2.1. Experiment Method

The main chemical composition of AISI 304 stainless steel (Castle Metals, Oak Brook, IL, USA) is shown in

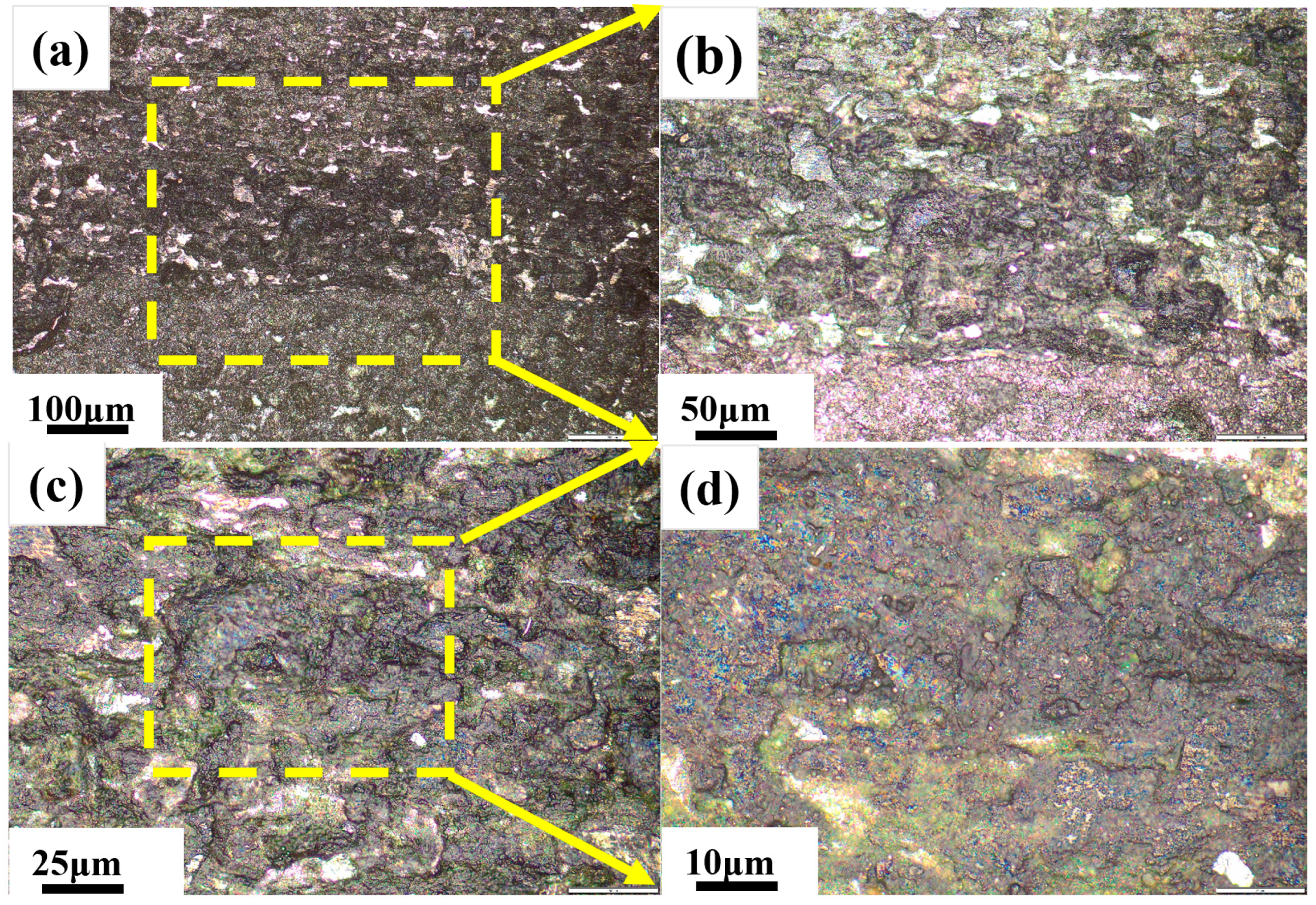

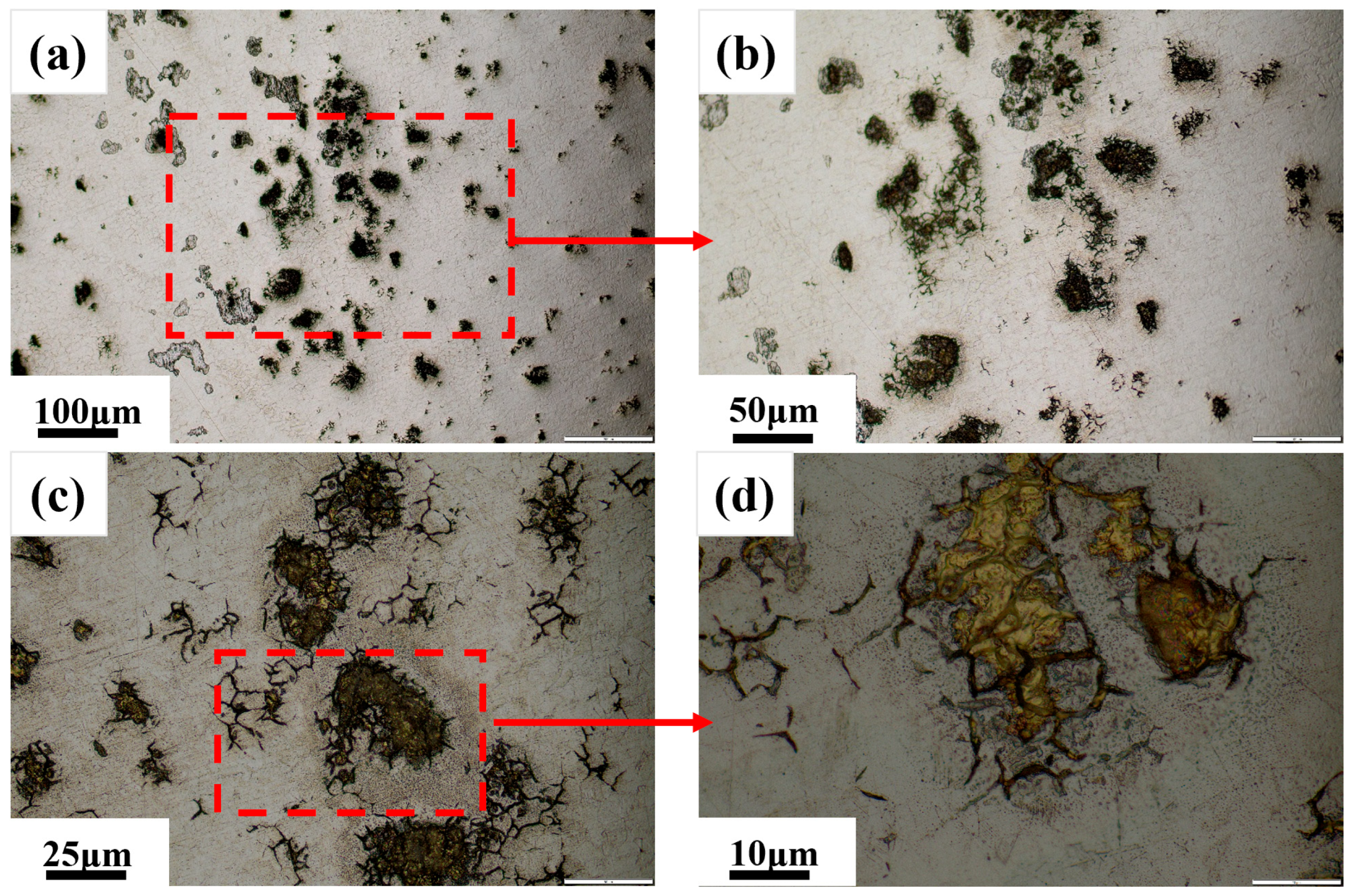

Table 1. Firstly, hot-rolled steel sheets containing visible dark band defects were subjected to macroscopic analysis, as shown in

Figure 1a. For the macroscopic and microstructural investigation, representative specimens (10 mm × 10 mm × 3 mm) were extracted from the defective white-hot-rolled sheet using wire electrode cutting, following the sampling schematic shown in

Figure 1b. Three specimens were sectioned along the rolling direction from the upper, middle, and lower regions of the defect-containing area. Secondly, the as-cut specimens were initially examined using an optical microscope (OLYMPUS, Tokyo, Japan) without surface preparation to document their macroscopic features. Subsequently, sequential preparation was required for microscopic analysis: the specimens were gently ground to achieve the partial removal of the thin defective layer and chemically etched in a 20% HCl (Sinopharm Group, Shanghai, China) solution for approximately 10 s, then thoroughly rinsed with anhydrous ethanol (Sinopharm Group, Shanghai, China) and dried with compressed air before re-examination under the optical microscope.

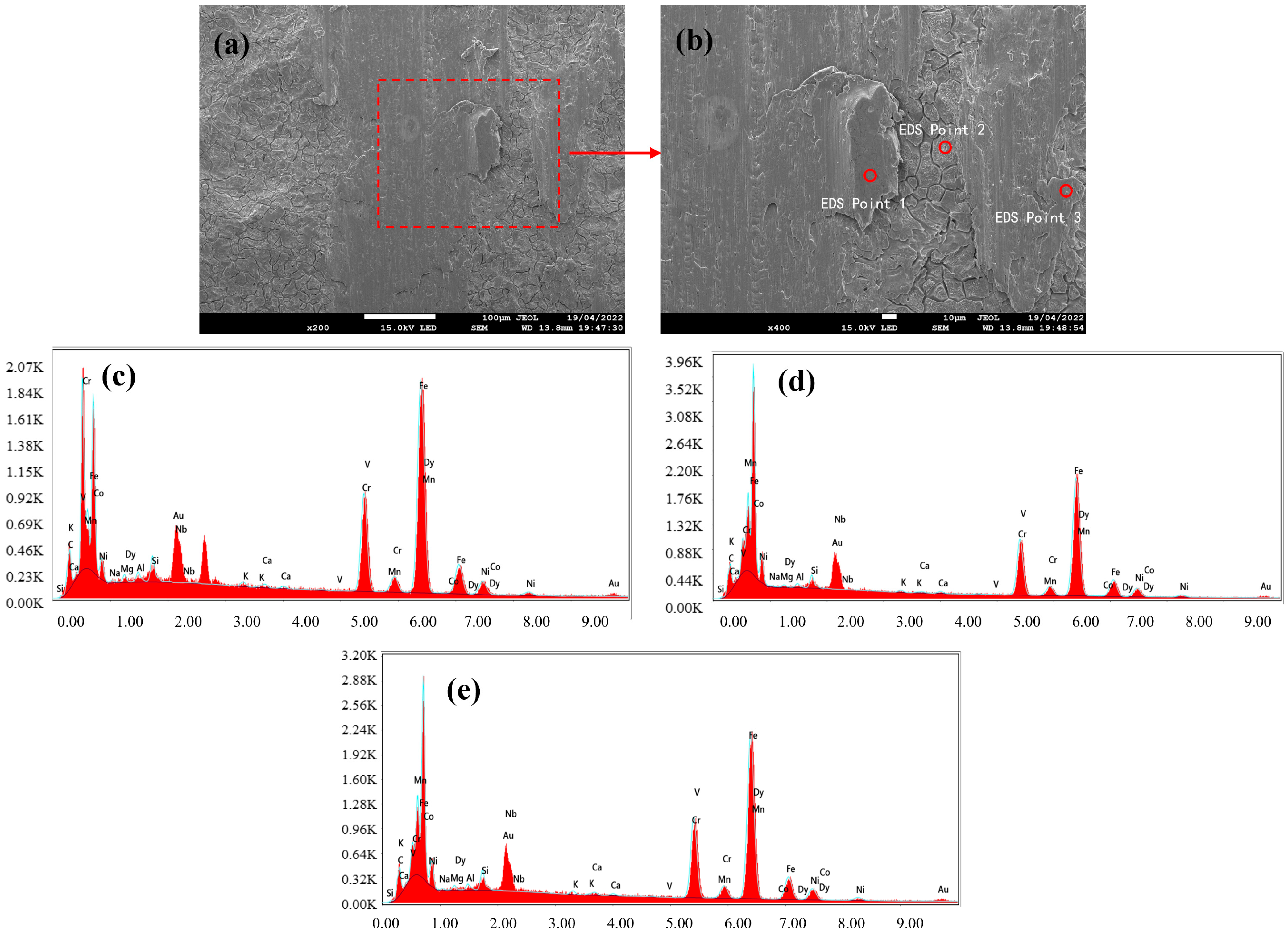

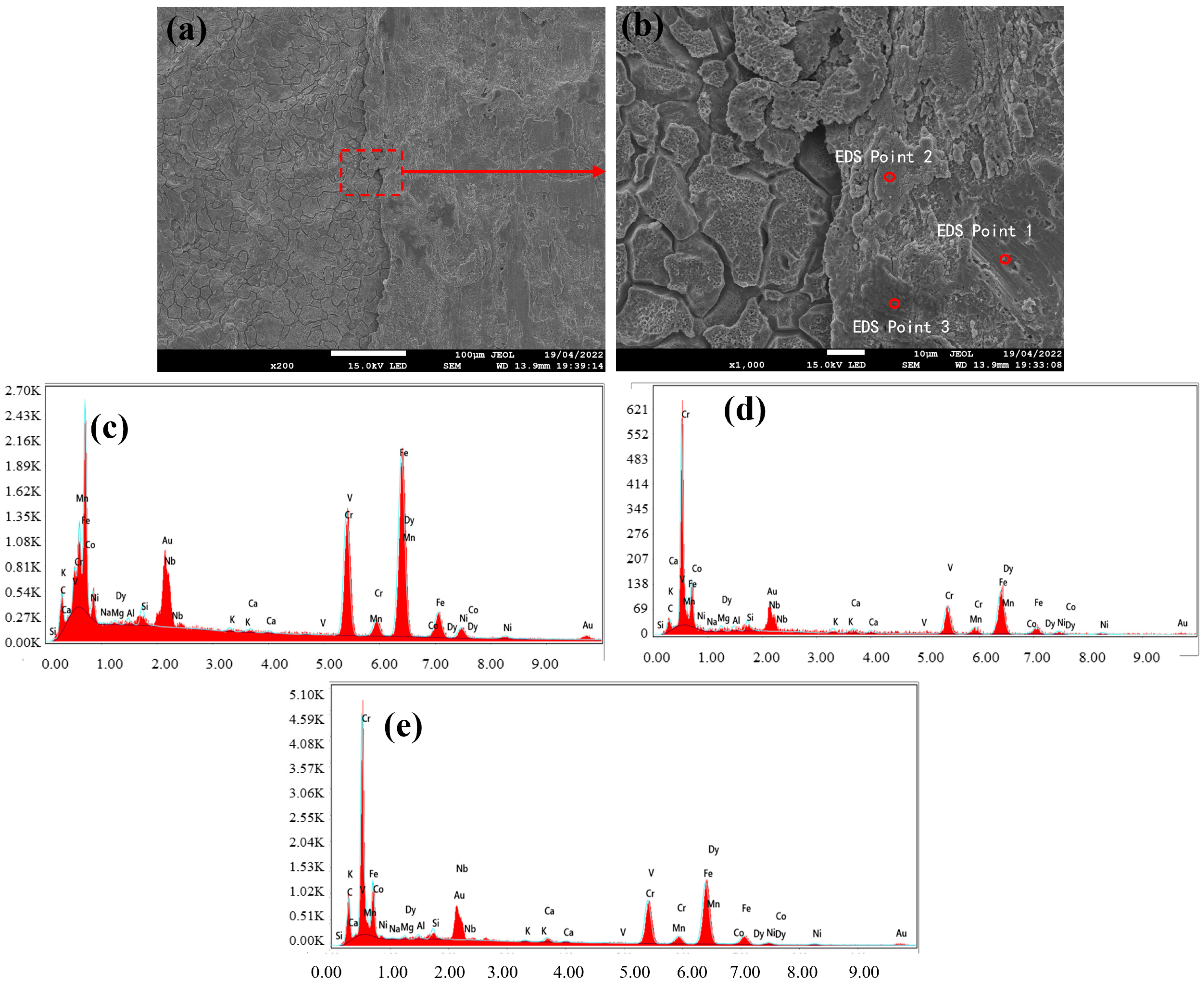

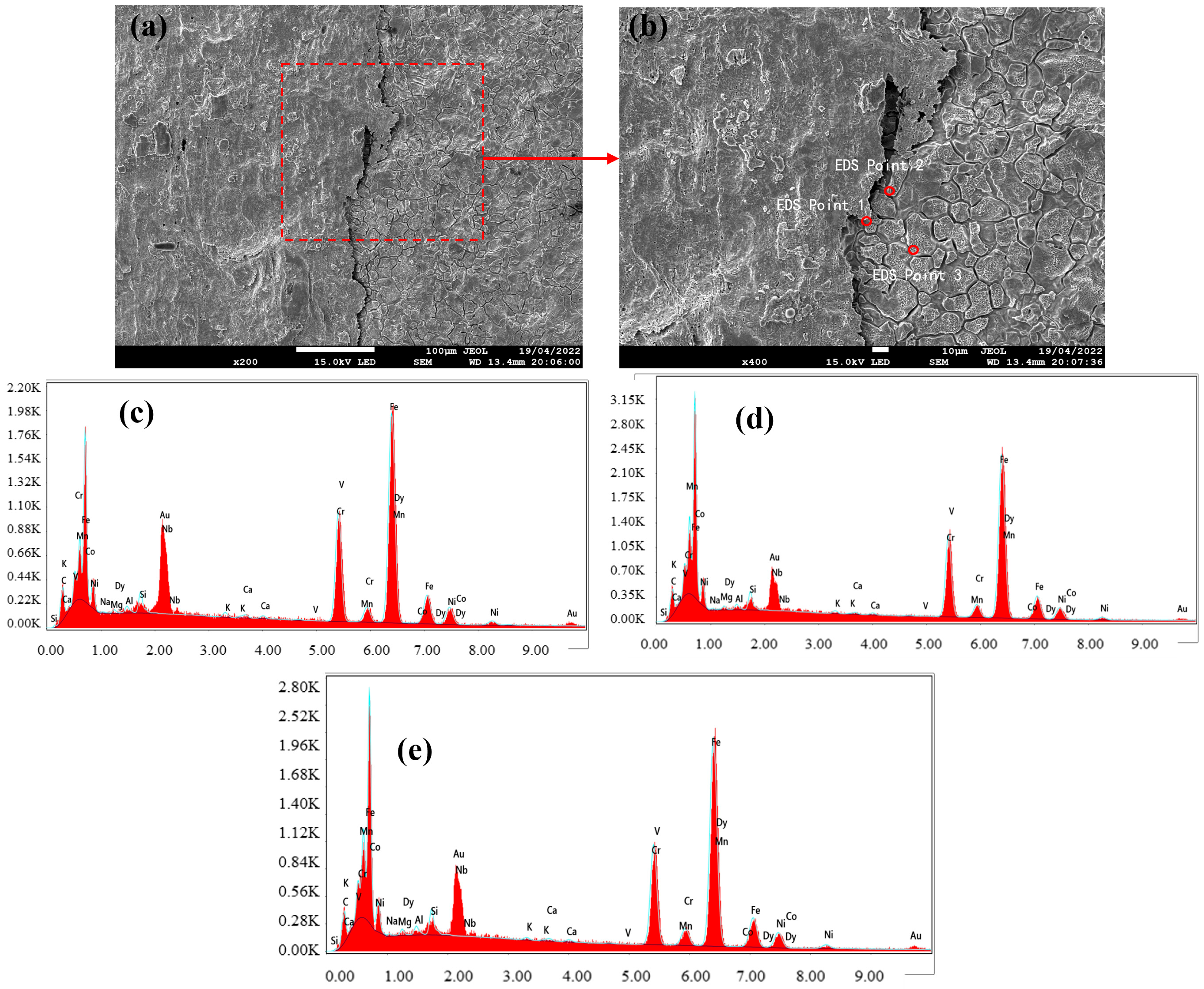

Additionally, for compositional analysis, the characterized specimens were transferred to a field emission scanning electron microscope equipped with energy-dispersive spectroscopy (SEM and EDS) equipment. And the SEM and EDS equipment were provided by Hitachi, Tokyo, Japan. Multiple spot analyses were performed on the defect zones to determine the elemental distributions and identify the potential causes of the black streaks’ formation.

2.2. Mathematic Method

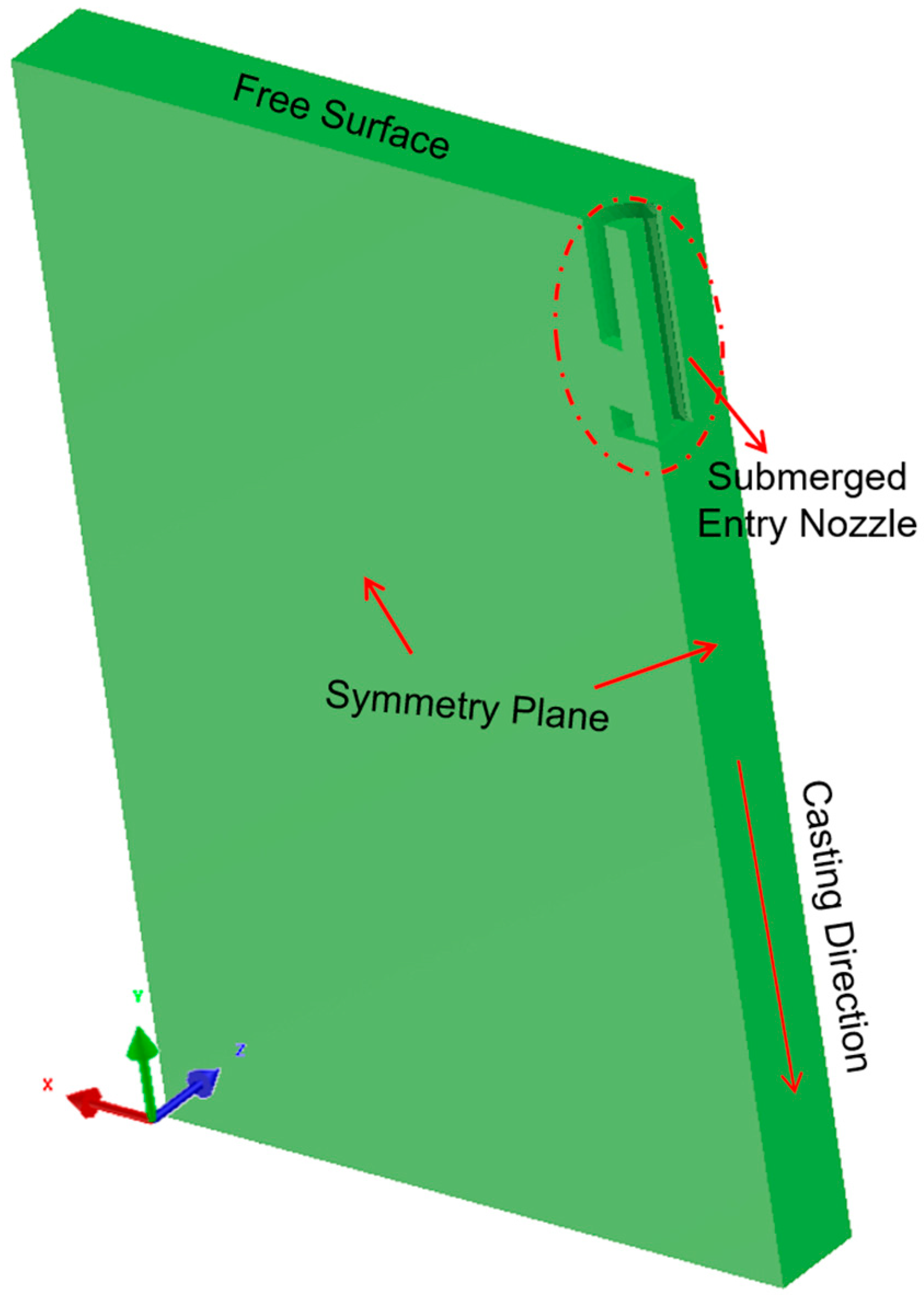

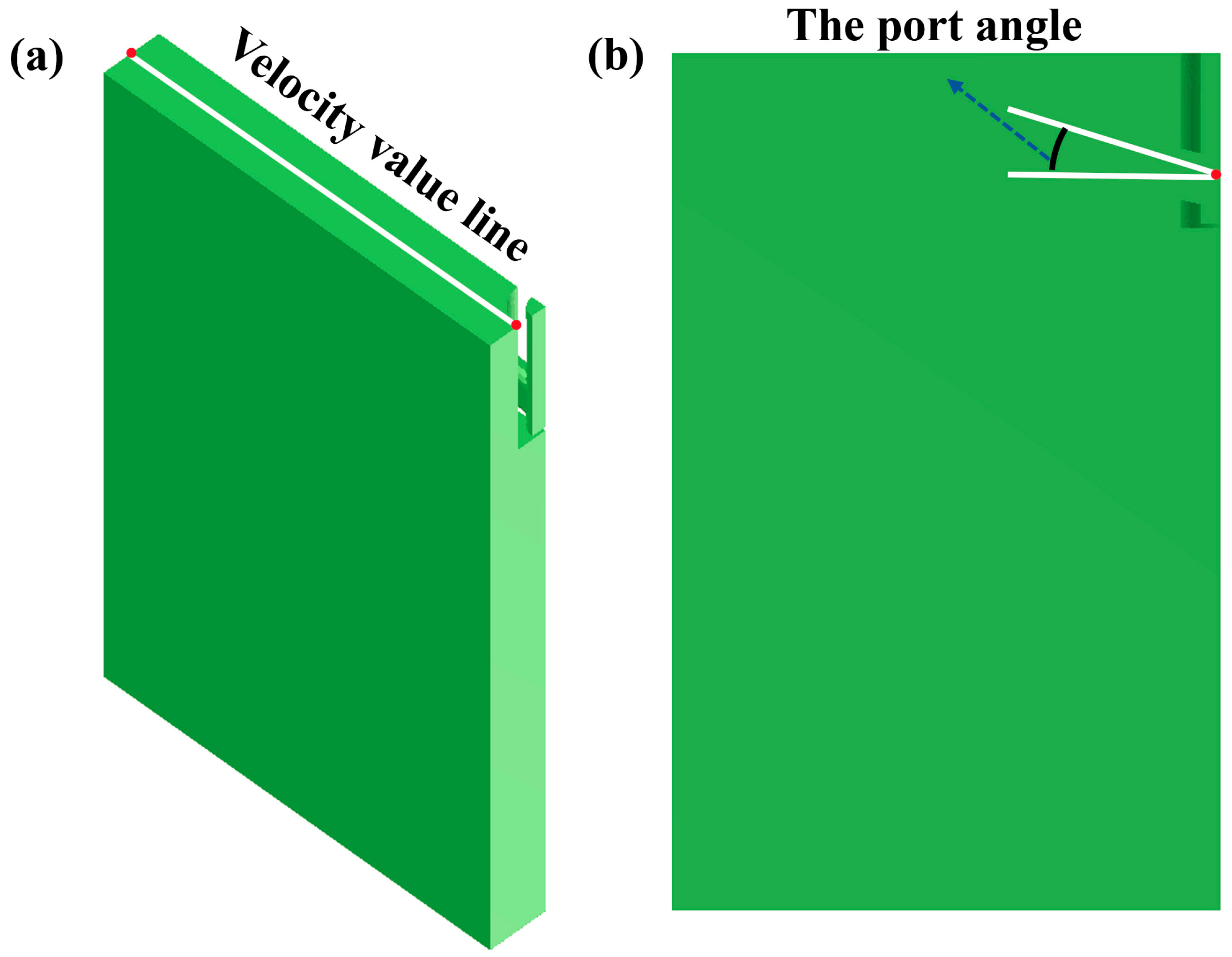

A three-dimensional computational model was developed to investigate the effects of the continuous casting process parameters on the flow field, temperature distribution, and free surface velocity of molten steel. Based on the simulation results, the process parameters were optimized to minimize defect formation. A quarter-symmetry CAD model (

Figure 2) was adopted to reduce the computational effort [

22].

The following assumptions were implemented:

(I) The complex heat transfer at the curved mold meniscus was not subjected to any additional special treatments.

(II) The effects of mold oscillation, the curvature, and electromagnetic stirring on the melt flow and heat transfer were considered by incorporating the equivalent thermal conductivity and heat transfer coefficient.

The three-dimensional incompressible viscous flow of molten steel within the mold was governed by the fundamental conservation laws of mass, momentum, and energy. The mathematical framework comprised the continuity equation, momentum equation, energy equation, and

quation, as shown in Equations (1)–(5) [

23,

24,

25]. The specific formulations are expressed as follows:

where

ρ is the melt density, kg/m

3, and

is the melt velocity, m/s.

is the velocity in the

j direction, m/s, and

is the distance in the

j direction, m.

is the velocity in the

i direction, m/s, and

is the distance in the i direction, m. The pressure, Pa, is expressed as

P, and the effective viscosity coefficient, kg/(m·s), is expressed as

. The enthalpy is expressed as

h, kJ/mol; the thermal conductivity and turbulent thermal conductivity are expressed as

, W/(m·°C); the node’s temperature is expressed as

T; the latent heat of fusion is expressed as

, J/Kg; and the volume fraction of the liquid is expressed as

. The turbulent kinetic energy is expressed as

K, J;

is the dissipation rate of the turbulent kinetic energy, W/m

3;

C1 and

C2 are empirical constants with values of 1.44 and 1.92; and

and

are empirical constants with values of 1.0 and 1.3.

The temperature-dependent thermo-physical properties were calculated based on the Fe database in the software (2018) used [

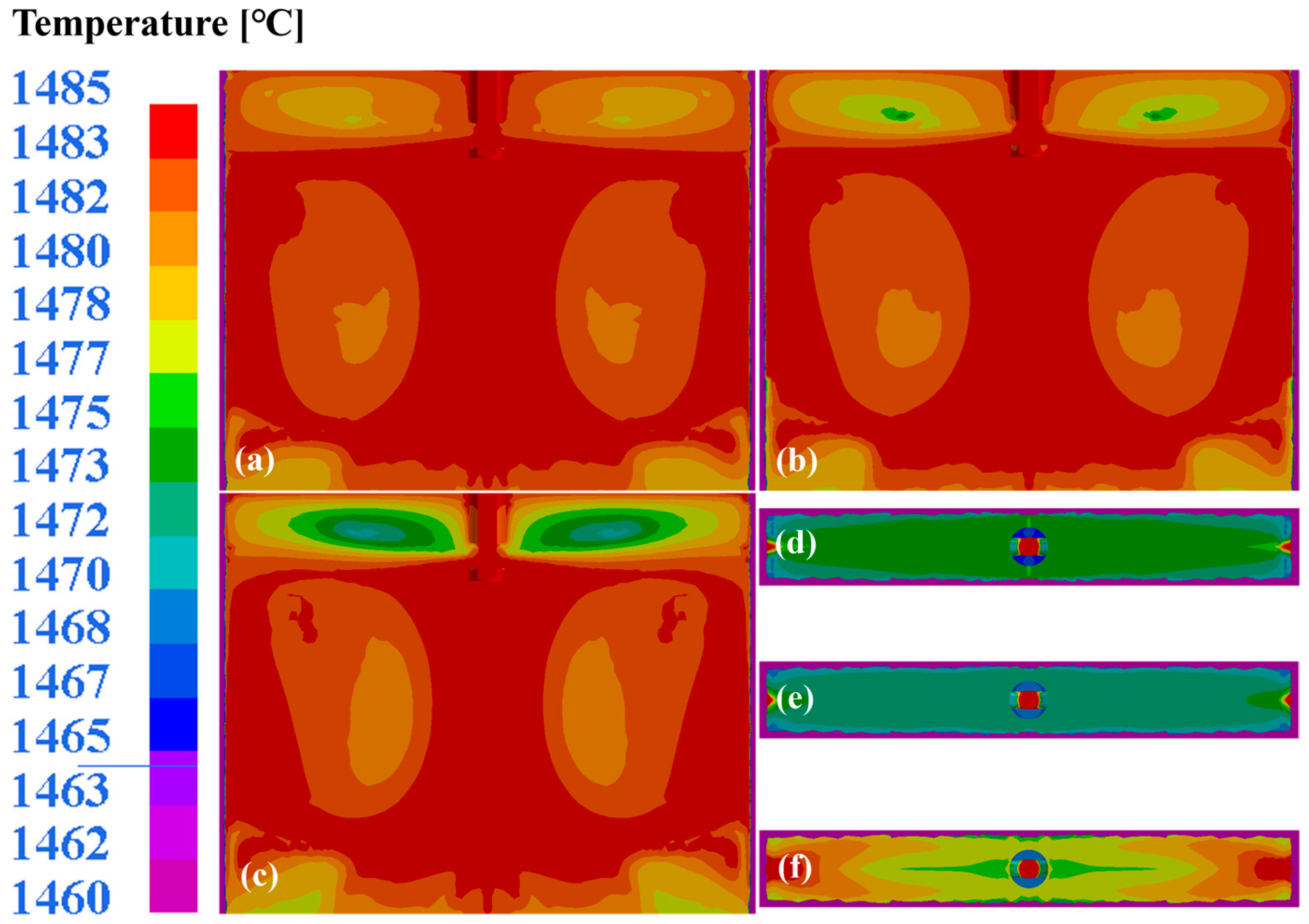

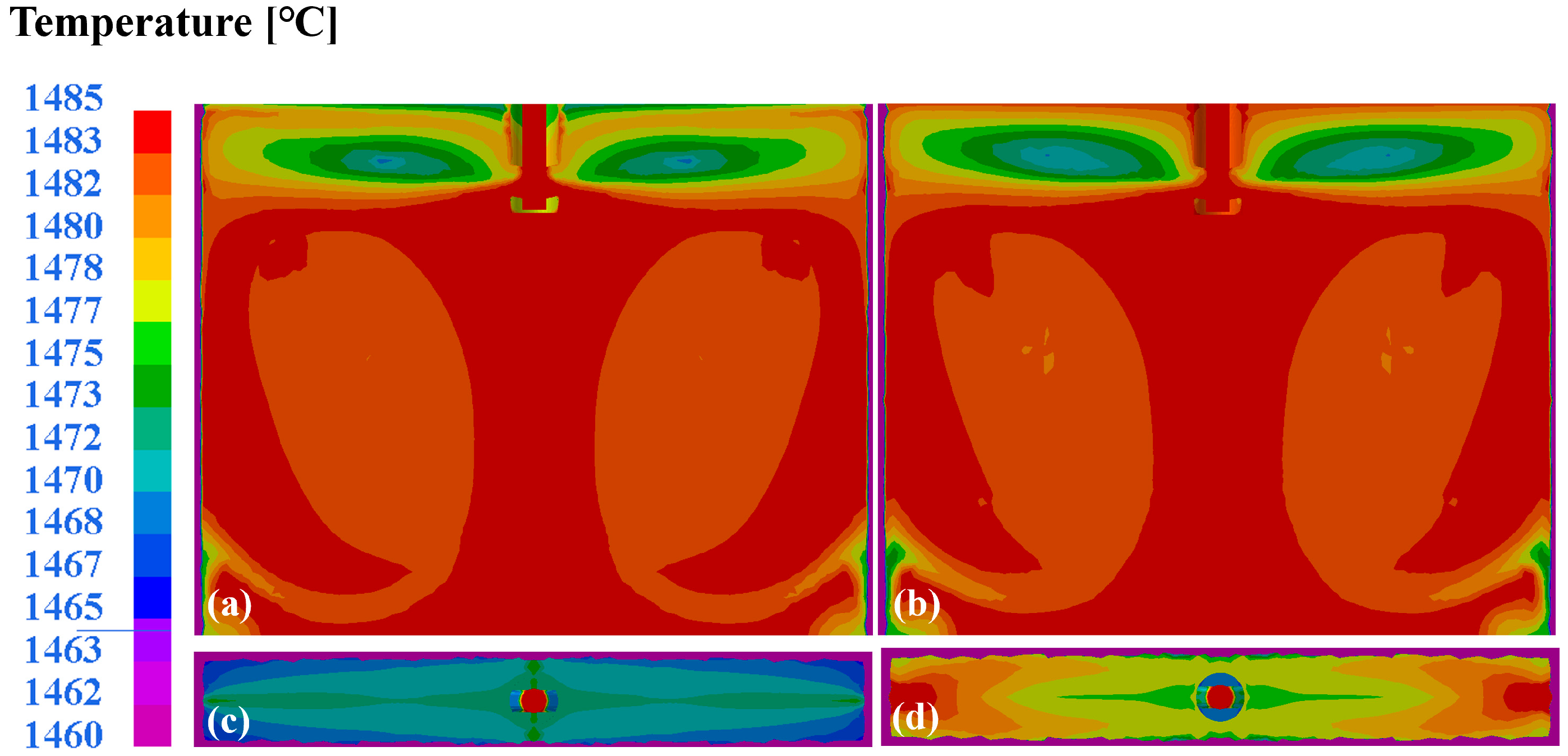

26], including the density, enthalpy, solid fraction, and thermal conductivity, which are shown in

Figure 3. To further account for the effect of mold oscillation, the curvature, and electromagnetic stirring on the melt flow and heat transfer, the thermal conductivity above the liquidus temperature (1464 °C) was 5 times higher than the original values, as in previous work [

27,

28,

29].

As for the flow and heat transfer boundary conditions, the following aspects were mainly considered.

(1)

Inlet boundary: The velocity inlet was defined, and it was calculated based on the principle of mass conservation using conversion factors including the casting speed, nozzle dimensions, and mold dimensions. The turbulent kinetic energy and turbulent kinetic energy dissipation rate were determined using Equations (6) and (7), respectively. As for the heat transfer, the molten steel’s temperature at the inlet was set to the casting temperature.

where

denotes the velocity of the inlet, m/s;

is the symbol for the nozzle’s hydraulic diameter, m.

(2) Symmetry plane: The velocity component perpendicular to the symmetry plane and the gradients of all the physical quantities along the normal direction of the symmetry plane were 0.

(3) Wall boundaries: Both the mold and nozzle walls were treated as no-slip solid walls. The normal velocity component and normal gradients of the other physical quantities at the wall surface were zero. Near-wall flow fields were resolved using standard wall functions. The average heat flux on both the narrow face and wide face of the mold was set to 2 MW/m2.

(4) Outlet: The velocity at the lower outlet of the mold was defined as the casting speed.

The necessary simulation parameters used in this modeling work are summarized and listed in

Table 2.

2.3. Grid Sensitivity and Model Verification

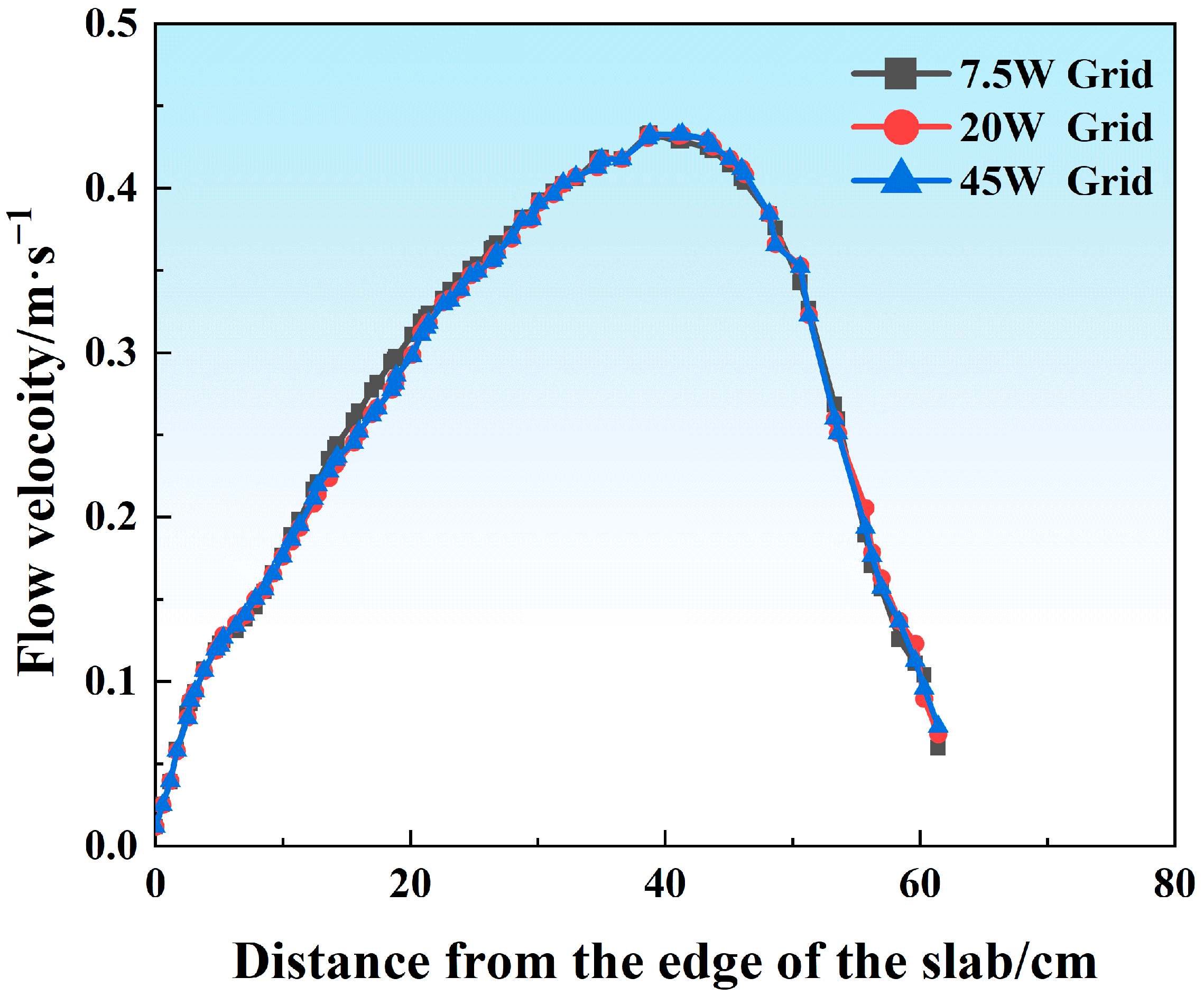

Hexa mesh and tetri mesh have been compared in convergence tests, and tetri mesh shows better performance and was used in this work. To further exclude the effect of the grid densities on the prediction accuracy of the Finite Element Method (FEM)model, various grid numbers (75,000, 200,000, 450,000) were generated in the CAD model (

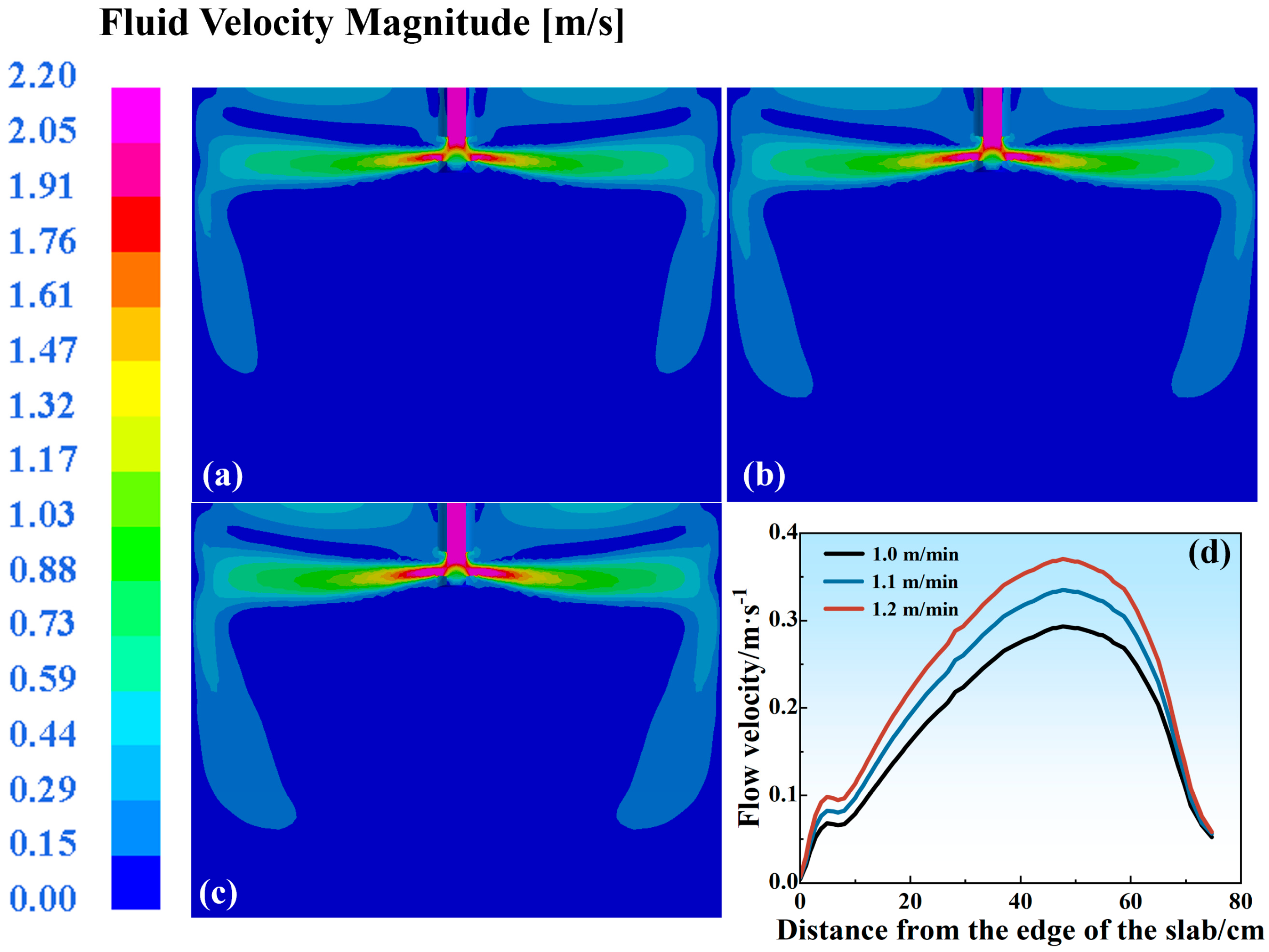

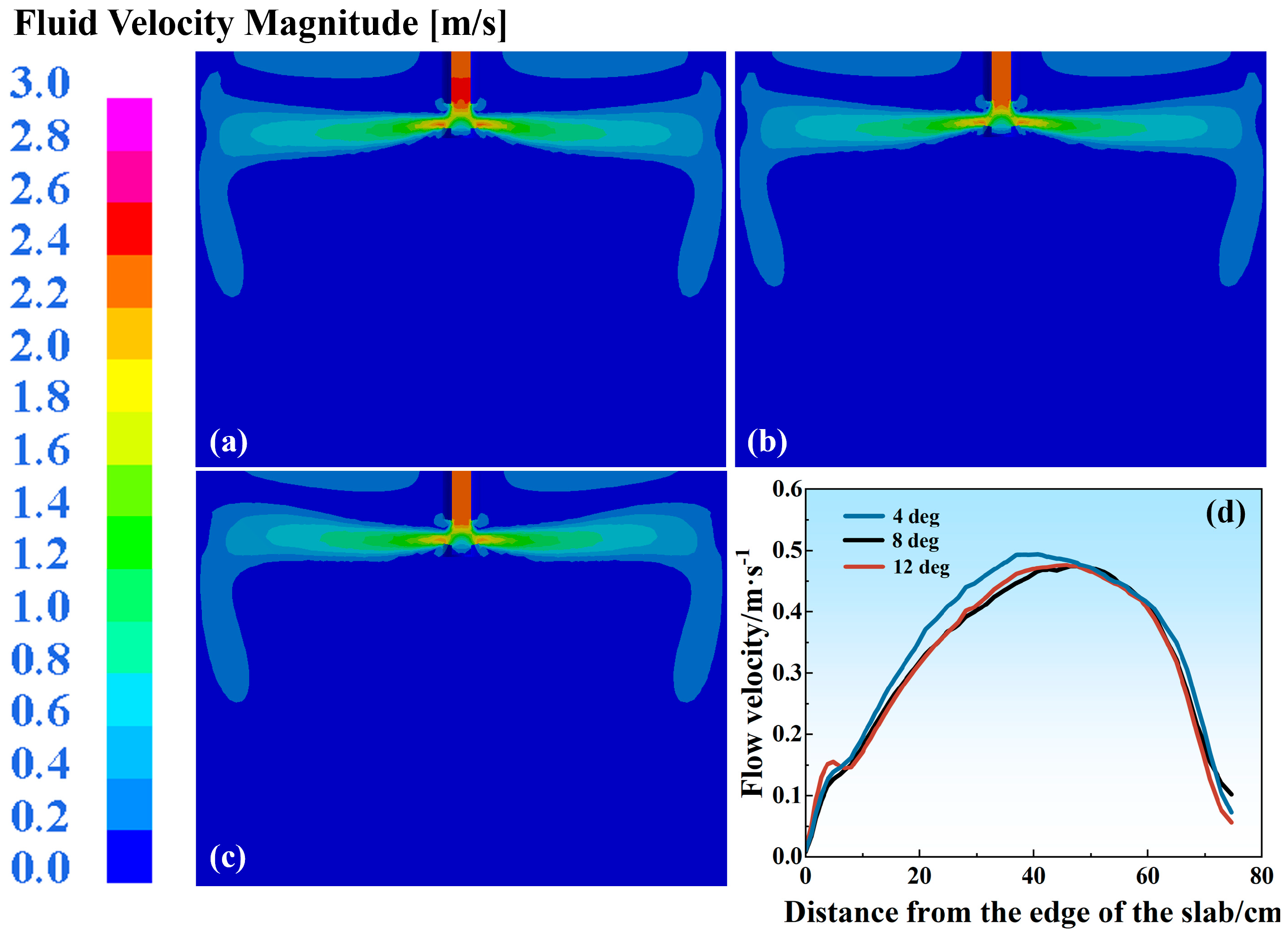

Figure 2), and the same model parameters were set in each case for further comparisons (1.0 m/min casting speed, SEN depth of 120 mm, port angle of 8 degrees (hereinafter abbreviated as deg)). The evolution of the free surface melt velocity was plotted, as shown in

Figure 4. It could be found that with an increase in the grid number from 75,000 to 450,000, the flow field’s evolution tended to be independent of the grid number and identical. In this case, to improve the computation efficiency and maintain the accuracy, a total grid number of 75,000 was enough to describe the flow characteristics in the current FEM system, which was also beneficial in terms of accelerating the computational speed.

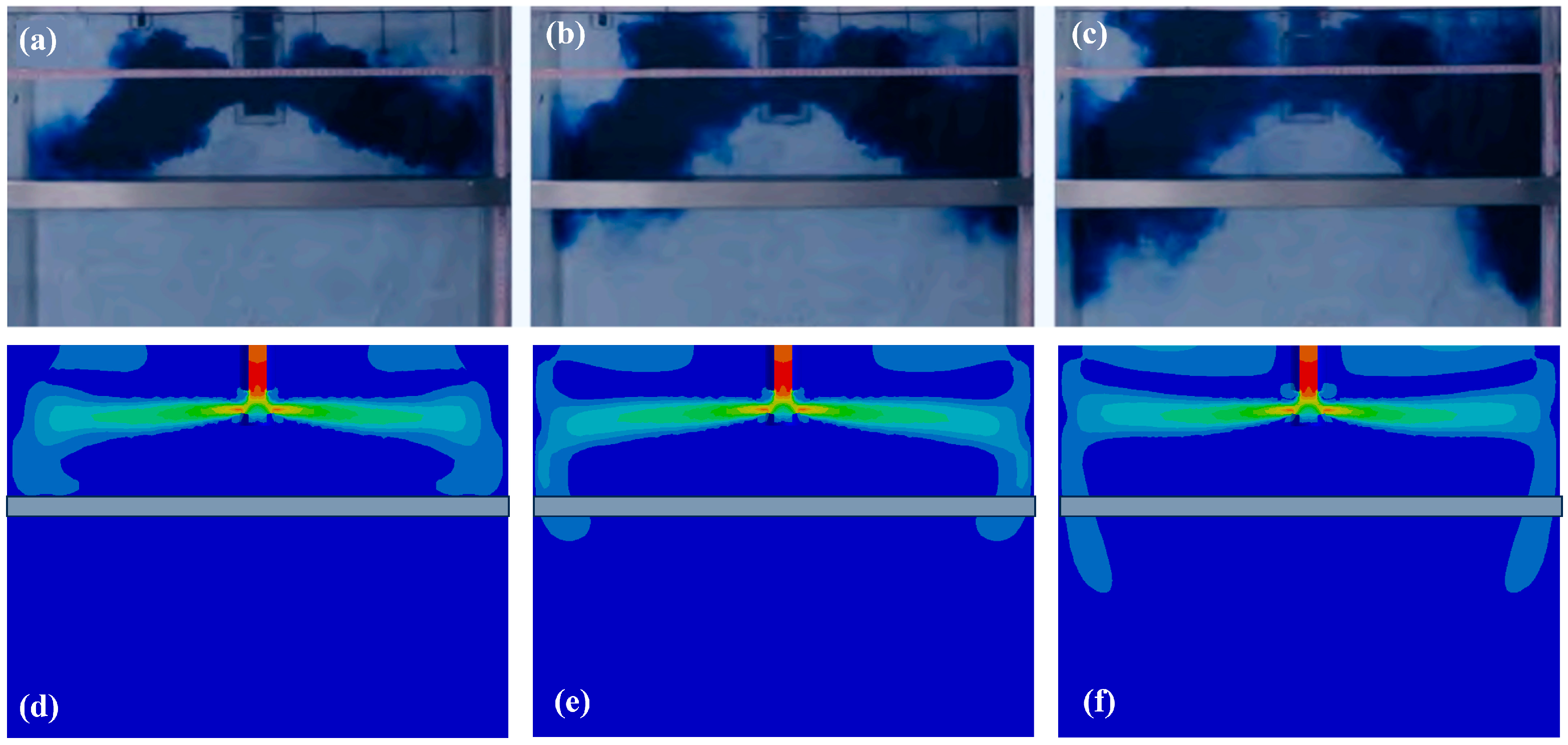

Moreover, to further validate the suitability of the model for predicting the fluid flow pattern in the mold region for stainless steel, a benchmark water analogy experiment [

30] was used to compare the results between mathematical modeling and an experiment, as shown in

Figure 5. The results indicate an identical flow field distribution in both the modeling and experiment, especially at the mold’s free surface, which in turn proves the suitability of the FEM model for flow field prediction. Regarding thermal field prediction, the heat flux distribution (

Figure 6a) in the mold region was simulated and compared with industrial data from the caster, as shown in

Figure 6. The average flux distribution in the mold region fluctuated at around 1.5 MW/m

2 (

Figure 6b), which was very close to the data from the caster shown in

Figure 6c.