1. Introduction

As the binder of the mixture, the performance of bitumen directly affects the road performance and service life of the bitumen pavement. The styrene–butadiene–styrene block copolymer (SBS) has been proven to significantly improve the high- and low-temperature performance, adhesion, resilience, and ductility of bitumen [

1]. It is a commonly used modification additive. SBS absorbs the light components of bitumen, including saturated and aromatic fractions, through the intermediate segment of butadiene. This process of absorption results in the solubilization of the light components, leading to the formation of a network structure [

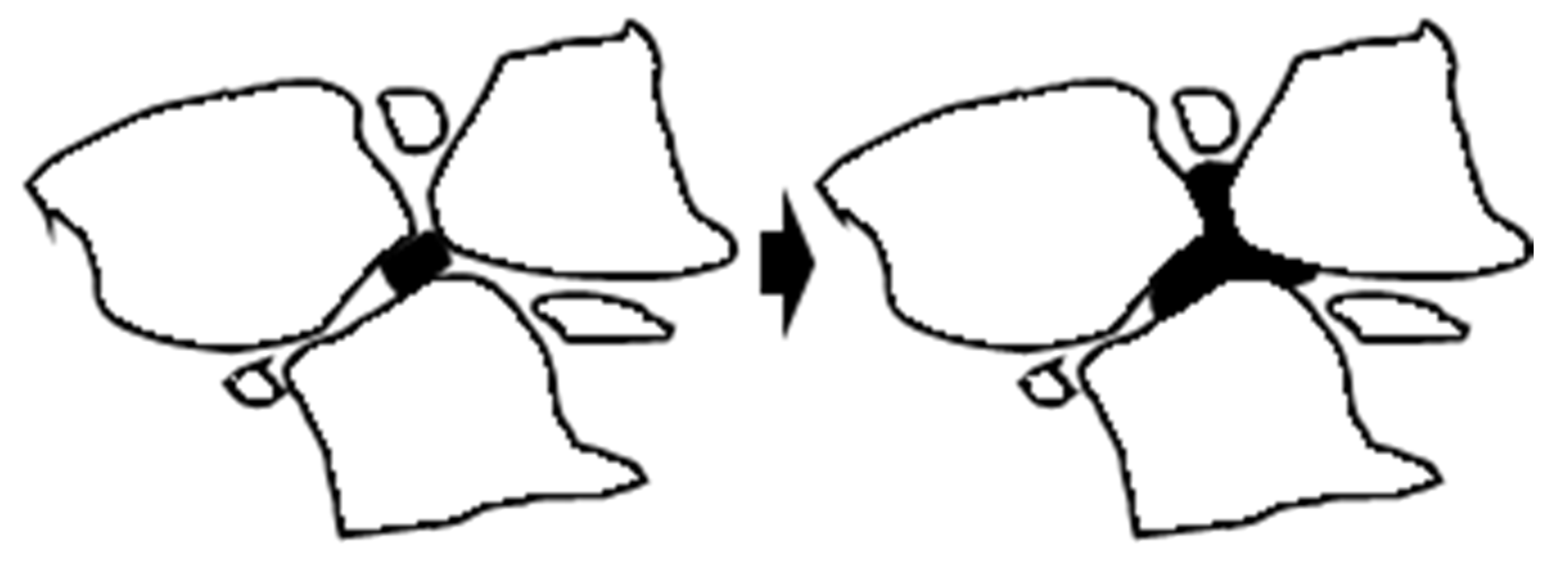

2]. Experimental studies have shown that the styrene chain segments interact with the polar components in bitumen via intermolecular forces; subsequent adsorption of these polar components onto the nodes of the swollen network gives rise to the formation of stable physical cross-linking sites [

3]. Simultaneously, the addition of a modest quantity of phase solvents and stabilizers during the designated preparation process and within the stipulated development conditions will ensure that SBS-modified bitumen exhibits optimal performance [

4].

Scholars in various countries have carried out extensive research into the SBS-modified bitumen modification mechanism, enhancement effect, and preparation process. Lu [

5] concluded that increasing the SBS content of modified bitumen decreases its stability and that star SBS-modified bitumen is less stable than linear SBS-modified bitumen at high temperatures. Zhang [

6] prepared high-viscosity bitumen using SBS, a plasticizer, and a crosslinker; tested the effect of different modifiers on its low-temperature performance; and carried out infrared spectroscopy tests and differential thermal analysis tests on the prepared high-viscosity bitumen to study the modification mechanism and microstructure of different polymers in high-viscosity bitumen. Sheng [

7] concluded that using a high-speed mixing method for desulfurization can reduce the agglomeration phenomenon of waste rubber powder particles, enhance the dissolution capacity, and improve the performance of waste rubber powder-modified bitumen. Shan [

8] explored the linear and nonlinear properties of SBS-modified bitumen using Fourier-transform rheology and stress decomposition. The results show that the nonlinear characteristics of modified bitumen are more obvious than those of matrix bitumen and increase with the increase in SBS content, and the modified bitumen shows viscoelastic behavior under all the test conditions, and SBS can reduce the fluidity of modified bitumen and increase its elasticity ratio.

Unlike SBS’s flexible network, the reinforcement of the crystalline zones in plastic granules enhances high-temperature performance. Polyethylene (PE) is a polymer made from ethylene through the polymerization of linear polymers. It belongs to the class of long-chain aliphatic hydrocarbon polymers. As a bitumen modifier, PE can improve its performance, mainly because it can form a network-like structure that constrains the movement of bitumen molecules, effectively enhancing its viscoelasticity and reducing its sensory characteristics when heated [

9]. KhanIM [

10] used dynamic shear rheometer (DSR) tests to show that both low-density polyethylene (LDPE) and high-density polyethylene (HDPE) improve the rutting resistance and temperature sensitivity of bitumen. Goutham [

11] obtained that waste plastics can be used as bitumen additives to increase the stability of bitumen mixtures, and a small amount of plastic can be used to replace some of the fibers by using spin compaction gauge (SCG) tests. Hu [

12] modified bitumen with recycled packaging waste polyethylene (WPE) instead of common polymer modifiers and showed that WPE improved the high-temperature stability, low-temperature crack resistance, service life, and water stability of bitumen mixtures. Liang [

13] investigated the behavior of the polyethylene phase in PE-modified bitumen by experimental and simulation methods. It was found that the reduction of polyethylene density and crystallinity resulted in easier migration of bitumen components into the intermolecular space, stronger interaction between the two, and higher solubility. Dalhat [

14] found that for every 2% increase in PE, the performance grade (PG) increased by one grade. Habib [

15] studied linear low-density polyethylene (LLDPE)- and HDPE-modified bitumen and found that thermoplastic copolymers significantly reduced base bitumen needle penetration, and the best modification effect was achieved when polyethylene blending was kept below 3 wt%. Wu [

16] summarized the effect of recycled waste plastics such as HDPE, LDPE, polypropylene (PP), and polystyrene (PS) on bitumen and concluded that waste plastics improved the stiffness, rutting resistance, fatigue resistance of matrix bitumen mixtures, etc., but the compatibility between recycled plastics and bitumen was poor. Mahyar [

17] utilized polyvinyl chloride (PVC) as an additive to improve the properties of bitumen and hot mix bitumen (HMA). The results showed that PVC improves the rheological properties of bitumen, and HMA specimens doped with PVC have better rutting resistance.

Currently, the most effective way to enhance the properties of bitumen is through the use of composite modification additives, which include thermoplastic elastomer materials, plastomer materials, and rubber-like materials. Fu [

18] prepared SBS/waste rubber powder-modified bitumen by the chemical modification method and analyzed the viscoelastic properties of modified bitumen by rheometer test. The results indicated that the composite modification of SBS and waste rubber powder has certain improvements on the modified bitumen’s low-temperature and high-temperature performance. Zhang [

19] used polyphosphoric acid and sulfur to improve the high-temperature performance and storage stability of SBS/SBR-modified bitumen. The test showed that polyphosphoric acid significantly improved the high-temperature performance of SBS/SBR-modified bitumen but reduced the storage stability. Ahmedzade [

20] prepared modified bitumen using 40% HDPE, 25% ethylene propylene diene monomer (EPDM), and 17.5% tire rubber in mass fraction. The test results showed that the modified bitumen could increase the softening point, reduce the needle penetration, as well as improve the high-temperature performance, but the improvement for fatigue life was slightly worse compared to SBS-modified bitumen. Guo [

21] used waste-reinforced polypropylene (RPP) and an SBS composite to prepare modified bitumen, and the test results showed that the composite modification of RPP and SBS further enhanced the cross-linking between the polymer and bitumen and significantly improved the rheological properties of bitumen. Ma [

22] prepared recycled rubber–plastic- and SBS-modified binder blends. The results showed that the recycled rubber–plastic-modified bitumen could form a continuous phase of rubber and plastic, which improved the compatibility of the binder mixture and the properties of the bitumen mixture. Saeed [

23] conducted rheological tests, Hamburg rutting tests, and dynamic creep tests and found that the high- and low-temperature properties and rutting resistance of the modified bitumen mixtures prepared by the addition of appropriate proportions of SBS and montmorillonite (MMT) were significantly improved. Zhe Hong [

24] conducted indoor experimental studies, which verified that the incorporation of low-density polyethylene (LDPE) and ethylene–vinyl acetate copolymer (EVA) as modifiers can significantly enhance the permanent deformation resistance and elastic modulus of modified bitumen. COSTA [

25] carried out a morphological structure analysis, storage stability test, and creep recovery test by adding EVA and HDPE to bitumen. The results showed that EVA-modified bitumen was similar to SBS-modified bitumen in terms of viscoelastic properties, but HDPE-modified bitumen was slightly higher than SBS-modified bitumen in terms of softening point and needle penetration. Mostafa [

26] prepared (styrene–butadiene rubber) SBR-/PP-modified bitumen and evaluated its performance by bending beam fatigue, indirect tensile fatigue, and modulus of resilience tests. The results showed that SBR/PP can significantly improve the fatigue resistance and service life of modified bitumen mixtures.

The process of dry modified bitumen involves adding the modifier straight to the aggregate and then mixing the resulting bitumen mixture. This eliminates issues with wet modified bitumen storage stability and other issues, and it requires no large equipment and is suitable for on-site construction. Yucel [

27] prepared dry warm mix rubber powder modified bitumen mixtures using different temperatures and compaction processes and investigated the effect of warm mixing agents on the internal structure and properties of dry rubberized bitumen mixtures. Shi [

28] prepared a high-viscosity bitumen modifier, SPR, from SBS/C9 petroleum resin blends and investigated the chemical properties of SPR and its modification effect on bitumen. The results showed that SPR had a good modification effect on bitumen. Movilla-Quesada [

29] used a dry process to prepare a polymer made by fusing waste polyethylene terephthalate (PET), HDPE, and PVC with aggregates at 180 °C, which was used to replace part of the bitumen, and then mixed with the bitumen to prepare bitumen mixtures. It was found that this polymer was stiffer than bitumen, thus improving the overall hardness of the mixture. Zhang [

30] used a twin-screw extruder to prepare a PE-modified bitumen masterbatch, and the prepared masterbatch was pelletized and then blended into the base bitumen using the blending method to prepare polyethylene-modified bitumen. The results show that the polyethylene masterbatch prepared by a twin-screw extruder has better compatibility with bitumen and can significantly improve the softening point and reduce the degree of needle penetration. A large number of studies have shown that there is little difference in the road performance of wet and dry modified bitumen. Even when the content is the same, such as for water stability, the mixture prepared using the dry process performs better than that prepared using the wet process.

In recent years, researchers’ focus in the field of polymer-modified bitumen has had a certain bias: more focus has been placed on the impact of different types of polymer modifiers on bitumen performance and the formulation of various modifiers, while there is relatively less research on the modification mechanism between polymer particle modifiers and bitumen. At the same time, although there have been studies on the preparation of bitumen modifier using a variety of polymers, and the performance and process of polymer modifier have been discussed, the research on the modification mechanism of multi-component polymer particle modifiers and bitumen, its distribution law in the mixture, and process control methods is still relatively scarce, and the related issues have not been clearly explained.

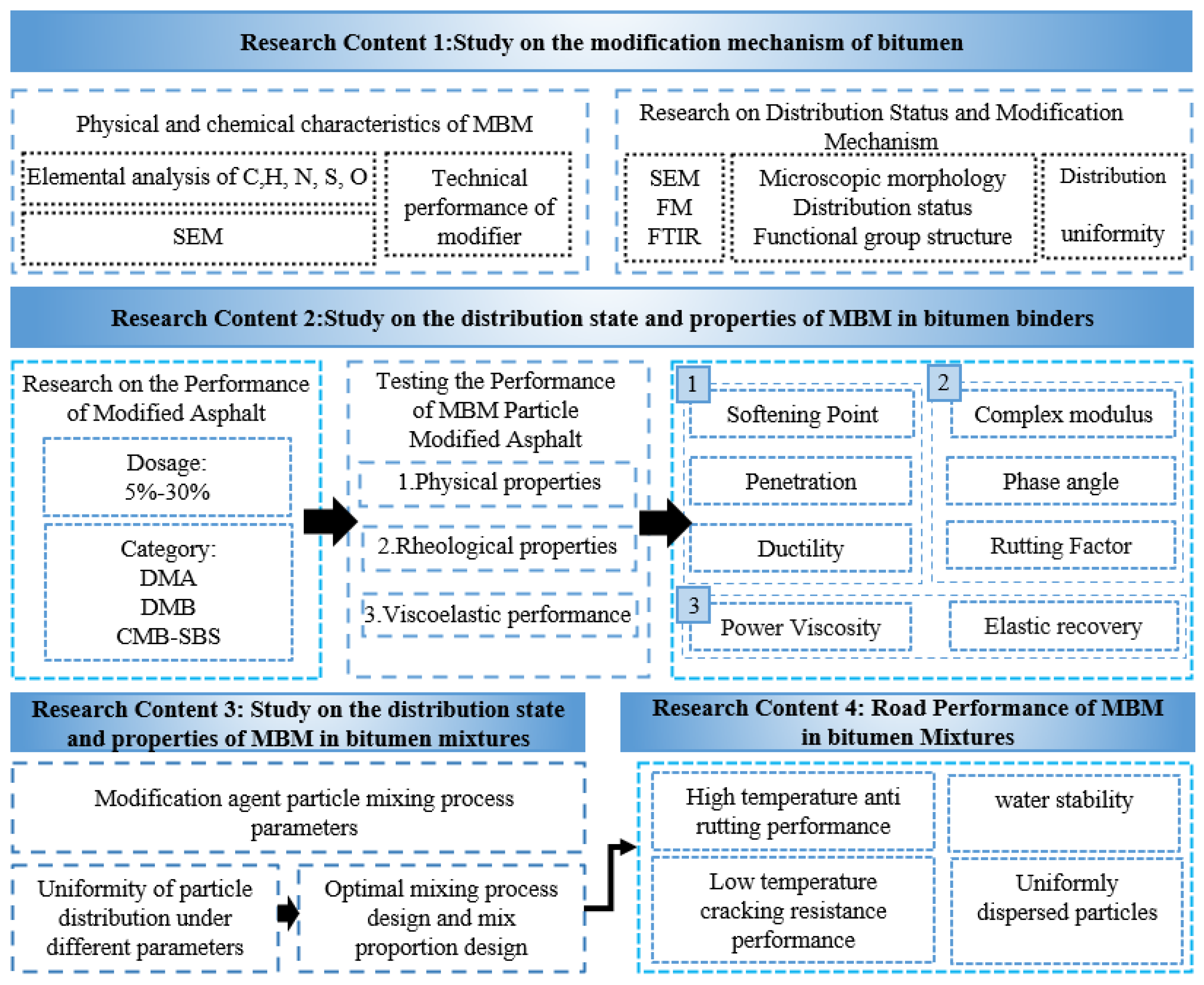

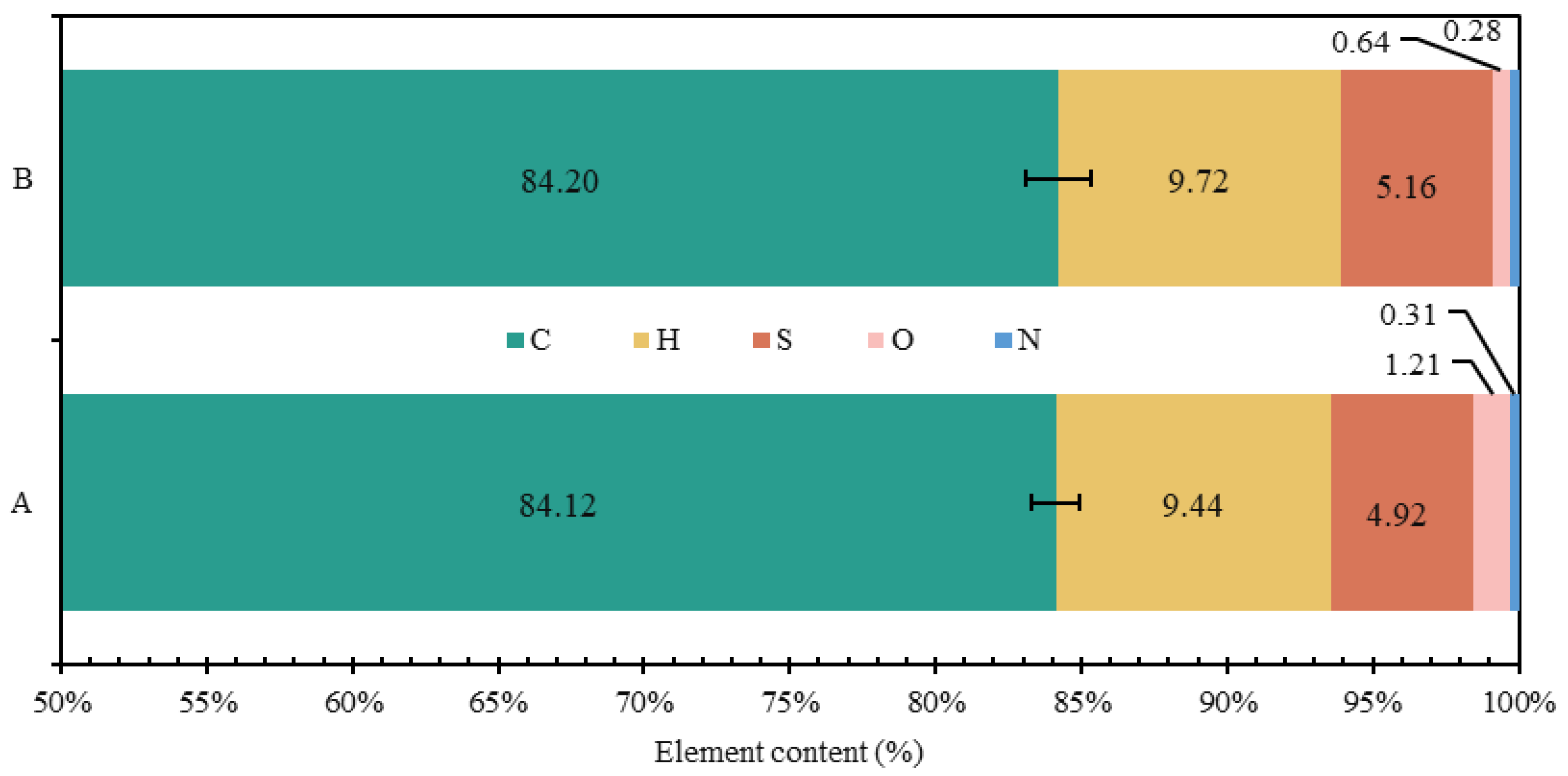

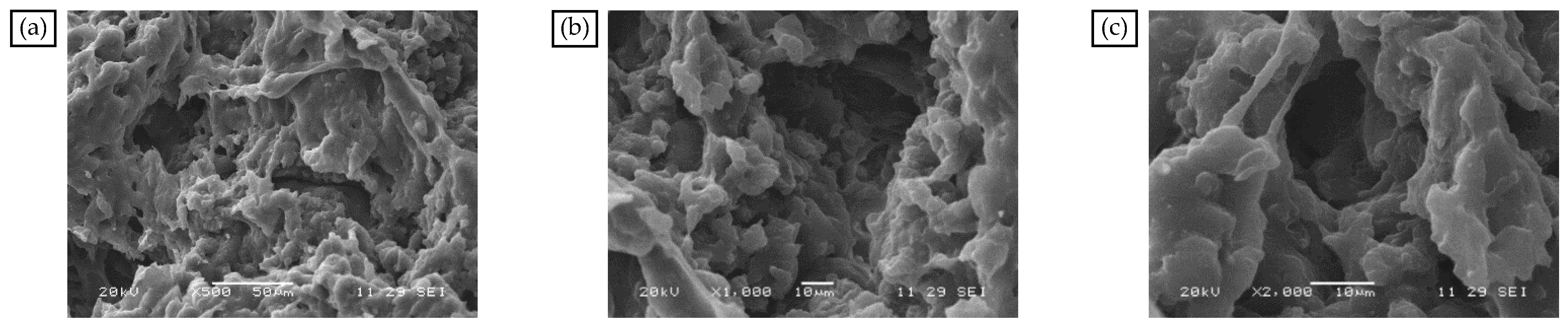

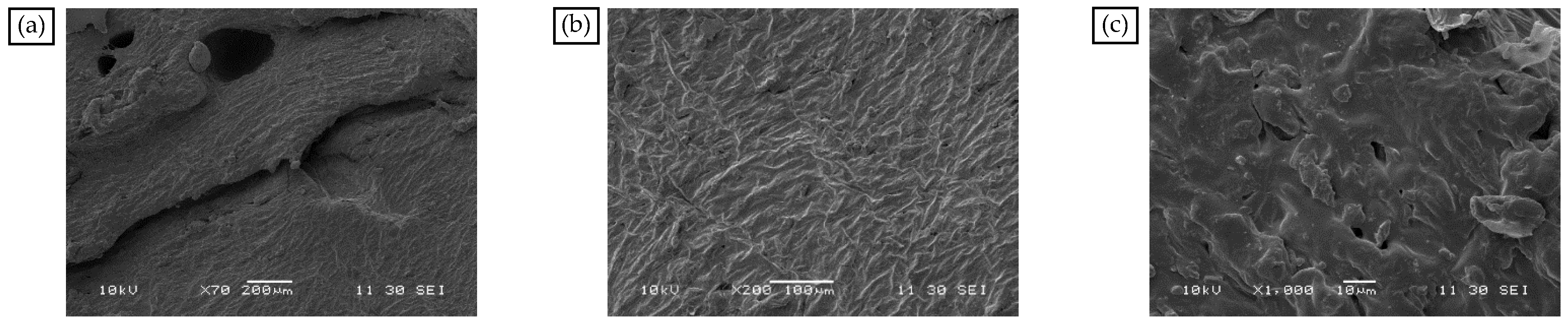

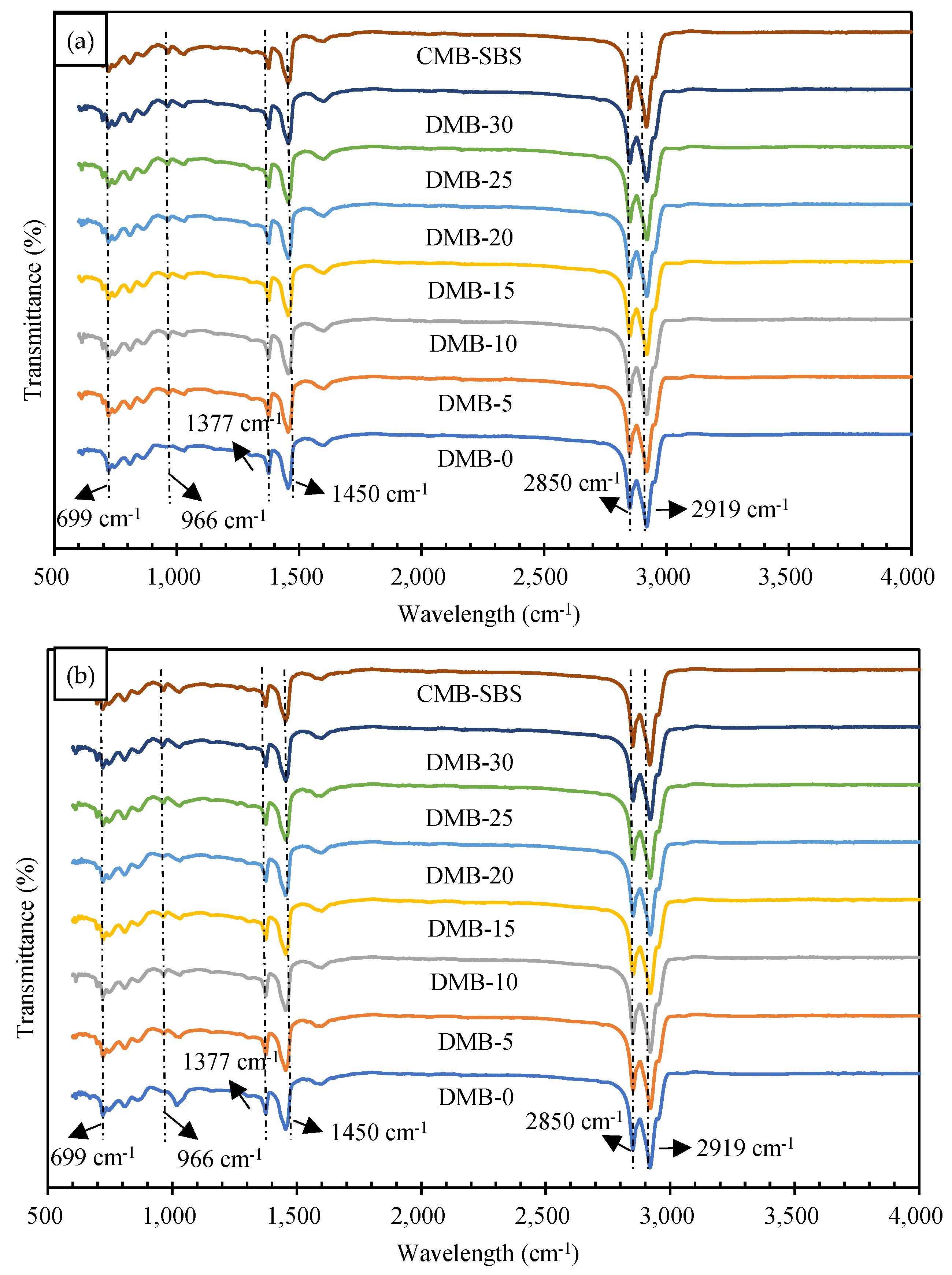

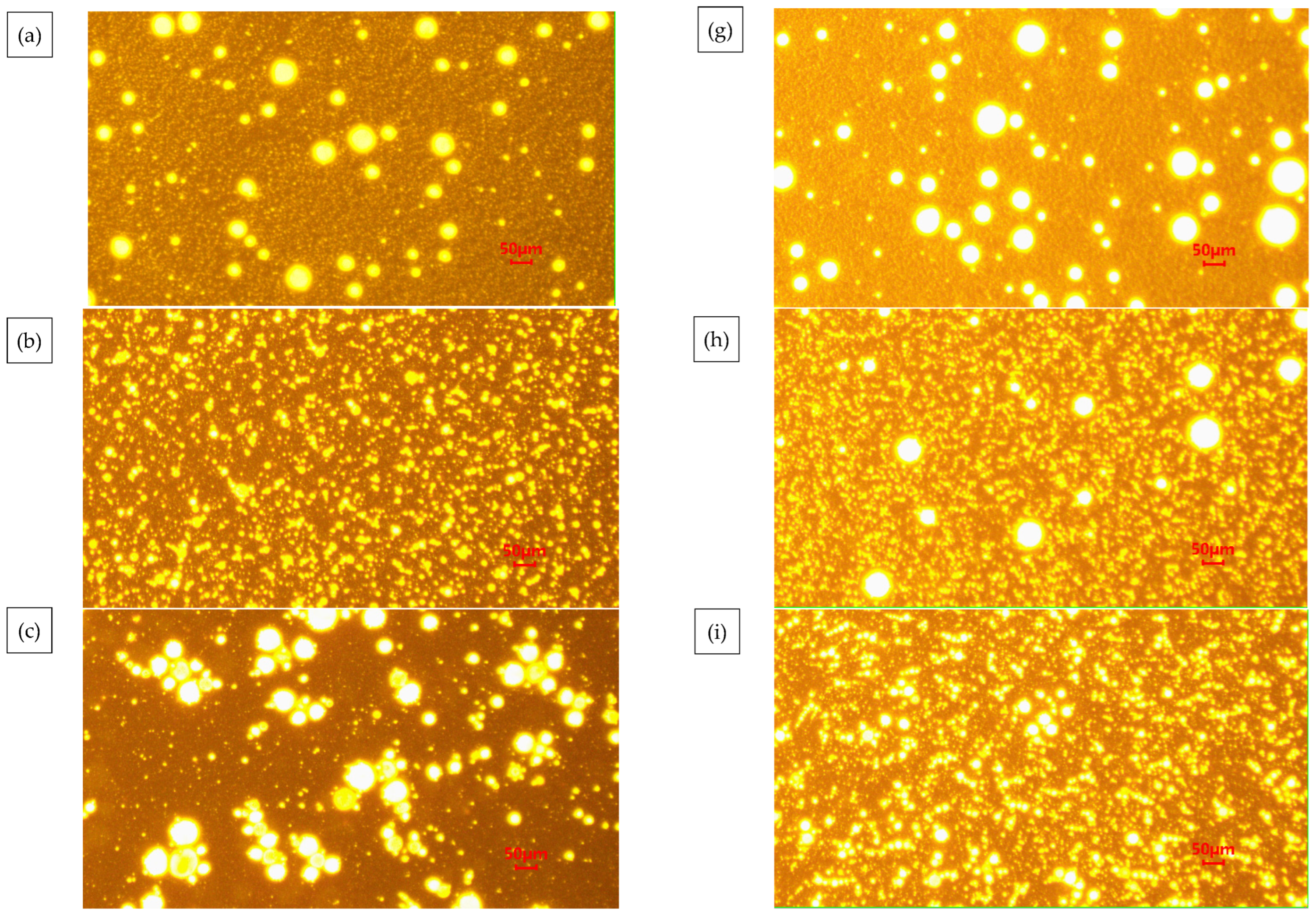

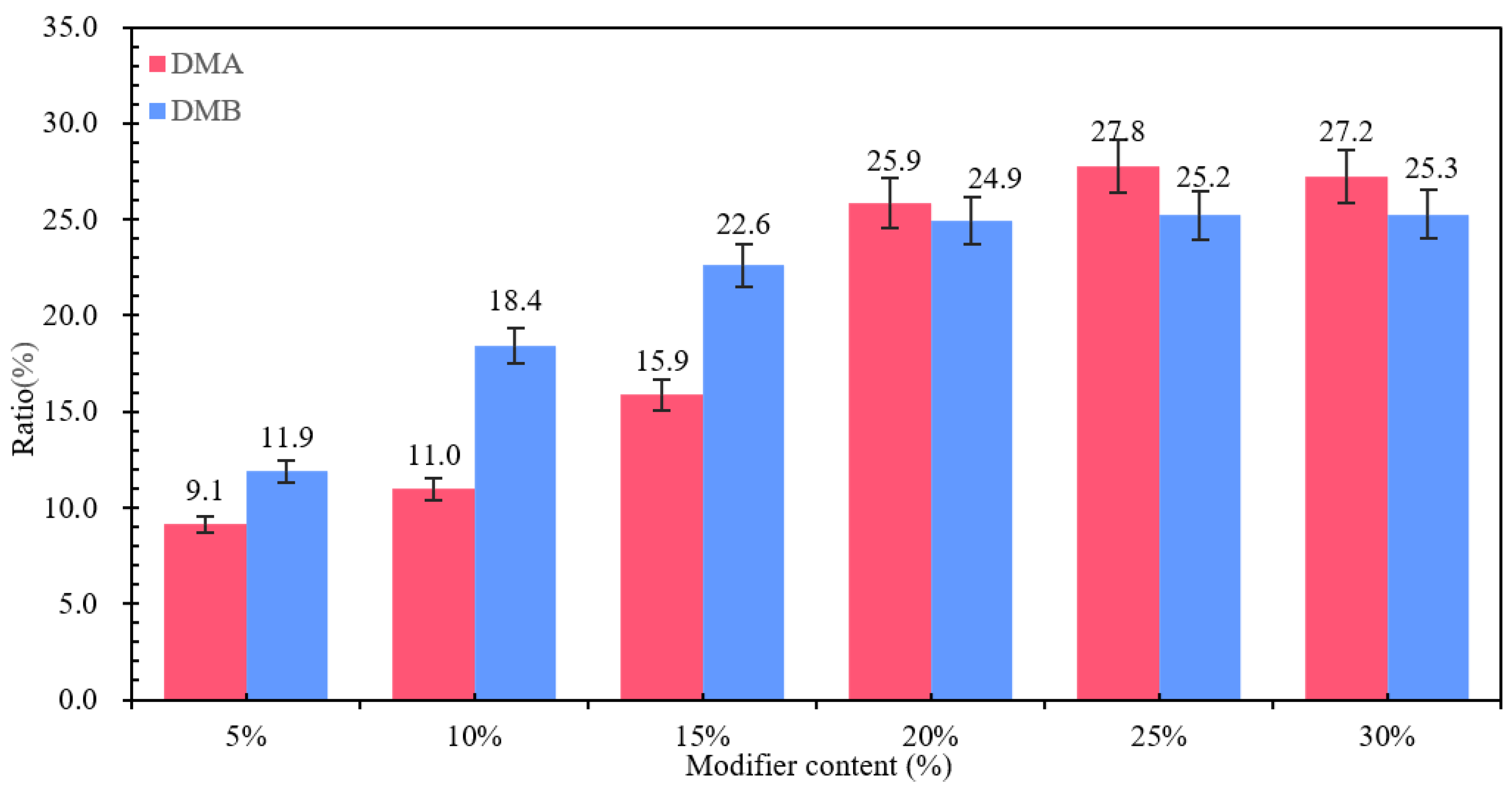

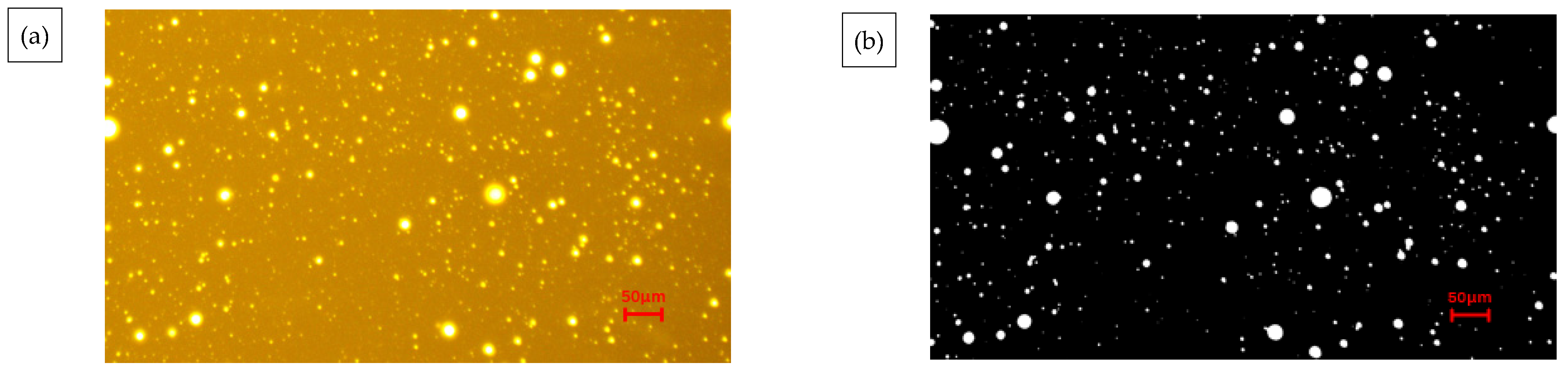

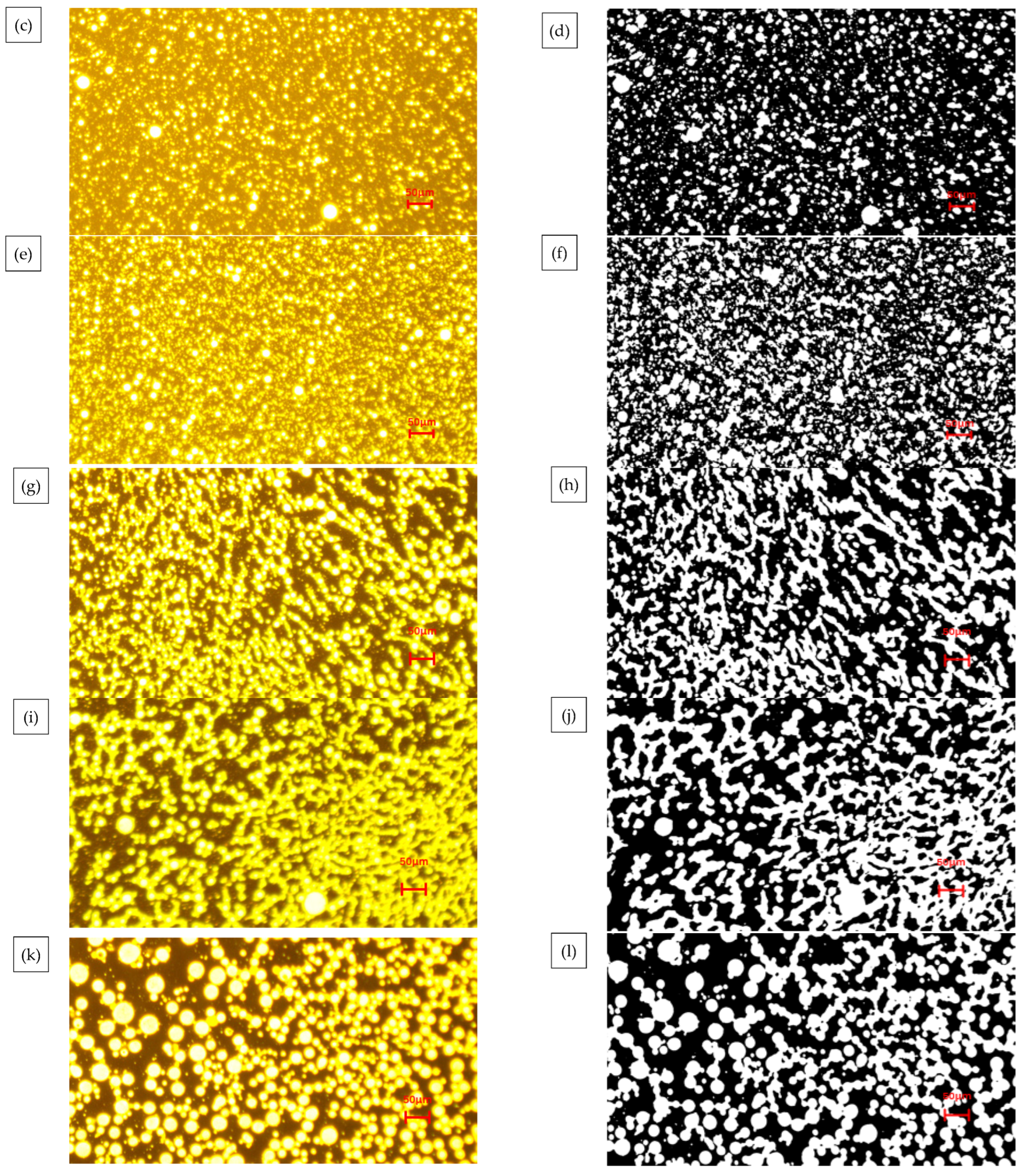

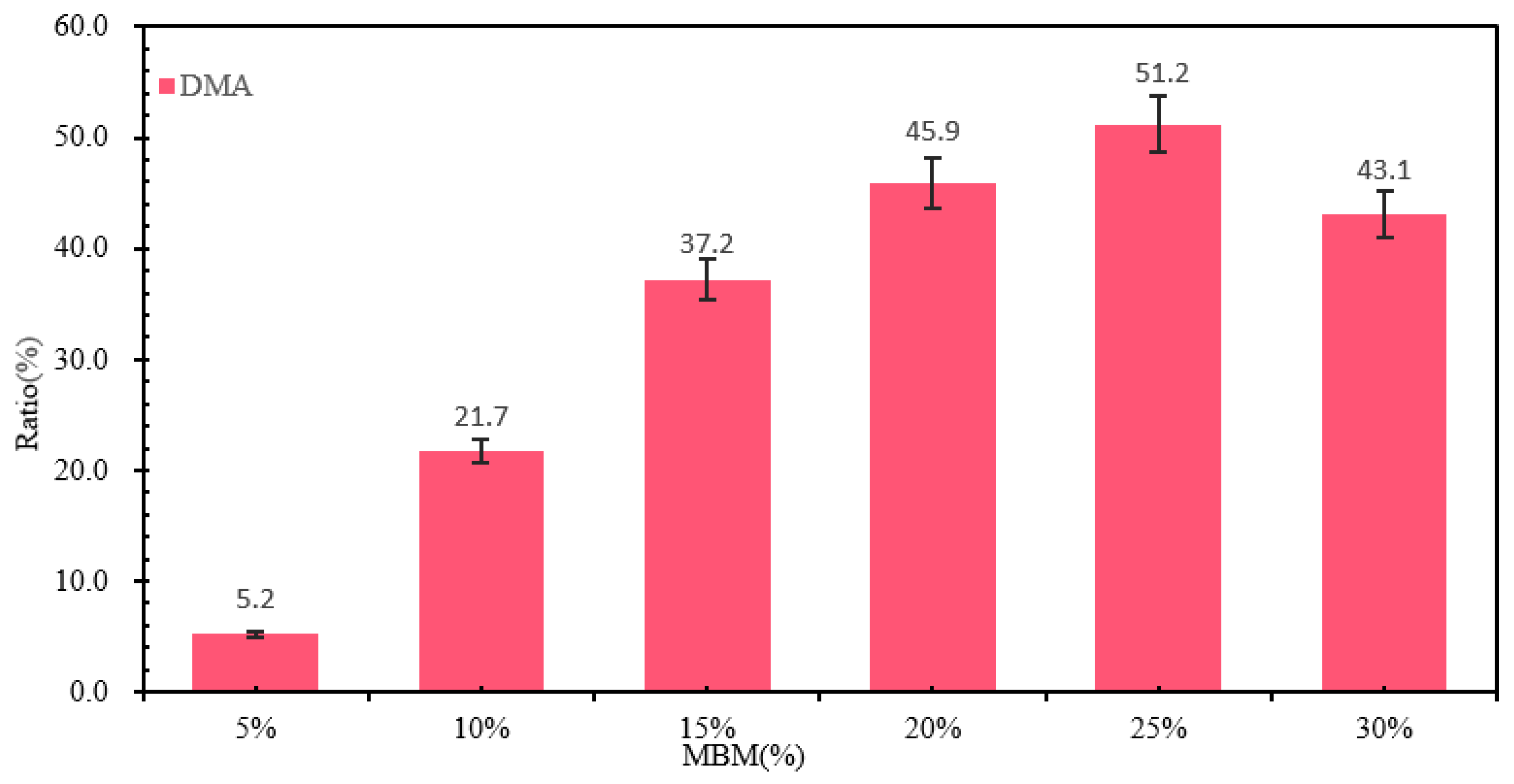

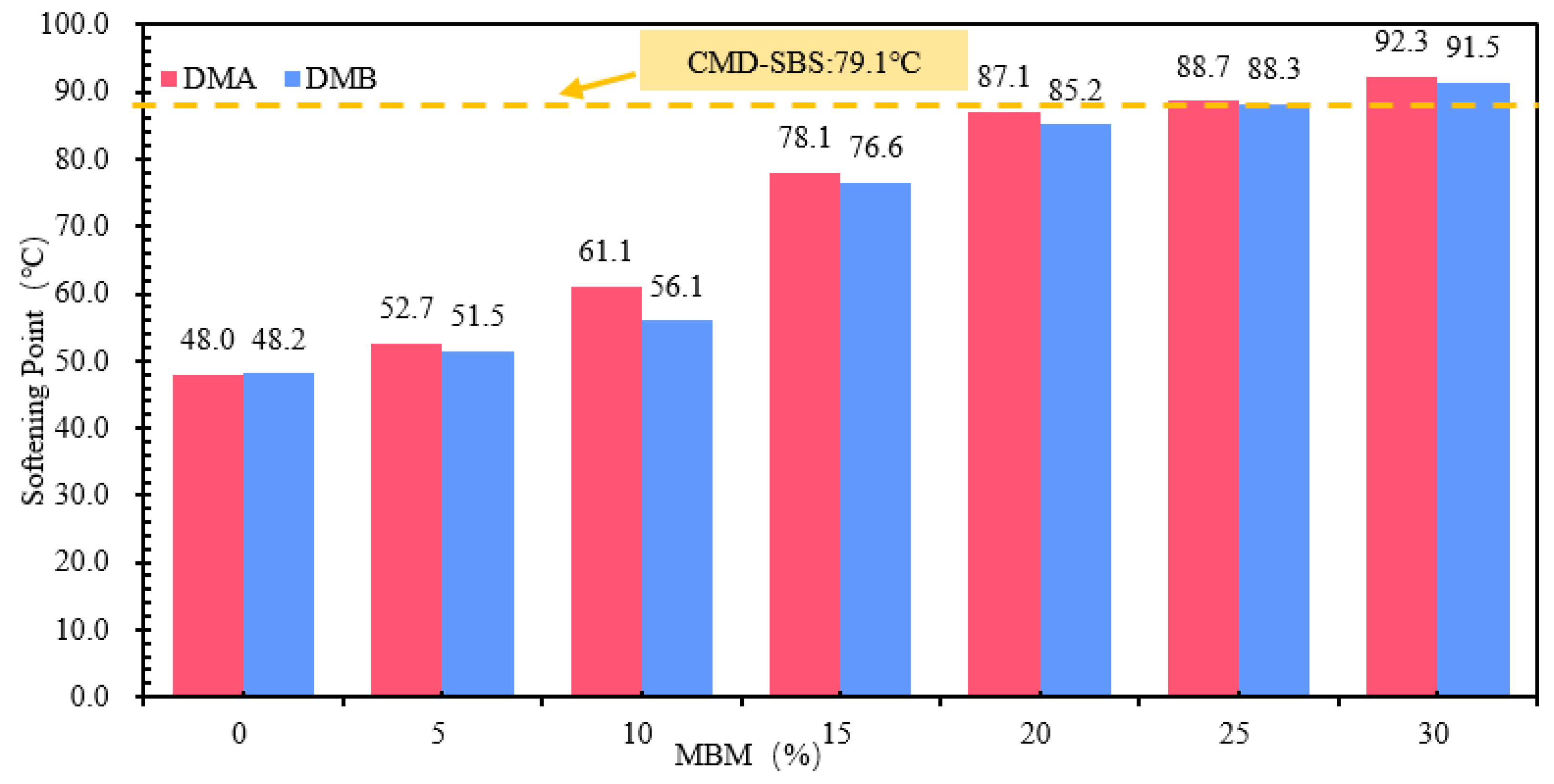

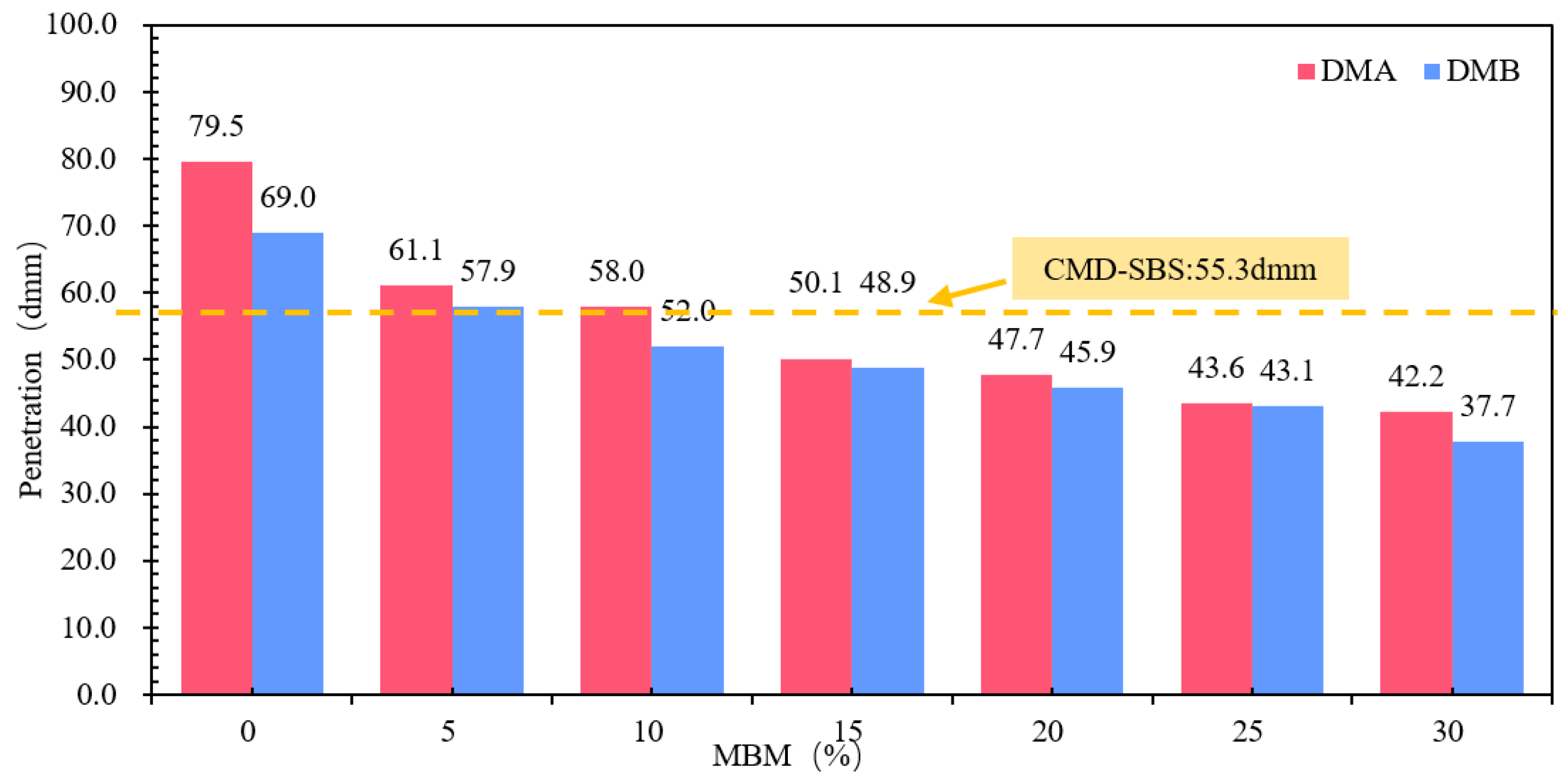

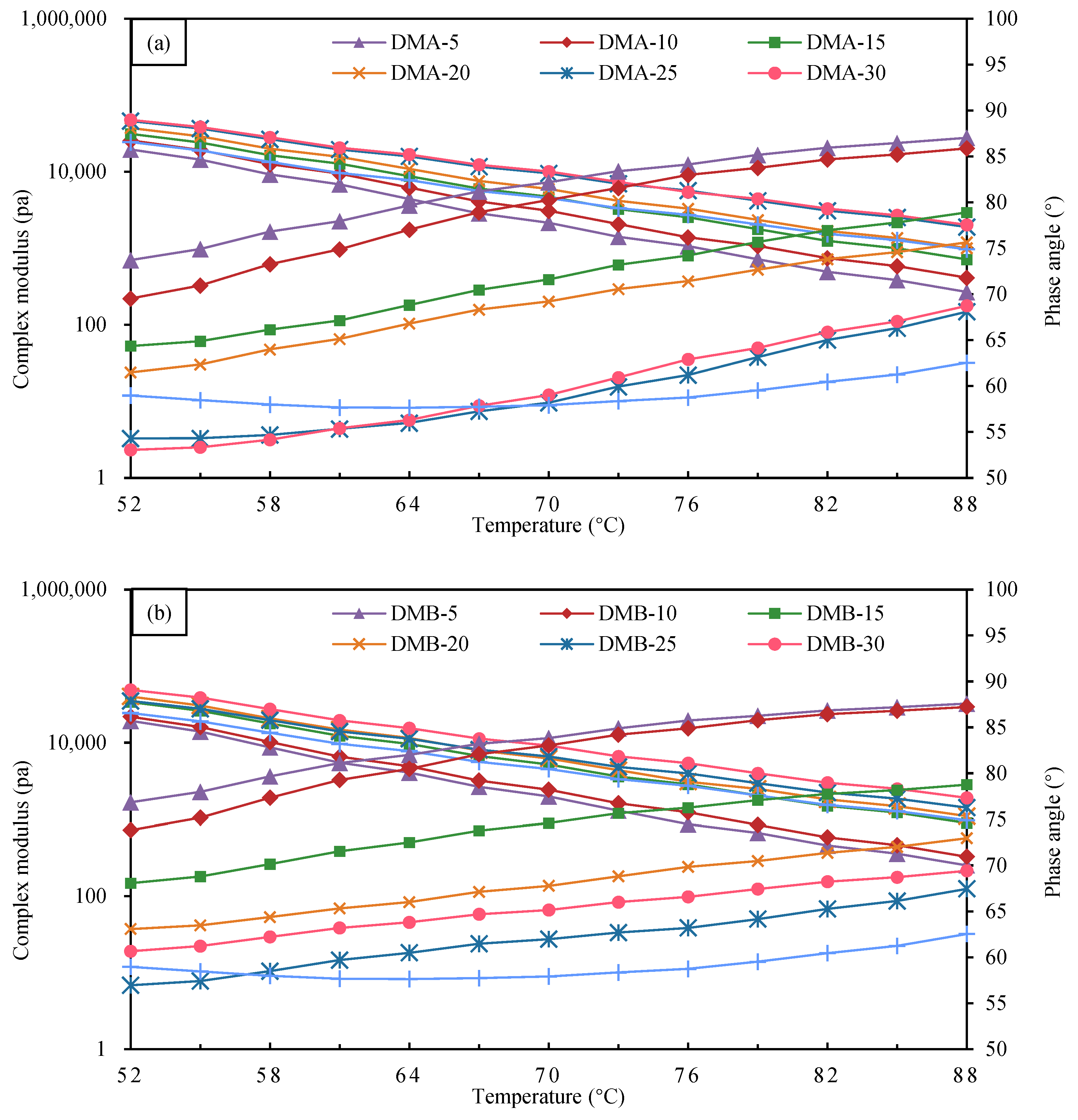

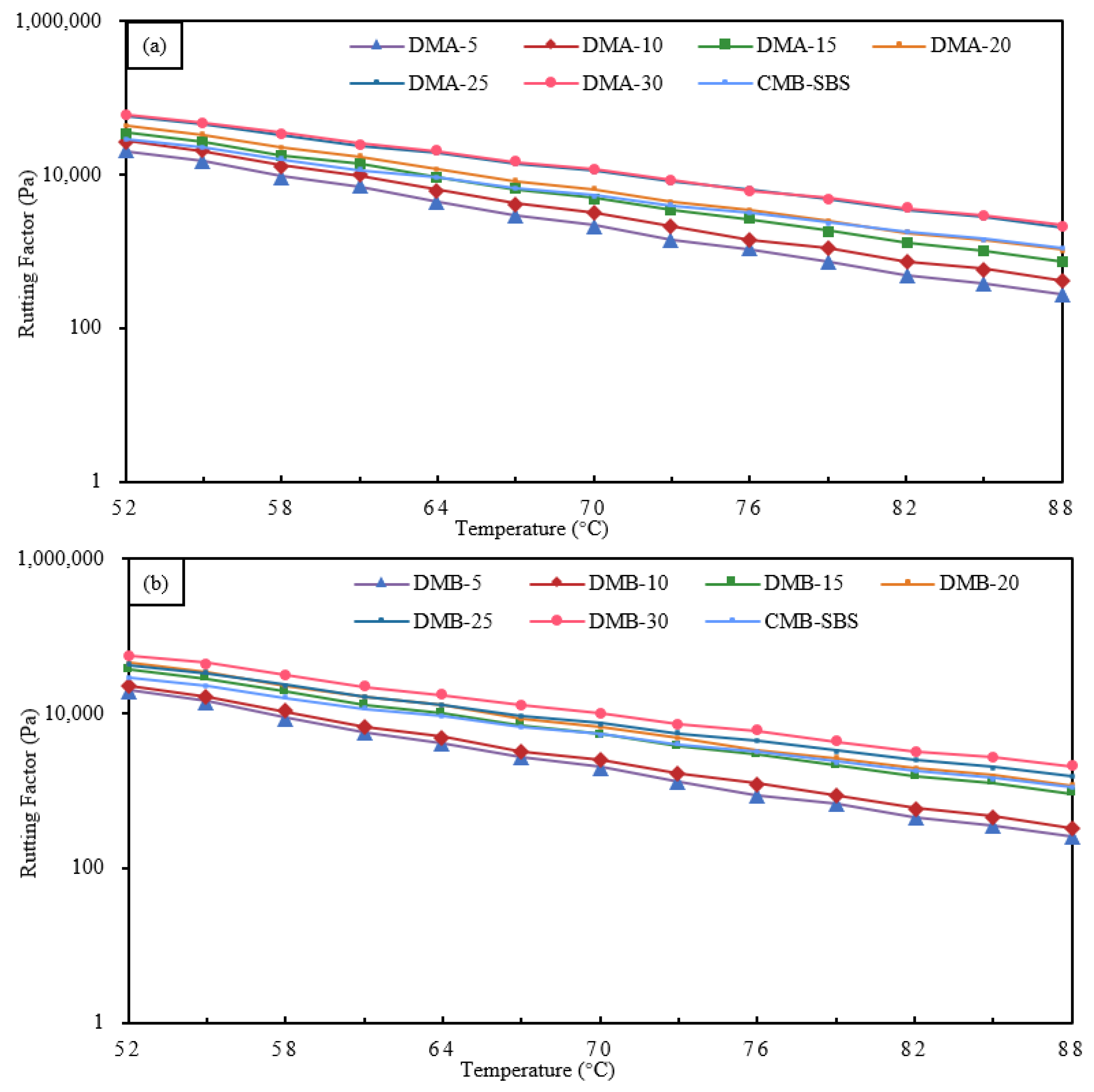

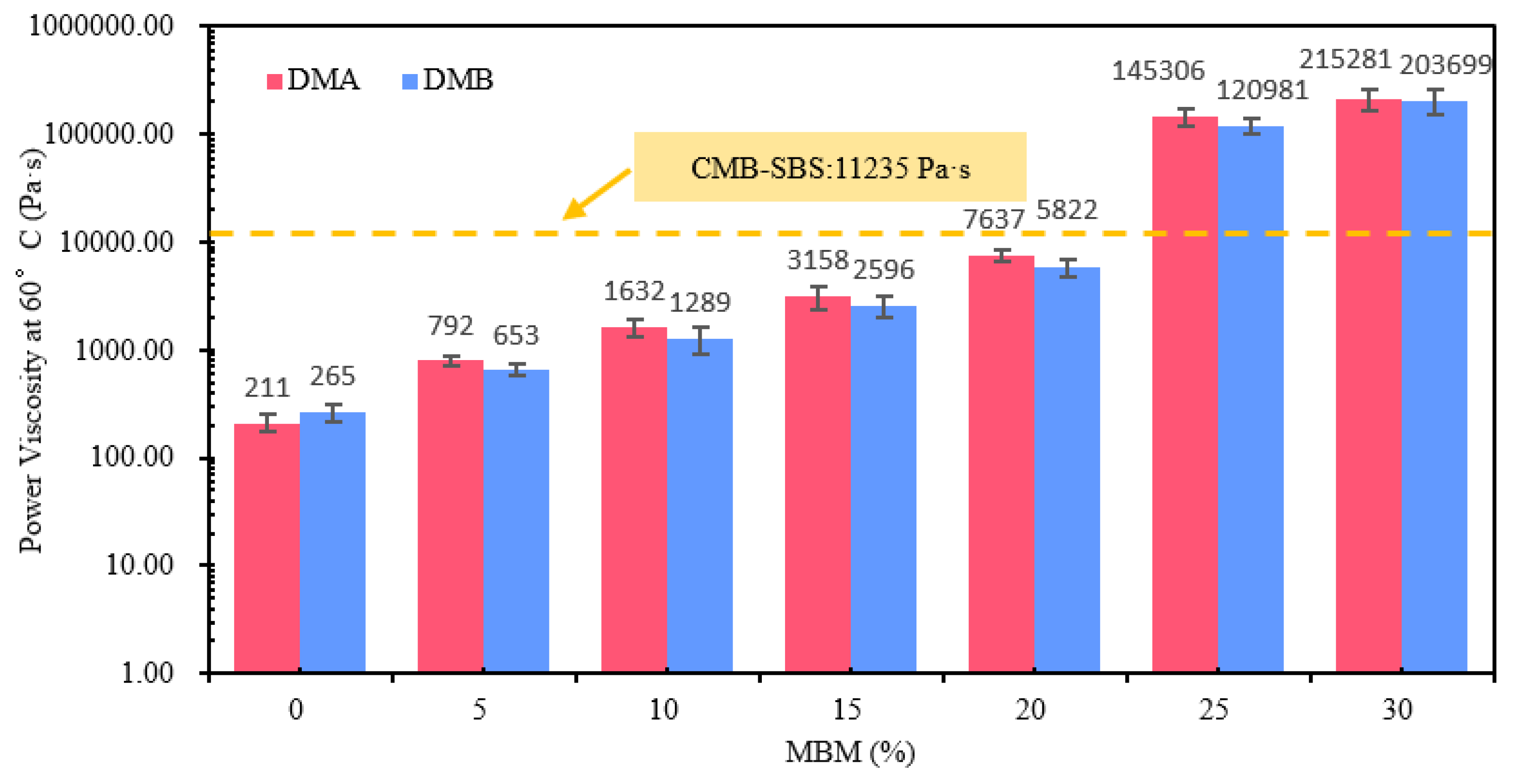

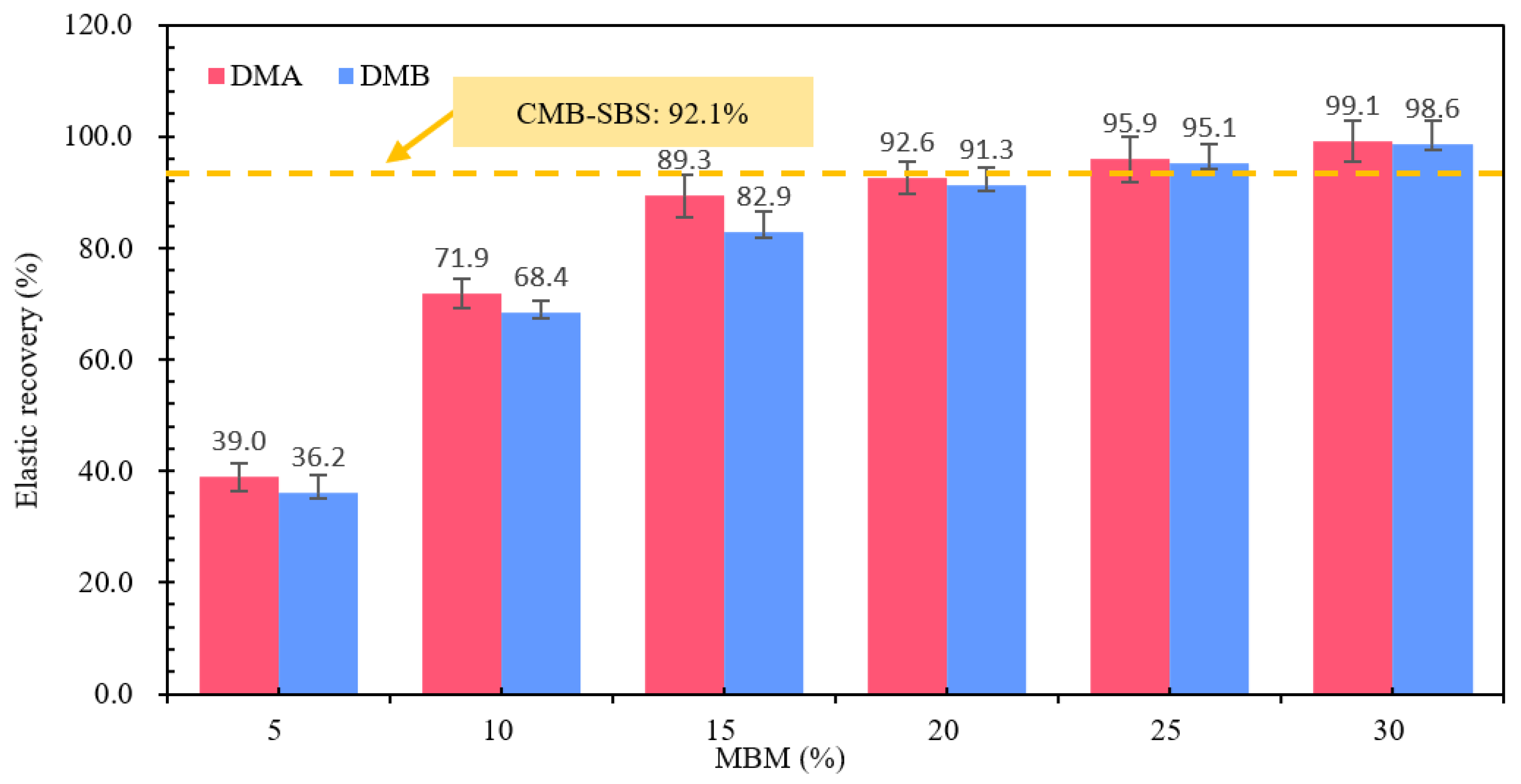

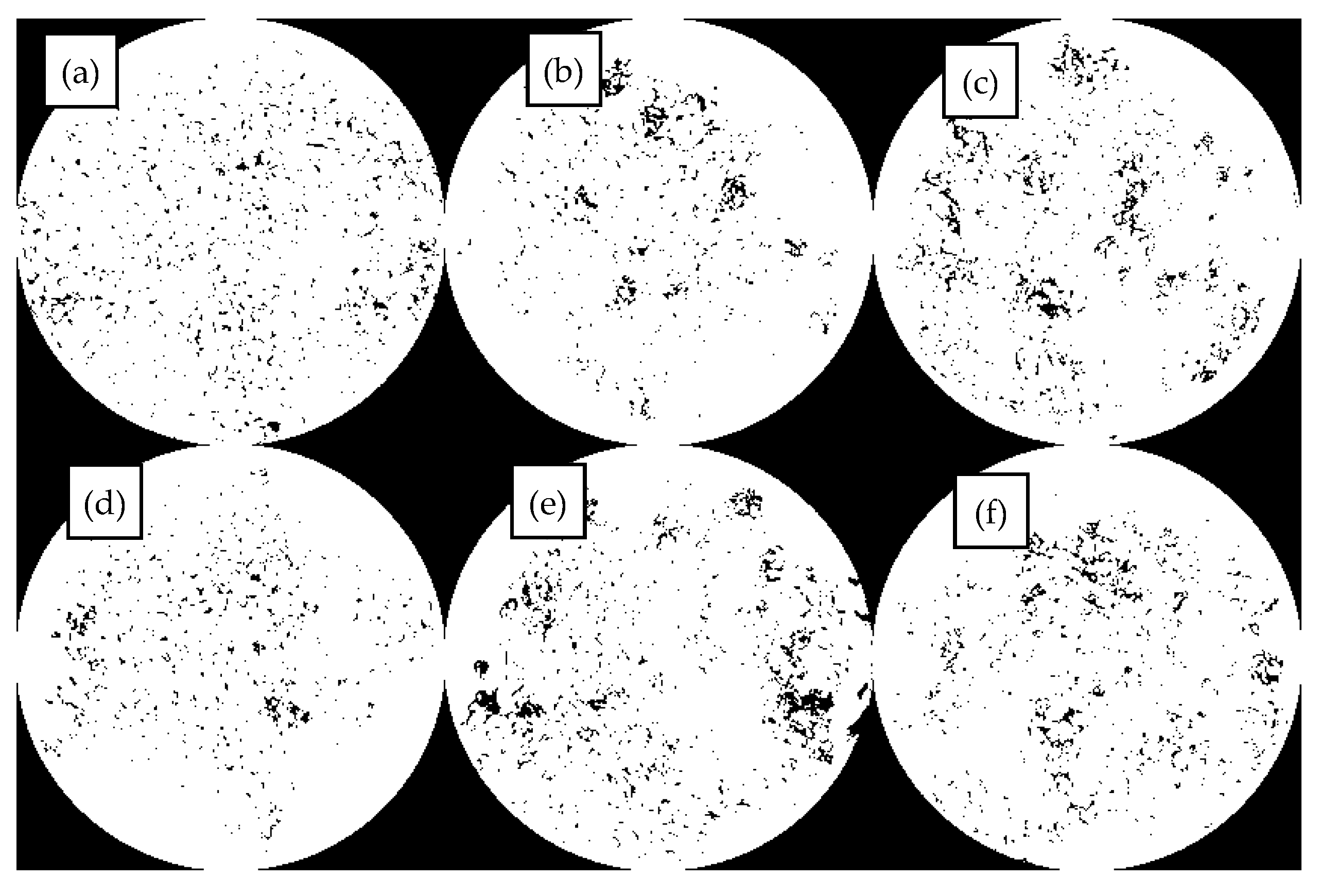

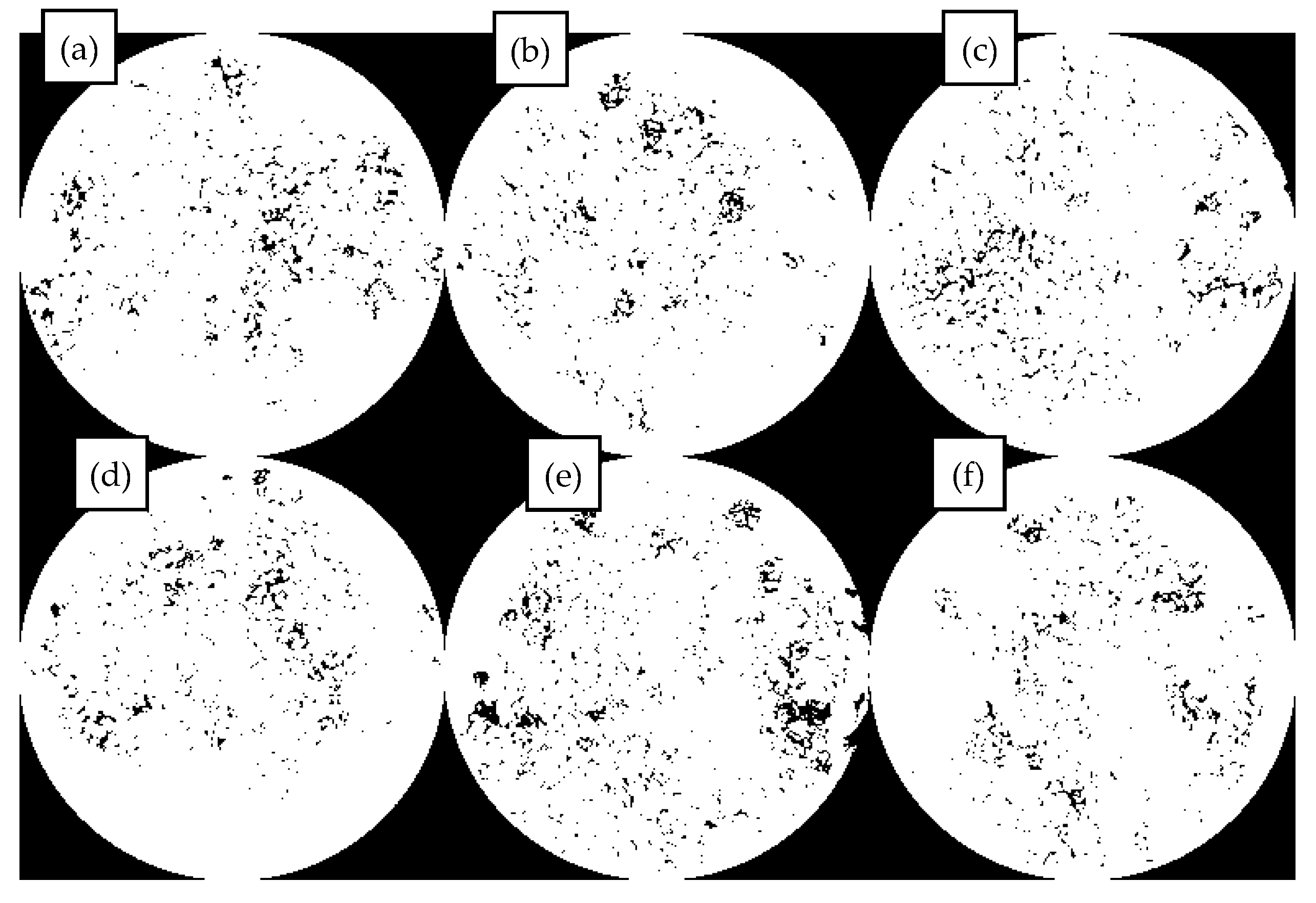

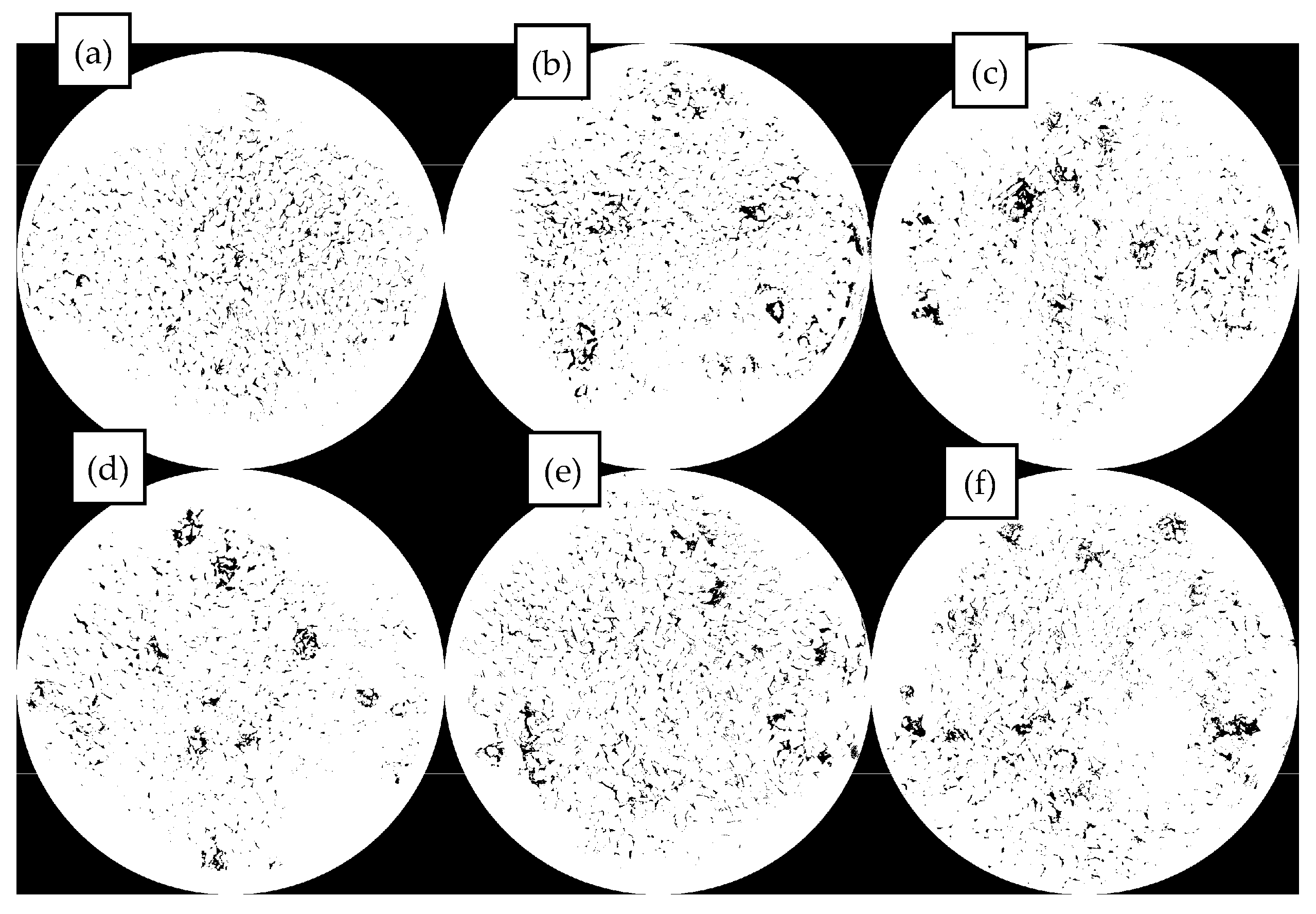

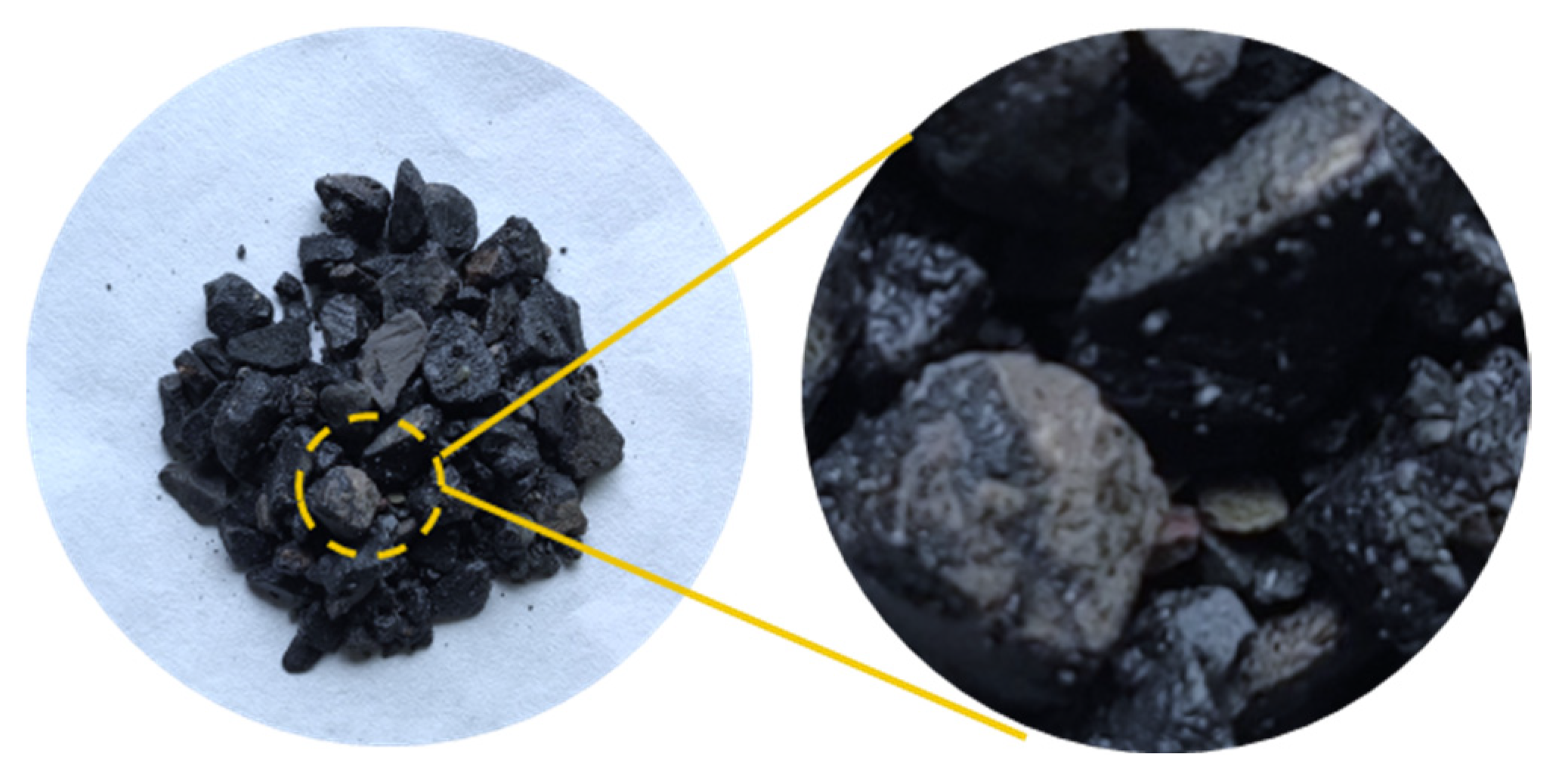

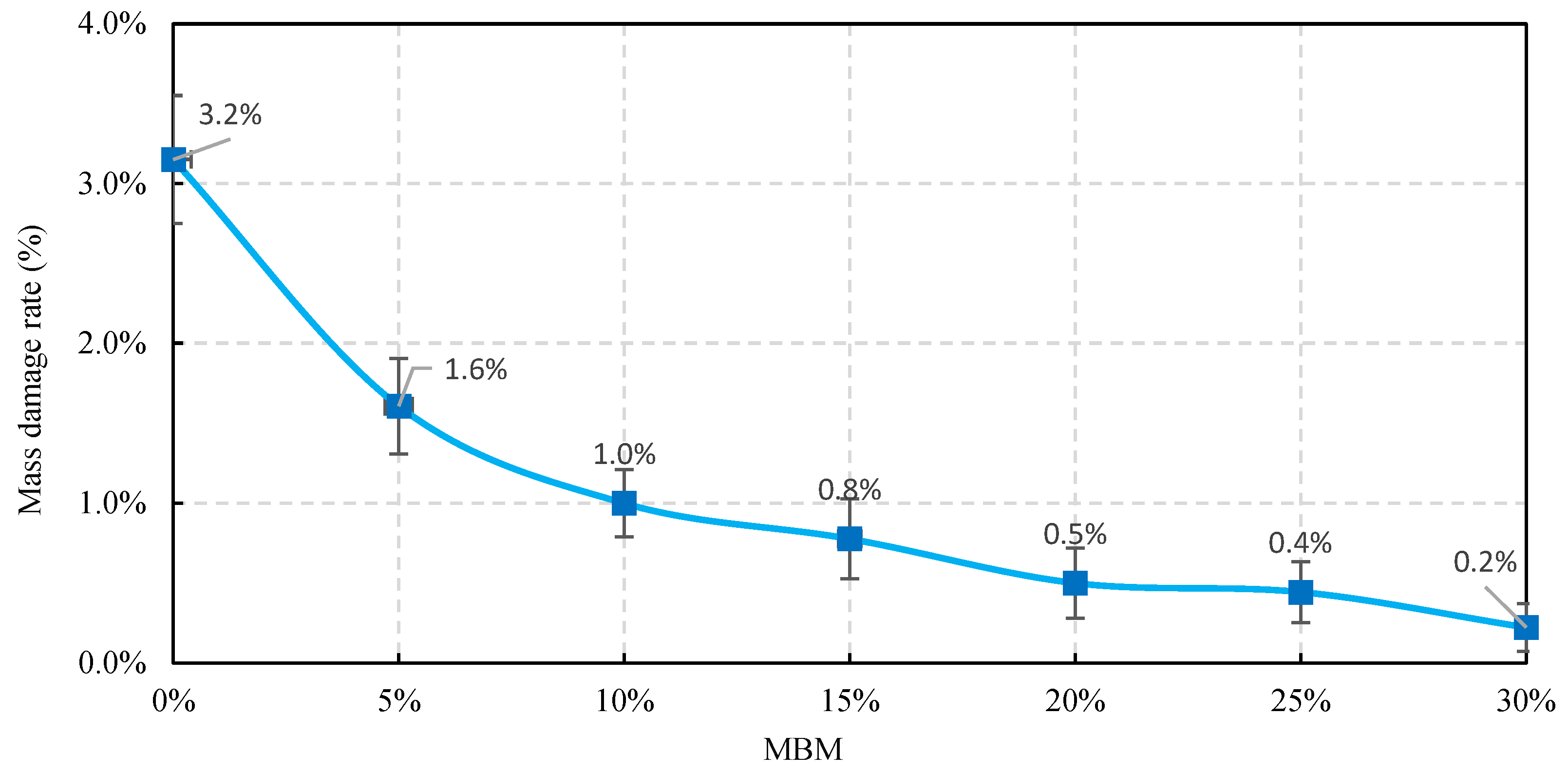

In order to solve the above problems, this study used SBS, PE, aromatic oil, and other polymers to prepare a multi-component polymer particle bitumen modifier (MBM) and carried out a series of studies through the “macro micro” cross-scale research method. At the micro level, with the help of element analyzer, scanning electron microscope (SEM), Fourier-transform infrared spectrometer (FTIR), fluorescence microscope (FM), and other technical means, the element composition of matrix bitumen, the microstructure of modifier, the change of functional groups in modified bitumen and the distribution of a polymer in bitumen were deeply explored so as to reveal the modification mechanism between a multi-component polymer and bitumen. In terms of macro-performance research, the physical properties, rheological properties, and viscoelastic properties of DMA and DMB with different dosages were tested by three index tests: the dynamic shear rheological test, the 60 °C dynamic viscosity test, and the elastic recovery test. At the same time, the changes in adhesion between different types of aggregates and different amounts of modified bitumen were explored.

This study aims to achieve multiple goals: First, optimize the material composition of MBM and solve the defects of existing modifiers in storage and transportation. The second is to reveal the interaction mechanism between MBM and bitumen and its distribution in the mixture. The third is to clarify the optimal mixing parameters and mixing amount under the direct casting process. Fourth, verify the improvement effect of MBM on the pavement performance of the mixture and provide a cost-effective modification scheme for small projects and maintenance scenarios.

The research results not only provide a new choice for the selection of materials in road maintenance and repair but also provide a theoretical basis for the performance control of bitumen mixture under the direct casting technology and have important significance for the promotion and application of multi-component polymer particle bitumen modifiers in the road field.