Evaluation of Resilience Parameters of Soybean Oil-Modified and Unmodified Warm-Mix Asphalts—A Way Forward towards Sustainable Pavements

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

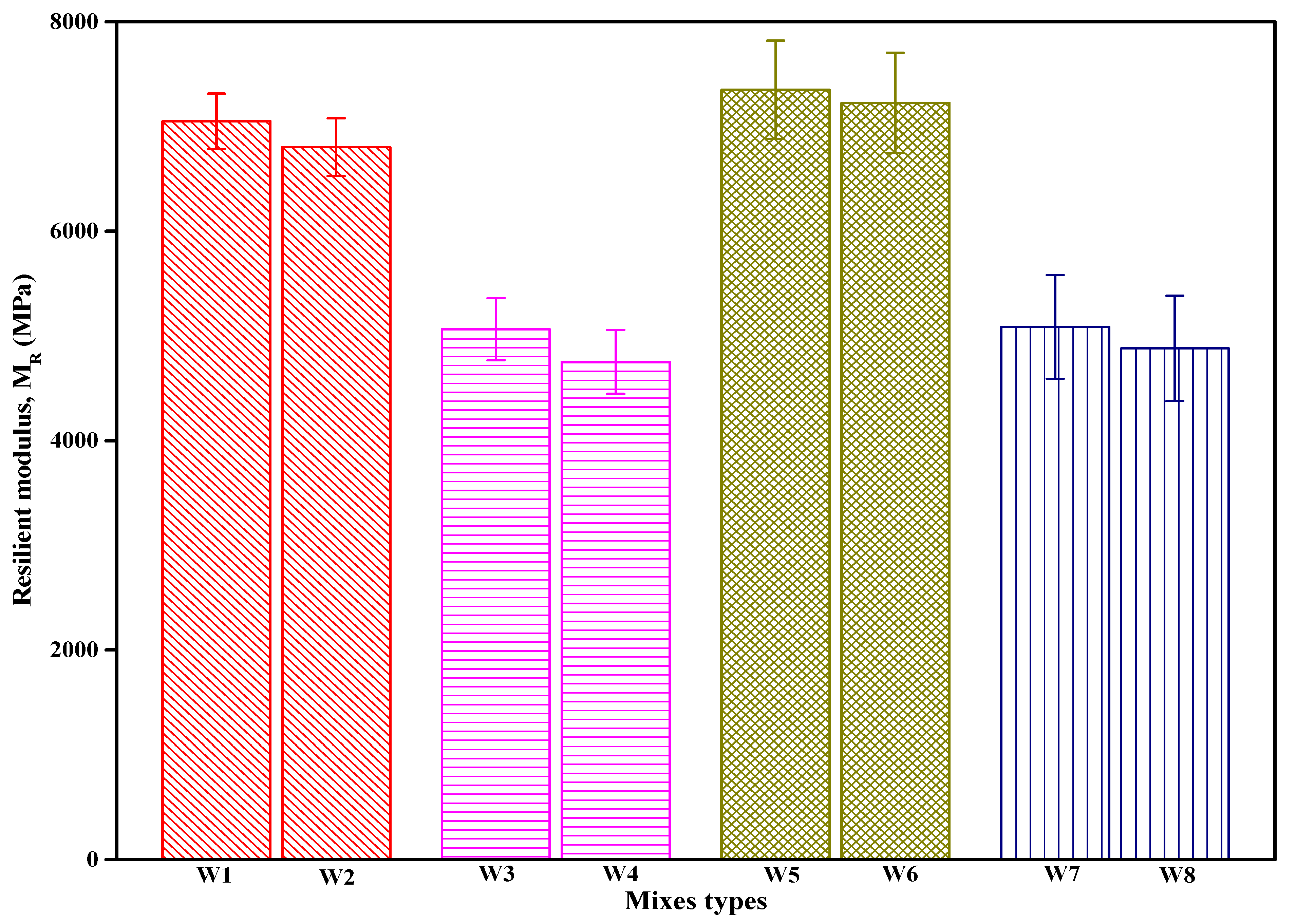

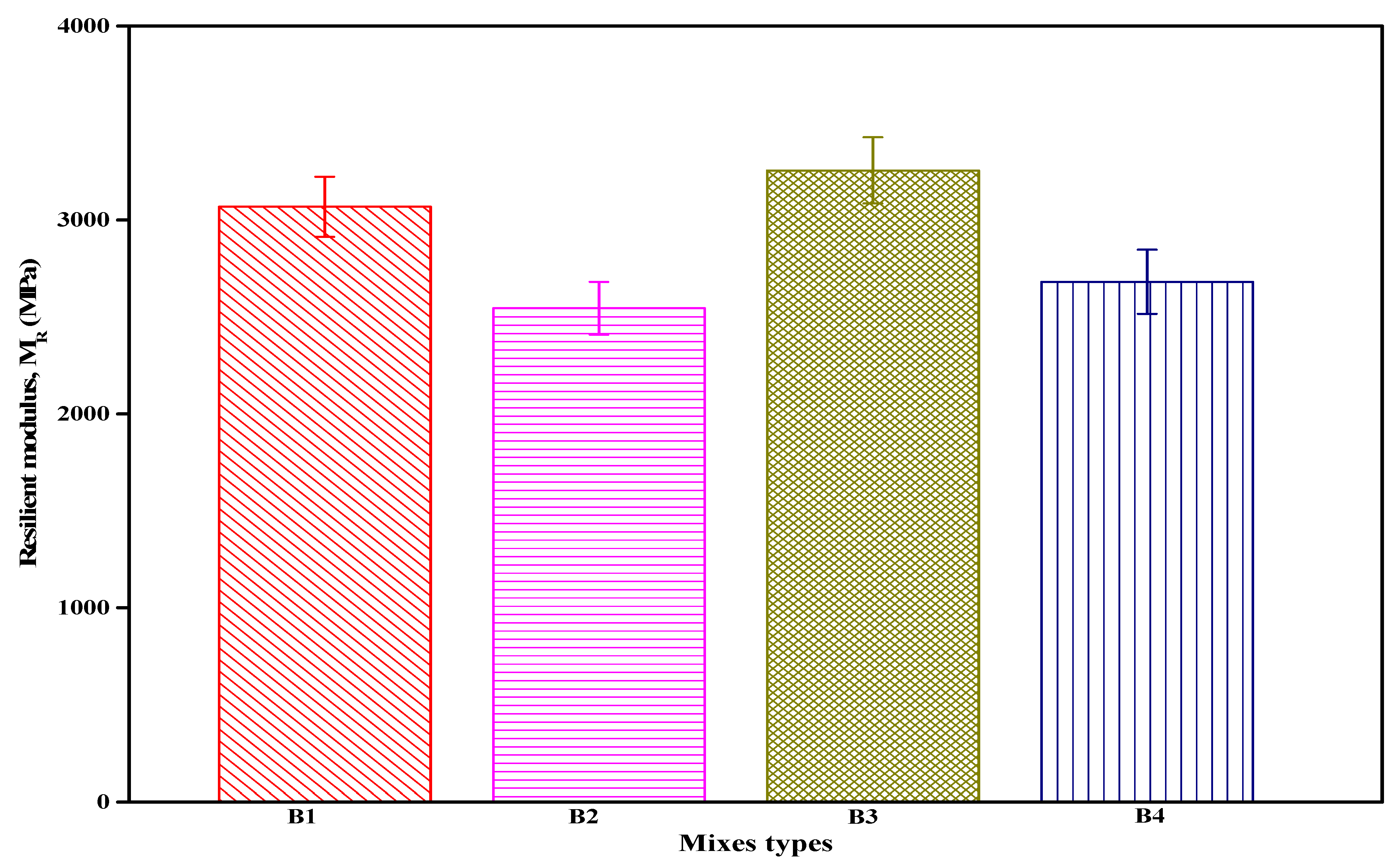

- The soybean-modified warm asphalt mixes showed a 20% to 32% reduction in load-carrying capacity, i.e., for the resilient modulus than the unmodified warm asphalt mixes.

- The values of the horizontal and vertical recoverable deformations remained comparable (3% to 7%) in both the soybean-modified and unmodified warm asphalt mixes.

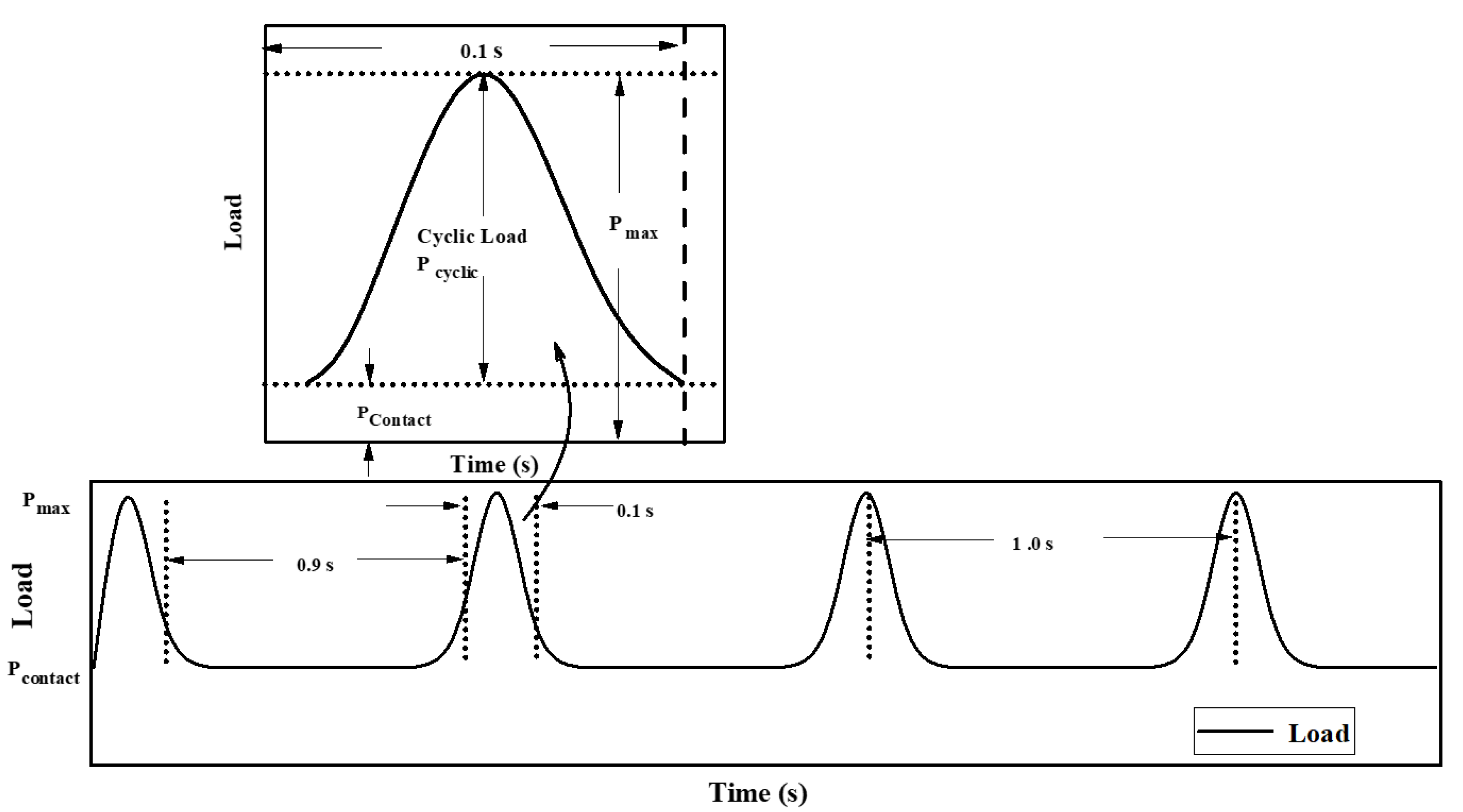

- A slight variability (2% to 7%) was observed in the time-response spectra, i.e., peak, unload, rest periods of loads and deformations during the resilient modulus tests performed on the soybean-modified and unmodified warm asphalt mixes.

- Each parameter obtained in the soybean-modified warm-mix asphalt resilient modulus test showed a reasonable correlation trend with the others, as depicted by the Pearson coefficient. Hence, the trends of the soybean-modified and unmodified warm-mix asphalt in resilient modulus tests are comparable.

- Soybean oil showed sustainable behavior as bio-binder, particularly in the deformation-time response for warm asphalt mixes. However, the effect of soybean in the reduction of the load-carrying capacity from a sustainability perspective needs to be investigated.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rahman, I.; Sharma, B.P.; Fetuu, E.; Yousaf, M. Do Roads Enhance Regional Trade? Evidence Based on China’s Provincial Data. J. Asian Financ. Econ. Bus. 2020, 7, 657–664. [Google Scholar] [CrossRef]

- Javid, M. Public and Private Infrastructure Investment and Economic Growth in Pakistan: An Aggregate and Disaggregate Analysis. Sustainability 2019, 11, 3359. [Google Scholar] [CrossRef] [Green Version]

- Holl, A. Transport Infrastructure, Agglomeration Economies, and Firm Birth: Empirical Evidence from Portugal. J. Reg. Sci. 2004, 44, 693–712. [Google Scholar] [CrossRef]

- Gibbons, S.; Lyytikäinen, T.; Overman, H.; Sanchis-Guarner, R. New road infrastructure: The effects on Arms. J. Urban Econ. 2019, 110, 35–50. [Google Scholar] [CrossRef]

- Lopez, M.A.G.; Holl, A.; Marsal, E.V. Suburbanization and highways in Spain when the Romans and the Bourbons still shape its cities. J. Urban Econ. 2015, 85, 52–67. [Google Scholar] [CrossRef]

- Coşar, A.K.; Demir, B. Domestic road infrastructure and international trade: Evidence from Turkey. J. Dev. Econ. 2016, 118, 232–244. [Google Scholar] [CrossRef]

- Ghani, E.; Goswami, A.G.; Kerr, W.R. Highway to Success: The Impact of the Golden Quadrilateral Project for the Location and Performance of Indian Manufacturing. Econ. J. 2015, 126, 317–357. [Google Scholar] [CrossRef]

- Thom, N.; Dawson, A. Sustainable Road Design: Promoting Recycling and Non-Conventional Materials. Sustainability 2019, 11, 6106. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.; Goulias, D.; Peterson, D. Recycled Asphalt Pavement Materials in Transport Pavement Infrastructure: Sustainability Analysis & Metrics. Sustainability 2021, 13, 8071. [Google Scholar] [CrossRef]

- Lee, J.; Edil, T.B.; Benson, C.H.; Tinjum, J. Building Environmentally and Economically Sustainable Transportation Infrastructure: Green Highway Rating System. J. Constr. Eng. Manag. 2013, 139, A4013006. [Google Scholar] [CrossRef]

- Ibrahim, A.H.; Shaker, M.A. Sustainability index for highway construction projects. Alex. Eng. J. 2019, 58, 1399–1411. [Google Scholar] [CrossRef]

- Yang, X.; You, Z.; Dia, Q.; Beale, J.M. Mechanical performance of asphalt mixtures modified by bio-oils derived from waste wood resources. Constr. Build. Mater. 2014, 51, 424–431. [Google Scholar] [CrossRef]

- Williams, R.C.; Peralta, J.; Puga, K.L.N. Development of Non-Petroleum-Based Binders for Use in Flexible Pavements—Phase II (Report No. IHRB Project TR-650); Iowa Department of Transportation, Iowa State University: Ames, IA, USA, 2015. [Google Scholar]

- Saravanan, U. On the use of linear viscoelastic constitutive relations to model asphalt. Int. J. Pavement Eng. 2012, 13, 360–373. [Google Scholar] [CrossRef]

- Elseifi, M.A.; Mohammad, L.N.; Cooper, S.B., III. Laboratory evaluation of asphalt mixtures containing sustainable technologies. J. Assoc. Asph. Paving Technol. 2011, 80, 227–254. [Google Scholar]

- Hajj, E.; Souliman, M.; Alavi, M.; Loría Salazar, L. Influence of hydro green bio asphalt on viscoelastic properties of reclaimed asphalt mixtures. Transp. Res. Rec. J. Transp. Res. Board 2013, 2371, 13–22. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Frank, R. Evaluation of Rejuvenator’s Effectiveness with Conventional Mix Testing for 100% Reclaimed Asphalt Pavement Mixtures. Transp. Res. Rec. J. Transp. Res. Board 2013, 2370, 17–25. [Google Scholar] [CrossRef] [Green Version]

- Podolsky, J.H.; Buss, A.; Williams, R.C.; Cochran, E.W. Effect of bio-derived/chemical additives on warm mix asphalt compaction and mix performance at low temperature. Cold Reg. Sci. Technol. 2017, 136, 52–61. [Google Scholar] [CrossRef]

- Elkashef, M.; Podolsky, J.; Williams, R.C.; Cochran, E.W. Introducing a soybean oil-derived material as a potential rejuvenator of asphalt through rheology, mix characterization and Fourier Transform Infrared analysis. Road Mater. Pavement Des. 2017, 19, 1–21. [Google Scholar] [CrossRef]

- Podolsky, J.H.; Williams, R.C.; Cochran, E. Effect of corn and soybean oil derived additives on polymer-modified HMA and WMA master curve construction and dynamic modulus performance. Int. J. Pavement Res. Technol. 2018, 11, 541–552. [Google Scholar] [CrossRef]

- Podolsky, J.H.; Chen, C.; Buss, A.F.; Williams, R.C.; Cochran, E.W. Effect of bio-derived/chemical additives on HMA and WMA compaction and dynamic modulus performance. Int. J. Pavement Eng. 2019, 22, 613–624. [Google Scholar] [CrossRef]

- Tarar, M.A.; Khan, A.H.; Rehman, Z.U. Evaluation of effects of soybean derived oil and aggregate petrology on the performance of asphalt mixes. Road Mater. Pavement Des. 2020, 23, 308–334. [Google Scholar] [CrossRef]

- Swamy, A.K.; Daniel, J.S. Effect of Mode of Loading on Viscoelastic and Damage Properties of Asphalt Concrete. Transp. Res. Rec. J. Transp. Res. Board 2012, 2296, 144–152. [Google Scholar] [CrossRef]

- Nejad, F.M.; Azarhoosh, A.R.; Hamedi, G.H. Laboratory Evaluation of Using Recycled Marble Aggregates on the Mechanical Properties of Hot Mix Asphalt. J. Mater. Civ. Eng. 2013, 25, 741–746. [Google Scholar] [CrossRef]

- Wen, H.; Bhusal, S.; Wen, B. Laboratory evaluation of waste cooking oil-based bio asphalt as an alternative binder for hot mix asphalt. J. Mater. Civ. Eng. 2013, 25, 1432–1437. [Google Scholar] [CrossRef]

- Feng, H.; Pettinari, M.; Hofko, B.; Stang, H. Study of the internal mechanical response of an asphalt mixture by 3-D discrete element modeling. Constr. Build. Mater. 2015, 77, 187–196. [Google Scholar] [CrossRef]

- Pan, P.; Kuang, Y.; Hu, X.; Zhang, X. A Comprehensive Evaluation of Rejuvenator on Mechanical Properties, Durability, and Dynamic Characteristics of Artificially Aged Asphalt Mixture. Materials 2018, 11, 1554. [Google Scholar] [CrossRef] [Green Version]

- Islam, R.; Kalevela, S.A.; Mendel, G. How the Mix Factors Affect the Dynamic Modulus of Hot-Mix Asphalt. J. Compos. Sci. 2019, 3, 72. [Google Scholar] [CrossRef] [Green Version]

- Kim, Y.; Lee, J.; Baek, C.; Yang, S.; Kwon, S.; Suh, Y. Performance Evaluation of Warm- and Hot-Mix Asphalt Mixtures Based on Laboratory and Accelerated Pavement Tests. Adv. Mater. Sci. Eng. 2012, 2012, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Ouf, M.S.; Abdolsamed, A.A. Controlling Rutting Performance of Hot Mix Asphalt. Int. J. Sci. Eng. Res. 2016, 6, 2229–5518. [Google Scholar]

- Al-Qadi, I.L.; Yoo, P.J.; Elseifi, M.A.; Nelson, S. Creep Behavior of Hot-Mix Asphalt due to Heavy Vehicular Tire Loading. J. Eng. Mech. 2009, 135, 1265–1273. [Google Scholar] [CrossRef]

- Ahmad, J.; Rahman, M.Y.A.; Hainin, M.R. Rutting Evaluation of Dense Graded Hot Mix Asphalt Mixture. Int. J. Eng. Technol. 2011, 11, 48–52. [Google Scholar]

- Huang, Y.; Wang, X.; Liu, Z.; Li, S. Dynamic modulus test and master curve analysis of asphalt mix with trapezoid beam method. Road Mater. Pavement Des. 2017, 18, 1–11. [Google Scholar] [CrossRef]

- Rahman, A.A.S.M.; Islam, M.R.; Tarefder, R.A. Assessment and modification of nationally-calibrated dynamic modulus predictive model for the implementation of Mechanistic-Empirical design. Int. J. Pavement Res. Technol. 2018, 11, 502–508. [Google Scholar] [CrossRef]

- Khedr, S.A.; Breakah, T.M. Rutting parameters for asphalt concrete for different aggregate structures. Int. J. Pavement Eng. 2011, 12, 13–23. [Google Scholar] [CrossRef]

- Ezzat, H.; El-Badawy, S.; Gabr, A.; Zaki, S.; Breakah, T. Predicted performance of hot mix asphalt modified with nano-montmorillonite and nano-silicon dioxide based on Egyptian conditions. Int. J. Pavement Eng. 2018, 21, 642–652. [Google Scholar] [CrossRef]

- Tarar, M.A.; Khan, A.H.; Rehman, Z.; Inam, A. Changes in the rheological characteristics of asphalt binders modified with soybean-derived materials. Int. J. Pavement Eng. 2019, 22, 233–248. [Google Scholar] [CrossRef]

- Airey, G.D.; Choi, Y. State of the Art Report on Moisture Sensitivity Test Methods for Bituminous Pavement Materials. Road Mater. Pavement Des. 2002, 3, 355–372. [Google Scholar] [CrossRef]

- Apeagyei, A.K.; Grenfell, J.R.A.; Airey, G.D. Moisture-induced strength degradation of aggregate–asphalt mastic bonds. Road Mater. Pavement Des. 2014, 15, 239–262. [Google Scholar] [CrossRef] [Green Version]

- Apeagyei, A.K.; Grenfell, J.R.A.; Airey, G.D. Influence of aggregate absorption and diffusion properties on moisture damage in asphalt mixtures. Road Mater. Pavement Des. 2015, 16, 404–422. [Google Scholar] [CrossRef]

- Goel, G.; Sachdeva, S.N. Stripping Phenomenon in Bituminous Mixes: An Overview. Int. J. Math. Sci. Appl. 2016, 6, 353–360. [Google Scholar]

- El-Tahan, D.; Gabr, A.; El-Badawy, S.; Shetawy, M. Evaluation of recycled concrete aggregate in asphalt mixes. Innov. Infrastruct. Solut. 2018, 3, 20. [Google Scholar] [CrossRef]

- Hamzah, M.O.; Hasan, M.R.M.; Ismail, M.R.; Shahadan, Z. Effects of Temperature on Abrasion Loss of Porous and Dense Asphalt Mixes. Eur. J. Sci. Res. 2010, 40, 589–597. [Google Scholar]

- Mohajerani, A.; Nguyen, B.T.; Tanriverdi, Y.; Chandrawanka, K. A new practical method for determining the LA abrasion value for aggregates. Soils Found. 2017, 57, 840–848. [Google Scholar] [CrossRef]

- Wua, J.; Hou, Y.; Wang, L.; Guo, M.; Meng, L.; Xiong, H. Haocheng Xiong a Analysis of coarse aggregate performance based on the modified Micro Deval abrasion test. Int. J. Pavement Res. Technol. 2018, 11, 185–194. [Google Scholar] [CrossRef]

- Mahmud, M.Z.H.; Yaacobb, H.; Jayab, R.P.; Hassanb, N.A. Laboratory investigation on the effects of flaky aggregates on dynamic creep and resilient modulus of asphalt mixtures. J. Teknol. (Sci. Eng.) 2014, 70, 107–110. [Google Scholar] [CrossRef] [Green Version]

- Tahmoorian, F.; Samali, B. Laboratory investigations on the utilization of RCA in asphalt mixtures. Int. J. Pavement Res. Technol. 2018, 11, 627–638. [Google Scholar] [CrossRef]

- Al-Rousan, T.; Masad, E.; Tutumluer, E.; Pan, T. Evaluation of image analysis techniques for quantifying aggregate shape characteristics. Constr. Build. Mater. 2007, 21, 978–990. [Google Scholar] [CrossRef]

- Arasan, S.; Hasiloglu, S.A.; Akbulut, S. Shape Properties of Natural and Crushed Aggregate using Image Analysis. Int. J. Civ. Struct. Eng. 2010, 1, 221–233. [Google Scholar]

- Wang, H.; Bu, Y.; Wang, Y.; Yang, X.; You, Z. The Effect of Morphological Characteristic of Coarse Aggregates Measured with Fractal Dimension on Asphalt Mixture’s High-Temperature Performance. Adv. Mater. Sci. Eng. 2016, 2016, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Galan, J.; Silva, L.; Pasandín, A.; Pérez, I. Evaluation of the Resilient Modulus of Hot-Mix Asphalt Made with Recycled Concrete Aggregates from Construction and Demolition Waste. Sustainability 2020, 12, 8551. [Google Scholar] [CrossRef]

- Rizvi, M.A.; Khan, A.H.; Rehman, Z.U.; Inam, A.; Masoud, Z. Evaluation of Linear Deformation and Unloading Stiffness Characteristics of Asphalt Mixtures Incorporating Various Aggregate Gradations. Sustainability 2021, 13, 8865. [Google Scholar] [CrossRef]

- Mackiewicz, P.; Szydło, A. Viscoelastic Parameters of Asphalt Mixtures Identified in Static and Dynamic Tests. Materials 2019, 12, 2084. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- White, G. A Synthesis on the Effects of Two Commercial Recycled Plastics on the Properties of Bitumen and Asphalt. Sustainability 2020, 12, 8594. [Google Scholar] [CrossRef]

- Sun, Y.; Gu, B.; Gao, L.; Li, L.; Guo, R.; Yue, Q.; Wang, J. Viscoelastic Mechanical Responses of HMAP under Moving Load. Materials 2018, 11, 2490. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Czech, K.R.; Gardziejczyk, W. Dynamic Stiffness of Bituminous Mixtures for the Wearing Course of the Road Pavement—A Proposed Method of Measurement. Materials 2020, 13, 1973. [Google Scholar] [CrossRef] [Green Version]

- Arulrajah, A.; Naeini, M.; Mohammadinia, A.; Horpibulsuk, S.; Leong, M. Recovered plastic and demolition waste blends as railway capping materials. Transp. Geotech. 2020, 22, 100320. [Google Scholar] [CrossRef]

| Mix ID | Asphalt Binders | Aggregates | Gradations | ||

|---|---|---|---|---|---|

| A | Ao | S | M | ||

| W1 | √ | - | √ | - | SUP-1 |

| W2 | √ | - | - | √ | |

| W3 | - | √ | √ | - | |

| W4 | - | √ | - | √ | |

| W5 | √ | - | √ | - | NH-A |

| W6 | √ | - | - | √ | |

| W7 | - | √ | √ | - | |

| W8 | - | √ | - | √ | |

| B | Bo | S | M | ||

| W9 | √ | - | √ | - | SUP-1 |

| W10 | √ | - | - | √ | |

| W11 | - | √ | √ | - | |

| W12 | - | √ | - | √ | |

| W13 | √ | - | √ | - | NH-A |

| W14 | √ | - | - | √ | |

| W15 | - | √ | √ | - | |

| W16 | - | √ | - | √ | |

| B | Bo | S | M | ||

| B1 | √ | - | - | √ | SUP-2 |

| B2 | - | √ | - | √ | |

| B3 | √ | - | - | √ | NH-A |

| B4 | - | √ | - | - | |

| (a) | ||||

|---|---|---|---|---|

| Description | Soybean Oil | |||

| Flash point (°C), ASTM D93 | 320 | |||

| Fire point (°C), ASTM D93 | 354 | |||

| Carbon residue (%), ASTM D189 | 0.37 | |||

| Dynamic viscosity @ 25 °C(Pa.S), AASHTO T-316 | 0.062 | |||

| Cloud point (°C), ASTM D5551 | −9 | |||

| Melting point (°C), ASTM D5440 | 0.5 | |||

| (b) | ||||

| Test Description | Type of Asphalt Binder | |||

| A | Ao | B | Bo | |

| Original asphalt binder (high temperature °C)AASHTO T315 | 68.9 | 54.1 | 65.3 | 53.6 |

| BBR (low temperature), AASHTO T313 | −17 | −24 | −23 | −29 |

| Performance grades (PG), AASHTO M320 | 64–16 | 52–22 | 64–22 | 52–28 |

| Viscosity (Pa.s) at 135 °C, AASHTO T316 | 0.462 | 0.250 | 0.445 | 0.242 |

| Viscosity (Pa.s) at 165 °C, AASHTO T316 | 0.116 | 0.125 | 0.110 | 0.115 |

| VTS | −3.557 | −1.890 | −3.381 | −2.053 |

| Mass change (%), AASHTO T240 | 0.078 | 0.083 | 0.056 | 0.068 |

| Penetration (1/10th mm), ASTM D5 | 43 | 49 | 65 | 68 |

| Softening point (°C), ASTM D36 | 54 | 47.1 | 48 | 45.6 |

| Ductility (cm), ASTM D113 | 100+ | 100+ | 100+ | 100+ |

| Flash and fire point (°C), ASTM D113 | 300 | 317 | 307 | 315 |

| Description | Type of Aggregate | Standards | |

|---|---|---|---|

| S | M | ||

| Water absorption (%) | 0.95 | 0.93 | ASTM C 127 |

| Soundness (fine) (%) | 3.8 | 4.5 | ASTM C 88 |

| Soundness (coarse) (%) | 4.65 | 6.98 | ASTM C 88 |

| Los Angeles aberration (%) | 23 | 24.5 | ASTM C 131 |

| Elongation index (%) | 7 | 3 | ASTM D 4791 |

| Flakiness index (%) | 9 | 5 | ASTM D 4791 |

| Fractured faces (%) | 100 | 100 | ASTM D 5821 |

| Uncompacted voids (fine) (%) | 45 | 44 | ASTM C 1252 |

| Sand equivalent (%) | 71 | 74 | ASTM D 2419 |

| Mix ID | Load (kN) | Tm (s) | T1 (s) | T2 (s) | Tc (s) | T55 (s) | TD (s) | Te (s) | Tf (s) | δh (mm) | δv (mm) | δtotal (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| W1 | 1198.29 | 0.11000 | 0.09900 | 0.09240 | 0.06600 | 0.05280 | 0.02310 | 0.02750 | 0.01870 | 0.00140 | 0.08550 | 0.08690 |

| W2 | 1165.23 | 0.11100 | 0.09980 | 0.09310 | 0.06650 | 0.05320 | 0.02330 | 0.02770 | 0.01880 | 0.00141 | 0.08620 | 0.08760 |

| W3 | 939.72 | 0.11900 | 0.10700 | 0.09970 | 0.07120 | 0.05700 | 0.02490 | 0.02970 | 0.02020 | 0.00145 | 0.09230 | 0.09380 |

| W4 | 907.75 | 0.11900 | 0.10700 | 0.10000 | 0.07160 | 0.05730 | 0.02510 | 0.02980 | 0.02030 | 0.00146 | 0.09280 | 0.09430 |

| W5 | 1222.13 | 0.11100 | 0.09980 | 0.09310 | 0.06650 | 0.05320 | 0.02330 | 0.02770 | 0.01880 | 0.00139 | 0.08620 | 0.08760 |

| W6 | 1210.35 | 0.11100 | 0.09990 | 0.09320 | 0.06660 | 0.05330 | 0.02330 | 0.02770 | 0.01890 | 0.00140 | 0.08630 | 0.08770 |

| W7 | 954.65 | 0.11200 | 0.10100 | 0.09420 | 0.06730 | 0.05390 | 0.02360 | 0.02810 | 0.01910 | 0.00144 | 0.08720 | 0.08860 |

| W8 | 923.15 | 0.11600 | 0.10400 | 0.09700 | 0.06930 | 0.05540 | 0.02430 | 0.02890 | 0.01960 | 0.00145 | 0.08980 | 0.09120 |

| W9 | 1096.39 | 0.11600 | 0.10400 | 0.09710 | 0.06940 | 0.05550 | 0.02430 | 0.02890 | 0.01970 | 0.00143 | 0.08990 | 0.09130 |

| W10 | 1067.33 | 0.11600 | 0.10500 | 0.09790 | 0.06990 | 0.05590 | 0.02450 | 0.02910 | 0.01980 | 0.00144 | 0.09060 | 0.09200 |

| W11 | 913.52 | 0.11900 | 0.10700 | 0.09980 | 0.07130 | 0.05700 | 0.02490 | 0.02970 | 0.02020 | 0.00147 | 0.09240 | 0.09390 |

| W12 | 889.45 | 0.11900 | 0.10700 | 0.10000 | 0.07140 | 0.05710 | 0.02500 | 0.02980 | 0.02020 | 0.00148 | 0.09250 | 0.09400 |

| W13 | 1132.23 | 0.11100 | 0.09990 | 0.09320 | 0.06660 | 0.05330 | 0.02330 | 0.02770 | 0.01890 | 0.00140 | 0.08630 | 0.08770 |

| W14 | 1109.35 | 0.11700 | 0.10500 | 0.09790 | 0.07000 | 0.05600 | 0.02450 | 0.02920 | 0.01980 | 0.00141 | 0.09070 | 0.09210 |

| W15 | 852.65 | 0.11600 | 0.10400 | 0.09700 | 0.06930 | 0.05540 | 0.02430 | 0.02890 | 0.01960 | 0.00144 | 0.08980 | 0.09120 |

| W16 | 823.15 | 0.11700 | 0.10500 | 0.09790 | 0.07000 | 0.05600 | 0.02450 | 0.02920 | 0.01980 | 0.00145 | 0.09070 | 0.09210 |

| B1 | 584.45 | 0.11600 | 0.10400 | 0.09700 | 0.06930 | 0.05540 | 0.02430 | 0.02890 | 0.01960 | 0.00146 | 0.09060 | 0.09200 |

| B2 | 494.87 | 0.11900 | 0.10700 | 0.09980 | 0.07130 | 0.05700 | 0.02490 | 0.02970 | 0.02020 | 0.00149 | 0.09250 | 0.09400 |

| B3 | 623.25 | 0.11700 | 0.10500 | 0.09790 | 0.07000 | 0.05600 | 0.02450 | 0.02920 | 0.01980 | 0.00147 | 0.08720 | 0.08860 |

| B4 | 514.34 | 0.11700 | 0.10500 | 0.09790 | 0.07000 | 0.05600 | 0.02450 | 0.02920 | 0.01980 | 0.00151 | 0.08610 | 0.08760 |

| Load (kN) | Tm (s) | T1 (s) | T2 (s) | Tc (s) | T55 (s) | TD (s) | Te (s) | Tf (s) | δh (mm) | δv (mm) | δtota (mm) | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Load(kN) | Pearson Corr. | 1 | −0.37007 | −0.35666 | −0.35665 | −0.35684 | −0.35421 | −0.36084 | −0.36444 | −0.34458 | −0.88334 | −0.34865 | −0.35739 |

| Sig. | -- | 0.02631 | 0.03274 | 0.03275 | 0.03265 | 0.03405 | 0.03062 | 0.02887 | 0.03959 | 9.88321 × 10−13 | 0.03716 | 0.03236 | |

| Tm (s) | Pearson Corr. | −0.37007 | 1 | 0.99595 | 0.99612 | 0.99626 | 0.9957 | 0.99507 | 0.99679 | 0.99267 | 0.55234 | 0.9961 | 0.99579 |

| Sig. | 0.02631 | -- | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 4.78096 × 10−4 | 0 | 0 | |

| T1 (s) | Pearson Corr. | −0.35666 | 0.99595 | 1 | 0.9994 | 0.99893 | 0.99854 | 0.99748 | 0.99876 | 0.99733 | 0.54857 | 0.99885 | 0.99881 |

| Sig. | 0.03274 | 0 | -- | 0 | 0 | 0 | 0 | 0 | 0 | 5.32052 × 10−4 | 0 | 0 | |

| T2 (s) | Pearson Corr. | −0.35665 | 0.99612 | 0.9994 | 1 | 0.9997 | 0.99944 | 0.99876 | 0.9992 | 0.9982 | 0.55396 | 0.99967 | 0.99966 |

| Sig. | 0.03275 | 0 | 0 | -- | 0 | 0 | 0 | 0 | 0 | 4.5638 × 10−4 | 0 | 0 | |

| Tc (s) | Pearson Corr. | −0.35684 | 0.99626 | 0.99893 | 0.9997 | 1 | 0.99982 | 0.99922 | 0.99932 | 0.99856 | 0.55177 | 0.99987 | 0.99987 |

| Sig. | 0.03265 | 0 | 0 | 0 | -- | 0 | 0 | 0 | 0 | 4.85904 × 10−4 | 0 | 0 | |

| T55 (s) | Pearson Corr. | −0.35421 | 0.9957 | 0.99854 | 0.99944 | 0.99982 | 1 | 0.99907 | 0.99919 | 0.99895 | 0.54864 | 0.99978 | 0.99978 |

| Sig. | 0.03405 | 0 | 0 | 0 | 0 | -- | 0 | 0 | 0 | 5.3103 × 10−4 | 0 | 0 | |

| TD (s) | Pearson Corr. | −0.36084 | 0.99507 | 0.99748 | 0.99876 | 0.99922 | 0.99907 | 1 | 0.99882 | 0.99728 | 0.55504 | 0.99916 | 0.99893 |

| Sig. | 0.03062 | 0 | 0 | 0 | 0 | 0 | -- | 0 | 0 | 4.42388 × 10−4 | 0 | 0 | |

| Te (s) | Pearson Corr. | −0.36444 | 0.99679 | 0.99876 | 0.9992 | 0.99932 | 0.99919 | 0.99882 | 1 | 0.99725 | 0.55563 | 0.99908 | 0.99898 |

| Sig. | 0.02887 | 0 | 0 | 0 | 0 | 0 | 0 | -- | 0 | 4.34876 × 10−4 | 0 | 0 | |

| Tf (s) | Pearson Corr. | −0.34458 | 0.99267 | 0.99733 | 0.9982 | 0.99856 | 0.99895 | 0.99728 | 0.99725 | 1 | 0.54036 | 0.99856 | 0.9986 |

| Sig. | 0.03959 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | -- | 6.69006 × 10−4 | 0 | 0 | |

| δh (mm) | Pearson Corr. | −0.88334 | 0.55234 | 0.54857 | 0.55396 | 0.55177 | 0.54864 | 0.55504 | 0.55563 | 0.54036 | 1 | 0.54437 | 0.55288 |

| Sig. | 9.88321 × 10−13 | 4.78096 × 10−4 | 5.32052 × 10−4 | 4.5638 × 10−4 | 4.85904 × 10−4 | 5.3103 × 10−4 | 4.42388 × 10−4 | 4.34876 × 10−4 | 6.69006 × 10−4 | -- | 5.98648 × 10−4 | 4.70652 × 10−4 | |

| δv (mm) | Pearson Corr. | −0.34865 | 0.9961 | 0.99885 | 0.99967 | 0.99987 | 0.99978 | 0.99916 | 0.99908 | 0.99856 | 0.54437 | 1 | 0.99982 |

| Sig. | 0.03716 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 5.98648 × 10−4 | -- | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tarar, M.A.; Khan, A.H.; Rehman, Z.u.; Abbass, W.; Ahmed, A.; Ali, E.; Sayed, M.M.; Aziz, M. Evaluation of Resilience Parameters of Soybean Oil-Modified and Unmodified Warm-Mix Asphalts—A Way Forward towards Sustainable Pavements. Sustainability 2022, 14, 8832. https://doi.org/10.3390/su14148832

Tarar MA, Khan AH, Rehman Zu, Abbass W, Ahmed A, Ali E, Sayed MM, Aziz M. Evaluation of Resilience Parameters of Soybean Oil-Modified and Unmodified Warm-Mix Asphalts—A Way Forward towards Sustainable Pavements. Sustainability. 2022; 14(14):8832. https://doi.org/10.3390/su14148832

Chicago/Turabian StyleTarar, Muhammad Akhtar, Ammad Hassan Khan, Zia ur Rehman, Wasim Abbass, Ali Ahmed, Elimam Ali, Mohamed Mahmoud Sayed, and Mubashir Aziz. 2022. "Evaluation of Resilience Parameters of Soybean Oil-Modified and Unmodified Warm-Mix Asphalts—A Way Forward towards Sustainable Pavements" Sustainability 14, no. 14: 8832. https://doi.org/10.3390/su14148832

APA StyleTarar, M. A., Khan, A. H., Rehman, Z. u., Abbass, W., Ahmed, A., Ali, E., Sayed, M. M., & Aziz, M. (2022). Evaluation of Resilience Parameters of Soybean Oil-Modified and Unmodified Warm-Mix Asphalts—A Way Forward towards Sustainable Pavements. Sustainability, 14(14), 8832. https://doi.org/10.3390/su14148832