1. Introduction

Bitumen or asphalt binder (as it is referred to in North America) is utilized in the production of asphalt mixtures for road construction and industrial application. It is a viscoelastic material whose behavior is temperature and time-dependent. Bitumen behaves as an elastic solid at lower temperatures and high loading frequencies, and as a viscous liquid at higher temperature and lower loading frequency [

1,

2]. This means that bitumen become soft at high temperatures and stiffens at lower temperatures. Further, the performance of asphalt concrete mixtures and their ability to resist pavement distresses, such as fatigue, thermal cracking and rutting, is directly dependent on the mechanical properties of bitumen. Therefore, the poor service life of asphalt pavements is related to bitumen properties [

3,

4]. To improve the service life and durability of pavements, bitumen should be modified with polymer modifiers [

5]. The most widely used modifiers of bitumen is the styrene-butadiene-styrene (SBS) copolymer [

6,

7]. The styrene component comprises of hard blocks that give bitumen the strength to be able to resist permanent deformation, while butadiene are soft blocks that give bitumen flexibility as a result increases resistance to thermal and fatigue cracking potential of bitumen at low and intermediate temperatures, respectively. When SBS is incorporated in asphalt, it undergoes swelling due to the absorption of the aromatic and saturate components of asphalt. The SBS polystyrene components are then evenly distributed in polybutadiene [

8]. SBS dosage between 3 and 6% [

9] is known to give the binder the much-needed elastic characteristics [

10]. After modification, bitumen forms the continuous phase whereas SBS forms the dispersed phase. Phase inversion increases with increase in the concentration of SBS [

11].

Although polymer modification of bitumen generally improves the mechanical properties of modified binders, there are concerns about poor stability during hot storage of PMB in general (140–180 °C). PMB comprises of a phase rich in polymer and a phase rich in bitumen. Phase separation is mostly influenced by density differences between these two phases [

12]. Other factors include those that are physicochemical in nature, such as solubility, molecular weight, polarity, microstructure properties and glass transition for bitumen and polymers, which influence compatibility [

13]. The instability in the storage of polymer-modified binders at microscopic scale is due to the phase separation process, where polymer modifiers essentially separate from the asphalt binder matrix. This phenomenon can be attributed to different factors such as bitumen type and the nature of the polymer modifiers [

14].

To counter these drawbacks, many strategies have been applied. These strategies include the use of antioxidants; sulfur vulcanization; use of functional and reactive polymers, and indeed the use of hydrophobic clay minerals [

14]. The use of antioxidants involves the use of materials or additives that retard the oxidative ageing while breaking down hydro peroxides, which are produced during oxidation [

15,

16,

17]. Even though, they reduce oxidation and consequently inhibit brittleness and possible cracking, which comes with bitumen ageing, they are not so useful in improving storage stability. Moreover, the prices for antioxidants are exorbitant. Sulfur vulcanization, on the other hand, is a chemical process that works in two ways: firstly, polymer molecules are chemically crosslinked, and secondly bitumen and polymers undergo chemical coupling through polysulfide and/or sulfide bonds [

18]. The former forms a stable polymer network and the latter directly reduces the separation of the PMB and consequently offers good storage stability. However, there are problems with sulfur vulcanization—such as oxidative ageing and their reliance on unsaturated polymers [

19]. Functional and reactive polymers involve incorporating chemical additives into bitumen to get the functionalized bitumen properties capable of improving storage stability. Many however focus on improving compatibility between bitumen and polymer by forming chemical or hydrogen bonds. An example of an additive used for this purpose is Maleic anhydride (MAH); however, recent researchers, such as Su et al. as cited in [

20], found that the chemical modification of bitumen with polydimethylsiloxane (PDMS)—silicone oil could also enhance the compatibility of modified asphalt binders and offer good storage stability. Hydrophobic clay minerals can be used in both PMB and base bitumen—for example, kaolinite and montmorillonite (MMT). Previous studies have shown that the application of kaolinite in PMB achieves two main objectives namely: (1) enhancing PMB’s storage stability by reducing the difference in density between bitumen and its polymer-modifiers; (2) improving resistance to ageing of PMB with characteristics of the dispersed clay platelets [

21].

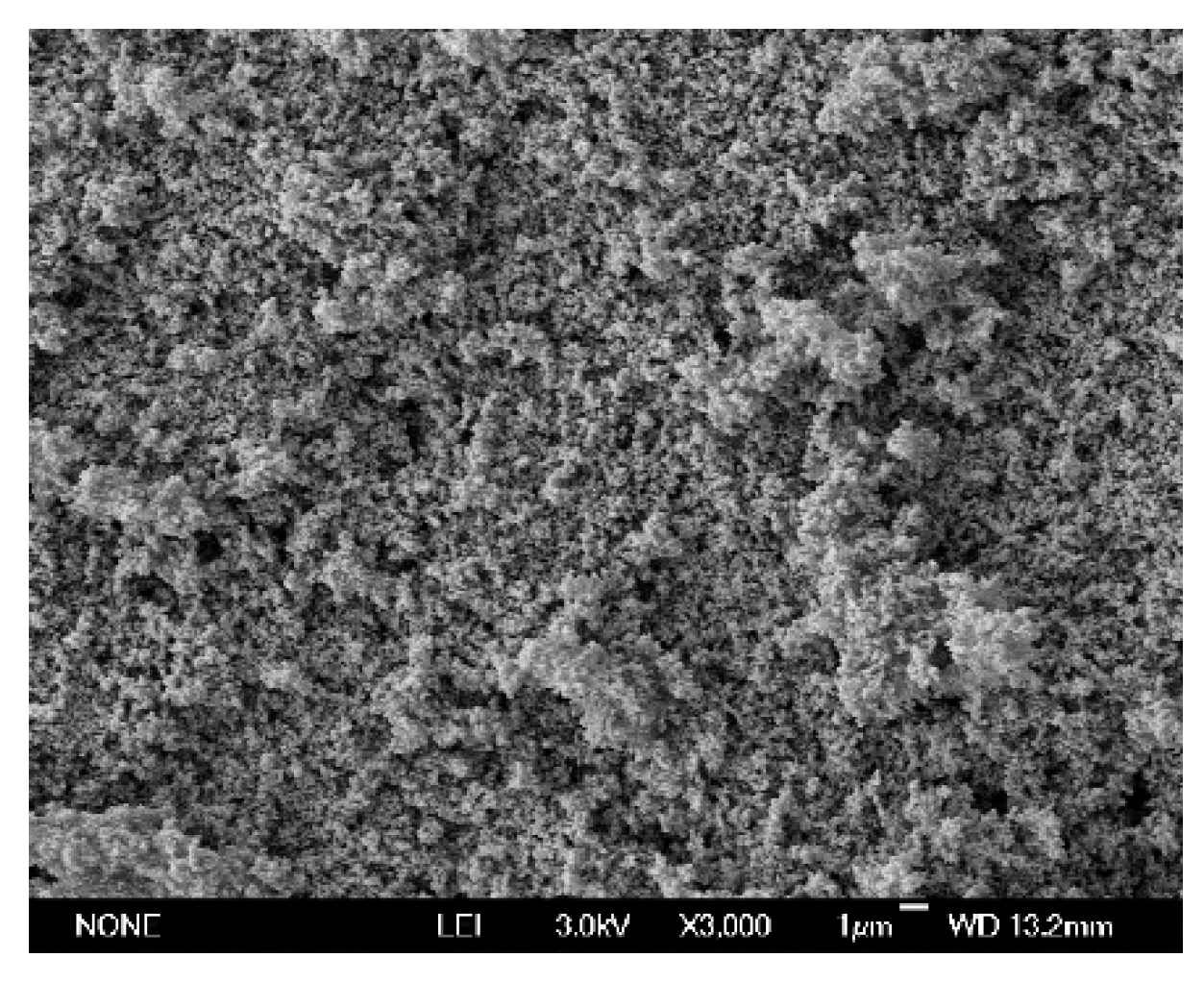

Beyond the hydrophobic clay minerals, asphalt modification with nanosilica has recently attracted interest among pavement researchers since the advent of nanotechnology. Nanosilica has high chemical purity, high surface area and stability, which makes it ideal for bitumen modification. However, nanomaterials, such as nanosilica, have a tendency to agglomerate because of their small particles and relatively higher surface energies of nanosilica coupled with frequent particle-to-particle interaction [

22]. The nanomaterial’s propensity to aggregate is a function of its surface properties [

23] and the medium in which nanomaterial is dispersed (i.e., viscosity and polarity) [

24,

25]. The nanomaterial’s surface properties (for instance surface capping chemistry as well as chemical surface moieties) play a critical role in ensuring that they are dispersed in polar and non-polar solvents [

26]. Further, it is worth noting that bitumen is comprised of high molecular hydrocarbons and other derivatives, which make nanomaterials, such as nanosilica, have poor dispersion and compatibility [

27]. Hence, the nanomaterial’s propensity to agglomerate can be readily controlled by modifying their surface characteristics and choosing a solvent like bitumen to enhance dispersion. In the present study, the surface of nanosilica was modified with polydimethylsiloxane (PDMS) or silicone oil thereby making nanosilica highly hydrophobic and more compatible with bitumen. This promotes the adsorbing of light oil in bitumen and adhesion with some components in bitumen thereby changing the original structural form of bitumen and consequently reducing the temperature sensitivity of the bitumen. Dhawale [

5] reported that the interactions between SBS polymers and nanosilica were because of the chains in PDMS surface treated nanosilica, which physically entangled with chains from SBS modifier to create a physical polymer–nanosilica network. Because of entanglements, SBS chains are immobilized, which leads to slower movement of molecules around nanosilica, thereby increasing the complex shear modulus. Furthermore, polymers and asphalt are bound together, hence the formed network prevent phase separation of PMB.

Extant literature on nanosilica found that the additive improves anti-aging property, fatigue and rutting of modified binders and mixtures [

24]; increases in strength of mixes, temperature stability and resistance to moisture susceptibility [

28]; increases in complex shear modulus [

29]; increases in viscosity [

30]. This research investigates the storage stability and physicochemical properties of SBS binders modified with silicone surface treated nanosilica. The benefit of using polydimethylsiloxane (PDMS) surface treated nanosilica lies in the fact that PDMS modification of the surface of nanosilica reduces the amount of silanol structures found on the surface of nanosilica and alters the functional group on the surface and the structure of the nanosilica at micro-level [

5]. As a result, the physical and chemical properties, such as nanosilica adsorption, are altered and the surface free energy (SFE) of the nanosilica filler and the concept of agglomeration between particles are lowered. In addition, PDMS has high hydrophobicity owing to its size and organic content. This high hydrophobicity on the surface of nanosilica promote an even distribution of particles in similar medium, such as bitumen. Moreover, the physical chain of the PDMS surface treated nanosilica enhances physical interaction between bitumen and SBS. Further, it is a well-known fact that temperature is elevated up to 200 °C during hot storage and processing of bitumen, therefore the bond energy in PDMS surface treated nanosilica is higher than C=C bonds due to the existence of Si–O–Si bonds, which can withstand thermal degradation at high temperatures.

2. Research Objective and Significance

During hot storage of polymer-modified bitumen (PMB), polymers tend to separate from the asphalt binders due to viscosity and density differences as well as incompatibility between the two components, which float and agglomerate at the top of the modified binders [

31,

32,

33]. The instability of PMB motivates pavement engineers and researchers to find new materials to improve the performance of PMB. On the other hand, the utilization of Aerosil R202 fumed silica (nanosilica) in bitumen modification remains largely unexplored [

5]. However, in quest to explore new and novel materials to mitigate storage instability concerns and phase separation of PMB, this study evaluated the potential use of Aerosil R202 fumed silica (herein nanosilica) to improve storage stability, physical and chemical properties of PMB. The performance indicators for storage stability and rheological characterization included Storage stability based on comparison of complex shear modulus between the tube test bottom and top portions of the samples. Further, Brookfield viscosity, rutting based on the Multiple Stress Creep Recovery (MSCR) test, resistance to fatigue cracking based on Linear Amplitude Sweep (LAS) test, chemical characterization employing Fourier Transform Infrared (FTIR) and Proton Nuclear Magnetic Resonance (

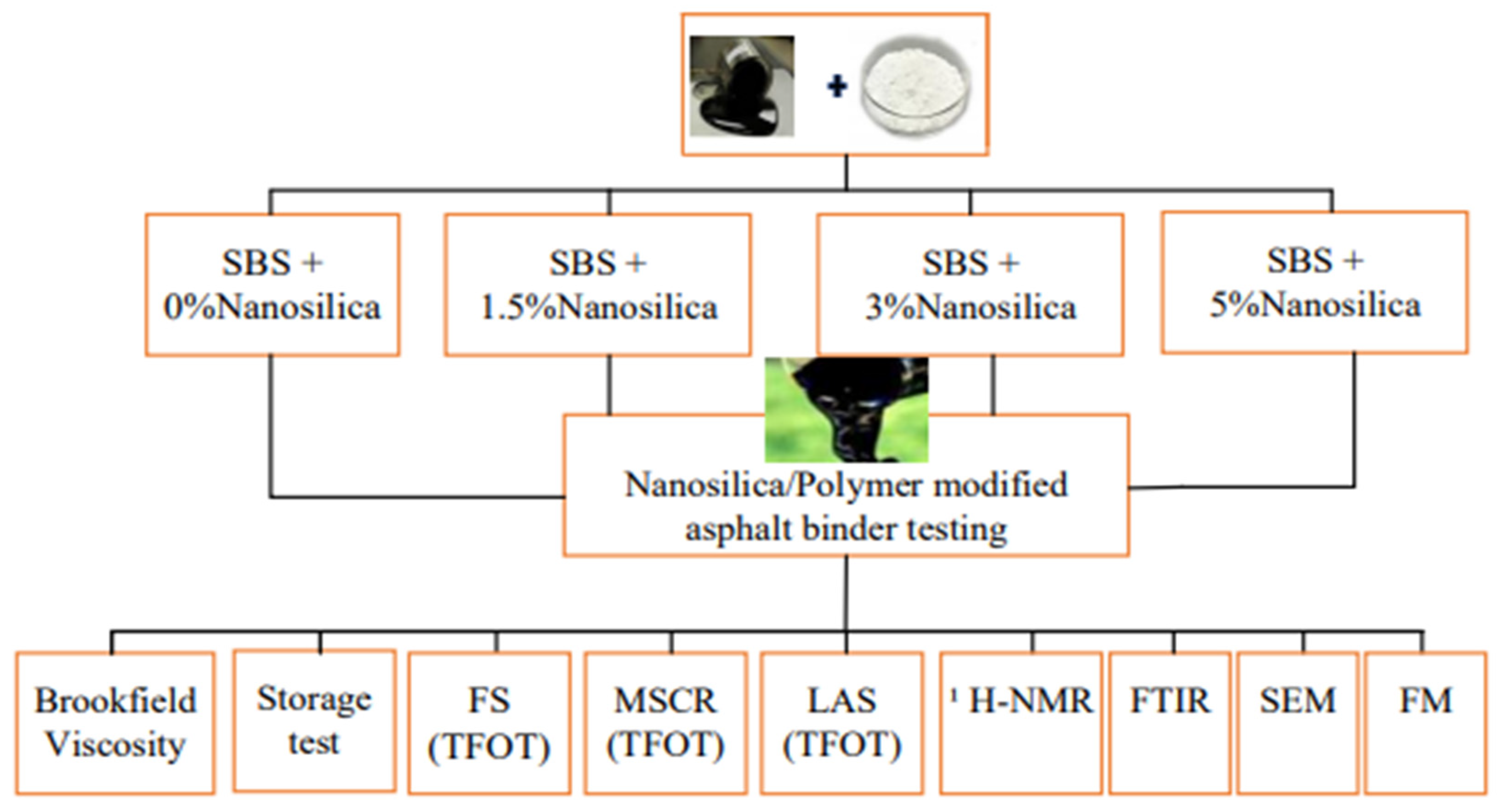

1H-NMR) tests were conducted on prepared samples. Morphological, compatibility and microstructure changes in nanosilica-modified binders were studied by Scanning Electron Microscopy (SEM) and Fluorescence Microscopy (FM) respectively. Thin-film oven test (TFOT) aged samples were utilized on rheological tests.

One of the benefits of using nanomaterials is the low-cost of producing the material as well as its superior performance [

11]. Researchers, such as Yu et al. [

34] found that modifying nanomaterial with polymers is cost-effective because both the amount of polymers and nanomaterials needed in composite blends is reduced while the compatibility of polymers with bitumen is increased. In this regard, the current study is significant because it seeks to promote the utilization of cost effective and sustainable construction materials to mitigate storage and phase separation concerns of PMB, which are currently the major drawbacks in the application of PMB. The study is also important because nanosilica generally improves the mechanical properties of asphalt binders, which may lead to the construction of more durable and high performing asphalt pavements. It is the authors’ considered view that the novelty of the paper lies in expanding the potential application of Aerosil R202 nanosilica in bitumen modification to address the aforementioned drawbacks of PMB.

5. Conclusions

This paper investigated the storage as well as physical and chemical properties of polymer modified asphalt-PMB (herein SBS asphalt) modified with nanosilica. The influence of the nanosilica dosage on properties of PMB binders, such as chemical and microstructure morphology, storage stability, viscosity, rutting, and fatigue resistance were compared. Based on rigorous experiments, and results thereof, the following conclusions were made:

Chemical analysis through FTIR tests established that an absorption peak 1050 cm−1 corresponded to the Si–O–Si bond in nanosilica powder; however, this peak shifted to higher wavelength of 1100 cm−1 when nanosilica was added to the asphalt binder. The two peaks around 966 cm−1 and 700 cm−1 corresponded to an SBS butadiene segments C=C bonds and SBS styrene segments C–H bending, which showed the presence of SBS in the modified asphalt binders. This shift indicates that asphalt interacted with the siloxane bond of the nanosilica powder to produce nanosilica modified asphalt binder.

The 1H NMR spectra results revealed that adding nanosilica to SBS modified asphalt increased the aromatic content of bitumen. Larger aromatic structures in bitumen give rise to improved interactions and can be correlated with the elastic behavior of bitumen at elevated temperature and longer loading times, whereas smaller aromatic structures inform more of the elastic behavior of bitumen at low temperature and short loading times. Hence the study concluded that the higher aromatic content in SBS/nanosilica modified bitumen can be beneficial to improving rutting resistance of bitumen.

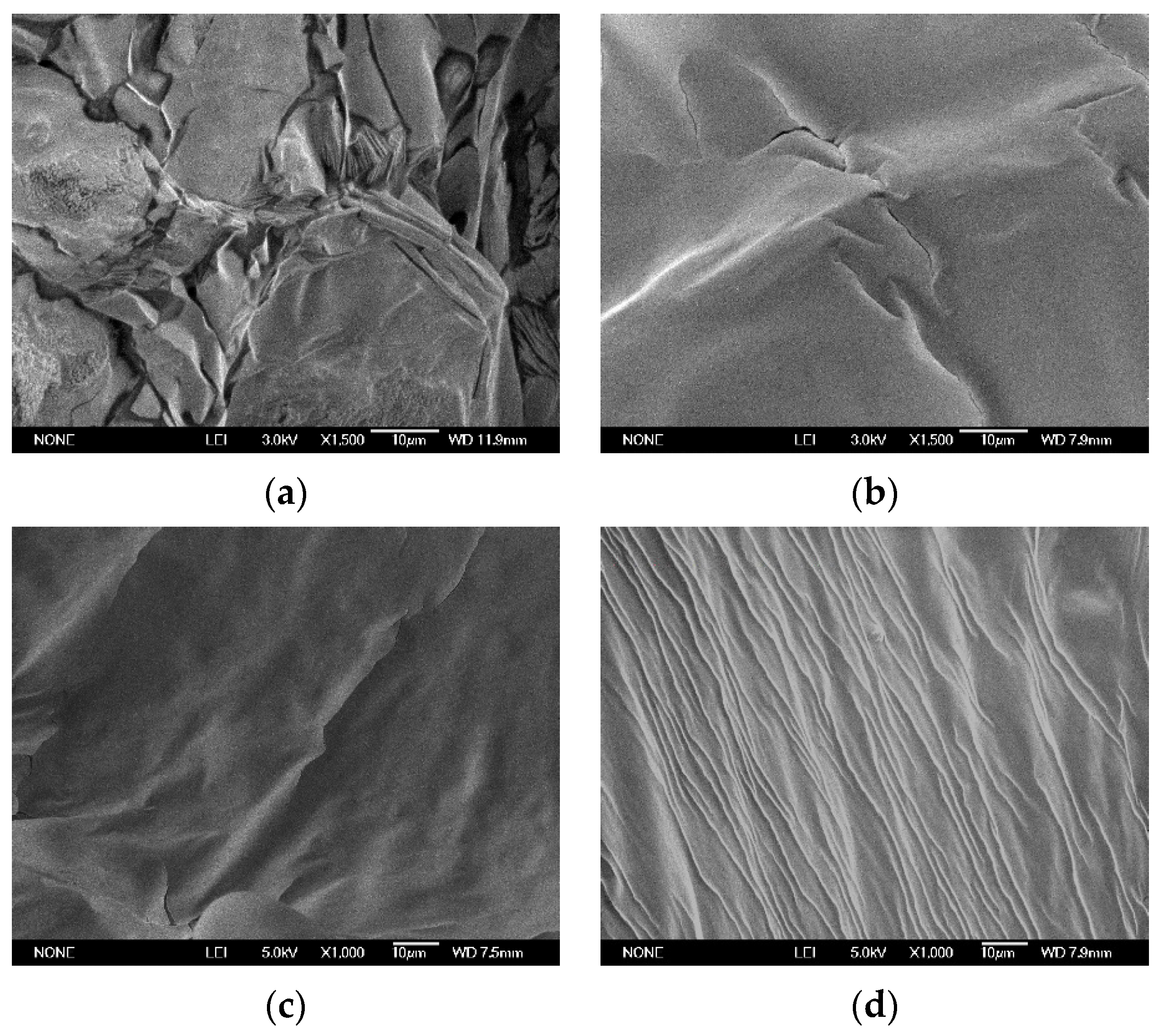

FM and SEM tests results led to the conclusion that nanosilica particles improved dispersion in the asphalt matrix. The improved dispersion is attributed to the surface modification of nanosilica with PDMS silicone oil, which is highly hydrophobic and makes nanosilica more compatible with asphalt. This is beneficial for adsorbing light oil in asphalt or bonding with some components in the asphalt. Hence, the original structural form of the asphalt was changed, and the temperature sensitivity of the asphalt after the modification was lowered, which improves the rutting resistance of asphalt binders. Further, a new polymer-nanosilica network structure was formed that binds white nanosilica particles and asphalt together. The improved dispersion is beneficial to modulus improvement. Another school of thought is that the increased aromatic content in bitumen found in the H-NMR test, would result into an improved interaction between bitumen and polymers, hence good dispersion.

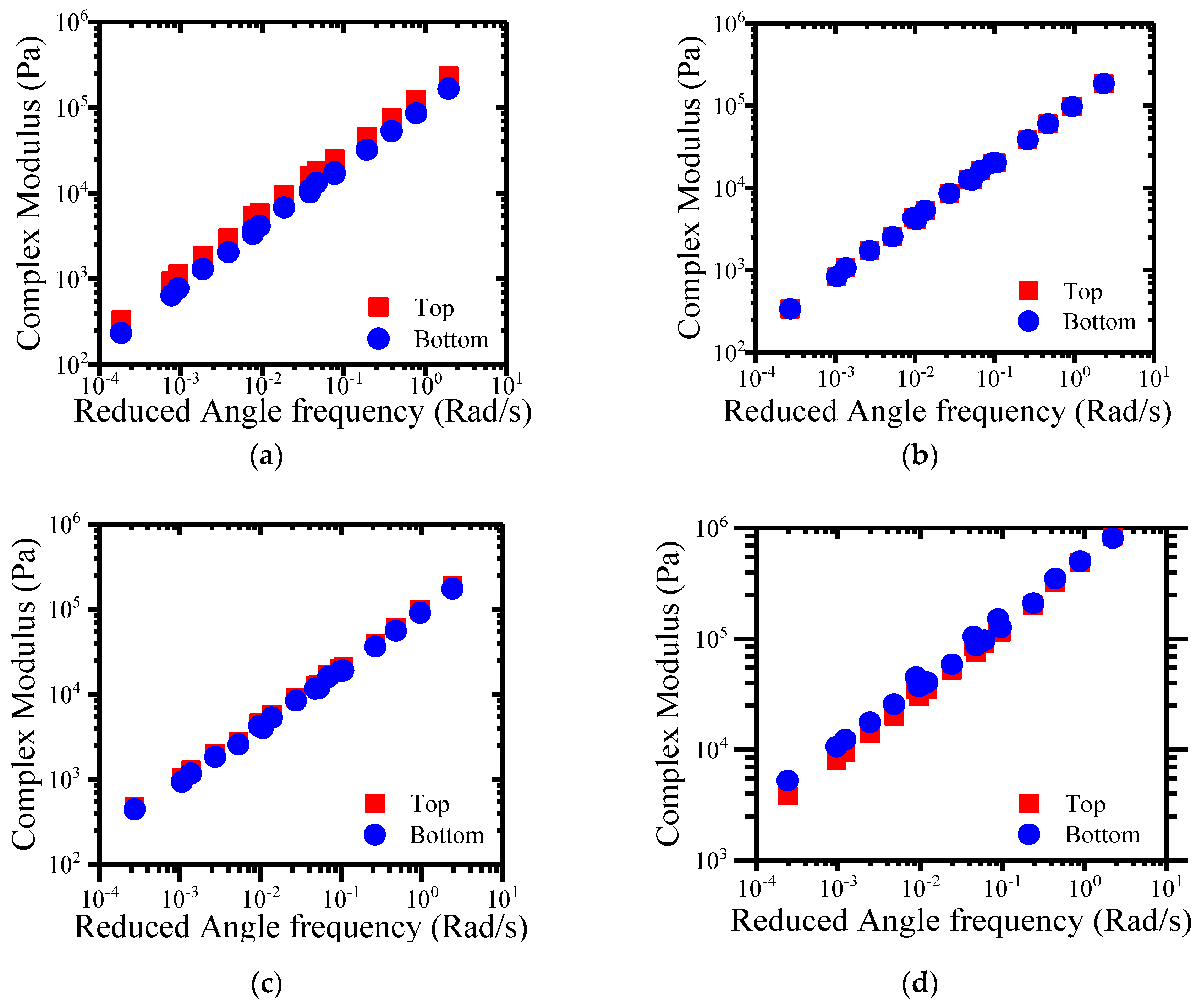

By comparing the complex modulus of the asphalt sample from the bottom and top portions of the hot storage tube, the addition of the nanosilica to PMB decreased the gap between top and bottom, thereby improving the storage stability. This was due to surface PDMS groups’ entanglements with the nanosilica and SBS chains, which created a physical network, thus slowing the movements around nanosilica particles that prevent phase separation. Further, the bond energy in PDMS surface treated nanosilica is higher than C=C bonds due to the existence of Si–O–Si bonds which can withstand thermal degradation at high temperatures. However, it should be mentioned that the storage stability was better when a low amount of 1.5% SNS was used and that increasing the amount of SNS resulted in less stability.

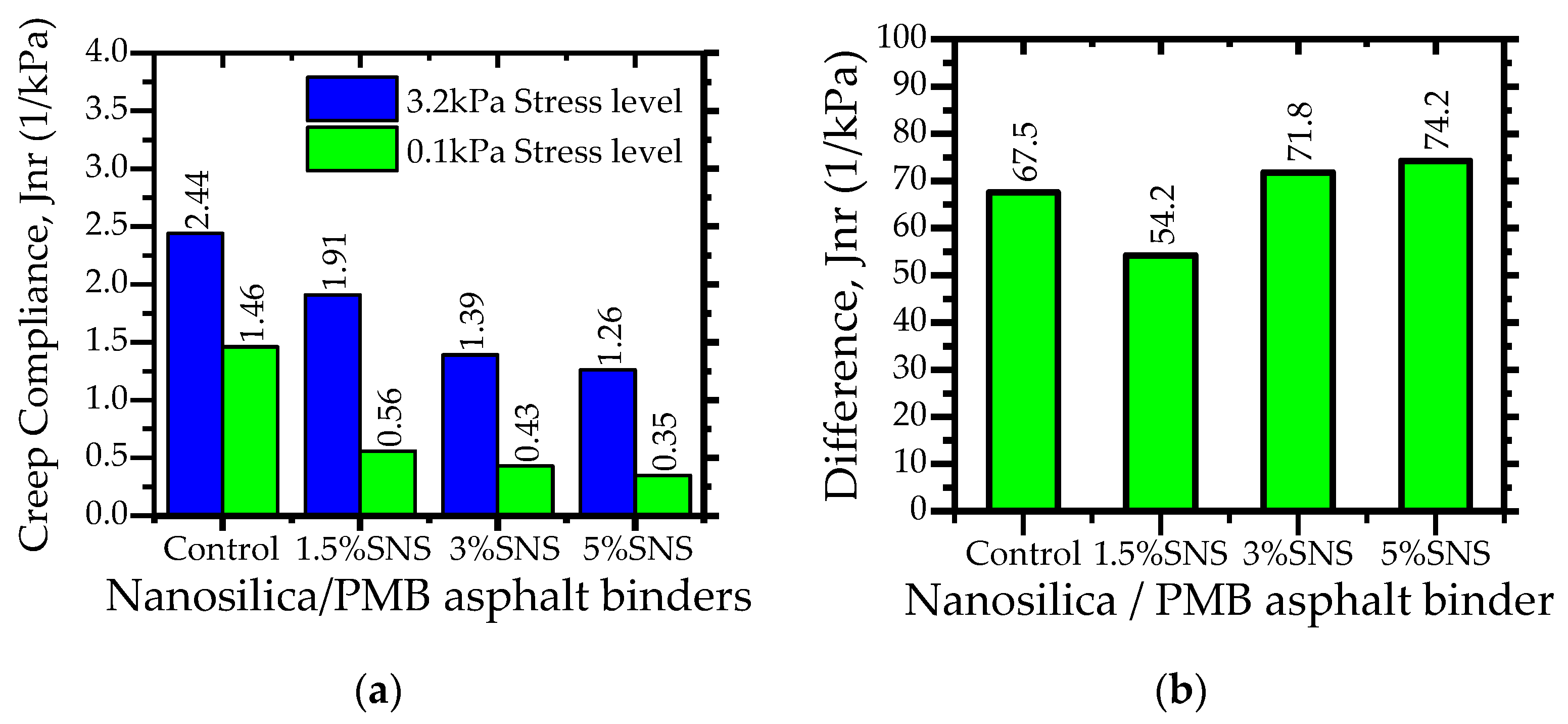

The addition of nanosilica powder to PMB binder’s increases resistance to permanent deformation by decreasing the permanent strain also known as non-recoverable creep compliance—Jnr (i.e., the residual strain in a specimen after creep and recoverable cycle divided by the applied stress). This is mainly due to increased binder stiffness and reduced temperature susceptibility of bitumen. Further, the higher aromatic content SBS/nanosilica modified bitumen has improved elastic properties during high temperature and longer loading times hence is beneficial to rutting resistance.

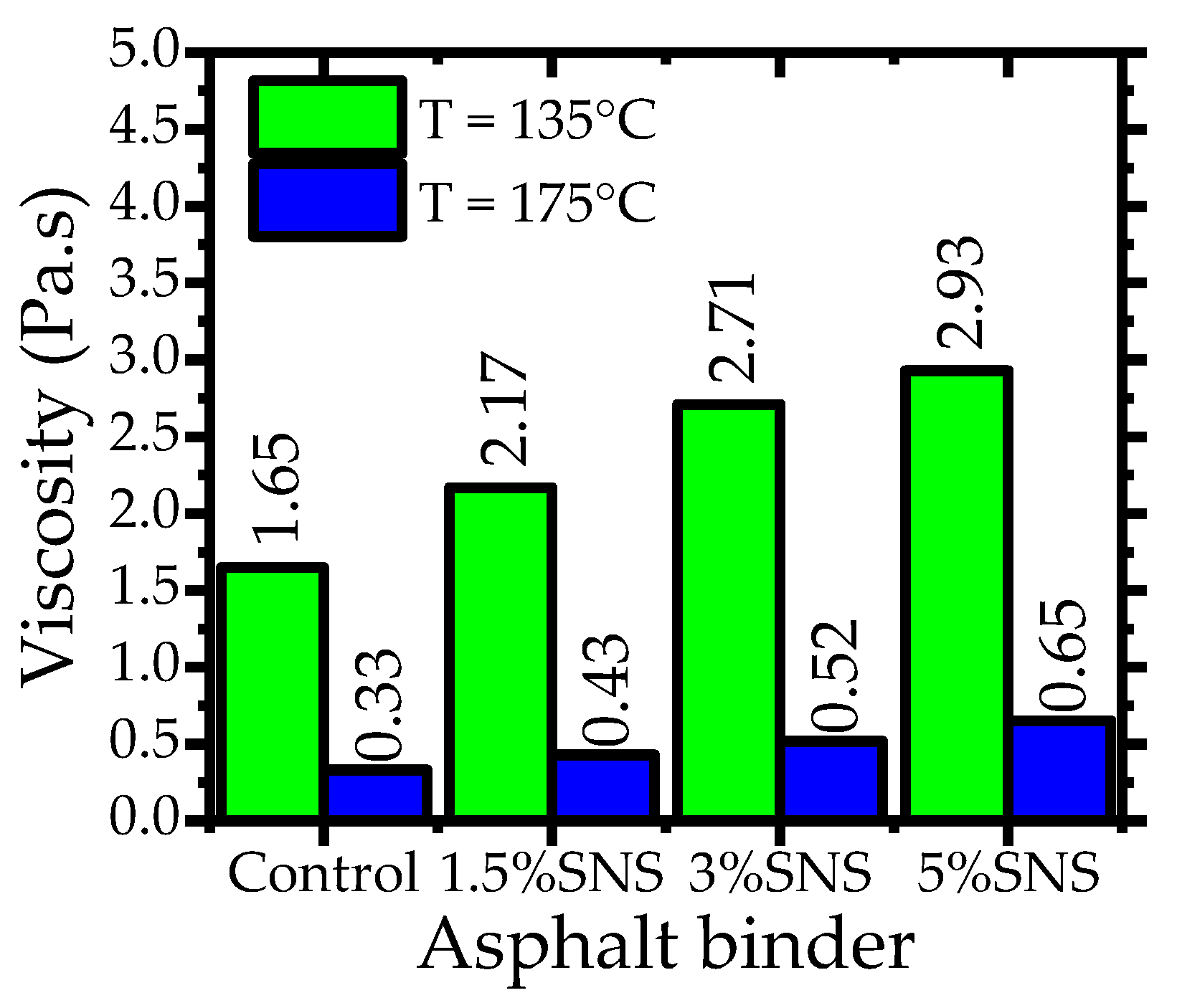

The viscosity of bitumen increased due to the addition of nanosilica. The resistance to the permanent deformation of bitumen may be partly due to increased viscosity, which results in a higher stiffness at elevated temperatures. However, the viscosity of all binders in this study met Superpave specification limits of less than 3.0Pa.s.

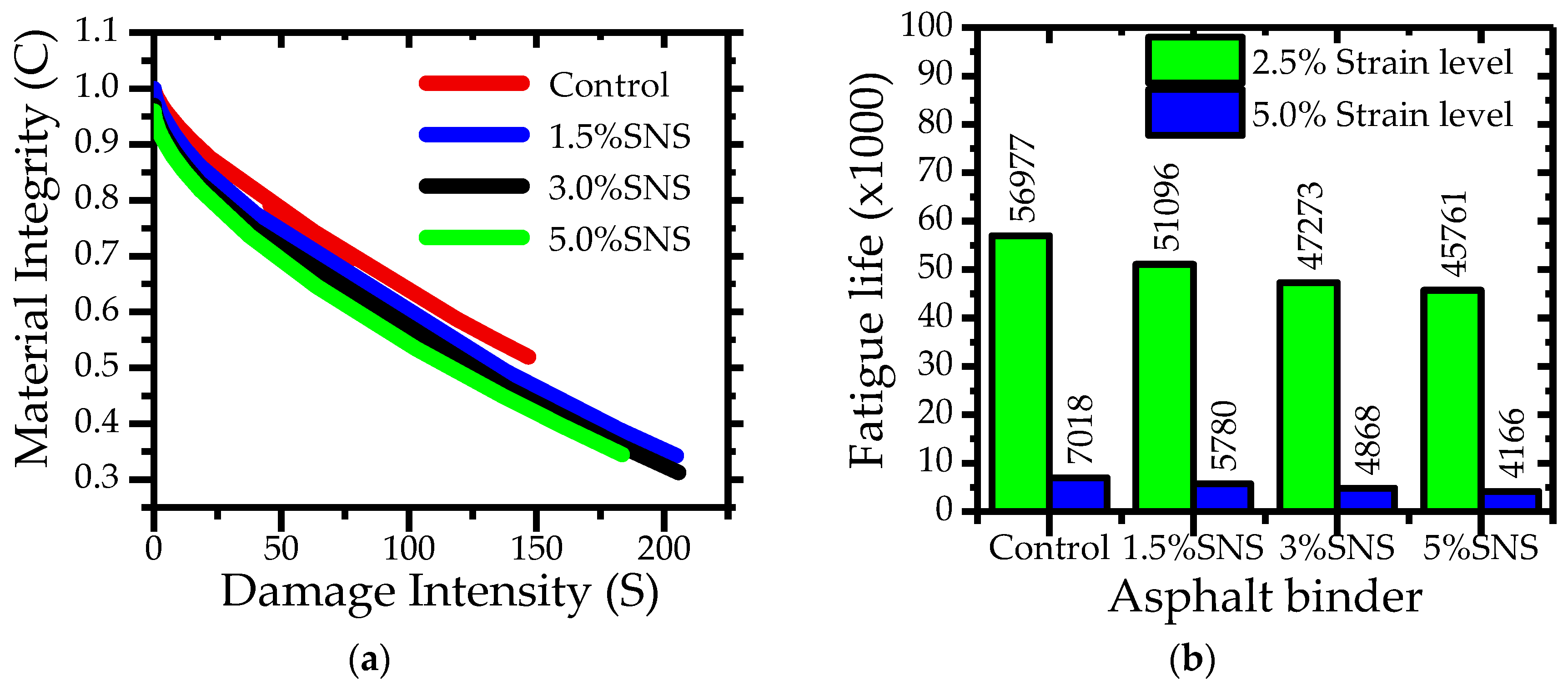

On the other hand, nanosilica was not beneficial to fatigue cracking improvement in PMB binders. Results revealed that the addition of nanosilica increases damage intensity and decreases fatigue life. This is attributed to the stiffening effect of nanosilica on PMB binders that reduces its flexibility at intermediate temperature.

The findings from this research highlight the significance of bitumen modification with nanosilica powder to improve storage stability and physicochemical properties. Further, the study has noted the importance of surface modification for nanosilica to improve dispersion in bitumen. In this regard, PDMS silicone oil surface-treated nanosilica was utilized. The chains in PDMS surface-treated nanosilica physically entangled with chains from SBS modifier to create a physical polymer–nanosilica network. Because of this physical entanglements, SBS chains were immobilized, which leads to slower movements around nanosilica, thereby reducing phase separation.

Besides, the good results obtained, the study had one limitation. Low temperature cracking performance was not undertaken. However, it is worth noting that PDMS silicone oil chemical treatment on the surface of nanosilica guarantees the hydrophobia of the product, which can improve, among others, the water-resistance of moisture sensitive formulations. In this regard, future research can consider moisture susceptibility of bitumen modified with silicone surface treated nanosilica.