Evaluation of Laser Powder Bed Fusion-Fabricated 316L/CuCrZr Bimetal Joint

Abstract

1. Introduction

2. Materials and Methods

3. Results

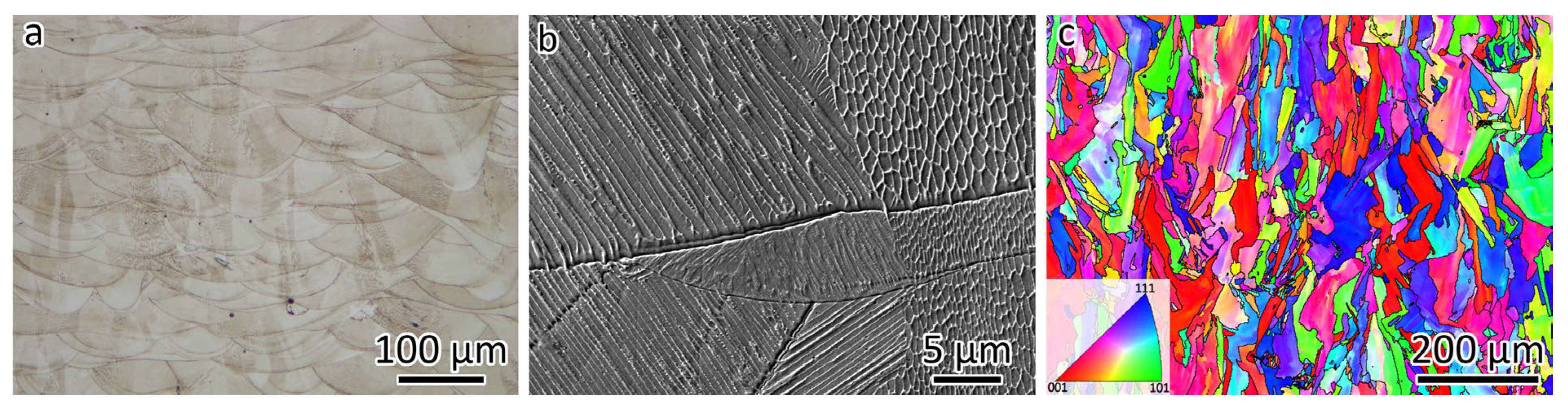

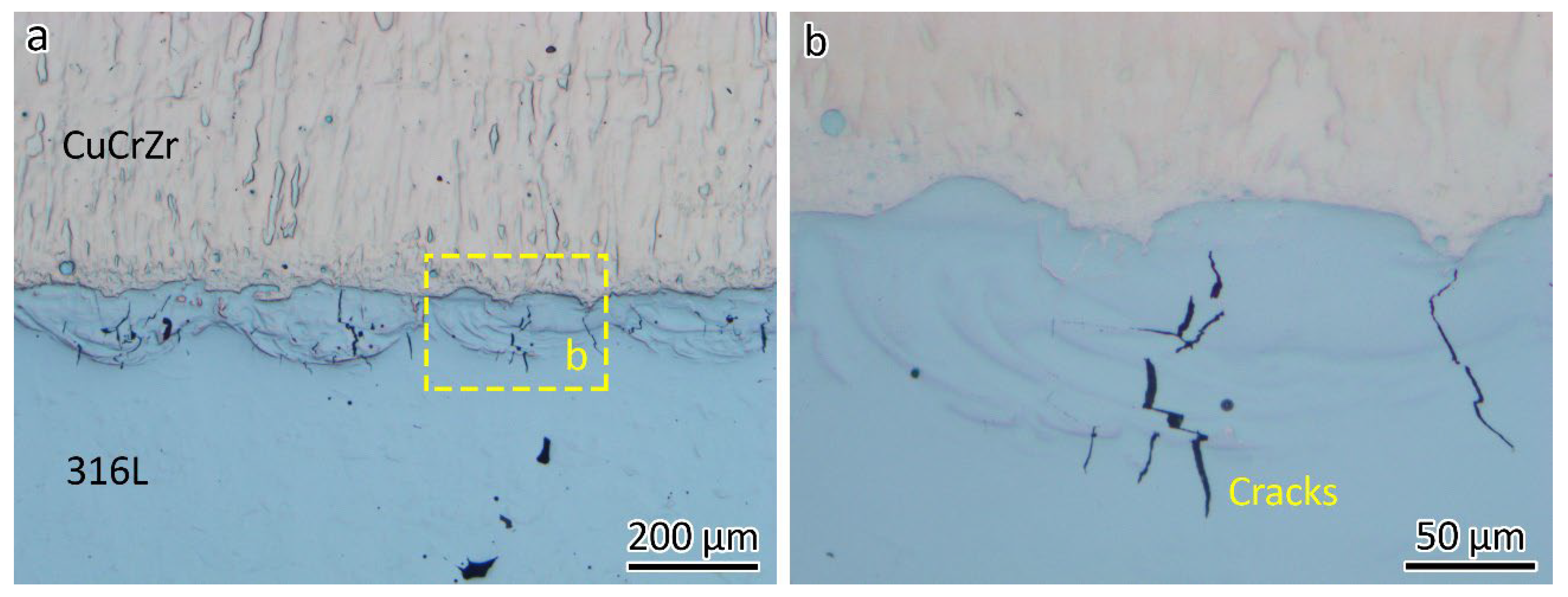

3.1. Microstructures of the LPBF-Fabricated 316L and CuCrZr

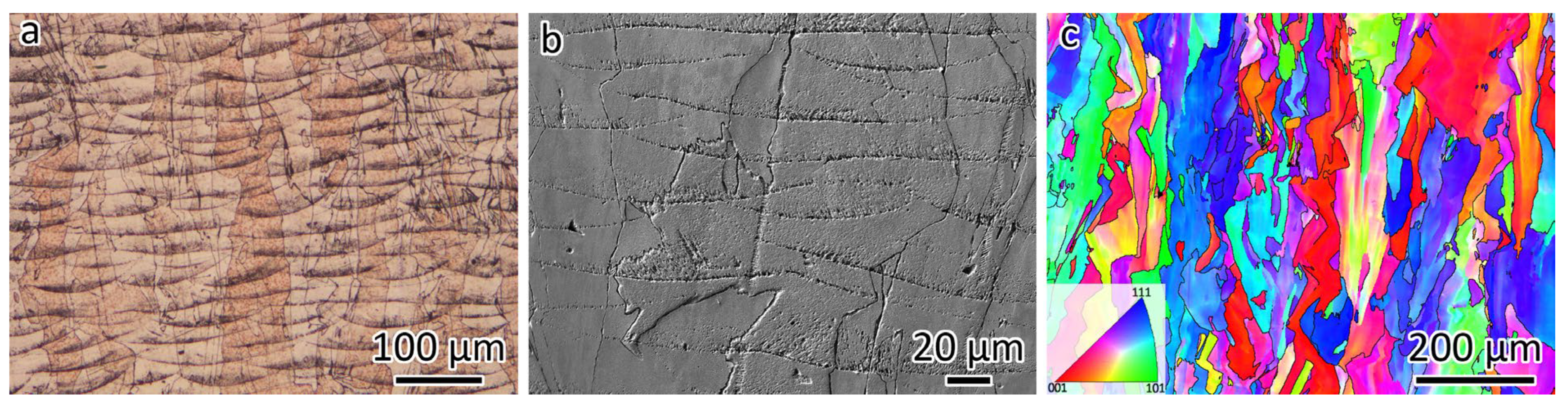

3.2. Microhardness, Tensile Properties, and Fracture Position of the Bimetal Joint

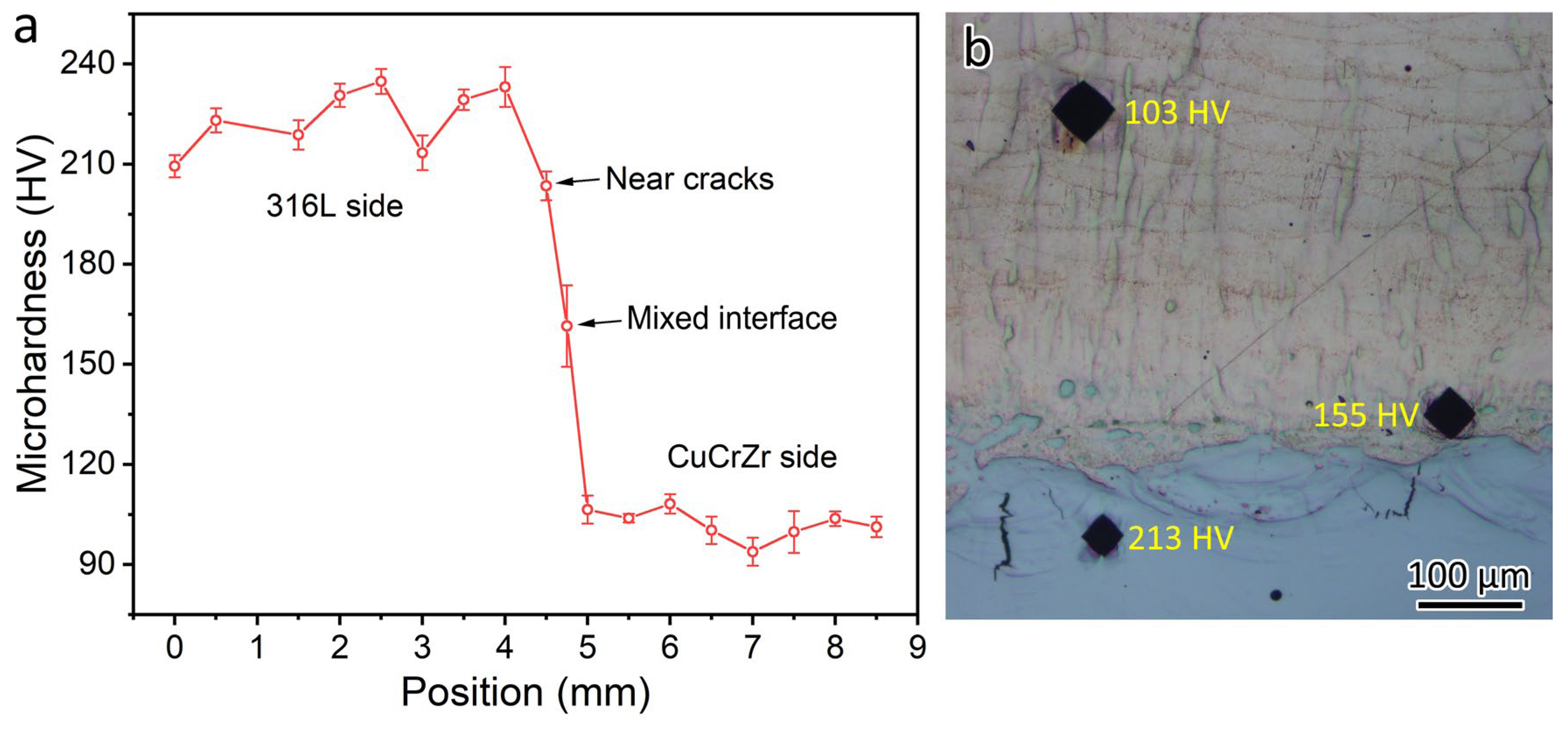

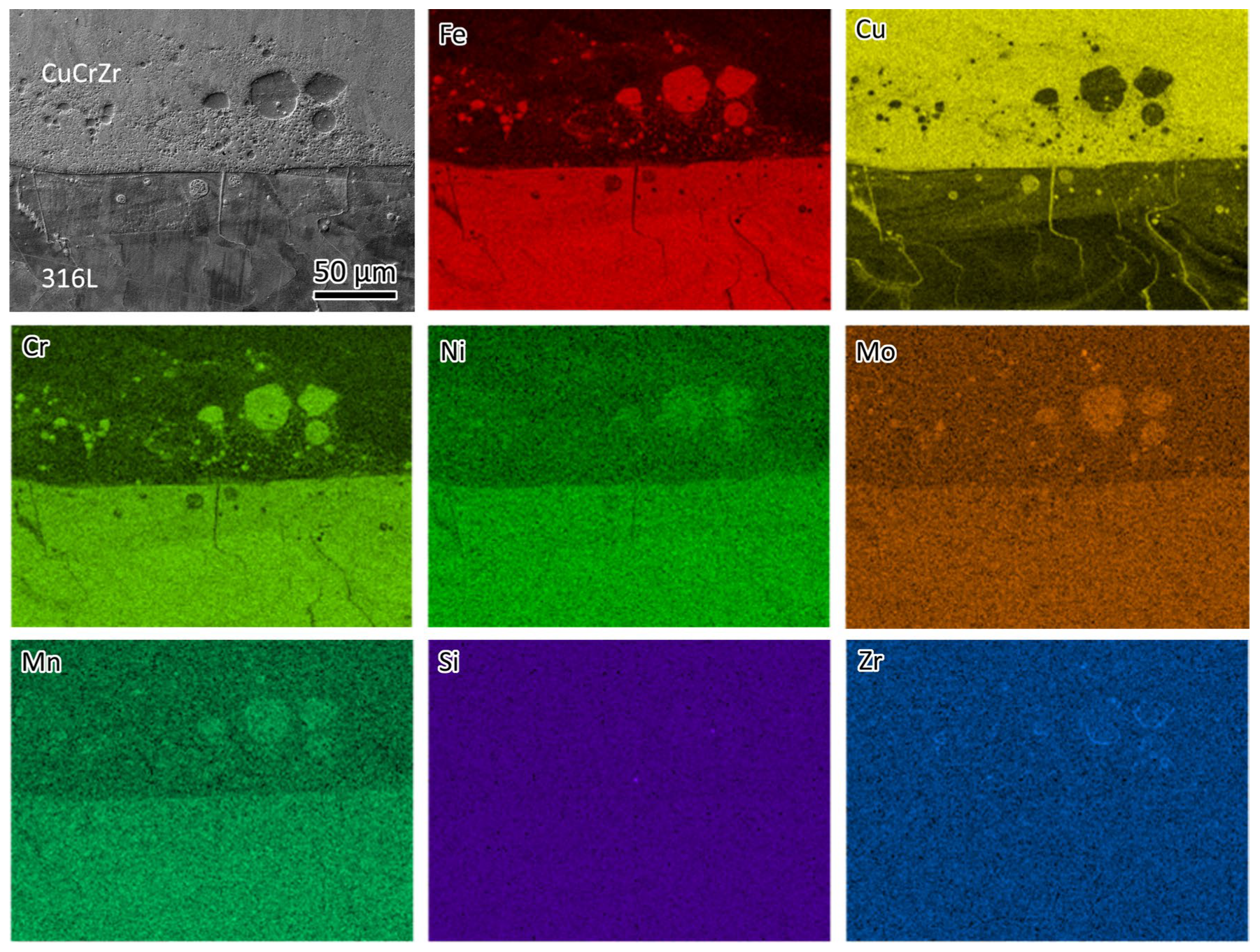

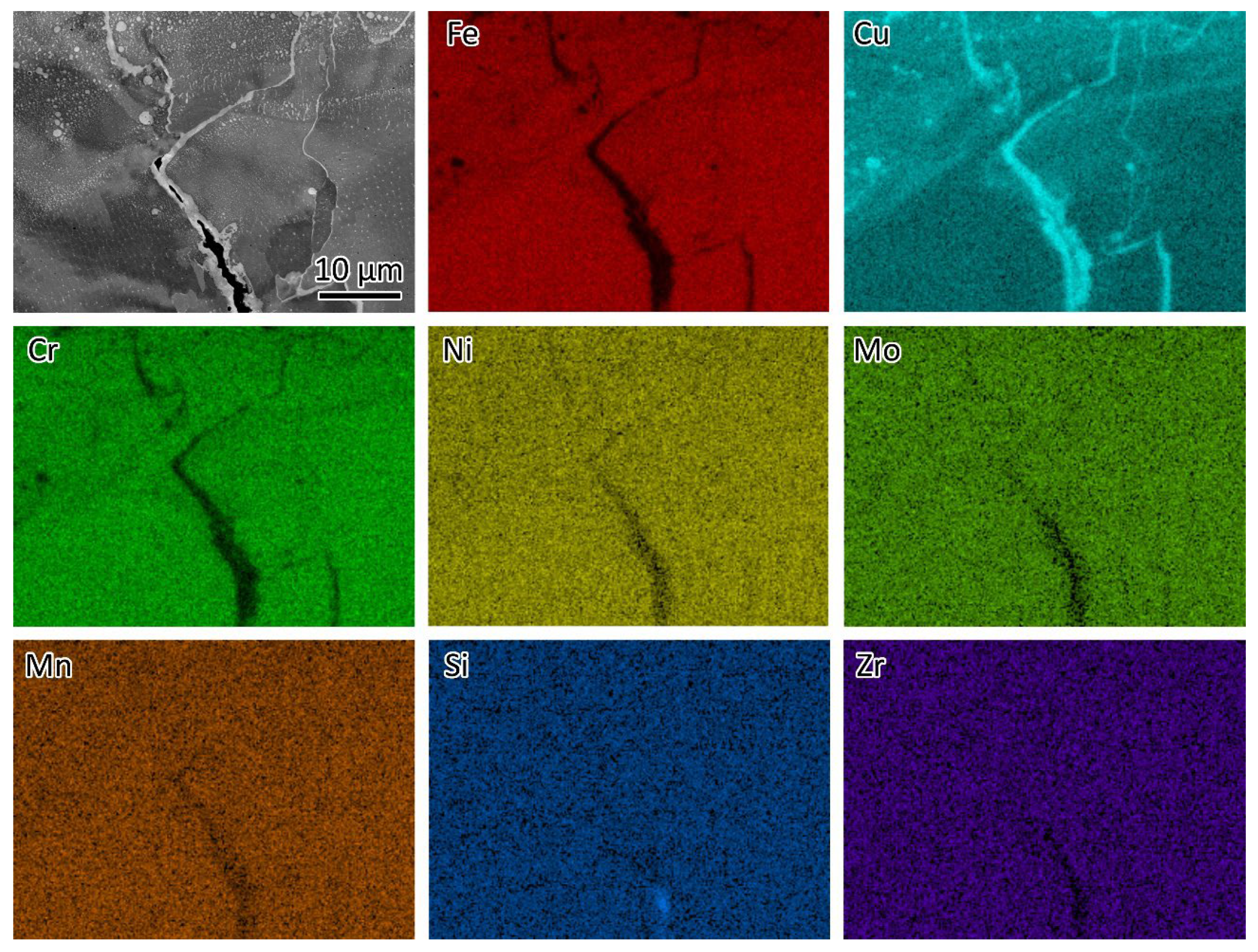

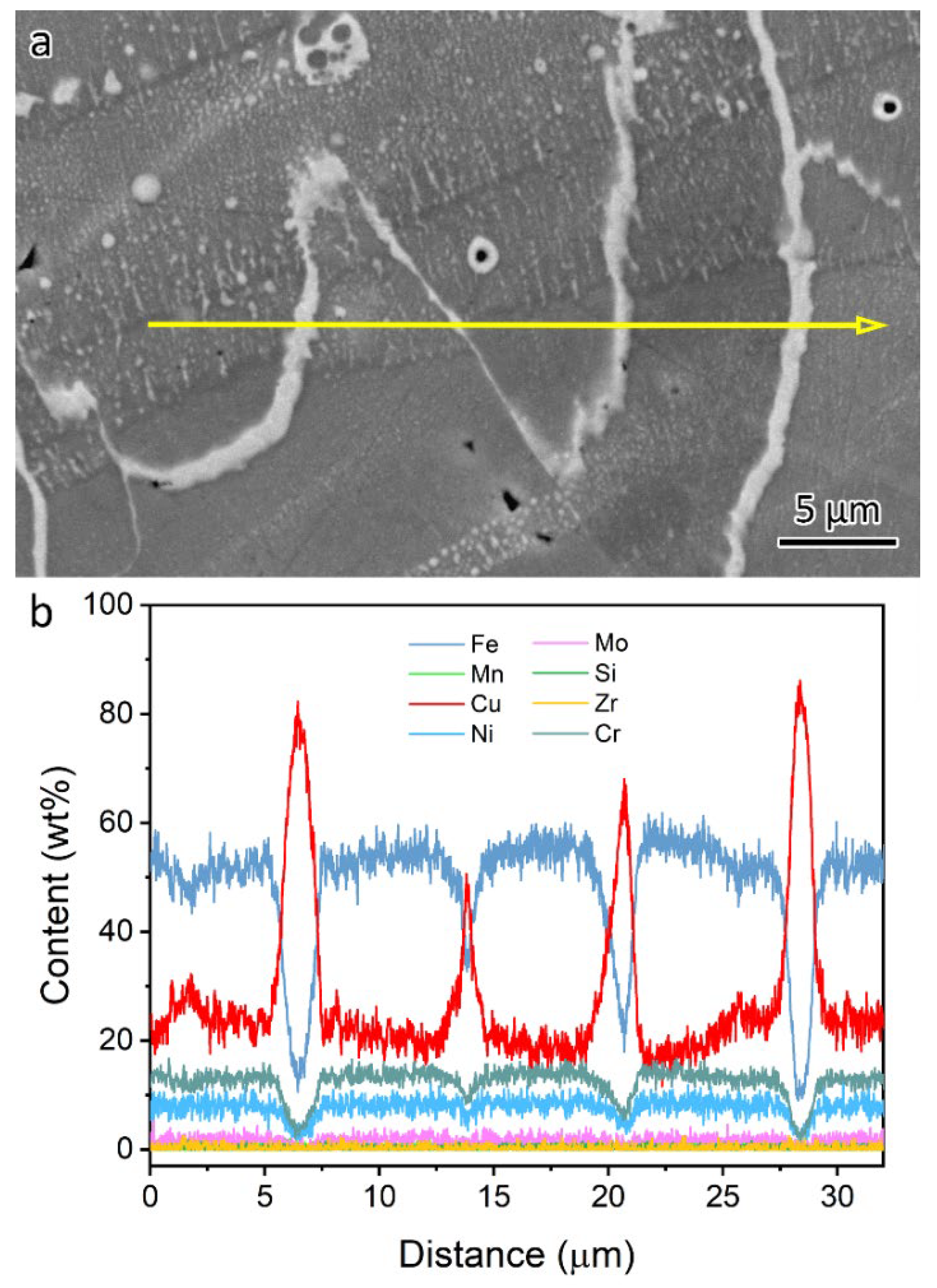

3.3. Microstructures at the Interface

4. Conclusions

- Tensile fracture occurring in the base material is not a definitive indicator of joint quality. A comprehensive microstructural analysis of the weld interface is crucial to assess the integrity of dissimilar material bonding;

- The grain size is 16.4 µm for LPBF-fabricated 316L and 20.9 µm for LPBF-fabricated CuCrZr. The grain size at the 316L/CuCrZr interface is approximately 5 µm. The primary reason for this small grain size is the formation of submicron-sized spherical 316L particles, which act as heterogeneous nucleation sites for CuCrZr due to the immiscibility of the Fe-Cu system;

- Cracks were observed at the 316L/CuCrZr interface, primarily near the 316L side, despite the tensile fracture occurring in the base material. EBSD analysis confirmed that the crack forms along the high-angle grain boundaries of 316L. The underlying mechanism is the immiscibility of the Fe-Cu system, which causes Cu to segregate at the grain boundaries;

- The LPBF-fabricated 316L/CuCrZr bimetal joint exhibits a yield strength of 203.0 MPa, a UTS of 287.5 MPa, and an elongation of 15.3%. The strength of the bimetal joint is similar to that of CuCrZr because the joint deforms and fractures only on the CuCrZr side during the tensile test. The bimetal structure fractured on the CuCrZr side due to its relatively lower strength compared to 316L (yield strength: 507.8 MPa, UTS: 633.3 MPa).

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhai, W.; Aishwarya; Shandro, R.; Zhou, W. Microstructure and mechanical properties of the wire arc additively manufactured 316L/ER70S-6 bimetal structure. Virtual Phys. Prototyp. 2024, 19, e2375105. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Heer, B. Additive manufacturing of multi-material structures. Mater. Sci. Eng. R Rep. 2018, 129, 1–16. [Google Scholar] [CrossRef]

- Zhang, P.; Qi, Y.; Cheng, Q.; Sun, X. Welding Dissimilar Alloys of CoCrFeMnNi High-Entropy Alloy and 304 Stainless Steel Using Gas Tungsten Arc Welding. J. Mater. Eng. Perform. 2023, 33, 3273–3282. [Google Scholar] [CrossRef]

- Meng, Y.; Fu, J.; Gong, M.; Zhang, S.; Gao, M.; Chen, H. Laser dissimilar welding of Al/Mg lap-joint with Ti interlayer through optimized 8-shaped beam oscillation. Opt. Laser Technol. 2023, 162, 109304. [Google Scholar] [CrossRef]

- Yang, C.; Chen, G.; Qiao, J.; Wu, C.; Zhou, M.; Zhang, G.; Shi, Q. Material flow during dissimilar friction stir welding of Al/Mg alloys. Int. J. Mech. Sci. 2024, 272, 109173. [Google Scholar] [CrossRef]

- Vetrivendan, E.; Varghese, P.; Krishnan, R.; Mathews, T.; Ningshen, S. Vacuum brazing of copper and SS316L using Ni–P eutectic alloy filler for nuclear applications. Weld. World 2022, 66, 2041–2052. [Google Scholar] [CrossRef]

- Zhai, W.; Wang, P.; Ng, F.L.; Zhou, W.; Nai, S.M.L.; Wei, J. Hybrid manufacturing of γ-TiAl and Ti–6Al–4V bimetal component with enhanced strength using electron beam melting. Compos. Part B Eng. 2021, 207, 108587. [Google Scholar] [CrossRef]

- Fan, H.; Shi, Q.; Wang, C.; Tian, Y.; Zhou, K.; Yang, S. Laser powder bed fusion of bimetallic stainless steel/Nickel-based superalloy: Interface and mechanical properties. Mater. Sci. Eng. A 2023, 877, 145193. [Google Scholar] [CrossRef]

- Xing, L.; Quanjie, W.; Qirui, Z.; Yingchun, G.; Wei, Z. Interface analyses and mechanical properties of stainless steel/nickel alloy induced by multi-metal laser additive manufacturing. J. Manuf. Process. 2023, 91, 53–60. [Google Scholar] [CrossRef]

- Wei, C.; Li, L.; Zhang, X.; Chueh, Y.-H. 3D printing of multiple metallic materials via modified selective laser melting. CIRP Ann. 2018, 67, 245–248. [Google Scholar] [CrossRef]

- Tan, C.; Zhou, K.; Ma, W.; Min, L. Interfacial characteristic and mechanical performance of maraging steel-copper functional bimetal produced by selective laser melting based hybrid manufacture. Mater. Des. 2018, 155, 77–85. [Google Scholar] [CrossRef]

- Wei, C.; Liu, L.; Cao, H.; Zhong, X.; Xu, X.; Gu, Y.; Cheng, D.; Huang, Y.; Li, Z.; Guo, W.; et al. Cu10Sn to Ti6Al4V bonding mechanisms in laser-based powder bed fusion multiple material additive manufacturing with different build strategies. Addit. Manuf. 2022, 51, 102588. [Google Scholar] [CrossRef]

- Wei, C.; Liu, L.; Gu, Y.; Huang, Y.; Chen, Q.; Li, Z.; Li, L. Multi-material additive-manufacturing of tungsten—Copper alloy bimetallic structure with a stainless-steel interlayer and associated bonding mechanisms. Addit. Manuf. 2022, 50, 102574. [Google Scholar] [CrossRef]

- Li, X.; Wang, Q.; Lu, L.; Guan, Y.; Zhou, W. Improving bonding strength of W/Cu dual metal interface through laser micro-structuring method. Light Adv. Manuf. 2024, 5, 33. [Google Scholar] [CrossRef]

- Sun, Z.; Tang, C.; Soh, V.; Lee, C.; Wu, X.; Sing, S.L.; Liu, A.Z.; Wei, S.; Zhou, K.; Tan, C.C.; et al. Laser powder bed fusion of 316L stainless steel and K220 copper multi-material. Virtual Phys. Prototyp. 2024, 19, e2356078. [Google Scholar] [CrossRef]

- Li, Z.; Kuai, Z.; Liu, B.; Chen, Y.; Li, H.; Wang, Y.; Huo, W.; Wei, M.; Yang, H.; Bai, P. Selective laser melting of 316L–CuCrZr bimetallic structure via IN718 transition layer. J. Mater. Res. Technol. 2023, 25, 3819–3834. [Google Scholar] [CrossRef]

- Noecker, F.F.; DuPont, J.N. Microstructural development and solidification cracking susceptibility of Cu deposits on steel: Part I. J. Mater. Sci. 2007, 42, 495–509. [Google Scholar] [CrossRef]

- Rinne, J.; Seffer, O.; Nothdurft, S.; Hermsdorf, J.; Kaierle, S.; Overmeyer, L. Investigations on the weld metal composition and associated weld metal cracking in laser beam welded steel copper dissimilar joints. J. Mater. Process. Technol. 2021, 296, 117178. [Google Scholar] [CrossRef]

- Yao, C.; Xu, B.; Zhang, X.; Huang, J.; Fu, J.; Wu, Y. Interface microstructure and mechanical properties of laser welding copper–steel dissimilar joint. Opt. Lasers Eng. 2009, 47, 807–814. [Google Scholar] [CrossRef]

- Du, X.; Xi, T.; Yang, C.; Zhao, H.; Yang, K. Cu addition retards the static recrystallization of cold-deformed 316L biomedical stainless steel. J. Mater. Res. Technol. 2022, 19, 1673–1677. [Google Scholar] [CrossRef]

- Xi, T.; Shahzad, M.B.; Xu, D.; Sun, Z.; Zhao, J.; Yang, C.; Qi, M.; Yang, K. Effect of copper addition on mechanical properties, corrosion resistance and antibacterial property of 316L stainless steel. Mater. Sci. Eng. C Mater. Biol. Appl. 2017, 71, 1079–1085. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Cui, X.; Wang, Y. Liquid phase separation in immiscible Cu–Fe alloys. Int. J. Cast Met. Res. 2017, 31, 87–92. [Google Scholar] [CrossRef]

- Zhai, W.; Zhou, W.; Nai, S.M.L. Grain refinement and strengthening of 316L stainless steel through addition of TiC nanoparticles and selective laser melting. Mater. Sci. Eng. A 2022, 832, 142460. [Google Scholar] [CrossRef]

- Zhu, Z.; Ng, F.L.; Seet, H.L.; Lu, W.; Liebscher, C.H.; Rao, Z.; Raabe, D.; Nai, S.M.L. Superior mechanical properties of a selective-laser-melted AlZnMgCuScZr alloy enabled by a tunable hierarchical microstructure and dual-nanoprecipitation. Mater. Today 2022, 52, 90–101. [Google Scholar] [CrossRef]

- Kaoumi, D.; Liu, J. Deformation induced martensitic transformation in 304 austenitic stainless steel: In-Situ vs. ex-situ transmission electron microscopy characterization. Mater. Sci. Eng. A 2018, 715, 73–82. [Google Scholar] [CrossRef]

- Zhai, W.; Zhou, W.; Nai, S.M.L. In-Situ formation of TiC nanoparticles in selective laser melting of 316L with addition of micronsized TiC particles. Mater. Sci. Eng. A 2022, 829, 142179. [Google Scholar] [CrossRef]

- Wei, F.; Cheng, B.; Kumar, P.; Wang, P.; Lee, J.J.; Seng, H.L.; Cheong, K.H.; Lau, K.B.; Tan, C.C. A comparative study of additive manufactured and wrought SS316L: Pre-existing dislocations and grain boundary characteristics. Mater. Sci. Eng. A 2022, 833, 142546. [Google Scholar] [CrossRef]

| 316L | Fe | Cr | Ni | Mo | Mn | Si | C |

| Balance | 16–18 | 10–14 | 2–3 | <2 | <0.75 | <0.03 | |

| CuCrZr | Cu | Cr | Zr | ||||

| Balance | 0.5–1.2 | 0.05–0.25 |

| Alloy | Laser Power (W) | Scan Speed (mm/s) | Layer Thickness (µm) | Hatching Spacing (µm) |

|---|---|---|---|---|

| 316L | 220 | 1100 | 30 | 90 |

| CuCrZr | 375 | 700 | 30 | 100 |

| Sample | Yield Strength (MPa) | UTS (MPa) | Elongation (%) |

|---|---|---|---|

| 316L | 507.8 ± 12.8 | 633.3 ± 2.6 | 36.1 ± 4.0 |

| CuCrZr | 201.7 ± 4.1 | 291.8 ± 5.0 | 15.2 ± 1.7 |

| Joint | 203.0 ± 9.3 | 287.5 ± 1.5 | 15.3 ± 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhai, W.; Li, G.; Zhou, W. Evaluation of Laser Powder Bed Fusion-Fabricated 316L/CuCrZr Bimetal Joint. Materials 2025, 18, 1434. https://doi.org/10.3390/ma18071434

Zhai W, Li G, Zhou W. Evaluation of Laser Powder Bed Fusion-Fabricated 316L/CuCrZr Bimetal Joint. Materials. 2025; 18(7):1434. https://doi.org/10.3390/ma18071434

Chicago/Turabian StyleZhai, Wengang, Guanchun Li, and Wei Zhou. 2025. "Evaluation of Laser Powder Bed Fusion-Fabricated 316L/CuCrZr Bimetal Joint" Materials 18, no. 7: 1434. https://doi.org/10.3390/ma18071434

APA StyleZhai, W., Li, G., & Zhou, W. (2025). Evaluation of Laser Powder Bed Fusion-Fabricated 316L/CuCrZr Bimetal Joint. Materials, 18(7), 1434. https://doi.org/10.3390/ma18071434