Enhanced Ferroelectric and Dielectric Properties of Niobium-Doped Lead-Free Piezoceramics

Abstract

1. Introduction

2. Synthesis of BNT-ST26 Powder

2.1. Powder Preparation

2.2. Characterization Techniques

3. Results and Discussion

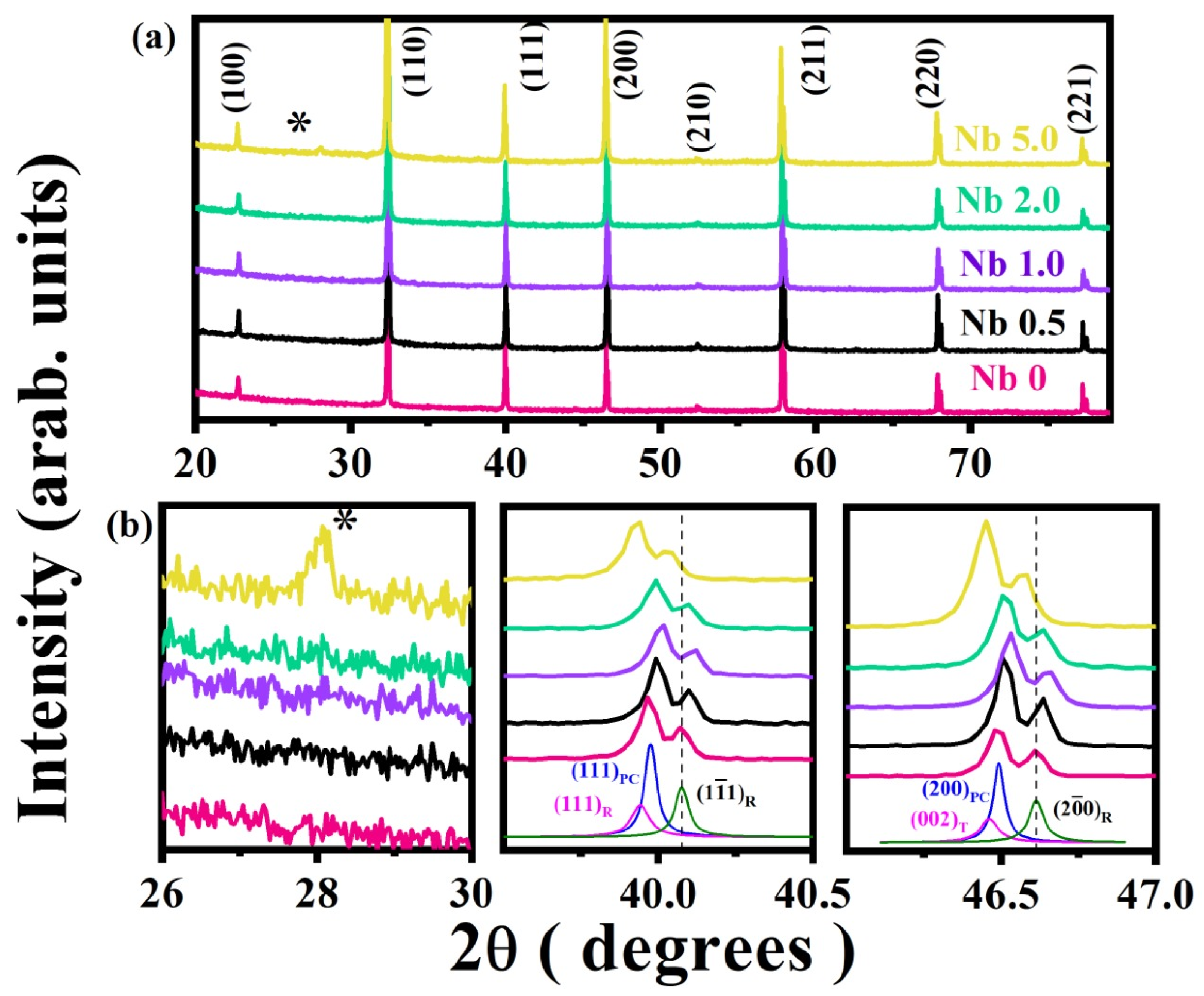

3.1. Structural Analysis

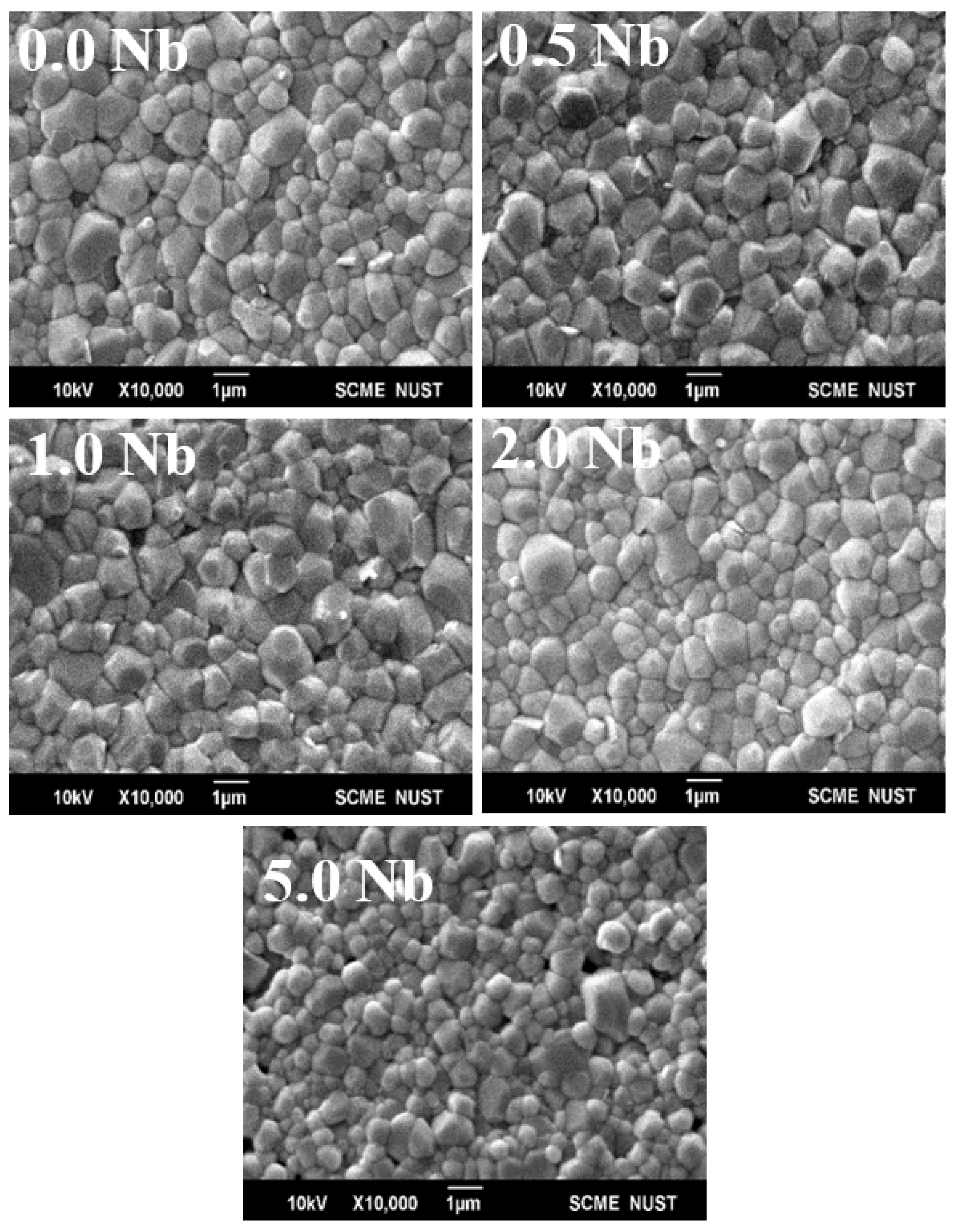

3.1.1. Microstructure

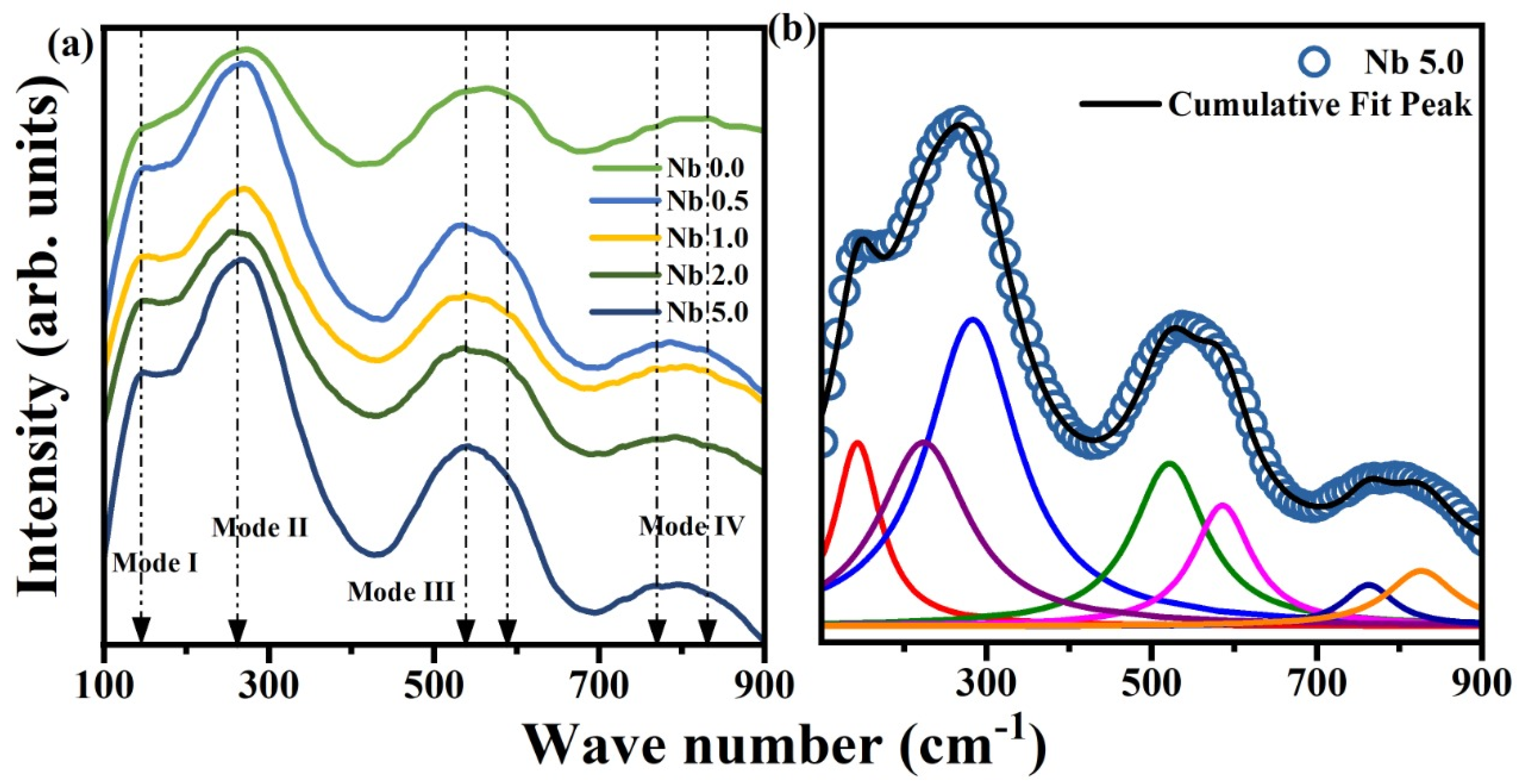

3.1.2. Raman

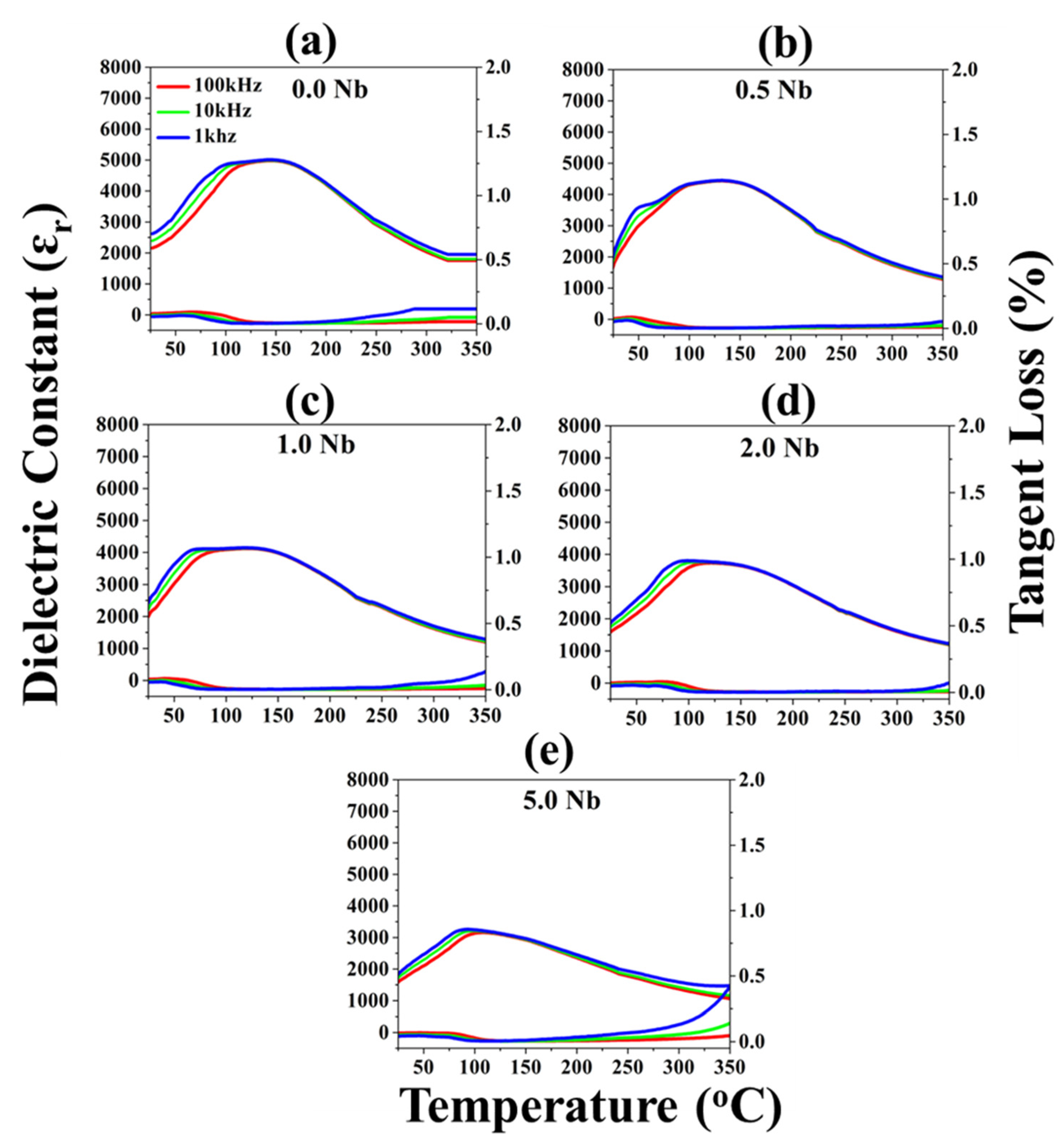

3.2. Dielectric Studies as a Function of Temperature

3.2.1. Ferroelectric Characterizations

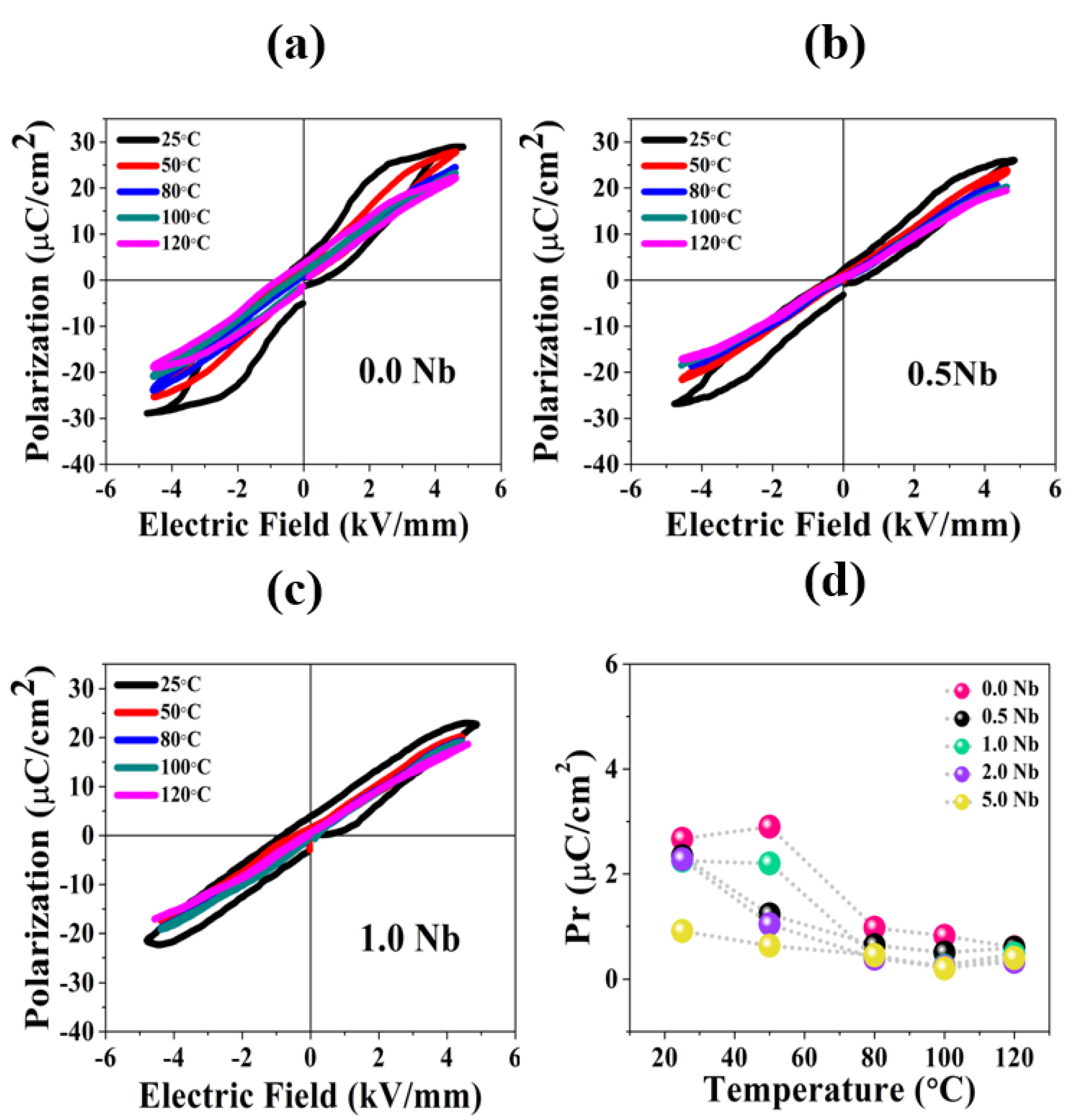

Polarization vs. Electric Field

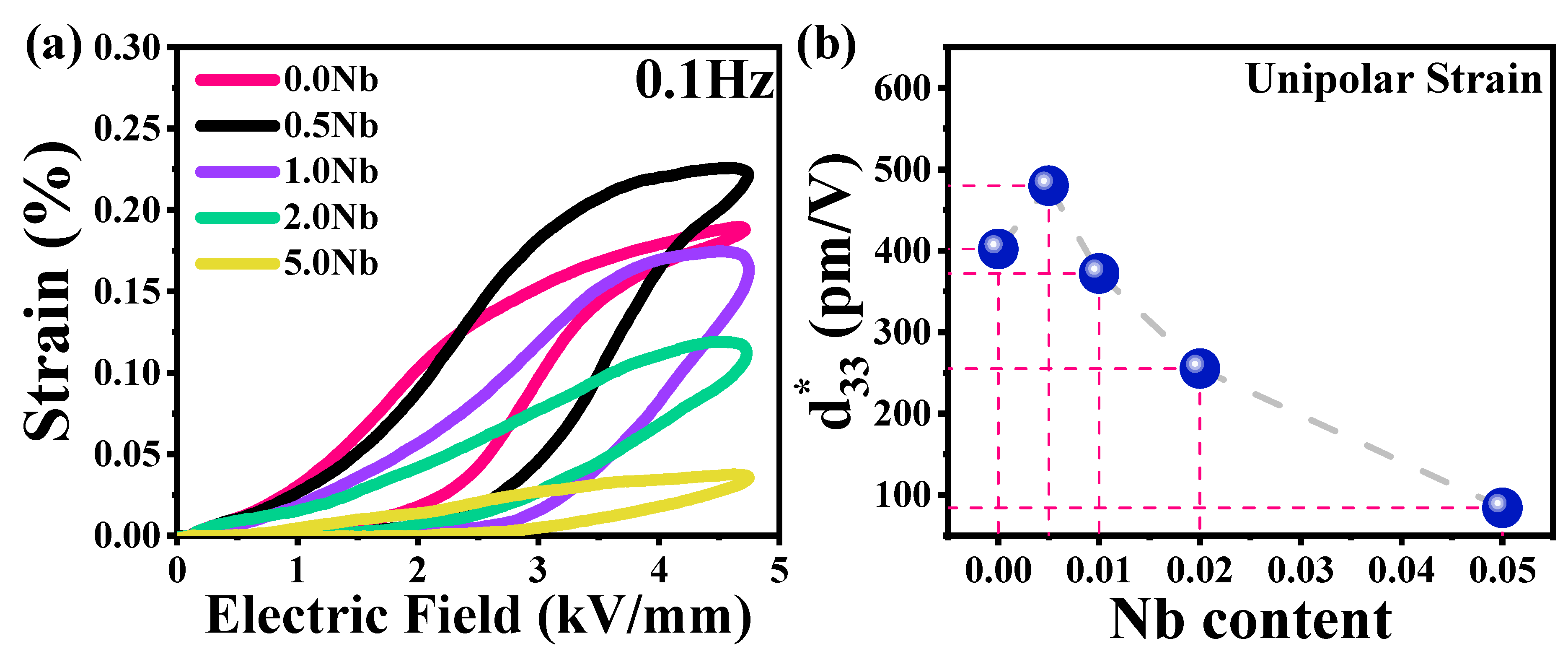

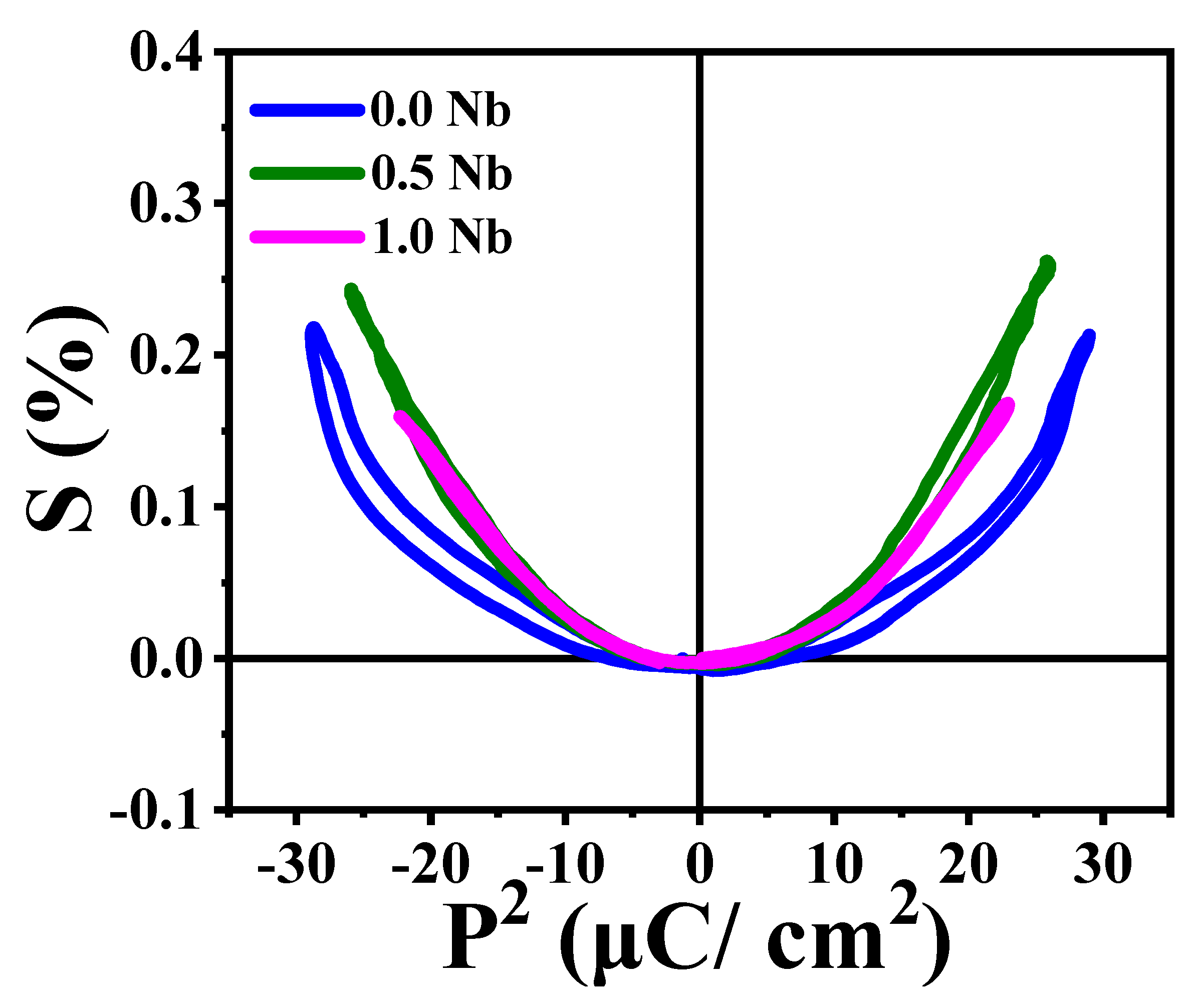

Strain vs. Electric Field Curves

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Jo, W.; Dittmer, R.; Acosta, M.; Zang, J.; Groh, C.; Sapper, E.; Wang, K.; Rödel, J. Giant electric-field-induced strains in lead-free ceramics for actuator applications—status and perspective. J. Electroceramics 2012, 29, 71–93. [Google Scholar] [CrossRef]

- Jaffe, B.; Cook, W.; Jaffe, H.J.P.C. The piezoelectric effect in ceramics. Piezoelectric Ceram. 1971, 1, 7–21. [Google Scholar]

- Saleem, M.; Kim, I.S.; Song, J.S.; Jeong, S.J.; Kim, M.S.; Yoon, S.; Korean, J. Ferroelectric properties and microwave sintering of BaTiO3 synthesized by using the alkoxide-hydroxide sol-gel process. Phys. Soc. 2014, 65, 92–97. [Google Scholar] [CrossRef]

- Rodel, J.; Klaus, W.J.; Seifert, T.P.; Anton, E.M.T.; Granzow, J. Perspective on the Development of Lead-free Piezoceramics. J. Am. Ceram. Soc. 2009, 92, 1153. [Google Scholar] [CrossRef]

- Saleem, M.; Butt, M.S.; Maqbool, A.; Umer, M.A.; Shahid, M.; Javaid, F.; Malik, R.A.; Jabbar, H.; Khalil, H.M.W.; Hwan, L.D.; et al. Percolation phenomena of dielectric permittivity of a microwave-sintered BaTiO3–Ag nanocomposite for high energy capacitor. J. Alloys Compd. 2020, 822, 153525. [Google Scholar] [CrossRef]

- Krauss, W.; Schütz, D.; Mautner, F.A.; Feteira, A.; Reichmann, K. Piezoelectric properties and phase transition temperatures of the solid solution of (1 − x)(Bi0.5Na0.5)TiO3–xSrTiO3. J. Eur. Ceram. Soc. 2010, 30, 1827–1832. [Google Scholar] [CrossRef]

- Yuan, Y.; Zhou, X.H.; Zhao, C.J.; Li, B.; Zhang, S.R. High-Temperature Capacitor Based on Ca-Doped Bi0.5Na0.5TiO3-BaTiO3 Ceramics. J. Electron. Mater. 2010, 39, 2471–2475. [Google Scholar] [CrossRef]

- Zhang, S.T.; Kounga, A.B.; Aulbach, E.; Ehrenberg, H.; Rödel, J. Giant strain in lead-free piezoceramics Bi0.5Na0.5TiO3–BaTiO3–K0.5Na0.5NbO3 system. Appl. Phys. Lett. 2007, 91, 112906. [Google Scholar] [CrossRef]

- Fuentes, S.; Zarate, R.A.; Chavez, E.; Muñoz, P.; Díaz-Droguett, D.; Leyton, P. Preparation of SrTiO3 nanomaterial by a sol–gel-hydrothermal Method. J. Mater. Sci. 2010, 45, 1448–1452. [Google Scholar] [CrossRef]

- Saleem, M.; Kim, I.S.; Kim, M.S.; Koo, B.K.; Jeong, S.J. Large signal electrical property of CuO-doped of a Bi0.5Na0.5TiO3–SrTiO3. J. Electroceram. 2018, 40, 88–98. [Google Scholar] [CrossRef]

- Saleem, M.; Kim, M.S.; Kim, I.S.; Jeong, S.J. Polarization and strain behaviors of 0.74 BiNaTiO3–0.26 SrTiO3/Bi0.5 (Na0.8K0.2) 0.5 TiO3 ceramic composite. Ceram. Int. 2016, 42, 13960–13968. [Google Scholar] [CrossRef]

- Maqbool, A.; Hussain, A.; Malik, R.A.; Rahman, J.U.; Zaman, A.; Song, T.K.; Kim, W.-J.; Kim, M.-H. Evolution of phase structure and giant strain at low driving fields in Bi-based lead-free incipient piezoelectrics. Mater. Sci. Eng. B 2015, 199, 105–112. [Google Scholar] [CrossRef]

- Sung, Y.S.; Kim, J.M.; Cho, J.H.; Song, T.K.; Kim, M.H.; Park, T.G. notRoles of lattice distortion in (1−x)(Bi0.5Na0.5)TiO3-xBaTiO3 ceramics. Appl. Phys. Lett. 2010, 96, 202901. [Google Scholar] [CrossRef]

- Parmar, K.; Negi, N.S. Influence of Na/Bi excess on structural, dielectric and multiferroic properties of lead free (Na0.5Bi0.5) 0.99 La0.01Ti0.988Fe0.012O3 ceramic. J. Alloys Compd. 2015, 618, 781–787. [Google Scholar] [CrossRef]

- Selvadurai, A.P.B.; Pazhnivelu, V.; Vasanth, B.K.; Jagadeeshwaran, C.; Murugaraj, R. Investigation of structural and optical spectroscopy of 5% Pr doped (Bi0.5Na0.5) TiO3 ferroelectric ceramics: Site depended study. J. Mater. Sci. Mater. Electron. 2015, 26, 7655–7665. [Google Scholar] [CrossRef]

- Duran, P.C.; Apel, F.G.; Utiereez, D.T.; Artaj, J.B.A.; Nares, M.A.M.; Oure, C. Metal citrate polymerized complex thermal decomposition leading to the synthesis of BaTiO3: Effects of the precursor structure on the BaTiO3 formation mechanism. J. Mater. Chem. 2001, 11, 1828. [Google Scholar] [CrossRef]

- Jeong, S.J.; Kim, M.S.; Jang, S.M.; Kim, I.S.; Mohsin, S.; Song, J.S. Comparative study of the polarization and strain of inclusion-type and layer-type 0.94 Bi (NaK) TiO3–0.06 BiAlO3/Bi (NaK) TiO3 ceramic composites. J. Alloys Compd. 2015, 646, 1058–1067. [Google Scholar] [CrossRef]

- Yimnirun, R.; Wongsaenmai, S.; Ananta, S.; Laosiritaworn, Y. Stress-dependent scaling behavior of dynamic hysteresis in bulk soft ferroelectric ceramic. Appl. Phys. Lett. 2006, 89, 242901. [Google Scholar] [CrossRef]

- Shannon, R.D. Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides. Acta. Crystal. 1976, A32, 751. [Google Scholar] [CrossRef]

- Rahman, J.U.; Hussain, A.; Maqbool, A.; Song, T.K.; Kim, W.J.; Kim, S.S.; Kim, M.H. Ferroelectric and impedance response of lead-free (B0.5N0.5) TiO3-BaZrO3 piezoelectric ceramics. Curr. Appl. Phys. 2014, 14, 331. [Google Scholar] [CrossRef]

- Yeo, H.-G.; Sung, Y.-S.; Song, T.; Cho, J.-H.; Kim, M.-H.; Park, T.-G. Donor doping effects on the ferroelectric and the piezoelectric properties of Pb-free (Bi0.5Na0.5) TiO3 ceramics. J. Korean Phys. Soc. 2009, 54, 896. [Google Scholar] [CrossRef]

- Pham, K.-N.; Hussain, A.; Ahn, C.W.; Kim, W.; Jeong, S.J.; Lee, J.-S. Giant strain in Nb-doped Bi0.5 (Na0.82K0.18) 0.5 TiO3 lead-free electromechanical ceramics. Mater. Lett. 2010, 64, 2219. [Google Scholar] [CrossRef]

- Malik, R.A.; Hussain, A.; Rahman, J.U.; Maqbool, A.; Song, T.-K.; Kim, W.-J.; Ryou, S.-Y.; Kim, M.-H. Structural transition and giant strain induced by A-and B-site concurrent donor doping in Bi0.5 (Na0.84K0.16) 0.5 TiO3–SrTiO3 ceramics. Mater. Lett. 2015, 143, 148–150. [Google Scholar] [CrossRef]

- Maqbool, A.; Hussain, A.; Rahman, J.U.; Song, T.K.; Kim, W.-J.; Lee, J.; Kim, M.-H. Enhanced electric field-induced strain and ferroelectric behavior of (Bi0.5Na0.5)TiO3–BaTiO3–SrZrO3 lead-free ceramics. Ceram. Int. 2014, 40, 11905–11914. [Google Scholar] [CrossRef]

- Khemakhem, H.; Simon, A.; Muhll, R.V.D.; Ravez, J. Relaxor or classical ferroelectric behaviour in ceramics with composition Ba1−xNaxTi1−xNbxO3. J. Phys. Condens. Matter 2000, 12, 5951–5959. [Google Scholar] [CrossRef]

- Schütz, D.; Deluca, M.; Krauss, W.; Feteira, A.; Jackson, T.; Reichmann, K. Lone-pair-induced covalency as the cause of temperature-and field-induced instabilities in bismuth sodium titanate. Adv. Funct. Mater. 2012, 22, 2285–2294. [Google Scholar] [CrossRef]

- Shin, D.J.; Lim, D.H.; Saleem, M.; Jeong, S.J. Fabrication and stability of base metal electrode (Ni) on a perovskite oxide co-fired multilayer piezoelectric device. J. Mater. Chem. 2021, C9, 10101–10111. [Google Scholar] [CrossRef]

- Saleem, M.; Hwan, L.D.; Kim, I.-s.; Kim, M.-S.; Maqbool, A.; Nisar, U.; Pervez, S.A.; Farooq, U.; Farooq, M.U.; Khalil, H.M.W. Revealing of Core Shell Effect on Frequency-Dependent Properties of Bi-based Relaxor/Ferroelectric Ceramic Composites. Sci. Rep. 2018, 8, 14146. [Google Scholar] [CrossRef]

- Wu, L.J.; Wu, J.M. Thickness-dependent dielectric properties of nanoscale Pt/(Pb, Ba) ZrO3/BaPbO3 capacitors. J. Cryst. Growth 2007, 308, 424–429. [Google Scholar] [CrossRef]

- Thomas, R.; Varadan, V.K.; Komarneni, S.; Dube, D.C. Diffuse phase transitions, electrical conduction, and low temperature dielectric properties of sol–gel derived ferroelectric barium titanate thin films. J. Appl. Phys. 2001, 90, 1480–1489. [Google Scholar] [CrossRef]

- Acosta, M.; Jo, W.; Rodel, J. Temperature- and Frequency-Dependent Properties of the 0.75Bi1/2Na1/2TiO3–0.25SrTiO3 Lead-Free Incipient Piezoceramic. J. Am. Ceram. Soc. 2014, 97, 1937–1943. [Google Scholar] [CrossRef]

- Jeong, S.J.; Lee, D.S.; Kim, M.S.; Jang, S.M.; Kim, I.S.; Saleem, M.; Song, J.S. Temperature dependence of polarization and strain of bismuth-based ceramic composites. J. Electroceram. 2014, 33, 230–238. [Google Scholar] [CrossRef]

- Maqbool, A.; Malik, R.A.; Hussain, A.; Akram, F.; Rafiq, M.A.; Saleem, M.; Khalid, F.A.; Song, T.K.; Kim, W.J.; Kim, M.H. Evolution of ferroelectric and piezoelectric response by heat treatment in pseudocubic BiFeO3–BaTiO3 ceramics. J. Electroceram. 2018, 41, 99–104. [Google Scholar] [CrossRef]

- Hiruma, Y.; Imai, Y.; Watanabe, Y.; Nagata, H.; Takenaka, T. Large electrostrain near the phase transition temperature of (Bi0.5Na0.5)TiO3–SrTiO3 ferroelectric ceramics. J. Appl. Phys. Lett. 2008, 92, 262904. [Google Scholar] [CrossRef]

- Yu, Z.; Krstic, D.V.; Binu, K.; Mukherje, K. Microstructure and properties of lead-free (Bi1/2Na1/2) TiO3 based piezoelectric ceramics doped with different cations. J. Mater. Sci. 2007, 23, 3544. [Google Scholar] [CrossRef]

- Izumi, M.; Yamamoto, K.; Suzuki, M.; Noguchi, Y.; Miyayama, M. Large electric-field-induced strain in solid solution single crystals. J. Appl. Phys. Lett. 2008, 93, 242903. [Google Scholar] [CrossRef]

- Zheng, X.D.; Chen, X.M. Temperature-stable high-ε dielectrics ceramics based on (1 − x) Ba5NdTi3Ta7O30/xBi4Ti3O12. J. Electroceram. 2003, 31, 37. [Google Scholar]

- Maqbool, A.; Hussain, A.; Rahman, J.U.; Malik, R.A.; Kim, M.S.; Song, T.K.; Kim, W.-J.; Lee, J.H.; Kim, M.-H. Structural, Ferroelectric and Field-Induced Strain Response of Nb-Modified (Bi0.5Na0.5)TiO3-SrZrO3 Lead-Free Ceramics. Ferroelectrics 2015, 488, 23–31. [Google Scholar] [CrossRef]

- Rahman, J.U.; Hussain, A.; Maqbool, A.; Malik, R.A.; Song, T.K.; Kim, M.H.; Lee, S.; Kim, W.J. Effect of donor doping on the ferroelectric and the piezoelectric properties of lead-free 0.97 (Bi0.5Na0.5Ti1−x Nbx) O3-0.03 BaZrO3 ceramics. J. Korean Phys. Soc. 2015, 67, 1240–1245. [Google Scholar] [CrossRef]

- Hussain, A.; Maqbool, A.; Malik, R.A.; Rahman, J.U.; Song, T.K.; Kim, W.J.; Kim, M.H. Na0.5Bi0.5TiO3–BaZrO3 textured ceramics prepared by reactive templated grain growth method. Ceram. Int. 2015, 41, S26–S30. [Google Scholar] [CrossRef]

- He, H.; Lu, X.; Li, M.; Wanga, Y. Thermal and compositional driven relaxor ferroelectric behaviours of lead-free Bi0.5Na0.5TiO3–SrTiO3 ceramics. J. Mater. Chem. C 2020, 8, 2411–2418. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, G.; Jiao, Z.; Fan, Y. High electrostrictive properties and energy storage performances with excellent thermal stability in Nb-doped Bi0.5Na0.5TiO3-based ceramics. RSC Adv. 2019, 9, 21355–21362. [Google Scholar] [CrossRef] [PubMed]

- Jeong-Ho, C.; Jung-Soo, P.; Sung-Won, K.; Young-Hun, J. Ferroelectric properties and core shell domain structures of Fe-modified 0.77 Bi0.5Na0.5TiO3-0.23SrTiO3 ceramics. J. Eur. Ceram. Soc. 2017, 37, 3313–3318. [Google Scholar]

- Malik, R.A.; Hussain, A.; Maqbool, A.; Zaman, A.; Song, T.K.; Kim, W.-J.; Kim, M.-H. Giant strain, thermally-stable high energy storage properties and structural evolution of Bi-based lead-free piezoceramics. J. Alloys Compd. 2016, 682, 302–310. [Google Scholar] [CrossRef]

- Alzaid, M.; Alsalh, F.; Malik, R.A.; Maqbool, A.; Almoisheer, N.; Hadia, N.M.A.; Mohamed, W.S. LiTaO3 assisted giant strain and thermally stable energy storage response for renewable energy storage applications. Ceram. Int. 2021, 47, 15710–15721. [Google Scholar] [CrossRef]

| Nb % | εr 1 kHz | tanδ 1 kHz | Tm (°C) | Pr (µC/cm2) | Ps (µC/cm2) | Smax (%) | d*33 ρm/V | Density g/cm3 |

|---|---|---|---|---|---|---|---|---|

| 0.0 | 5009.4 | 0.0041 | 140 | 2.67 | 28.9 | 0.22 | 480 | 5.5 |

| 0.5 | 4450.3 | 0.0029 | 137 | 2.34 | 26.0 | 0.265 | 576 | 5.7 |

| 1.0 | 4144.6 | 0.0030 | 123 | 2.25 | 22.6 | 0.17 | 370 | 5.7 |

| 2.0 | 3804.4 | 0.0086 | 109 | 2.28 | 18.3 | 0.075 | 165 | 5.6 |

| 5.0 | 3257.2 | 0.0096 | 101 | 0.91 | 13.1 | 0.07 | 155 | 5.6 |

| Composition | Emax | Smax | d*33 (pm/V) | References |

|---|---|---|---|---|

| BNT-ST26–Nb | 4.6 | 0.265% | 576 | Our Work |

| BNT–ST26 | 4.6 | 0.22% | 480 | Our Work |

| BNT–ST24 | 7.0 | 0.20% | 266 | 2020 [41] |

| BNT–ST25 | 4.0 | 0.28% | 600 | 2014 [31] |

| BNT–ST28 | 6.0 | 0.29% | 488 | 2008 [34] |

| BNT–BT–KNN | 8.0 | 0.45% | 560 | 2007 [8] |

| BNT–BKT–Nb | 5.0 | 0.21% | 420 | 2019 [42] |

| BNT–BKT–Nb | 7.0 | 0.448 | 641 | 2010 [22] |

| BNT–ST23–Fe | 2.0 | 0.11% | 550 | 2017 [43] |

| BNT–SZ–Nb | 8.0 | 0.22 | 315 | 2015 [38] |

| BNT–BZ–Nb | 6.0 | 0.17 | 283 | 2015 [39] |

| BNT–BT–SZ | 4.0 | 0.235 | 590 | 2014 [24] |

| BNBT–SZ–Nb | 3.0 | 0.20 | 830 | 2015 [12] |

| BNKT–ST–Ta | 4.0 | 0.33 | 830 | 2016 [44] |

| BNKT–ST–LT | 4.0 | 0.35 | 875 | 2022 [45] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naeem, F.; Saleem, M.; Jabbar, H.; Tanvir, G.; Asif, F.; Baluch, A.H.; Irfan, M.; Ghaffar, A.; Maqbool, A.; Rafiq, T. Enhanced Ferroelectric and Dielectric Properties of Niobium-Doped Lead-Free Piezoceramics. Materials 2023, 16, 477. https://doi.org/10.3390/ma16020477

Naeem F, Saleem M, Jabbar H, Tanvir G, Asif F, Baluch AH, Irfan M, Ghaffar A, Maqbool A, Rafiq T. Enhanced Ferroelectric and Dielectric Properties of Niobium-Doped Lead-Free Piezoceramics. Materials. 2023; 16(2):477. https://doi.org/10.3390/ma16020477

Chicago/Turabian StyleNaeem, Faysal, Mohsin Saleem, Hamid Jabbar, Gulraiz Tanvir, Fiza Asif, Abrar H. Baluch, Muhammad Irfan, Abdul Ghaffar, Adnan Maqbool, and Tayyab Rafiq. 2023. "Enhanced Ferroelectric and Dielectric Properties of Niobium-Doped Lead-Free Piezoceramics" Materials 16, no. 2: 477. https://doi.org/10.3390/ma16020477

APA StyleNaeem, F., Saleem, M., Jabbar, H., Tanvir, G., Asif, F., Baluch, A. H., Irfan, M., Ghaffar, A., Maqbool, A., & Rafiq, T. (2023). Enhanced Ferroelectric and Dielectric Properties of Niobium-Doped Lead-Free Piezoceramics. Materials, 16(2), 477. https://doi.org/10.3390/ma16020477