Effect of Laser Parameters on Surface Morphology and Material Removal Mechanism of Ablation Grooves in CFRP Composites Using Finite Element Simulations

Abstract

1. Introduction

2. Materials and Methods

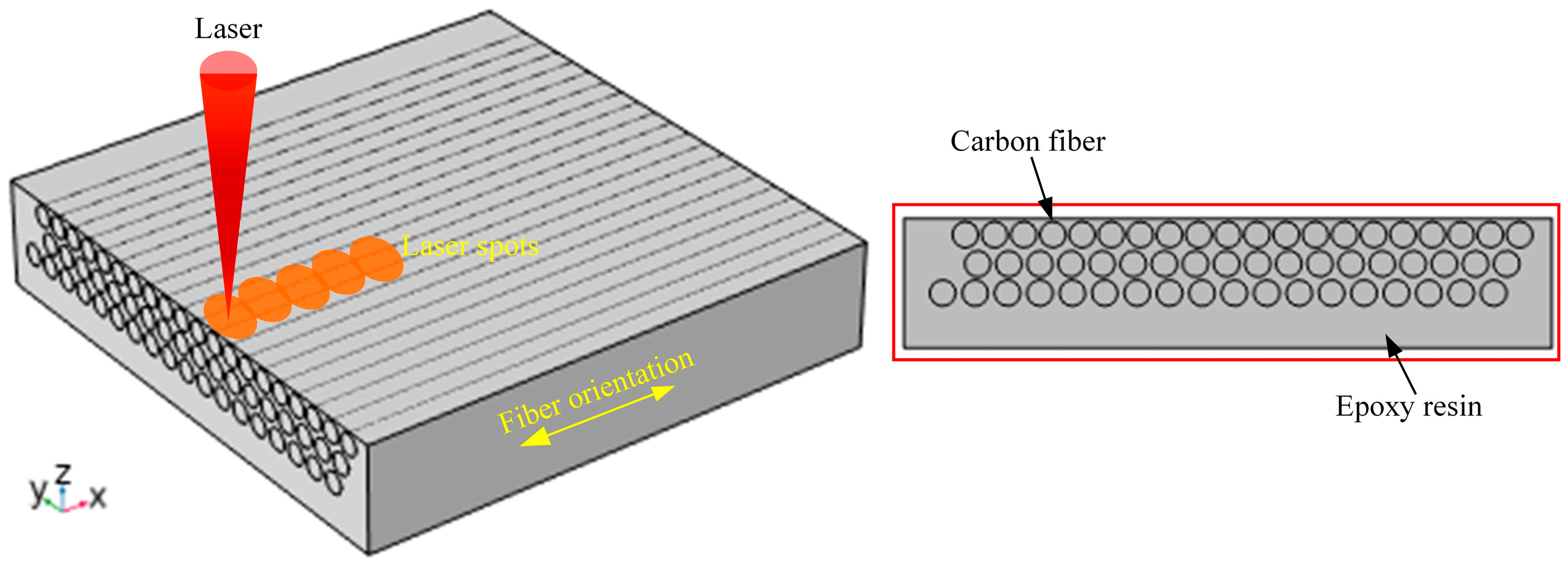

2.1. Modeling and Simulation of Laser-Ablated CFRP

2.1.1. Analysis of Ablation Behavior of CFRP

2.1.2. Finite Element Modeling

2.1.3. Coupled Physical Modeling of Laser Ablation

2.1.4. Meshing and Boundary Conditions

2.1.5. Control Equations and Assumptions

- The nanosecond laser energy beam becomes a first-order Gaussian distribution and will be replaced with a Gaussian heat source;

- The material is completely removed once it reaches the vaporization temperature of the component material;

- Heat generated within the material due to chemical reactions occurring during processing is not considered;

- Heat loss from thermal radiation is not considered and the laser energy is fully absorbed by the material;

- The absorption of nanosecond laser energy by the material is constant;

- The focal plane is assumed to be the processing plane and the spot diameter does not change;

- The resin matrix is heated and decomposes directly into the residual carbon and organic gases of the final product, without regard to multi-step pyrolysis reactions and intermediate pyrolysis products of the material;

- The volume change in the composite material during the body ablation process is neglected.

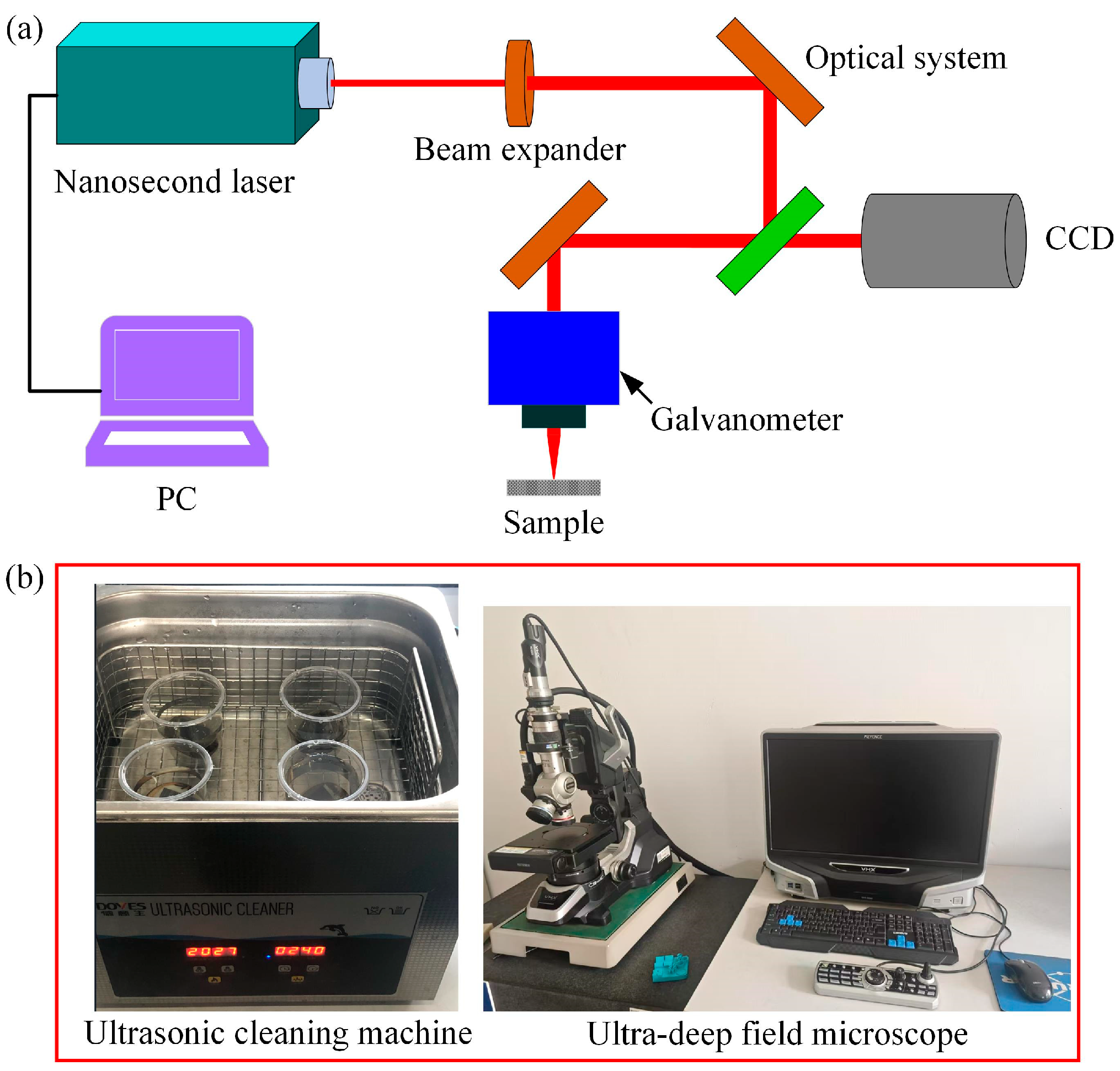

2.2. Experimental Setup

3. Results and Discussion

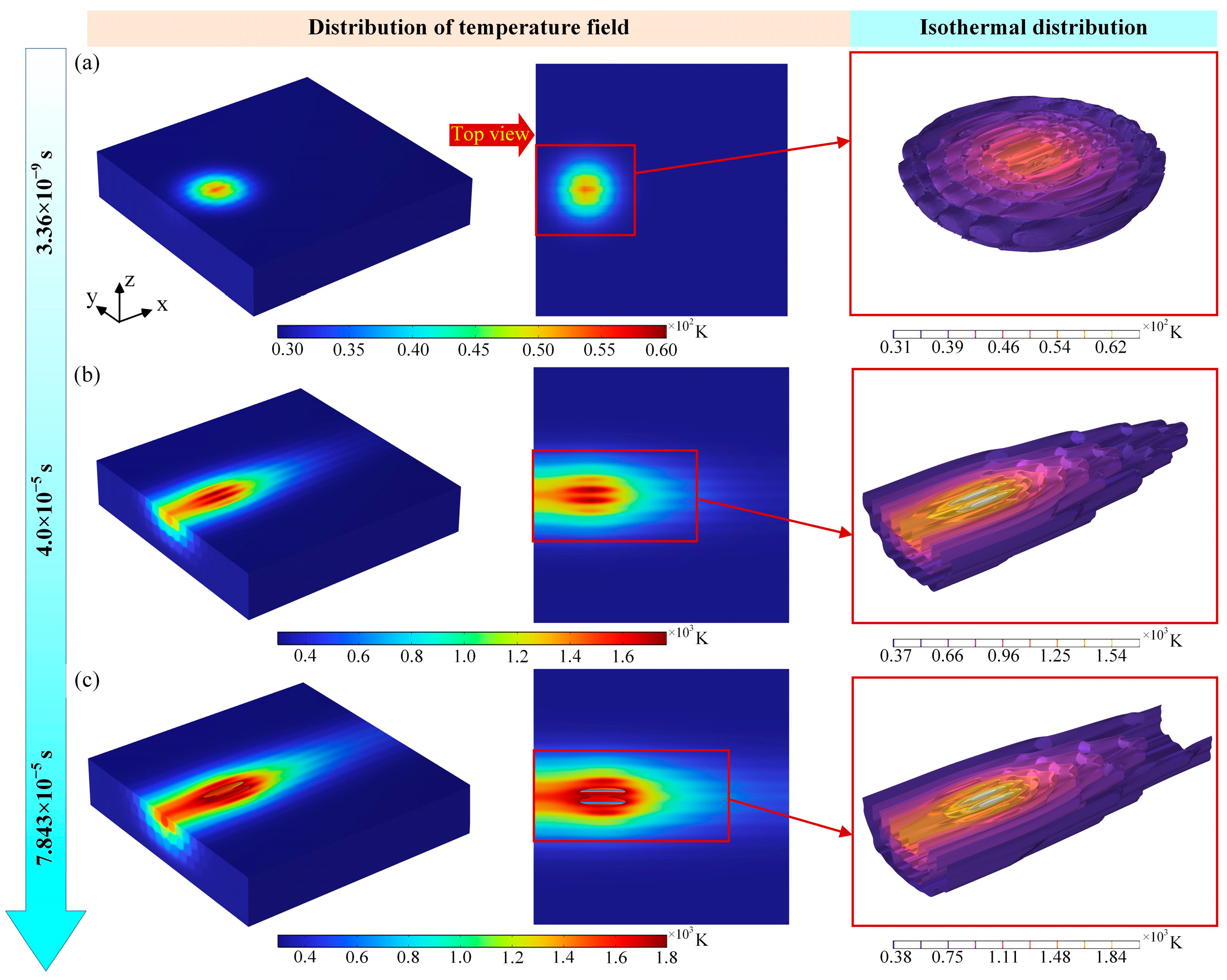

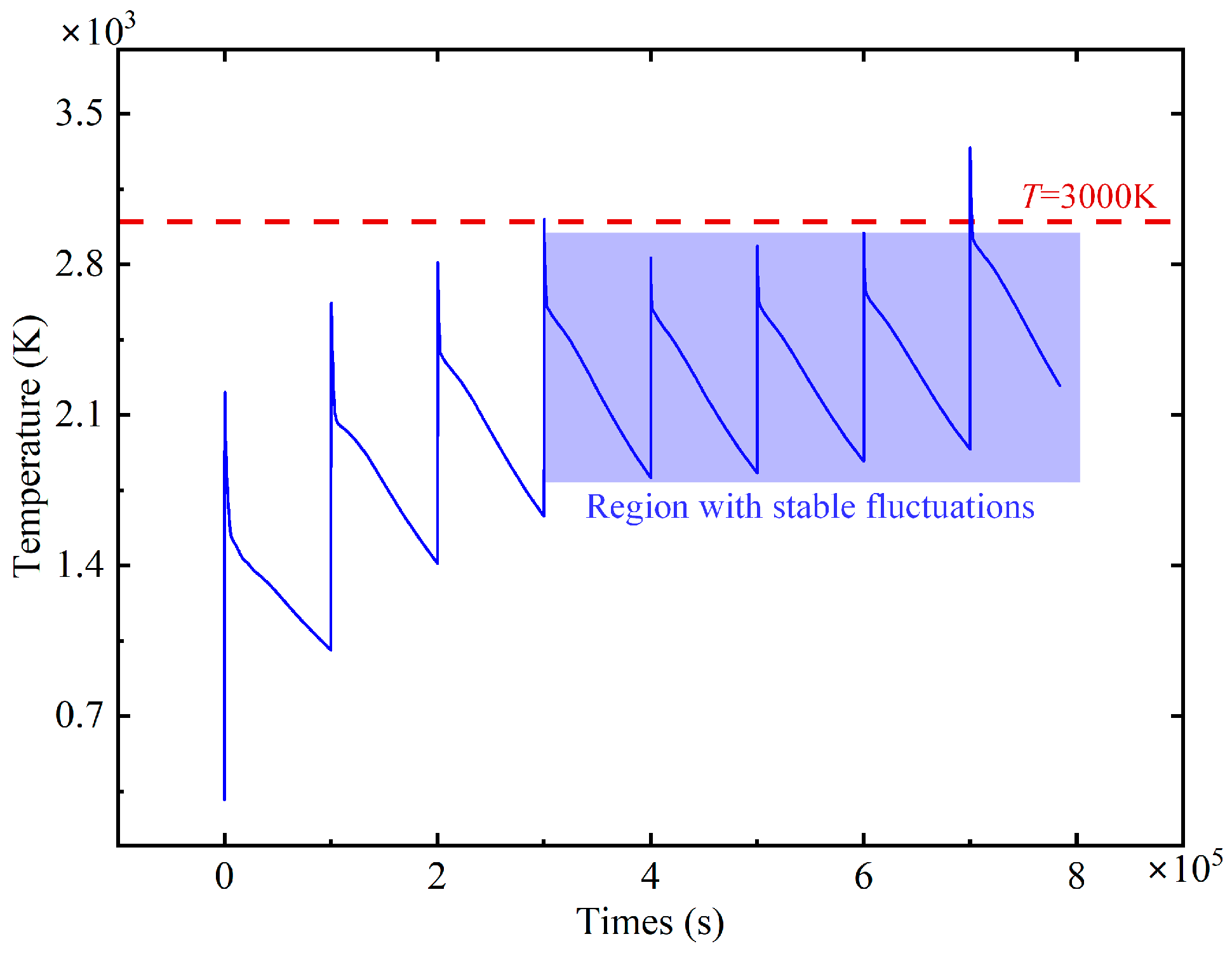

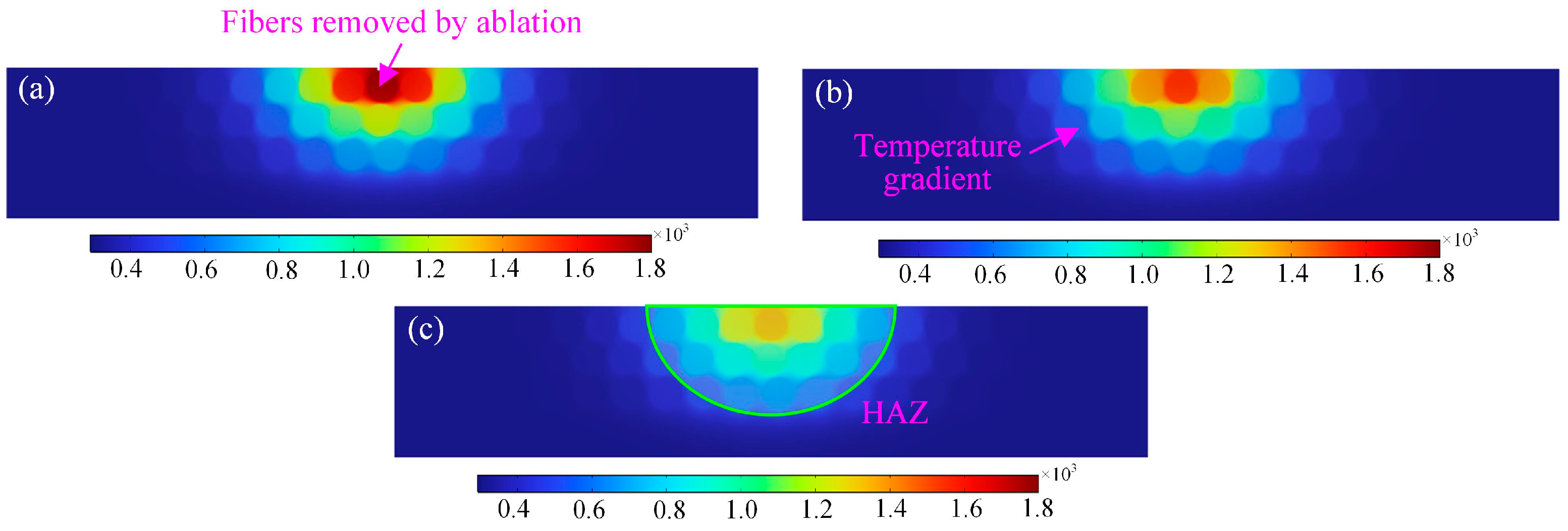

3.1. Evolution of the Transient Temperature Field Under Laser Action

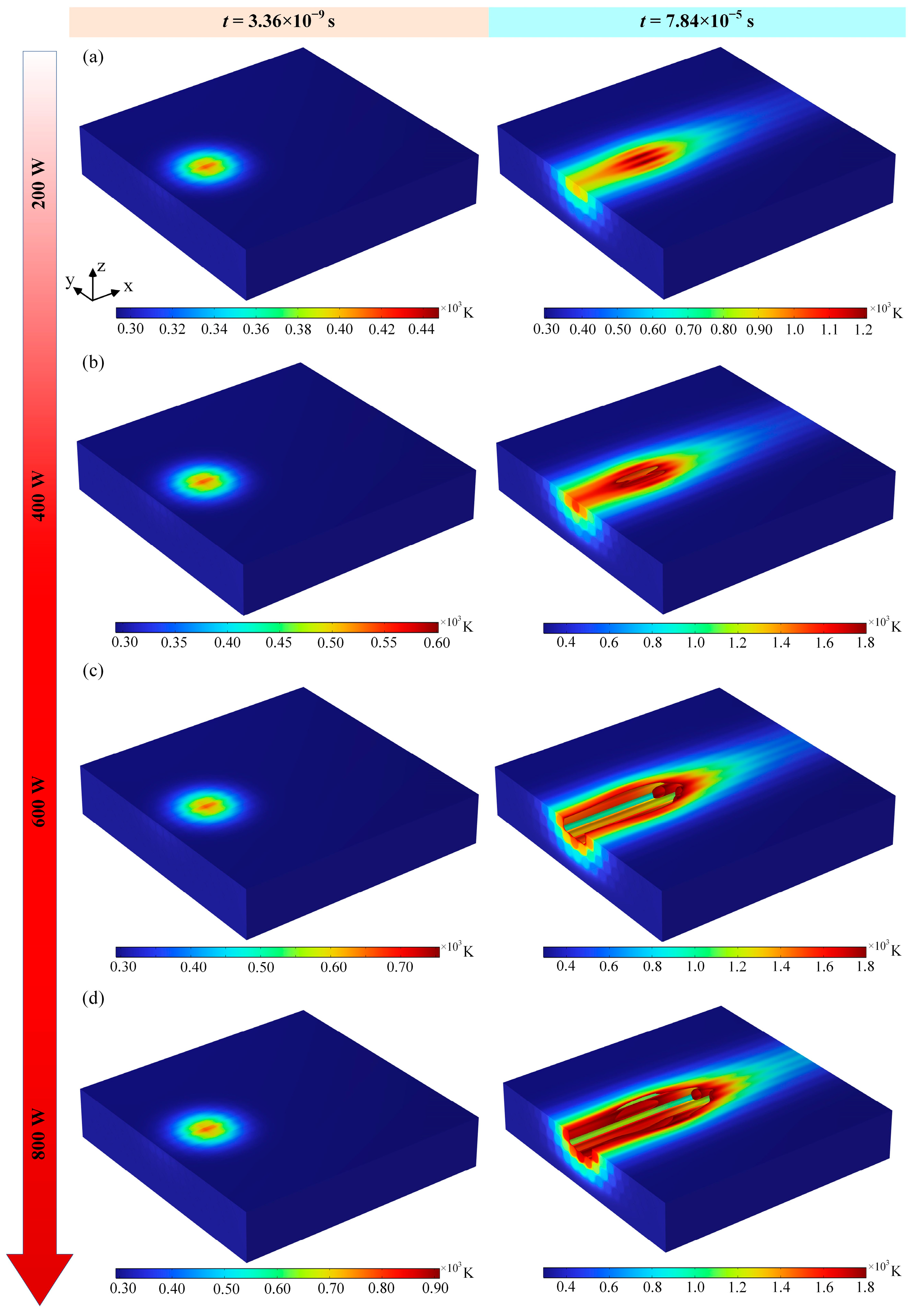

3.2. Effect of Laser Power on Temperature Field and HAZ

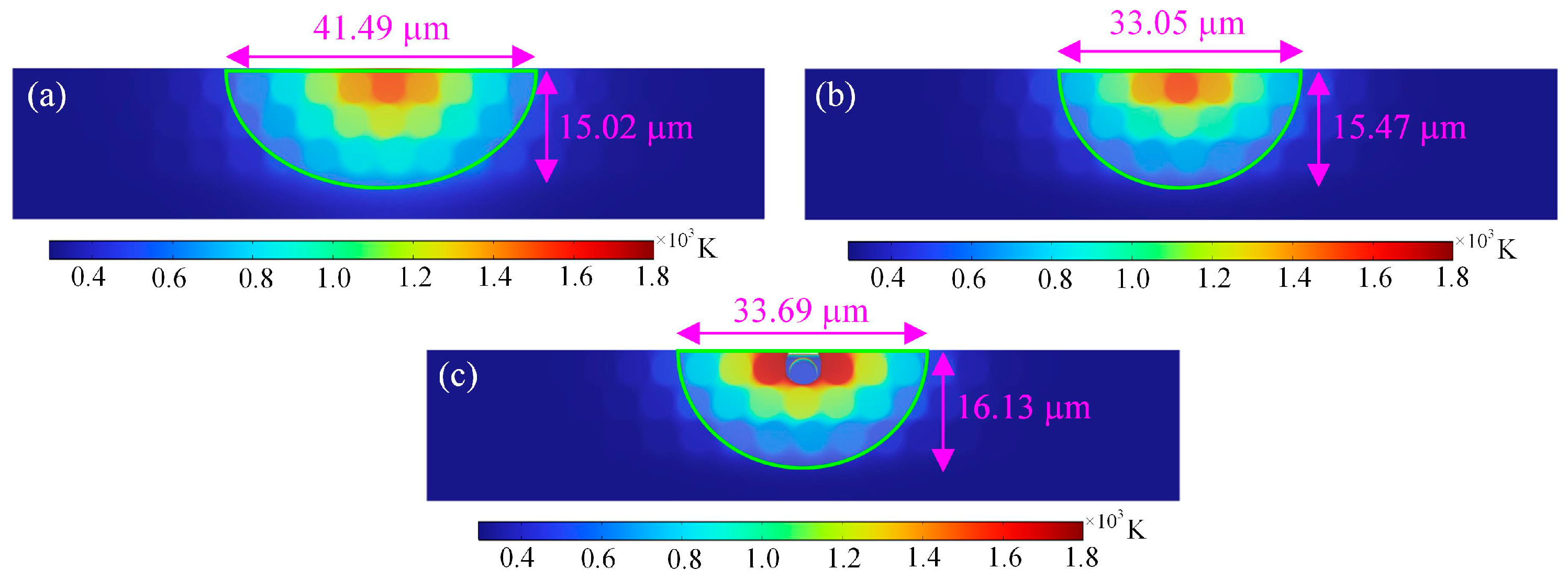

3.3. Effect of Laser Pulse Frequency on Temperature Field and HAZ

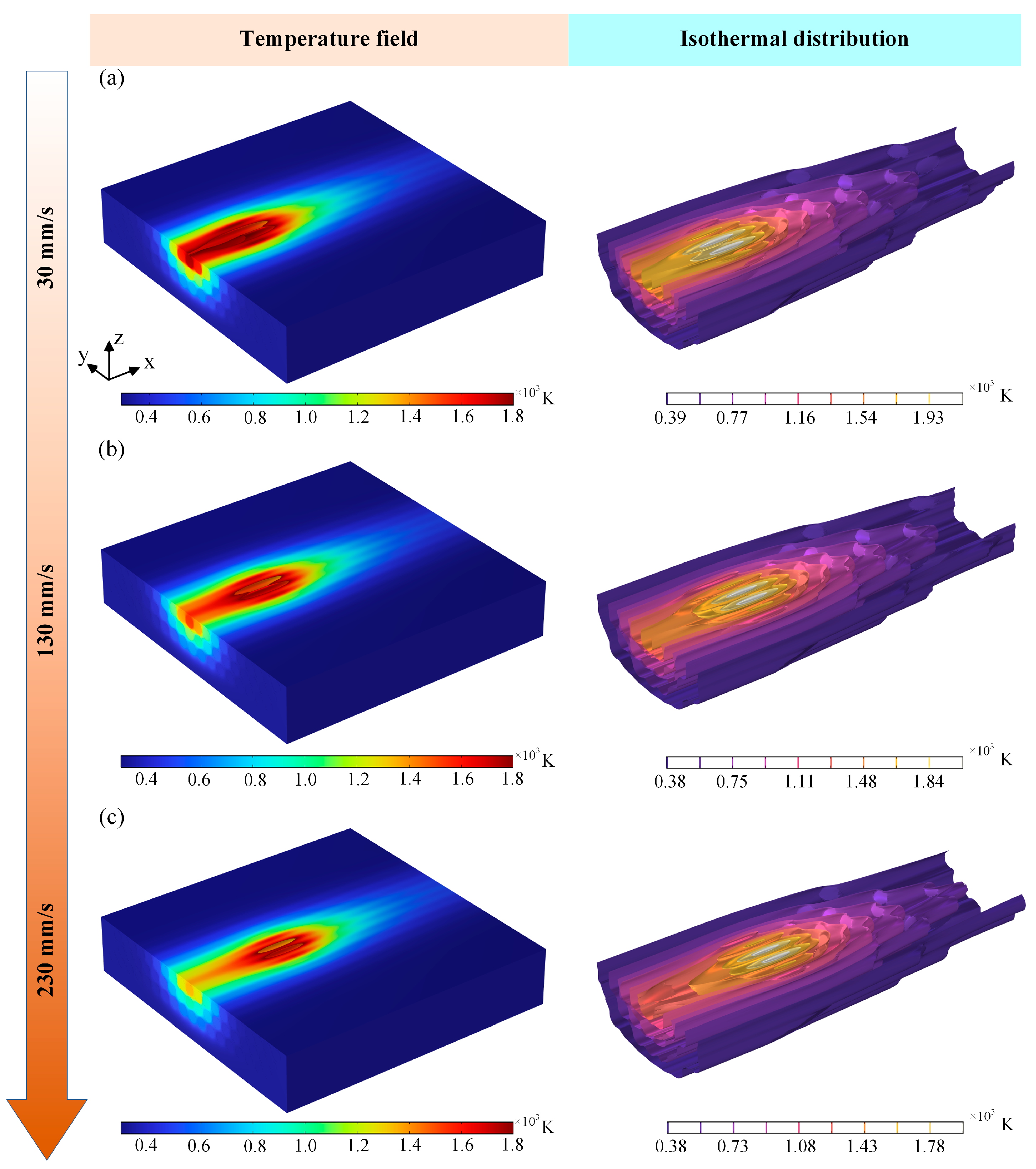

3.4. Effect of Laser Scanning Speed on Temperature Field and HAZ

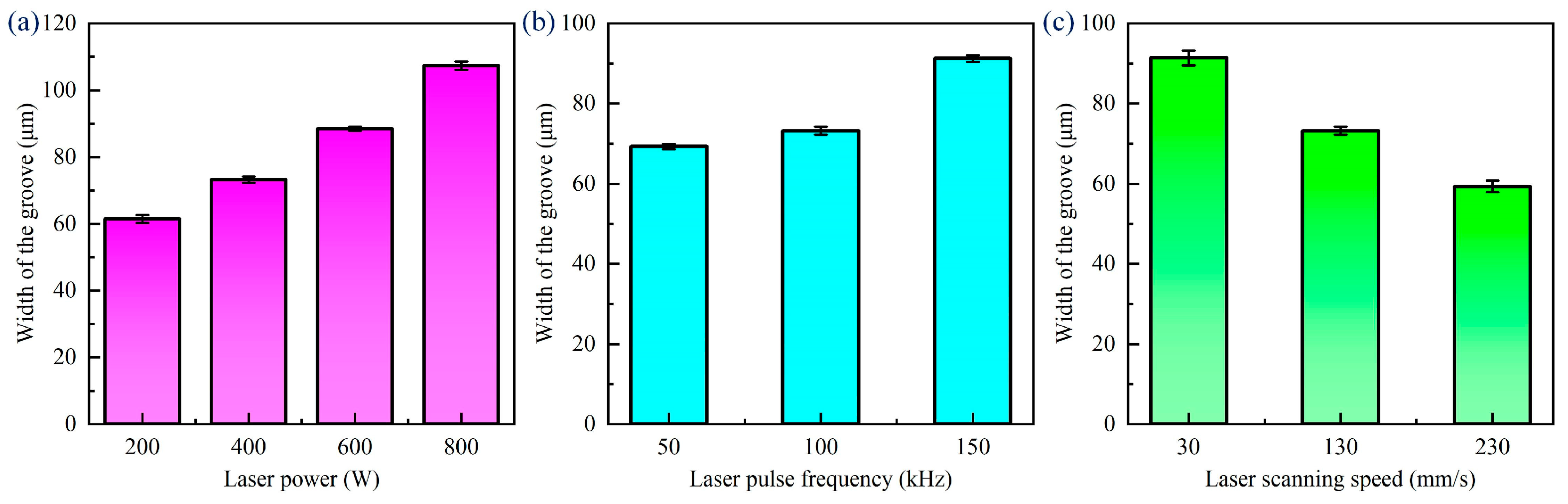

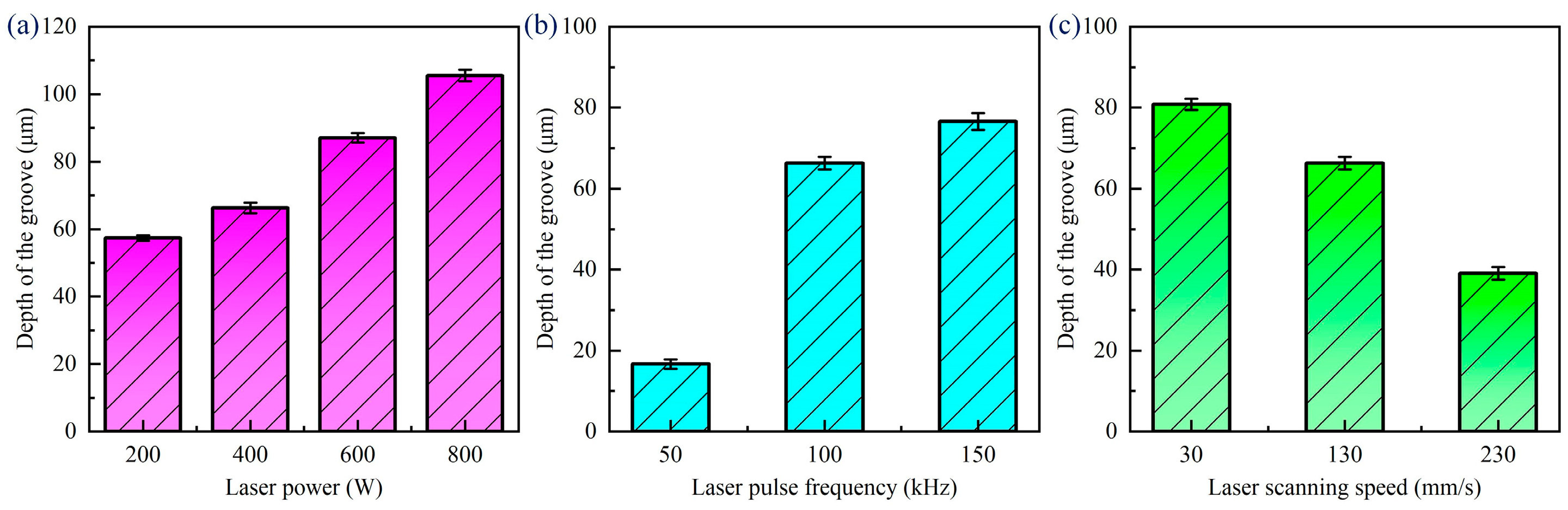

3.5. Effect of Laser Parameters on Groove Profile

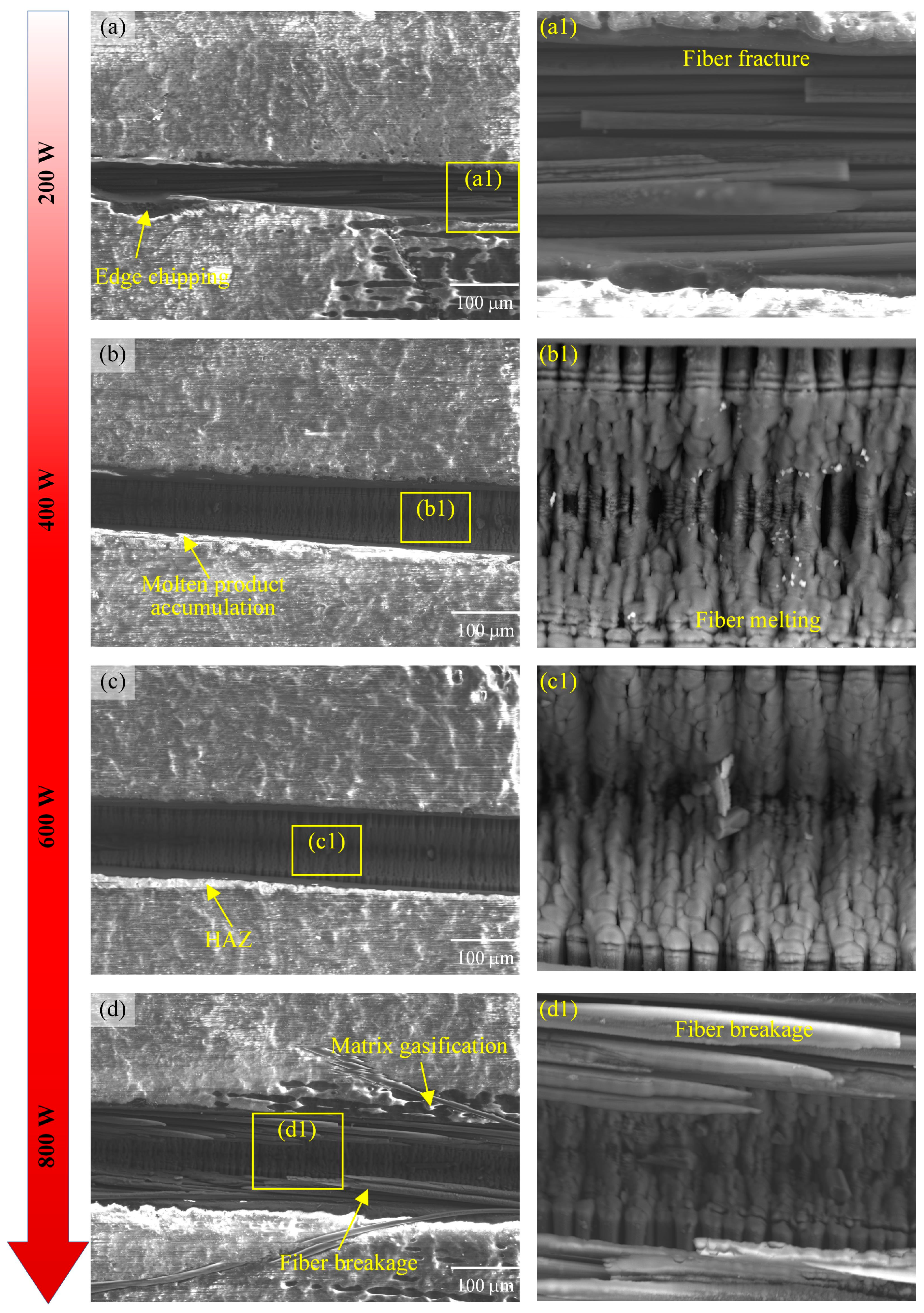

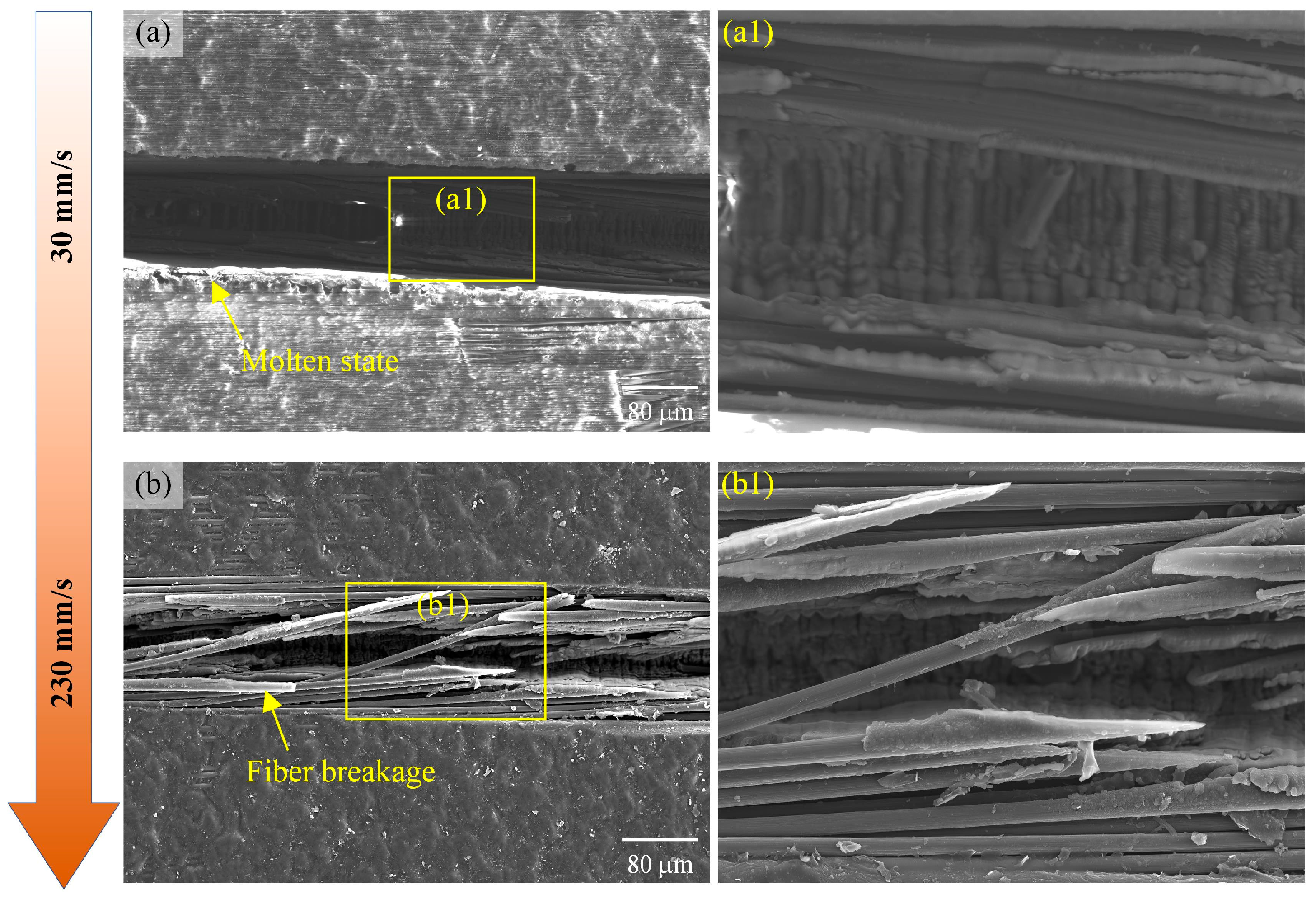

3.6. Effect of Laser Parameters on Surface Ablation Morphology

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, F.; Yin, J.; Ma, J.; Jia, Z.; Yang, F.; Niu, B. Effects of cutting edge radius and fiber cutting angle on the cutting-induced surface damage in machining of unidirectional CFRP composite laminates. Int. J. Adv. Manuf. Technol. 2017, 91, 3107–3120. [Google Scholar] [CrossRef]

- Capello, E.; Tagliaferri, V. Drilling Damage of GFRP and Residual Mechanical Behavior—Part I: Drilling Damage Generation. J. Compos. Technol. Res. 2001, 23, 122–130. [Google Scholar] [CrossRef]

- Kim, M.; Lee, M.; Cho, G.; Lee, S.K. Effect of the Fiber Orientation and the Radial Depth of Cut on the Flank Wear in End Milling of CFRP. Int. J. Precis. Eng. Manuf. 2020, 21, 1187–1199. [Google Scholar] [CrossRef]

- Dong, Z.; Wang, Z.; Ran, Y.; Bao, Y.; Kang, R. Advances in Ultrasonic Vibration-assisted Milling of Carbon Fiber Reinforced Ceramic Matrix Composites. Jixie Gongcheng Xuebao/J. Mech. Eng. 2024, 60, 26–56. [Google Scholar] [CrossRef]

- Meng, Q.; Cai, J.; Cheng, H.; Zhang, K. Investigation of CFRP cutting mechanism variation and the induced effects on cutting response and damage distribution. Int. J. Adv. Manuf. Technol. 2020, 106, 2893–2907. [Google Scholar] [CrossRef]

- Li, M.; Jiang, X.; Su, T. The influence of hole quality on mechanical behavior and strain distribution of open-hole CFRP laminates subject to different machining processes. Polym. Compos. 2022, 43, 9218–9230. [Google Scholar] [CrossRef]

- Xu, J.; El Mansori, M. Numerical studies of frictional responses when cutting hybrid CFRP/Ti composite. Int. J. Adv. Manuf. Technol. 2016, 87, 657–675. [Google Scholar] [CrossRef]

- Wang, X.; Wang, F.; Jin, X.; Fu, R.; Shi, Y. Numerical prediction of the chip formation and damage response in CFRP cutting with a novel strain rate based material model. Compos. Struct. 2022, 294, 115746. [Google Scholar] [CrossRef]

- Durante, M.; Boccarusso, L.; De Fazio, D.; Langella, A. Circular cutting strategy for drilling of carbon fiber-reinforced plastics (CFRPs). Mater. Manuf. Process 2019, 34, 554–566. [Google Scholar] [CrossRef]

- Wang, Z.; Bao, Y.; Feng, K.; Li, B.; Dong, Z.; Kang, R.; Wang, Y. Characterization, quantitative evaluation, and formation mechanism of surface damage in ultrasonic vibration assisted scratching of Cf/SiC composites. J. Eur. Ceram. Soc. 2024, 44, 4502–4523. [Google Scholar] [CrossRef]

- Groppetti, R.; Armanni, A.; Cattaneo, A.; Franceschini, G. Contribution to the study of the delamination of carbon fibre reinforced plastic (CFRP) laminated composites during piercing and cutting by hydro jet machining (HJM) and hydro abrasive jet machining (HAJM). In Computer Aided Design in Composite Material Technology III; Springer: Dordrecht, The Netherlands, 1992. [Google Scholar] [CrossRef]

- Sun, D.; Han, F.; Ying, W.; Jin, C. Surface integrity of water jet guided laser machining of CFRP. Procedia CIRP 2018, 71, 71–74. [Google Scholar] [CrossRef]

- Abrate, S.; Walton, D. Machining of composite materials. Part II Non-traditional methods. Compos. Manuf. 1992, 3, 85–94. [Google Scholar] [CrossRef]

- Ding, W.; Zhao, L.; Chen, M.; Cheng, J.; Chen, G.; Lei, H.; Liu, Z.; Geng, F.; Wang, S.; Xu, Q. Determination of stress waves and their effect on the damage extension induced by surface defects of KDP crystals under intense laser irradiation. Optica 2023, 10, 671. [Google Scholar] [CrossRef]

- Wang, P.; Zhang, Z.; Liu, D.; Qiu, W.; Zhang, Y.; Zhang, G. Comparative investigations on machinability and surface integrity of CFRP plate by picosecond laser vs laser induced plasma micro-drilling. Opt. Laser Technol. 2022, 151, 108022. [Google Scholar] [CrossRef]

- Shen, Y.; Yang, T.; Liu, C.; Liu, S.; Du, Y. Cutting force modeling in orthogonal cutting of UD-CFRP considering the variable thickness of uncut material. Int. J. Adv. Manuf. Technol. 2021, 114, 1623–1634. [Google Scholar] [CrossRef]

- Wang, D.; Onawumi, P.Y.; Ismail, S.O.; Dhakal, H.N.; Popov, I.; Silberschmidt, V.V.; Roy, A. Machinability of natural-fibre-reinforced polymer composites: Conventional vs ultrasonically-assisted machining. Compos. Part A Appl. Sci. Manuf. 2019, 119, 188–195. [Google Scholar] [CrossRef]

- Altin Karataş, M.; Motorcu, A.R.; Gökkaya, H. Optimization of machining parameters for kerf angle and roundness error in abrasive water jet drilling of CFRP composites with different fiber orientation angles. J. Brazilian Soc. Mech. Sci. Eng. 2020, 42, 173. [Google Scholar] [CrossRef]

- Tian, J.; Kang, R.; Dong, Z.; Liu, Z.; Guo, D.; Bao, Y. Multi-scale machining damages of CFRP circular cell honeycomb during end face machining. J. Manuf. Process 2023, 86, 282–293. [Google Scholar] [CrossRef]

- Leone, C.; Papa, I.; Tagliaferri, F.; Lopresto, V. Investigation of CFRP laser milling using a 30 W Q-switched Yb:YAG fiber laser: Effect of process parameters on removal mechanisms and HAZ formation. Compos. Part A Appl. Sci. Manuf. 2013, 55, 129–142. [Google Scholar] [CrossRef]

- Tao, N.; Chen, G.; Fan, L.; Wang, B.; Li, M.; Fang, W. Temperature-dependent material removal during pulsed laser processing of CFRP composites. Opt. Laser Technol. 2021, 144, 107445. [Google Scholar] [CrossRef]

- Ding, W.; Chen, M.; Cheng, J.; Liu, H.; Zhao, L.; Yang, H.; Cheng, X.; Liu, Z.; Xu, Q.; Tan, C. Laser damage evolution by defects on diamond fly-cutting KDP surfaces. Int. J. Mech. Sci. 2023, 237, 107794. [Google Scholar] [CrossRef]

- Ding, W.; Cheng, J.; Zhao, L.; Wang, Z.; Yang, H.; Liu, Z.; Xu, Q.; Wang, J.; Geng, F.; Chen, M. Determination of intrinsic defects of functional KDP crystals with flawed surfaces and their effect on the optical properties. Nanoscale 2022, 14, 10041–10050. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Liu, H.; Gao, R.; Liu, X.; Yu, X.; Song, F.; Liu, L. Numerical simulation of paint stripping on CFRP by pulsed laser. Opt. Laser Technol. 2022, 145, 107450. [Google Scholar] [CrossRef]

- Oliveira, V.; Sharma, S.P.; de Moura, M.F.S.F.; Moreira, R.D.F.; Vilar, R. Surface treatment of CFRP composites using femtosecond laser radiation. Opt. Lasers Eng. 2017, 94, 37–43. [Google Scholar] [CrossRef]

- Jiao, H.; Lin, Z.; Zhang, G.; Zhou, J.; Huang, Y.; Long, Y. Scribing of surface-braided CFRP with picosecond laser: Thermal damage formation and removal mechanism analysis. Appl. Phys. A Mater. Sci. Process 2024, 130, 120. [Google Scholar] [CrossRef]

- Kumar, D.; Liedl, G.; Gururaja, S. Formation of sub-wavelength laser induced periodic surface structure and wettability transformation of CFRP laminates using ultra-fast laser. Mater. Lett. 2020, 276, 128282. [Google Scholar] [CrossRef]

- Leone, C.; Mingione, E.; Genna, S. Laser cutting of CFRP by Quasi-Continuous Wave (QCW) fibre laser: Effect of process parameters and analysis of the HAZ index. Compos. Part B Eng. 2021, 224, 109146. [Google Scholar] [CrossRef]

- Ohkubo, T.; Sato, Y.; Matsunaga, E.-i.; Tsukamoto, M. Three-dimensional numerical simulation during laser processing of CFRP. Appl. Surf. Sci. 2017, 417, 104–107. [Google Scholar] [CrossRef]

- Contuzzi, N.; Casalino, G. Statistical modelling and optimization of nanosecond Nd:YAG Q-switched laser scarfing of carbon fiber reinforced polymer. Opt. Laser Technol. 2022, 147, 107599. [Google Scholar] [CrossRef]

- Ohkubo, T.; Tsukamoto, M.; Sato, Y. Numerical simulation of combustion effects during laser processing of carbon fiber reinforced plastics. Appl. Phys. A Mater. Sci. Process 2016, 122, 196. [Google Scholar] [CrossRef]

- Wang, P.; Zhang, Z.; Hao, B.; Wei, S.; Qiu, W.; Huang, Y.; Zhang, G. Study on anisotropic heat transfer thermal damage in nanosecond pulsed laser processing of CFRP. Polym. Compos. 2023, 44, 5964–5983. [Google Scholar] [CrossRef]

- Negarestani, R.; Li, L.; Sezer, H.K.; Whitehead, D.; Methven, J. Nano-second pulsed DPSS Nd:YAG laser cutting of CFRP composites with mixed reactive and inert gases. Int. J. Adv. Manuf. Technol. 2010, 49, 553–566. [Google Scholar] [CrossRef]

- Mathew, J.; Goswami, G.L.; Ramakrishnan, N.; Naik, N.K. Parametric studies on pulsed Nd:YAG laser cutting of carbon fibre reinforced plastic composites. J. Mater. Process Technol. 1999, 89–90, 198–203. [Google Scholar] [CrossRef]

- Weber, R.; Graf, T.; Freitag, C.; Feuer, A.; Kononenko, T.; Konov, V.I. Processing constraints resulting from heat accumulation during pulsed and repetitive laser materials processing. Opt. Express 2017, 25, 3966–3979. [Google Scholar] [CrossRef] [PubMed]

- Cenna, A.A.; Mathew, P. Analysis and prediction of laser cutting parameters of fibre reinforced plastics (FRP) composite materials. Int. J. Mach. Tools Manuf. 2002, 42, 105–113. [Google Scholar] [CrossRef]

- Fürst, A.; Mahrle, A.; Hipp, D.; Klotzbach, A.; Hauptmann, J.; Wetzig, A.; Beyer, E. Dual Wavelength Laser Beam Cutting of High-Performance Composite Materials. Adv. Eng. Mater. 2017, 19, 1600356. [Google Scholar] [CrossRef]

- Ren, X.; Fan, J.; Pan, R.; Sun, K. Modeling and process parameter optimization of laser cutting based on artificial neural network and intelligent optimization algorithm. Int. J. Adv. Manuf. Technol. 2023, 127, 1177–1188. [Google Scholar] [CrossRef]

- Lee, Y.J.; Lee, J.R.; Ihn, J.B. Composite repair patch evaluation using pulse-echo laser ultrasonic correlation mapping method. Compos. Struct. 2018, 204, 395–401. [Google Scholar] [CrossRef]

- Wang, P.; Zhang, Z.; Hao, B.; Wei, S.; Huang, Y.; Zhang, G. Investigation on heat transfer and ablation mechanism of CFRP by different laser scanning directions. Compos. Part B Eng. 2023, 262, 110827. [Google Scholar] [CrossRef]

- Wang, J.; Yang, Y.; Qi, J.; Liu, Z.; Zhou, L. Thermodynamic simulation, surface morphology and bending property of carbon fiber reinforced polymer composite material subjected to laser cleaning. Opt. Laser Technol. 2022, 152, 108099. [Google Scholar] [CrossRef]

- Song, Y.; Cao, H.; Zheng, W.; Qu, D.; Liu, L.; Yan, C. Cutting force modeling of machining carbon fiber reinforced polymer (CFRP) composites: A review. Compos. Struct. 2022, 299, 116096. [Google Scholar] [CrossRef]

- Zhu, M.; Ouyang, J.; Tian, Y.; Guo, W.; Zhang, Z.; Mativenga, P.; Li, L. Understanding factors affecting the process efficiency, quality and carbon emission in laser drilling of CFRP composite via tailored sequence multiple-ring scanning. Compos. Part B Eng. 2024, 272, 111156. [Google Scholar] [CrossRef]

- Jia, Z.; Chen, C.; Wang, F.; Ma, J.; Yang, F. Three-dimensional oblique cutting model for sub-surface damage analysis in CFRP/Ti stack composite machining. Int. J. Adv. Manuf. Technol. 2018, 96, 643–655. [Google Scholar] [CrossRef]

- Xu, L.Y.; Lu, J.R.; Li, K.M.; Hu, J. Removal mechanism of CFRP by laser multi direction interaction. Opt. Laser Technol. 2021, 143, 107281. [Google Scholar] [CrossRef]

- Chai, Q.; Luo, Y.; Qian, X.; Zhang, Y.; Zhao, L. Investigation on ablative process of CFRP laminates under laser irradiations. Opt. Laser Technol. 2024, 174, 110687. [Google Scholar] [CrossRef]

- Zhang, Y.; Qiao, H.; Zhao, J.; Cao, Z.; Yu, Y. Numerical simulation of water jet–guided laser micromachining of CFRP. Mater. Today Commun. 2020, 25, 101456. [Google Scholar] [CrossRef]

- Xu, H.; Hu, J. Modeling of the material removal and heat affected zone formation in CFRP short pulsed laser processing. Appl. Math. Model. 2017, 46, 354–364. [Google Scholar] [CrossRef]

| Name | Unit | Value |

|---|---|---|

| Atomic mass of fiber | kg | 1.993 × 10−26 |

| Density of fiber | kg/m3 | 1850 |

| Density of epoxy resin | kg/m3 | 1250 |

| Thermal diffusivity of fiber | cm2·s−1 | 0.38 |

| Thermal diffusivity of epoxy resin | cm2·s−1 | 0.001 |

| Thermal conductivity of fiber | W/m/K | 5 |

| Thermal conductivity of epoxy resin | W/m/K | 0.2 |

| Specific heat capacity of fiber | J/kg/K | 710 |

| Specific heat capacity of epoxy resin | J/kg/K | 1200 |

| Vaporization temperature of fiber | °C | 3627 |

| Vaporization temperature of epoxy resin | °C | 527 |

| Decomposition temperature of fiber | °C | 880 |

| Decomposition temperature of epoxy resin | °C | 425 |

| Name | Unit | Value |

|---|---|---|

| Scanning speed | mm/s | 30/130/230 |

| Power | W | 200/400/600/800 |

| Pulse repetition rate | kHz | 50/100/150 |

| Spot diameter | μm | 35 |

| Pulse width | ns | 16.8 |

| Laser wavelength | nm | 355 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, J.; Wang, B.; Jiang, Q.; Hao, X. Effect of Laser Parameters on Surface Morphology and Material Removal Mechanism of Ablation Grooves in CFRP Composites Using Finite Element Simulations. Materials 2025, 18, 790. https://doi.org/10.3390/ma18040790

Song J, Wang B, Jiang Q, Hao X. Effect of Laser Parameters on Surface Morphology and Material Removal Mechanism of Ablation Grooves in CFRP Composites Using Finite Element Simulations. Materials. 2025; 18(4):790. https://doi.org/10.3390/ma18040790

Chicago/Turabian StyleSong, Juan, Bangfu Wang, Qingyang Jiang, and Xiaohong Hao. 2025. "Effect of Laser Parameters on Surface Morphology and Material Removal Mechanism of Ablation Grooves in CFRP Composites Using Finite Element Simulations" Materials 18, no. 4: 790. https://doi.org/10.3390/ma18040790

APA StyleSong, J., Wang, B., Jiang, Q., & Hao, X. (2025). Effect of Laser Parameters on Surface Morphology and Material Removal Mechanism of Ablation Grooves in CFRP Composites Using Finite Element Simulations. Materials, 18(4), 790. https://doi.org/10.3390/ma18040790