Influence of Surface Damage on Weld Quality and Joint Strength of Collision-Welded Aluminium Joints

Abstract

1. Introduction

- Use of exclusively undamaged/scratch-free components:

- This approach requires considerable effort in terms of handling and storage of the semi-finished products within the production process. In addition, it leads to high rejection rates, as even components with minor damage from previous process steps must be sorted out.

- 2.

- Identification and evaluation of critical scratches:

- In this approach, only components with scratches deemed critical are discarded, or alternatively, the process parameters—such as collision velocity—are adjusted so that a sufficiently strong joint is achieved even in the presence of non-critical scratches.

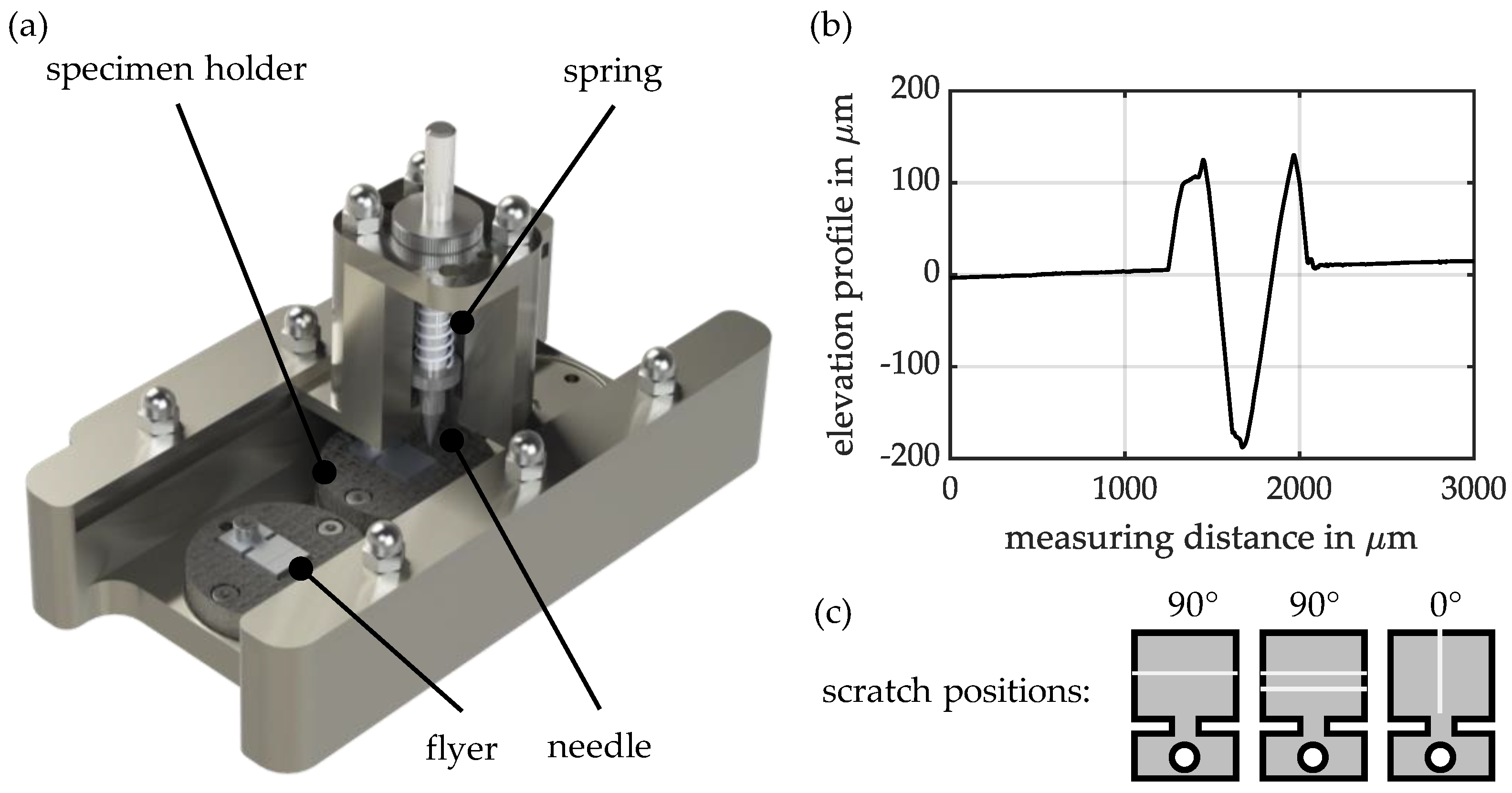

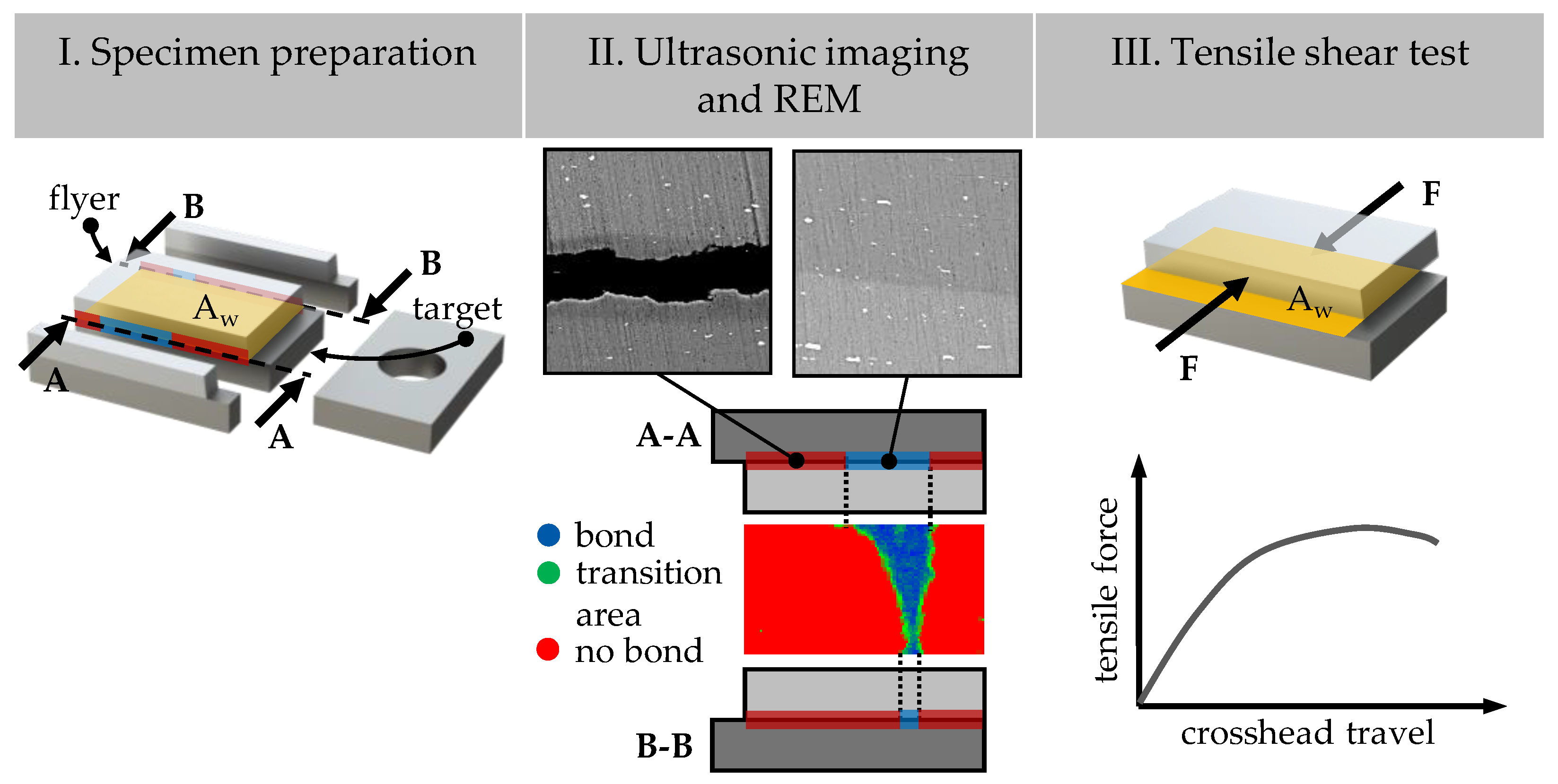

2. Materials and Methods

3. Results

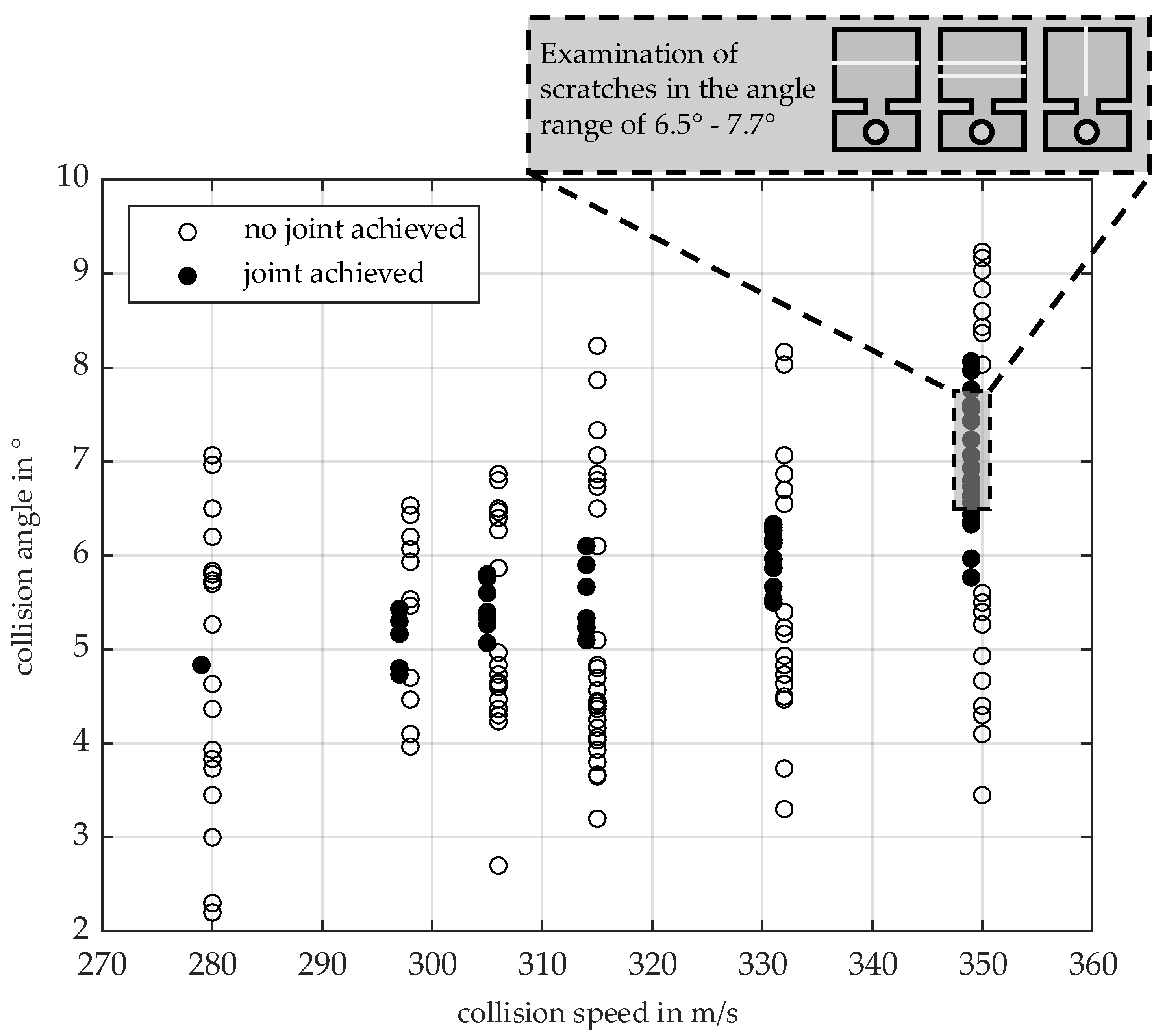

3.1. Welding Process Window

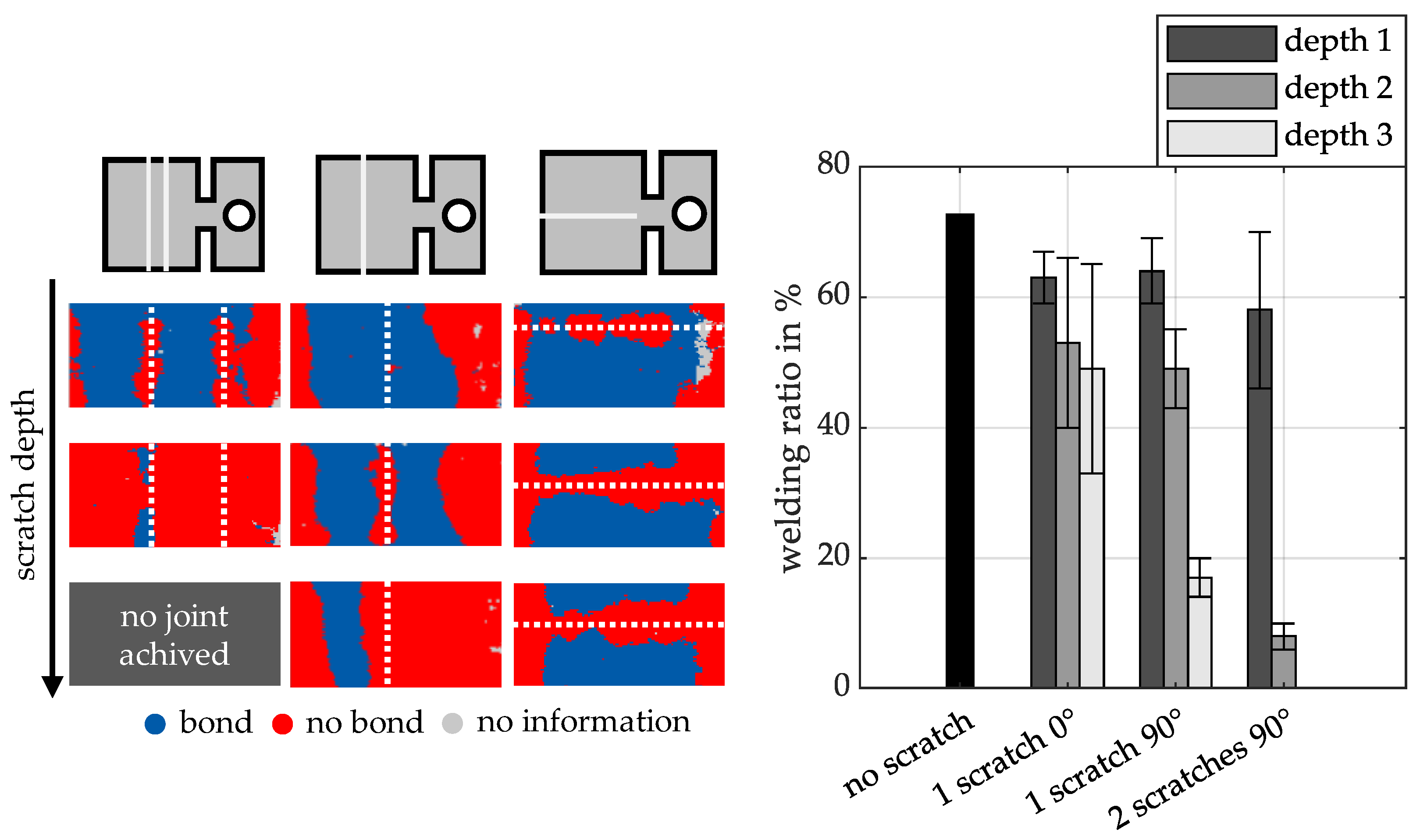

3.2. Welding Ratio

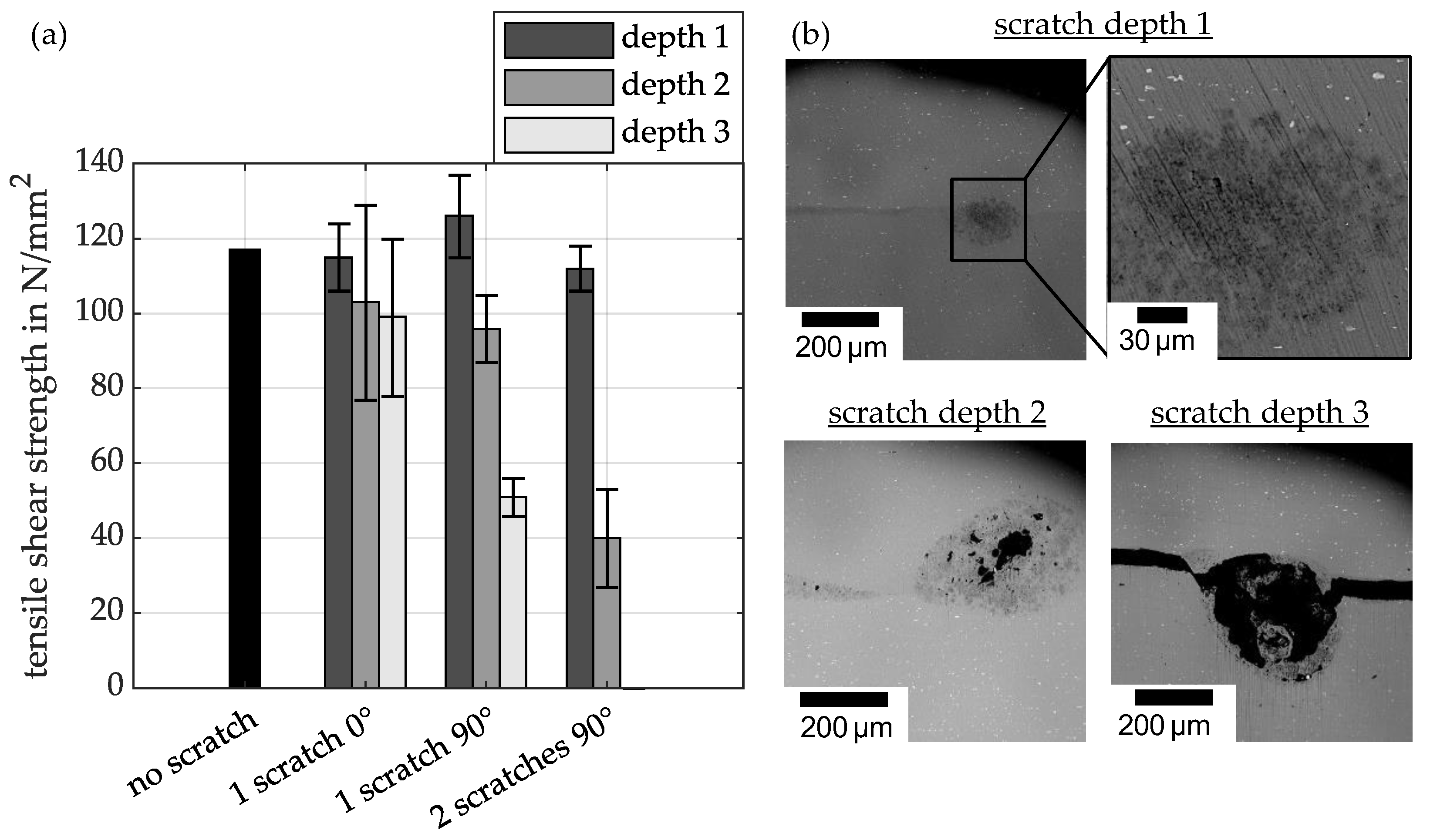

3.3. Tensile Shear Test

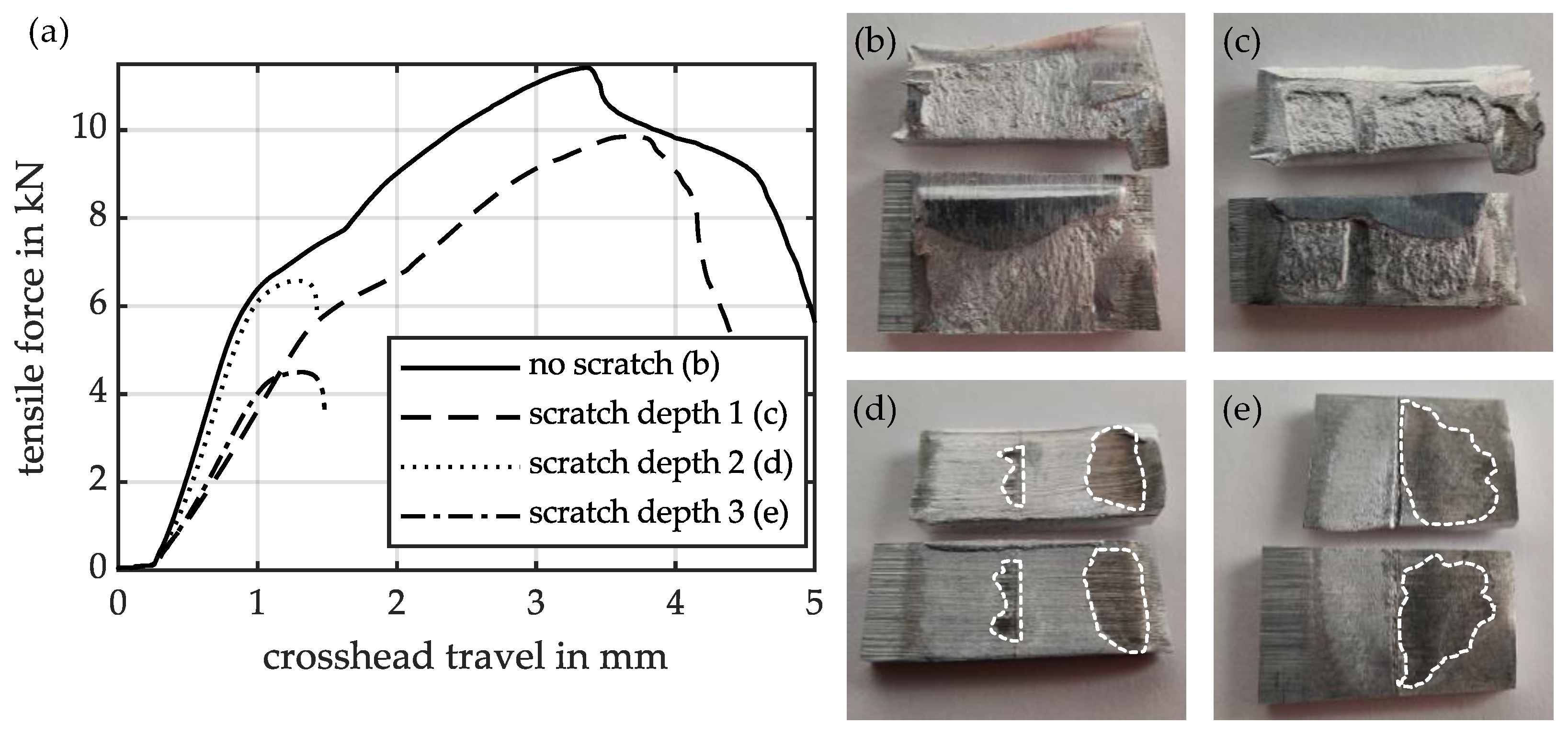

3.4. High-Speed Images

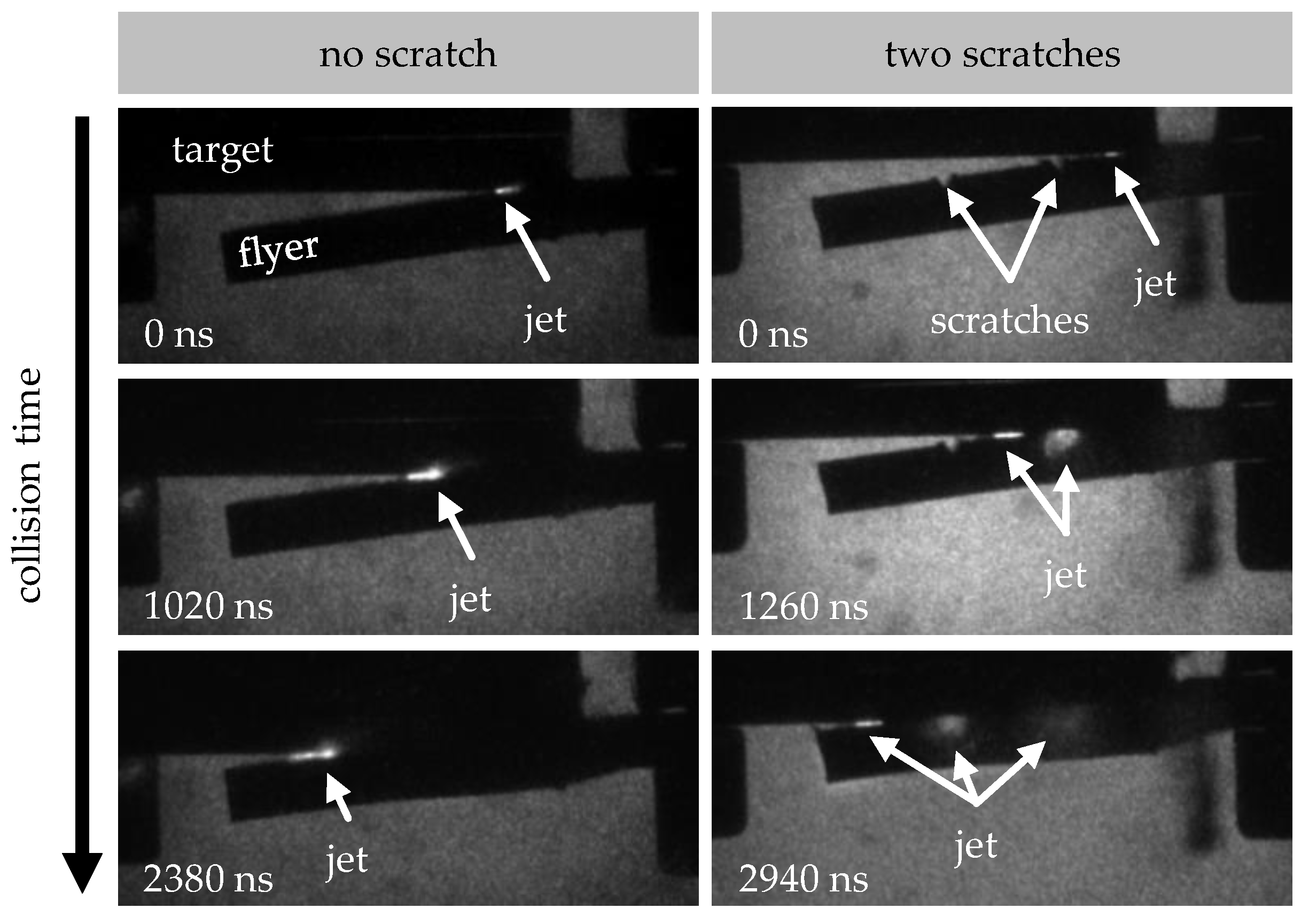

4. Discussion

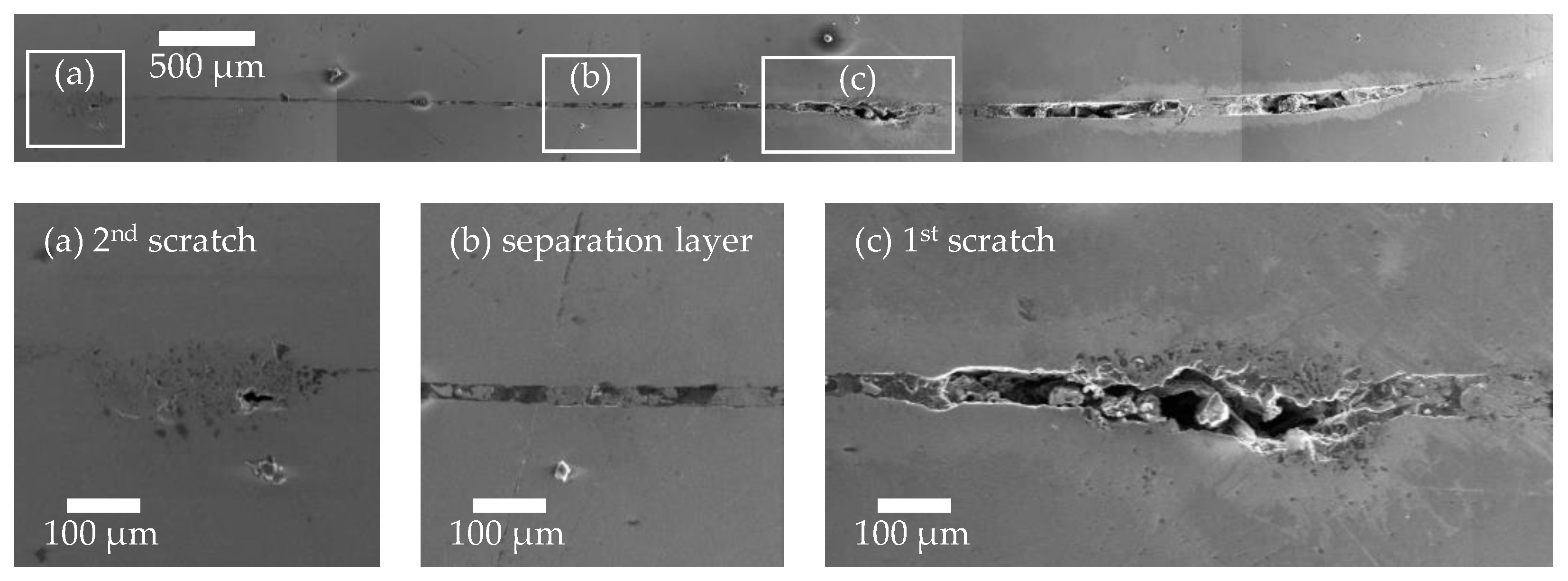

- Jet inclusion in the scratch: As the collision progresses, the jet hits the scratch and becomes part of it. Depending on the size of the scratch, it is either completely or partially filled. The resulting heat, which has also been observed in collision welding tests at low collision angles [37], can cause the material to melt locally. Combined with the removed material, this creates a pronounced intermediate layer. Similar findings were reported in EMPW welding processes involving ground surfaces [42]. In particular, structures running perpendicular to the welding direction lead to increased interlayer formation, which can be attributed to jet inclusions.

- Jet interruption due to scratch geometry: In some cases, the jet is deflected or interrupted so strongly by the scratches (the indentation and the elevations at the edges of the scratches, see scratch profile in Figure 1) that there is insufficient energy left for surface cleaning and activation. SEM images in Figure 8 show vortex structures indicating such jet disturbance. Notably, this prevents joint formation in large areas before the scratch, whereas a joint is formed after the scratch. This suggests strong turbulence in the closing collision gap, hindering the jet and connection formation in the area in front of the scratch. The turbulent atmosphere escapes from both sides of the collision gap via the scratch, creating atmospheric conditions again after the scratch that enable joint formation.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Miraftabzadeh, S.M.; Longo, M.; Foiadelli, F. Mobility and Future Trends. In Emerging Battery Technologies to Boost the Clean Energy Transition, 1st ed.; Passerini, S., Barelli, L., Baumann, M., Peters, J., Weil, M., Eds.; Springer: Cham, Switzerland, 2024; Volume 1, pp. 3–11. [Google Scholar] [CrossRef]

- Crippa, M.; Guizzardi, D.; Pagani, F.; Banja, M.; Muntean, M.; Schaaf, E.; Monforti-Ferrario, F.; Becker, W.; Quadrelli, R.; Risquez Martin, A.; et al. GHG Emissions of all World Countries 2024; Publications Office of the European Union: Luxembourg, 2024. [Google Scholar] [CrossRef]

- EDGAR (Emissions Database for Global Atmospheric Research). IEA-EDGAR Fossil CO2 Emissions. 2024. Available online: https://edgar.jrc.ec.europa.eu/report_2024#data_download (accessed on 7 April 2025).

- IEA (International Energy Agency). Global Total Final Consumption by Fuel in the Net Zero Scenario, 2010–2050. 2025. Available online: www.iea.org/data-and-statistics/charts/global-total-final-consumption-by-fuel-in-the-net-zero-scenario-2010-2050 (accessed on 7 April 2025).

- Timmers, V.R.J.H.; Achten, P.A.J. Non-exhaust PM emissions from electric vehicles. Atmos. Environ. 2016, 134, 10–17. [Google Scholar] [CrossRef]

- Lopez, B.; Wang, X.; Chen, L.W.A.; Ma, T.; Mendez-Jimenez, D.; Cobb, L.C.; Frederickson, C.; Fang, T.; Hwang, B.; Shiraiwa, M.; et al. Metal contents and size distributions of brake and tire wear particles dispersed in the near-road environment. Sci. Total Environ. 2023, 883, 163561. [Google Scholar] [CrossRef]

- European Environment Agency (EEA). Air Quality in Europe 2022. Available online: https://www.eea.europa.eu/publications/air-quality-in-europe-2022 (accessed on 7 April 2025).

- Köllner, C. Unterschätzte Umweltgefahr Reifenabrieb. Available online: https://www.springerprofessional.de/fahrwerk/schadstoffe/unterschaetzte-umweltgefahr-reifenabrieb-/15490524 (accessed on 7 April 2025).

- Organisation for Economic Co-Operation and Development (OECD). Non-Exhaust Particulate Emissions from Road Transport. Available online: https://doi.org/10.1787/4a4dc6ca-en (accessed on 7 April 2025).

- European Commission. Questions and Answers: Commission Proposal on the New Euro 7 Standards. Available online: https://ec.europa.eu/commission/presscorner/detail/en/QANDA_22_6496 (accessed on 7 April 2025).

- Allgemeiner Deutscher Automobil-Club e.V. (ADAC). Euro-7-Abgasnorm: Anforderungen, Grenzwerte, Einführungsfristen. Available online: https://www.adac.de/rund-ums-fahrzeug/autokatalog/abgasnormen/euro-7 (accessed on 7 April 2025).

- Visnic, B. Europe’s Dust Buster. Available online: https://www.sae.org/news/2023/05/brakes-sustainability-dust-regulations (accessed on 7 April 2025).

- Kole, P.J.; Löhr, A.J.; Van Belleghem, F.G.; Ragas, A.M. Wear and Tear of Tyres: A Stealthy Source of Microplastics in the Environment. Int. J. Environ. Res. Public Health 2017, 14, 1265. [Google Scholar] [CrossRef] [PubMed]

- The International Transport Forum (OECD). Lightening Up: How Less Heavy Vehicles Can Help Cut CO2 Emissions. Available online: https://www.itf-oecd.org/less-heavy-vehicles-cut-co2-emissions (accessed on 7 April 2025).

- Bandivadekar, A.; Bodek, K.; Cheah, L.; Evans, C.; Groode, T.; Heywood, J.; Kasseris, E.; Kromer, M.; Weiss, M. On the Road in 2035: Reducing Transportation’s Petroleum Consumption and GHG Emissions; MIT Laboratory for Energy and the Environment: Cambridge, MA, USA, 2008. [Google Scholar]

- Köllner, C. So Lassen Sich Brems- und Reifenabrieb Reduzieren. Available online: https://www.springerprofessional.de/fahrwerk/partikel---feinstaub/so-lassen-sich-brems--und-reifenabrieb-reduzieren/18816284 (accessed on 7 April 2025).

- Beddows, D.C.S.; Harrison, R.M. PM10 and PM2.5 emission factors for non-exhaust particles from road vehicles: Dependence upon vehicle mass and implications for battery electric vehicles. Atmos. Environ. 2021, 244, 117886. [Google Scholar] [CrossRef]

- Tisza, M.; Lukács, Z. High strength aluminum alloys in car manufacturing. IOP Conf. Ser. Mater. Sci. Eng. 2018, 418, 012033. [Google Scholar] [CrossRef]

- Kang, M.; Kim, C. A Review of Joining Processes for High Strength 7xxx Series Aluminum Alloys. J. Weld. Join. 2017, 35, 79–88. [Google Scholar] [CrossRef]

- Olabode, M.; Kah, P.; Martikainen, J. Aluminium alloys welding processes: Challenges, joint types and process selection. Proc. Inst. Mech. Eng. Part B J. Eng. Manufact. 2013, 227, 1129–1137. [Google Scholar] [CrossRef]

- Tao, Y.; Luo, S.; Zhang, J.; Wang, X.; Chen, X.; Hu, Z.; Nagaumi, H. Effect of aging state on microstructure and properties of heat affected zone in Al–Mg–Si–Cu alloy welded joints. J. Mater. Res. Technol. 2024, 33, 3045–3057. [Google Scholar] [CrossRef]

- MachineMFG. Aluminum Welding: Techniques, Challenges, and Applications. Available online: https://shop.machinemfg.com/aluminum-welding-techniques-challenges-and-applications (accessed on 6 May 2025).

- Agudo, L.; Eyidi, D.; Schmaranzer, C.H.; Arenholz, E.; Jank, N.; Bruckner, J.; Pyzalla, A.R. Intermetallic FexAly-phases in a steel/Al-alloy fusion weld. J. Mater. Sci. 2007, 42, 4205–4214. [Google Scholar] [CrossRef]

- Khedr, M.; Hamada, A.; Järvenpää, A.; Elkatatny, S.; Abd-Elaziem, W. Review on the Solid-State Welding of Steels: Diffusion Bonding and Friction Stir Welding Processes. Metals 2023, 13, 54. [Google Scholar] [CrossRef]

- Kapil, A.; Sharma, A. Magnetic pulse welding: An efficient and environmentally friendly multi-material joining technique. J. Clean. Prod. 2015, 100, 35–58. [Google Scholar] [CrossRef]

- Niessen, B. Untersuchungen zur Robustheit von Kollisionsschweißprozessen bei Minimalem Energieeintrag. Ph.D. Thesis, TU Darmstadt, Darmstadt, Germany, 2022. [Google Scholar] [CrossRef]

- Atabaki, M.M.; Nikodinovski, M.; Chenier, P.; Ma, J.; Harooni, M.; Kovacevic, R. Welding of Aluminum Alloys to Steels: An Overview. J. Manuf. Sci. Prod. 2014, 14, 59–78. [Google Scholar] [CrossRef]

- Golovashchenko, S. Electromagnetic Forming and Joining for Automotive Applications. In Proceedings of the 2nd international Conference on High Speed Forming, Dortmund, Germany, 20–21 March 2006; Kleiner, M., Ed.; Institute of Forming Technology and Lightweight Construction, Universität Dortmund: Dortmund, Germany, 2006; Volume 1, pp. 201–206. [Google Scholar] [CrossRef]

- Weddeling, C.; Woodward, S.; Nellesen, J.; Psyk, V.; Marré, M.; Brosius, A.; Tekkaya, A.E.; Daehn, G.S.; Tillmann, W. Development of design principles for form-fit joints in lightweight frame structures. In Proceedings of the 4th International Conference on High Speed Forming, Columbus, OH, USA, 9–10 March 2010; Babusci, K., Daehn, G., Marré, M., Tekkaya, A.E., Weddeling, C., Zhang, Y., Eds.; Manufacturing Institute, The Ohio State University: Columbus, OH, USA, 2010; Volume 1, pp. 137–148. [Google Scholar] [CrossRef]

- Wang, X.; Li, C.; Zhou, Y.; Xu, C.; Dai, M. Mechanism of the discharge behavior in electromagnetic pulse welding: Combination of electron emission and electric field. Mater. Today Commun. 2023, 36, 106726. [Google Scholar] [CrossRef]

- Stankevic, V.; Lueg-Althoff, J.; Hahn, M.; Tekkaya, A.E.; Zurauskiene, N.; Dilys, J.; Klimantavicius, J.; Kersulis, S.; Simkevicius, C.; Balevicius, S. Magnetic Field Measurements during Magnetic Pulse Welding Using CMR-B-Scalar Sensors. Sensors 2020, 20, 5925. [Google Scholar] [CrossRef]

- Marschner, O.; Pabst, C.; Schäfer, R.; Pasquale, P. Suitable Design for Electromagnetic Pulse Processes. In Proceedings of the 9th International Conference on High Speed Forming, Online, 13–15 October 2021; Institute of Forming Technology an Lightweight Construction, Universität Dortmund: Dortmund, Germany, 2021; Volume 1, pp. 1–9. [Google Scholar] [CrossRef]

- Zerbst, U.; Madia, M.; Klinger, C.; Bettge, D.; Murakami, Y. Defects as a root cause of fatigue failure of metallic components. III: Cavities, dents, corrosion pits, scratches. Eng. Fail. Anal. 2019, 97, 759–776. [Google Scholar] [CrossRef]

- Bellmann, J.; Lueg-Althoff, J.; Niessen, B.; Böhme, M.; Schumacher, E.; Beyer, E.; Leyens, C.; Tekkaya, A.E.; Groche, P.; Wagner, M.F.-X.; et al. Particle Ejection by Jetting and Related Effects in Impact Welding Processes. Metals 2020, 10, 1108. [Google Scholar] [CrossRef]

- Deutsches Institut für Normung e. V. DIN EN 573-3 Aluminium and Aluminium Alloys—Chemical Composition and form of Wrought Products—Part 3: Chemical Composition and form of Products; German Version EN 573-3:2019+A2:2023; Beuth Verlag GmbH: Berlin, Germany, 2024. [Google Scholar]

- Deutsches Institut für Normung e. V. DIN 50125 Testing of Metallic Materials—Tensile Test Pieces; Beuth Verlag GmbH: Berlin, Germany, 2022. [Google Scholar]

- Kraus, S.O.; Bruder, J.; Groche, P. The Influence of Weld Interface Characteristics on the Bond Strength of Collision Welded Aluminium–Steel Joints. Materials 2024, 17, 3863. [Google Scholar] [CrossRef]

- Tsakiris, V.; Kappel, W.; Alecu, G. Solid State diffusion welding of Cu-Fe/Al/Ag and Al-Ni dissimilar metals. J. Optoel. Adv. Mat. 2011, 13, 1176–1180. [Google Scholar] [CrossRef]

- Böhme, M.; Sharafiev, S.; Schumacher, E.; Böhm, S.; Wagner, M.F.X. On the microstructure and the origin of intermetallic phase seams in magnetic pulse welding of aluminium and steel. Materialwiss. Werkstofftech. 2019, 50, 958–964. [Google Scholar] [CrossRef]

- Niessen, B.; Schumacher, E.; Lueg-Althoff, J.; Bellmann, J.; Böhme, M.; Böhm, S.; Tekkaya, A.E.; Beyer, E.; Leyens, C.; Wagner, M.F.-X.; et al. Interface Formation during Collision Welding of Aluminum. Metals 2020, 10, 1202. [Google Scholar] [CrossRef]

- Groche, P.; Niessen, B. The Energy Balance in Aluminum–Copper High-Speed Collision Welding. J. Manuf. Mater. Process. 2021, 5, 62. [Google Scholar] [CrossRef]

- Cui, J.; Sun, T.; Geng, H.; Yuan, W.; Li, G.; Zhang, X. Effect of surface treatment on the mechanical properties and microstructures of Al-Fe single-lap joint by magnetic pulse welding. Int. J. Adv. Manuf. Technol. 2018, 98, 1081–1092. [Google Scholar] [CrossRef]

- Kraus, S.O.; Bruder, J.; Schuller, F.; Groche, P. High-Speed Images of Process Window Determination for AA6110-T6—AA6060-T6 Material Combination in Collision Welding; TUdata, TU Darmstadt: Darmstadt, Germany, 2025. [Google Scholar] [CrossRef]

| Alloy | Alloying Elements | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | |

| AA6060-T6 | 0.30–0.60 | 0.10–0.30 | 0.10 | 0.10 | 0.35–0.60 | 0.05 | 0.15 | 0.10 | 0.15 |

| AA6110A-T6 | 0.70–1.10 | 0.50 | 0.30–0.80 | 0.30–0.90 | 0.70–1.10 | 0.05–0.25 | 0.20 | 0.20 | 0.15 |

| Description | Number of Scratches (scr) | Orientation | Depth (d) in µm |

|---|---|---|---|

| 1scr-0°-d1 | 1 | 0° | 15–30 |

| 1scr-0°-d2 | 1 | 0° | 50–80 |

| 1scr-0°-d3 | 1 | 0° | 170–200 |

| 1scr-90°-d1 | 1 | 90° | 15–30 |

| 1scr-90°-d2 | 1 | 90° | 50–80 |

| 1scr-90°-d3 | 1 | 90° | 170–200 |

| 2scr-90°-d1 | 2 | 90° | 15–30 |

| 2scr-90°-d2 | 2 | 90° | 50–80 |

| 2scr-90°-d3 | 2 | 90° | 170–200 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kraus, S.O.; Bruder, J.; Schuller, F.; Groche, P. Influence of Surface Damage on Weld Quality and Joint Strength of Collision-Welded Aluminium Joints. Materials 2025, 18, 2944. https://doi.org/10.3390/ma18132944

Kraus SO, Bruder J, Schuller F, Groche P. Influence of Surface Damage on Weld Quality and Joint Strength of Collision-Welded Aluminium Joints. Materials. 2025; 18(13):2944. https://doi.org/10.3390/ma18132944

Chicago/Turabian StyleKraus, Stefan Oliver, Johannes Bruder, Florian Schuller, and Peter Groche. 2025. "Influence of Surface Damage on Weld Quality and Joint Strength of Collision-Welded Aluminium Joints" Materials 18, no. 13: 2944. https://doi.org/10.3390/ma18132944

APA StyleKraus, S. O., Bruder, J., Schuller, F., & Groche, P. (2025). Influence of Surface Damage on Weld Quality and Joint Strength of Collision-Welded Aluminium Joints. Materials, 18(13), 2944. https://doi.org/10.3390/ma18132944