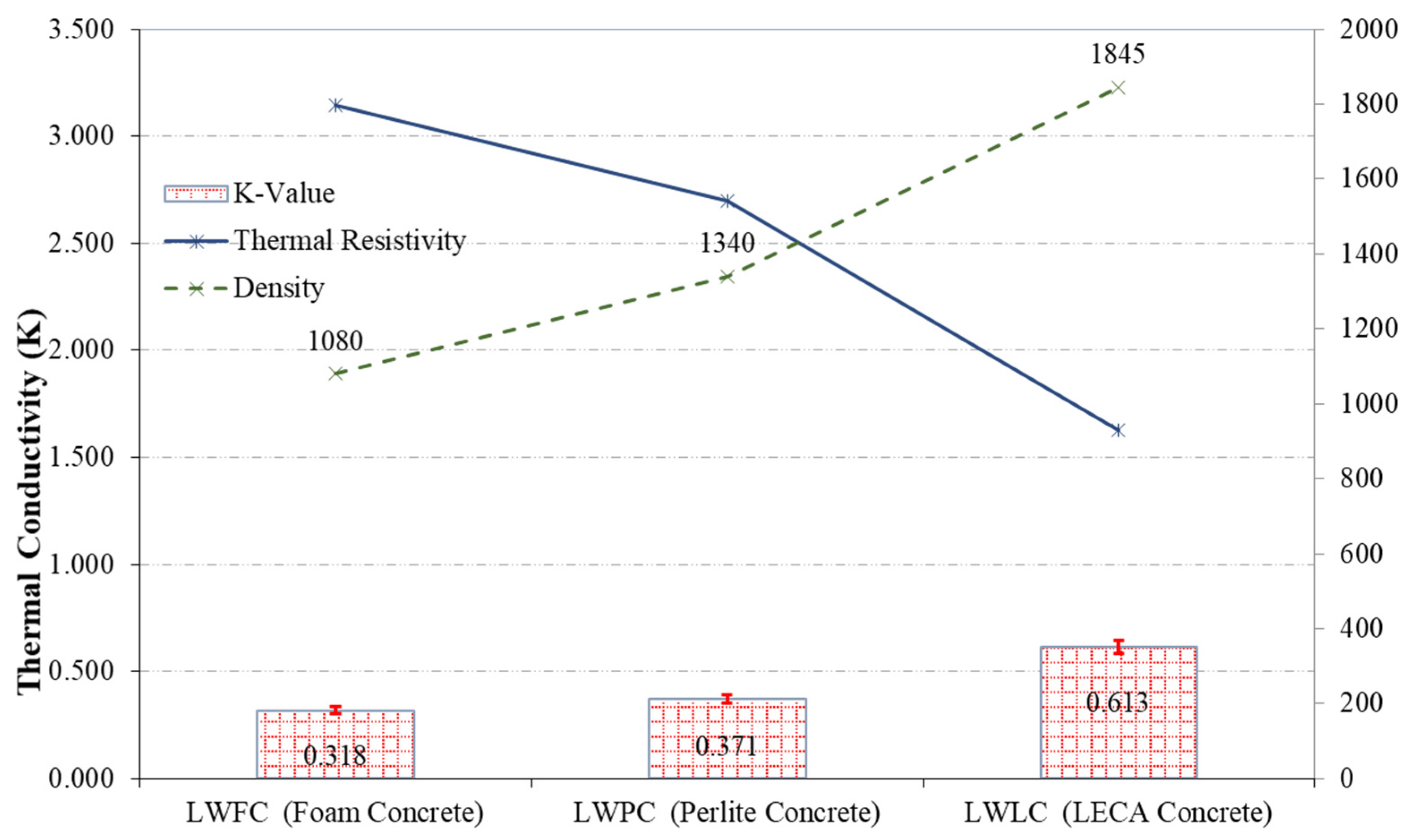

3.3. Thermal Properties of the Studied Lightweight Concrete Mixes

3.4. Discussion

4. Conclusions

- As a general finding, increasing SCM (GGBS and Flyash) content in the concrete mixture increased its thermal conductivity.

- GGBS showed a high impact on thermal properties, as the thermal conductivity increased four times when the dosage increased from low to high.

- Sustainability should be checked when GGBS is used at high dosages. GGBS was found to have a high thermal conductivity, which may produce structures with higher energy dissipation than those produced using concrete incorporating lower dosages or no GGBS replacement. When conducting a full lifecycle assessment of the structure, the CO2 emission saving generated from the use of less cement in the concrete mix may be offset by the larger energy losses due to the higher thermal conductivity of the concrete incorporating high dosages of GGBS.

- Due to the different heat transmission methodologies and different sample geometry and preparation, the reported thermal conductivity value in accordance with ASTM D5334-14 is found to be higher by 3 to 6 times than the values reported using steady-state thermal transmission by the heat flow meter apparatus in accordance with ASTM C518-15.

- The ternary-blended mixture (50% GGBS and 5% of microsilica) with 40% recycled aggregate had the second lowest thermal conductivity among the structural mixtures.

- Substituting 40% of natural aggregates with recycled aggregates has negligible impact on the thermal properties of concrete incorporating GGBS, as the concrete experienced just a 1% difference in thermal conductivity and resistivity between NAC and RAC.

- Fly ash showed more impact on RAC compared with NAC, as the thermal conductivity of RAC increased by 2.6 times when fly ash content increased from 26% to 35%, while the increase was only 1.3% for NAC.

- The conductivity measurements for lightweight foam concrete and perlite concrete reported the lowest thermal conductivity results.

- LECA concrete expressed a relatively high thermal conductivity as a lightweight concrete mixture, which is very close to the normal-weight structural concrete mixtures despite its lower dry density of 1845 kg/m3.

- Sustainability considerations in construction should not be only based on one factor related to the cement contribution of CO2, but other factors, such as the effects of the SCMs on the thermal properties of concrete, should also be accounted for.

5. Future Study and Recommendations

Author Contributions

Funding

Conflicts of Interest

References

- Sabouni, R.; Abdulhameed, H. The Mechanical Properties and durability of High Strength Concrete with fly ash Incorporating UAE Local Materials. In Proceedings of the ConMat’15 Conference, Whistler, BC, Canada, 19–21 August 2015. [Google Scholar]

- Sabouni, R.; Abdulhameed, H.R. Optimization of Sustainable Concrete Mixes Containing Binary and Ternary Blends. Key Eng. Mater. 2020, 853, 131–141. [Google Scholar] [CrossRef]

- Sabouni, R.; Abdulhameed, H. Investigation on Performance of Concrete Incorporating Silica Fume and Local UAE Materials. Key Eng. Mater. 2019, 803, 222–227. [Google Scholar] [CrossRef]

- Kim, S.-W.; Park, W.-S.; Jang, Y.-I.; Yun, S.-H.; Yun, H.-D.; Kim, D.-G. The effect of mineral admixture on the compressive strength development of concrete. Contemp. Eng. Sci. 2015, 8, 541–547. [Google Scholar] [CrossRef]

- Celik, K.; Meral, C.; Manico, M.; Metha, P.K.; Monteiro, P. A comparative study of self-consolidating concretes incorporating high-volume natural pozzolan or high-volume fly ash. Constr. Build. Mater. 2014, 67, 14–19. [Google Scholar] [CrossRef]

- Naik, R.; Singh, S. Influence of fly ash on setting and hardening characteristics of concrete systems. ACI Mater. J. 1997, 94, 355–360. [Google Scholar]

- Al-Shaibani, A.; Sabouni, R. Sustainability Considerations of Concrete Mixes Incorporating Slag as Partial Re-placement of Cement in Concrete in the UAE. Key Eng. Mater. 2016, 677, 217–223. [Google Scholar] [CrossRef]

- Khartabil, A.; Al Martini, S. Thermal Transmission Properties of Sustainable Concrete with Supplementary Cementitious Materials. Key Eng. Mater. 2020, 853, 142–149. [Google Scholar] [CrossRef]

- Koniorczyk, M.; Grymin, W. Influence of the Thermal Conductivity and Ambient Temperature Uncertainty on the Heat Losses through the ExternalWall. Build. J. 2021, 11, 84. [Google Scholar] [CrossRef]

- Noh, H.; Kang, H.; Kim, M.; Park, H. Estimation Model for Effective Thermal Conductivity of Reinforced Concrete Containing Multiple Round Rebars. Int. J. Concr. Struct. Mater. 2018, 12, 65. [Google Scholar] [CrossRef]

- Misri, Z.; Ibrahim, M.H.W.; A Awal, A.S.M.; Desa, M.S.M.; Ghadzali, N.S. Review on factors influencing thermal conductivity of concrete incorporating various type of waste materials. IOP Conf. Ser. Earth Environ. Sci. 2018, 140, 012141. [Google Scholar] [CrossRef]

- Sargam, Y.; Wang, K.; Alleman, J.E. Effects of Modern Concrete Materials on Thermal Conductivity. J. Mater. Civ. Eng. 2020, 32, 04020058. [Google Scholar] [CrossRef]

- Chen, G.; Li, F.; Jing, P.; Geng, J.; Si, Z. Effect of Pore Structure on Thermal Conductivity and Mechanical Properties of Au-toclaved Aerated Concrete. Mater. J. 2021, 14, 339. [Google Scholar] [CrossRef] [PubMed]

- Mydin, M.O.; Awang, H.; Roslan, A.F. Determination of lightweight foamed concrete thermal properties integrating various additives. Elixir Cem. Concr. Compos. Int. J. 2012, 48, 9286–9291. [Google Scholar]

- ACI Committee 122. ACI 122R-14: Guide to Thermal Properties of Concrete and Masonry Systems, Reported by ACI/TMS Committee 122; The Masonry Society: Farmington Hills, MI, USA, 2014. [Google Scholar]

- Du, Y.; Ge, Y. Multiphase Model for Predicting the Thermal Conductivity of Cement Paste and Its Applications. Materials 2021, 14, 4525. [Google Scholar] [CrossRef] [PubMed]

- Yeheyis, M.; Hewage, K.; Alam, M.S.; Eskicioglu, C.; Sadiq, R. An overview of construction and demolition waste management in Canada: A lifecycle analysis approach to sustainability. Clean Technol. Environ. Policy 2012, 15, 81–91. [Google Scholar] [CrossRef]

- Al Martini, S.; Khartabil, A.; Neithalath, N. Rheological Properties of Recycled Aggregate Concrete Incorporating Supplementary Cementitious Materials. ACI Mater. J. 2021, 118, 241–253. [Google Scholar]

- Al Martini, S.; AL Mzayyen, N.; Sabouni, R.; Shahria, A. Investigation on Bond Performance Between Basalt FRP Rebars and Recycled aggregate concrete CSCE 2021 Annual Conference. In Proceedings of the Canadian Society of Civil Engineering Annual Conference 2021, Virtual, 26–29 May 2021; 248, pp. 695–705. [Google Scholar]

- Smith, J.; Tighe, S. Recycled Concrete Aggregate Coefficient of Thermal Expansion. Transportation Research Record. J. Transp. Res. Board 2009, 2113, 53–61. [Google Scholar] [CrossRef]

- ASTM D5334-14; ASTM Subcommittee D18.12 on Rock Mechanics. Standard Test Method for Determination of Thermal Conductivity of Soil and Soft Rock by Thermal Needle Probe Procedure. American Society for Testing and Materials: West Conshohocken, PA, USA, 2014.

- ASTM C518-15; Subcommittee C16.30 on Thermal Measurement. Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus. American Society for Testing and Materials: West Conshohocken, PA, USA, 2015.

- BS EN 197-1:2019; Cement—Composition, Specifications and Conformity Criteria for Common Types of Cement. The British Standards Institution: London, UK, 2022.

- BS 8500-1:2015; Concrete—Complementary British Standard to BS EN 206. Method of Specifying and Guidance for the Specifier (+A1:2016). The British Standards Institution (BSI Standards Limited): London, UK, 2016.

- Thermtest Inc. Transient Line Source Thermtest Portable Thermal Conductivity Meter Brochure; Thermtest Inc.: Hanwell, NB, Canada, 2017. [Google Scholar]

- Niall, D.; West, R.; Kinnane, O.; McCormack, S. Influence of Ground Granulated Blast furnace Slag on the thermal properties of PCM-concrete composite panels. In Proceedings of the Advanced Building Skins Conference 2016, Bern, Switzerland, 10–11 October 2016; pp. 963–973. [Google Scholar]

- Choktaweekarna, P.; Tangtermsirikul, S. A model for predicting the coefficient of thermal expansion of cementitious paste. ScienceAsia 2009, 35, 57–63. [Google Scholar] [CrossRef]

| Mixtures Group | Description | Symbol | Grade (MPa) | OPC (%) | GGBS (%) | Flyash (%) | Microsilica (%) | Dry Density (kg/m3) |

|---|---|---|---|---|---|---|---|---|

| Structural Concrete (SC) | C50 low GGBS | SC50G36 | 50 | 64 | 36 | - | - | 2490 |

| C50 mid GGBS | SC50G50 | 50 | 50 | 50 | - | - | 2500 | |

| C60 GGBS + MS | SC60G50M5 | 60 | 45 | 50 | - | 5 | 2460 | |

| C50 high GGBS | SC50G65 | 50 | 35 | 65 | - | - | 2490 | |

| C50 low Flyash | SC50F26 | 50 | 74 | - | 26 | - | 2470 | |

| C50 mid Flyash | SC50F35 | 50 | 65 | - | 35 | - | 2470 | |

| Recycled Aggregate Concrete (RAC) | C50 low GGBS | RAC50G36 | 50 | 64 | 36 | - | - | 2460 |

| C60 GGBS + MS | RAC60G50M5 | 60 | 45 | 50 | - | 5 | 2480 | |

| C50 high GGBS | RAC50G65 | 50 | 35 | 65 | - | - | 2465 | |

| C50 low Flyash | RAC50F26 | 50 | 74 | - | 26 | - | 2450 | |

| C50 mid Flyash | RAC50F35 | 50 | 65 | - | 35 | - | 2455 | |

| Lightweight Concrete | Foam Concrete | LWFC | 1 | 100 | - | - | - | 1080 |

| Perlite Concrete | LWPC | 8 | 100 | - | - | - | 1340 | |

| LECA Concrete | LWLC | 50 | 67 | 26 | - | 7 | 1845 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al Martini, S.; Khartabil, A.; Sabouni, R. Evaluation of Thermal Conductivity of Sustainable Concrete Having Supplementary Cementitious Materials (SCMs) and Recycled Aggregate (RCA) Using Needle Probe Test. Sustainability 2023, 15, 109. https://doi.org/10.3390/su15010109

Al Martini S, Khartabil A, Sabouni R. Evaluation of Thermal Conductivity of Sustainable Concrete Having Supplementary Cementitious Materials (SCMs) and Recycled Aggregate (RCA) Using Needle Probe Test. Sustainability. 2023; 15(1):109. https://doi.org/10.3390/su15010109

Chicago/Turabian StyleAl Martini, Samer, Ahmad Khartabil, and Reem Sabouni. 2023. "Evaluation of Thermal Conductivity of Sustainable Concrete Having Supplementary Cementitious Materials (SCMs) and Recycled Aggregate (RCA) Using Needle Probe Test" Sustainability 15, no. 1: 109. https://doi.org/10.3390/su15010109

APA StyleAl Martini, S., Khartabil, A., & Sabouni, R. (2023). Evaluation of Thermal Conductivity of Sustainable Concrete Having Supplementary Cementitious Materials (SCMs) and Recycled Aggregate (RCA) Using Needle Probe Test. Sustainability, 15(1), 109. https://doi.org/10.3390/su15010109