Effect of a ZrO2 Seed Layer on an Hf0.5Zr0.5O2 Ferroelectric Device Fabricated via Plasma Enhanced Atomic Layer Deposition

Abstract

1. Introduction

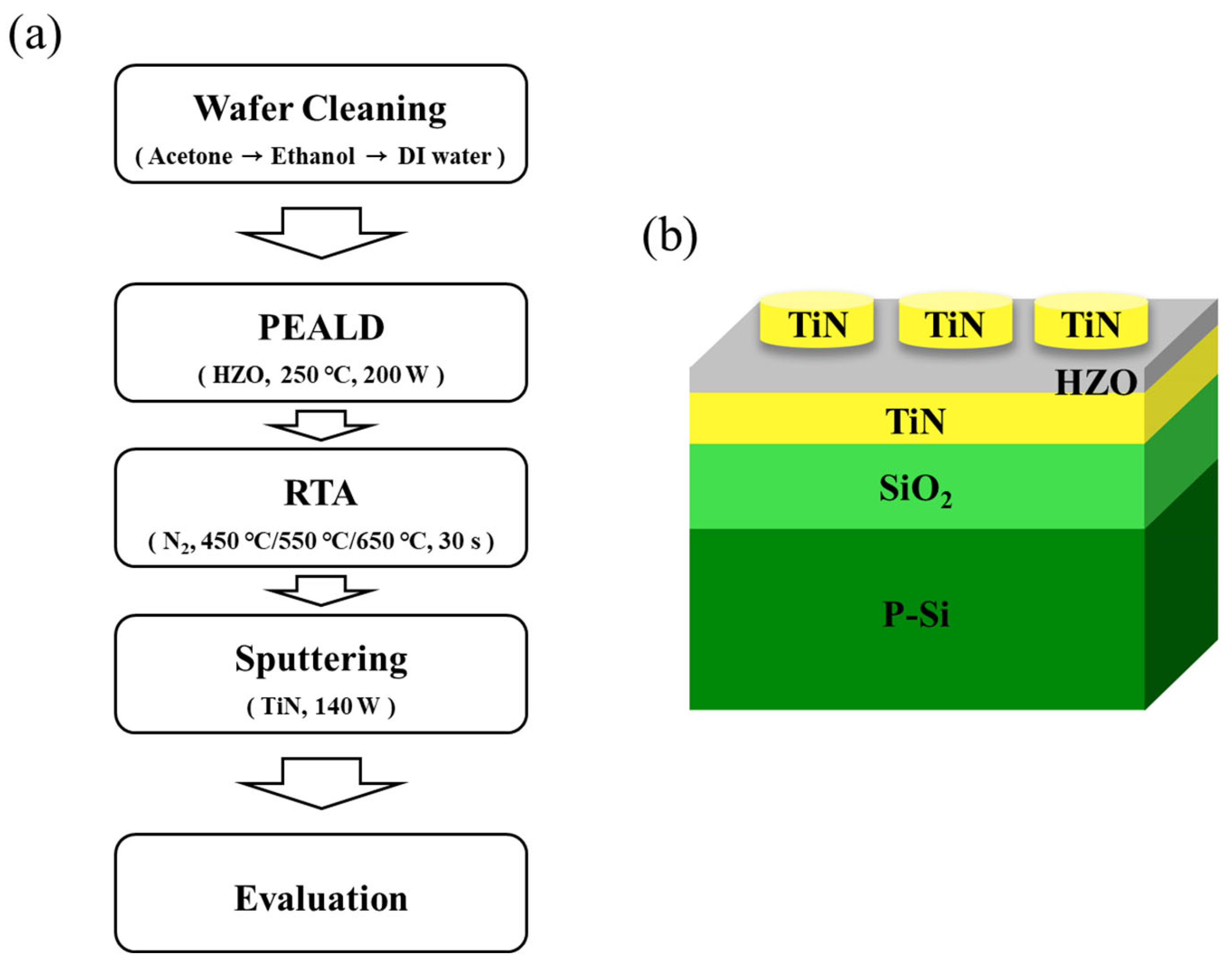

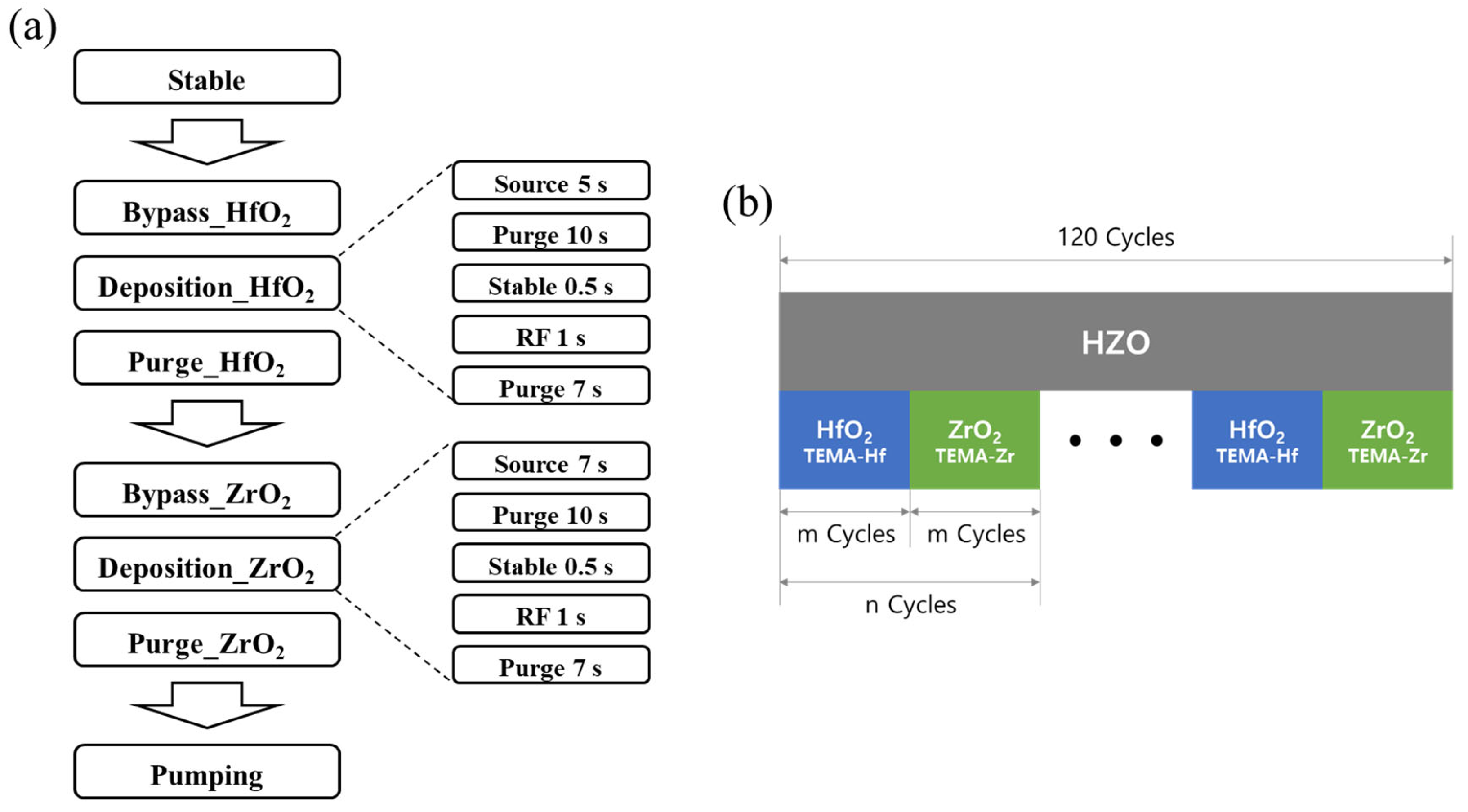

2. Materials and Methods

2.1. HZO Ferroelectric Device Fabrication

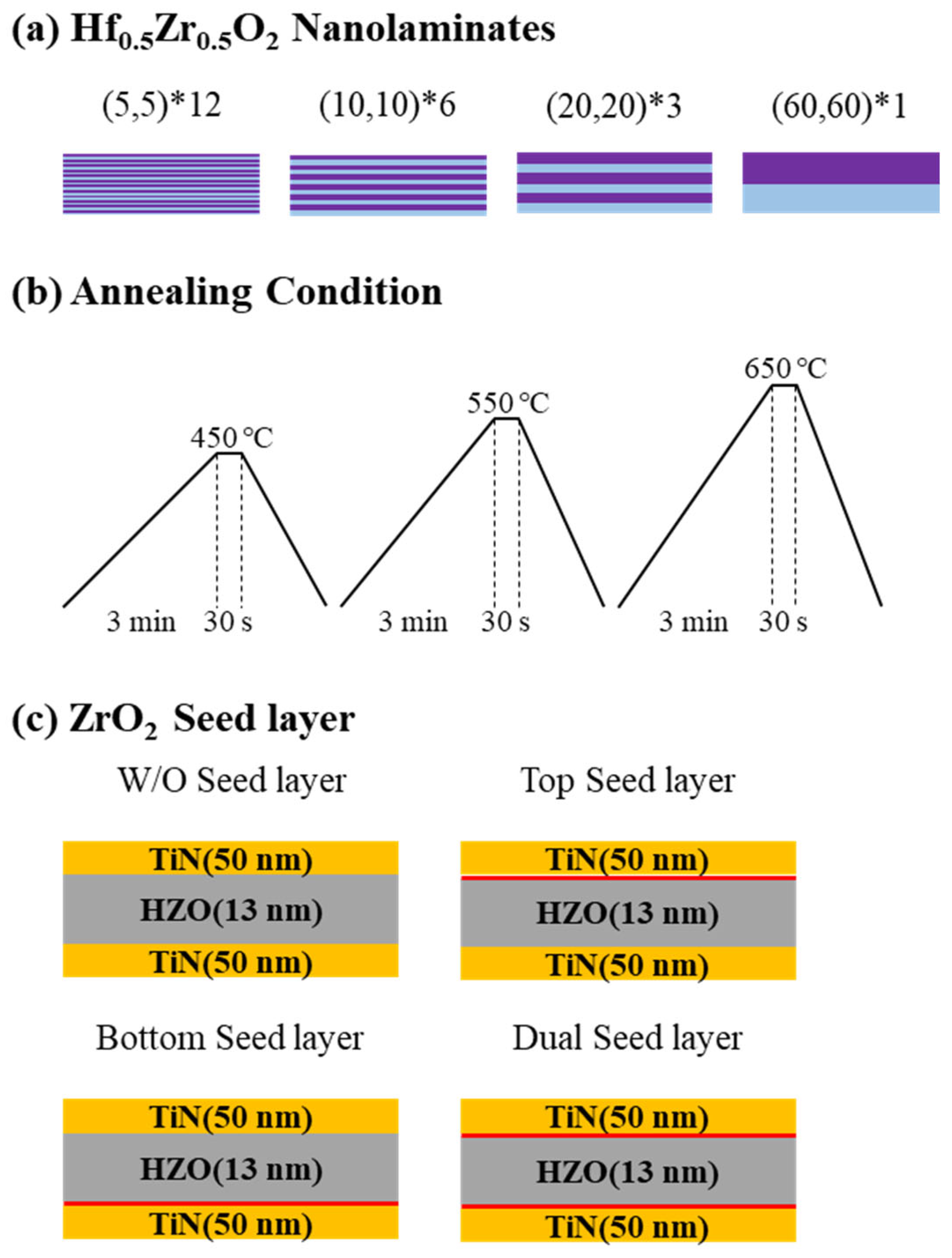

2.2. Variables

2.3. Evaluation

3. Results

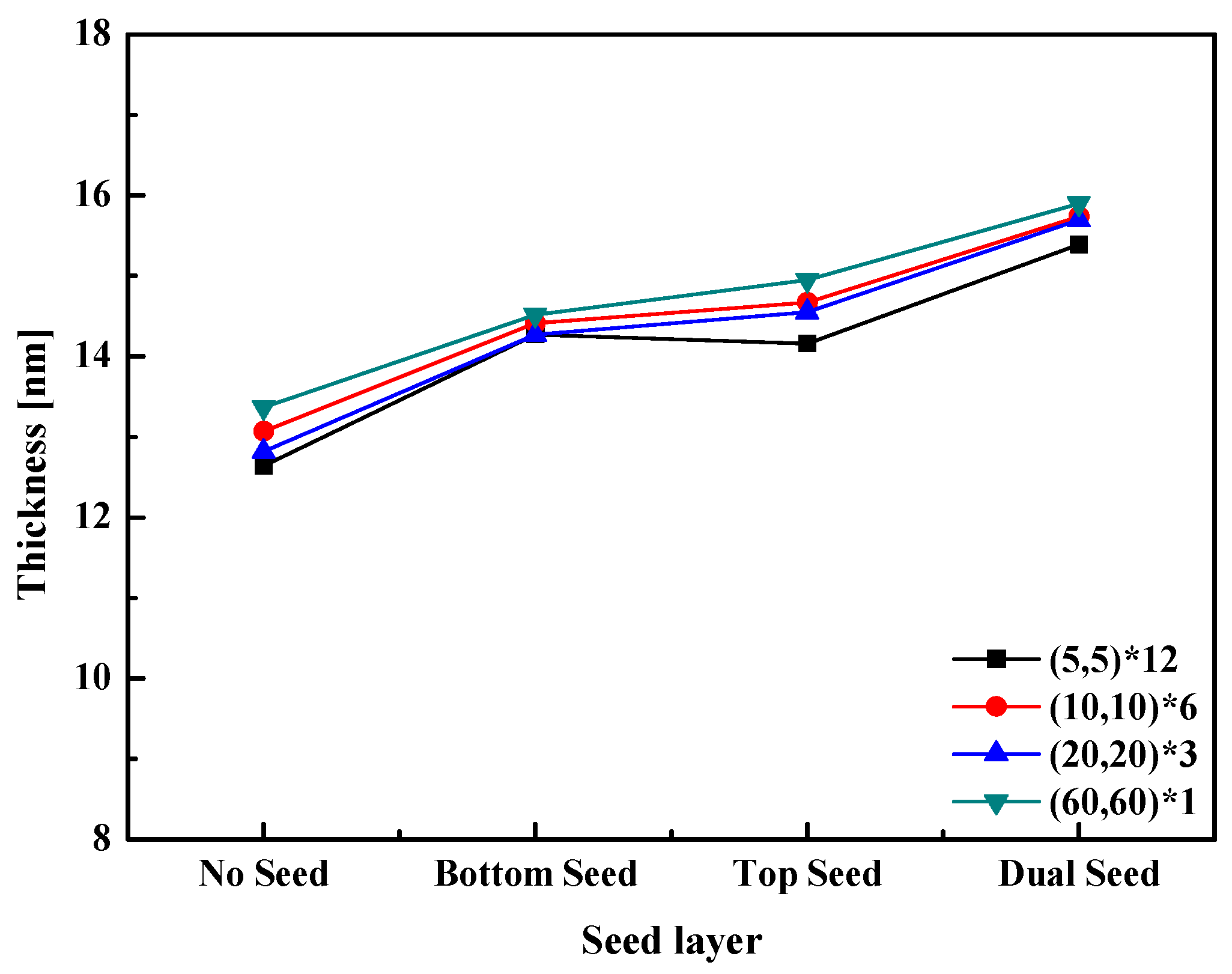

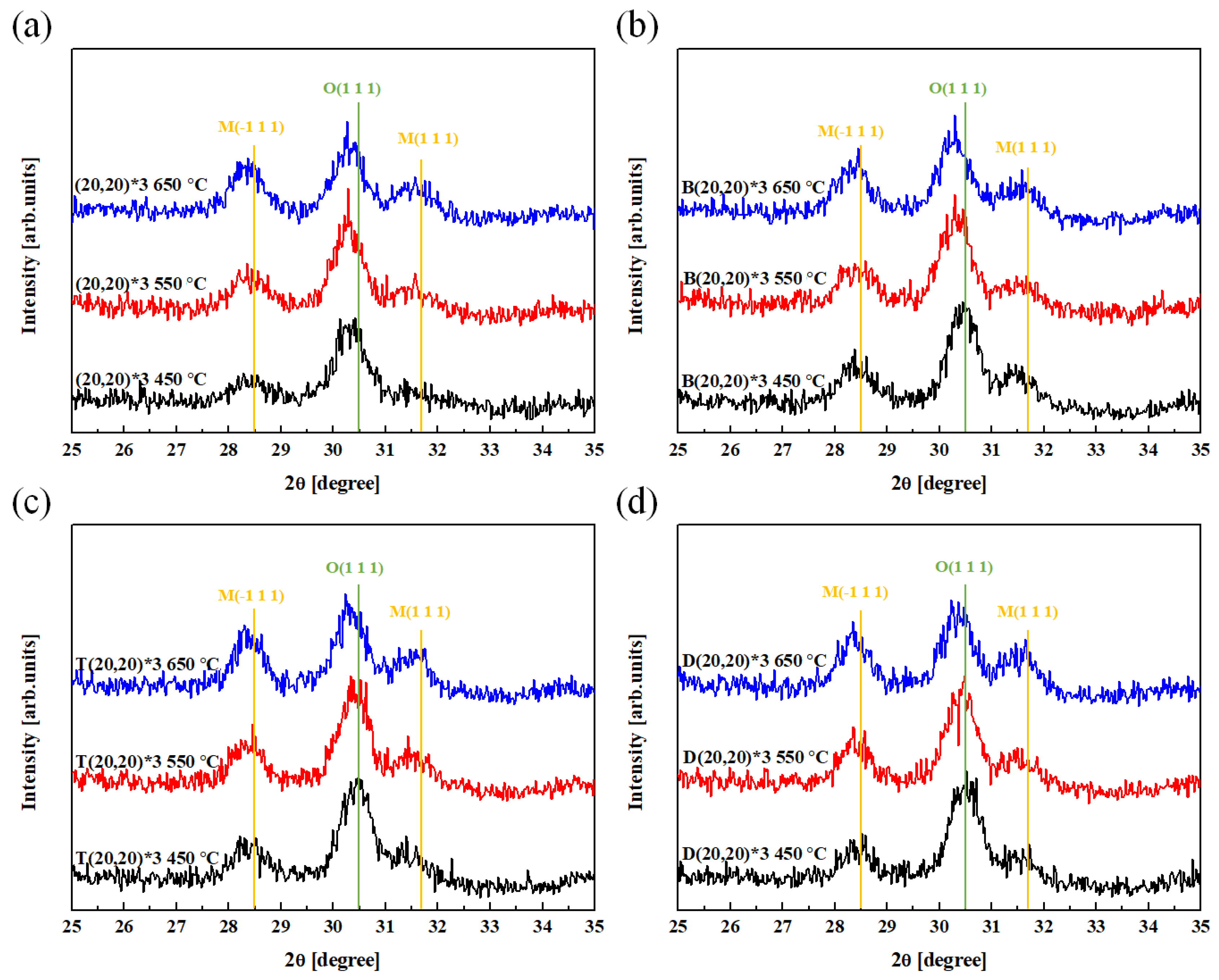

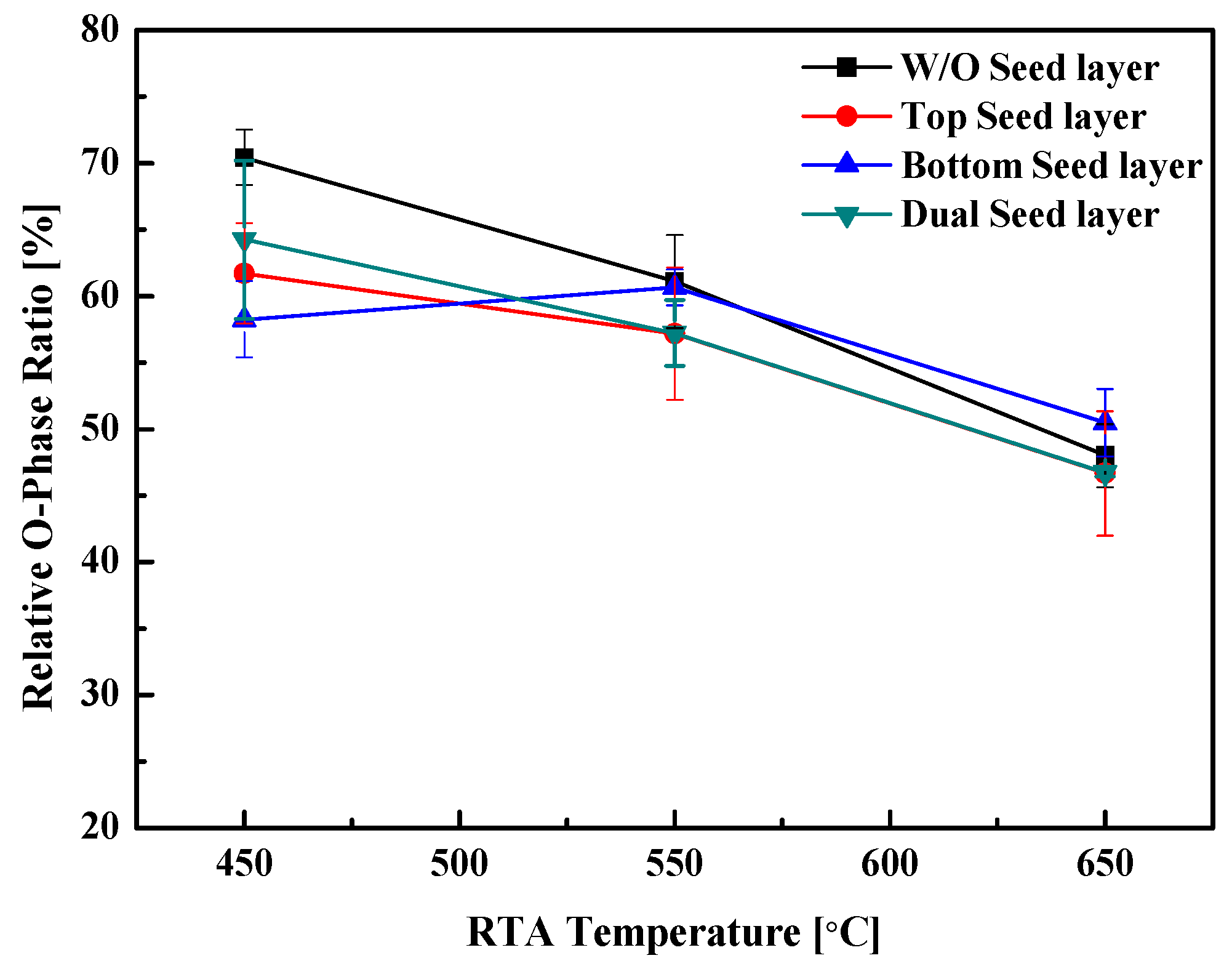

3.1. HZO Thin Film Characteristics

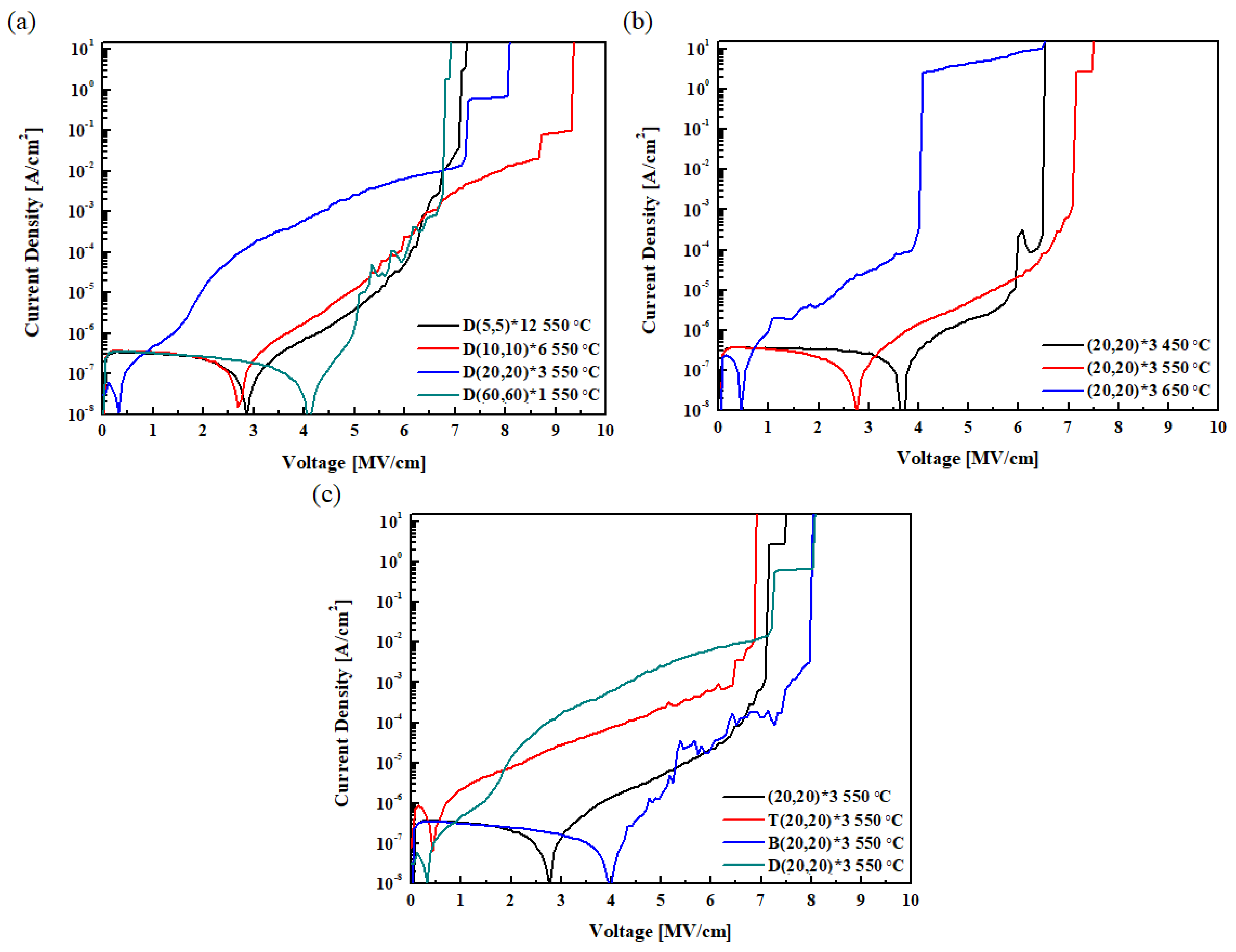

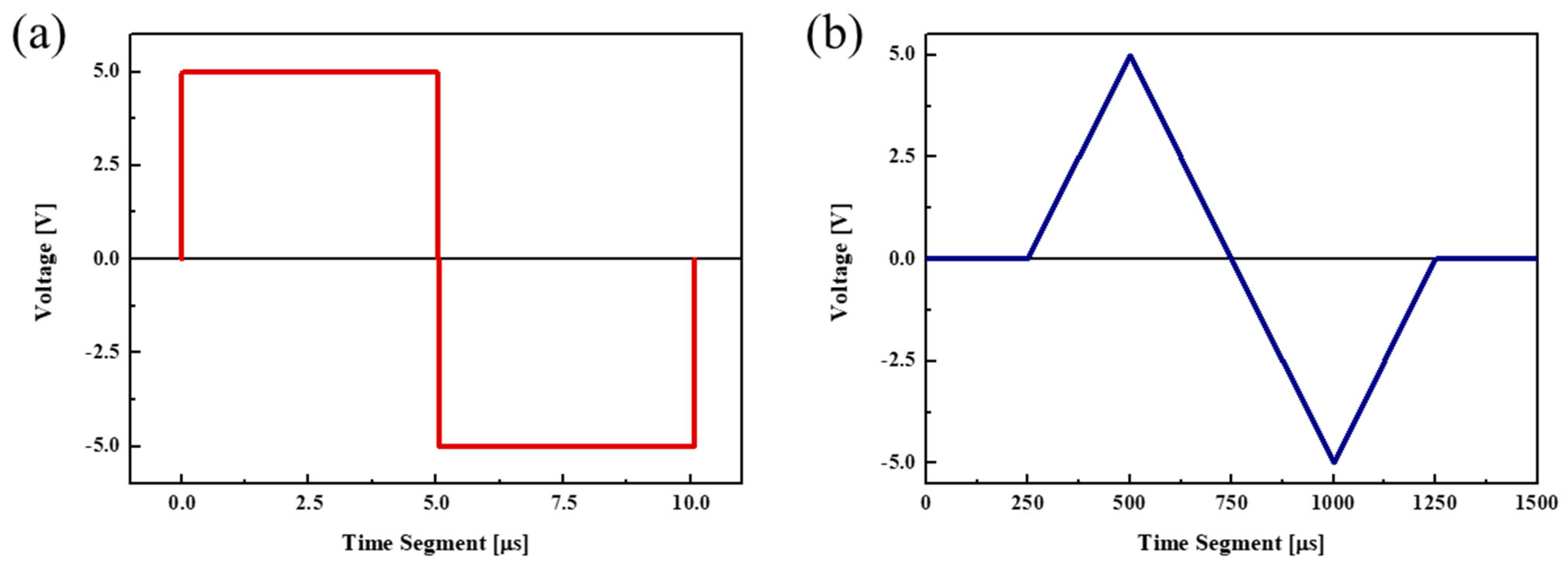

3.2. MFM Device Electrical Characteristics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jeong, H.; Song, K.-W.; Park, I.H.; Kim, T.-H.; Lee, Y.S.; Kim, S.-G.; Seo, J.; Cho, K.; Lee, K.; Shin, H.; et al. A New Capacitorless 1T DRAM Cell: Surrounding Gate MOSFET With Vertical Channel (SGVC Cell). IEEE Trans. Nanotechnol. 2007, 6, 352–357. [Google Scholar] [CrossRef]

- Sakui, K.; Harada, N. Dynamic Flash Memory with Dual Gate Surrounding Gate Transistor (SGT). In Proceedings of the 2021 IEEE International Memory Workshop (IMW), Dresden, Germany, 16–19 May 2021; IEEE: Dresden, Germany, 2021; pp. 1–4. [Google Scholar]

- Lomenzo, P.D.; Li, S.; Pintilie, L.; Istrate, C.M.; Mikolajick, T.; Schroeder, U. Memory Window Enhancement in Antiferroelectric RAM by Hf Doping in ZrO2. IEEE Electron Device Lett. 2022, 43, 1447–1450. [Google Scholar] [CrossRef]

- Wong, H.S.P.; Raoux, S.; Kim, S.; Liang, J.; Reifenberg, J.P.; Rajendran, B.; Asheghi, M.; Goodson, K.E. Phase Change Memory. Proc. IEEE 2010, 98, 2201–2227. [Google Scholar] [CrossRef]

- Guo, R.; You, L.; Zhou, Y.; Lim, Z.S.; Zou, X.; Chen, L.; Ramesh, R.; Wang, J. Non-volatile memory based on the ferroelectric photovoltaic effect. Nat. Commun. 2013, 4, 1990. [Google Scholar] [CrossRef]

- Luo, Q.; Cheng, Y.; Yang, J.; Cao, R.; Ma, H.; Yang, Y.; Huang, R.; Wei, W.; Zheng, Y.; Gong, T.; et al. A highly CMOS compatible hafnia-based ferroelectric diode. Nat. Commun. 2020, 11, 1391. [Google Scholar] [CrossRef]

- Böscke, T.S.; Müller, J.; Bräuhaus, D.; Schröder, U.; Böttger, U. Ferroelectricity in hafnium oxide thin films. Appl. Phys. Lett. 2011, 99, 102903. [Google Scholar] [CrossRef]

- Müller, J.; Schröder, U.; Böscke, T.S.; Müller, I.; Böttger, U.; Wilde, L.; Sundqvist, J.; Lemberger, M.; Kücher, P.; Mikolajick, T.; et al. Ferroelectricity in yttrium-doped hafnium oxide. J. Appl. Phys. 2011, 110, 114113. [Google Scholar] [CrossRef]

- Mueller, S.; Mueller, J.; Singh, A.; Riedel, S.; Sundqvist, J.; Schroeder, U.; Mikolajick, T. Incipient Ferroelectricity in Al-Doped HfO2 Thin Films. Adv. Funct. Mater. 2012, 22, 2412–2417. [Google Scholar] [CrossRef]

- Müller, J.; Böscke, T.S.; Bräuhaus, D.; Schröder, U.; Böttger, U.; Sundqvist, J.; Kücher, P.; Mikolajick, T.; Frey, L. Ferroelectric Zr0.5Hf0.5O2 thin films for nonvolatile memory applications. Appl. Phys. Lett. 2011, 99, 112901. [Google Scholar] [CrossRef]

- Müller, J.; Böscke, T.S.; Schröder, U.; Mueller, S.; Bräuhaus, D.; Böttger, U.; Frey, L.; Mikolajick, T. Ferroelectricity in Simple Binary ZrO2 and HfO2. Nano Lett. 2012, 12, 4318–4323. [Google Scholar] [CrossRef]

- Kim, S.J.; Mohan, J.; Summerfelt, S.R.; Kim, J. Ferroelectric Hf0.5Zr0.5O2 Thin Films: A Review of Recent Advances. JOM 2019, 71, 246–255. [Google Scholar] [CrossRef]

- Chouprik, A.; Negrov, D.; Tsymbal, E.Y.; Zenkevich, A. Defects in ferroelectric HfO2. Nanoscale 2021, 13, 11635–11678. [Google Scholar] [CrossRef]

- Wang, C.; Qiao, H.; Kim, Y. Perspective on the switching behavior of HfO2-based ferroelectrics. J. Appl. Phys. 2021, 129, 010902. [Google Scholar] [CrossRef]

- Kim, H.J.; Park, M.H.; Kim, Y.J.; Lee, Y.H.; Jeon, W.; Gwon, T.; Moon, T.; Kim, K.D.; Hwang, C.S. Grain size engineering for ferroelectric Hf0.5Zr0.5O2 films by an insertion of Al2O3 interlayer. Appl. Phys. Lett. 2014, 105, 192903. [Google Scholar] [CrossRef]

- Onaya, T.; Nabatame, T.; Sawamoto, N.; Ohi, A.; Ikeda, N.; Nagata, T.; Ogura, A. Improvement in ferroelectricity of HfxZr1−xO2 thin films using top- and bottom-ZrO2 nucleation layers. APL Mater. 2019, 7, 061107. [Google Scholar] [CrossRef]

- Xiao, W.; Liu, C.; Peng, Y.; Zheng, S.; Feng, Q.; Zhang, C.; Zhang, J.; Hao, Y.; Liao, M.; Zhou, Y. Performance Improvement of Hf0.5Zr0.5O2-Based Ferroelectric-Field-Effect Transistors with ZrO2 Seed Layers. IEEE Electron Device Lett. 2019, 40, 714–717. [Google Scholar] [CrossRef]

- Xiao, W.; Liu, C.; Peng, Y.; Zheng, S.; Feng, Q.; Zhang, C.; Zhang, J.; Hao, Y.; Liao, M.; Zhou, Y. Memory Window and Endurance Improvement of Hf0.5Zr0.5O2-Based FeFETs with ZrO2 Seed Layers Characterized by Fast Voltage Pulse Measurements. Nanoscale Res. Lett. 2019, 14, 254. [Google Scholar] [CrossRef]

- Gaddam, V.; Das, D.; Jeon, S. Insertion of HfO2 Seed/Dielectric Layer to the Ferroelectric HZO Films for Heightened Remanent Polarization in MFM Capacitors. IEEE Trans. Electron Devices 2020, 67, 745–750. [Google Scholar] [CrossRef]

- Kim, H. Characteristics and applications of plasma enhanced-atomic layer deposition. Thin Solid Films 2011, 519, 6639–6644. [Google Scholar] [CrossRef]

- Lao, S.X.; Martin, R.M.; Chang, J.P. Plasma enhanced atomic layer deposition of HfO2 and ZrO2 high-k thin films. J. Vac. Sci. Technol. A 2005, 23, 488–496. [Google Scholar] [CrossRef]

- Cao, R.; Wang, Y.; Zhao, S.; Yang, Y.; Zhao, X.; Wang, W.; Zhang, X.; Lv, H.; Liu, Q.; Liu, M. Effects of Capping Electrode on Ferroelectric Properties of Hf0.5Zr0.5O2 Thin Films. IEEE Electron Device Lett. 2018, 39, 1207–1210. [Google Scholar] [CrossRef]

- Kim, H.; Kashir, A.; Oh, S.; Hwang, H. A new approach to achieving strong ferroelectric properties in TiN/Hf0.5Zr0.5O2/TiN devices. Nanotechnology 2021, 32, 055703. [Google Scholar] [CrossRef] [PubMed]

- Ghiyasiyan-Arani, M.; Salavati-Niasari, M. Comparative study on electrochemical hydrogen storage of nanocomposites based on S or N doped graphene quantum dots and nanostructured titanium niobate. J. Alloys Compd. 2022, 899, 163379. [Google Scholar] [CrossRef]

- Park, M.H.; Kim, H.J.; Lee, G.; Park, J.; Lee, Y.H.; Kim, Y.J.; Moon, T.; Kim, K.D.; Hyun, S.D.; Park, H.W.; et al. A comprehensive study on the mechanism of ferroelectric phase formation in hafnia-zirconia nanolaminates and superlattices. Appl. Phys. Rev. 2019, 6, 041403. [Google Scholar] [CrossRef]

- Weeks, S.L.; Pal, A.; Narasimhan, V.K.; Littau, K.A.; Chiang, T. Engineering of Ferroelectric HfO2–ZrO2 Nanolaminates. ACS Appl. Mater. Interfaces 2017, 9, 13440–13447. [Google Scholar] [CrossRef]

- Hyuk Park, M.; Joon Kim, H.; Jin Kim, Y.; Lee, W.; Moon, T.; Seong Hwang, C. Evolution of phases and ferroelectric properties of thin Hf0.5Zr0.5O2 films according to the thickness and annealing temperature. Appl. Phys. Lett. 2013, 102, 242905. [Google Scholar] [CrossRef]

- Choi, Y.; Han, C.; Shin, J.; Moon, S.; Min, J.; Park, H.; Eom, D.; Lee, J.; Shin, C. Impact of Chamber/Annealing Temperature on the Endurance Characteristic of Zr:HfO2 Ferroelectric Capacitor. Sensors 2022, 22, 4087. [Google Scholar] [CrossRef]

- Jõgiaas, T.; Kull, M.; Seemen, H.; Ritslaid, P.; Kukli, K.; Tamm, A. Optical and mechanical properties of nanolaminates of zirconium and hafnium oxides grown by atomic layer deposition. J. Vac. Sci. Technol. A 2020, 38, 022406. [Google Scholar] [CrossRef]

- Zhou, D.; Xu, J.; Li, Q.; Guan, Y.; Cao, F.; Dong, X.; Müller, J.; Schenk, T.; Schröder, U. Wake-up effects in Si-doped hafnium oxide ferroelectric thin films. Appl. Phys. Lett. 2013, 103, 192904. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, Y.; Yang, Q.; Jiang, J.; Fan, P.; Liao, M. The effects of oxygen vacancies on ferroelectric phase transition of HfO2-based thin film from first-principle. Comput. Mater. Sci. 2019, 167, 143–150. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, J.-N.; Oh, M.-J.; Yoon, C.-B. Effect of a ZrO2 Seed Layer on an Hf0.5Zr0.5O2 Ferroelectric Device Fabricated via Plasma Enhanced Atomic Layer Deposition. Materials 2023, 16, 1959. https://doi.org/10.3390/ma16051959

Song J-N, Oh M-J, Yoon C-B. Effect of a ZrO2 Seed Layer on an Hf0.5Zr0.5O2 Ferroelectric Device Fabricated via Plasma Enhanced Atomic Layer Deposition. Materials. 2023; 16(5):1959. https://doi.org/10.3390/ma16051959

Chicago/Turabian StyleSong, Ji-Na, Min-Jung Oh, and Chang-Bun Yoon. 2023. "Effect of a ZrO2 Seed Layer on an Hf0.5Zr0.5O2 Ferroelectric Device Fabricated via Plasma Enhanced Atomic Layer Deposition" Materials 16, no. 5: 1959. https://doi.org/10.3390/ma16051959

APA StyleSong, J.-N., Oh, M.-J., & Yoon, C.-B. (2023). Effect of a ZrO2 Seed Layer on an Hf0.5Zr0.5O2 Ferroelectric Device Fabricated via Plasma Enhanced Atomic Layer Deposition. Materials, 16(5), 1959. https://doi.org/10.3390/ma16051959