AHP-Based Evaluation of Hybrid Kenaf/Flax/Glass Fiber-Reinforced Biocomposites for Unmanned Maritime Vehicle Applications

Highlights

- Seawater aging reduces the mechanical performance of hybrid composites.

- Kenaf/flax/glass fiber-reinforced composites are potential materials used in seawater conditions.

- The AHP method is an effective decision-making method to select the optimal material.

- GKFKG ranks the optimal configuration for UMVs in the marine environment.

Abstract

1. Introduction

2. Materials and Methodology

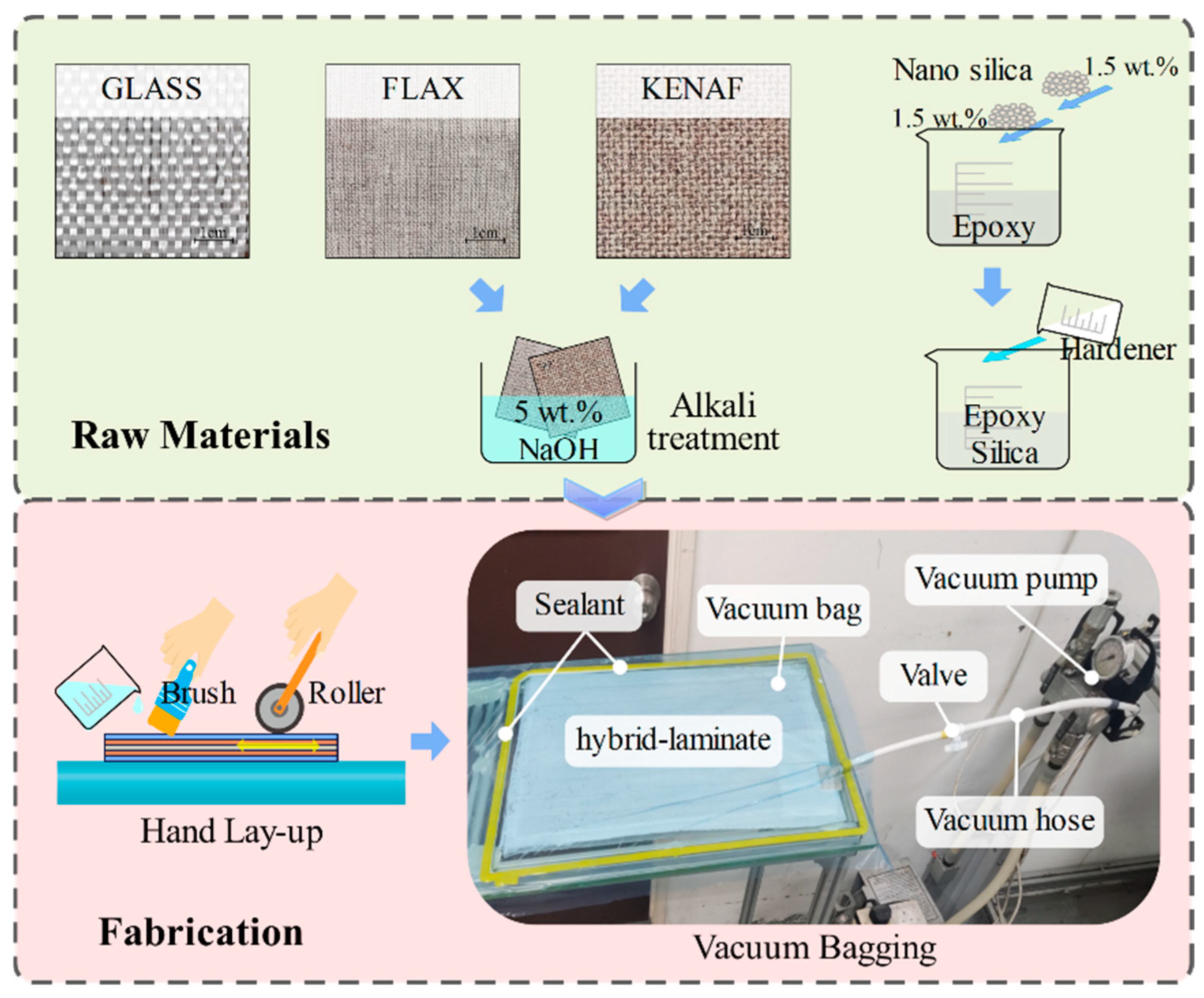

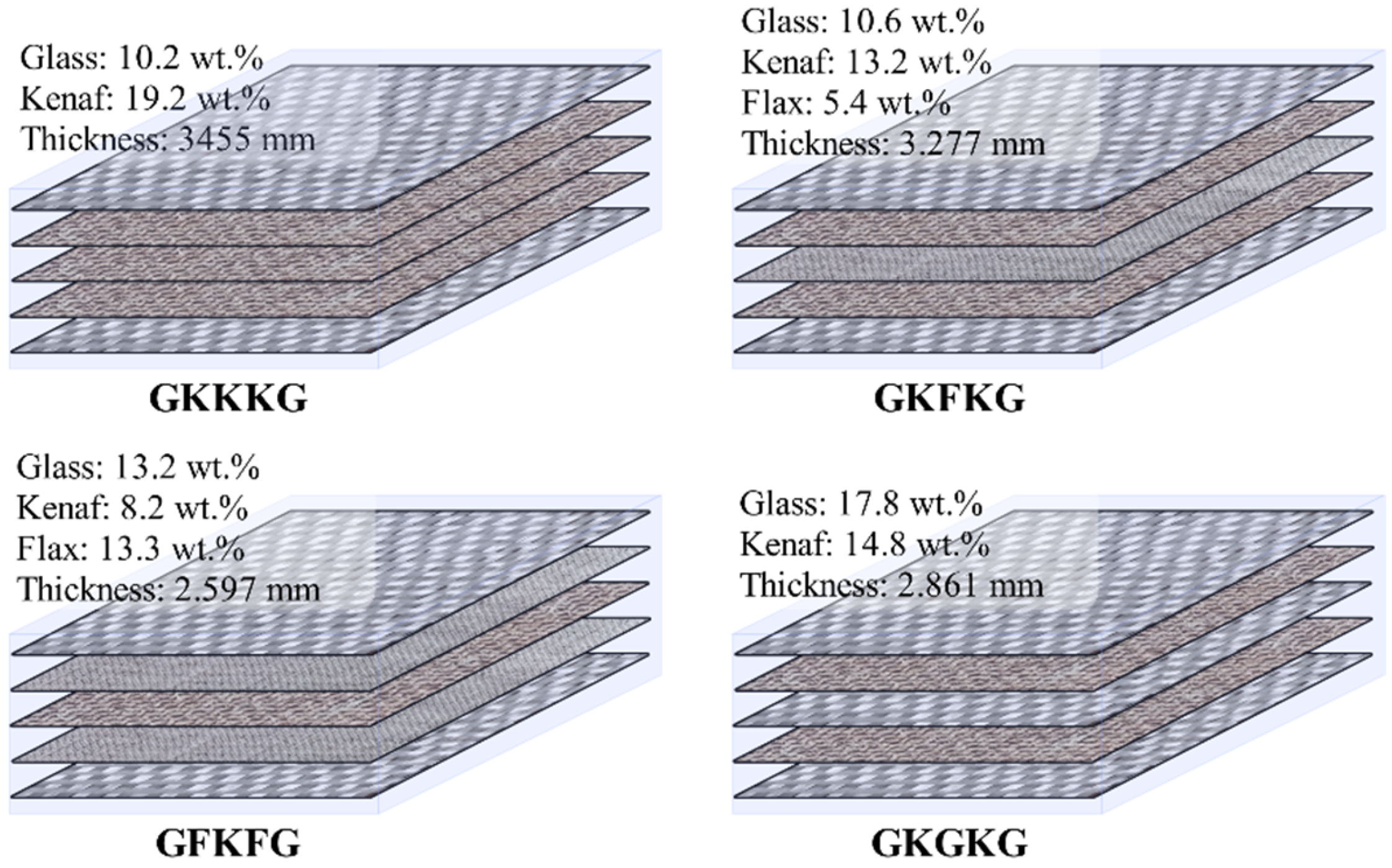

2.1. Materials and Fabrication Method

2.2. Artificial Seawater Aging Process

2.3. Tensile Testing

2.4. Flexural Testing

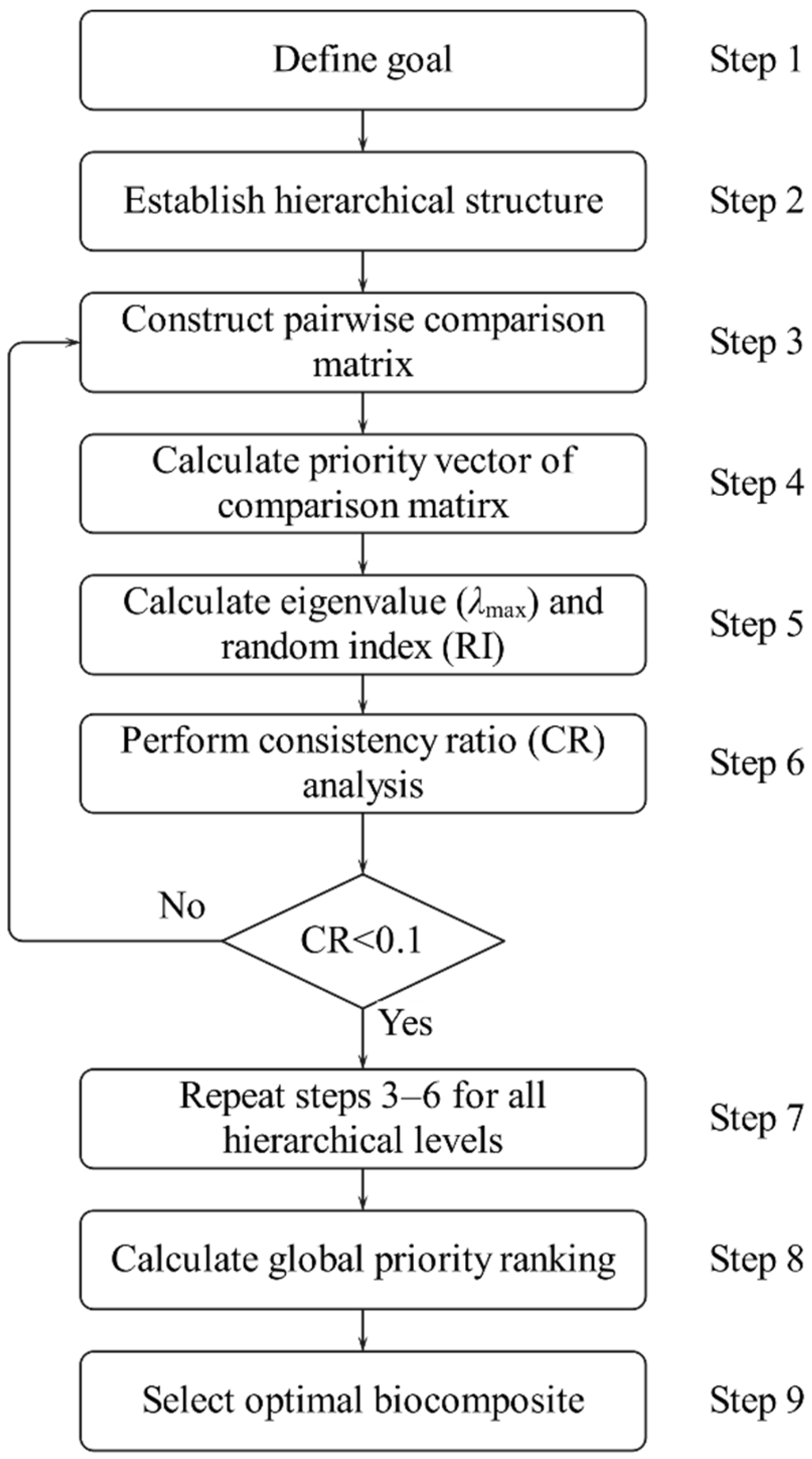

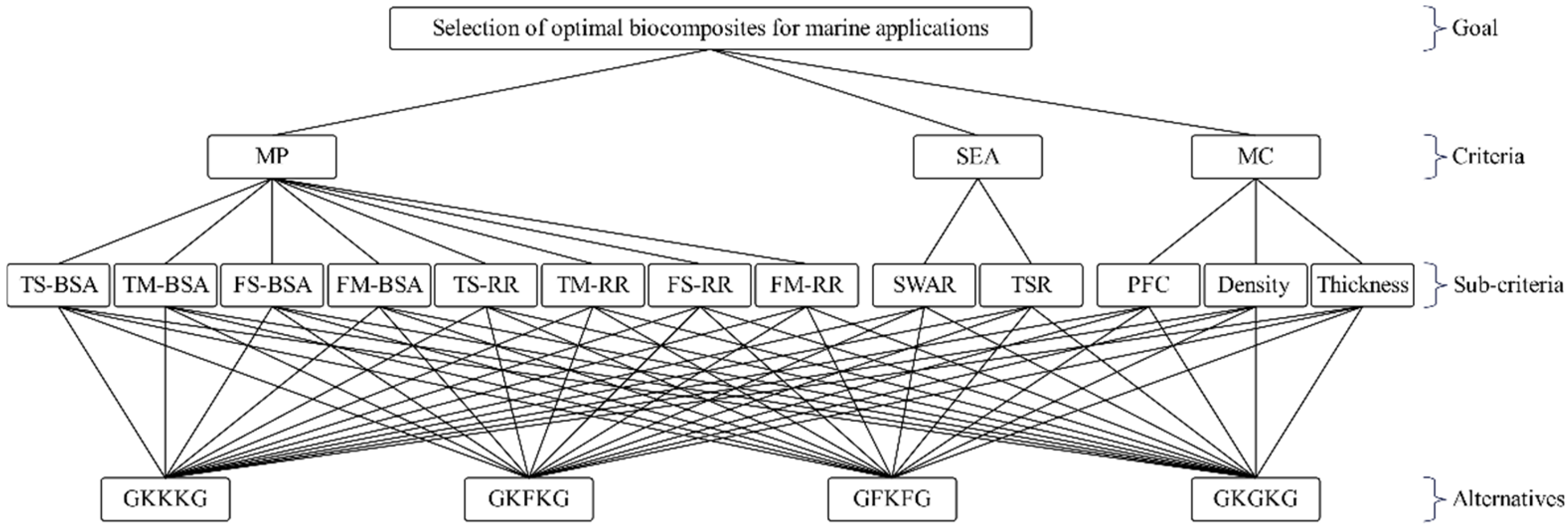

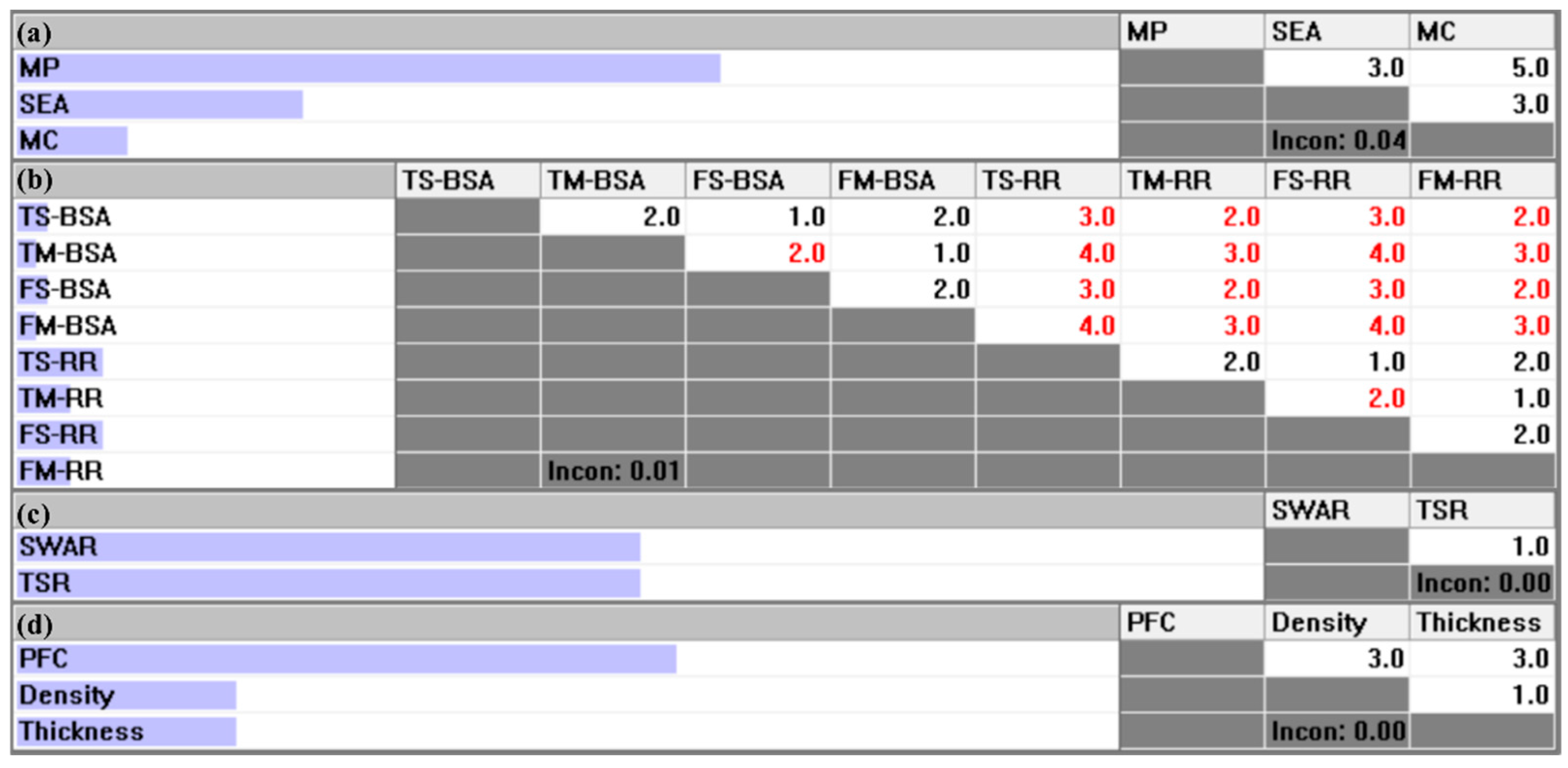

2.5. Analytic Hierarchy Process (AHP) Method

3. Results and Discussion

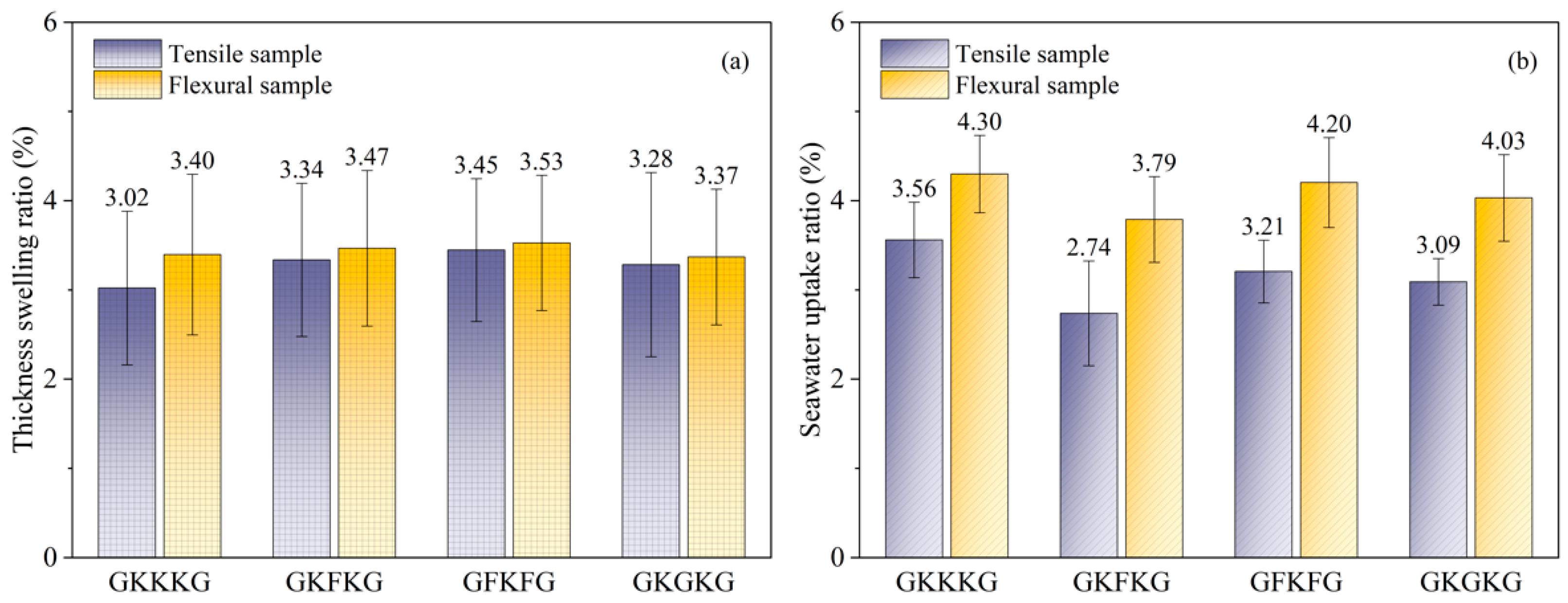

3.1. Thickness Swelling and Seawater Uptake

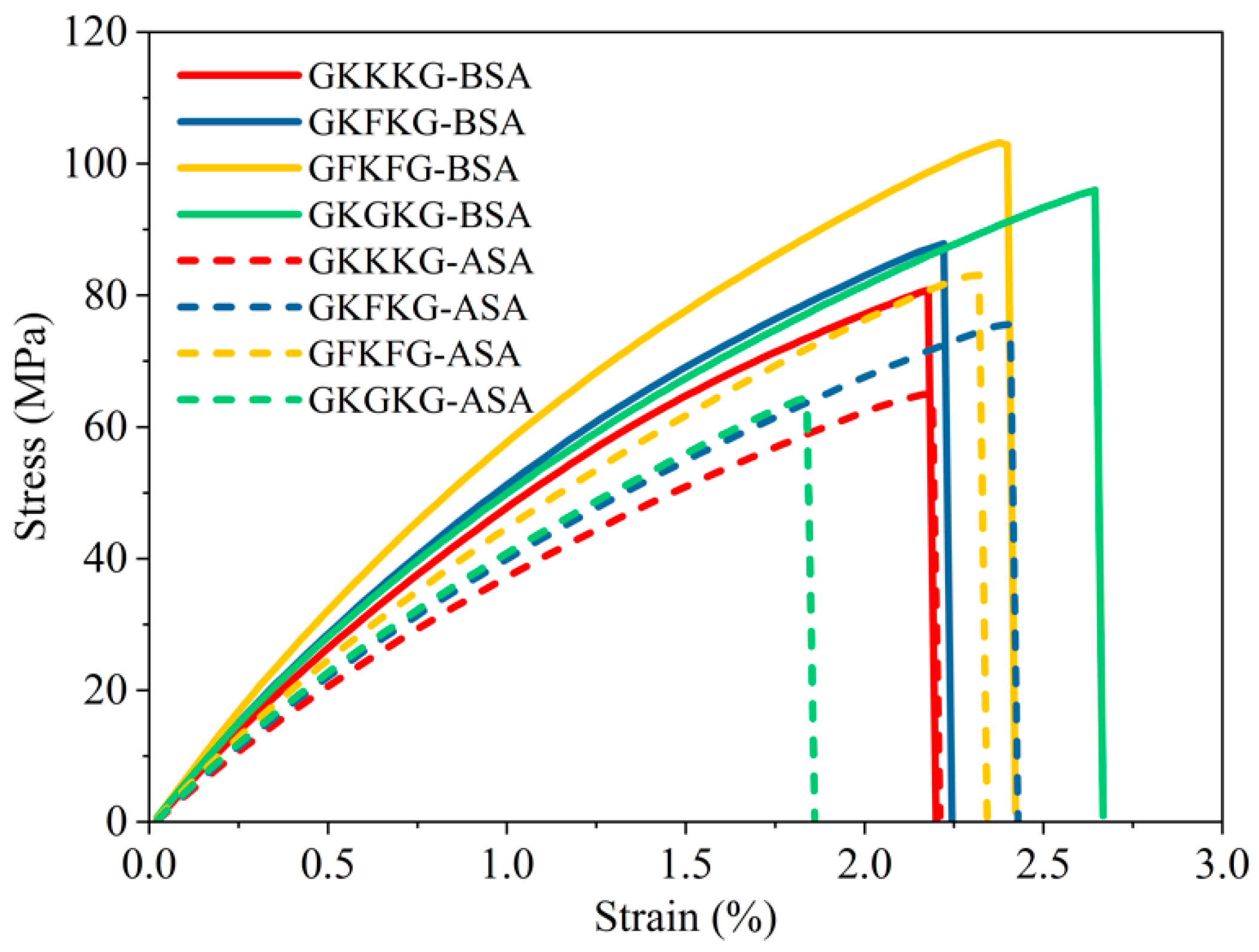

3.2. Tensile Properties

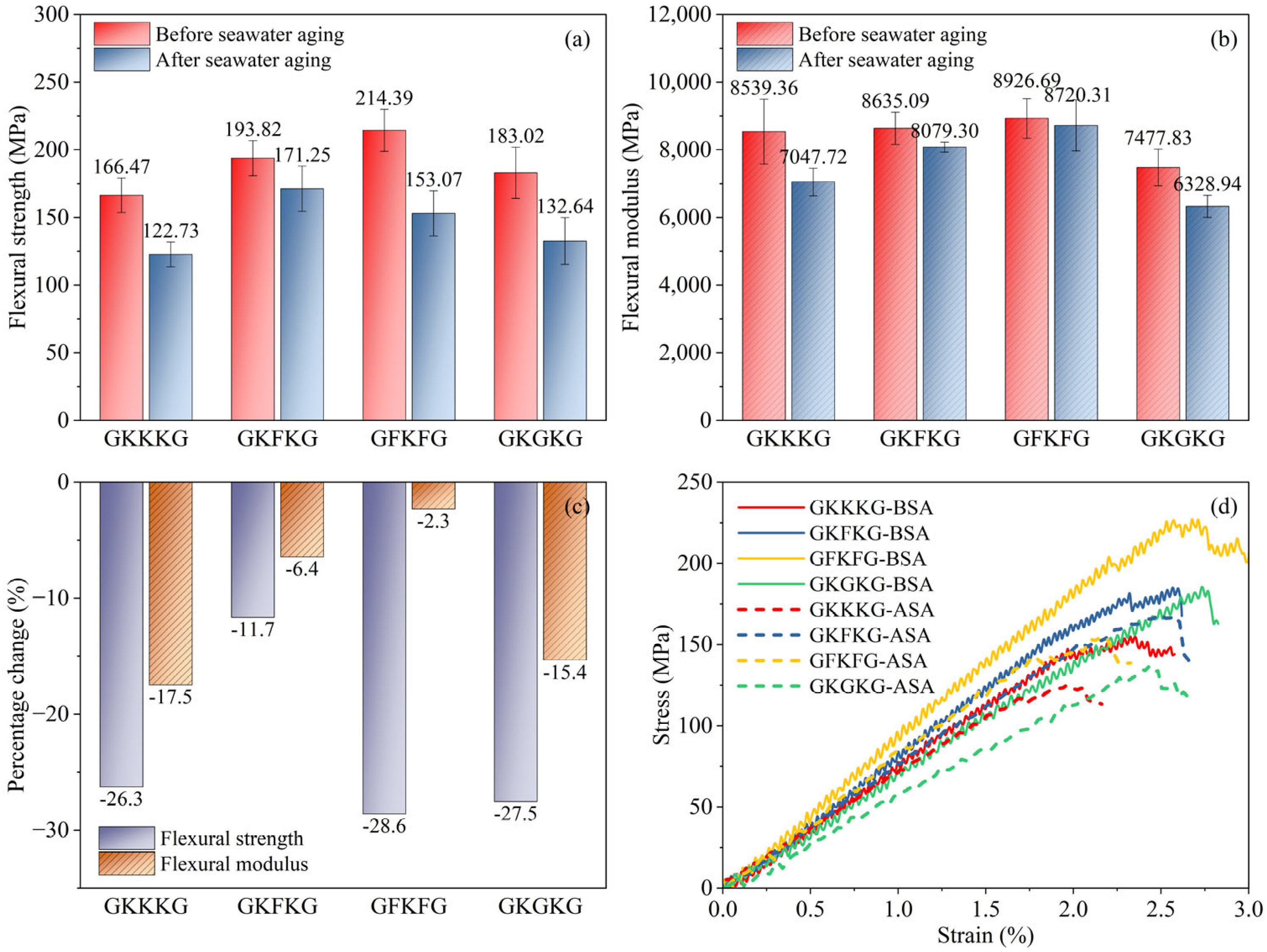

3.3. Flexural Properties

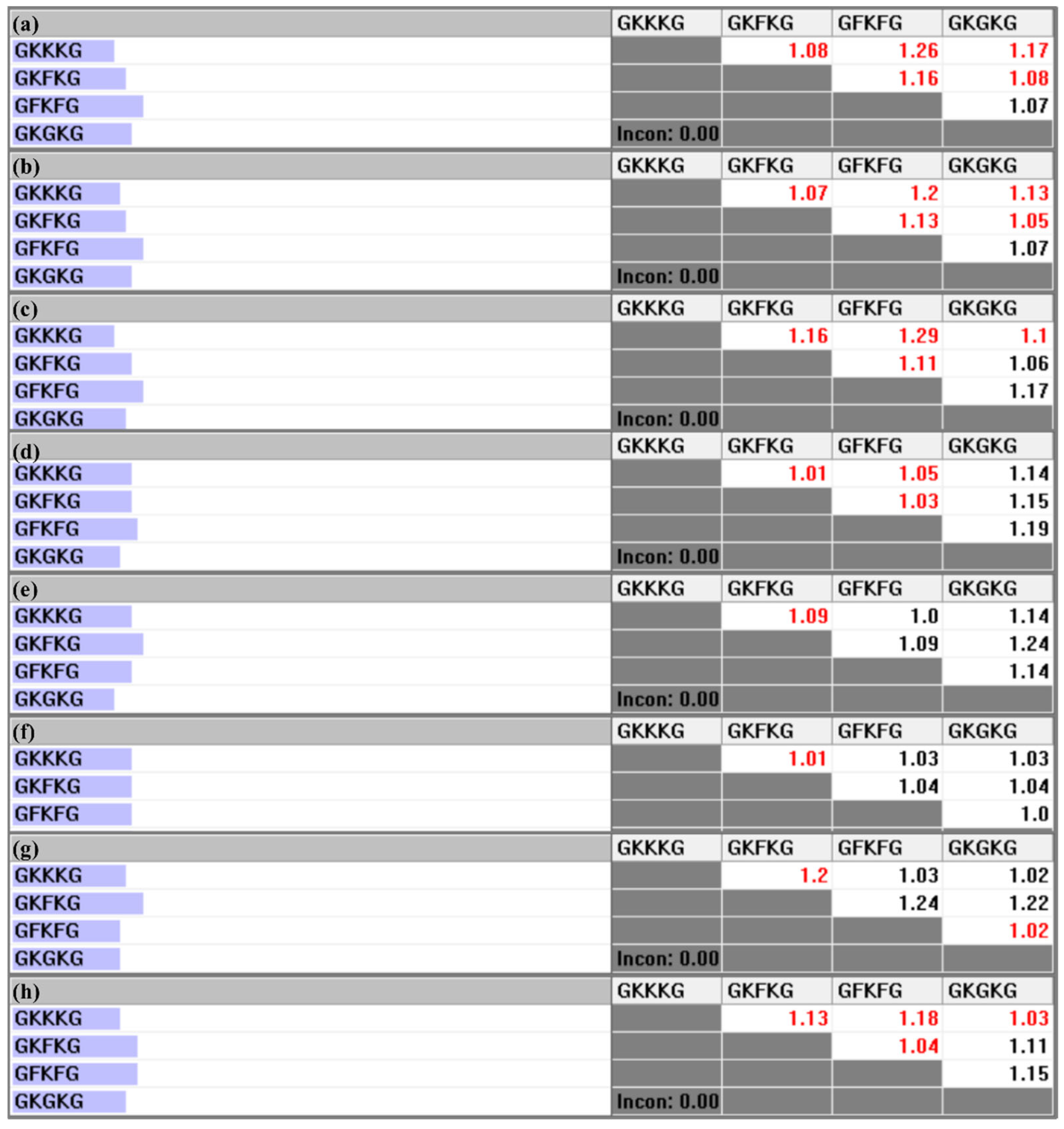

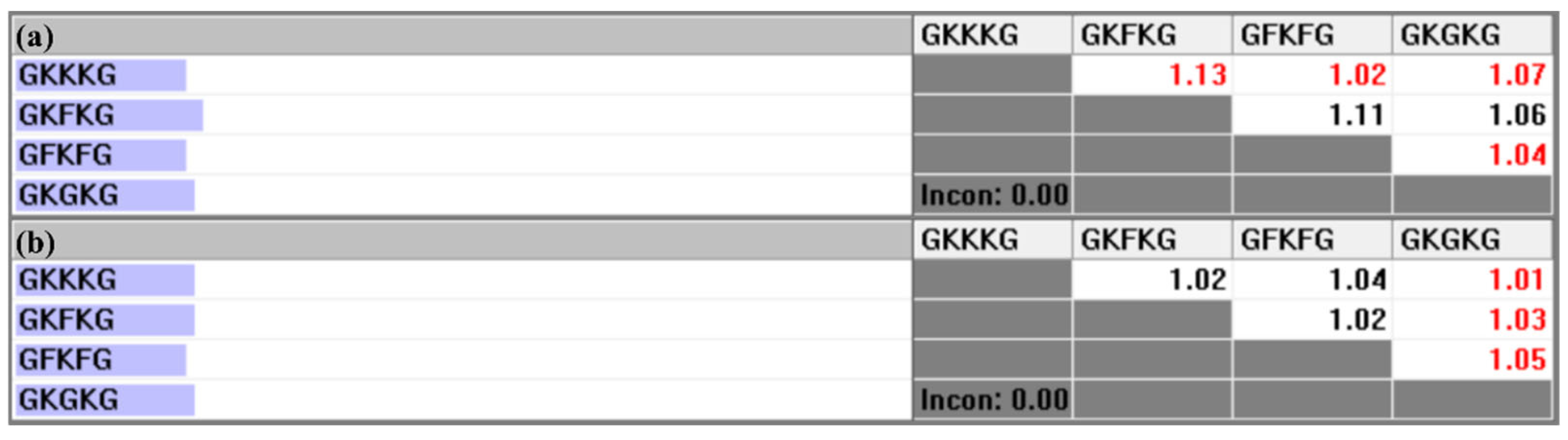

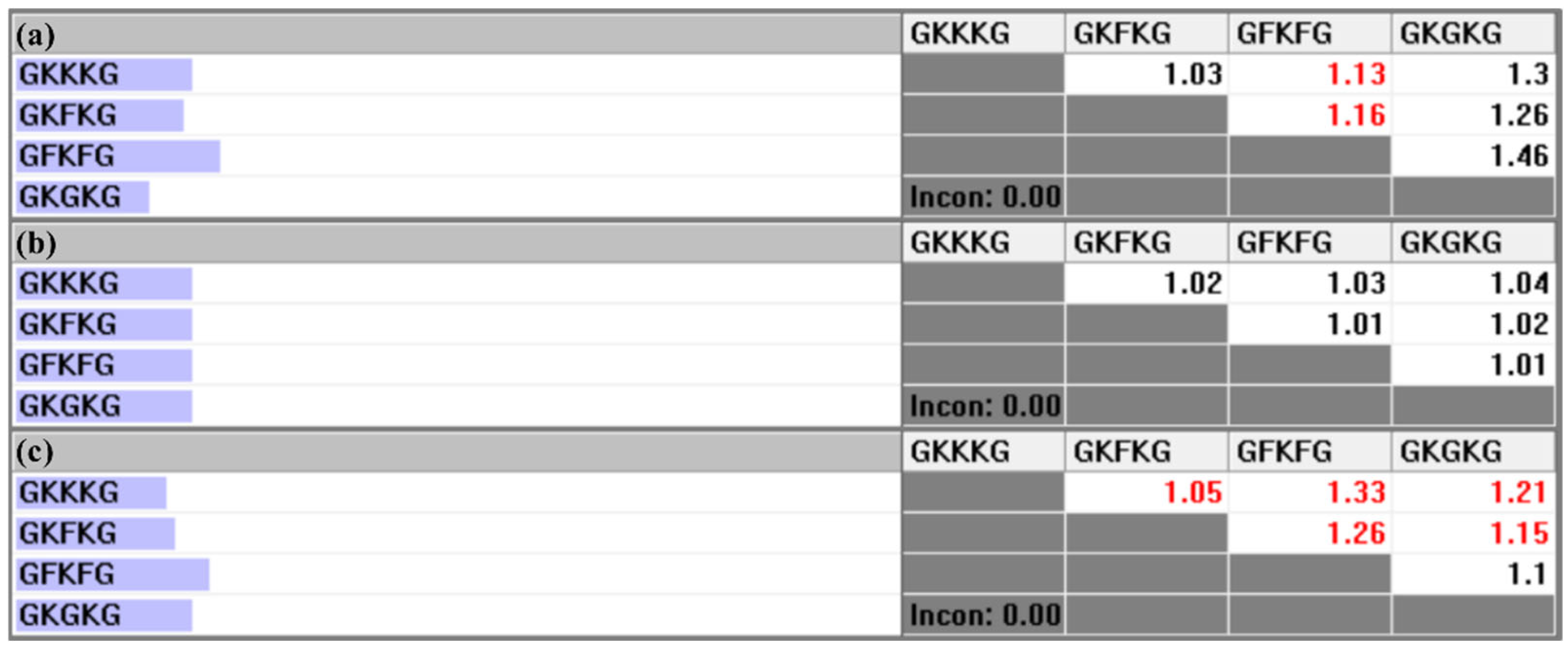

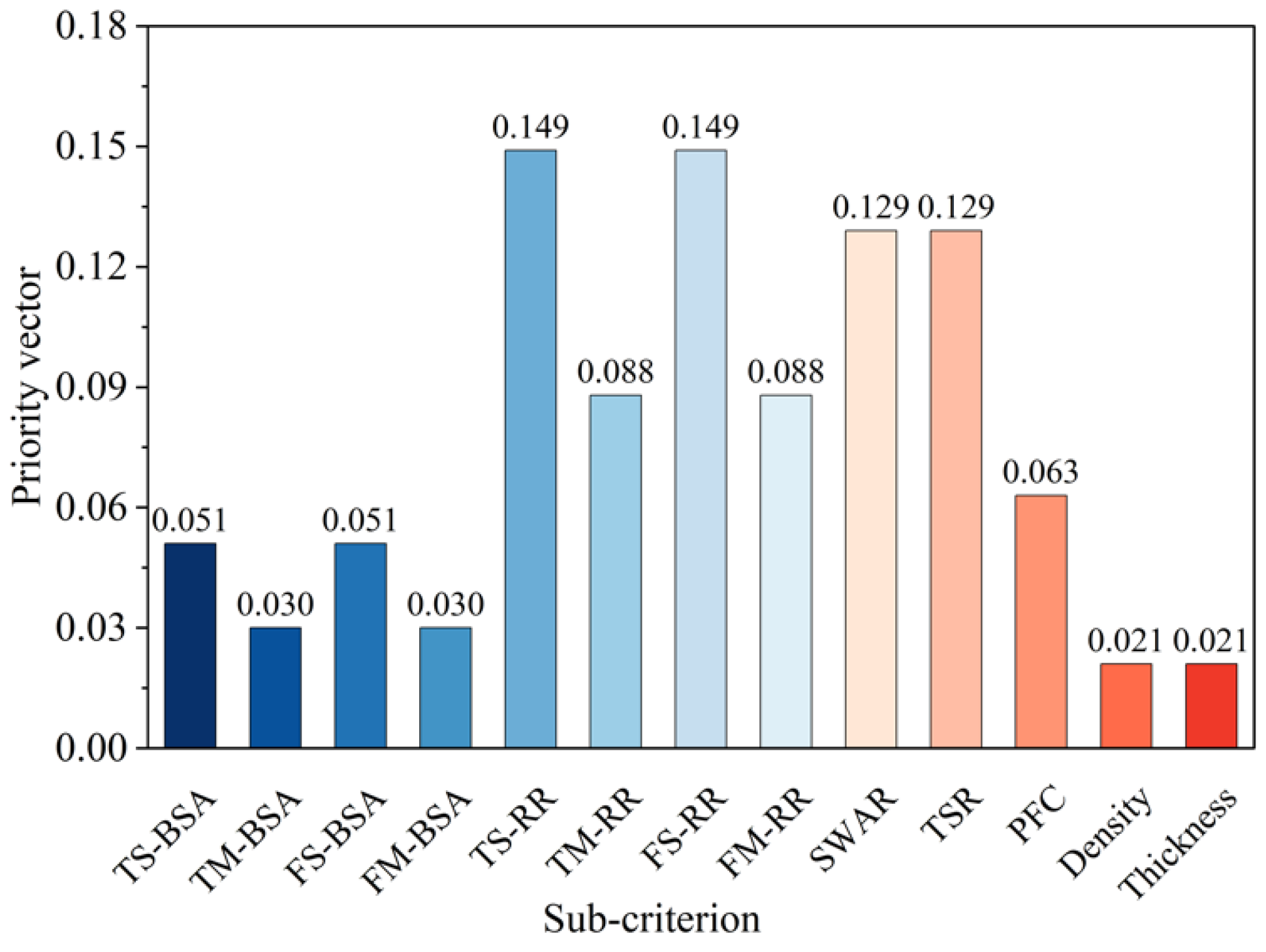

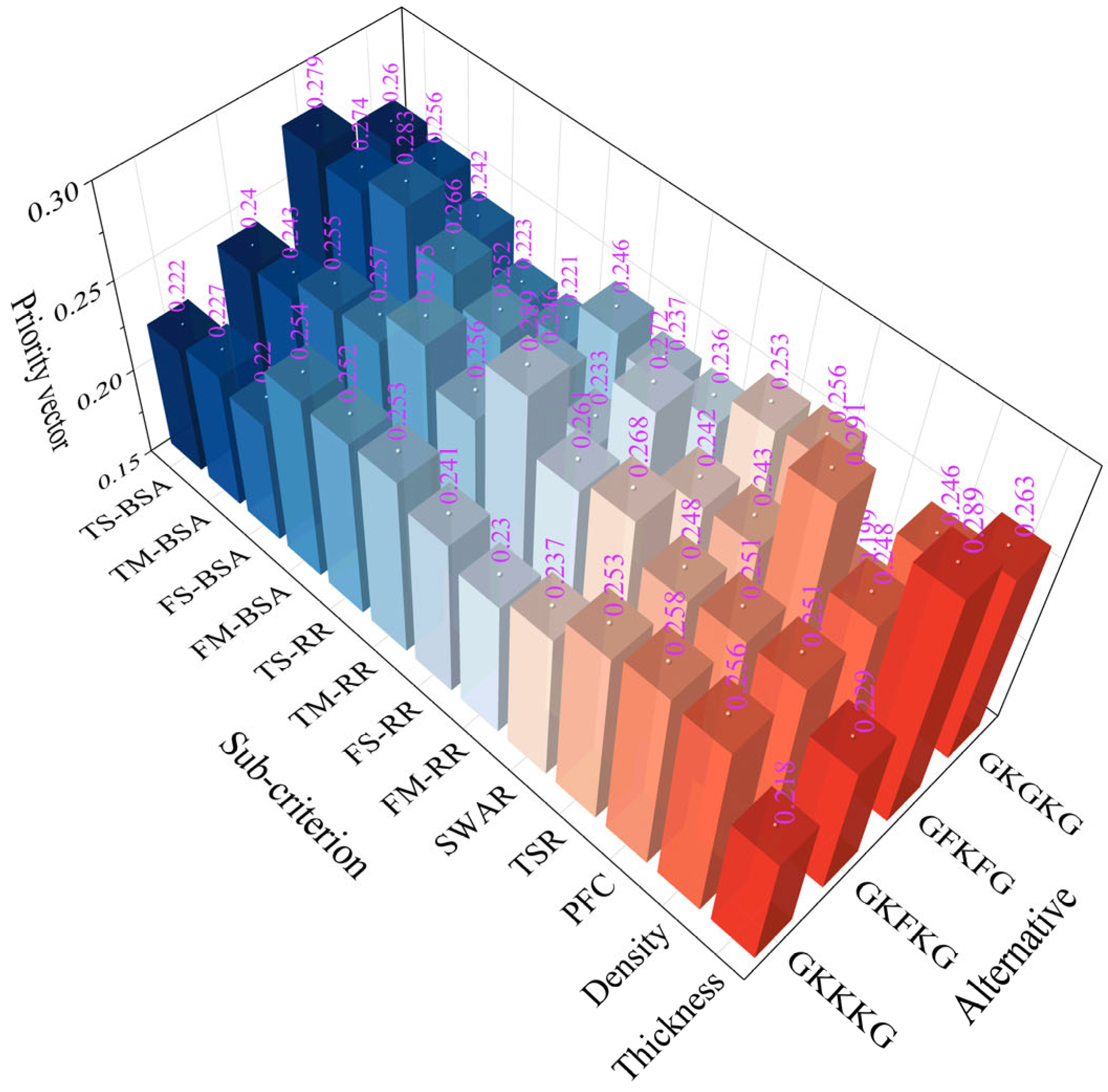

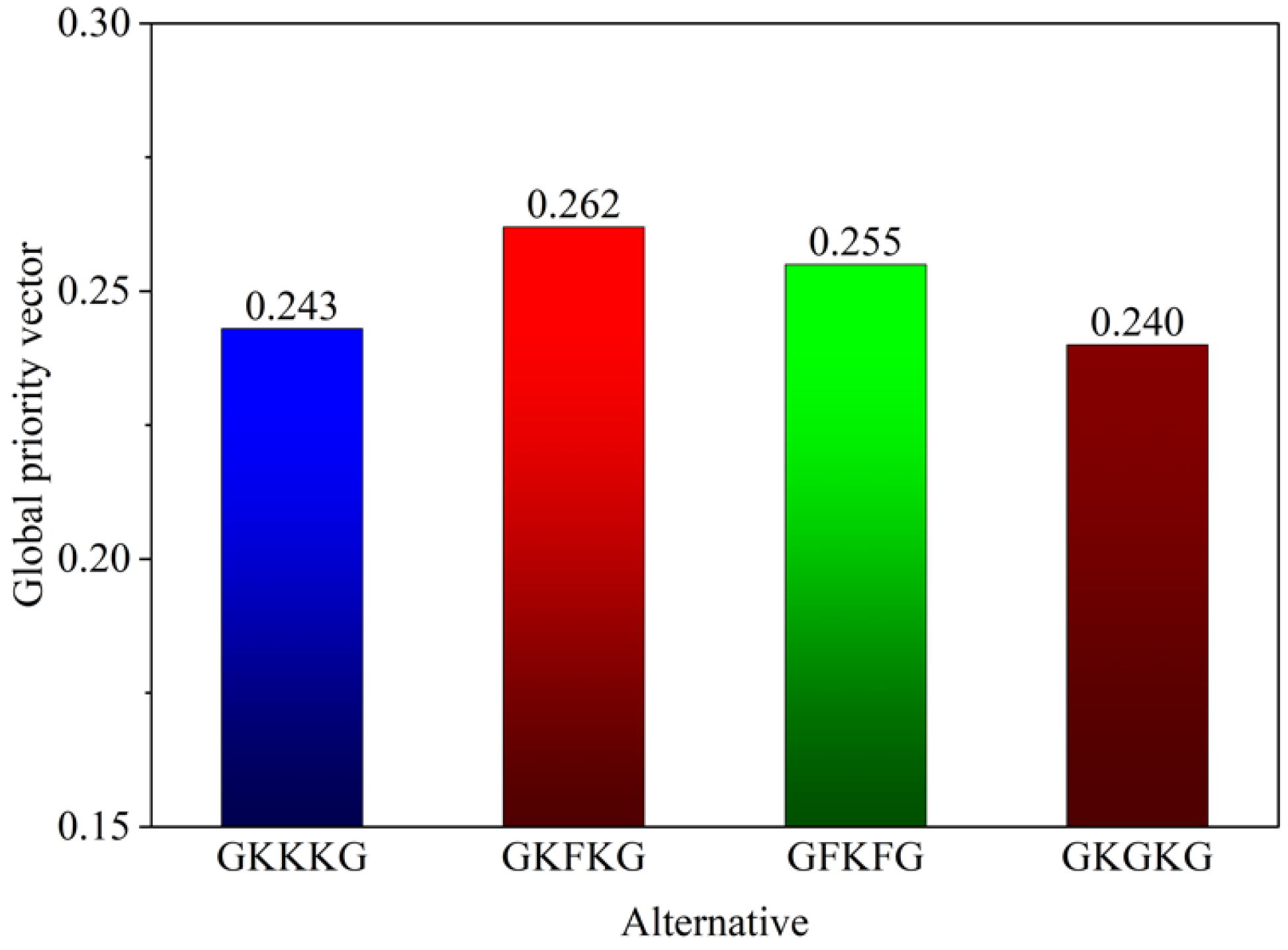

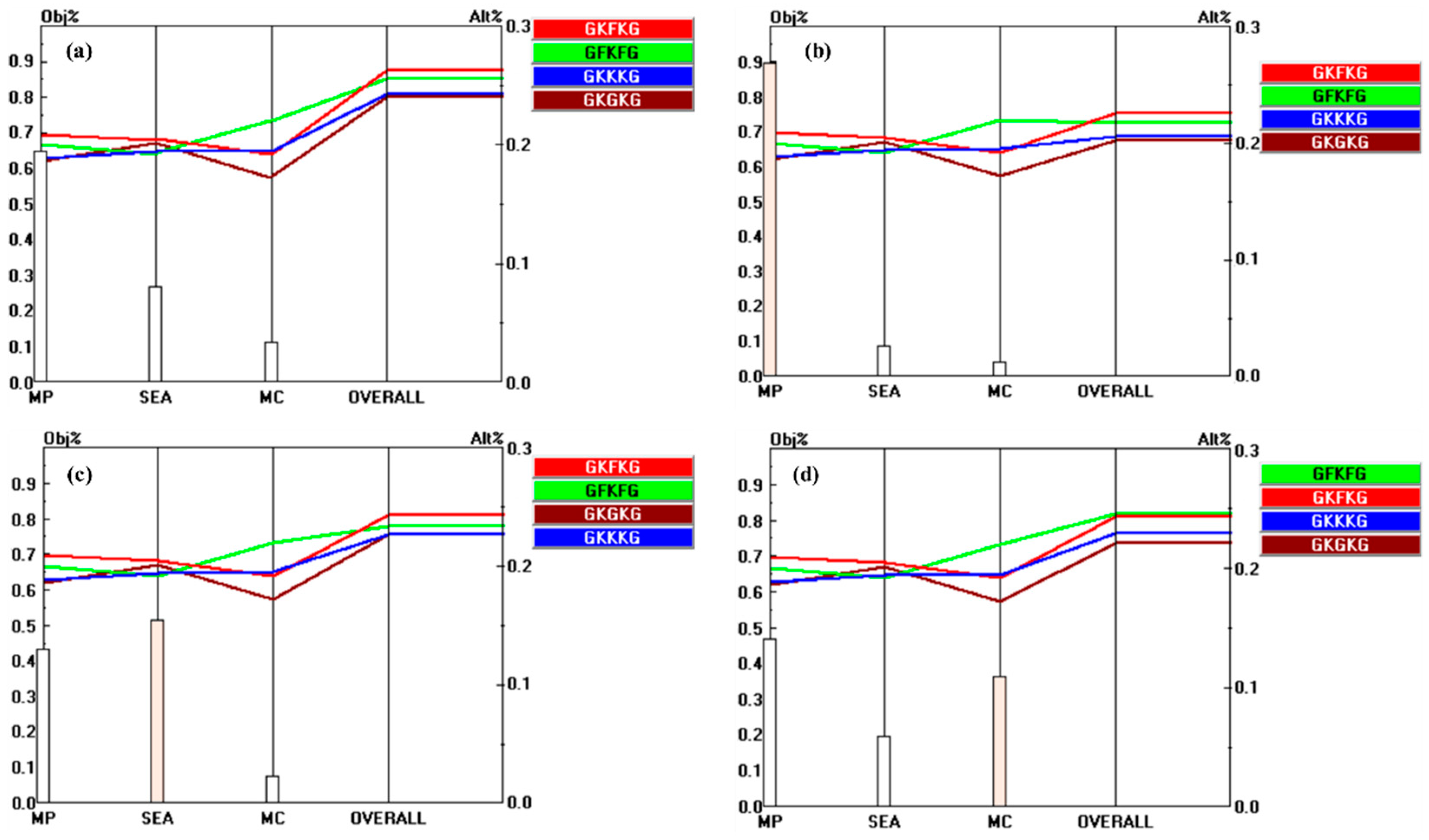

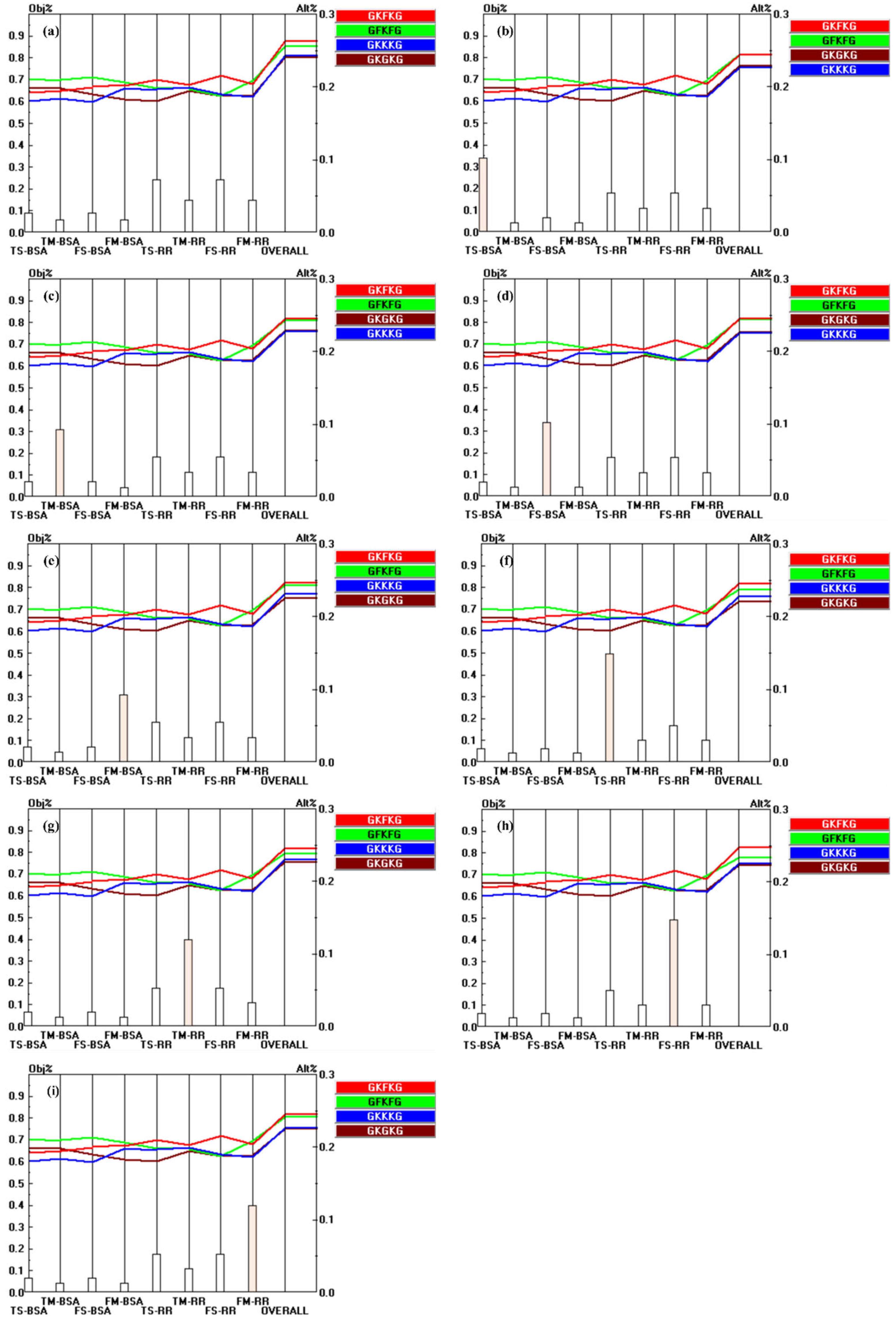

3.4. AHP Analysis

4. Conclusions

- Seawater immersion negatively impacted the mechanical properties of composite materials. After seawater aging, GFKFG exhibited the highest tensile strength and tensile modulus, while GKFKG showed the greatest elongation. In addition, GFKFG exhibited the highest flexural strength and flexural modulus, while GKGKG showed the greatest reduction in flexural properties.

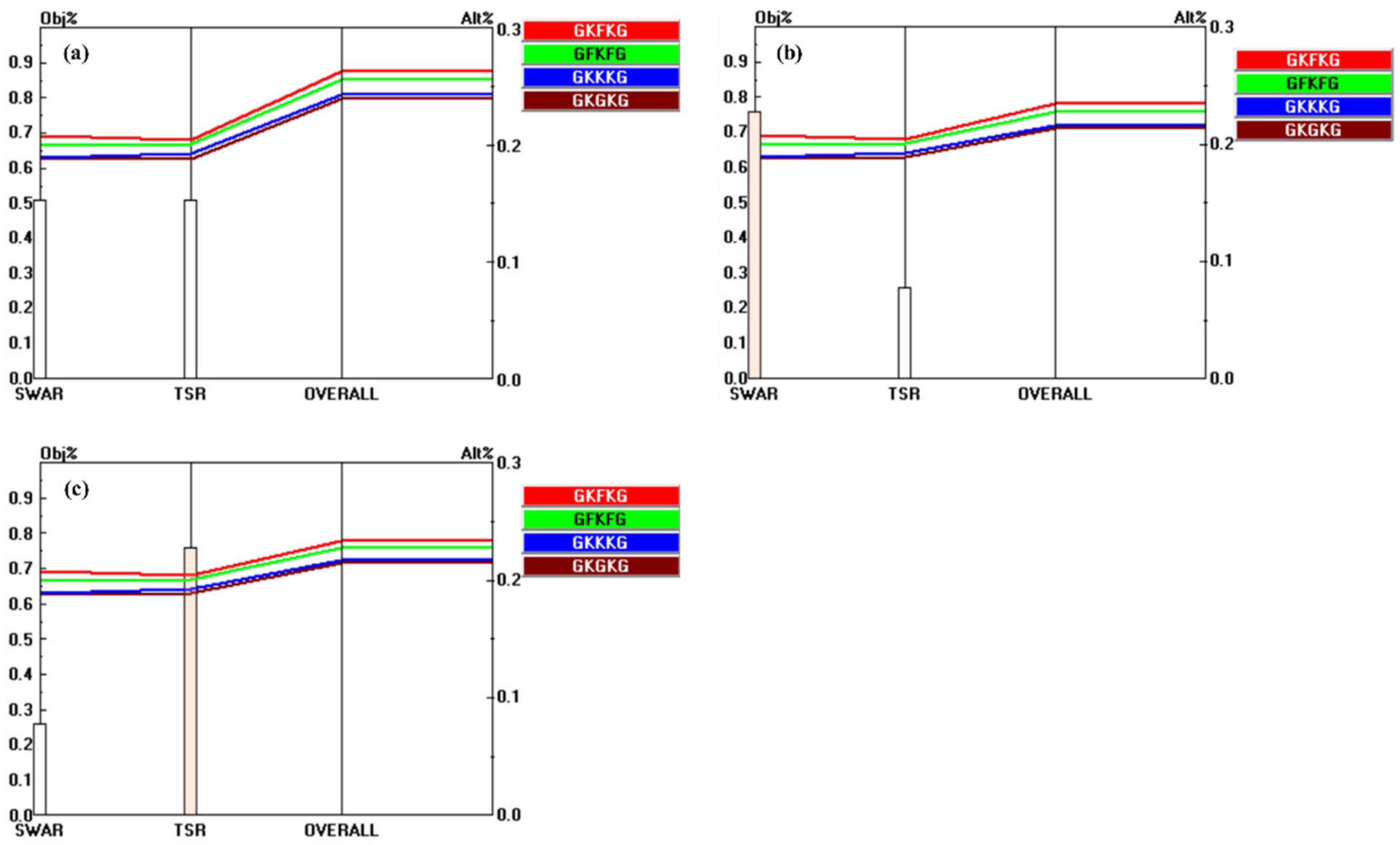

- Following the AHP analysis, GKFKG emerged as the optimal alternative, fulfilling both the global objectives and operational criteria, while the remaining alternatives were ranked in descending order: GFKFG, GKKKG, and GKGKG.

- The consistency ratios for all pairwise comparison matrices are below the acceptable threshold of 0.1, confirming the reliability and validity of the AHP results.

- The sensitivity analysis further demonstrated the stability of the AHP method. GKFKG maintained the highest priority in most scenarios following a 25% increase in criterion weights, while GFKFG led the ranking for the sub-criteria TS-BSA, TM-BSA, and FS-BSA. These results also highlight the positive synergistic effect of kenaf, flax, and glass fibers as reinforcing fibers in the composites.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bai, X.; Li, B.; Xu, X.; Xiao, Y. A Review of Current Research and Advances in Unmanned Surface Vehicles. J. Marine Sci. Appl. 2022, 21, 47–58. [Google Scholar] [CrossRef]

- Ghazali, M.H.M.; Satar, M.H.A.; Rahiman, W. Unmanned Surface Vehicles: From a Hull Design Perspective. Ocean. Eng. 2024, 312, 118977. [Google Scholar] [CrossRef]

- Verfuss, U.K.; Aniceto, A.S.; Harris, D.V.; Gillespie, D.; Fielding, S.; Jiménez, G.; Johnston, P.; Sinclair, R.R.; Sivertsen, A.; Solbø, S.A.; et al. A Review of Unmanned Vehicles for the Detection and Monitoring of Marine Fauna. Mar. Pollut. Bull. 2019, 140, 17–29. [Google Scholar] [CrossRef] [PubMed]

- Martin, A.Y. Unmanned Maritime Vehicles: Technology Evolution and Implications. Mar. Technol. Soc. J. 2013, 47, 72–83. [Google Scholar] [CrossRef]

- Jovanović, I.; Perčić, M.; BahooToroody, A.; Fan, A.; Vladimir, N. Review of Research Progress of Autonomous and Unmanned Shipping and Identification of Future Research Directions. J. Mar. Eng. Technol. 2024, 23, 82–97. [Google Scholar] [CrossRef]

- Neira, J.; Sequeiros, C.; Huamani, R.; Machaca, E.; Fonseca, P.; Nina, W. Review on Unmanned Underwater Robotics, Structure Designs, Materials, Sensors, Actuators, and Navigation Control. J. Robot. 2021, 2021, 5542920. [Google Scholar] [CrossRef]

- Elkolali, M.; Alcocer, A. Design and Testing of a Composite Pressure Hull for Deep Autonomous Underwater Vehicles. IEEE Access 2022, 10, 85831–85842. [Google Scholar] [CrossRef]

- Huang, Y.; Sultan, M.T.H.; Shahar, F.S.; Grzejda, R.; Łukaszewicz, A. Hybrid Fiber-Reinforced Biocomposites for Marine Applications: A Review. J. Compos. Sci. 2024, 8, 430. [Google Scholar] [CrossRef]

- Begum, S.; Fawzia, S.; Hashmi, M.S.J. Polymer Matrix Composite with Natural and Synthetic Fibres. Adv. Mater. Process. Technol. 2020, 6, 547–564. [Google Scholar] [CrossRef]

- Andrew, J.J.; Dhakal, H.N. Influence of Seawater Ageing on the Physical and Mechanical Properties of the Natural Fiber-Reinforced Composites. In Aging Effects on Natural Fiber-Reinforced Polymer Composites: Durability and Life Prediction; Muthukumar, C., Krishnasamy, S., Thiagamani, S.M.K., Siengchin, S., Eds.; Springer: Singapore, 2022; ISBN 978-981-16-8360-2. [Google Scholar]

- Jeyaguru, S.; Thiagamani, S.M.K.; Rangappa, S.M.; Siengchin, S. Experimental Studies on the Absorption, Swelling and Erosion Performance of Hybrid Woven Kevlar/Hemp Reinforced Epoxy Composites. Express Polym. Lett. 2023, 17, 353–372. [Google Scholar] [CrossRef]

- Verma, R.; Shukla, M.; Shukla, D.K. Effect of Glass Fiber Hybridization on the Mechanical Properties of Unidirectional, Alkali-treated Kenaf-epoxy Composites. Polym. Compos. 2022, 43, 7483–7499. [Google Scholar] [CrossRef]

- Cai, M.; Liu, J.; Zhang, X.; Ma, Q.; Wang, D.; Waterhouse, G.I.N.; Sun, B. Mechanical Stability of Carbon/Ramie Fiber Hybrid Composites Under Hygrothermal Aging. Appl Compos. Mater 2024, 1–20. [Google Scholar] [CrossRef]

- Ahmad Nadzri, S.N.Z.; Md Shah, A.U.; Sultan, M.T.H.; Safri, S.N.A.; Shahar, F.S.; Basri, A.A. Failure Mechanisms of Kenaf/Glass Sandwich Laminates Subjected to Low Velocity Impact Loading. J. Ind. Text. 2022, 51, 4167S–4183S. [Google Scholar] [CrossRef]

- Balakrishnan, T.S.; Sultan, M.T.H.; Shahar, F.S.; Nayak, S.Y.; Shah, A.U.M.; Sebaey, T.A.; Basri, A.A. Hybridization of Woven Kenaf and Unidirectional Glass Fibre Roving for Unsaturated Polyester Composite. Iran. Polym. J. 2024, 33, 1231–1244. [Google Scholar] [CrossRef]

- Khan, T.; Sultan, M.T.H.; Shah, A.U.M.; Ariffin, A.H.; Jawaid, M. The Effects of Stacking Sequence on the Tensile and Flexural Properties of Kenaf/Jute Fibre Hybrid Composites. J. Nat. Fibers 2021, 18, 452–463. [Google Scholar] [CrossRef]

- Oguz, Z.A.; Erklig, A.; Bozkurt, Ö.Y. Effects of Hydrothermal Seawater Aging on the Mechanical Properties and Water Absorption of Glass/Aramid/Epoxy Hybrid Composites. Int. Polym. Process. 2021, 36, 79–93. [Google Scholar] [CrossRef]

- Azman, M.A.; Asyraf, M.R.M.; Khalina, A.; Petrů, M.; Ruzaidi, C.M.; Sapuan, S.M.; Wan Nik, W.B.; Ishak, M.R.; Ilyas, R.A.; Suriani, M.J. Natural Fiber Reinforced Composite Material for Product Design: A Short Review. Polymers 2021, 13, 1917. [Google Scholar] [CrossRef]

- Sachs, J.D.; Schmidt-Traub, G.; Mazzucato, M.; Messner, D.; Nakicenovic, N.; Rockström, J. Six Transformations to Achieve the Sustainable Development Goals. Nat. Sustain. 2019, 2, 805–814. [Google Scholar] [CrossRef]

- Manral, A.; Radhakrishnan, S.; Dwivedi, S.P.; Sharma, B.; Gupta, P.; Chaudhary, V. Effect of Water Ageing on Mechanical Performance of Kenaf/PLA Bio-Composites. Biomass Conv. Bioref. 2025, 15, 6113–6130. [Google Scholar] [CrossRef]

- Guo, R.; Xian, G.; Li, C.; Hong, B.; Huang, X.; Xin, M.; Huang, S. Water Uptake and Interfacial Shear Strength of Carbon/Glass Fiber Hybrid Composite Rods under Hygrothermal Environments: Effects of Hybrid Modes. Polym. Degrad. Stab. 2021, 193, 109723. [Google Scholar] [CrossRef]

- Parameswaranpillai, J.; Jacob, J.; Dominic, C.D.; Muthukumar, C.; Thiagamani, S.M.K.; Jayakumar, A.; Siengchin, S.; Radoor, S. Effect of Water Absorption on the Tensile, Flexural, Fracture Toughness and Impact Properties of Biocomposites. In Aging Effects on Natural Fiber-Reinforced Polymer Composites: Durability and Life Prediction; Muthukumar, C., Krishnasamy, S., Thiagamani, S.M.K., Siengchin, S., Eds.; Springer: Singapore, 2022; ISBN 978-981-16-8360-2. [Google Scholar]

- Nosbi, N.; Akil, H.M.; Mohd Ishak, Z.A.; Abu Bakar, A. Degradation of Compressive Properties of Pultruded Kenaf Fiber Reinforced Composites after Immersion in Various Solutions. Mater. Des. 2010, 31, 4960–4964. [Google Scholar] [CrossRef]

- Zhang, Z.; Ji, Q.; Guo, Z.; Li, C.; Guo, R.; Tian, J.; Zhang, Z.; He, T.; Xian, G. Design, Preparation, and Mechanical Properties of Glass Fiber Reinforced Thermoplastic Self-Anchor Plate Cable Exposed in Alkaline Solution Environment. Polym. Compos. 2024, 45, 11687–11700. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N. Effect of Water, Seawater and Alkaline Solution Ageing on Mechanical Properties of Flax Fabric/Epoxy Composites Used for Civil Engineering Applications. Constr. Build. Mater. 2015, 99, 118–127. [Google Scholar] [CrossRef]

- Rubino, F.; Nisticò, A.; Tucci, F.; Carlone, P. Marine Application of Fiber Reinforced Composites: A Review. J. Mar. Sci. Eng. 2020, 8, 26. [Google Scholar] [CrossRef]

- Huang, Y.; Sultan, M.T.H.; Shahar, F.S.; Łukaszewicz, A.; Oksiuta, Z.; Grzejda, R. Kenaf Fiber-Reinforced Biocomposites for Marine Applications: A Review. Materials 2025, 18, 999. [Google Scholar] [CrossRef] [PubMed]

- Velasco-Parra, J.A.; Valencia, F.R.; Lopez-Arraiza, A.; Ramón-Valencia, B.; Castillo-López, G. Jute Fibre Reinforced Biocomposite: Seawater Immersion Effects on Tensile Properties and Its Application in a Ship Hull Design by Finite-Element Analysis. Ocean Eng. 2023, 290, 116301. [Google Scholar] [CrossRef]

- Zhong, X.; Zhu, Y.; Liu, S.; Fu, J.; Lin, H.; He, C. Performance Analysis of Four Plant Fiber/Polyvinyl Chloride Composites under Two Degradation Conditions with Water or Seawater with Xenon Lamp. BioResources 2020, 15, 4672–4688. [Google Scholar] [CrossRef]

- Davies, P.; Arhant, M.; Grossmann, E. Seawater Ageing of Infused Flax Fibre Reinforced Acrylic Composites. Compos. Part C Open Access 2022, 8, 100246. [Google Scholar] [CrossRef]

- Davies, P.; Le Gall, M.; Niu, Z.; Catarino, A.I.; De Witte, Y.; Everaert, G.; Dhakal, H.; Park, C.H.; Demeyer, E. Recycling and Ecotoxicity of Flax/PLA Composites: Influence of Seawater Aging. Compos. Part C Open Access 2023, 12, 100379. [Google Scholar] [CrossRef]

- Ambekar, A.M.; Muralishwara, K.; Hindi, J.; Acharya, S.; Naik, N.; Gurumurthy, B.M.; Hiremath, P.; Kasip, K. Effect of Seawater Absorption on Mechanical and Flexural Properties of Pineapple Leaf Fiber Reinforced Epoxy Nanoclay Composites. ES Mater. Manuf. 2023, 22, 1067. [Google Scholar] [CrossRef]

- Santulli, C.; Fiore, V. Seawater Aging and Its Degradation Effects on the Mechanical Properties of Biocomposites. In Biocomposites for Industrial Applications; Muthukumar, C., Thiagamani, S.M.K., Krishnasamy, S., Parameswaranpillai, J., Siengchin, S., Eds.; Woodhead Publishing: Cambridge, UK, 2024; ISBN 978-0-323-91866-4. [Google Scholar]

- Tahir, D.; Karim, M.R.; Wu, S.; Rehan, M.; Tahir, M.; Zaigham, S.B.; Riaz, N. Impact of Fiber Diameter on Mechanical and Water Absorption Properties of Short Bamboo Fiber-Reinforced Polyester Composites. Int. Polym. Process. 2024, 39, 317–326. [Google Scholar] [CrossRef]

- Alaseel, B.H.; Mohamed Nainar, M.A.; Nordin, N.A.; Yahya, Z.; Abdul Rahim, M.N. Effect of Water Absorption on Flexural Properties of Kenaf/Glass Fibres Reinforced Unsaturated Polyester Hybrid Composites Rod. Pertanika J. Sci. Technol. 2022, 30, 397–412. [Google Scholar] [CrossRef]

- Mishra, C.; Ranjan Deo, C.; Baskey, S. Influence of Moisture Absorption on Mechanical Properties of Kenaf/Glass Reinforced Polyester Hybrid Composite. Mater. Today Proc. 2021, 38, 2596–2600. [Google Scholar] [CrossRef]

- Kaysar, M.A.; Ahmed, S.J.; Jamil, A.T.M.K.; Habib, M.M.; Dayan, M.A.R.; Mamun-Or-Rashid; Gafur, M.A. Impact of NaOH Treatment on the Chemical, Structural, Physico-Mechanical, and Thermal Characteristics of Jute Species. Fibers Polym. 2024, 25, 1765–1777. [Google Scholar] [CrossRef]

- Rahman, H.; Yeasmin, F.; Khan, S.A.; Hasan, M.Z.; Roy, M.; Uddin, M.B.; Khan, R.A. Fabrication and Analysis of Physico-Mechanical Characteristics of NaOH Treated PALF Reinforced LDPE Composites: Effect of Gamma Irradiation. J. Mater. Res. Technol. 2021, 11, 914–928. [Google Scholar] [CrossRef]

- Thandavamoorthy, R.; Devarajan, Y.; Thanappan, S. Analysis of the Characterization of NaOH-Treated Natural Cellulose Fibre Extracted from Banyan Aerial Roots. Sci. Rep. 2023, 13, 12579. [Google Scholar] [CrossRef]

- Ismail, N.F.; Mohd Radzuan, N.A.; Sulong, A.B.; Muhamad, N.; Che Haron, C.H. The Effect of Alkali Treatment on Physical, Mechanical and Thermal Properties of Kenaf Fiber and Polymer Epoxy Composites. Polymers 2021, 13, 2005. [Google Scholar] [CrossRef]

- Velmurugan, G.; Chohan, J.S.; Abraar, S.M.; Sathish, R.; Murugan, S.S.; Nagaraj, M.; Kumar, S.S.; Shankar, V.S.; Raja, D.E. Investigation of Nano SiO2 Filler Loading on Mechanical and Flammability Properties of Jute-Based Hybrid Polypropylene Composites. Silicon 2023, 15, 7247–7263. [Google Scholar] [CrossRef]

- Liu, X.; Fang, Y.; Gao, H. Effect of SiO2 Nano-Interphase on the Water Absorption Mechanism of Natural Fiber Reinforced Composites: A Multi-Scale Study. Appl. Surf. Sci. 2023, 637, 157942. [Google Scholar] [CrossRef]

- Sagari, K.V.; Prasad, K. Investigation on Physical and Mechanical Behavior of Nano-Silica Particle Filled Woven Jute/Kenaf Hybrid Nanocomposites. Polym. Compos. 2024, 46, 4506–4518. [Google Scholar] [CrossRef]

- Emrahi, R.; Rostamiyan, Y.; Hashemi-Tilehnoee, M. Influences of Nano-SiO2 on the Tensile, Flexural, and Compressive Characteristics of the Open-Hole Carbon Fiber-Reinforced Polymer Laminated Composites: Experimental Study. Funct. Compos. Struct. 2023, 5, 035001. [Google Scholar] [CrossRef]

- Pant, S.; Kumar, A.; Ram, M.; Klochkov, Y.; Sharma, H.K. Consistency Indices in Analytic Hierarchy Process: A Review. Mathematics 2022, 10, 1206. [Google Scholar] [CrossRef]

- Saaty, T.L. A Scaling Method for Priorities in Hierarchical Structures. J. Math. Psychol. 1977, 15, 234–281. [Google Scholar] [CrossRef]

- Saaty, T.L. How to Make a Decision: The Analytic Hierarchy Process. Eur. J. Oper. Res. 1990, 48, 9–26. [Google Scholar] [CrossRef]

- Bekraoui, N.; El Qoubaa, Z. Weibull Integrated AHP for The Selection of Natural Fiber Composites Material. Jordan J. Mech. Ind. Eng. 2023, 17, 55–67. [Google Scholar] [CrossRef] [PubMed]

- Naveen, J.; Jawaid, M.; Zainudin, E.S.; Sultan, M.T.H.; Yahaya, R.B. Selection of Natural Fiber for Hybrid Kevlar/Natural Fiber Reinforced Polymer Composites for Personal Body Armor by Using Analytical Hierarchy Process. Front. Mater. 2018, 5, 52. [Google Scholar] [CrossRef]

- Balakrishnan, T.S.; Sultan, M.T.H.; Naveen, J.; Shahar, F.S.; Najeeb, M.I.; Shah, A.U.M.; Khan, T.; Sebaey, T.A. Selection of Natural Fibre for Pultruded Hybrid Synthetic/Natural Fibre Reinforced Polymer Composites Using Analytical Hierarchy Process for Structural Applications. Polymers 2022, 14, 3178. [Google Scholar] [CrossRef]

- Mahesh, V.; Mahesh, V.; Harursampath, D. Influence of Alkali Treatment on Physio-Mechanical Properties of Jute–Epoxy Composite. Adv. Mater. Process. Technol. 2022, 8, 380–391. [Google Scholar] [CrossRef]

- Xiao, X.; Cheng, M.; Zhong, Y. Effects of Alkali Treatment on the Mechanical Properties and Moisture Absorption Behavior of Flax/Polypropylene Composites. J. Nat. Fibers 2022, 19, 9201–9222. [Google Scholar] [CrossRef]

- Ghani, M.U.; Siddique, A.; Abraha, K.G.; Yao, L.; Li, W.; Khan, M.Q.; Kim, I.-S. Performance Evaluation of Jute/Glass-Fiber-Reinforced Polybutylene Succinate (PBS) Hybrid Composites with Different Layering Configurations. Materials 2022, 15, 1055. [Google Scholar] [CrossRef]

- Xiao, H.; Sultan, M.T.H.; Shahar, F.S.; Gaff, M.; Hui, D. Recent Developments in the Mechanical Properties of Hybrid Fiber Metal Laminates in the Automotive Industry: A Review. Rev. Adv. Mater. Sci. 2023, 62, 20220328. [Google Scholar] [CrossRef]

- Bakhshi, B.; Heydarian, M. Study of Mechanical, Flame, and Water Stability of Phenolic Resin/Carbon Fiber/Nanosilica Composites. Polym. Compos. 2021, 42, 3892–3898. [Google Scholar] [CrossRef]

- D1141-98; Standard Practice for Preparation of Substitute Ocean Water. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2021.

- D570-22; Standard Test Method for Water Absorption of Plastics. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2022.

- D3039; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2014.

- D790; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2017.

- Hambali, A.; Sapuan, S.M.; Ismail, N.; Nukman, Y. Material Selection of Polymeric Composite Automotive Bumper Beam Using Analytical Hierarchy Process. J. Cent. South Univ. Technol. 2010, 17, 244–256. [Google Scholar] [CrossRef]

- Sugiman, S.; Setyawan, P.D.; Anshari, B. Water Absorption and Impact Strength of Alkali-Treated Bamboo Fiber/Polystyrene-Modified Unsaturated Polyester Composites. J. Appl. Sci. Eng. 2020, 23, 9–20. [Google Scholar] [CrossRef]

- Mohammed, M.; Jawad, A.J.M.; Mohammed, A.M.; Oleiwi, J.K.; Adam, T.; Osman, A.F.; Dahham, O.S.; Betar, B.O.; Gopinath, S.C.B.; Jaafar, M. Challenges and Advancement in Water Absorption of Natural Fiber-Reinforced Polymer Composites. Polym. Test. 2023, 124, 108083. [Google Scholar] [CrossRef]

- Verma, R.; Shukla, M.; Shukla, D.K. Effect of Glass Fibre Hybridization on the Water Absorption and Thickness of Alkali Treated Kenaf-Epoxy Composites. Mater. Today Proc. 2021, 44, 2093–2096. [Google Scholar] [CrossRef]

- Ramesh, M.; Tamil Selvan, M.; Niranjana, K. Hygrothermal Aging, Kinetics of Moisture Absorption, Degradation Mechanism and Their Influence on Performance of the Natural Fibre Reinforced Composites. In Aging Effects on Natural Fiber-Reinforced Polymer Composites: Durability and Life Prediction; Muthukumar, C., Krishnasamy, S., Thiagamani, S.M.K., Siengchin, S., Eds.; Springer: Singapore, 2022; pp. 257–277. ISBN 978-981-16-8360-2. [Google Scholar]

- Wang, Y.; Wang, W.; Wang, D.; Liu, Y.; Liu, J. Study on the Influence of Sample Size and Test Conditions on the Capillary Water Absorption Coefficient of Porous Building Materials. J. Build. Eng. 2021, 43, 103120. [Google Scholar] [CrossRef]

- Nan, J.; Zhi, C.; Meng, J.; Miao, M.; Yu, L. Seawater Aging Effect on Fiber-Reinforced Polymer Composites: Mechanical Properties, Aging Mechanism, and Life Prediction. Text. Res. J. 2023, 93, 3393–3413. [Google Scholar] [CrossRef]

- Ramón Valencia, F.; Lopez-Arraiza, A.; Múgica, J.I.; Aurrekoetxea, J.; Suarez, J.C.; Ramón-Valencia, B. Influence of Seawater Immersion in Low Energy Impact Behavior of a Novel Colombian Fique Fiber Reinforced Bio-Resin Laminate. DYNA 2015, 82, 170–177. [Google Scholar] [CrossRef]

- Chow, C.P.L.; Xing, X.S.; Li, R.K.Y. Moisture Absorption Studies of Sisal Fibre Reinforced Polypropylene Composites. Compos. Sci. Technol. 2007, 67, 306–313. [Google Scholar] [CrossRef]

- Fiore, V.; Sanfilippo, C.; Calabrese, L. Influence of Sodium Bicarbonate Treatment on the Aging Resistance of Natural Fiber Reinforced Polymer Composites under Marine Environment. Polym. Test. 2019, 80, 106100. [Google Scholar] [CrossRef]

- José-Trujillo, E.; Rubio-González, C.; Rodríguez-González, J.A. Study of Seawater Effect on the Mechanical and Thermomechanical Properties of Hybrid Multiwall Carbon Nanotube/Graphene Nanoplatelet-Glass Fiber/Epoxy Laminates. Polym. Compos. 2022, 43, 8673–8686. [Google Scholar] [CrossRef]

- Oğuz, Z.A.; Erkliğ, A. Hydrothermal Aging Effect on the Tensile Properties of Hybrid Aramid/Glass/Epoxy Composites: Comparison of Distilled Water and Seawater. J. Compos. Mater. 2022, 56, 3695–3714. [Google Scholar] [CrossRef]

- Zakaria, N.A.; Ishak, M.R.; Mustapha, F.; Yidris, N. Tensile Properties of a Hybrid Kenaf-Glass Fibre Composite Shaft. Mater. Today: Proc. 2023, 74, 492–498. [Google Scholar] [CrossRef]

- Taylor, D. CHAPTER 8—Composites: Brittle Fracture in Fibre Composite Materials. In The Theory of Critical Distances; Taylor, D., Ed.; Elsevier Science Ltd.: Oxford, 2007; pp. 141–161. ISBN 978-0-08-044478-9. [Google Scholar]

- Das, S.C.; Paul, D.; Grammatikos, S.A.; Siddiquee, M.A.B.; Papatzani, S.; Koralli, P.; Islam, J.M.M.; Khan, M.A.; Shauddin, S.M.; Khan, R.A.; et al. Effect of Stacking Sequence on the Performance of Hybrid Natural/Synthetic Fiber Reinforced Polymer Composite Laminates. Compos. Struct. 2021, 276, 114525. [Google Scholar] [CrossRef]

- José-Trujillo, E.; Rubio-González, C.; Rodríguez-González, J.A. Evaluation of the Piezoresistive Response of GFRP with a Combination of MWCNT and GNP Exposed to Seawater Aging. Appl. Compos. Mater. 2024, 31, 467–488. [Google Scholar] [CrossRef]

- Bhat, A.; Budholiya, S.; Raj, S.A.; Sultan, M.T.; Hui, D.; Shah, A.U.M.; Safri, S.N.A. Review on Nanocomposites Based on Aerospace Applications. Nanotechnol. Rev. 2021, 10, 237–253. [Google Scholar] [CrossRef]

- Chowdary, M.S.; Raghavendra, G.; Kumar, M.S.R.N.; Ojha, S.; Boggarapu, V. Influence of Nano-Silica on Enhancing the Mechanical Properties of Sisal/Kevlar Fiber Reinforced Polyester Hybrid Composites. Silicon 2022, 14, 539–546. [Google Scholar] [CrossRef]

- Saaty, T.L.; Ozdemir, M. Negative Priorities in the Analytic Hierarchy Process. Math. Comput. Model. 2003, 37, 1063–1075. [Google Scholar] [CrossRef]

- Liang, J.; Yang, J. Application of the AHP Method on the Optimization with Undesirable Priorities. Eng. Comput. 2022, 38, 2137–2153. [Google Scholar] [CrossRef]

- Bagheri, M.; Zaiton Ibrahim, Z.; Mansor, S.; Abd Manaf, L.; Akhir, M.F.; Talaat, W.I.A.W.; Beiranvand Pour, A. Application of Multi-Criteria Decision-Making Model and Expert Choice Software for Coastal City Vulnerability Evaluation. Urban Sci. 2021, 5, 84. [Google Scholar] [CrossRef]

- Kurbatova, A.; Abu-Qdais, H.A. Using Multi-Criteria Decision Analysis to Select Waste to Energy Technology for a Mega City: The Case of Moscow. Sustainability 2020, 12, 9828. [Google Scholar] [CrossRef]

- Lipovetsky, S. AHP Priorities and Markov-Chapman-Kolmogorov Steady-States Probabilities. Int. J. Anal. Hierarchy Process 2015, 7, 349–363. [Google Scholar] [CrossRef]

- Junaid, M.; uz Zaman, U.K.; Naseem, A.; Ahmad, Y.; Aqeel, A.B. Material Selection in Additive Manufacturing for Aerospace Applications Using Multi-Criteria Decision Making. MATEC Web Conf. 2024, 398, 01012. [Google Scholar] [CrossRef]

- Skrzek, K.; Mazgajczyk, E.; Dybała, B. Application of Fuzzy Logic-Based Expert Advisory Systems in Optimizing the Decision-Making Process for Material Selection in Additive Manufacturing. Materials 2025, 18, 324. [Google Scholar] [CrossRef]

| Materials | Tensile Strength (MPa) | Young’s Modulus (GPa) | Elongation at Break (%) | Density (g/cm3) |

|---|---|---|---|---|

| Kenaf fiber | 930 | 53 | 1.6 | 1.2 |

| Flax fiber | 1400 | 70 | 1.6 | 1.4 |

| Glass fiber | 1950 | 72 | 2.7 | 2.55 |

| Epoxy | 54.5 | 3.1 | 2.6 | 1.1 |

| Relative Intensity Scale | Definition | Explanation |

|---|---|---|

| 1 | Equal importance | Two factors are equally important. |

| 3 | Slightly more importance | Experience slightly favors one factor over the other. |

| 5 | Strong importance | Experience strongly favors one factor over the other. |

| 7 | Very strong importance | One factor is strongly favored, and its dominance is demonstrated in practice. |

| 9 | Extreme importance | Evidence favoring one over another is of the highest possible order of affirmation. |

| 2, 4, 6, 8 | Intermediate value between two adjacent judgments | Applied when compromise is needed. |

| Type of Composite | Average Tensile Strength (MPa) | Retention Rate of Strength (%) | Average Tensile Modulus (MPa) | Retention Rate of Modulus (%) | ||

|---|---|---|---|---|---|---|

| Before | After | Before | After | |||

| GKKKG | 82.26 | 65.59 | 79.73 | 5654.60 | 4408.61 | 77.97 |

| GKFKG | 88.98 | 77.21 | 86.77 | 6043.76 | 4748.39 | 78.57 |

| GFKFG | 103.38 | 82.52 | 79.82 | 6810.36 | 5163.99 | 75.83 |

| GKGKG | 96.46 | 67.74 | 70.23 | 6362.40 | 4815.28 | 75.68 |

| Type of Composite | Average Flexural Strength (MPa) | Retention Rate of Strength (%) | Average Flexural Modulus (MPa) | Retention Rate of Modulus (%) | ||

|---|---|---|---|---|---|---|

| Before | After | Before | After | |||

| GKKKG | 166.47 | 122.73 | 73.72 | 8539.36 | 7047.72 | 82.53 |

| GKFKG | 192.82 | 171.25 | 88.36 | 8635.09 | 8079.3 | 93.56 |

| GFKFG | 214.39 | 153.07 | 71.40 | 8926.69 | 8720.31 | 97.69 |

| GKGKG | 183.02 | 132.64 | 72.47 | 7477.83 | 6328.94 | 84.64 |

| Laminate | TS-BSA (MPa) | TM-BSA (MPa) | FS-BSA (MPa) | FM-BSA (MPa) | TS-RR (%) | TM-RR (%) | FS-RR (%) | FM-RR (%) | SWAR (%) | TSR (%) | PFC (wt.%) | Density (g/cm3) | Thickness (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GKKKG | 82.26 | 5654.60 | 166.47 | 8539.36 | 79.73 | 77.97 | 73.72 | 82.53 | 4.30 | 3.40 | 19.19 | 1.244 | 3.455 |

| GKFKF | 88.98 | 6043.76 | 193.82 | 8635.09 | 86.77 | 78.57 | 88.36 | 93.56 | 3.79 | 3.47 | 18.61 | 1.267 | 3.277 |

| GFKFG | 103.38 | 6810.36 | 214.39 | 8926.69 | 79.82 | 75.83 | 71.40 | 97.69 | 4.20 | 3.53 | 21.59 | 1.284 | 2.597 |

| GKGKG | 96.46 | 6362.40 | 183.02 | 7477.83 | 70.23 | 75.68 | 72.47 | 84.64 | 4.03 | 3.37 | 14.81 | 1.298 | 2.861 |

| Types of priorities | P | P | P | P | P | P | P | P | N | N | P | N | N |

| Rank | Initial State | SEA | MC | TS-BSA | TM-BSA | FS-BSA |

|---|---|---|---|---|---|---|

| 1 | GKFKG (0.262) | GKFKG (0.243) | GFKFG (0.245) | GKFKG (0.243) | GKFKG (0.245) | GKFKG (0.245) |

| 2 | GFKFG (0.255) | GFKFG (0.234) | GKFKG (0.243) | GFKFG (0.243) | GFKFG (0.243) | GFKFG (0.244) |

| 3 | GKKKG (0.243) | GKGKG (0.227) | GKKKG (0.229) | GKGKG (0.229) | GKGKG (0.229) | GKGKG (0.226) |

| 4 | GKGKG (0.240) | GKKKG (0.226) | GKGKG (0.221) | GKKKG (0.226) | GKKKG (0.227) | GKKKG (0.226) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Y.; Sultan, M.T.H.; Łukaszewicz, A.; Shahar, F.S.; Oksiuta, Z. AHP-Based Evaluation of Hybrid Kenaf/Flax/Glass Fiber-Reinforced Biocomposites for Unmanned Maritime Vehicle Applications. Materials 2025, 18, 3731. https://doi.org/10.3390/ma18163731

Huang Y, Sultan MTH, Łukaszewicz A, Shahar FS, Oksiuta Z. AHP-Based Evaluation of Hybrid Kenaf/Flax/Glass Fiber-Reinforced Biocomposites for Unmanned Maritime Vehicle Applications. Materials. 2025; 18(16):3731. https://doi.org/10.3390/ma18163731

Chicago/Turabian StyleHuang, Yang, Mohamed Thariq Hameed Sultan, Andrzej Łukaszewicz, Farah Syazwani Shahar, and Zbigniew Oksiuta. 2025. "AHP-Based Evaluation of Hybrid Kenaf/Flax/Glass Fiber-Reinforced Biocomposites for Unmanned Maritime Vehicle Applications" Materials 18, no. 16: 3731. https://doi.org/10.3390/ma18163731

APA StyleHuang, Y., Sultan, M. T. H., Łukaszewicz, A., Shahar, F. S., & Oksiuta, Z. (2025). AHP-Based Evaluation of Hybrid Kenaf/Flax/Glass Fiber-Reinforced Biocomposites for Unmanned Maritime Vehicle Applications. Materials, 18(16), 3731. https://doi.org/10.3390/ma18163731