The Effect of Gypsum on the Self-Hardening of Sapropel in Thermal Insulating Wood Chips Composite

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials Used in Experiments

2.2. Specimen Preparation

2.3. Test Methods

3. Results and Discussion

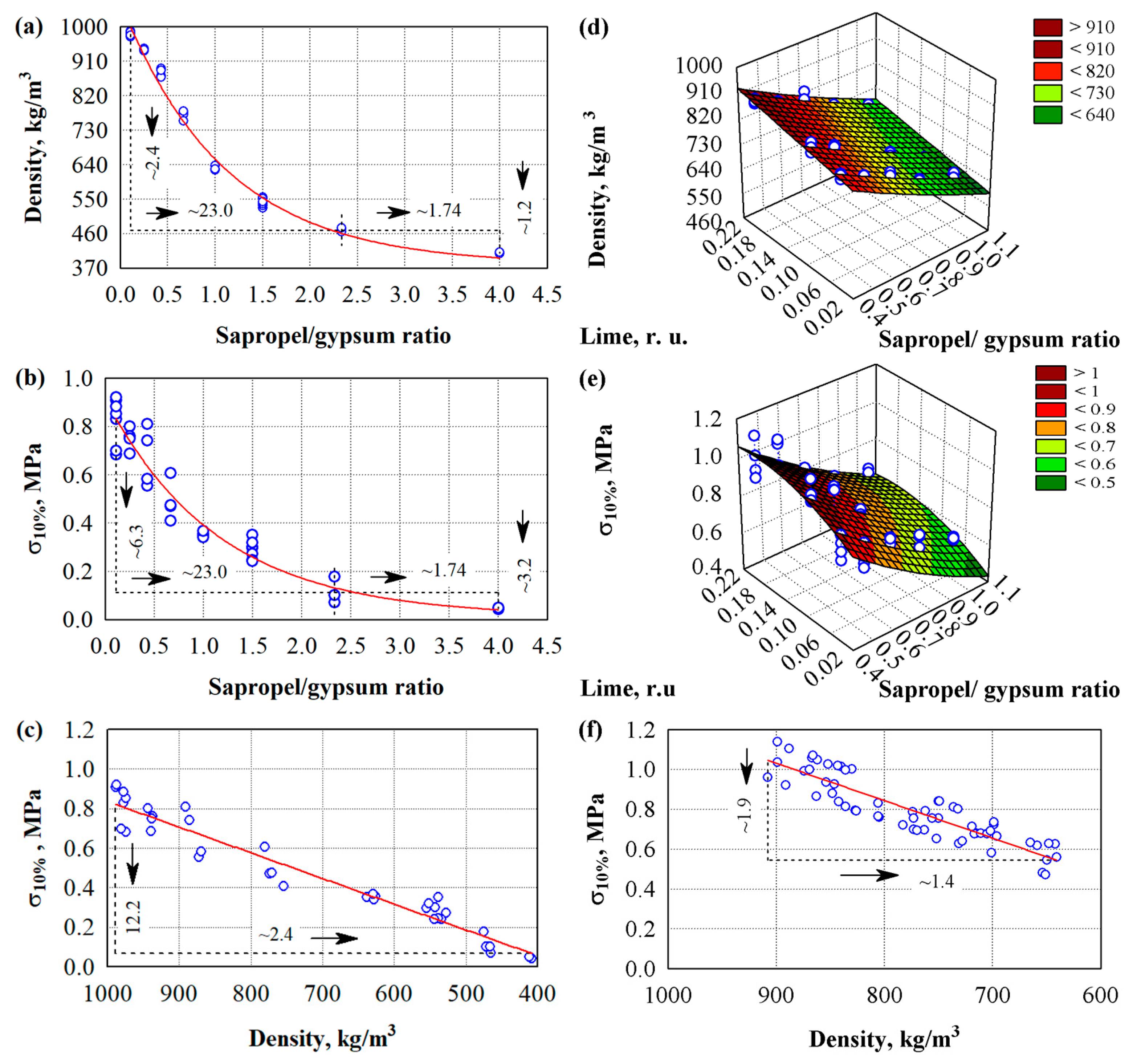

3.1. Analysis of the Compressive Stress of Binding Material

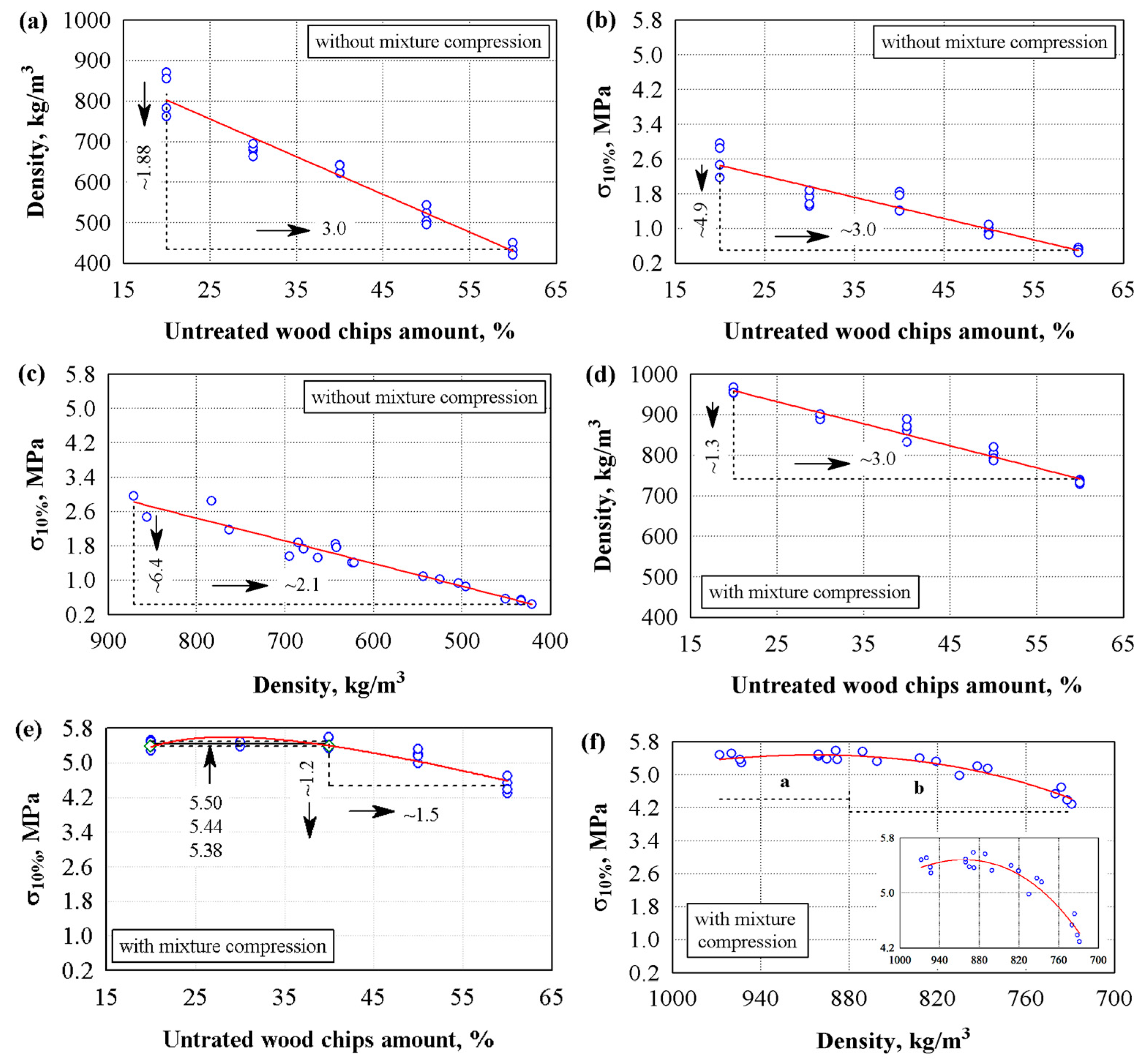

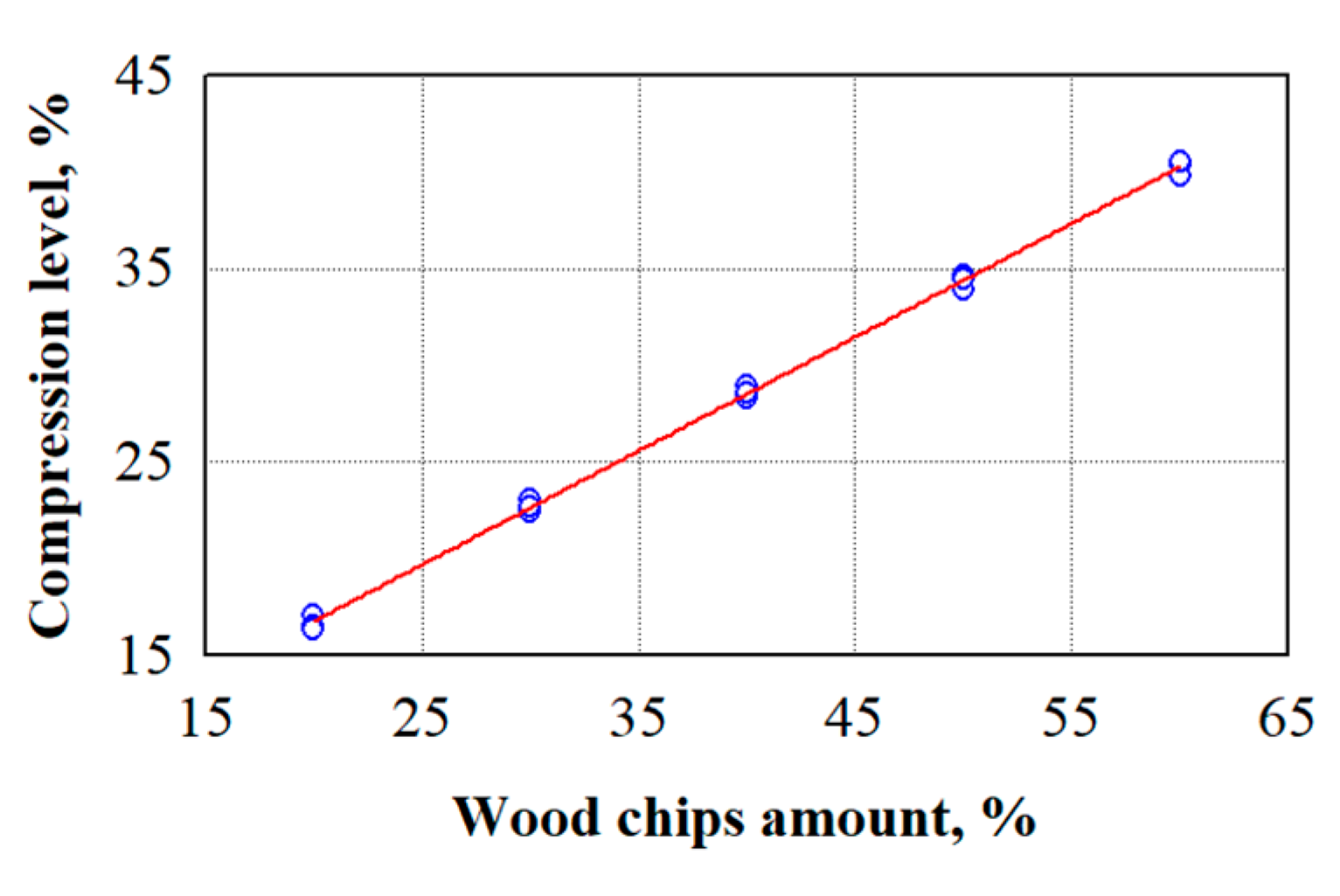

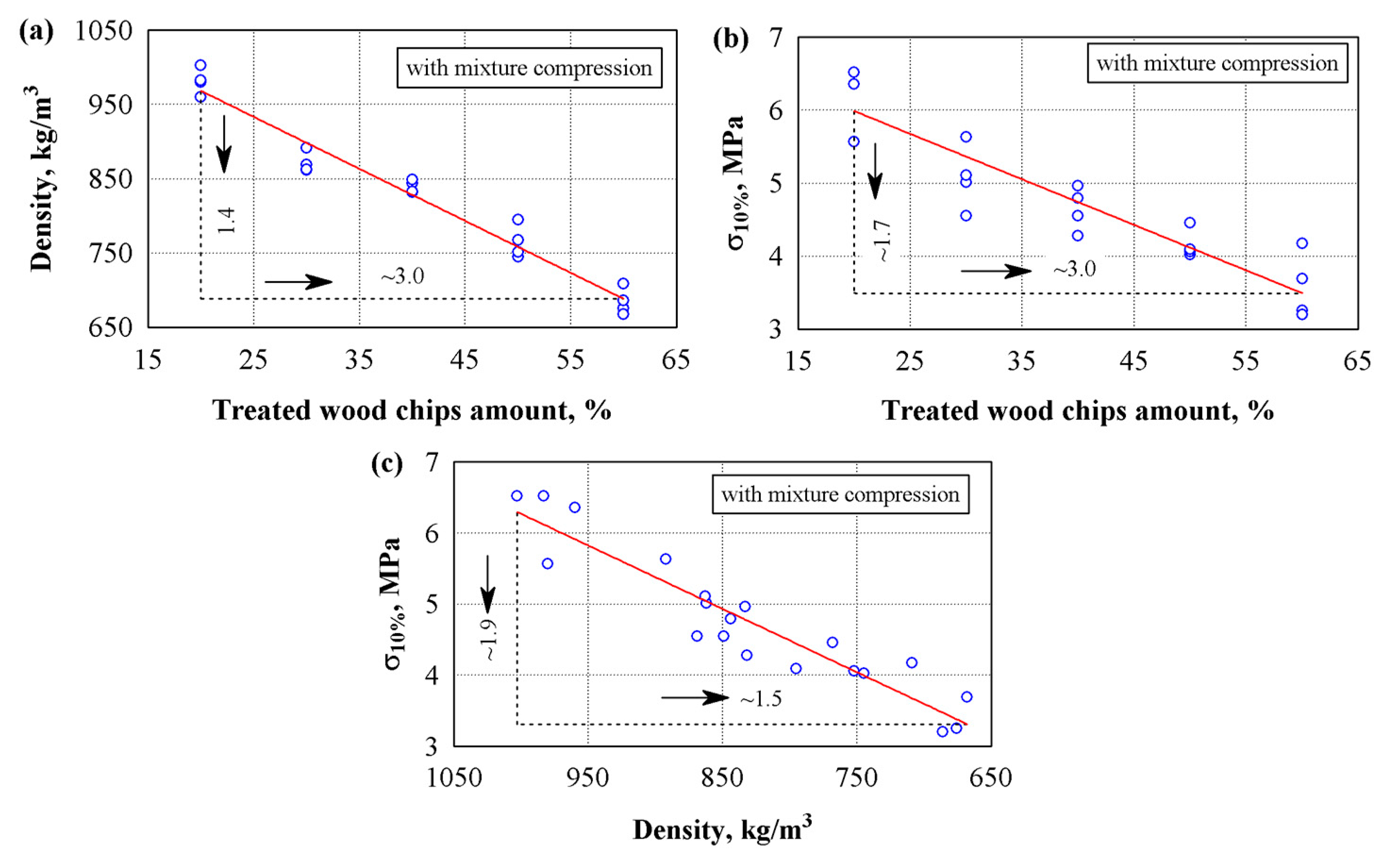

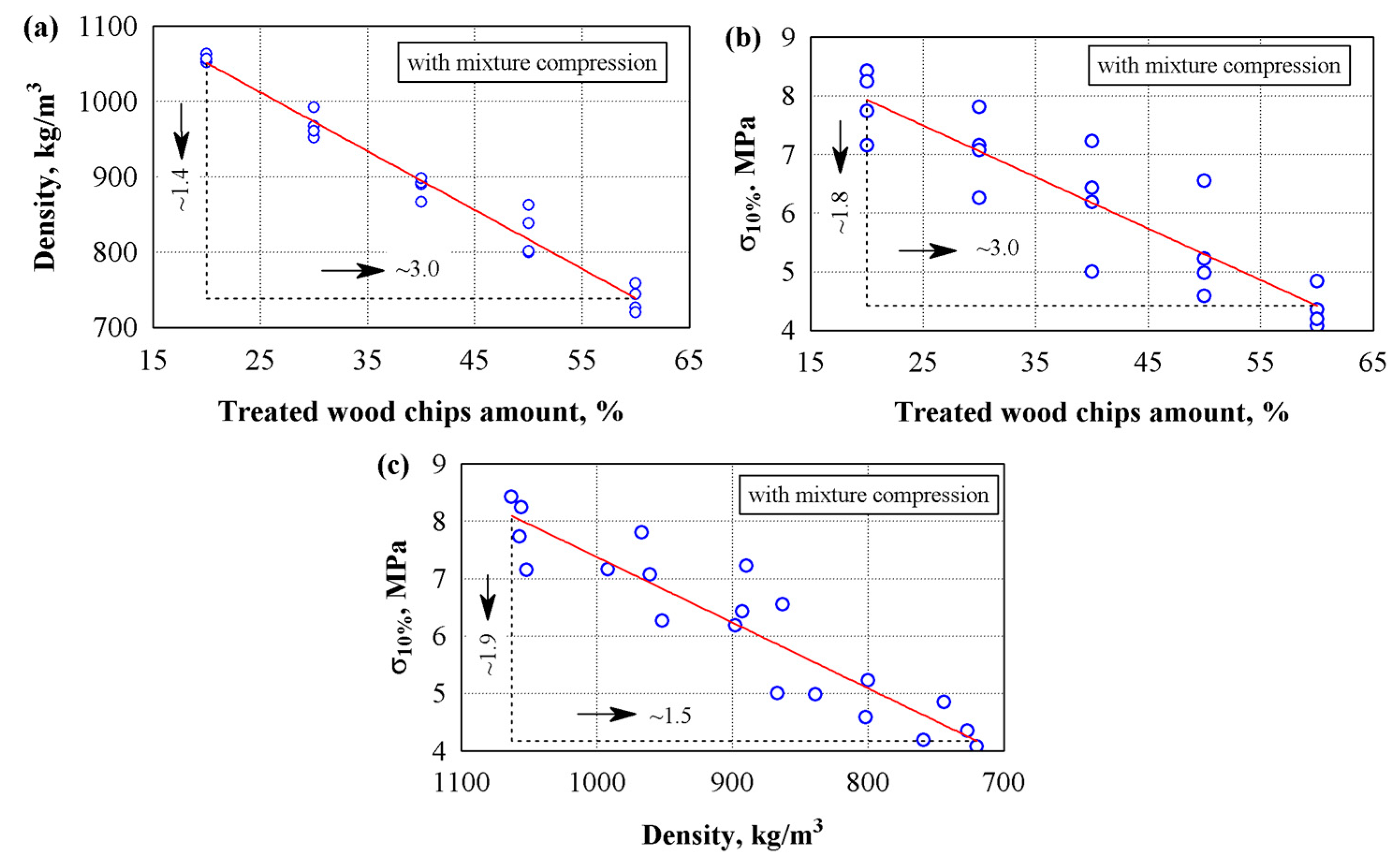

3.2. Analysis of the Compressive Stress of the Composite

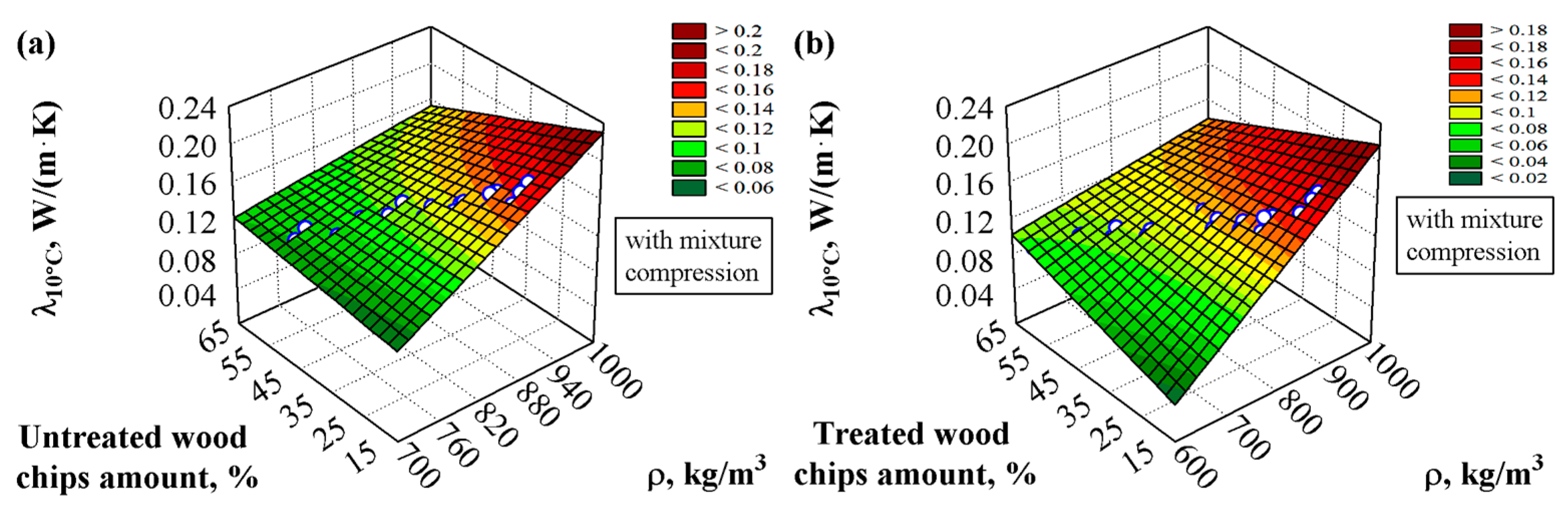

3.3. Analysis of the Thermal Conductivity

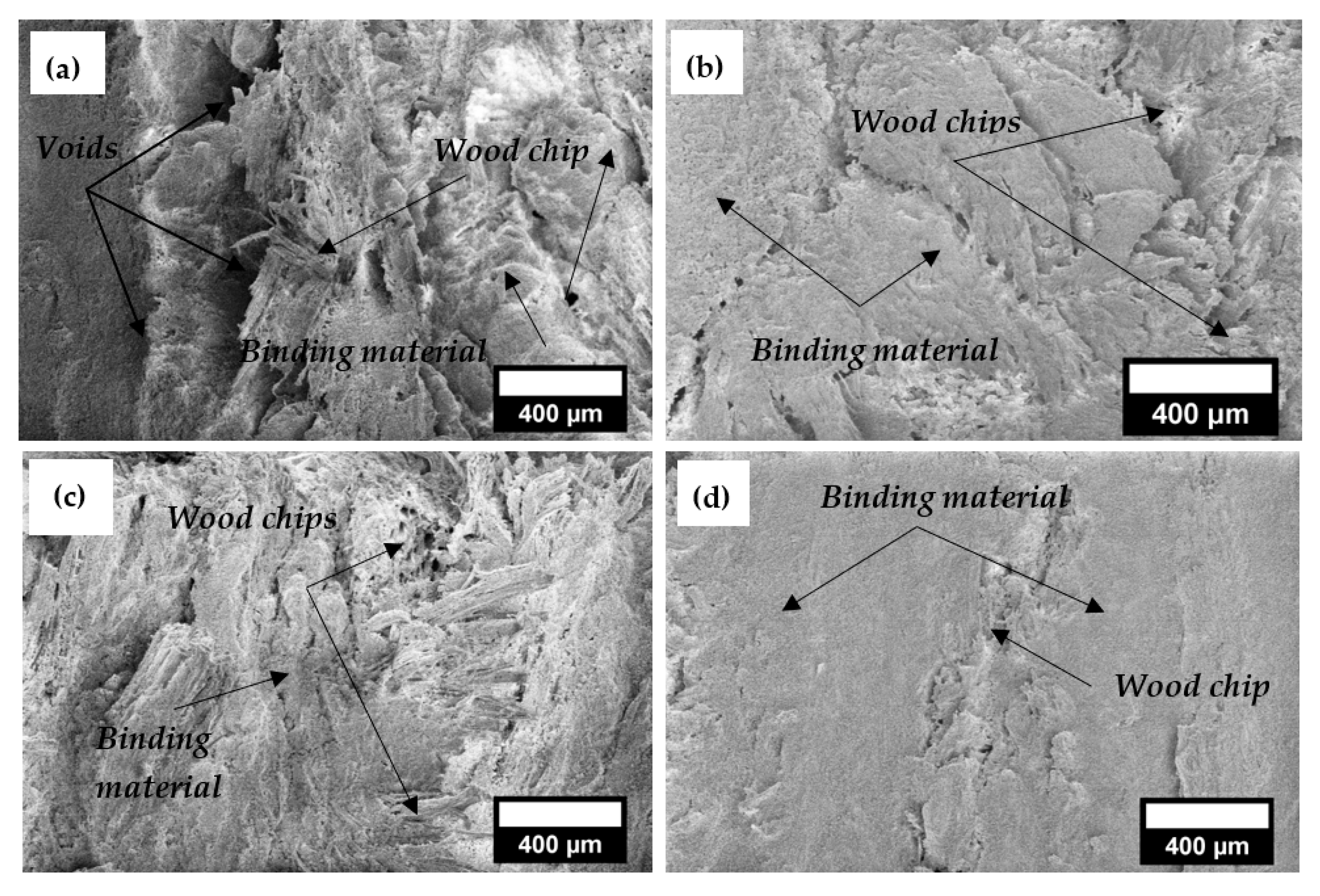

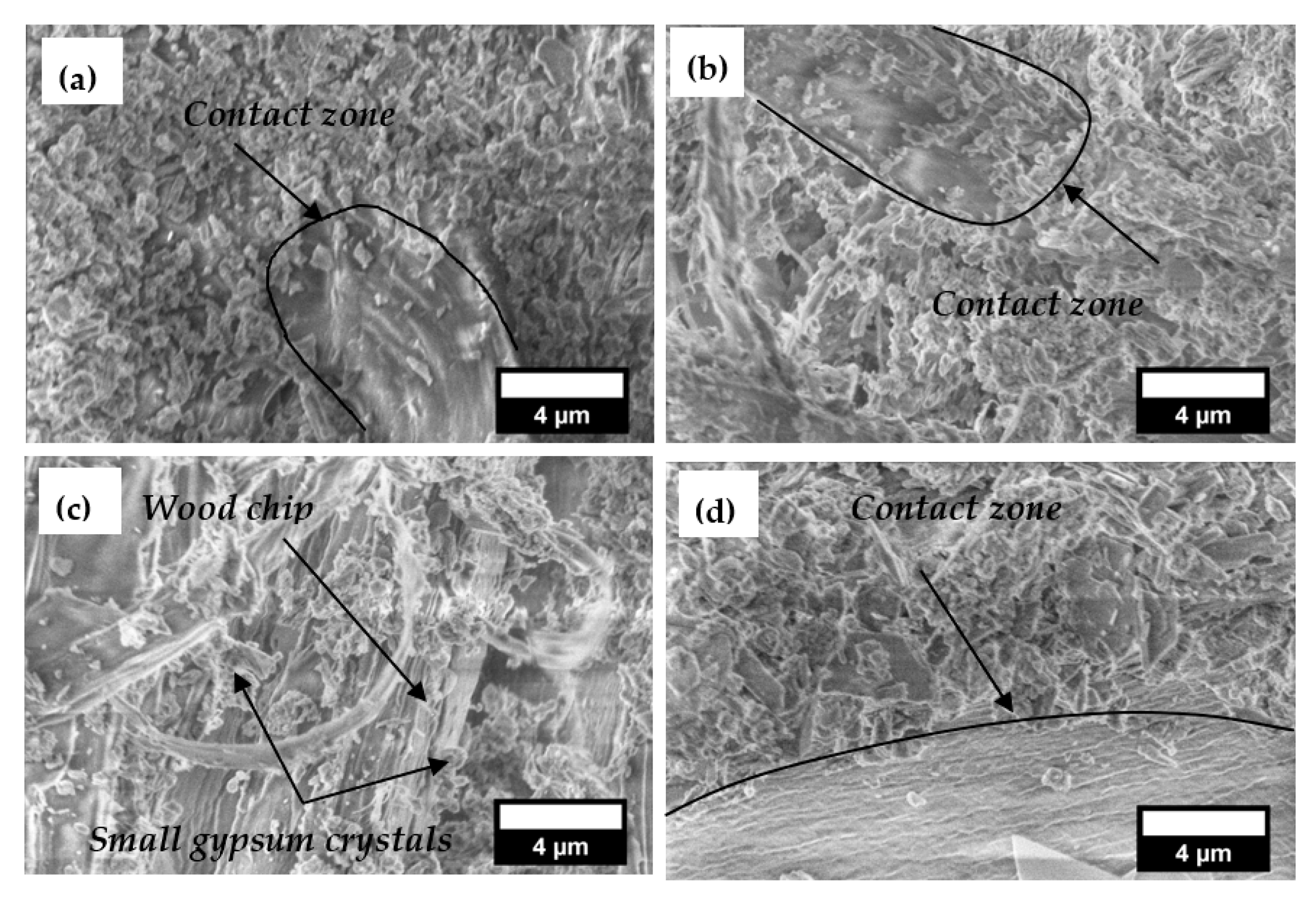

3.4. Analysis of the Microstructure

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bekmezci, M.; Ay, H.; Sen, F. Chapter 7-Green composite materials and their applications. In Green Sustainable Process for Chemical and Environmental Engineering and Science; Altalhi, I., Altalhi, T., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 159–182. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T. A review of natural fiber composites: Properties, modification and processing techniques, characterization, applications. J. Mater. Sci. 2020, 55, 829–892. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Morreale, M. Green composites: A brief review, Composites Part A. Appl. Sci. Manuf. 2011, 42, 579–588. [Google Scholar] [CrossRef]

- Campilho, R.D.S.G. Natural Fiber Composites, 1st ed.; CRC Press: Boca Raton, FL, USA, 2015; p. 368. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibres and their application perspectives, Composites Part A. Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Le Digabel, F.; Boquillon, N.; Dole, P.; Monties, B.; Averous, L. Properties of thermoplastic composites based on wheat-straw lignocellulosic fillers. J. Appl. Polym. Sci. 2004, 93, 428–436. [Google Scholar] [CrossRef]

- Ngo, T.D.; Minh-Tan, T.-T.; Wei, H. Triticale straw and its thermoplastic biocomposites. Sci. Eng. Compos. Mater. 2014, 22, 343–351. [Google Scholar] [CrossRef]

- Mohammed, A.A.B.A.; Omran, A.A.B.; Hasan, Z.; Ilyas, R.A.; Sapuan, S.M. Wheat Biocomposite Extraction, Structure, Properties and Characterization: A Review. Polymers 2021, 13, 3624. [Google Scholar] [CrossRef]

- Liu, X.; Wang, J.; Liu, T.; Cheng, Q.; Li, A.; Li, Y.; Liu, Z.; Sun, J.; Liu, D. Study on Epoxy Resin Composite Reinforced with Rice Straw Fiber. Materials 2023, 16, 1370. [Google Scholar] [CrossRef]

- Keijsers, E.; Oever, M.; Dam, J.; Lansbergen, A.; Koning, C.; Akker, H. The development of reed composite fiber boards using partially bio-based, formaldehyde- and monomeric isocyanate-free resins. Reinf. Plast. 2020, 64, 195–203. [Google Scholar] [CrossRef]

- Caponetto, R.; Cuomo, M.; Detommaso, M.; Giuffrida, G.; Presti, A.L.; Nocera, F. Performance Assessment of Giant Reed-Based Building Components. Sustainability 2023, 15, 2114. [Google Scholar] [CrossRef]

- Shadhin, M.; Rahman, M.; Jayaraman, R. Novel cattail fiber composites: Converting waste biomass into reinforcement for composites. Bioresour. Bioprocess. 2021, 8, 101. [Google Scholar] [CrossRef]

- Tomczak, D.; Woźniak, M.; Ratajczak, I.; Sip, A.; Baranowska, M.; Bula, K.; Čabalová, I.; Bubeníková, T.; Borysiak, S. Caffeine-treated wood as an innovative filler for advanced polymer composites. J. Wood Chem. Technol. 2023, 43, 271–288. [Google Scholar] [CrossRef]

- Turgut, P.; Algin, H.M. Limestone dust and wood sawdust as brick material. Build. Environ. 2007, 42, 3399–3403. [Google Scholar] [CrossRef]

- Batool, F.; Islam, K.; Cakiroglu, C.; Shahriar, A. Effectiveness of wood waste sawdust to produce medium- to low-strength concrete materials. J. Build. Eng. 2021, 44, 103237. [Google Scholar] [CrossRef]

- Aigbomian, E.P.; Fan, M. Development of Wood-Crete building materials from sawdust and waste paper. Constr. Build. Mater. 2013, 40, 361–366. [Google Scholar] [CrossRef]

- Teuber, L.; Osburg, V.-S.; Toporowski, W.; Militz, H.; Krause, A. Wood polymer composites and their contribution to cascading utilisation. J. Clean. Prod. 2016, 110, 9–15. [Google Scholar] [CrossRef]

- Faraca, G.; Boldrin, A.; Astrup, T. Resource quality of wood waste: The importance of physical and chemical impurities in wood waste for recycling. Waste Manag. 2019, 87, 135–147. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Natural binders and solid bridge type binding mechanisms in briquettes and pellets made from corn stover and switch grass. Bioresour. Technol. 2010, 101, 1082–1090. [Google Scholar] [CrossRef] [PubMed]

- Khlifi, S.; Lajili, M.; Belghith, S.; Mezlini, S.; Tabet, F.; Jeguirim, M. Briquettes Production from Olive Mill Waste under Optimal Temperature and Pressure Conditions: Physico-Chemical and Mechanical Characterizations. Energies 2020, 13, 1214. [Google Scholar] [CrossRef]

- Mili, M.; Hashmi, S.A.R.; Ather, M.; Hada, V.; Markandeya, N.; Kamble, S.; Mohapatra, M.; Rathore, S.K.S.; Srivastava, A.K.; Verma, S. Novel lignin as natural-biodegradable binder for various sectors–A review. J. Appl. Polym. Sci. 2022, 139, 51951. [Google Scholar] [CrossRef]

- Liew, K.; Tan, Y.; Albert, C.M.; Raman, V.; Boyou, M. Potential of Using Natural and Synthetic Binder in Wood Composites. Forests 2022, 13, 844. [Google Scholar] [CrossRef]

- Ferreira, A.M.; Pereira, J.; Almeida, M.; Ferra, J.; Paiva, N.; Martins, J.; Magalhães, F.D.; Carvalho, L.H. Low-cost natural binder for particleboards production: Study of manufacture conditions and stability. Int. J. Adhes. Adhes. 2019, 93, 102325. [Google Scholar] [CrossRef]

- Kajikawa, S.; Horikoshi, M.; Tanaka, S.; Umemura, K.; Kanayama, K. Molding of wood powder with a natural binder. Procedia Eng. 2017, 207, 113–118. [Google Scholar] [CrossRef]

- Nakanishi, E.Y.; Cabral, M.R.; Souza Gonçalves, P.; Santos, V.; Savastano Junior, H. Formaldehyde-free particleboards using natural latex as the polymeric binder. J. Clean. Prod. 2018, 195, 1259–1269. [Google Scholar] [CrossRef]

- Sleinus, D.; Sinka, M.; Korjakins, A.; Obuka, V.; Nikolajeva, V.; Brencis, R.; Savicka, E. Properties of Sound Absorption Composite Materials Developed Using Flax Fiber, Sphagnum Moss, Vermiculite, and Sapropel. Materials 2023, 16, 1060. [Google Scholar] [CrossRef]

- Vėjelis, S.; Karimova, M.B.; Kuatbayeva, T.K.; Kairytė, A.; Šeputytė-Jucikė, J. Sapropel as a Binding Material for Wood Processing Waste in the Development of Thermal Insulation Biocomposite. Materials 2023, 16, 2230. [Google Scholar] [CrossRef] [PubMed]

- Balčiūnas, G.; Žvironaitė, J.; Vėjelis, S.; Jagniatinskis, A.; Gaidučis, S. Ecological, thermal and acoustical insulating composite from hemp shives and sapropel binder. Ind. Crops Prod. 2016, 91, 286–294. [Google Scholar] [CrossRef]

- Brencis, R.; Pleiksnis, S.; Skujans, J.; Adamovics, A.; Gross, U. Lightweight Composite Building Materials with Hemp (Cannabis sativa L.). Chem. Eng. Trans. 2017, 57, 1375–1380. [Google Scholar] [CrossRef]

- Stankevica, K.; Vincevica-Gaile, Z.; Klavins, M. Freshwater sapropel (gyttja): Its description, properties and opportunities of use in contemporary agriculture. Agron. Res. 2016, 14, 929–947. [Google Scholar]

- Kozlovska, J. Research of Sapropel Use for Heat Production and Environmental Assessment. Ph.D. Thesis, Technika, Vilnius, Lithuania, 2012; p. 154. [Google Scholar]

- Obuka, V. Sapropel for the Development of Biocomposite Materials: Properties and Application Possibilities. Ph.D. Thesis, University of Latvia, Riga, Latvia, 2021. [Google Scholar]

- Guedri, A.; Yahya, K.; Hamdi, N.; Baeza-Urrea, O.; Wagner, J.-F.; Zagrarni, M.F. Properties Evaluation of Composite Materials Based on Gypsum Plaster and Posidonia Oceanica Fibers. Buildings 2023, 13, 177. [Google Scholar] [CrossRef]

- Nindiyasari, F.; Griesshaber, E.; Zimmermann, T.; Manian, A.P.; Randow, C.; Ziegler, A.; Zimmermann, T.; Zehbe, R.; Fleck, C. Characterization and mechanical properties investigation of the cellulose/gypsum composite. J. Compos. Mater. 2015, 50, 657–672. [Google Scholar] [CrossRef]

- Trociński, A.; Wieruszewski, M.; Kawalerczyk, J.; Mirski, R. Properties of fiber-gypsum composite formed on the basis of hemp (Cannabis sativa L.) fibers grown in Poland and natural gypsum. For. Wood Technol. 2023, 121, 29–36. [Google Scholar] [CrossRef]

- Jia, R.; Wang, Q.; Feng, P. A comprehensive overview of fibre-reinforced gypsum-based composites (FRGCs) in the construction field. Compos. Part B. Eng. 2021, 205, 108540. [Google Scholar] [CrossRef]

- Kaya, A.İ.; Yalçin, Ö.Ü.; Türker, Y. Physical, Mechanical and Thermal Properties of Red Pine Wood-Gypsum Particleboard. Bilge Int. J. Sci. Technol. Res. 2021, 5, 139–145. [Google Scholar] [CrossRef]

- Lushnikova, N.; Dvorkin, L. 25-Sustainability of gypsum products as a construction material. In Woodhead Publishing Series in Civil and Structural Engineering, Sustainability of Construction Materials, 2nd ed.; Khatib, J.M., Ed.; Woodhead Publishing: Cambridge, UK, 2016; pp. 643–681. [Google Scholar] [CrossRef]

- Vavřínová, N.; Stejskalová, K.; Teslík, J.; Kubenková, K.; Majer, J. Research of Mechanical and Thermal Properties of Composite Material Based on Gypsum and Straw. J. Renew. Mater. 2022, 10, 1859. [Google Scholar] [CrossRef]

- Klin, S. Rheological Properties of Building Gypsum Fresh Pastes. Arch. Hydro-Eng. Environ. Mech. 2005, 52, 265–282. [Google Scholar]

- Morales-Conde, M.J.; Rodríguez-Liñán, C.; Pedreño-Rojas, M.A. Physical and mechanical properties of wood-gypsum composites from demolition material in rehabilitation works. Constr. Build. Mater. 2016, 114, 6–14. [Google Scholar] [CrossRef]

- Mutuk, T.; Arpacioğlu, K.; Alişir, S.; Demir, G. Thermal and mechanical evaluation of natural fibers reinforced gypsum plaster composite. J. Met. Mater. Miner. 2023, 33, 116–123. [Google Scholar] [CrossRef]

- Pedreño-Rojas, M.A.; Morales-Conde, M.J.; Rubio-de-Hita, P.; Pérez-Gálvez, F. Impact of Wetting—Drying Cycles on the Mechanical Properties and Microstructure of Wood Waste—Gypsum Composites. Materials 2019, 12, 1829. [Google Scholar] [CrossRef]

- Shiroma, L.; Camarini, G.; Beraldo, A.L. Effect of wood particle treatment on the properties of gypsum plaster pastes and composites. Matéria 2016, 21, 1032–1044. [Google Scholar] [CrossRef]

- Wu, T.; Yue, K.; Wang, S.; Liang, B.; Wu, P.; Lu, W.; Xu, C.; Sun, K. Experimental investigation on mechanical properties and fire performance of innovative wheat straw-gypsum composites as building sheathing panels. Ind. Crop. Prod. 2024, 208, 117897. [Google Scholar] [CrossRef]

- Available online: https://www.ecolotus.lt/ (accessed on 4 December 2024).

- EN 12570; Industrial Valves-Method for Sizing the Operating Element. European Committee for Standardization: Brussels, Belgium, 2022.

- EN 13820; Thermal Insulating Materials for Building Applications-Determination of Organic. European Committee for Standardization: Brussels, Belgium, 2003.

- EN 459-1; Building lime-Part 1: Definitions, Specifications and Conformity Criteria. European Committee for Standardization: Brussels, Belgium, 2015.

- EN ISO 29470; Thermal Insulating Products for Building Applications-Determination of the Apparent Density. European Committee for Standardization: Brussels, Belgium, 2020.

- EN ISO 29469; Thermal Insulating Products for Building Applications-Determination of Compression Behaviour. European Committee for Standardization: Brussels, Belgium, 2022.

- EN 12664; Thermal Performance of Building Materials and Products-Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods-Dry and Moist Products of Medium and Low Thermal Resistance. European Committee for Standardization: Brussels, Belgium, 2001.

- Data Science Textbook. 2020. Available online: https://docs.tibco.com/data-science/textbook (accessed on 3 September 2024).

- Elert, K.; Alaminos, R.A.; Benavides-Reyes, C.; Burgos-Ruiz, M. The effect of lime addition on weathering resistance and mechanical strength of gypsum plasters and renders. Cem. Concr. Compos. 2023, 139, 105012. [Google Scholar] [CrossRef]

- Naciri, K.; Aalil, I.; Chaaba, A. Eco-friendly gypsum-lime mortar with the incorporation ofrecycledwaste brick. Constr. Build. Mater. 2022, 325, 126770. [Google Scholar] [CrossRef]

- Weng, L.P.; Koopal, L.K.; Hiemstra, T.; Meeussen, J.C.L.; Van Riemsdijk, W.H. Interactions of calcium and fulvic acid at the goethite-water interface. Geochim. Cosmochim. Acta 2005, 69, 325–339. [Google Scholar] [CrossRef]

- Ejaz, M.F.; Riaz, M.R.; Azam, R.; Hameed, R.; Fatima, A.; Deifalla, A.F.; Mohamed, A.M. Physico-Mechanical Characterization of Gypsum-Agricultural Waste Composites for Developing Eco-Friendly False Ceiling Tiles. Sustainability 2022, 14, 9797. [Google Scholar] [CrossRef]

- Kairytė, A.; Makowska, S.; Vaitkus, S.; Kremensas, A.; Vėjelis, S.; Balčiūnas, G. Impact of tung oil and sodium silicate-coated wood chips on the performance of cement-based thermal insulation composites. J. Mater. Res. Technol. 2025, 35, 6123–6136. [Google Scholar] [CrossRef]

- Tuğluca, M.S.; Özdoğru, E.; İlcan, H.; Özçelikci, E.; Ulugöl, H.; Şahmaran, M. Characterization of chemically treated waste wood fiber and its potential application in cementitious composites. Cem. Concr. Compos. 2023, 137, 104938. [Google Scholar] [CrossRef]

| Sampling Place of Sapropel | Water Content, Mass % | Acidity (pH) | Content of Organic Matter, Mass % |

|---|---|---|---|

| Lake Gervinis, the District of Alytus, Lithuania | 93.0 | 5.7–7.4 | 92.0 |

| Content of Water, % | Consistency, mm | Initial Setting Time, min | Final Setting Time, min | Density of Dry Hardened Gypsum, kg/m3 | Compressive Strength of Dry Hardened Gypsum, MPa |

|---|---|---|---|---|---|

| 60 | 160 | 10 | 15 | 1350 | 9.5 |

| The Size of the Sieve Mesh, mm | ||||||

|---|---|---|---|---|---|---|

| 10 | 5 | 2.5 | 1.25 | 0.63 | 0.315 | 0 |

| Residues of Wood Chips on Sieves, wt.% | ||||||

| 1.5 | 38.8 | 50.8 | 3.0 | 4.3 | 1.3 | 0.3 |

| Sapropel, % | Gypsum, % | Sapropel/ Gypsum | Lime, % * | Lime, r. u. ** | Water, % *** | |

|---|---|---|---|---|---|---|

| Water from Sapropel | Total Water Content | |||||

| 10 20 30 40 50 60 70 80 | 90 80 70 60 50 40 30 20 | 0.11 0.25 0.43 0.67 1.00 1.50 2.33 4.00 | – | – | 30 | 60 |

| 30 | 70 | 0.43 | 5; 10; 20 | 0.05; 0.10; 0.20 | ||

| 35 | 65 | 0.54 | 5; 10; 20 | 0.05; 0.10; 0.20 | ||

| 40 | 60 | 0.67 | 5; 10; 20 | 0.05; 0.10; 0.20 | ||

| 45 | 55 | 0.82 | 5; 10; 20 | 0.05; 0.10; 0.20 | ||

| 50 | 50 | 1 | 5; 10; 20 | 0.05; 0.10; 0.20 | ||

| Sapropel, % | Gypsum, % | Lime, % * | Water, % | Wood chips, % | ||

|---|---|---|---|---|---|---|

| Water from Sapropel | Total Water Content | Chemically Untreated | Chemically Treated | |||

| 30 | 70 | 10 | 30 | 80 | 20; 25; 30; 35; 40; 45; 50; 55; 60 | – |

| 30 | 70 | 10 | 30 | 60 | 20; 25; 30; 35; 40; 45; 50; 55; 60 | – |

| 30 | 70 | 10 | 30 | 60 | – | 20; 25; 30; 35; 40; 45; 50; 55; 60 |

| Sapropel, % | Gypsum, % | Lime, % * | Water, % | Wood chips, % | ||

|---|---|---|---|---|---|---|

| Water from Sapropel | Total Water Content | Chemically Untreated | Chemically Treated | |||

| 30 | 70 | 10 | 30 | 60 | 20; 25; 30; 35; 40; 45; 50; 55; 60 | – |

| 30 | 70 | 10 | 30 | 60 | – | 20; 25; 30; 35; 40; 45; 50; 55; 60 |

| – | 100 | 10 | – | 60 | 20; 25; 30; 35; 40; 45; 50; 55; 60 | – |

| – | 100 | 10 | – | 60 | – | 20; 25; 30; 35; 40; 45; 50; 55; 60 |

| No. | Equations of Composite Characteristics | Units |

|---|---|---|

| (2) | ) | kg/m3 |

| (3) | s/g) | MPa |

| (4) | MPa | |

| (5) | kg/m3 | |

| (6) | MPa | |

| (7) | kg/m3 | |

| (8) | MPa | |

| (9) | MPa | |

| (10) | MPa | |

| (11) | W/(m·K) |

| Equation No./Figure No. | No. of Specimens | Statistical Characteristics | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R | R2 | *R2 | F | p | ||||||||

| 2/1a | 37 | −0.1 | 6.531 | −0.912 | – | – | 0.995 | 0.989 | 0.988 | 21.5 | 15,033 | 0 |

| 3/1b | 37 | 0.01373 | −0.1023 | −0.8696 | – | – | 0.968 | 0.937 | 0.933 | 0.071 | 731 | 0 |

| 4/1c | 37 | −0.4631 | 0.00130 | – | – | – | 0.971 | 0.942 | 0.940 | 0.067 | 568 | 0 |

| 5/1d | 60 | 1006.755 | −468.139 | 434.79 | 81.07 | – | 0.980 | 0.961 | 0.958 | 15.8 | 388.8 | 0 |

| 6/1e | 60 | 1.23829 | −1.10564 | 2.44309 | 0.30147 | −6.66552 | 0.888 | 0.789 | 0.773 | 0.0782 | 51.3 | 0 |

| 4/1f | 60 | −0.6597 | 0.00188 | – | – | – | 0.896 | 0.803 | 0.799 | 0.074 | 236 | 0 |

| 7/2a | 20 | 988.950 | −9.3075 | – | – | – | 0.976 | 0.953 | 0.951 | 30.7 | 369 | 0 |

| 8/2b | 20 | 3.4347 | −0.0489 | – | – | – | 0.943 | 0.890 | 0.884 | 0.26 | 146 | 0 |

| 4/2c | 20 | −1.7808 | 0.00528 | – | – | – | 0.971 | 0.944 | 0.941 | 0.18 | 302 | 0 |

| 7/2d | 20 | 1068.35 | −5.440 | – | – | – | 0.983 | 0.967 | 0.965 | 14.9 | 531 | 0 |

| 9/2e | 20 | 9.09291 | −0.06130 | −50.0117 | – | – | 0.911 | 0.830 | 0.798 | 0.17 | 45.6 | 0 |

| 10/2f | 20 | 51.6786 | −0.02557 | −20864 | – | – | 0.960 | 0.922 | 0.907 | 0.12 | 105 | 0 |

| 7/4a | 20 | 1108.45 | −7.000 | – | – | – | 0.979 | 0.959 | 0.956 | 21.7 | 417 | 0 |

| 8/4b | 20 | 7.23665 | −0.06235 | – | – | – | 0.919 | 0.844 | 0.835 | 0.40 | 97.4 | 0 |

| 4/4c | 20 | −2.6382 | 0.00891 | – | – | – | 0.939 | 0.881 | 0.874 | 0.35 | 133 | 0 |

| 7/5a | 20 | 1207.50 | −7.8100 | – | – | – | 0.988 | 0.976 | 0.974 | 18.3 | 726 | 0 |

| 8/5b | 20 | 9.6895 | −0.08781 | – | – | – | 0.900 | 0.810 | 0.799 | 0.64 | 76.5 | 0 |

| 4/5c | 20 | −4.0518 | 0.01143 | – | – | – | 0.926 | 0.858 | 0.849 | 0.55 | 108 | 0 |

| 11/6a | 27 | −0.3333 | 0.591·10−3 | 0.004102 | −0.53·10 −5 | – | 0.988 | 0.976 | 0.971 | 0.0035 | 310 | 0 |

| 11/6b | 27 | −0.1059 | 0.000315 | 0.002726 | −0.44·10 −5 | – | 0.988 | 0.977 | 0.973 | 0.0027 | 328 | 0 |

| 11/7a | 27 | −0.2827 | 0.536·10−3 | 0.00505 | −0.66·10 −5 | – | 0.981 | 0.963 | 0.956 | 0.053 | 201 | 0 |

| 11/7b | 27 | −0.3048 | 0.546·10−3 | 0.005416 | −0.70·10 −5 | – | 0.979 | 0.959 | 0.951 | 0.0048 | 182 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Šeputytė-Jucikė, J.; Vėjelis, S.; Vaitkus, S.; Kairytė, A.; Kremensas, A.; Balčiūnas, G. The Effect of Gypsum on the Self-Hardening of Sapropel in Thermal Insulating Wood Chips Composite. Materials 2025, 18, 2217. https://doi.org/10.3390/ma18102217

Šeputytė-Jucikė J, Vėjelis S, Vaitkus S, Kairytė A, Kremensas A, Balčiūnas G. The Effect of Gypsum on the Self-Hardening of Sapropel in Thermal Insulating Wood Chips Composite. Materials. 2025; 18(10):2217. https://doi.org/10.3390/ma18102217

Chicago/Turabian StyleŠeputytė-Jucikė, Jurga, Sigitas Vėjelis, Saulius Vaitkus, Agnė Kairytė, Arūnas Kremensas, and Giedrius Balčiūnas. 2025. "The Effect of Gypsum on the Self-Hardening of Sapropel in Thermal Insulating Wood Chips Composite" Materials 18, no. 10: 2217. https://doi.org/10.3390/ma18102217

APA StyleŠeputytė-Jucikė, J., Vėjelis, S., Vaitkus, S., Kairytė, A., Kremensas, A., & Balčiūnas, G. (2025). The Effect of Gypsum on the Self-Hardening of Sapropel in Thermal Insulating Wood Chips Composite. Materials, 18(10), 2217. https://doi.org/10.3390/ma18102217