Mechanical Behavior of Topology-Optimized Lattice Structures Fabricated by Additive Manufacturing

Highlights

- Lattice structures with maximum bulk modulus and elastic isotropy are designed.

- The mechanical properties of topology-optimized lattice structures are examined.

- The topology-optimized lattice structure has better load-bearing capability.

- The loading-direction dependency of topology-optimized lattices is reduced.

Abstract

1. Introduction

2. Materials and Methods Topology Optimization Method Based on Abaqus

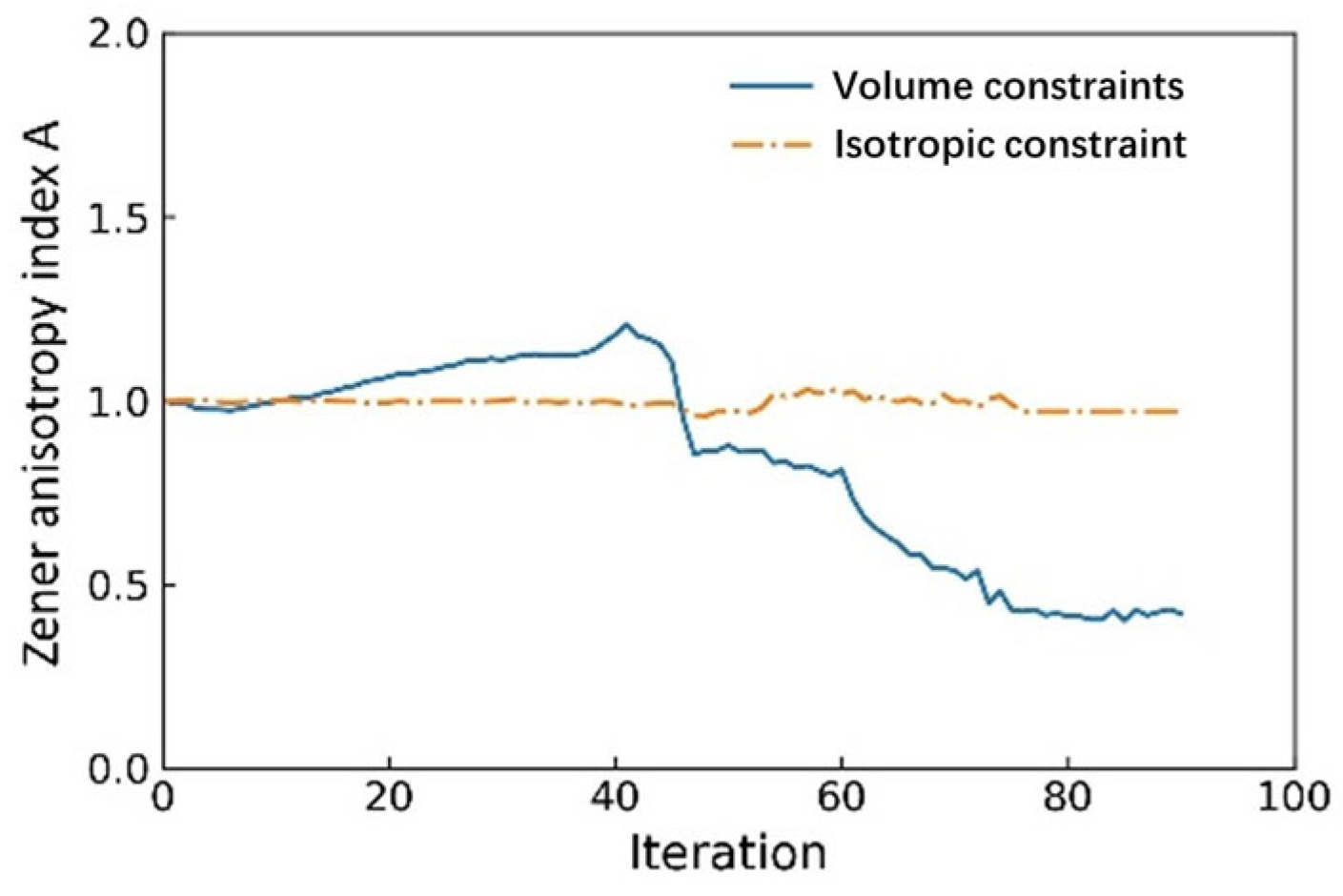

2.1. Optimization of Maximizing Bulk Modulus Considering Volume Constraints

2.2. Optimization of Maximizing Bulk Modulus Considering Volume and Isotropic Constraints

3. Design and Experiments

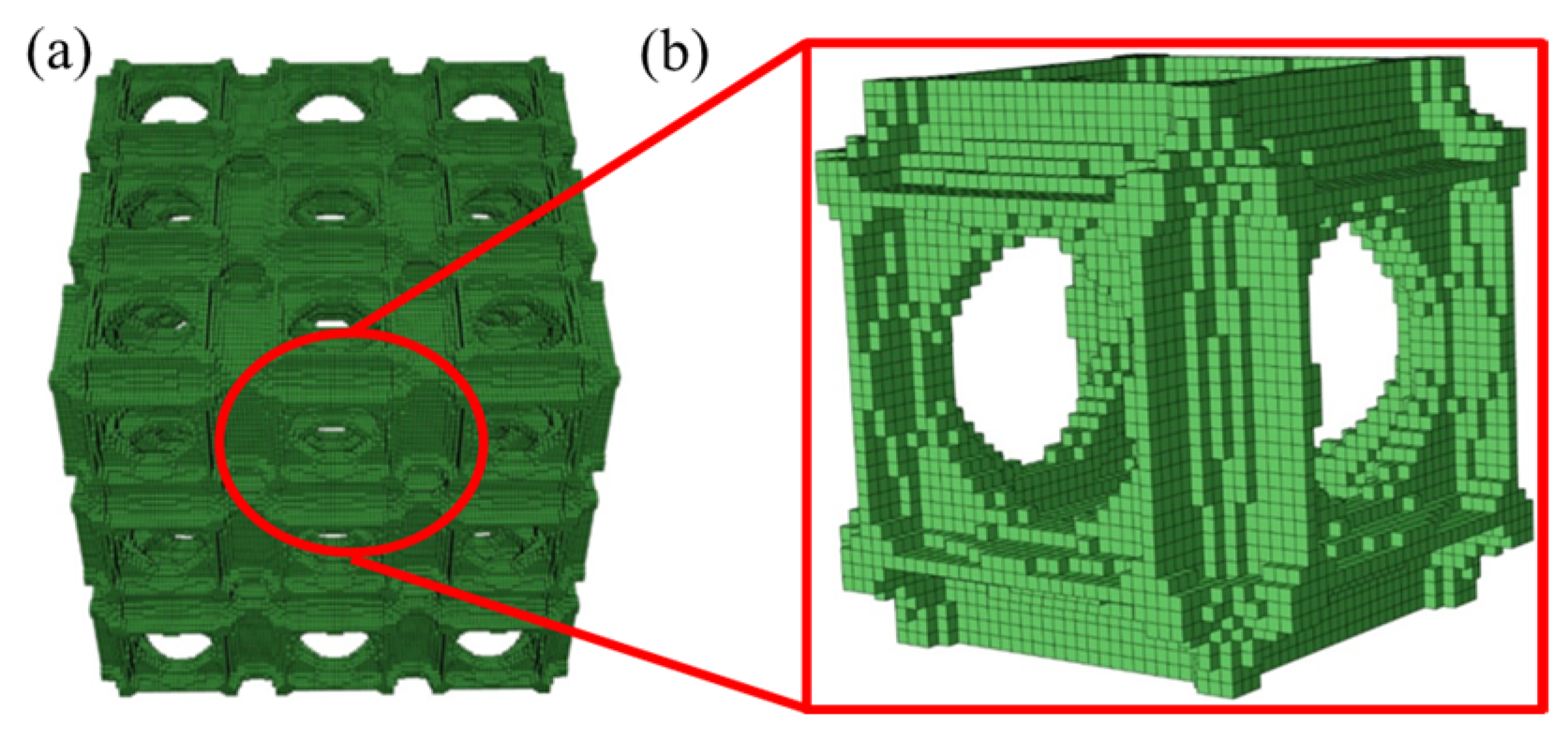

3.1. Structural Design of Topology Optimization Lattice Structure

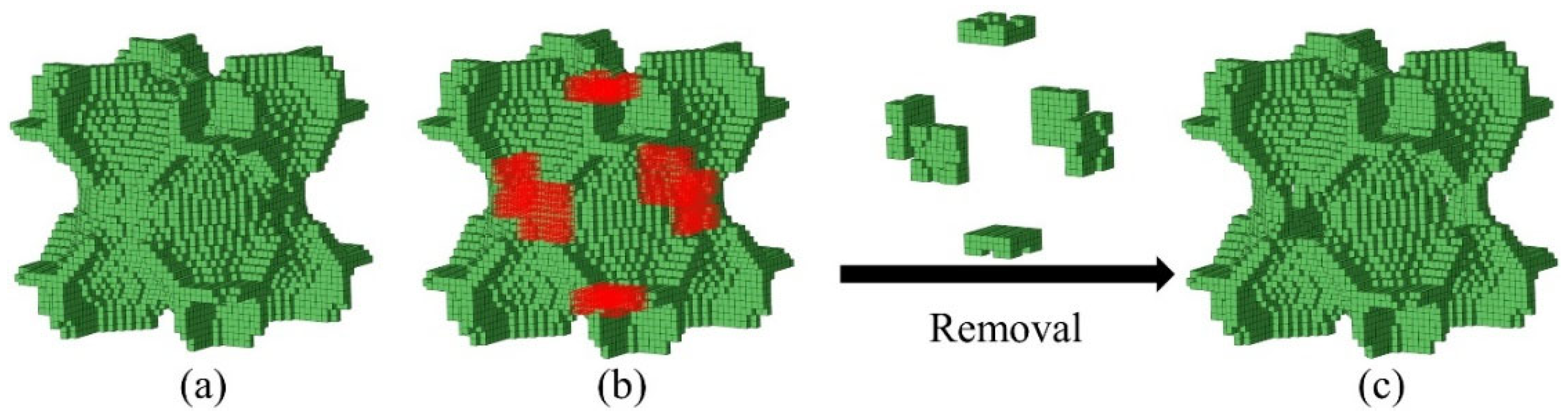

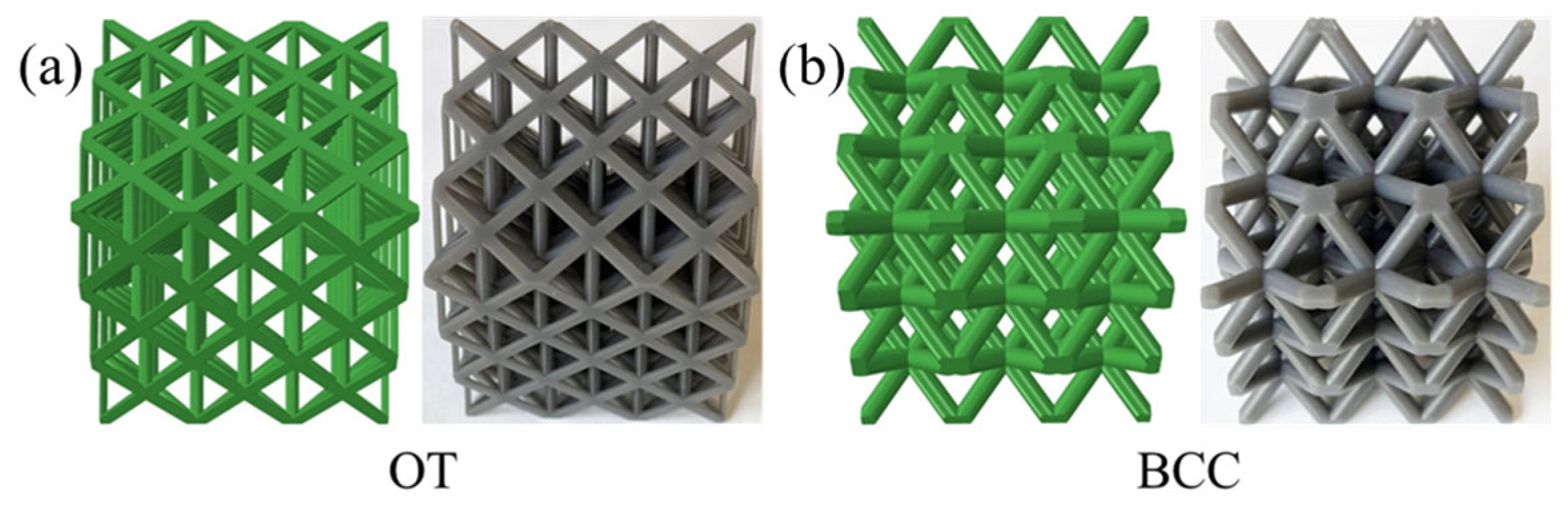

3.2. Preparation of Topology-Optimized Lattice Structure

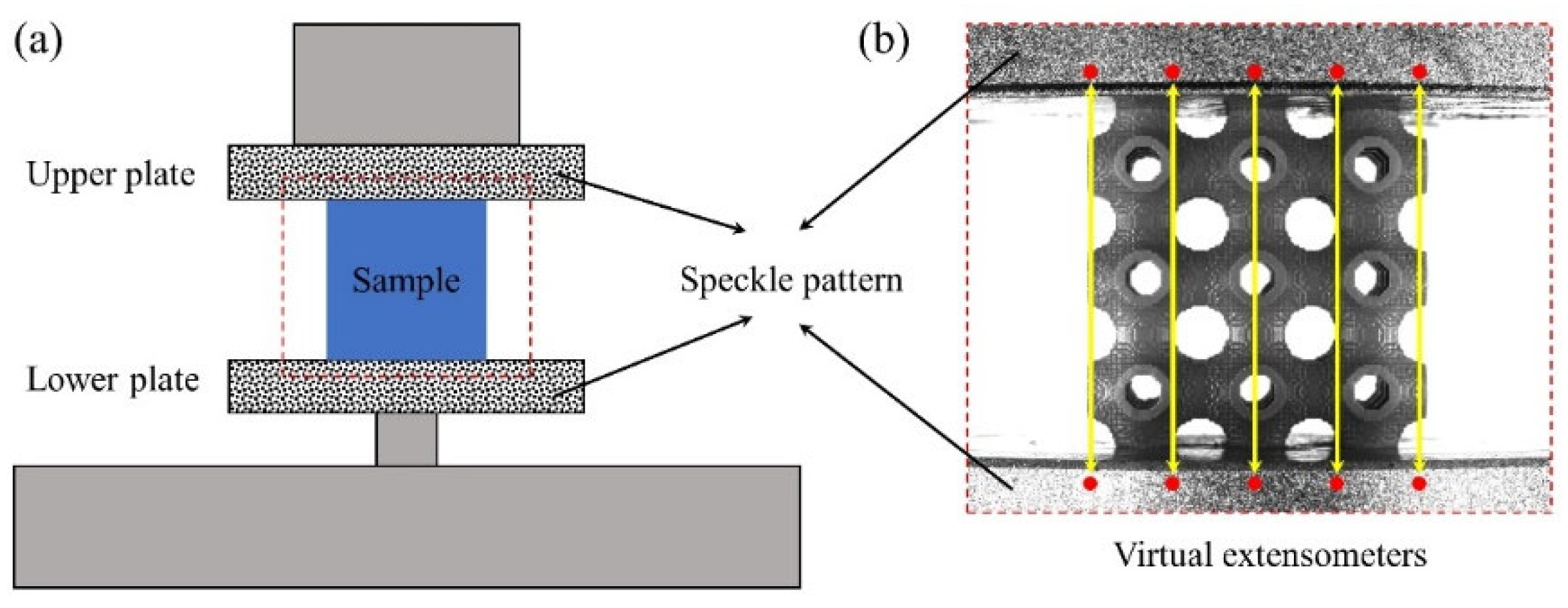

3.3. Compression Tests on the Topology-Optimized Lattice Structures

3.4. Finite Element Analysis

4. Results and Discussion

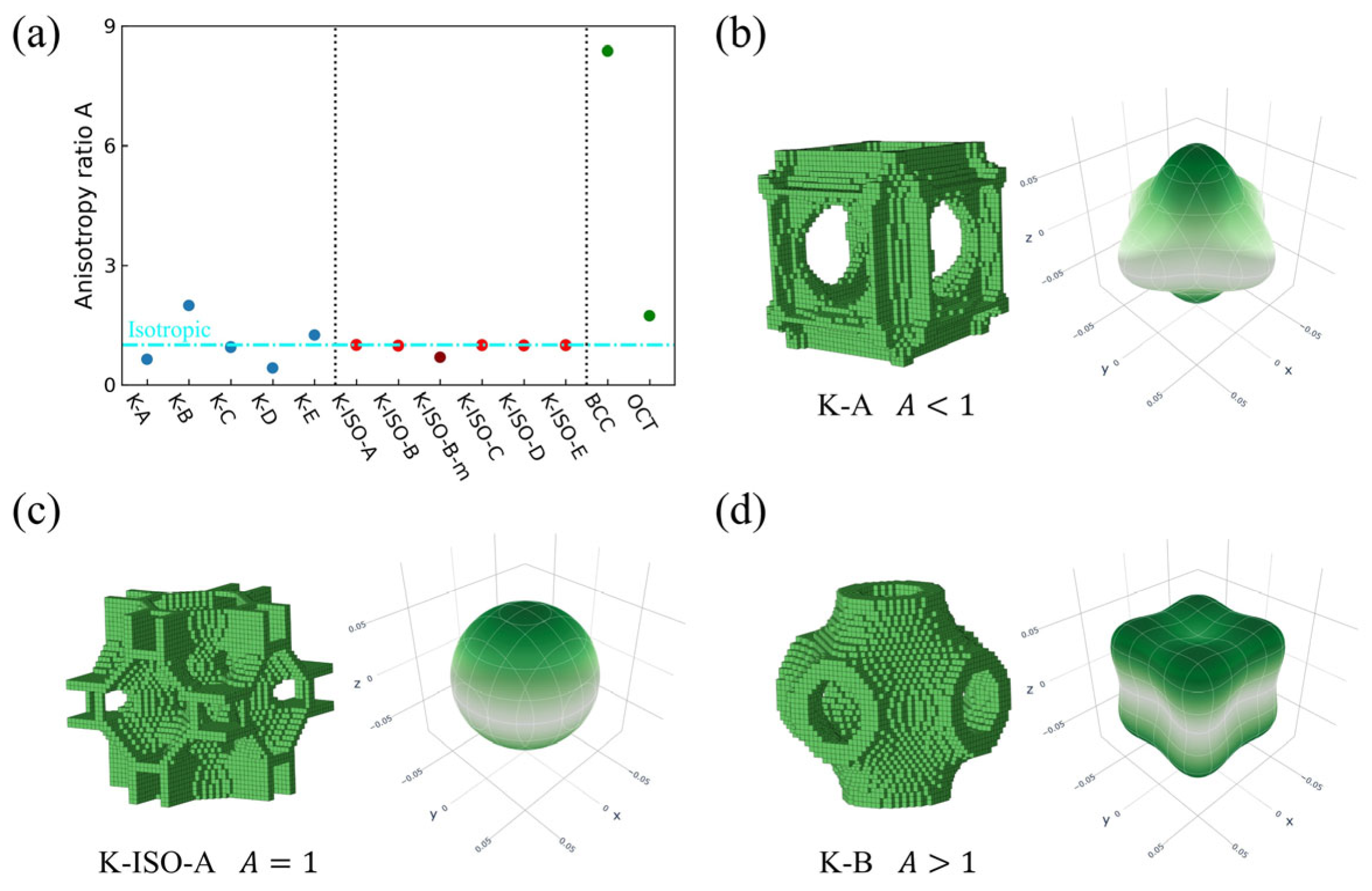

4.1. Elastic Properties of the Topology-Optimized RVEs

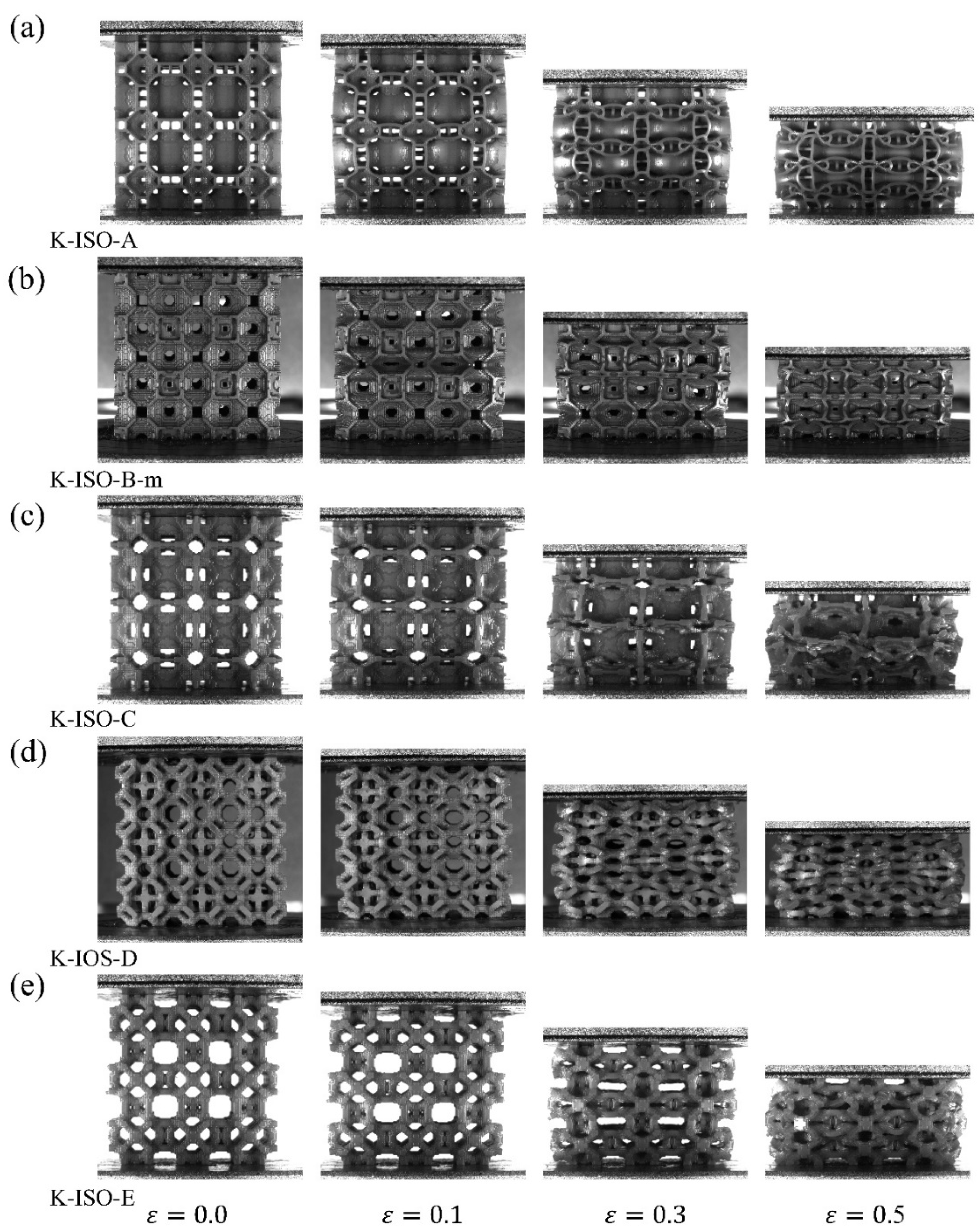

4.2. Quasi Static Experimental Results of Additively Manufactured Lattice Structures

4.3. Mechanical Properties of Topology-Optimized Lattice Structures

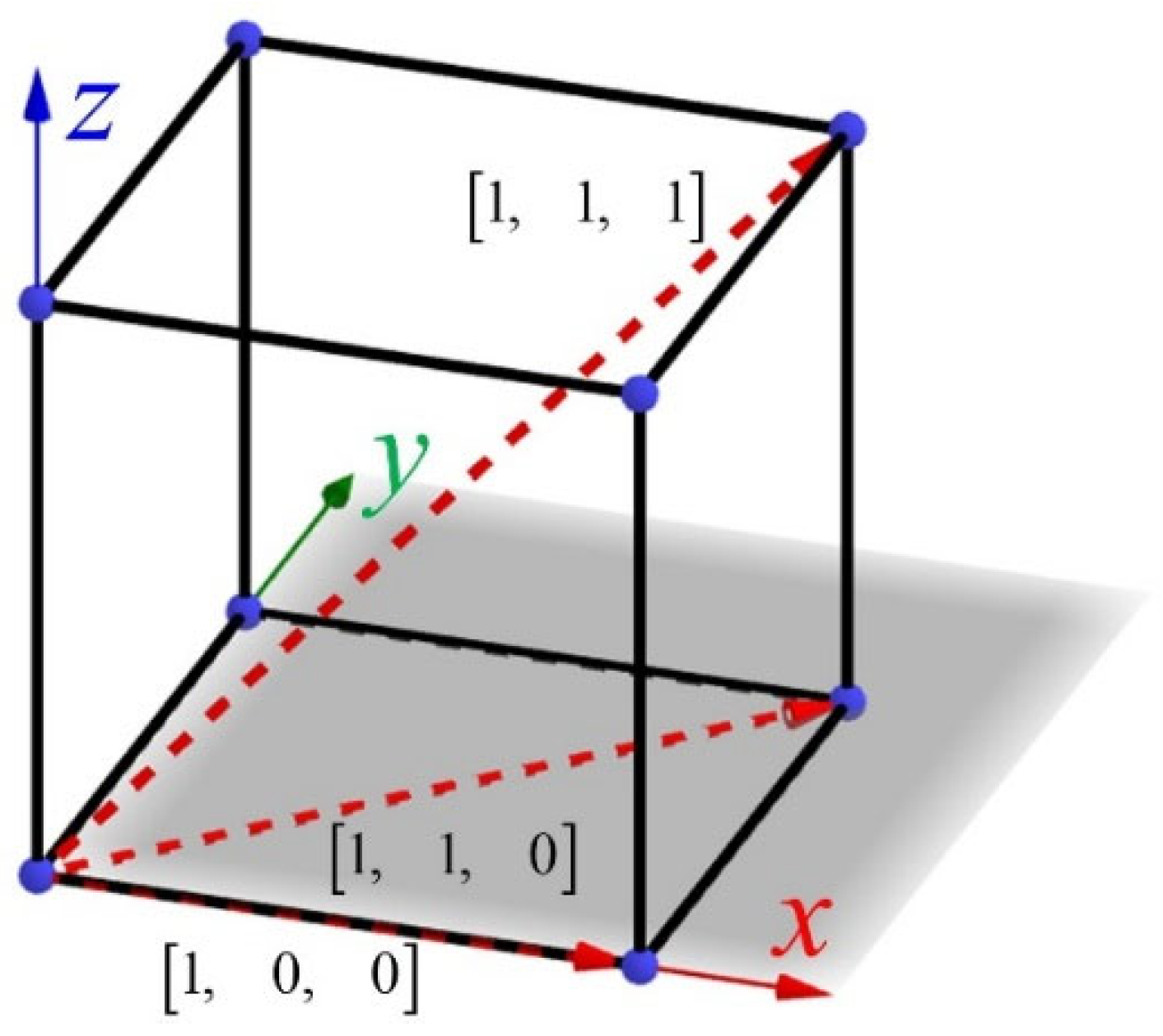

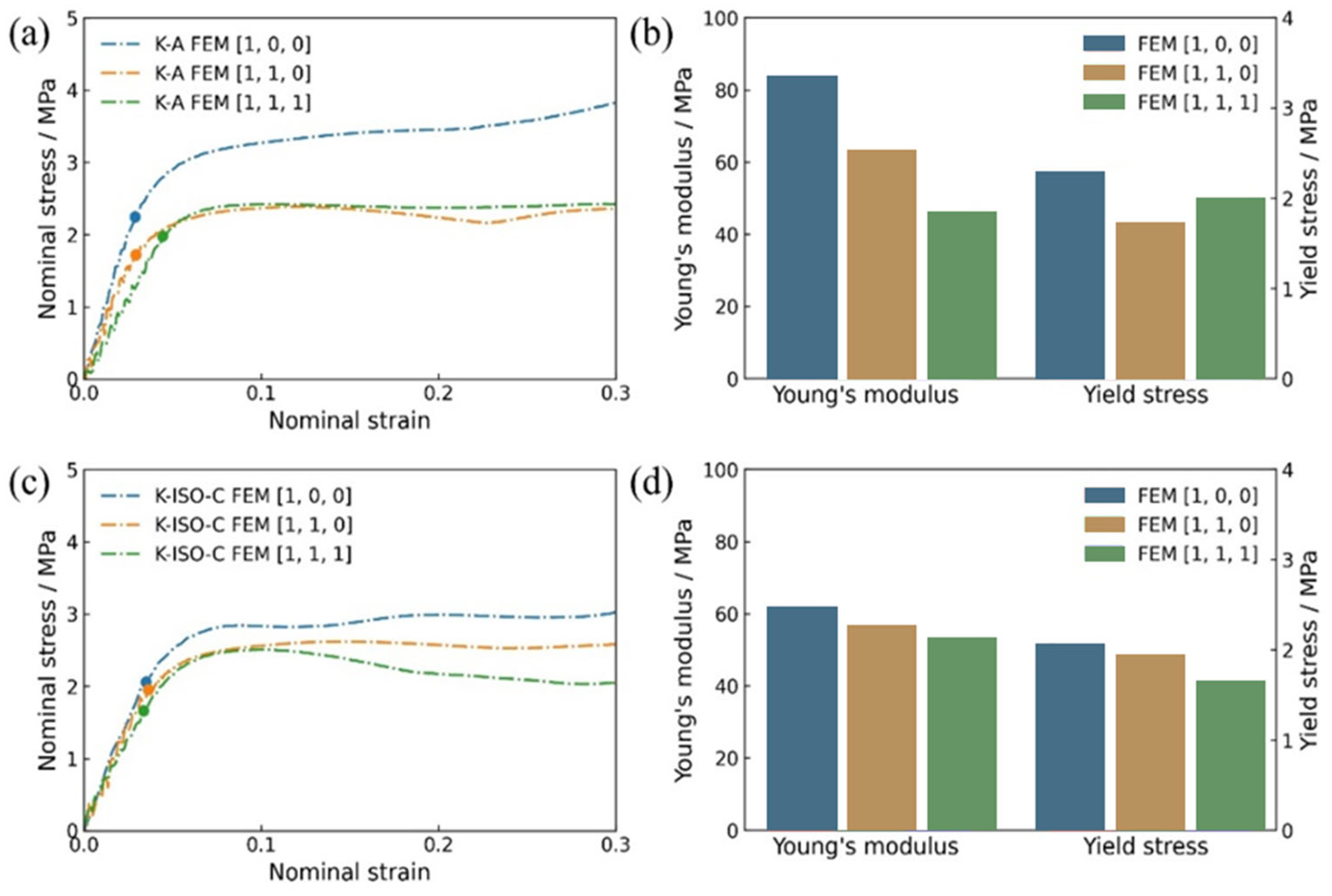

4.4. Direction Dependence of Topology-Optimized Lattice Structures

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| BESO | Bidirectional evolutionary structural optimization |

| SLA | Stereo Lithography Appearance |

| OT | Octet-truss |

| BCC | Body-centered cubic |

| RVE | Representative volume element |

| CFE | Crushing force efficiency |

| SEA | Specific energy absorption |

| FEM | Finite element method |

References

- Berger, J.B.; Wadley, H.N.G.; McMeeking, R.M. Mechanical metamaterials at the theoretical limit of isotropic elastic stiffness. Nature 2017, 543, 533–537. [Google Scholar] [CrossRef]

- Zhang, P.; Yu, P.; Zhang, R.; Chen, X.; Tan, H. Grid octet truss lattice materials for energy absorption. Int. J. Mech. Sci. 2023, 259, 108616. [Google Scholar] [CrossRef]

- Li, Z.; Gao, W.; Wang, M.Y.; Wang, C.H.; Luo, Z. Three-dimensional metamaterials exhibiting extreme isotropy and negative Poisson’s ratio. Int. J. Mech. Sci. 2023, 259, 108617. [Google Scholar] [CrossRef]

- Farrokhabadi, A.; Chronopoulos, D. Composite curved hourglass cellular structures: Design optimization for stiffness response and crashworthiness performance. Compos. Struct. 2024, 330, 117834. [Google Scholar] [CrossRef]

- Song, W.D.; Mu, K.L.; Feng, G.Z.; Huang, Z.; Liu, Y.; Huang, X.; Xiao, L.J. Mechanical properties of 3D printed interpenetrating phase composites with TPMS architectures. Thin-Walled Struct. 2023, 193, 111210. [Google Scholar] [CrossRef]

- Omidi, M.; St-Pierre, L. Fracture toughness of semi-regular lattices. Int. J. Solids. Struct. 2023, 270, 112233. [Google Scholar] [CrossRef]

- Li, C.; Yan, X.; Wan, D.; Yang, G.; Hu, D. Crushing behavior and energy absorption of the thousands-of-eyes-Bodhi-inspired novel hierarchical cellular structure. Compos. Struct. 2023, 311, 116804. [Google Scholar] [CrossRef]

- Xiao, L.J.; Mu, K.L.; Liu, S.; Song, W.D. Experimental study on the fracture behavior of 3D printed interpenetrating phase composites with triply periodic minimal surface architectures. Thin-Walled Struct. 2025, 208, 112847. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, Y.; Yang, F.; Jiang, F.; Xu, F.; Tan, Y.; Su, L. A hybrid architectural metamaterial combing plate lattice and hollow-truss lattice with advanced mechanical performances. Addit. Manuf. 2023, 76, 103764. [Google Scholar] [CrossRef]

- Gharehbaghi, H.; Farrokhabadi, A.; Noroozi, Z. Introducing a new hybrid surface strut-based lattice structure with enhanced energy absorption capacity. Mech. Adv. Mater. Struct. 2024, 31, 2955. [Google Scholar] [CrossRef]

- Weng, Z.; Huang, X.; Peng, S.; Zheng, L.; Wu, L. 3D printing of ultra-high viscosity resin by a linear scan-based vat photopolymerization system. Nat. Commun. 2023, 14, 4303. [Google Scholar] [CrossRef]

- Kang, S.G.; Gainov, R.; Heußen, D.; Bieler, S.; Sun, Z.; Weinberg, K.; Dehm, G.; Ramachandramoorthy, R. Green laser powder bed fusion based fabrication and rate-dependent mechanical properties of copper lattices. Mater. Des. 2023, 231, 112023. [Google Scholar] [CrossRef]

- Song, W.D.; Li, R.Z.; Feng, G.Z.; Xiao, L.J. Dynamic mechanical behaviors and deformation mechanism of hybrid triply periodic minimal surface structures. Int. J. Impact Eng. 2025, 203, 105359. [Google Scholar] [CrossRef]

- Frenzel, T.; Findeisen, C.; Kadic, M.; Gumbsch, P.; Wegener, M. Tailored buckling microlattices as reusable light-weight shock absorbers. Adv. Mater. 2016, 28, 5865–5870. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Lian, X.; Zhu, S.; Li, M.; Wang, B.; Wu, L. A re-usable negative stiffness mechanical metamaterial composed of Bi-material systems for high energy dissipation and shock isolation. Compos. Struct. 2023, 322, 117366. [Google Scholar] [CrossRef]

- Zhao, A.; Liu, C.; Zheng, Y.; Zhang, A.; He, P.; Chen, H.; Wu, G.; Zhang, M.; Wu, T.; Gu, G. Evaluation of shock migration performance for a multi-stable mechanical metamaterial. Compos. Struct. 2023, 321, 117312. [Google Scholar] [CrossRef]

- Meng, Z.; Qin, W.; Mei, T.; Chen, C. Bi-material sinusoidal beam-based temperature responsive multistable metamaterials. Int. J. Solids. Struct. 2023, 277, 112343. [Google Scholar] [CrossRef]

- Li, Y.J.; Gancheva, T.; Estakhrianhaghighi, E.; Favis, B.D.; Akbarzadeh, A. Material extrusion of quaternary co-continuous biopolymers: A strategy for realizing lightweight cellular solids with high impact toughness. Addit. Manuf. 2023, 77, 103805. [Google Scholar] [CrossRef]

- Yang, H.; Ma, L. 1D to 3D multi-stable architected materials with zero Poisson’s ratio and controllable thermal expansion. Mater. Des. 2020, 188, 108430. [Google Scholar] [CrossRef]

- Gross, M.F.; Schneider, J.L.G.; Chen, Y.; Kadic, M.; Wegener, M. Dispersion engineering by hybridizing the back-folded soft mode of monomode elastic metamaterials with stiff acoustic modes. Adv. Mater. 2023, 36, 7553. [Google Scholar]

- Wu, Y.; Fang, J.; Wu, C.; Li, C.; Sun, G.; Li, Q. Additively manufactured materials and structures: A state-of-the-art review on their mechanical characteristics and energy absorption. Int. J. Mech. Sci. 2023, 246, 108102. [Google Scholar] [CrossRef]

- Lan, X.; Yang, S.; Dong, Y.; Wang, Z.; Li, H. Phenomenological methods for defining elasticity and failure of double-arrowhead metamaterials. Int. J. Mech. Sci. 2023, 252, 108361. [Google Scholar] [CrossRef]

- Ravichander, B.; Jagdale, S.H.; Jabed, A.; Kumar, G. Mechanical and corrosion behavior of sheet-based 316L TPMS structures. Int. J. Mech. Sci. 2023, 254, 108439. [Google Scholar] [CrossRef]

- Chai, X.; Ma, Z.; Wu, S.; Shang, H.; Wang, X.; Meng, D. Semi-open discrete mechanical metamaterials and application in robotics. Extreme. Mech. Lett. 2023, 62, 102031. [Google Scholar] [CrossRef]

- Abu-Mualla, M.; Huang, J. Inverse design of 3D cellular materials with physics-guided machine learning. Mater. Des. 2023, 232, 112103. [Google Scholar] [CrossRef]

- Daynes, S. Isotropic cellular structure design strategies based on triply periodic minimal surfaces. Addit. Manuf. 2024, 81, 104010. [Google Scholar] [CrossRef]

- Li, T.T.; Li, Y.N. 3D tiled auxetic metamaterial: A new family of mechanical metamaterial with high resilience and mechanical hysteresis. Adv. Mater. 2024, 935, 2309604. [Google Scholar] [CrossRef]

- Yin, H.; Zhang, W.; Zhu, L.; Meng, F.; Liu, J.; Wen, G. Review on lattice structures for energy absorption properties. Compos. Struct. 2023, 304, 116397. [Google Scholar] [CrossRef]

- Deshpande, V.S.; Ashby, M.F.; Fleck, N.A. Foam topology bending versus stretching dominated architectures. Acta. Mater. 2001, 49, 1035–1040. [Google Scholar] [CrossRef]

- Ha, N.S.; Lu, G. A review of recent research on bio-inspired structures and materials for energy absorption applications. Compos. Part B-Eng. 2020, 181, 107496. [Google Scholar] [CrossRef]

- Reda, H.; Karathanasopoulos, N.; Elnady, K.; Ganghoffer, J.F.; Lakiss, H. The role of anisotropy on the static and wave propagation characteristics of two-dimensional architectured materials under finite strains. Mater. Des. 2018, 147, 134–145. [Google Scholar] [CrossRef]

- Fu, J.; Sun, P.; Du, Y.; Li, H.; Zhou, X.; Tian, Q. Isotropic design and mechanical characterization of TPMS-based hollow cellular structures. Compos. Struct. 2022, 279, 114818. [Google Scholar] [CrossRef]

- Khawale, R.P.; Bhattacharyya, S.; Rai, R.; Dargush, G.F. Efficient dynamic topology optimization of 2D metamaterials based on a complementary energy formulation. Compos. Struct. 2024, 299, 107371. [Google Scholar] [CrossRef]

- Xiao, L.; Li, S.; Song, W.; Xu, X.; Gao, S. Process-induced geometric defect sensitivity of Ti–6Al–4V lattice structures with different mesoscopic topologies fabricated by electron beam melting. Mat. Sci. Eng. A-Struct. 2020, 778, 139092. [Google Scholar] [CrossRef]

- Dong, G.Y.; Tang, Y.L.; Li, D.W.; Zhao, Y.Y.F. Design and optimization of solid lattice hybrid structures fabricated by additive manufacturing. Addit. Manuf. 2020, 33, 101116. [Google Scholar] [CrossRef]

- Li, H.; Liu, R.Y.; Wang, H.J.; Xin, R.L.; Xu, Z.B.; Yu, Z.L. Ant-inspired bionic design method for the support structure of the fengyun-3 satellite payload infilled with lattice structure. Materials 2023, 16, 736. [Google Scholar] [CrossRef]

- Almesmari, A.; Barsoum, I.; Al-Rub, R.K.A. Modelling, optimization, and testing of novel cuboidal spherical plate lattice structures. Virtual. Phys. Prototy 2024, 19, 2308514. [Google Scholar] [CrossRef]

- Yun, K.S. Microstructure design of porous viscoelastic composites with prescribed relaxation moduli by multi-material topology optimization. Int. J. Solids Struct. 2023, 281, 112411. [Google Scholar] [CrossRef]

- Liu, H.; Chen, L.; Shi, T.; Xia, Q. M-VCUT level set method for the layout and shape optimization of stiffeners in plate. Compos. Struct. 2022, 293, 115614. [Google Scholar] [CrossRef]

- Feppon, F. Density-based topology optimization with the null space optimizer: A tutorial and a comparison. Struct. Multidiscip. Optim. 2024, 67, 4. [Google Scholar] [CrossRef]

- Sigmund, O. Materials with prescribed constitutive parameters-an inverse homogenization problem. Int. J. Solids Struct. 1994, 31, 2313–2329. [Google Scholar] [CrossRef]

- Zheng, J.; Zhu, S.F.; Soleymani, F. A new efficient parametric level set method based on radial basis function-finite difference for structural topology optimization. Compos. Struct. 2024, 297, 107364. [Google Scholar] [CrossRef]

- Guibert, A.T.R.; Bookwala, M.; Kim, H.A. Level-set topology optimization of heat sinks with phase-change material. Int. J. Heat. Mass. Tran. 2024, 231, 125818. [Google Scholar] [CrossRef]

- Wang, Y.; Luo, Z.; Zhang, N.; Qin, Q. Topological shape optimization of multifunctional tissue engineering scaffolds with level set method. Struct. Multidiscip. Optim. 2016, 54, 333–347. [Google Scholar] [CrossRef]

- Yang, J.S.; Chen, J.B.; Beer, M. Seismic topology optimization considering first-passage probability by incorporating probability density evolution method and bi-directional evolutionary structural optimization. Eng. Struct. 2024, 314, 118382. [Google Scholar] [CrossRef]

- Yan, X.; Xu, Q.; Hua, H.; Huang, W.; Huang, X. Concurrent optimization of macrostructures and material microstructures and orientations for maximizing natural frequency. Eng. Struct. 2020, 209, 109997. [Google Scholar] [CrossRef]

- Rostami, P.; Marzbanrad, J. Hybrid algorithms for handling the numerical noise in topology optimization. Acta Mech. Sin. 2020, 36, 536. [Google Scholar] [CrossRef]

- Guo, X.; Zhang, W.; Zhang, J.; Yuan, J. Explicit structural topology optimization based on moving morphable components (MMC) with curved skeletons. Comput. Methods Appl. Mech. Eng. 2016, 310, 711–748. [Google Scholar] [CrossRef]

- Du, Y.; Li, H.; Luo, Z.; Tian, Q. Topological design optimization of lattice structures to maximize shear stiffness. Adv. Eng. Softw. 2017, 112, 211–221. [Google Scholar] [CrossRef]

- Li, H.; Yao, B.; Li, Z.; Peng, Y.; Fan, H. Compressive properties and deformation mechanism of selective laser melting of Ti6Al4V porous femoral implants based on topological optimization. Compos. Struct. 2023, 321, 117326. [Google Scholar] [CrossRef]

- Xiao, Z.F.; Yang, Y.Q.; Xiao, R.; Bai, Y.C.; Song, C.H.; Wang, D. Evaluation of topology-optimized lattice structures manufactured via selective laser melting. Mater. Des. 2018, 143, 27. [Google Scholar] [CrossRef]

- Alkhatib, S.E.; Karrech, A.; Sercombe, T.B. Isotropic energy absorption of topology optimized lattice structure. Thin-Walled Struct. 2018, 143, 27. [Google Scholar] [CrossRef]

- Wang, W.M.; Feng, D.W.; Yang, L.; Li, S.; Wang, L.C. Topology optimization of self-supporting lattice structure. Addit. Manuf. 2023, 67, 103507. [Google Scholar] [CrossRef]

- Carstensen, J.V.; Lotfi, R.; Chen, W.; Szyniszewski, S.; Gaitanaros, S.; Schroers, J.; Guest, J.K. Topology-optimized bulk metallic glass cellular materials for energy absorption. Scr. Mater. 2021, 208, 114361. [Google Scholar] [CrossRef]

- Chen, L.; Che, J.J.; Liang, S.X.; Wang, Y.J. Multiscale topology optimization of gradient lattice structure based on volume parametric modeling. Compos. Struct. 2024, 328, 117746. [Google Scholar] [CrossRef]

- Daynes, S. High stiffness topology optimized lattice structures with increased toughness by porosity constraints. Mater. Des. 2023, 232, 112183. [Google Scholar] [CrossRef]

- Bao, Y.H.; Wei, Z.S.; Jia, Z.Y.; Wang, D.Z.; Zhang, X.P.; Kang, Z. Mechanical metamaterial design with the customized low-frequency bandgap and negative Poisson’s ratio via topology optimization. Extreme. Mech. Lett. 2024, 67, 102124. [Google Scholar] [CrossRef]

- Radman, A. Combination of BESO and harmony search for topology optimization of microstructures for materials. Appl. Math. Model. 2021, 90, 650. [Google Scholar] [CrossRef]

- Zhao, M.; Li, X.W.; Zhang, D.Z.; Zhai, W. Geometry effect on mechanical properties and elastic isotropy optimization of bamboo-inspired lattice structures. Addit. Manuf. 2023, 64, 103438. [Google Scholar] [CrossRef]

- Jiang, F.; Seetoh, L.P.; Lee, H.; Lim, G.Y.; Lim, D.K.J.; Singham, J.; Qi, C.; Lai, C.Q. Compound nested lattices with programmable isotropy and elastic stiffness up to the theoretical limit. Compos. Part B-Eng. 2024, 284, 111656. [Google Scholar] [CrossRef]

- Takezawa, A.; Yonekura, K.; Koizumi, Y.; Zhang, X.P.; Kitamura, M. Isotropic Ti–6Al–4V lattice via topology optimization and electron-beam melting. Addit. Manuf. 2018, 22, 634. [Google Scholar] [CrossRef]

- Gao, J.; Li, H.; Luo, Z.; Gao, L.; Li, P. Topology optimization of micro-structured materials featured with the specific mechanical properties. Int. J. Comput. Methods 2020, 17, 1850144. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, Y.; Lu, X.; Liao, Z.; Qu, J. Evolutionary topology optimization for mechanical metamaterials with auxetic property. Int. J. Mech. Sci. 2020, 179, 105638. [Google Scholar] [CrossRef]

- Song, J.; Wang, Y.; Zhou, W.; Fan, R.; Yu, B.; Lu, Y.; Li, L. Topology optimization-guided lattice composites and their mechanical characterizations. Compos. Part B-Eng. 2018, 160, 402–411. [Google Scholar] [CrossRef]

- Mao, H.; Rumpler, R.; Göransson, P. An inverse method for characterisation of the static elastic Hooke’s tensors of solid frame of anisotropic open-cell materials. Int. J. Eng. Sci. 2020, 147, 103198. [Google Scholar] [CrossRef]

- Belardi, V.G.; Trupiano, S.; Fanelli, P.; Vivio, F. Overall elastic characterization of equivalent FE models for aluminum foams through computational homogenization approach and genetic algorithm optimization. Eur. J. Mech.-A/Solids 2024, 103, 105189. [Google Scholar] [CrossRef]

- Zhao, M.; Cui, J.M.; Chen, L.; Jin, K.Y.; Zeng, Z. Enhanced mechanical properties and energy absorption of lattice metamaterials inspired by crystal imperfections. Compos. Struct. 2025, 356, 118894. [Google Scholar] [CrossRef]

- Intrigila, C.; Micheletti, A.; Nodargi, N.A.; Bisegna, P. Mechanical response of multistable tensegrity-like lattice chains. Addit. Manuf. 2023, 74, 103724. [Google Scholar] [CrossRef]

- Guedes, J.M.; Kikuchi, N. Preprocessing and postprocessing for materials based on the homogenization method with adaptive finite element methods. Comput. Methods Appl. Mech. Eng. 1990, 83, 143. [Google Scholar] [CrossRef]

- Hollister, S.J.; Kikuchi, N. Homogenization theory and digital imaging: A basis for studying the mechanics and design principles of bone tissue. Biotechnol. Bioeng. 2010, 43, 586. [Google Scholar] [CrossRef]

- Khdir, Y.K.; Kanit, T.; Zaïri, F.; Naït-Abdelaziz, M. Computational homogenization of elastic–plastic composites. Int. J. Solids Struct. 2013, 50, 2829. [Google Scholar] [CrossRef]

- Duan, S.; Xi, L.; Wen, W.; Fang, D. Mechanical performance of topology-optimized 3D lattice materials manufactured via selective laser sintering. Compos. Struct. 2020, 238, 111985. [Google Scholar] [CrossRef]

- Bonatti, C.; Mohr, D. Large deformation response of additively-manufactured FCC metamaterials: From octet truss lattices towards continuous shell mesostructures. Int. J. Plast. 2017, 92, 122–147. [Google Scholar] [CrossRef]

- Zhang, J.; Xie, S.C.; Jing, K.K.; Wang, H.; Li, T.; He, G.D. Study on isotropic design of triply periodic minimal surface structures under an elastic modulus compensation mechanism. Compos. Struct. 2024, 342, 118266. [Google Scholar] [CrossRef]

- Huang, X.; Radman, A.; Xie, Y.M. Topological design of microstructures of cellular materials for maximum bulk or shear modulus. Comp. Mater. Sci. 2011, 50, 1861–1870. [Google Scholar] [CrossRef]

- Huang, X.; Xie, Y. Convergent and mesh-independent solutions for the bi-directional evolutionary structural optimization method. Finite Elem. Anal. Des. 2007, 43, 1039–1049. [Google Scholar] [CrossRef]

- Huang, X.; Xie, Y. Evolutionary topology optimization of continuum structures with an additional displacement constraint. Struct. Multidiscip. Optim. 2010, 40, 409–416. [Google Scholar] [CrossRef]

- Radman, A.; Huang, X.; Xie, Y.M. Topological optimization for the design of microstructures of isotropic cellular materials. Eng. Optim. 2013, 45, 1331–1348. [Google Scholar] [CrossRef]

- Tancogne-Dejean, T.; Mohr, D. Elastically-isotropic truss lattice materials of reduced plastic anisotropy. Int. J. Solids Struct. 2018, 138, 24–39. [Google Scholar] [CrossRef]

- Wang, J.H.; Liu, X.M.; Wang, Y. Topology optimization of micro-channel reactors using an improved multi-objective algorithm. Chem. Eng. J. 2023, 458, 141420. [Google Scholar] [CrossRef]

- Yu, S.; Sun, J.; Bai, J. Investigation of functionally graded TPMS structures fabricated by additive manufacturing. Mater. Des. 2019, 182, 108021. [Google Scholar] [CrossRef]

- Yu, G.J.; Xiao, L.J.; Song, W.D. Deep learning-based heterogeneous strategy for customizing responses of lattice structures. Int. J. Mech. Sci. 2022, 229, 107531. [Google Scholar] [CrossRef]

- Gaillac, R.; Pullumbi, P.; Coudert, F.X. ELATE: An open-source online application for analysis and visualization of elastic tensors. J. Phys. Condens. Matter 2016, 28, 275201. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Gu, D.D.; Yuan, L.H.; Shi, X.Y.; Shi, K.Y.; Sun, J.F.; Chen, W.X.; Wang, J. Topological optimisation and laser additive manufacturing of force-direction-sensitive NiTi porous structures with large deformation recovery behavior. Virtual Phys. Prototyp. 2024, 19, 5249. [Google Scholar] [CrossRef]

- Ma, S.Y.; Zhu, R.Q.; Yang, S.; Yang, Q.D.; Wei, K.; Qu, Z.L. Influence of geometric imperfections on the mechanical behavior for Invar 36 alloy lattice structures fabricated by selective laser melting. Int. J. Mech. Sci. 2024, 274, 109252. [Google Scholar] [CrossRef]

- Zhao, M.; Zhang, D.Z.; Li, Z.; Zhang, T.; Zhou, H.; Ren, Z. Design, mechanical properties, and optimization of BCC lattice structures with taper struts. Compos. Struct. 2022, 295, 115830. [Google Scholar] [CrossRef]

| Topology | Number | Measured Dimensions (mm) | Mass (g) |

|---|---|---|---|

| K-A | 1 | 36.78 × 36.37 × 36.36 | 12.20 |

| 2 | 36.75 × 36.37 × 36.40 | 12.19 | |

| K-B | 1 | 36.22 × 36.64 × 36.17 | 12.16 |

| 2 | 36.24 × 36.50 × 36.15 | 12.16 | |

| K-C | 1 | 36.55 × 36.50 × 36.49 | 12.03 |

| 2 | 36.32 × 35.47 × 36.20 | 12.07 | |

| K-D | 1 | 36.34 × 36.34 × 36.33 | 12.05 |

| 2 | 36.30 × 36.34 × 36.26 | 12.12 | |

| K-E | 1 | 36.26 × 36.51 × 36.26 | 12.19 |

| 2 | 36.26 × 36.43 × 36.17 | 12.14 | |

| K-ISO-A | 1 | 36.65 × 36.76 × 36.28 | 12.15 |

| 2 | 36.66 × 36.78 × 36.18 | 12.08 | |

| K-ISO-B-m | 1 | 36.40 × 36.56 × 36.19 | 12.10 |

| 2 | 36.47 × 36.52 × 36.28 | 12.07 | |

| K-ISO-C | 1 | 36.30 × 36.42 × 36.09 | 12.18 |

| 2 | 36.41 × 36.50 × 36.12 | 12.12 | |

| K-ISO-D | 1 | 36.23 × 36.37 × 36.05 | 12.10 |

| 2 | 36.30 × 36.37 × 36.12 | 12.11 | |

| K-ISO-E | 1 | 36.18 × 36.34 × 36.18 | 11.97 |

| 2 | 36.21 × 36.36 × 36.20 | 12.01 | |

| OT | 1 | 36.15 × 36.19 × 36.14 | 12.01 |

| 2 | 36.19 × 36.36 × 36.17 | 12.05 | |

| BCC | 1 | 36.30 × 36.37 × 36.22 | 11.80 |

| 2 | 36.24 × 36.29 × 36.24 | 11.95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, W.; Zhao, L.; Liu, J.; Liu, S.; Yu, G.; Qin, B.; Xiao, L. Mechanical Behavior of Topology-Optimized Lattice Structures Fabricated by Additive Manufacturing. Materials 2025, 18, 3614. https://doi.org/10.3390/ma18153614

Song W, Zhao L, Liu J, Liu S, Yu G, Qin B, Xiao L. Mechanical Behavior of Topology-Optimized Lattice Structures Fabricated by Additive Manufacturing. Materials. 2025; 18(15):3614. https://doi.org/10.3390/ma18153614

Chicago/Turabian StyleSong, Weidong, Litao Zhao, Junwei Liu, Shanshan Liu, Guoji Yu, Bin Qin, and Lijun Xiao. 2025. "Mechanical Behavior of Topology-Optimized Lattice Structures Fabricated by Additive Manufacturing" Materials 18, no. 15: 3614. https://doi.org/10.3390/ma18153614

APA StyleSong, W., Zhao, L., Liu, J., Liu, S., Yu, G., Qin, B., & Xiao, L. (2025). Mechanical Behavior of Topology-Optimized Lattice Structures Fabricated by Additive Manufacturing. Materials, 18(15), 3614. https://doi.org/10.3390/ma18153614