Abstract

Additive manufacturing technologies enable the design of complex lightweight structures for electric powertrain applications. This study evaluates the topology optimization and conceptual additive manufacturing of a real electric vehicle gearbox housing, aiming to reduce weight while maintaining structural stiffness. Based on an existing industrial component, a topology-optimized design featuring an X-shaped rib structure was developed. The manufacturing concept combines Laser Metal Deposition (LMD) with a pre-machined turned part. A comparative material study was carried out using finite element simulations to assess aluminum, magnesium, titanium, and stainless steel in terms of weight, deformation, and natural frequency. The results indicate that aluminum alloys offer the best balance of stiffness and weight due to their high specific modulus and favorable processability. The optimized design achieved a simulated weight reduction of approximately 21% with only a minor increase in rotational deformation. A cost analysis of different manufacturing methods suggests that, while conventional casting remains more economical at higher volumes, additive processes are becoming increasingly viable for small series. The study provides a theoretical foundation for future development of lightweight functionally integrated gearbox housings in electric mobility.

1. Introduction

Increasing electric vehicles’ powertrain efficiency represents a key area of focus within the automotive industry. Utilizing gearboxes facilitates the use of lighter electric motors that operate at higher maximum rotational speeds, leading to cost reductions. Achieving extended range in vehicles is of significant importance and can be realized through the implementation of lightweight designs in drivetrain components such as gearbox housings. Additive manufacturing (AM), particularly of aluminum alloys, enables the production of lightweight drivetrain components. This study explores the conceptual application of AM to a gearbox housing with dimensions up to 300 mm, which must also fulfill mechanical functions within an electric vehicle drivetrain. This article builds on previous work presented at the 38th International Electric Vehicle Symposium and Exhibition (EVS 38) [1].

The development of novel manufacturing technologies has led to significant advancements in the efficiency and speed of aluminum part production, thereby enhancing the competitiveness of this technology [2]. Technologies such as Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS) allow for the realization of complex geometries tailored to specific functional requirements. Additive manufacturing by laser melting of aluminum alloys is also employed in other branches of industry, where it can be used to manufacture gearbox housings [3]. Another widespread AM process is Laser Metal Deposition (LMD), which is increasingly being used in a variety of industrial sectors [4]. This is an AM technology that offers significant design flexibility, enabling the creation of complex geometries [5]. In particular, LMD enables the manufacturing of complex designs that would be difficult or impossible to achieve using conventional methods [6]. Recent research has also demonstrated the feasibility of using LMD for dissimilar material combinations, such as titanium on stainless steel, by carefully controlling process parameters to reduce interfacial defects and phase formation [7]. Furthermore, titanium alloys themselves have been extensively studied in the context of LMD, with process parameters significantly affecting microstructure and mechanical properties [8]. In addition to its geometric flexibility, it has been demonstrated that LMD can be a sustainable and efficient method for processing aluminum alloys, making it increasingly attractive for structural applications in e-mobility [9]. A study on LMD of stainless steels has shown that, despite processing challenges, excellent mechanical properties can be obtained through tailored heat treatment strategies, making them viable for structurally demanding applications [10]. A hybrid additive manufacturing (HAM) methodology combining LMD and milling was developed, offering improved process control, reduced material waste, and greater flexibility in manufacturing complex components [11].

The use of HAM represents a promising approach to overcoming the key limitations of metal AM, such as insufficient surface quality, residual stresses, and dimensional inaccuracies. By integrating additive and subtractive processes (e.g., SLM combined with milling), HAM enables improved surface finish, reduced post-processing, and enhanced geometric precision [12]. However, challenges remain regarding process complexity, material compatibility, and system integration. While AM offers material savings and design freedom, its high energy consumption continues to pose sustainability concerns. Hybrid Additive–Subtractive Manufacturing (HASM) integrates additive and subtractive processes within a single setup to enable the efficient production of highly precise and geometrically complex components [13]. In this context, topology optimization plays a key role in designing functionally optimized structures tailored to the capabilities of HASM, with the current challenges being residual stresses and part distortion.

Topology optimization for metal additive manufacturing increasingly incorporates specific process requirements such as support structures and build orientation, as well as manufacturing constraints directly within the design process [14]. This enables improved manufacturability and optimized component performance. Topology optimization can be implemented in the design of a component to achieve lightweight structures and to identify non-critical regions where material can be removed without compromising its structural behavior [15,16]. By combining AM with topology optimization, highly efficient lightweight designs become feasible that are specifically adapted to load paths and weight. A topology optimization method for reducing gearbox radiated noise is proposed based on a validated noise prediction model [17]. By targeting surface areas with the highest acoustic contribution, noise-reducing features such as ribs can be effectively placed, resulting in significant noise reduction and improved design efficiency, with potential for application in damping layer integration and lightweight gearbox design. A structural–acoustic coupled method was developed to improve the noise radiation characteristics of a gearbox housing [18]. Using topology optimization, design modifications were identified that led to a measurable reduction in the overall sound pressure levels. A topology optimization approach was applied to a gearbox housing for an agricultural electric vehicle, leading to structural design modifications that effectively reduced noise emissions under operating conditions [19]. A major challenge in AM is the gap between idealized topology-optimized designs and the constraints of real-world fabrication. Topology optimization frameworks are proposed that integrate manufacturing limits and account for process-induced uncertainties [20].

This study focuses on the optimization and manufacturing of a specific gearbox housing used in electric vehicle drivetrains. The noise level of electric vehicles (EVs) with multi-speed gearboxes is a topic of ongoing research, driven by the goal of developing quieter and more comfortable vehicles. Optimizing gearbox housings has the potential to substantially reduce noise generation, thereby enhancing user perception and evaluation [21]. Furthermore, gearbox housings are being analyzed in the commercial vehicle sector with regard to reduced weight and noise emission [22]. Additive manufacturing, and more specifically 3D metal printing, have already become firmly established in a considerable proportion of the electromobility industry [23]. This technology facilitates the production of components that have been developed with specific consideration for the requirements of electromobility. With regard to AM, the most significant cost parameters are typically the processing costs, with machine and labor costs accounting for the largest shares [24]. For larger parts, material costs can constitute the second-largest expense, potentially exceeding labor costs depending on the type of material [25]. However, it is also possible that manufacturing costs for components may be exceeded by pre- and post-processing costs [26]. In the case of parts with highly complex geometries, AM can be more suitable and cost-effective [27]. AM-manufactured components, however, often require post-processing due to the quality of their surface [28,29]. This may apply to the relevant functional surfaces of the component. For the housing in question, this applies to the mounting points/surfaces of the gearbox and its components. Nevertheless, this is not a disadvantage specific to AM as it may also be necessary for a component manufactured using aluminum casting. AM can be economically competitive with conventional machining if factors such as part orientation and post-processing are optimized [25]. Furthermore, reusing metal powder improves the economic feasibility.

Further research and development are required to fully realize the benefits of AM, including functional integration and increased power density, as well as expanding its application areas. Nevertheless, challenges related to cost calculation and process chain optimization persist. High processing costs, process-induced defects, and limited material choices remain key limitations of AM [30].

In addition, new approaches such as hybrid material combinations (e.g., aluminum with magnesium or titanium) are evaluated to further enhance mechanical performance while minimizing weight. Numerical simulations, including structural and modal analyses, are employed to validate the design. Building upon previous work by the authors [31], the paper explores the combined use of topology optimization and additive manufacturing techniques to design a gearbox housing that meets the structural and lightweight demands of electric vehicle powertrains.

2. Methods

2.1. Lightweight Design

The following section examines the application of topology optimization to a specific gearbox housing supplied by an industrial project partner (see Figure 1a). The objective is to achieve a significant weight reduction and preserve the housings’ stiffness. It is part of a planetary gearbox, carries two ring gears, and is exposed to both static and dynamic loads. Static loads act on the flanges where the housing is mounted. Additional torsional loads are incurred by the tooth mesh during gearbox operation. Consequently, the torsional stiffness is regarded as a relevant comparison parameter.

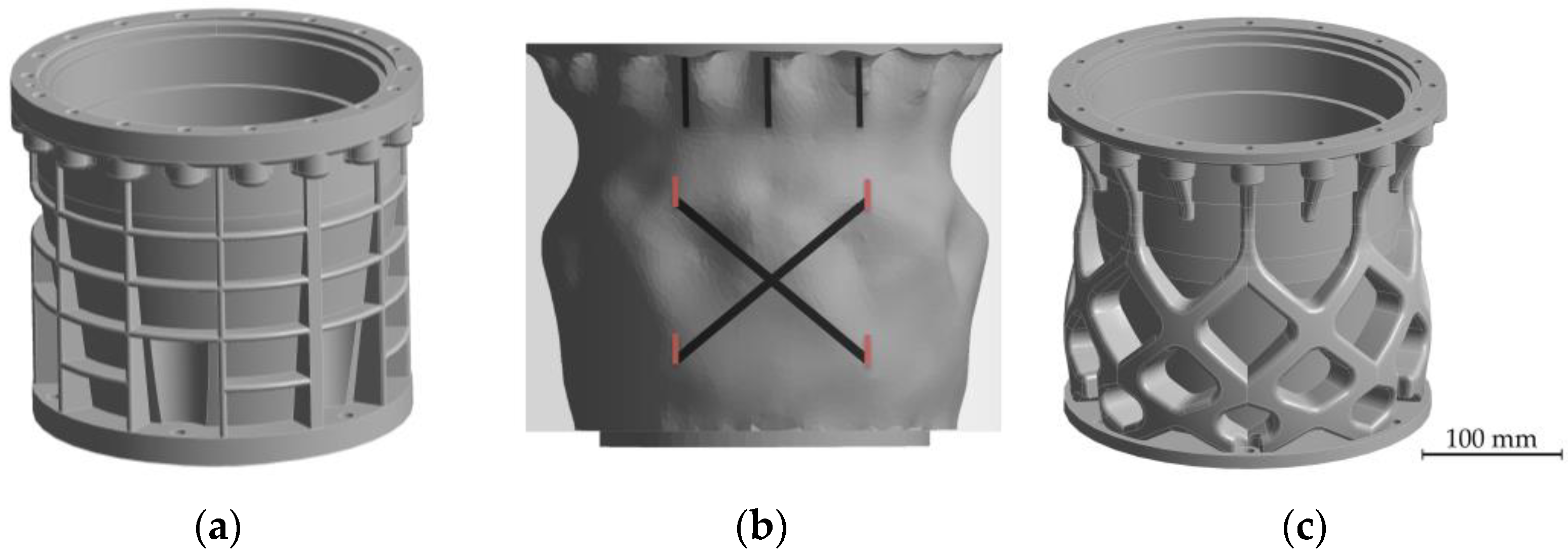

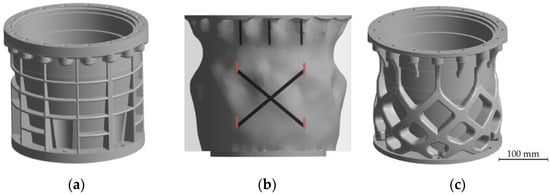

Figure 1.

(a) Original gearbox housing; (b) optimization region and optimization result; (c) optimized housing.

An integral design approach was used to propose a monolithic lightweight gearbox housing. Based on the defined load cases (static mounting forces and dynamic forces from gear meshing), the specific optimization region, and other boundary constraints (e.g., min. wall thickness), the topology optimization is performed. The topology optimization problem was formulated as a mass minimization under torsional stiffness and volume constraints, applying a density-based material interpolation scheme with penalization (penalty parameter = 3; minimum density = 0.001). Two static load cases representing forward and reverse driving were considered, corresponding to an operating point of 150 kW with a maximum output torque of 2400 Nm; due to industrial confidentiality, the detailed force vectors and constraint definitions cannot be disclosed. Cyclic symmetry with eight sectors was enforced, reflecting the geometry and bolting pattern of the ring gears. The design space comprised the complete housing except for the functional mounting faces, which were treated as non-design regions. The topology optimization did not include additive manufacturing-specific constraints such as overhang angle limitations or support minimization. Consequently, the resulting design may require additional support structures during manufacturing. The optimization was carried out using the Scpip algorithm integrated in ANSYS 2024 R2, while the underlying finite element analyses were solved with the iterative PCG solver.

The result of the topology optimization shows an X-shaped structure, as indicated in Figure 1b. The ring gear mounting points are located directly at the tips of the X-structure. Thus, the load will be passed directly on to the supporting structure. This structure’s shape and location strongly affect the housing’s torsional stiffness. That allows reducing the housing’s wall thickness. Additionally, stiffening ribs are indicated at the designated mounting points on the upper flange.

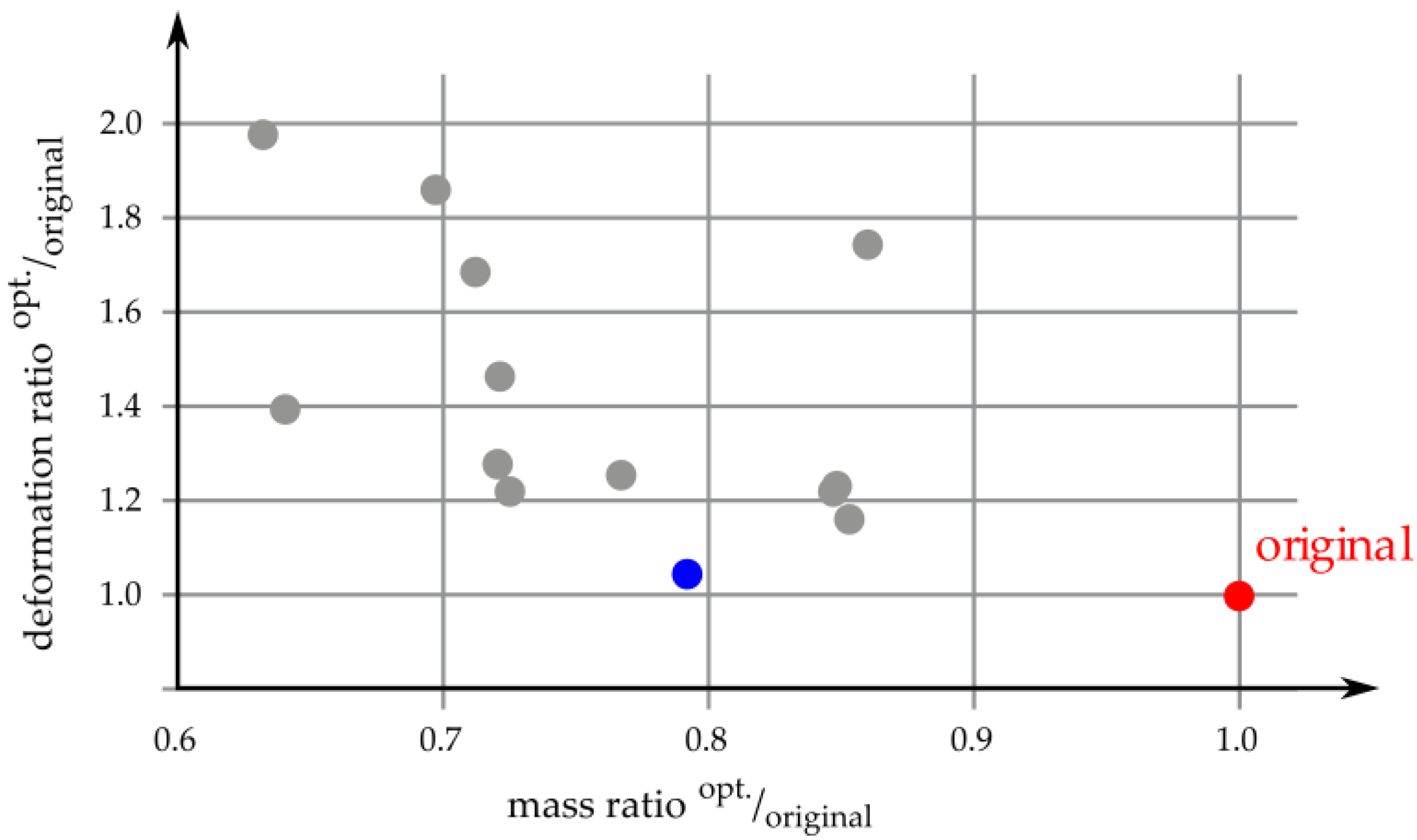

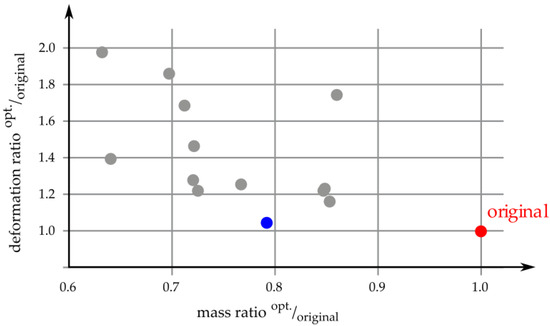

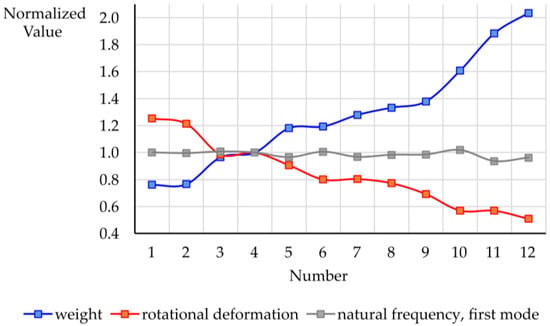

Building upon the topology-optimized geometry, parameter optimizations were performed to refine the outer profile of the housing. The characteristic X-shaped rib structure served as the design basis, while variations in rib width and height, as well as adjustments to the thickness of the turned part and the flanges, were thoroughly evaluated. Uniform aluminum material was used throughout this phase. Thirteen design variants were developed and assessed, and the configuration providing the best trade-off between reduced mass and acceptable torsional deformation was selected for further analysis (marked by the blue dot in Figure 2). This selected design serves as the foundation for subsequent steps, including detailed simulation and the development of a hybrid manufacturing concept.

Figure 2.

Results of the optimization showing normalized mass and deformation ratios for thirteen stiffening structure variants.

For the selected optimized design (see Figure 1c), the weight was reduced by approximately 21% compared to the original housing, while torsional deformation increased by only about 5%, remaining within acceptable design limits. This final geometry serves as the basis for both the additive manufacturing concept and the hybrid material study below.

2.2. Additive Manufacturing Concept

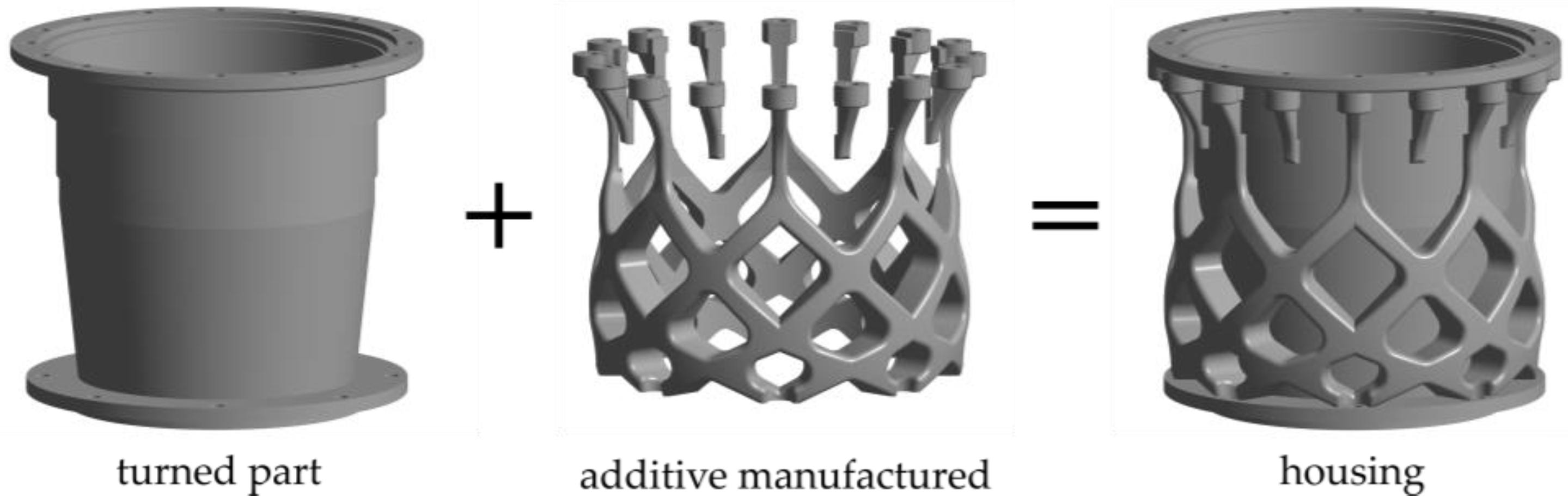

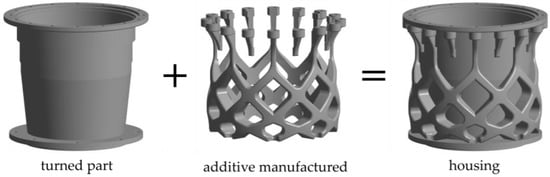

In the case of the optimized housing, additive manufacturing is feasible but requires careful evaluation regarding size, mass, and economic viability. The manufacturing concept shown in Figure 3 was developed. It is based on Laser Metal Deposition and includes a hybrid material design idea.

Figure 3.

Manufacturing concept combining the turned part and the additively manufactured structure.

The inner part is a turned component that serves as a support structure for the AM process. Figure 3 shows a view of the housing with localized reinforcement in high-load areas achieved by this hybrid material approach. The turned part’s geometry is provided by the dimensions of the bearings, the ring gears, and sealings.

The outer profile of the turned part follows both the inner profile and the intention of non-complex manufacturing. To decrease additive manufacturing time and material consumption, the mounting flanges are added to the turning part. While this is more challenging for AM, it should provide benefits in terms of cost. Printed flanges are technically feasible but significantly increase the time required for printing due to their volume. The outer profile (see Figure 3, additive manufactured) will be created using LMD. As this allows adding complex structures directly on 3D surfaces, the stiffening structure as described above can be produced without further processing steps.

Compared to integral SLM manufacturing, the proposed hybrid approach reduces build time and material consumption by limiting additive processing to the outer rib structure while using a pre-machined core for functional interfaces. This also mitigates residual stress and distortion issues commonly observed in large SLM parts as the bulk of the component is produced by conventional turning. However, this approach introduces challenges such as metallurgical compatibility at the interface, potential formation of brittle intermetallic phases, and thermal stress management. These issues require careful process parameter control and may necessitate interlayers or post-processing heat treatments. However, the technical viability of the component was confirmed through consultation with an industrial partner.

2.3. Material Selection and Simulation

The primary material selected was aluminum due to its compatibility with LMD processes and favorable specific mechanical properties. However, a hybrid approach integrating magnesium and titanium in high-stress areas was also evaluated to enhance mechanical strength without significantly increasing weight. Finite element analysis and modal analysis were used to evaluate the structural and dynamic behavior of the optimized housing under various operational loads. The simulation setup follows the methodology established in [31]. These simulations analyzed deformation, stress distribution, and natural frequencies to ensure that the design met torsional stiffness requirements and minimized potential resonance issues.

The verification model was meshed with ten-node tetrahedral elements (SOLID187) using a global element size of 4 mm. The solid mesh comprised approximately 1.78 × 105 SOLID187 elements; in total (including contact elements), the model contained about 2.27 × 105 elements and 3.29 × 105 nodes. Static simulations were solved in ANSYS using the iterative PCG solver, and the above introduced load cases were applied. Convergence was controlled via solver residuals, and a mesh influence study was conducted to balance accuracy and computational effort. Validation relied on plausibility checks, confirming that displacements and stresses were consistent with the applied torque and modeled supports. In addition, a modal analysis of the same model was carried out using the Block Lanczos eigensolver to compute the natural frequencies and mode shapes. The extracted eigenfrequencies and effective modal masses provide the basis for evaluating potential resonance phenomena and ensuring noise, vibration, and harshness (NVH) compliance. The results show a shift in natural frequencies compared to the original design, which can reduce the risk of resonance at typical operating speeds. This analysis is particularly relevant as EV components must be designed with stricter NVH requirements to ensure driver comfort [32]. The following material study represents an extension of the outlined approach with a view to examining further aspects.

The utilization of LMD in conjunction with turning can result in substantial reductions in material consumption, machine time, and build rates. Laser manufacturing is very expensive compared to conventional processes such as turning and milling, which is why the focus here must be on significant cost reduction. In addition to the above-presented combination of different manufacturing processes, the use of various materials will also be examined. This is to determine whether, in addition to the advantages of the manufacturing combination, benefits in the mechanical behavior of the structure can be achieved.

Testing the behavior of the housing with different materials, an aluminum alloy, a titanium alloy, a magnesium alloy, and a stainless steel were selected to cover a wide range of commonly used metals. Table 1 shows the details of the chosen materials. All selected materials are compatible with LMD in principle. However, detailed manufacturing aspects such as processing parameters were not considered at this stage as the focus is on mechanical suitability.

Table 1.

Properties of considered materials.

In Table 1, the specific modulus is calculated for each material to support a comparative assessment. The specific modulus is defined as the ratio of a material’s Young’s modulus to its density , expressed as

It represents the stiffness-to-weight efficiency of a material and is a key indicator in lightweight design. A higher specific modulus implies that a material can provide greater stiffness per unit mass, making it particularly suitable for applications where both mechanical performance and weight reduction are critical.

The materials used in this study, as listed in Table 1, were selected based on their theoretical compatibility with the LMD process. While all individual materials are considered processable via LMD under controlled conditions, the combination of dissimilar materials introduces additional metallurgical and thermal challenges. These include the formation of brittle intermetallic phases, differences in thermal expansion coefficients, and potential residual stresses at the interface.

Recent research has also demonstrated the feasibility of using LMD for dissimilar material combinations, such as titanium on stainless steel, by carefully controlling process parameters to reduce interfacial defects and phase formation [7]. Strategies such as laser beam offsetting and tailored thermal management are considered promising approaches to mitigate the formation of undesirable phases. The use of interlayers (e.g., nickel) represents another potential method to improve joint integrity. However, these approaches require further experimental validation and are not yet widely established in industrial practice.

Therefore, the material combinations are to be understood as theoretically viable configurations for simulation purposes. Their practical implementation would necessitate additional process development to ensure metallurgical compatibility and structural reliability. This assumption forms the basis of the comparative evaluation of mechanical performance and weight efficiency in the present study. For comparability, the geometry was kept constant across all the material variants. While this isolates the effect of material properties, it does not exploit the full potential of high-stiffness materials, which represents a methodological limitation.

As described in the topology optimization section, all the optimized housings will be compared to the original housing and its specific mechanical behavior. In the present material study, the stiffness of the housing is also compared and evaluated based on its rotational stiffness. This is determined by fixing the housing on one side, applying the known mechanical loads from the gear mesh, and measuring the deformation (rotational) at the opposite end. Additionally, in this study, a modal analysis will be performed under the same boundary conditions to gain insights into whether the choice of materials has an impact on the natural frequencies of the housing. Knowledge of the natural frequencies is important if the dynamic and acoustic behavior of the gearbox is to be evaluated in the further development steps. The authors presented a method for this in a previous article [32].

3. Results

While the Section 2 includes selected findings to illustrate the design and development process, the following section focuses on the key results regarding material performance and cost efficiency that are central to the study’s objectives. The presented study is based on a fully simulated approach; no experimental validation was conducted. Manufacturing-induced imperfections or residual stresses were not considered and may influence real-world performance. Additionally, no design modifications were implemented to adapt the design to the material.

3.1. Material Study Results

Table 2 shows the results of the material study. It is to be read as follows. The turned part material and stiffening structure material columns show the material assigned to each part of the housing for the simulation. Details of the materials are provided in Table 1. The result parameters include weight, rotational deformation, and first natural frequency. The maximum stress at the highest load results in a safety factor against plastic deformation, which is well below the critical values. Consequently, stress will not be further examined in this study. The version column indicates that there are two different versions for the same material combination. Initially, the results indicate that moving the flanges (the upper or lower end of the turned part, cf. Figure 3) from the turned part into the LMD part could offer advantages. Version 1 corresponds to the geometry shown in Figure 3, while version 2 has the flanges manufactured additively. Depending on the density of the material, this could increase the cost of additive manufacturing, but it could also significantly reduce the weight.

Table 2.

Evaluation of material combinations for the gearbox housing.

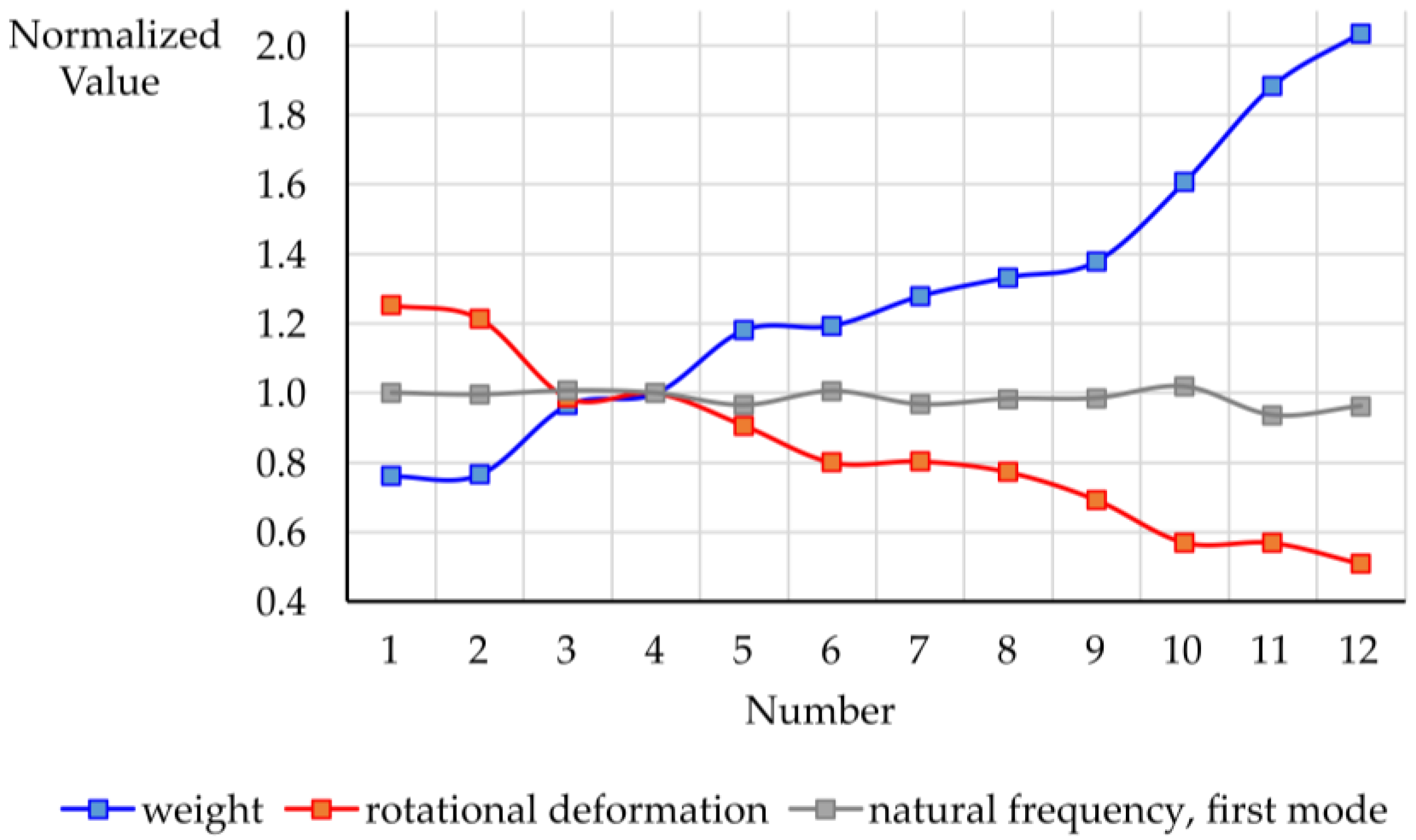

The data from Table 2 were plotted in Figure 4, normalized using the aluminum–aluminum combination as the baseline (see no. 4 in Table 2). As weight increases from version 1 to 12, rotational deformation generally decreases. This behavior follows the general trend that Young’s modulus increases with density among the considered materials; see Table 1. Due to the used materials, there was no significant improvement in stiffness when taking the increased weight into account. Considering the specific modulus, as shown in Table 1, the ratio of Young’s modulus to density of the aluminum alloy (AlSi7Mg) is the best among the considered materials. This indicates that the aluminum alloy is the best choice for achieving high stiffness with low weight, regardless of the geometry, as confirmed by the simulation results.

Figure 4.

Material study results.

Comparing part numbers 6 and 7, a notable observation can be made. As both have the same material combination but come from different geometry variants, the flanges remain the same material (aluminum in this case). Both the resulting rotational deformation and the weight remain at the same level. This indicates that both the turned part and the stiffening structure have a similar influence on the rotational stiffness. All the results for the first mode of natural frequencies remain almost constant. Therefore, the choice of material appears to have a negligible effect on the natural frequencies. This could also be explained by the specific modulus provided in Table 1.

From a manufacturing aspect, the use of aluminum alloys for both the turned part and the stiffening structure is the most practical option. This is because, even when different versions of aluminum alloys are used, they have a similar melting temperature, which makes it easier to adjust the LMD process. In addition, properties such as corrosion resistance, temperature resistance, and biocompatibility, which are offered by titanium alloys, are not relevant for the given application in a gearbox housing. Aluminum therefore fulfils all the requirements and typically offers lower material costs compared to magnesium or titanium.

As previously noted, the geometry used for all the material variants remained unchanged throughout the study. This means that the structural layout, including wall thicknesses, rib structures, and flange dimensions, was not further adapted to the specific mechanical properties of each material. While this approach allows for a direct evaluation of material effects under identical boundary conditions, it does not fully exploit the mechanical potential of high-stiffness materials.

In particular, the use of stainless steel for the turned part (see variants 9–12 in Table 2) resulted in significantly lower rotational deformation compared to aluminum or magnesium. This indicates a considerable stiffness reserve that could be exploited through geometric refinement. For instance, reducing the wall thicknesses of the turned part could lead to substantial weight savings without compromising structural integrity, particularly with respect to rotational deformation. Such an approach would be especially relevant for high-stiffness materials like stainless steel or titanium, where the mechanical performance exceeds the baseline requirements. However, this potential was not explored in the present study as the focus was placed on evaluating material effects under a fixed topology-optimized geometry.

3.2. Cost Evaluation

In this section, three different manufacturing approaches for the optimized housing are evaluated: hybrid manufacturing using LMD, full additive manufacturing using SLM, and conventional aluminum casting. LMD is intended for the application of the external profile structure to the turned part. The costs shown include only the application of the structure, excluding the turned part.

In additive manufacturing, cost models vary in their level of detail and scope. These models can be broadly classified into three categories [33]. Task-based models estimate costs for individual phases such as production-related costs, focusing on specific operations and resource consumption. Method-based models are characterized by their accounting perspective and are based on qualitative and quantitative assumptions. Level-based models take a more holistic view, incorporating supply chain, product development, and operational cost to evaluate the full production environment.

The costs associated with an additively manufactured component depend largely on the selected AM process and can be categorized on the process level into three distinct categories: pre-processing cost, processing cost, and post-processing cost [28]. Pre-processing includes all the preparatory activities prior to the actual build. This encompasses the design or adaptation of the 3D model (design for AM), selection of appropriate process parameters, and machine setup.

The processing cost, therefore, refers to the manufacturing of the part. Cost drivers in this phase include the raw material (e.g., metal powder or wire), machine operating time, including energy consumption and depreciation, and operator supervision. Depending on the selected process, efficiency and material utilization can vary significantly due to factors such as deposition rates or material waste. With regard to processing costs, a sensitivity analysis can provide a detailed assessment of the most important cost drivers. A comprehensive study identified material cost, machine utilization, and layer thickness as the parameters having the greatest influence on unit costs [34]. Other contributing factors include labor and energy costs, although to a lesser extent.

Post-processing often accounts for a substantial portion of the total cost. This phase involves all the subsequent operations, such as removal of support structures, heat treatment, surface finishing (e.g., machining and grinding), and quality assurance activities. Some processes may require extensive post-processing, which can exceed the cost of the build itself.

The cost data analyzed in this study are based on quotations provided by industrial SLM service providers, each calculated based on the supplied CAD geometry. These quotations represent total prices for the manufactured part, reflecting the provider’s internal cost structure and pricing model. Since the quotations do not include a detailed breakdown of individual cost components, it is not possible to distinguish between pre-processing, processing, and post-processing costs within the available data.

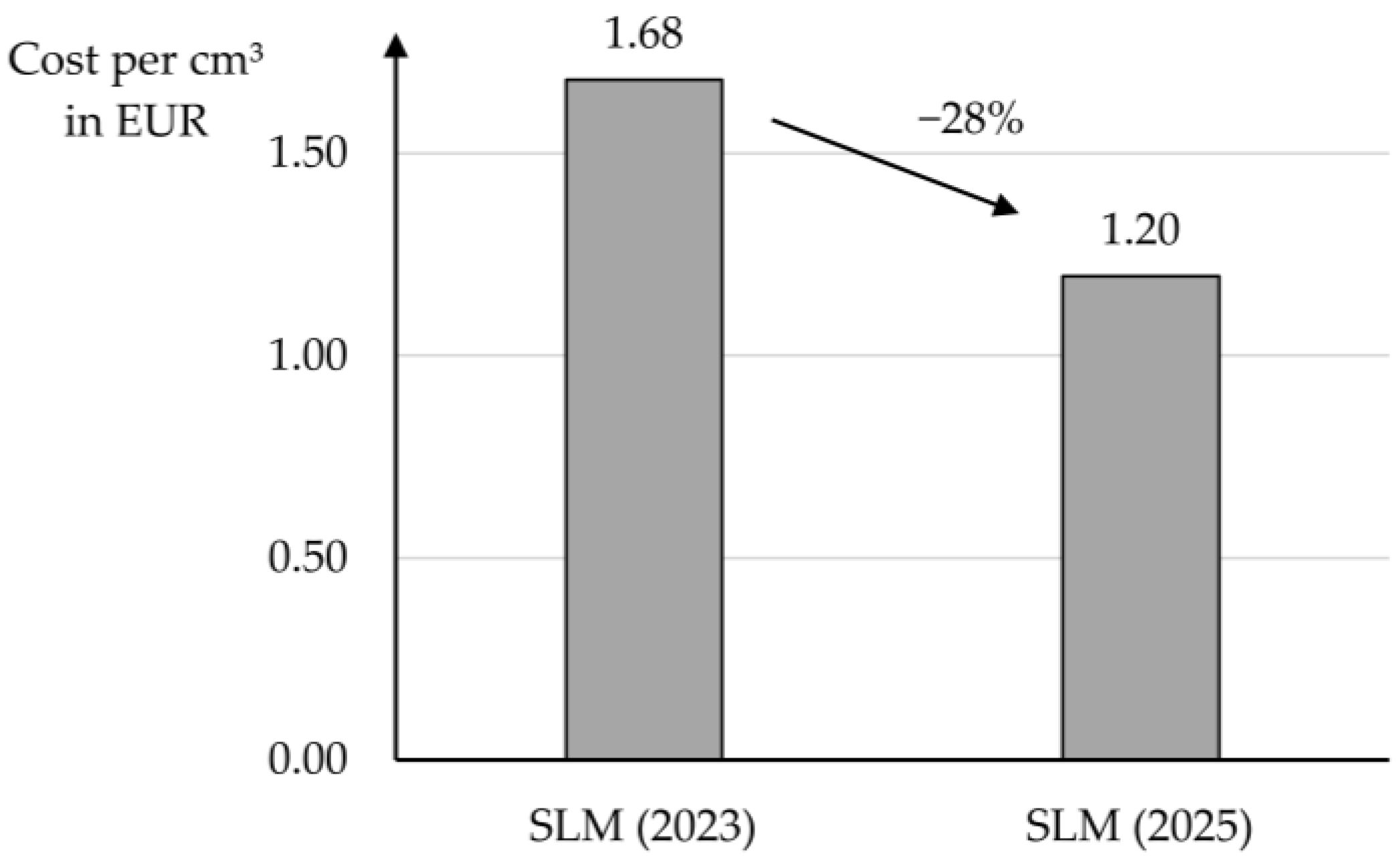

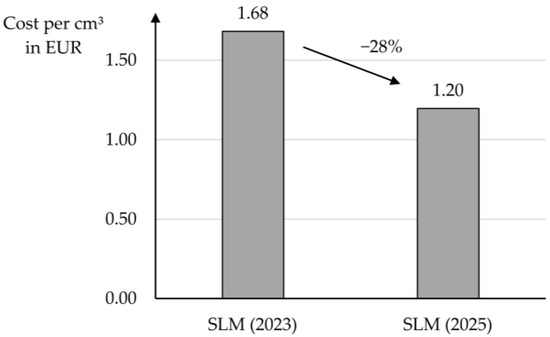

These quotations typically include standard steps involved in the build process, such as required support structures. However, extensive post-processing steps, such as machining or heat treatment, require additional expenses that are not included in the shown costs. The analysis is therefore limited to the quoted manufacturing cost for the as-built part. Figure 5 illustrates a comparison of the normalized costs of the aluminum housing fabricated via SLM. In the context of additive manufacturing, volumetric cost, expressed in EUR/cm3 (or USD/cm3), can be used to estimate production expenses as they allow for a direct comparison between different materials, machine types, and process parameters.

Figure 5.

Difference in normalized costs for Selective Laser Melting across manufacturing service providers.

The price shown represents the most cost-effective of several quotes from manufacturing service providers. The authors observed a substantial decline in the market price, decreasing by approximately 28% compared to the price two years ago. This development can be attributed to a combination of factors. The possible causes include technological advancements in additive manufacturing, increased market competition, and fluctuations in raw material prices (metal powder). Furthermore, learning effects and investments in research and development of new machines and processes may have also contributed to an optimization of production costs, thereby leading to a reduction in price. Since machine investment and processing costs represent the largest share of the total production cost in SLM, the greatest potential for further cost reductions may be found in key drivers such as machine leasing/ownership price and improvements in build speed [28,35]. The costs in Figure 5 are in alignment with the typical range reported for analogous AM processes and materials. For AlSi10Mg processed via laser powder bed fusion, volumetric production costs are reported in the recent literature ranging from 0.7 to 1.85 EUR/cm3, based on machine hourly rates and build rate [36].

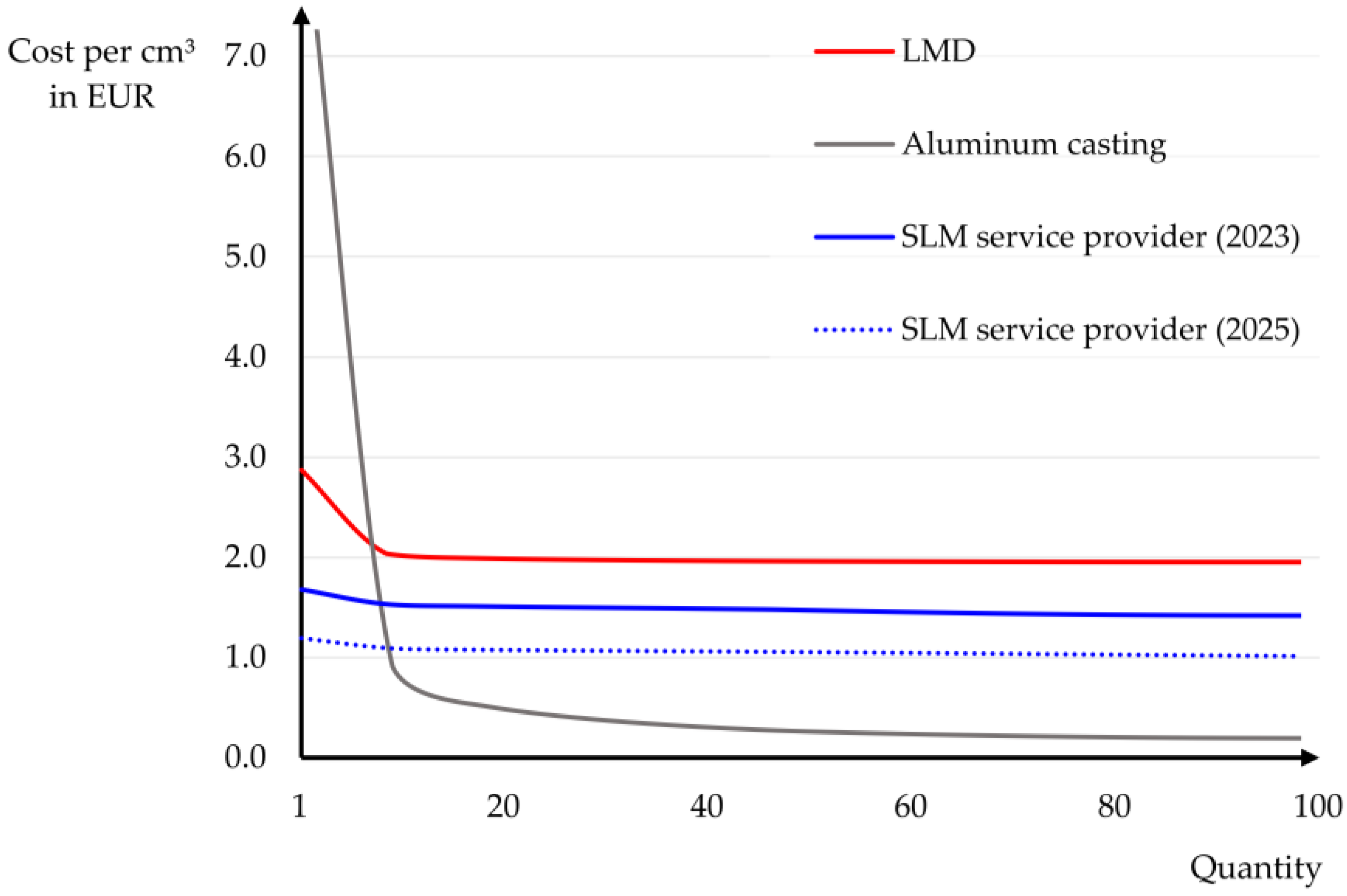

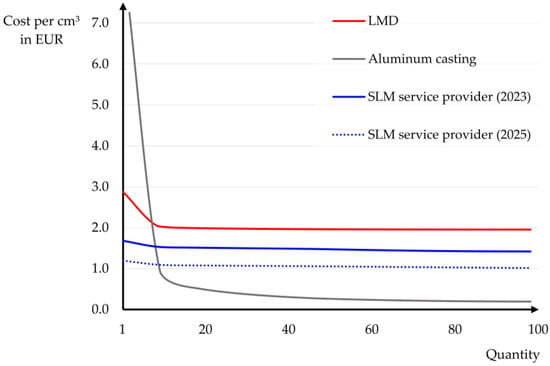

For the cost estimation of SLM, previously obtained quotes from contract manufacturing service providers were used. Moreover, the cost of aluminum casting is incorporated into the analysis. As the number of units produced is low (up to 100), aluminum die-casting is not included in this evaluation. The financial outlay required for LMD and aluminum casting was derived from an industry project partner.

Before comparing the cost per unit volume across different manufacturing methods, it is important to note that the underlying cost model is based on aggregated quotes and generalized assumptions as a detailed breakdown of the individual cost drivers was not available within the scope of this work. While this provides a useful baseline, it does not include a breakdown of individual specific cost factors such as machine hourly rates, energy consumption, powder utilization efficiency, or post-processing requirements. These factors can vary significantly depending on the machine setup, operator experience, and part geometry.

Figure 6 shows the cost per volume unit against the quantity of units. This figure presents a comparison of the production costs between traditional manufacturing methods and those utilizing AM methods. Both fixed and variable costs are taken into account for the manufacturing process. The total cost of LMD is compared to the cost of manufacturing methods that do not consider hybrid design.

Figure 6.

Manufacturing cost comparison for different manufacturing methods.

The traditional casting method is characterized by high fixed costs, which, however, exhibit a pronounced decrease with increasing production quantities due to the relatively low variable costs. Consequently, a cost per unit volume of approximately 0.20 EUR/cm3 can be achieved at a production quantity of 100 units. In contrast, the hybrid manufacturing method emerges as the most expensive variant as the variable costs exhibit a relatively modest decline with increasing production quantities. A similar trend is observed for the contract manufacturer’s quote for SLM printing. Nevertheless, some providers are able to offer more substantial discounts for larger production quantities due to more efficient utilization of assembly space. This enables the realization of a cost per unit volume of less than 1.0 EUR/cm3 for SLM-manufactured aluminum components at a production quantity of 100 units.

4. Conclusions

This study demonstrates that topology optimization combined with additive manufacturing enable significant weight reduction regarding gearbox housings for electric vehicle applications while maintaining the required mechanical properties. A hybrid manufacturing concept, integrating turning and LMD, was developed to facilitate the production of complex optimized geometries. Although the feasibility of this approach was confirmed on the basis of a simulation study, the economic evaluation revealed that it does not offer a cost advantage over full additive manufacturing or conventional casting under the current conditions. A more detailed cost breakdown and sensitivity analysis would further enhance the robustness of this evaluation and support future design decisions.

The simulative material study showed that aluminum alloys remain the preferred choice due to their superior specific modulus and favorable manufacturing characteristics. Alternative material combinations provided no significant benefits in terms of torsional stiffness or dynamic behavior. However, the use of steel for the turned part demonstrated a considerable increase in stiffness, opening up new design possibilities, such as reducing wall thickness to achieve a lighter design without sacrificing mechanical performance. Further optimization potential exists based on the fact that the maximum stress is well below the allowable values. Building on these findings, subsequent research could explore concurrent optimization of geometry and material selection, where both the structural layout and material selection are iteratively adapted to maximize weight efficiency and mechanical performance. This would allow for a more comprehensive exploitation of the material-specific advantages and could further enhance the lightweight potential of hybrid gearbox housing designs.

The main limitations of this study include its exclusive reliance on numerical simulations, the absence of experimental validation, and the simplified cost analysis.

Future work will focus on optimizing hybrid manufacturing strategies to improve cost efficiency and exploring material and design adaptations further to meet specific load and NVH requirements. Additionally, topology optimization and additive manufacturing offer promising potential for further weight and efficiency improvements in EV powertrains when applied to other drivetrain components.

Author Contributions

Conceptualization, S.J. and T.L.; methodology, S.J.; software, S.J. and T.L.; validation, S.J. and T.L.; formal analysis, S.J. and T.L.; investigation, S.J. and T.L.; resources, S.J.; data curation, S.J. and T.L.; writing—original draft preparation, S.J. and T.L.; writing—review and editing, S.J. and T.L.; visualization, S.J. and T.L.; supervision, S.J.; project administration, S.J.; funding acquisition, S.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the German Federal Ministry of Research, Technology and Space (BMFTR), grant number 13FH527KA9.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| AM | Additive Manufacturing |

| DMLS | Direct Metal Laser Sintering |

| EV | Electric Vehicle |

| HAM | Hybrid Additive Manufacturing |

| HASM | Hybrid Additive–Subtractive Manufacturing |

| LMD | Laser Metal Deposition |

| NVH | Noise, Vibration, and Harshness |

| SLM | Selective Laser Melting |

References

- Jäger, S.; Linde, T. Review of the Cost-Situation of a Lightweight Electric Vehicle Gearbox Housing through Topology Optimization and Additive Manufacturing. In Proceedings of the 38th International Electric Vehicle Symposium and Exhibition (EVS 38) Proceedings, Gothenburg, Sweden, 15–18 June 2025. [Google Scholar]

- Hermann, F.; Vogt, S.; Göbel, M.; Möller, M.; Frey, K. Laser Metal Deposition of AlSi10Mg with high build rates. Procedia CIRP 2022, 111, 210–213. [Google Scholar] [CrossRef]

- Magerramova, L.; Isakov, V.; Shcherbinina, L.; Gukasyan, S.; Petrov, M.; Povalyukhin, D.; Volosevich, D.; Klimova-Korsmik, O. Design, Simulation and Optimization of an Additive Laser-Based Manufacturing Process for Gearbox Housing with Reduced Weight Made from AlSi10Mg Alloy. Metals 2022, 12, 67. [Google Scholar] [CrossRef]

- Ghasempour-Mouziraji, M.; Lagarinhos, J.; Afonso, D.; Alves de Sousa, R. A review study on metal powder materials and processing parameters in Laser Metal Deposition. Opt. Laser Technol. 2024, 170, 110226. [Google Scholar] [CrossRef]

- Barreiro, P.; Armutcu, G.; Pfrimmer, S.; Hermes, J. Quality improvement of an aluminum gearbox housing by implementing additive manufacturing. Forsch. Ingenieurwesen 2022, 86, 605–616. [Google Scholar] [CrossRef]

- Barreiro, P.; Bronner, A.; Hoffmeister, J.; Hermes, J. New improvement opportunities through applying topology optimization combined with 3D printing to the construction of gearbox housings. Forsch. Im Ingenieurwesen 2019, 83, 669–681. [Google Scholar] [CrossRef]

- Cui, D.; Aggarwal, A.; Leparoux, M. Laser metal deposition of titanium on stainless steel with high powder flowrate for high interfacial strength. Int. J. Mater. Form. 2024, 17, 18. [Google Scholar] [CrossRef]

- Zhong, C.; Liu, J.; Zhao, T.; Schopphoven, T.; Fu, J.; Gasser, A.; Schleifenbaum, J.H. Laser Metal Deposition of Ti6Al4V—A Brief Review. Appl. Sci. 2020, 10, 764. [Google Scholar] [CrossRef]

- Bruzzo, F.; Medapati, M.P.R.; Pullini, D.; Ronco, F.; Bertinetti, A.; Tommasi, A.; Riede, M.; Lòpez, E.; Brückner, F. Sustainable laser metal deposition of aluminum alloys for the automotive industry. J. Laser Appl. 2022, 34, 042004. [Google Scholar] [CrossRef]

- Muslim, T.; Karagoz, T.; Kurama, S.; Sezer, P.; Yazici, O.F.; Ozkok, R. Laser metal deposition of 17–4 PH stainless steel: Geometrical, microstructural, and mechanical properties investigation for structural applications. CIRP J. Manuf. Sci. Technol. 2023, 41, 69–79. [Google Scholar] [CrossRef]

- González-Barrio, H.; Calleja-Ochoa, A.; Norberto López de Lacalle, L.; Lamikiz, A. Hybrid manufacturing of complex components: Full methodology including laser metal deposition (LMD) module development, cladding geometry estimation and case study validation. Mech. Syst. Signal Process. 2022, 179, 109337. [Google Scholar] [CrossRef]

- Armstrong, M.; Mehrabi, H.; Naveed, N. An overview of modern metal additive manufacturing technology. J. Manuf. Process. 2022, 84, 1001–1029. [Google Scholar] [CrossRef]

- Liu, J.; Huang, J.; Zheng, Y.; Hou, S.; Xu, S.; Ma, Y.; Huang, C.; Zou, B.; Li, L. Challenges in topology optimization for hybrid additive–subtractive manufacturing: A review. Comput.-Aided Des. 2023, 161, 103531. [Google Scholar] [CrossRef]

- Ibhadode, O.; Zhang, Z.; Sixt, J.; Nsiempba, K.M.; Orakwe, J.; Martinez-Marchese, A.; Ero, O.; Shahabad, S.I.; Bonakdar, A.; Toyserkani, E. Topology optimization for metal additive manufacturing: Current trends, challenges, and future outlook. Virtual Phys. Prototyp. 2023, 18, e2181192. [Google Scholar] [CrossRef]

- Bendsøe, M.P.; Sigmund, O. Topology Optimization: Theory, Methods, and Applications, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2011; ISBN 364207698X. [Google Scholar]

- Sigmund, O.; Maute, K. Topology optimization approaches. Struct. Multidiscip. Optim. 2013, 48, 1031–1055. [Google Scholar] [CrossRef]

- Qi, L.; Zhou, J.; Jin, P.; Wang, M.; Su, Y.; Zhou, H.; Liu, G.; Song, L. Low noise optimization of two-stage gearbox housing structure based on acoustic contribution analysis and topology optimization. J. Mech. Sci. Technol. 2023, 37, 4533–4544. [Google Scholar] [CrossRef]

- Kim, B.-S.; Han, H.-W.; Chung, W.-J.; Park, Y.-J. Optimization of gearbox housing shape for agricultural UTV using structural-acoustic coupled analysis. Sci. Rep. 2024, 14, 4145. [Google Scholar] [CrossRef] [PubMed]

- Son, G.-H.; Kim, B.-S.; Cho, S.-J.; Park, Y.-J. Optimization of the Housing Shape Design for Radiated Noise Reduction of an Agricultural Electric Vehicle Gearbox. Appl. Sci. 2020, 10, 8414. [Google Scholar] [CrossRef]

- Li, Z.; Wang, L.; Lv, T. Additive manufacturing-oriented concurrent robust topology optimization considering size control. Int. J. Mech. Sci. 2023, 250, 108269. [Google Scholar] [CrossRef]

- Shi, Z.; Liu, B.; Yue, H.; Wu, X.; Wang, S. Noise Reduction of Two-Speed Automatic Transmission for Pure Electric Vehicles. Vehicles 2023, 5, 248–265. [Google Scholar] [CrossRef]

- Gillich, N.; Sîrbu, N.; Vlase, S.; Marin, M. Study of Metallic Housing of the Adder Gearbox to Reduce the Noise and to Improve the Design Solution. Metals 2021, 11, 912. [Google Scholar] [CrossRef]

- Schuhmann, D.; Rockinger, C.; Merkel, M.; Harrison, D.K. A Study on Additive Manufacturing for Electromobility. World Electr. Veh. J. 2022, 13, 154. [Google Scholar] [CrossRef]

- Kokare, S.; Oliveira, J.P.; Santos, T.G.; Godina, R. Environmental and economic assessment of a steel wall fabricated by wire-based directed energy deposition. Addit. Manuf. 2023, 61, 103316. [Google Scholar] [CrossRef]

- Ferreira, B.; Brandão, F.; Borille, A.; Gonçalves, A.; Leite, M.; Ribeiro, I. Assessment of the technical, environmental and economic trade-offs in the early stage of metal additive manufacturing adoption. Prog. Addit. Manuf. 2025, 1–23. [Google Scholar] [CrossRef]

- Khorasani, M.; Ghasemi, A.; Rolfe, B.; Gibson, I. Additive manufacturing a powerful tool for the aerospace industry. Rapid Prototyp. J. 2022, 28, 87–100. [Google Scholar] [CrossRef]

- Mecheter, A.; Tarlochan, F.; Kucukvar, M. A Review of Conventional versus Additive Manufacturing for Metals: Life-Cycle Environmental and Economic Analysis. Sustainability 2023, 15, 12299. [Google Scholar] [CrossRef]

- Khanna, N.; Salvi, H.; Karaş, B.; Fairoz, I.; Shokrani, A. Cost Modelling for Powder Bed Fusion and Directed Energy Deposition Additive Manufacturing. J. Manuf. Mater. Process. 2024, 8, 142. [Google Scholar] [CrossRef]

- Xu, J.; Fei, Y.; Zhu, Y.; Yu, W.; Yao, D.; Zhou, J.G. A Review of Non-Powder-Bed Metal Additive Manufacturing: Techniques and Challenges. Materials 2024, 17, 4717. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Fang, J.; Wu, C.; Li, C.; Sun, G.; Li, Q. Additively manufactured materials and structures: A state-of-the-art review on their mechanical characteristics and energy absorption. Int. J. Mech. Sci. 2023, 246, 108102. [Google Scholar] [CrossRef]

- Jäger, S.; Schätzle, J.; Linde, T. Top-Down Validation Framework for Efficient and Low Noise Electric-Driven Vehicles with Multi-Speed Gearbox. World Electr. Veh. J. 2022, 13, 228. [Google Scholar] [CrossRef]

- Jäger, S.; Linde, T.; Von Schulz, K. Product Development Methodology Targeting Efficiency and Acoustics of E-Mobility Gearboxes. Tus (Tribol. Und Schmier.) 2024, 71, 33–41. [Google Scholar] [CrossRef]

- Kadir, A.Z.A.; Yusof, Y.; Wahab, M.S. Additive manufacturing cost estimation models—A classification review. Int. J. Adv. Manuf. Technol. 2020, 107, 4033–4053. [Google Scholar] [CrossRef]

- Mandolini, M.; Sartini, M.; Favi, C.; Germani, M. Cost Sensitivity Analysis for Laser Powder Bed Fusion. Proc. Des. Soc. 2022, 2, 1411–1420. [Google Scholar] [CrossRef]

- Rahmani, R.; Bashiri, B.; Lopes, S.I.; Hussain, A.; Maurya, H.S.; Vilu, R. Sustainable Additive Manufacturing: An Overview on Life Cycle Impacts and Cost Efficiency of Laser Powder Bed Fusion. J. Manuf. Mater. Process. 2025, 9, 18. [Google Scholar] [CrossRef]

- Ferreira, B.T.; de Campos, A.A.; Casati, R.; Gonçalves, A.; Leite, M.; Ribeiro, I. Technological capabilities and sustainability aspects of metal additive manufacturing. Prog. Addit. Manuf. 2024, 9, 1737–1773. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).