In Situ Observation of Deformation in a Sn-3Ag-0.5Cu/Cu Solder Joint Using High-Voltage Transmission Electron Microscopy

Abstract

1. Introduction

2. Materials and Methods

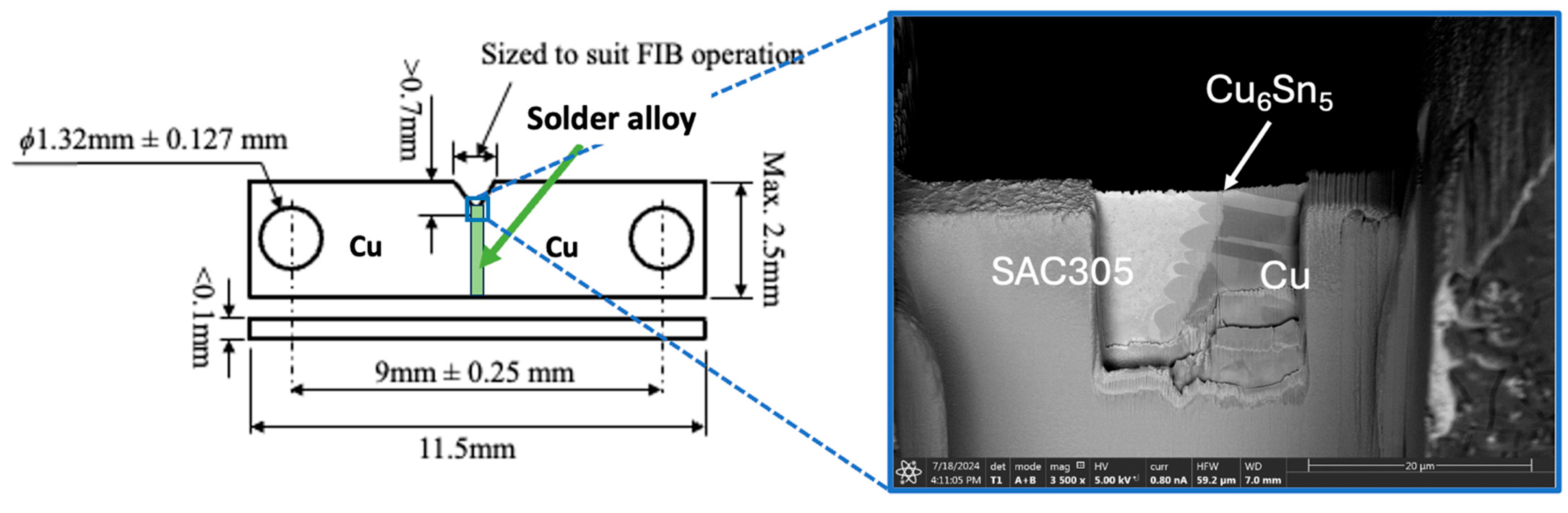

2.1. Sample Preparation

2.2. In Situ Tensile Testing Conditions

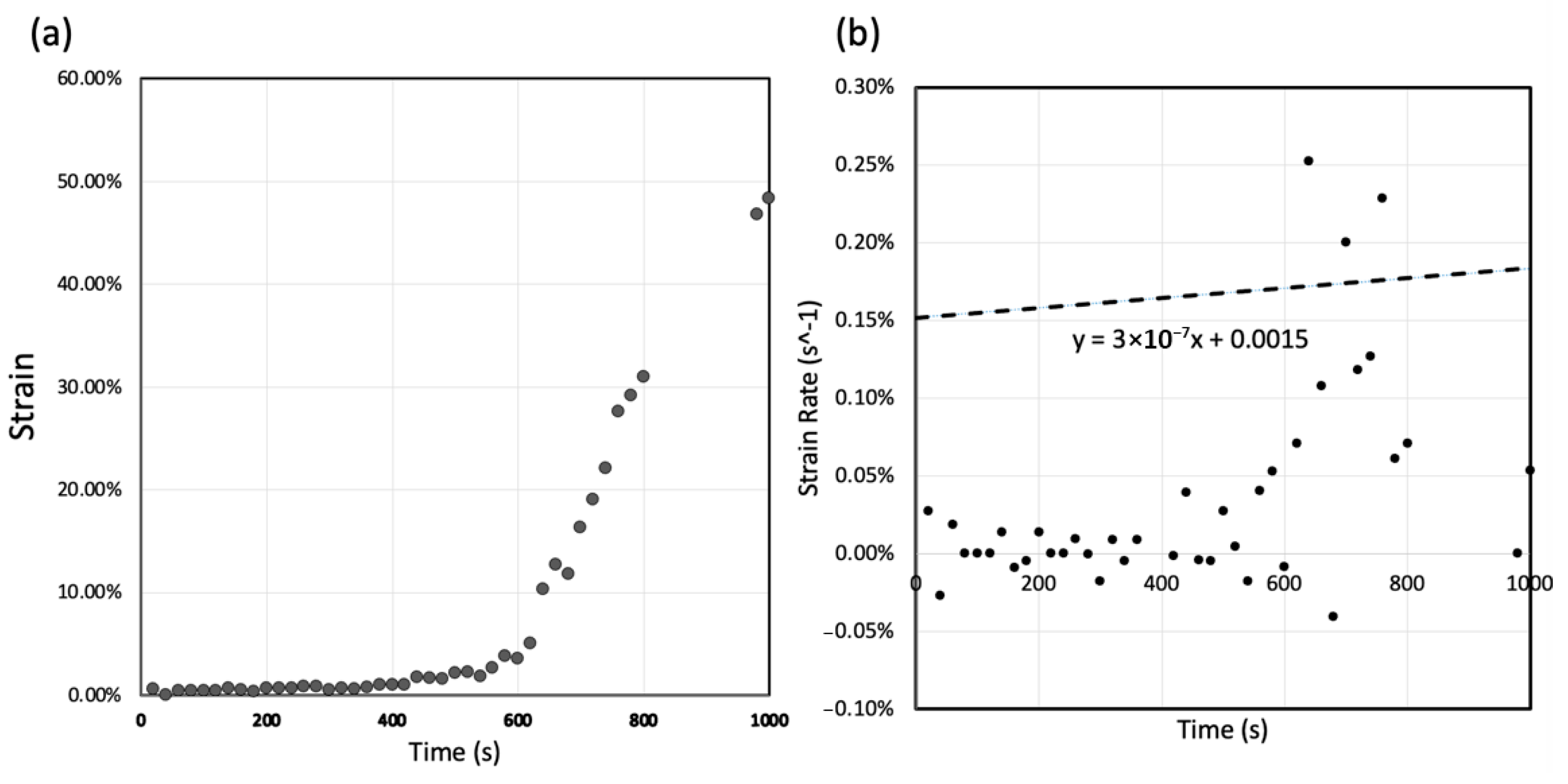

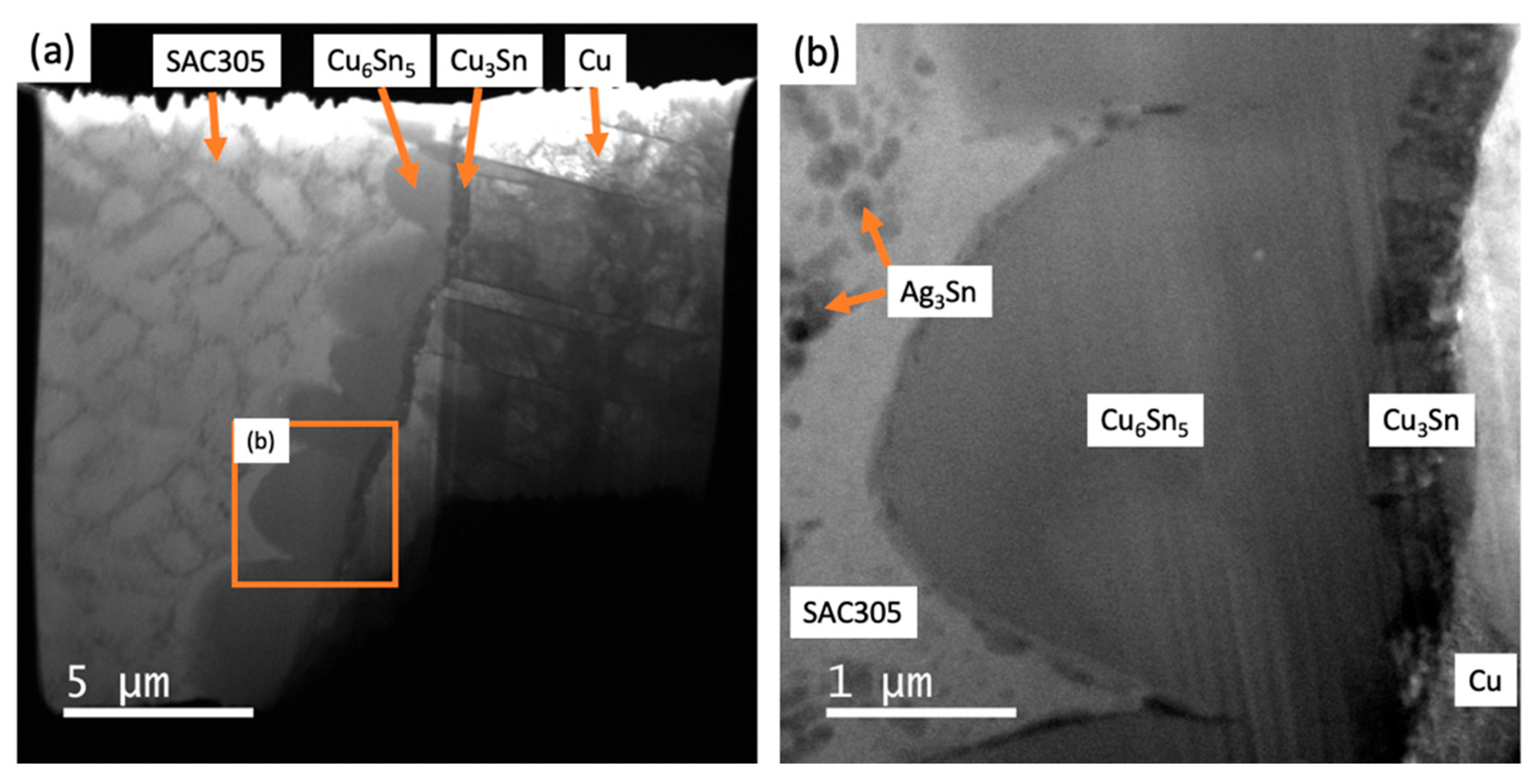

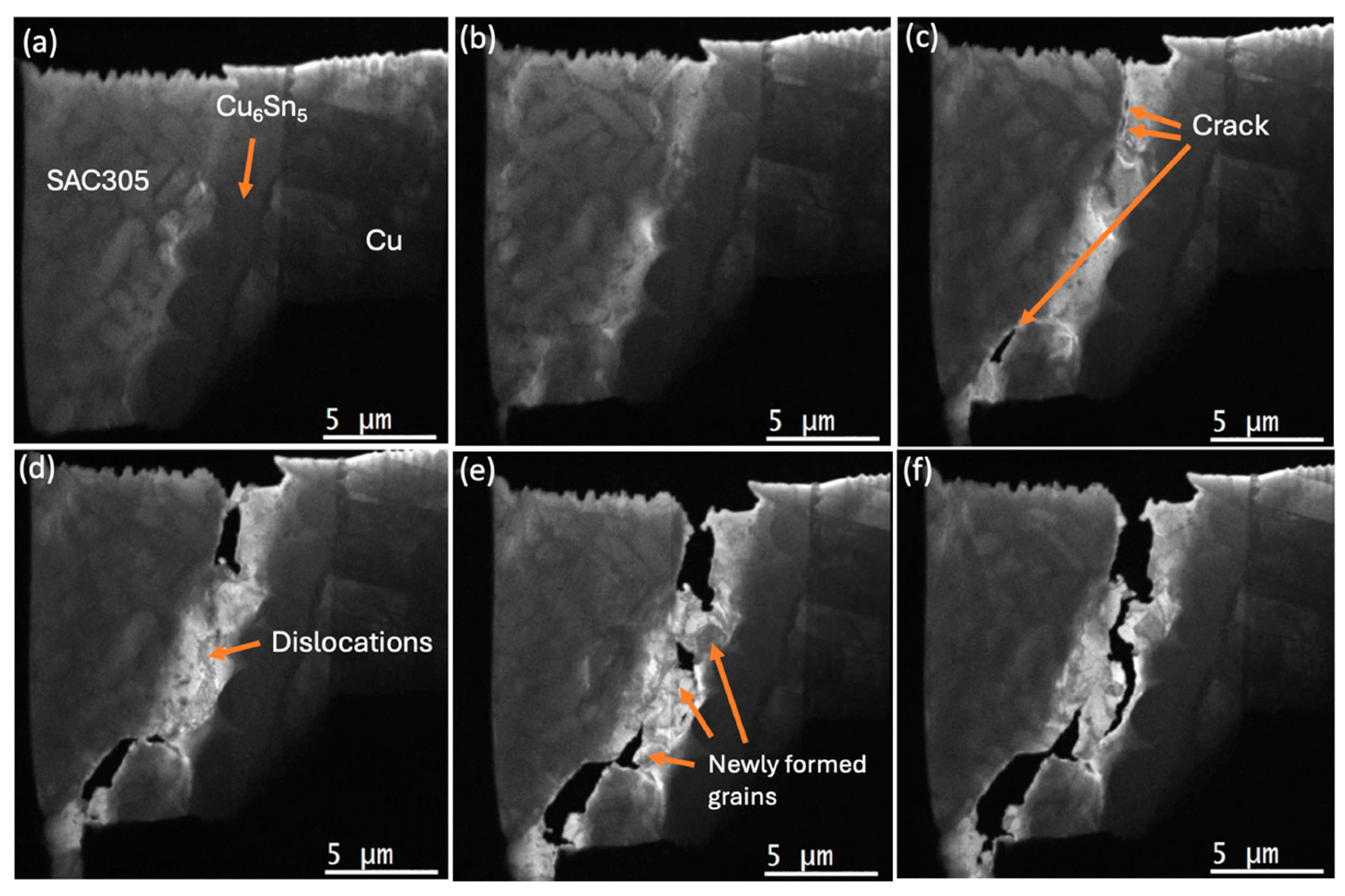

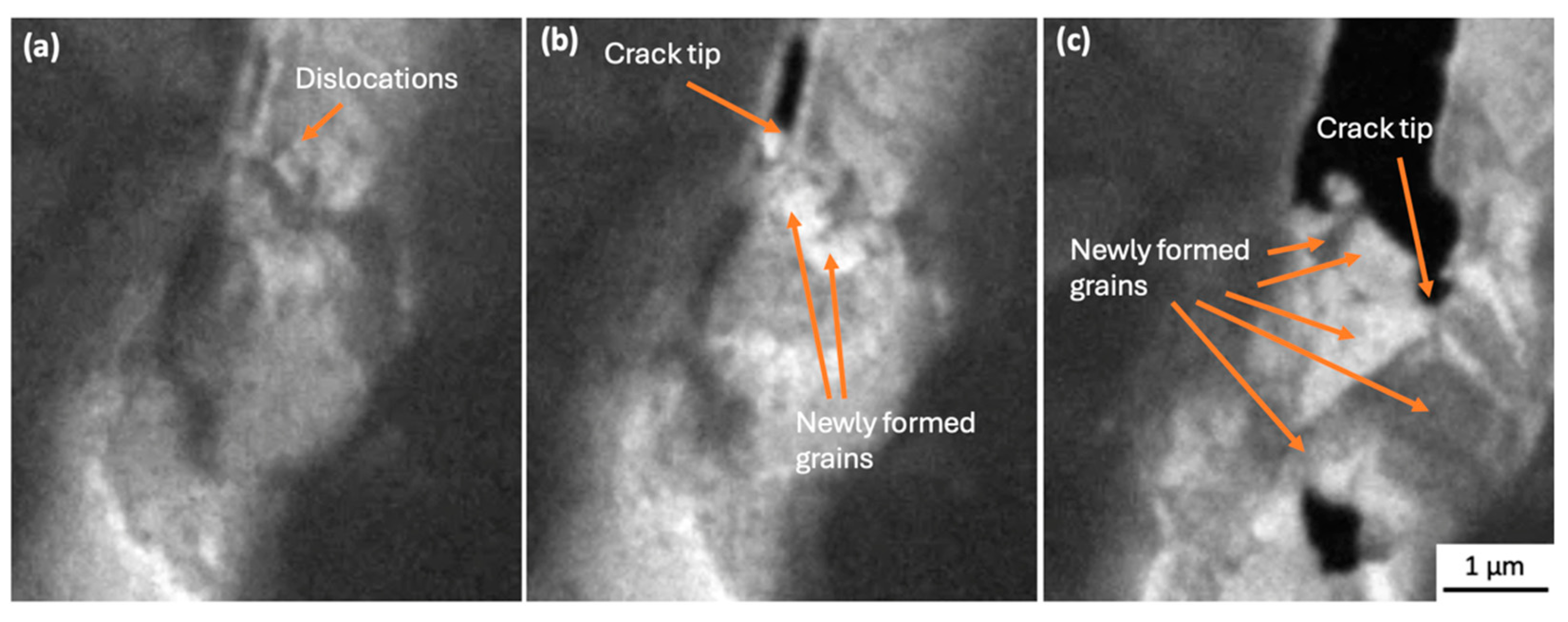

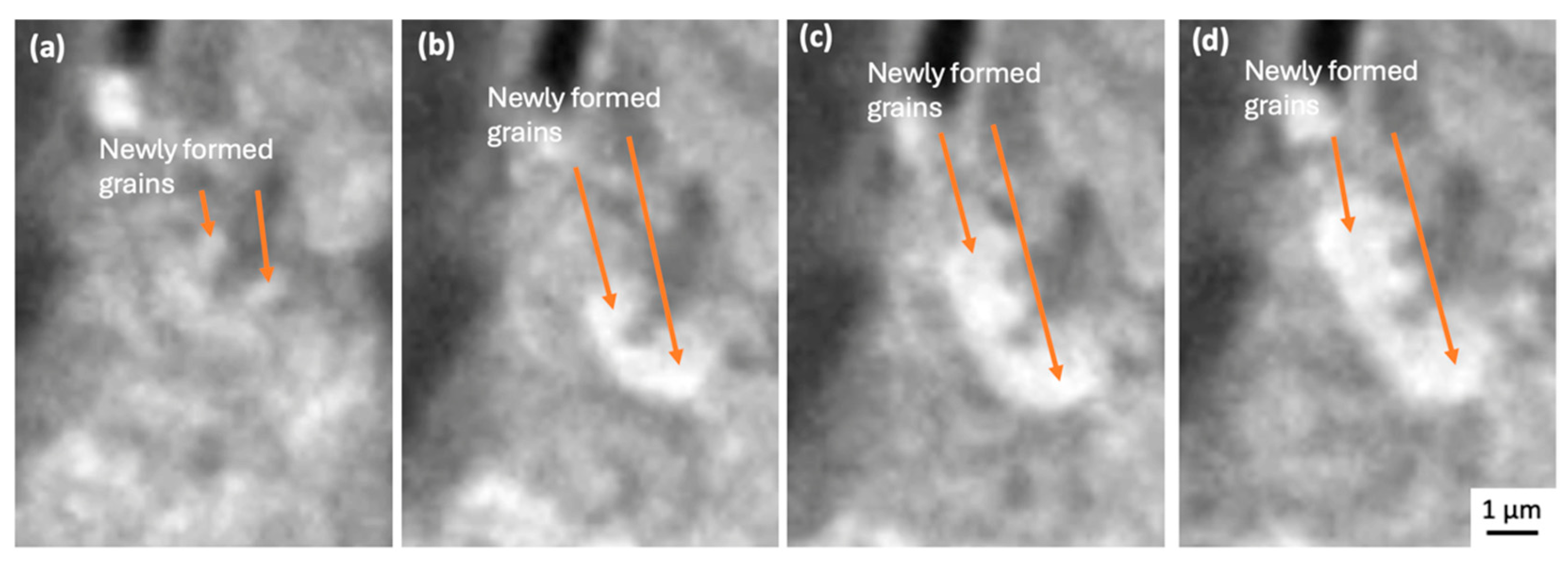

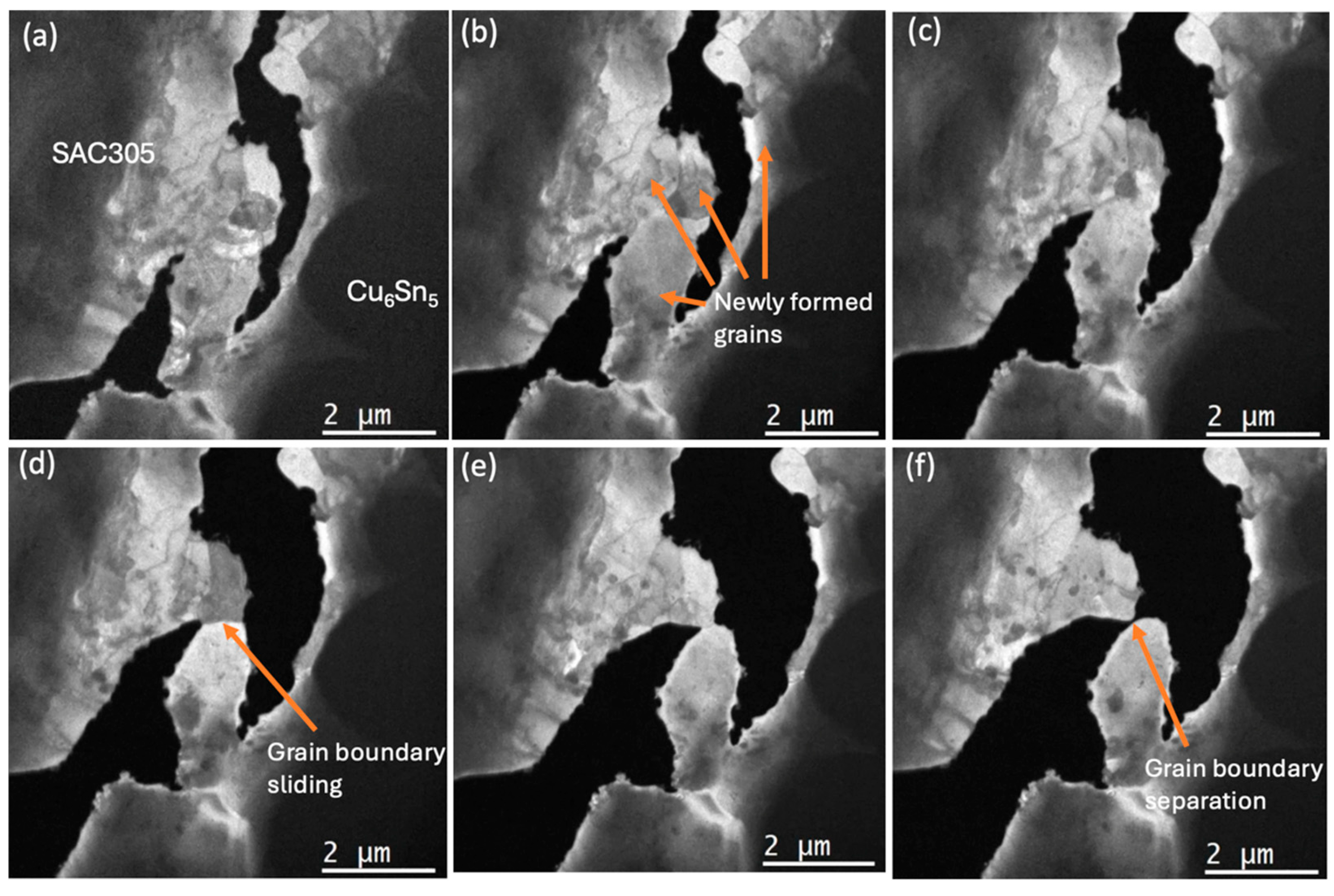

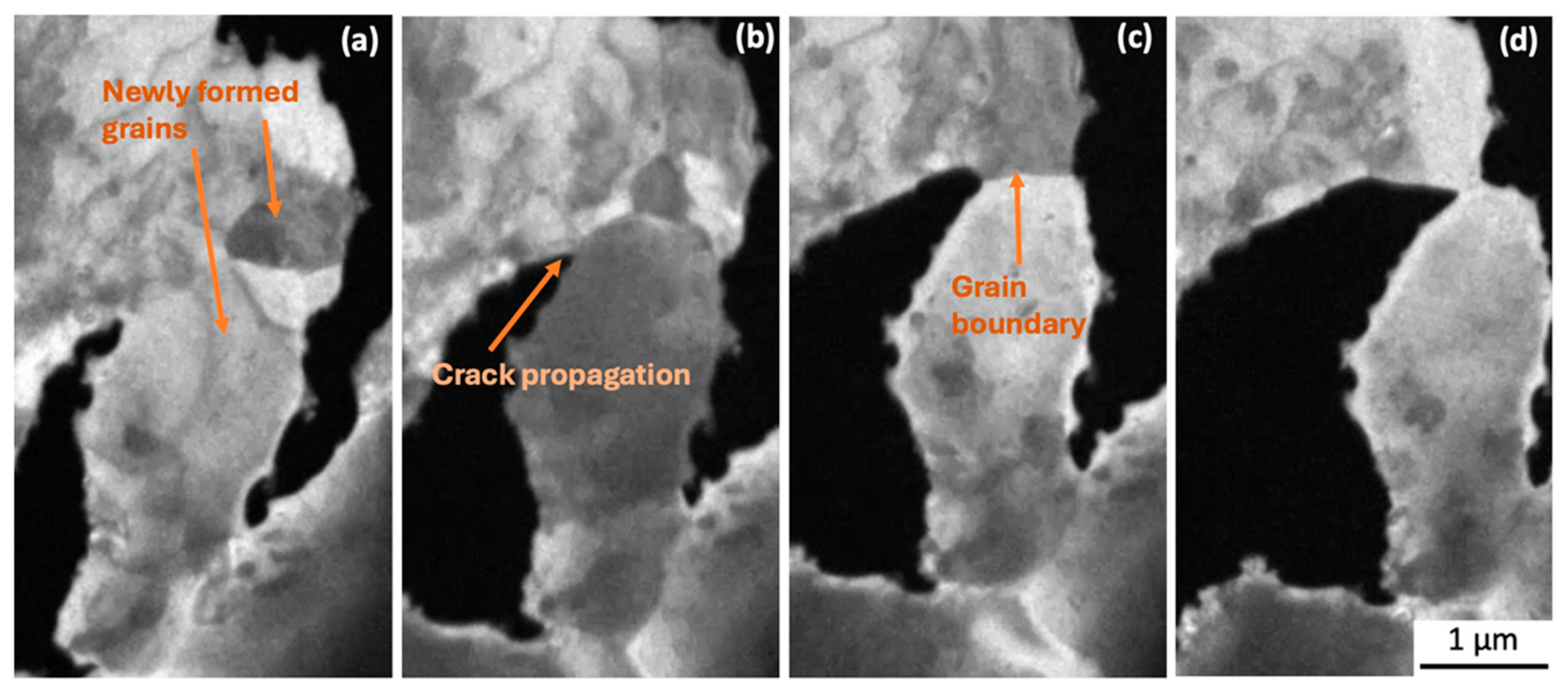

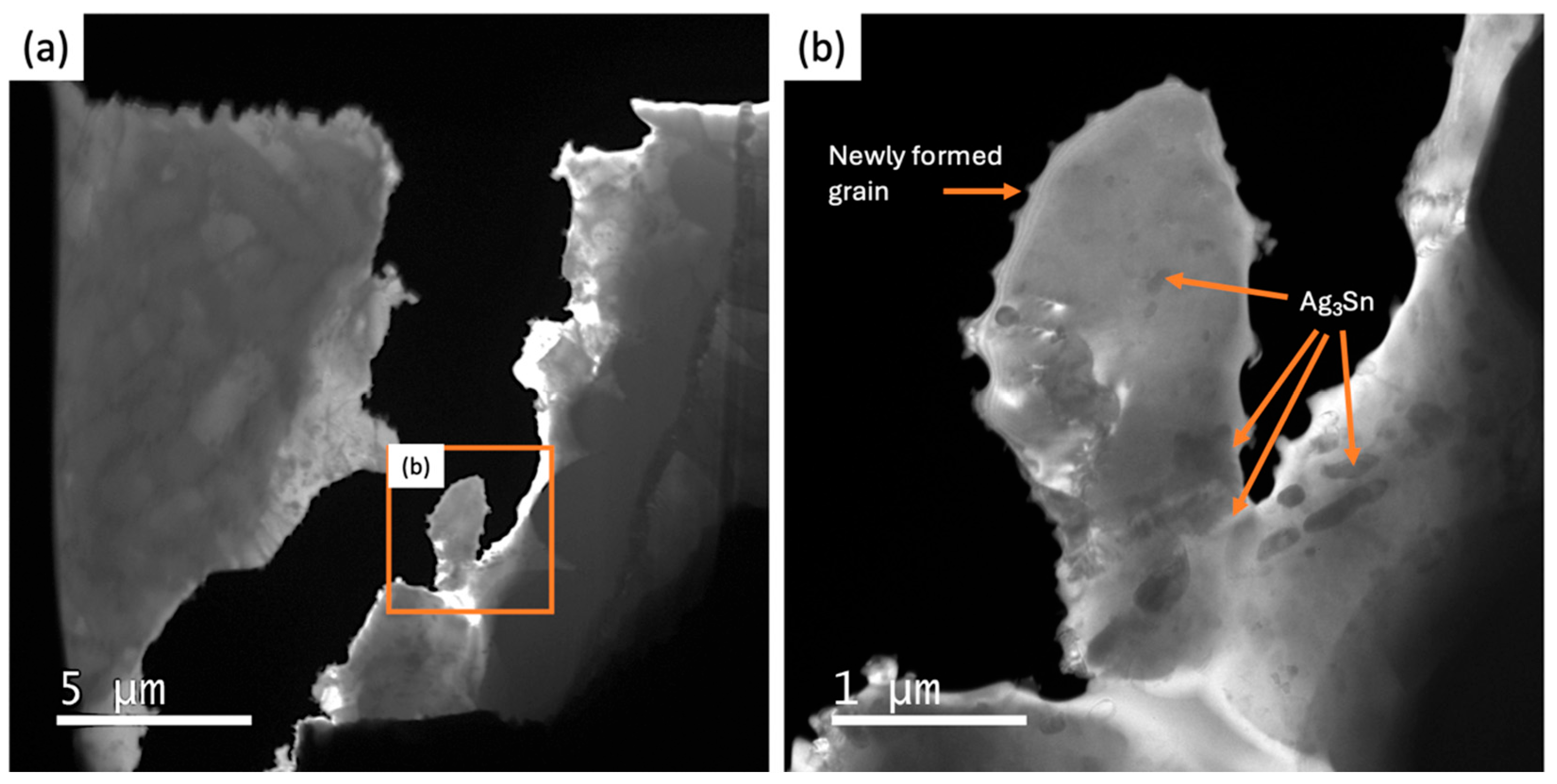

3. Results

4. Discussions

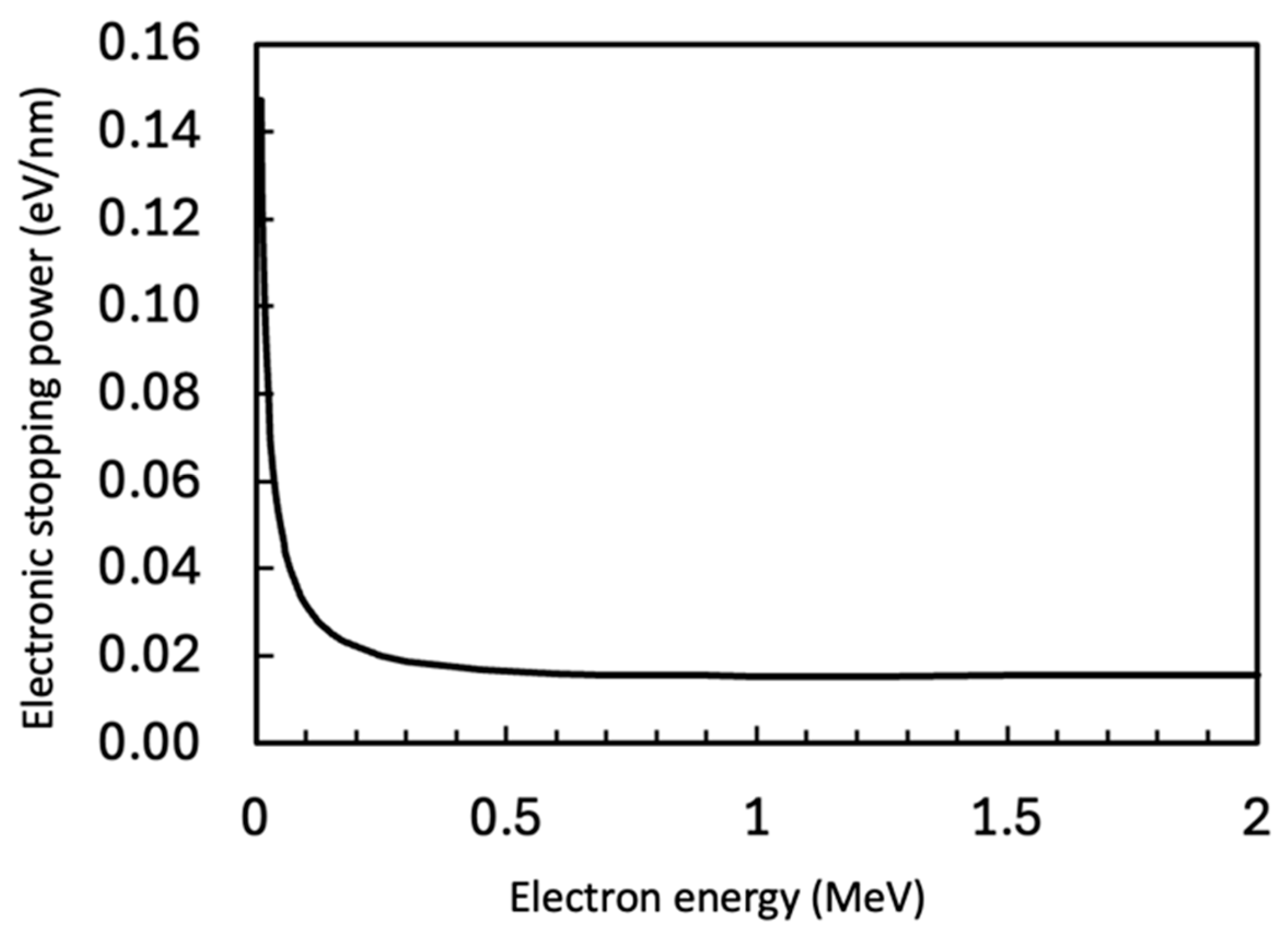

4.1. Electron Beam Interactions with Sample

4.1.1. Electronic Stopping Power and Beam Heating

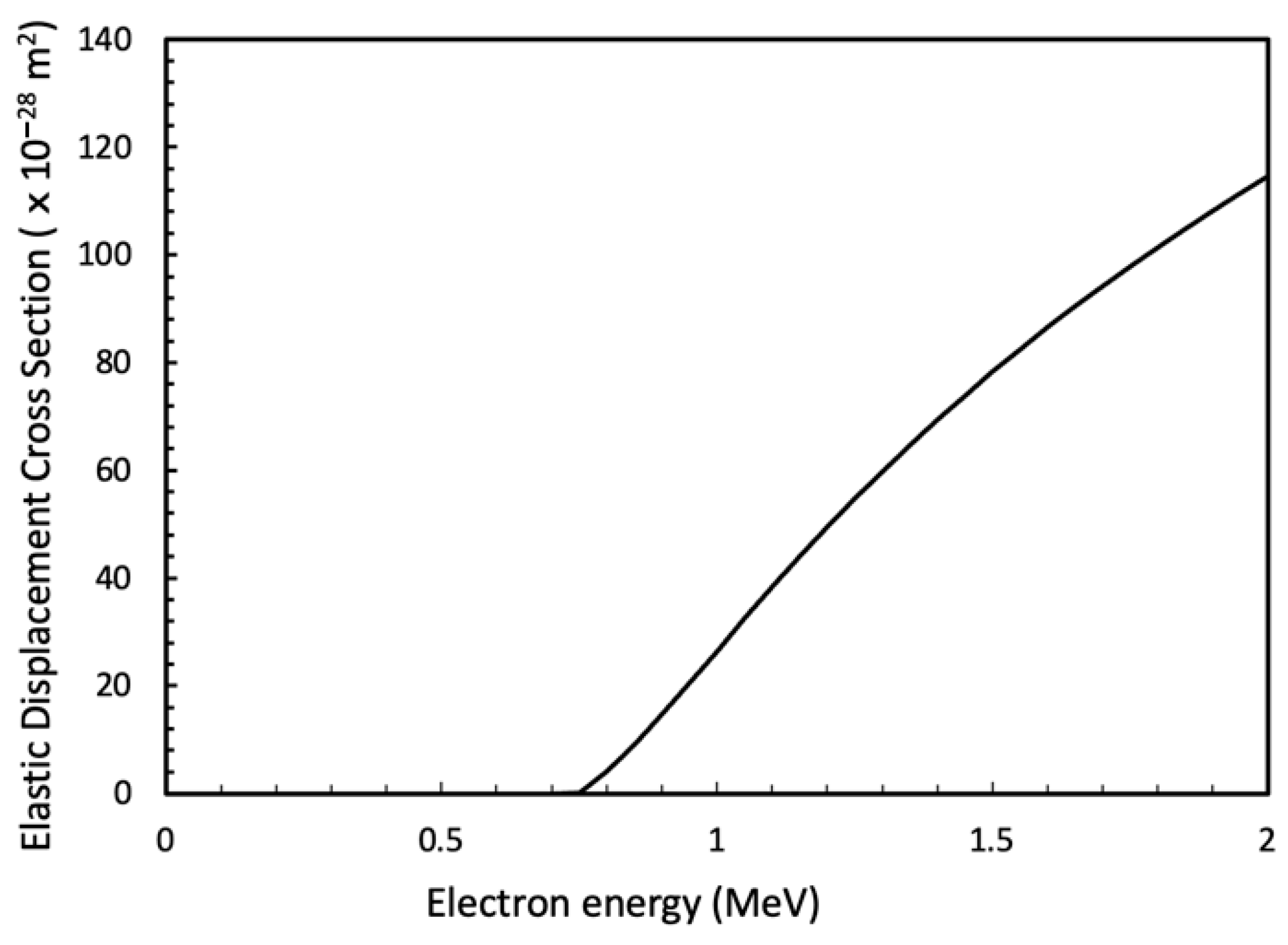

4.1.2. Knock-On Damage

4.2. Dynamic and Static Recrystallisation

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tu, P.L.; Chan, Y.C.; Lai, J.K.L. Effect of intermetallic compounds on the thermal fatigue of surface mount solder joints. IEEE Trans. Compon. Packag. Manuf. Technol. Part B 1997, 20, 87–93. [Google Scholar] [CrossRef]

- Bieler, T.R.; Jiang, H.; Lehman, L.P.; Kirkpatrick, T.; Cotts, E.J. Influence of Sn grain size and orientation on the thermomechanical response and reliability of Pb-free solder joints. In Proceedings of the 56th Electronic Components and Technology Conference 2006, San Diego, CA, USA, 30 May–2 June 2006; p. 6. [Google Scholar]

- Davis, J.A.; Bozack, M.J.; Evans, J.L. Effect of (Au, Ni) Sn4 Evolution on Sn-37Pb/ENIG Solder Joint Reliability Under Isothermal and Temperature-Cycled Conditions. IEEE Trans. Compon. Packag. Technol. 2007, 30, 32–41. [Google Scholar] [CrossRef]

- Nousiainen, O.; Kangasvieri, T.; Rautioaho, R.; Vähäkangas, J. Thermal fatigue endurance of Sn3Ag0.5Cu0.5In0.05Ni and Sn2.5Ag0.8Cu0.5Sb solders in composite solder joints of LTCC/PWB assemblies. Solder. Surf. Mt. Technol. 2011, 23, 30–39. [Google Scholar] [CrossRef]

- Bieler, T.R.; Zhou, B.; Blair, L.; Zamiri, A.; Darbandi, P.; Pourboghrat, F.; Lee, T.-K.; Liu, K.-C. The Role of Elastic and Plastic Anisotropy of Snin Recrystallization and Damage Evolution DuringThermal Cycling in SAC305 Solder Joints. J. Electron. Mater. 2012, 41, 283–301. [Google Scholar] [CrossRef]

- Arfaei, B.; Mahin-Shirazi, S.; Joshi, S.; Anselm, M.; Borgesen, P.; Cotts, E.; Wilcox, J.; Coyle, R. Reliability and failure mechanism of solder joints in thermal cycling tests. In Proceedings of the 2013 IEEE 63rd Electronic Components and Technology Conference, Las Vegas, NV, USA, 28–31 May 2013; pp. 976–985. [Google Scholar]

- Tegehall, P.-E.; Wetter, G. Impact of laminate cracks under solder pads on the fatigue lives of ball grid array solder joints. Microelectron. Reliab. 2015, 55, 2354–2370. [Google Scholar] [CrossRef]

- Ben Romdhane, E.; Roumanille, P.; Guédon-Gracia, A.; Pin, S.; Nguyen, P.; Frémont, H. From early microstructural evolution to intergranular crack propagation in SAC solders under thermomechanical fatigue. Microelectron. Reliab. 2021, 126, 114288. [Google Scholar] [CrossRef]

- Bender, E.; Bernstein, J.B.; Boning, D.S. Modern Trends in Microelectronics Packaging Reliability Testing. Micromachines 2024, 15, 398. [Google Scholar] [CrossRef]

- Xian, J.W.; Xu, Y.L.; Stoyanov, S.; Coyle, R.J.; Dunne, F.P.E.; Gourlay, C.M. The role of microstructure in the thermal fatigue of solder joints. Nat. Commun. 2024, 15, 4258. [Google Scholar] [CrossRef]

- Darveaux, R.; Reichman, C.; Islam, N. Interface failure in lead free solder joints. In Proceedings of the 56th Electronic Components and Technology Conference 2006, San Diego, CA, USA, 30 May–2 June 2006; p. 12. [Google Scholar]

- Liu, D.-S.; Kuo, C.-Y.; Hsu, C.-L.; Shen, G.-S.; Chen, Y.-R.; Lo, K.-C. Failure mode analysis of lead-free solder joints under high speed impact testing. Mater. Sci. Eng. A 2008, 494, 196–202. [Google Scholar] [CrossRef]

- Jing, J.; Gao, F.; Johnson, J.; Liang, F.Z.; Williams, R.L.; Qu, J. Brittle Versus Ductile Failure of a Lead-Free Single Solder Joint Specimen Under Intermediate Strain Rate. IEEE Trans. Compon. Packag. Manuf. Technol. 2011, 1, 1456–1464. [Google Scholar] [CrossRef]

- Tsukamoto, H.; Nishimura, T.; Suenaga, S.; McDonald, S.D.; Sweatman, K.W.; Nogita, K. The influence of solder composition on the impact strength of lead-free solder ball grid array joints. Microelectron. Reliab. 2011, 51, 657–667. [Google Scholar] [CrossRef]

- Coyle, R.J.; Sweatman, K.; Arfaei, B. Thermal Fatigue Evaluation of Pb-Free Solder Joints: Results, Lessons Learned, and Future Trends. JOM 2015, 67, 2394–2415. [Google Scholar] [CrossRef]

- Min, K.E.; Jang, J.W.; Kang, S.; Kim, C.; Yi, S. Identification of Solder Joint Failure Modes Using Machine Learning. IEEE Trans. Compon. Packag. Manuf. Technol. 2023, 13, 2032–2039. [Google Scholar] [CrossRef]

- Yin, L.; Wentlent, L.; Yang, L.; Arfaei, B.; Oasaimeh, A.; Borgesen, P. Recrystallization and Precipitate Coarsening in Pb-Free Solder Joints During Thermomechanical Fatigue. J. Electron. Mater. 2012, 41, 241–252. [Google Scholar] [CrossRef]

- Liu, S.Q.; McDonald, S.; Sweatman, K.; Nogita, K. The effects of precipitation strengthening and solid solution strengthening on strain rate sensitivity of lead-free solders: Review. Microelectron. Reliab. 2018, 84, 170–180. [Google Scholar] [CrossRef]

- Haasen, P. Physical Metallurgy, 3rd ed.; Cambridge University Press: New York, NY, USA, 1996. [Google Scholar]

- Gu, T.; Gourlay, C.M.; Britton, T.B. The Role of Lengthscale in the Creep of Sn-3Ag-0.5Cu Solder Microstructures. J. Electron. Mater. 2021, 50, 926–938. [Google Scholar] [CrossRef]

- Zhou, J.; Yao, T.; Cao, D.; Lian, J.; Lu, F. In-situ TEM study of radiation-induced amorphization and recrystallization of hydroxyapatite. J. Nucl. Mater. 2018, 512, 307–313. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, L. In-situ TEM investigation of dislocation healing and recrystallization in nanoscratched silicon at elevated temperatures up to 800 °C. J. Mater. Res. Technol. 2024, 31, 1939–1944. [Google Scholar] [CrossRef]

- Hu, X.J.; Sun, W.; Liao, J.L.; Zhang, Y.H.; Wang, B.; Shuai, S.S.; Liu, C.; Zeng, G. The influences of microstructural length scale on the tensile properties and deformation mechanisms of Sn-3.0Ag-0.5Cu solder alloys. Mater. Sci. Eng. A 2024, 916, 147300. [Google Scholar] [CrossRef]

- Chang, J.; Kang, S.K.; Lee, J.-H.; Kim, K.-S.; Lee, H.M. Recrystallization as a Growth Mechanism for Whiskers on Plastically Deformed Sn Films. J. Electron. Mater. 2015, 44, 3486–3499. [Google Scholar] [CrossRef]

- Kuwano, N.; Binti Lias, M.; Nordin, N.A.; Soejima, Y.; bin Nayan, A.R. Preliminary Study on Deformation and Recrystallization Behavior of Pure Tin for Mitigation of Whisker Growth. Solid State Phenom. 2018, 273, 107–111. [Google Scholar] [CrossRef]

- Tan, X.F.; Somidin, F.; McDonald, S.D.; Bermingham, M.J.; Maeno, H.; Matsumura, S.; Nogita, K. In Situ Observation of Liquid Solder Alloys and Solid Substrate Reactions Using High-Voltage Transmission Electron Microscopy. Materials 2022, 15, 510. [Google Scholar] [CrossRef] [PubMed]

- NISTIR 4999; NIST Standard Reference Database 124. National Institute of Standards and Technology, US. Department of Commerce: Gaithersburg, MD, USA, 2017. [CrossRef]

- Lesueur, P.D. Cascades de déplacement dam les solides polyatomiques. Philos. Mag. A 1981, 44, 905–929. [Google Scholar] [CrossRef]

- Yasuda, K.; Costantini, J.-M.; Baldinozzi, G. 1.06-Radiation-Induced Effects on Material Properties of Ceramics: Mechanical and Dimensional Properties. In Comprehensive Nuclear Materials, 2nd ed.; Konings, R.J.M., Stoller, R.E., Eds.; Elsevier: Oxford, UK, 2020; pp. 153–185. [Google Scholar]

- Konobeyev, A.Y.; Fischer, U.; Korovin, Y.A.; Simakov, S.P. Evaluation of effective threshold displacement energies and other data required for the calculation of advanced atomic displacement cross-sections. Nucl. Energy Technol. 2017, 3, 169–175. [Google Scholar] [CrossRef]

- Montheillet, F.; Lépinoux, J.; Weygand, D.; Rauch, E. Dynamic and Static Recrystallization. Adv. Eng. Mater. 2001, 3, 587–589. [Google Scholar] [CrossRef]

- Huang, K.; Logé, R.E. A review of dynamic recrystallization phenomena in metallic materials. Mater. Des. 2016, 111, 548–574. [Google Scholar] [CrossRef]

- Zhou, B.; Bieler, T.R.; Lee, T.-k.; Liu, W. Characterization of Recrystallization and Microstructure Evolution in Lead-Free Solder Joints Using EBSD and 3D-XRD. J. Electron. Mater. 2013, 42, 319–331. [Google Scholar] [CrossRef]

- Sunada, T.; Otsuka, M.; Yamagata, H.; Fujiwara, M. Dynamic Recrystallization of Pure Tin. J. Jpn. Inst. Met. 1999, 63, 467–473. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nogita, K.; Tan, X.F.; Zhou, J.; McDonald, S.D.; Sweatman, K.; Somidin, F.; Zeng, G.; Maeno, H.; Yasuda, K.; Gourlay, C.M. In Situ Observation of Deformation in a Sn-3Ag-0.5Cu/Cu Solder Joint Using High-Voltage Transmission Electron Microscopy. Materials 2025, 18, 3925. https://doi.org/10.3390/ma18163925

Nogita K, Tan XF, Zhou J, McDonald SD, Sweatman K, Somidin F, Zeng G, Maeno H, Yasuda K, Gourlay CM. In Situ Observation of Deformation in a Sn-3Ag-0.5Cu/Cu Solder Joint Using High-Voltage Transmission Electron Microscopy. Materials. 2025; 18(16):3925. https://doi.org/10.3390/ma18163925

Chicago/Turabian StyleNogita, Kazuhiro, Xin Fu Tan, Jiye Zhou, Stuart D. McDonald, Keith Sweatman, Flora Somidin, Guang Zeng, Hiroshi Maeno, Kazuhiro Yasuda, and Christopher M. Gourlay. 2025. "In Situ Observation of Deformation in a Sn-3Ag-0.5Cu/Cu Solder Joint Using High-Voltage Transmission Electron Microscopy" Materials 18, no. 16: 3925. https://doi.org/10.3390/ma18163925

APA StyleNogita, K., Tan, X. F., Zhou, J., McDonald, S. D., Sweatman, K., Somidin, F., Zeng, G., Maeno, H., Yasuda, K., & Gourlay, C. M. (2025). In Situ Observation of Deformation in a Sn-3Ag-0.5Cu/Cu Solder Joint Using High-Voltage Transmission Electron Microscopy. Materials, 18(16), 3925. https://doi.org/10.3390/ma18163925