LIPSS Applied to Wide Bandgap Semiconductors and Dielectrics: Assessment and Future Perspectives

Abstract

1. Introduction

2. LIPSS Models’ Overview

3. Surface Modifications of WBS and Dielectrics

4. Non-Conventional Techniques for LIPSS Fabrication

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Teghil, R.; D’Alessio, L.; De Bonis, A.; Ferro, D.; Galasso, A.; Lanza, G.; Santagata, A.; Villani, P.; Sordelet, D.J. Ultra-short pulse laser ablation of Al70Cu20Fe10 alloy: Nanoparticles generation and thin films deposition. Thin Solid Films 2009, 517, 1880–1886. [Google Scholar] [CrossRef]

- Teghil, R.; De Bonis, A.; Galasso, A.; Villani, P.; Santagata, A.; Ferro, D.; Barinov, S.M. Nanostructured thin films obtained by ultra-short pulse laser deposition of vanadium carbide. Appl. Surf. Sci. 2009, 255, 5220–5223. [Google Scholar] [CrossRef]

- Curcio, M.; De Bonis, A.; Brutti, S.; Santagata, A.; Teghil, R. Pulsed laser deposition of thin films of TiO2 for Li-Ion batteries. Appl. Surf. Sci. Adv. 2021, 4, 100090. [Google Scholar] [CrossRef]

- De Bonis, A.; Galasso, A.; Latini, A.; Rau, J.V.; Santagata, A.; Curcio, M.; Teghil, R. Femtosecond pulsed laser deposition of chromium diboride-rich thin films. Coatings 2019, 9, 777. [Google Scholar] [CrossRef]

- De Bonis, A.; Rau, J.V.; Santagata, A.; Teghil, R. Diamond-like carbon thin films produced by femtosecond pulsed laser deposition of fullerite. Surf. Coat. Technol. 2011, 205, 3747–3753. [Google Scholar] [CrossRef]

- D’Alessio, L.; Salvi, A.M.; Teghil, R.; Marotta, V.; Santagata, A.; Brunetti, B.; Ferro, D.; De Maria, G. Silicon supported TiC films produced by pulsed laser ablation. Appl. Surf. Sci. 1998, 134, 53–62. [Google Scholar] [CrossRef]

- Teghil, R.; Santagata, A.; De Bonis, A.; Galasso, A.; Villani, P. Chromium carbide thin films deposited by ultra-short pulse laser deposition. Appl. Surf. Sci. 2009, 255, 7729–7733. [Google Scholar] [CrossRef]

- De Bonis, A.; Uskoković, V.; Barbaro, K.; Fadeeva, I.; Curcio, M.; Imperatori, L.; Teghil, R.; Rau, J.V. Pulsed laser deposition temperature effects on strontium-substituted hydroxyapatite thin films for biomedical implants. Cell Biol. Toxicol. 2020, 36, 537–551. [Google Scholar] [CrossRef] [PubMed]

- Bellucci, A.; Mastellone, M.; Girolami, M.; Serpente, V.; Generosi, A.; Paci, B.; Mezzi, A.; Kaciulis, S.; Carducci, R.; Polini, R.; et al. nanocrystalline lanthanum boride thin films by femtosecond pulsed laser deposition as efficient emitters in hybrid thermionic-photovoltaic energy converters. Appl. Surf. Sci. 2020, 513, 145829. [Google Scholar] [CrossRef]

- Bellucci, A.; Mastellone, M.; Orlando, S.; Girolami, M.; Generosi, A.; Paci, B.; Soltani, P.; Mezzi, A.; Kaciulis, S.; Polini, R.; et al. Lanthanum (Oxy)boride thin films for thermionic emission applications. Appl. Surf. Sci. 2019, 479, 296–302. [Google Scholar] [CrossRef]

- Bellucci, A.; Cappelli, E.; Orlando, S.; Medici, L.; Mezzi, A.; Kaciulis, S.; Polini, R.; Trucchi, D.M. Fs-Pulsed laser deposition of PbTe and PbTe/Ag thermoelectric thin films. Appl. Phys. A Mater. Sci. Process. 2014, 117, 401–407. [Google Scholar] [CrossRef][Green Version]

- Bellucci, A.; Mastellone, M.; Mezzi, A.; Kaciulis, S.; Polini, R.; Medici, L.; Trucchi, D.M. Thermoelectric analysis of ZnSb thin films prepared by Ns-pulsed laser deposition. J. Nanosci. Nanotechnol. 2017, 17, 1564–1570. [Google Scholar] [CrossRef] [PubMed]

- Bellucci, A.; Mastellone, M.; Girolami, M.; Orlando, S.; Medici, L.; Mezzi, A.; Kaciulis, S.; Polini, R.; Trucchi, D.M. ZnSb-based thin films prepared by Ns-PLD for thermoelectric applications. Appl. Surf. Sci. 2017, 418, 589–593. [Google Scholar] [CrossRef]

- De Bonis, A.; Galasso, A.; Marotta, V.; Orlando, S.; Santagata, A.; Teghil, R.; Veronesi, S.; Villani, P.; Giardini, A. Pulsed laser ablation of indium tin oxide in the nano and femtosecond regime: Characterization of transient species. Appl. Surf. Sci. 2006, 252, 4632–4636. [Google Scholar] [CrossRef]

- D’Alessio, L.; Ferro, D.; Marotta, V.; Santagata, A.; Teghil, R.; Zaccagnino, M. Laser ablation and deposition of Bioglass® 45S5 thin films. Appl. Surf. Sci. 2001, 183, 10–17. [Google Scholar] [CrossRef]

- De Bonis, A.; Galasso, A.; Ibris, N.; Sansone, M.; Santagata, A.; Teghil, R. Ultra-short pulsed laser deposition of thin silver films for surface enhanced raman scattering. Surf. Coat. Technol. 2012, 207, 279–285. [Google Scholar] [CrossRef]

- Curcio, M.; De Bonis, A.; Santagata, A.; Galasso, A.; Teghil, R. Effect of laser pulse duration on properties of metal and metal carbide nanoparticles obtained by laser in liquid synthesis. Opt. Laser Technol. 2021, 138, 106916. [Google Scholar] [CrossRef]

- De Bonis, A.; Curcio, M.; Santagata, A.; Galasso, A.; Teghil, R. Transition metal carbide core/shell nanoparticles by ultra-short laser ablation in liquid. Nanomaterials 2020, 10, 145. [Google Scholar] [CrossRef]

- Birnbaum, M. Semiconductor surface damage produced by ruby lasers. J. Appl. Phys. 1965, 36, 3688–3689. [Google Scholar] [CrossRef]

- Bonse, J. Quo Vadis LIPSS? Recent and future trends on laser-induced periodic surface structures. Nanomaterials 2020, 10, 1950. [Google Scholar] [CrossRef]

- Bonse, J.; Gräf, S. Maxwell meets Marangoni—A review of theories on laser-induced periodic surface structures. Laser Photon. Rev. 2020, 14, 2000215. [Google Scholar] [CrossRef]

- Huang, M.; Zhao, F.; Cheng, Y.; Xu, N.; Xu, Z. Origin of laser-induced near-subwavelength ripples: Interference between surface plasmons and incident laser. ACS Nano 2009, 3, 4062–4070. [Google Scholar] [CrossRef]

- Shugaev, M.V.; Gnilitskyi, I.; Bulgakova, N.M.; Zhigilei, L.V. Mechanism of single-pulse ablative generation of laser-induced periodic surface structures. Phys. Rev. B 2017, 96, 205429. [Google Scholar] [CrossRef]

- Ivanov, D.S.; Lipp, V.P.; Blumenstein, A.; Kleinwort, F.; Veiko, V.P.; Yakovlev, E.; Roddatis, V.; Garcia, M.E.; Rethfeld, B.; Ihlemann, J.; et al. Experimental and theoretical investigation of periodic nanostructuring of Au with ultrashort UV laser pulses near the damage threshold. Phys. Rev. Appl. 2015, 4, 064006. [Google Scholar] [CrossRef]

- Rudenko, A.; Abou-Saleh, A.; Pigeon, F.; Mauclair, C.; Garrelie, F.; Stoian, R.; Colombier, J.P. High-frequency periodic patterns driven by non-radiative fields coupled with marangoni convection instabilities on laser-excited metal surfaces. Acta Mater. 2020, 194, 93–105. [Google Scholar] [CrossRef]

- Guosheng, Z.; Fauchet, P.M.; Siegman, A.E. Growth of spontaneous periodic surface structures on solids during laser illumination. Phys. Rev. B 1982, 26, 5366–5381. [Google Scholar] [CrossRef]

- Sipe, J.E.; Young, J.F.; Preston, J.S.; Van Driel, H.M. Laser-induced periodic surface structure. I. Theory. Phys. Rev. B 1983, 27, 1141–1154. [Google Scholar] [CrossRef]

- Temple, P.A.; Soileau, M.J. Polarization charge model for laser-induced ripple patterns in dielectric materials. IEEE J. Quantum Electron. 1981, 17, 2067–2072. [Google Scholar] [CrossRef]

- Bonch-Bruevich, A.M. surface electromagnetic waves in optics. Opt. Eng. 1992, 31, 718. [Google Scholar] [CrossRef]

- Keilmann, F.; Bai, Y.H. Periodic surface structures frozen into CO2 laser-melted quartz. Appl. Phys. A Solids Surf. 1982, 29, 9–18. [Google Scholar] [CrossRef]

- Derrien, T.J.Y.; Krüger, J.; Bonse, J. Properties of surface plasmon polaritons on lossy materials: Lifetimes, periods and excitation conditions. J. Opt. 2016, 18, 115007. [Google Scholar] [CrossRef]

- Bonse, J.; Rosenfeld, A.; Krüger, J. On the role of surface plasmon polaritons in the formation of laser-induced periodic surface structures upon irradiation of silicon by femtosecond-laser pulses. J. Appl. Phys. 2009, 106, 104910. [Google Scholar] [CrossRef]

- Golosov, E.V.; Ionin, A.A.; Kolobov, Y.R.; Kudryashov, S.I.; Ligachev, A.E.; Makarov, S.V.; Novoselov, Y.N.; Seleznev, L.V.; Sinitsyn, D.V.; Sharipov, A.R. Near-threshold femtosecond laser fabrication of one-dimensional subwavelength nanogratings on a graphite surface. Phys. Rev. B 2011, 83, 115426. [Google Scholar] [CrossRef]

- Van Driel, H.M.; Sipe, J.E.; Young, J.F. Laser-induced periodic surface structure on solids: A universal phenomenon. Phys. Rev. Lett. 1982, 49, 1955–1958. [Google Scholar] [CrossRef]

- Young, J.F.; Sipe, J.E.; Van Driel, H.M. Laser-induced periodic surface structure. III. Fluence regimes, the role of feedback, and details of the induced topography in germanium. Phys. Rev. B 1984, 30, 2001–2015. [Google Scholar] [CrossRef]

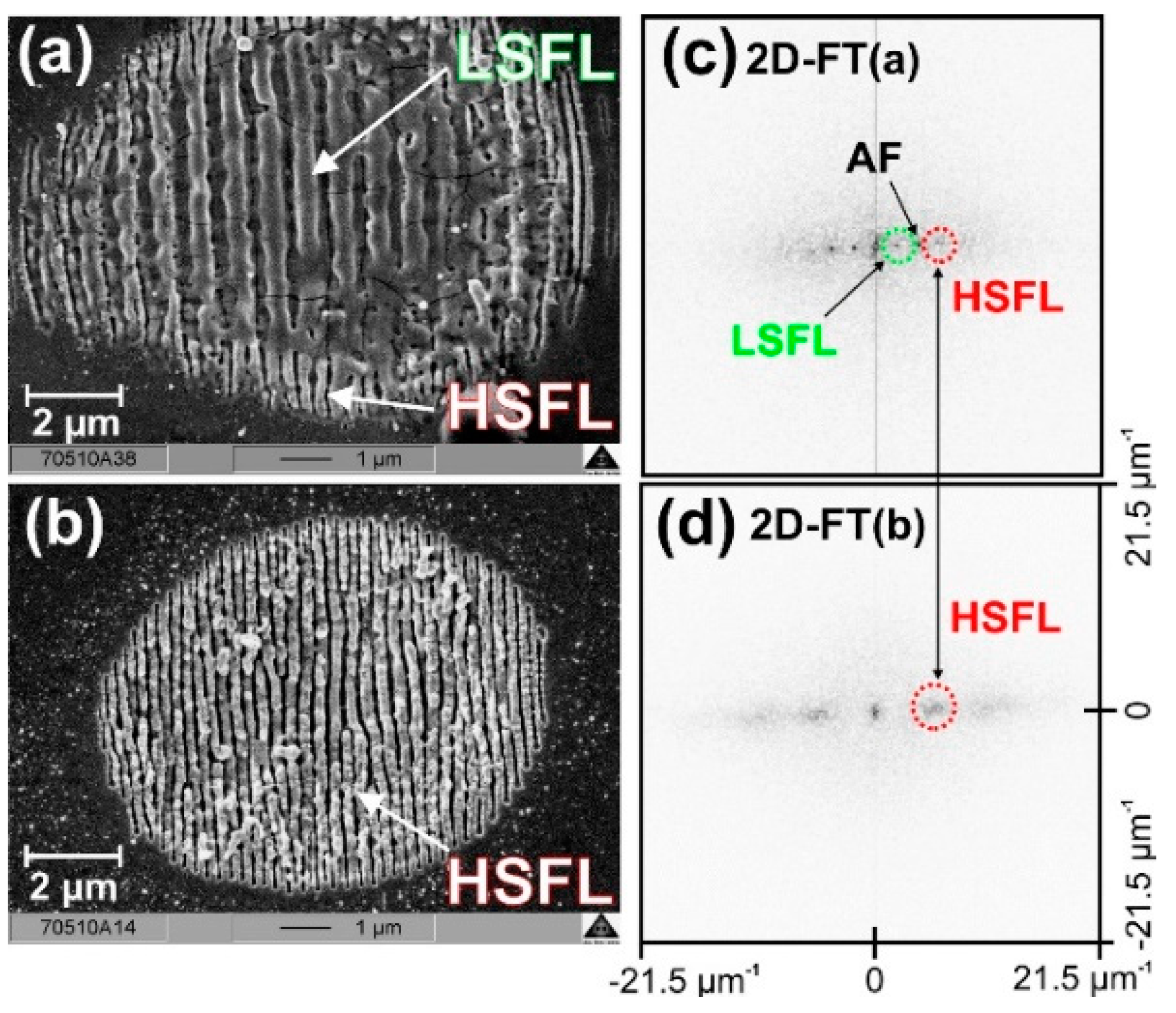

- Höhm, S.; Rosenfeld, A.; Krüger, J.; Bonse, J. Femtosecond laser-induced periodic surface structures on silica. J. Appl. Phys. 2012, 112, 014901. [Google Scholar] [CrossRef]

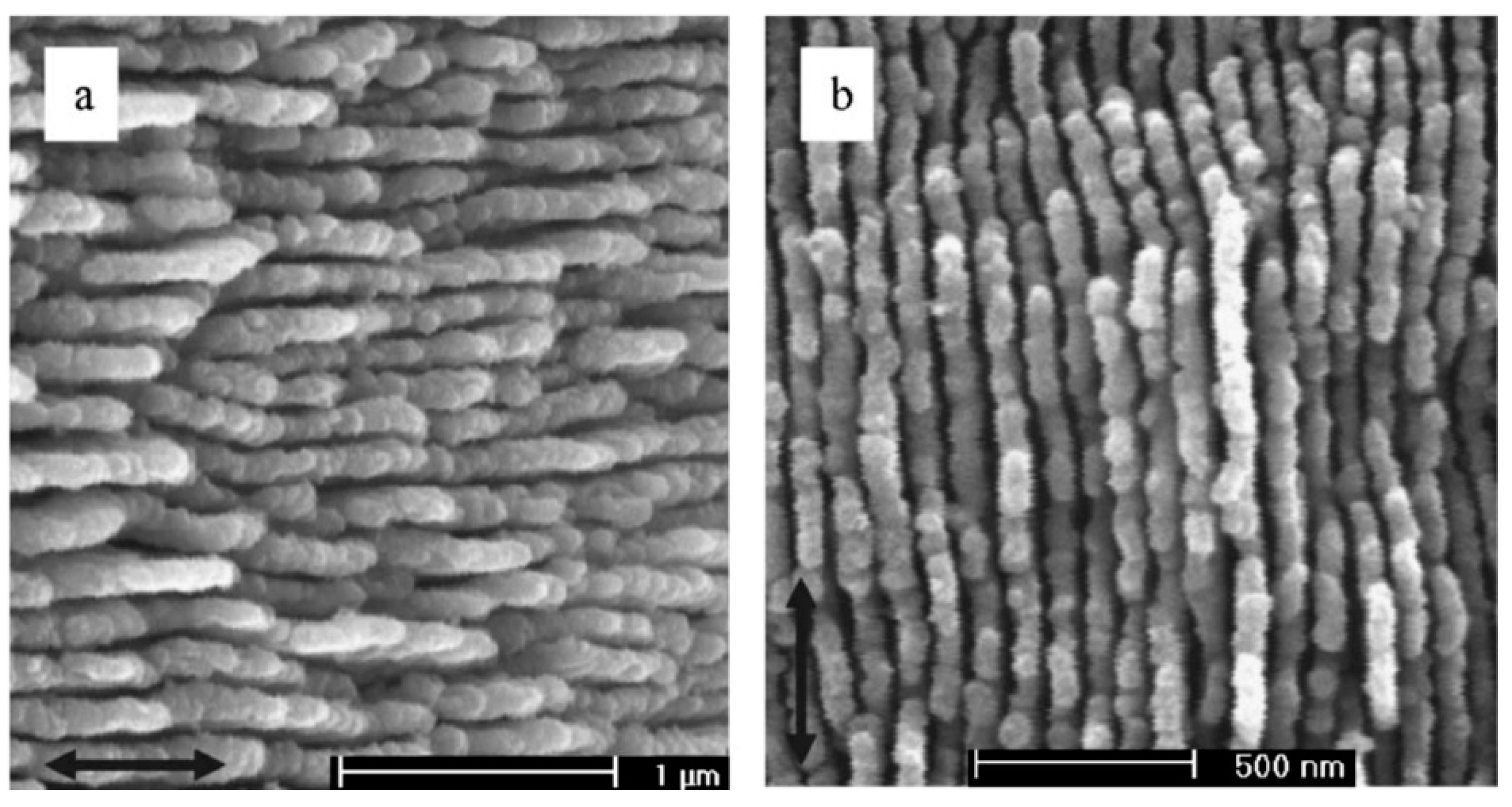

- Dufft, D.; Rosenfeld, A.; Das, S.K.; Grunwald, R.; Bonse, J. Femtosecond laser-induced periodic surface structures revisited: A comparative study on ZnO. J. Appl. Phys. 2009, 105, 034908. [Google Scholar] [CrossRef]

- Zhang, H.; Colombier, J.-P.; Witte, S. Laser-induced periodic surface structures: Arbitrary angles of incidence and polarization states. Phys. Rev. B 2020, 101, 245430. [Google Scholar] [CrossRef]

- He, S.; Nivas, J.J.; Anoop, K.K.; Vecchione, A.; Hu, M.; Bruzzese, R.; Amoruso, S. Surface structures induced by ultrashort laser pulses: Formation mechanisms of ripples and grooves. Appl. Surf. Sci. 2015, 353, 1214–1222. [Google Scholar] [CrossRef]

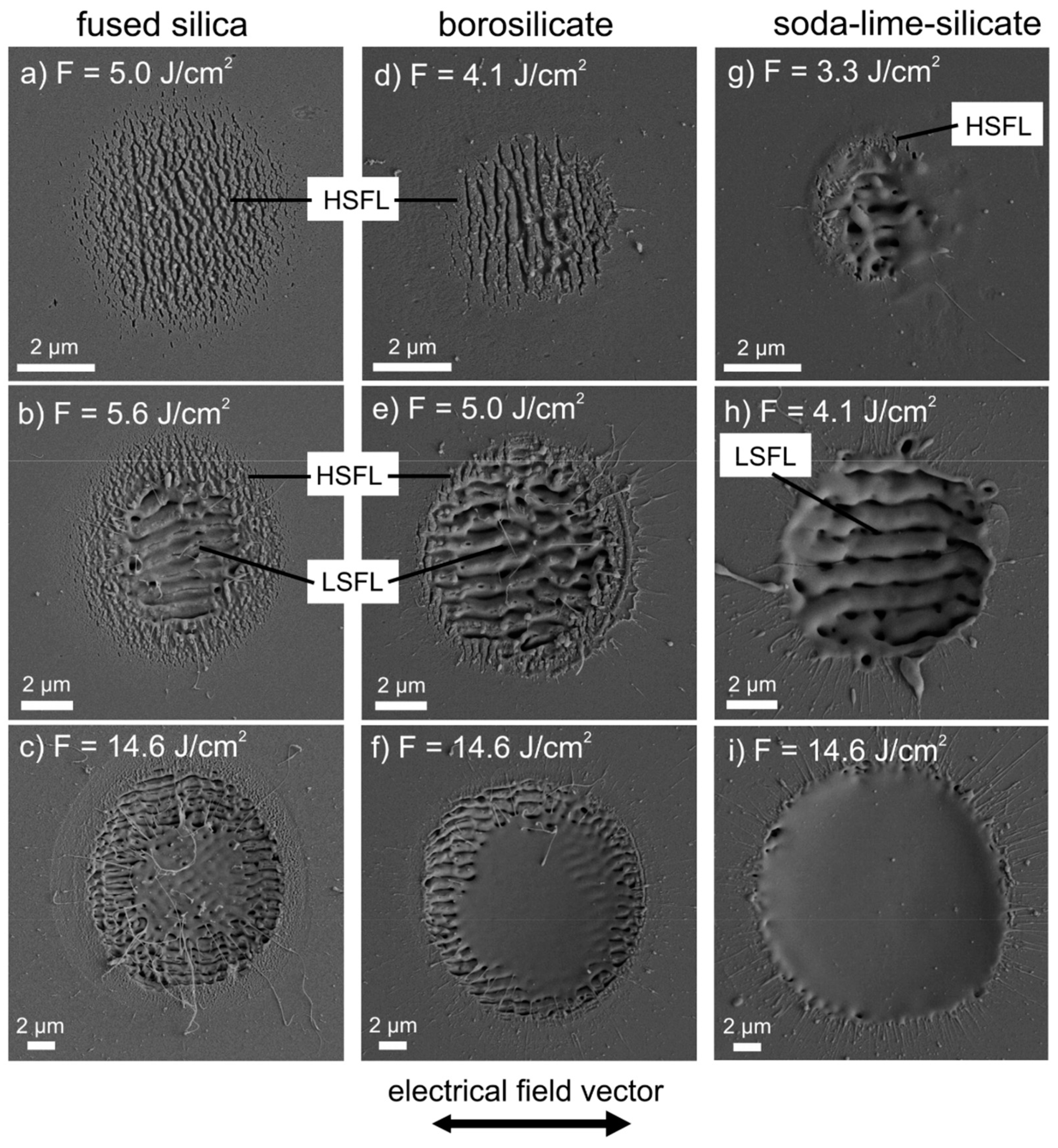

- Gräf, S.; Kunz, C.; Engel, S.; Derrien, T.; Müller, F. Femtosecond laser-induced periodic surface structures on fused silica: The impact of the initial substrate temperature. Materials 2018, 11, 1340. [Google Scholar] [CrossRef]

- Deng, G.; Xiao, Y.; Yang, M.; Zhou, H.; Yang, H.; Feng, G.; Zhou, S. Femtosecond laser induced surface nanostructures on SrTiO3. Laser Phys. Lett. 2019, 16, 056007. [Google Scholar] [CrossRef]

- Gräf, S.; Kunz, C.; Müller, F. Formation and properties of laser-induced periodic surface structures on different glasses. Materials 2017, 10, 933. [Google Scholar] [CrossRef]

- Zhang, H.; Colombier, J.-P.; Li, C.; Faure, N.; Cheng, G.; Stoian, R. Coherence in ultrafast laser-induced periodic surface structures. Phys. Rev. B 2015, 92, 174109. [Google Scholar] [CrossRef]

- Rudenko, A.; Colombier, J.-P.; Höhm, S.; Rosenfeld, A.; Krüger, J.; Bonse, J.; Itina, T.E. Spontaneous periodic ordering on the surface and in the bulk of dielectrics irradiated by ultrafast laser: A shared electromagnetic origin. Sci. Rep. 2017, 7, 12306. [Google Scholar] [CrossRef]

- Skolski, J.Z.P.; Römer, G.R.B.E.; Obona, J.V.; Ocelik, V.; Huis in ’t Veld, A.J.; De Hosson, J.T.M. Laser-induced periodic surface structures: Fingerprints of light localization. Phys. Rev. B 2012, 85, 075320. [Google Scholar] [CrossRef]

- Déziel, J.-L.; Dumont, J.; Gagnon, D.; Dubé, L.J.; Messaddeq, S.H.; Messaddeq, Y. Toward the formation of crossed laser-induced periodic surface structures. J. Opt. 2015, 17, 075405. [Google Scholar] [CrossRef]

- Skolski, J.Z.P.; Römer, G.R.B.E.; Vincenc Obona, J.; Huis in ’t Veld, A.J. Modeling laser-induced periodic surface structures: Finite-difference time-domain feedback simulations. J. Appl. Phys. 2014, 115, 103102. [Google Scholar] [CrossRef]

- Buschlinger, R.; Nolte, S.; Peschel, U. Self-organized pattern formation in laser-induced multiphoton ionization. Phys. Rev. B 2014, 89, 184306. [Google Scholar] [CrossRef]

- Shimotsuma, Y.; Kazansky, P.G.; Qiu, J.; Hirao, K. Self-organized nanogratings in glass irradiated by ultrashort light pulses. Phys. Rev. Lett. 2003, 91, 247405. [Google Scholar] [CrossRef]

- Shimotsuma, Y.; Hirao, K.; Qiu, J.; Kazansky, P.G. Nano-Modification inside Transparent Materials by Femtosecond Laser Single Beam. Mod. Phys. Lett. B 2005, 19, 225–238. [Google Scholar] [CrossRef]

- Derrien, T.J.; Sarnet, T.; Sentis, M.; Itina, T.E. Application of a two-temperature model for the investigation of the periodic structure formation on Si surface in femtosecond laser interactions. J. Optoelectron. Adv. Mater. 2010, 12, 610–615. [Google Scholar]

- Tsibidis, G.D.; Skoulas, E.; Papadopoulos, A.; Stratakis, E. Convection roll-driven generation of supra-wavelength periodic surface structures on dielectrics upon irradiation with femtosecond pulsed lasers. Phys. Rev. B 2016, 94, 081305. [Google Scholar] [CrossRef]

- Bonse, J.; Gräf, S. Ten open questions about laser-induced periodic surface structures. Nanomaterials 2021, 11, 3326. [Google Scholar] [CrossRef] [PubMed]

- Schaffer, C.B.; Brodeur, A.; Mazur, E. Laser-induced breakdown and damage in bulk transparent materials induced by tightly focused femtosecond laser pulses. Meas. Sci. Technol. 2001, 12, 1784–1794. [Google Scholar] [CrossRef]

- Gedvilas, M.; Mikšys, J.; Berzinš, J.; Stankevič, V.; Račiukaitis, G. Multi-photon absorption enhancement by dual-wavelength double-pulse laser irradiation for efficient dicing of sapphire wafers. Sci. Rep. 2017, 7, 5218. [Google Scholar] [CrossRef]

- Gattass, R.R.; Mazur, E. Femtosecond laser micromachining in transparent materials. Nat. Photon. 2008, 2, 219–225. [Google Scholar] [CrossRef]

- Höhm, S.; Herzlieb, M.; Rosenfeld, A.; Krüger, J.; Bonse, J. Laser-induced periodic surface structures on fused silica upon cross-polarized two-color double-Fs-pulse irradiation. Appl. Surf. Sci. 2015, 336, 39–42. [Google Scholar] [CrossRef]

- Jia, T.Q.; Zhao, F.L.; Huang, M.; Chen, H.X.; Qiu, J.R.; Li, R.X.; Xu, Z.Z.; Kuroda, H. Alignment of nanoparticles formed on the surface of 6H-SiC crystals irradiated by two collinear femtosecond laser beams. Appl. Phys. Lett. 2006, 88, 111117. [Google Scholar] [CrossRef]

- Ozkan, A.M.; Malshe, A.P.; Railkar, T.A.; Brown, W.D.; Shirk, M.D.; Molian, P.A. Femtosecond laser-induced periodic structure writing on diamond crystals and microclusters. Appl. Phys. Lett. 1999, 75, 3716–3718. [Google Scholar] [CrossRef]

- Calvani, P.; Bellucci, A.; Girolami, M.; Orlando, S.; Valentini, V.; Polini, R.; Trucchi, D.M. Black diamond for solar energy conversion. Carbon N. Y. 2016, 105, 401–407. [Google Scholar] [CrossRef]

- Girolami, M.; Bellucci, A.; Mastellone, M.; Orlando, S.; Orsini, A.; Salvatori, S.; Trucchi, D.M. Transport properties of photogenerated charge carriers in black diamond films. Ceram. Int. 2019, 45, 9544–9547. [Google Scholar] [CrossRef]

- Bird, R.E.; Hulstrom, R.L.; Lewis, L.J. Terrestrial solar spectral data sets. Sol. Energy 1983, 30, 563–573. [Google Scholar] [CrossRef]

- Tavkhelidze, A.; Jangidze, L.; Mebonia, M.; Piotrowski, K.; Więckowski, J.; Taliashvili, Z.; Skhiladze, G.; Nadaraia, L. Geometry-induced quantum effects in periodic nanostructures. Phys. Status Solidi Appl. Mater. Sci. 2017, 214, 334. [Google Scholar] [CrossRef]

- Tavkhelidze, A.; Bibilashvili, A.; Jangidze, L.; Gorji, N.E. Fermi-level tuning of G-doped layers. Nanomaterials 2021, 11, 505. [Google Scholar] [CrossRef]

- Dong, X.; Wang, Y.; Song, X. Physical mechanisms for the optical properties of the femtosecond-laser-treated black diamond. J. Phys. Condens. Matter. 2020, 32, 165502. [Google Scholar] [CrossRef]

- Dong, X.; Qiao, R.; Wang, T.; An, Y.; Wang, Y. Engineering a bandgap-regulable intermediate-band material based on diamond. Carbon N. Y. 2022, 191, 106–111. [Google Scholar] [CrossRef]

- dos Santos, R.B.; Rivelino, R.; de Brito Mota, F.; Gueorguiev, G.K.; Kakanakova-Georgieva, A. Dopant species with Al–Si and N–Si bonding in the MOCVD of AlN implementing trimethylaluminum, ammonia and silane. J. Phys. D. Appl. Phys. 2015, 48, 295104. [Google Scholar] [CrossRef]

- Oliveira, M.I.A.; Rivelino, R.; de Brito Mota, F.; Gueorguiev, G.K. Optical properties and quasiparticle band gaps of transition-metal atoms encapsulated by silicon cages. J. Phys. Chem. C 2014, 118, 5501–5509. [Google Scholar] [CrossRef]

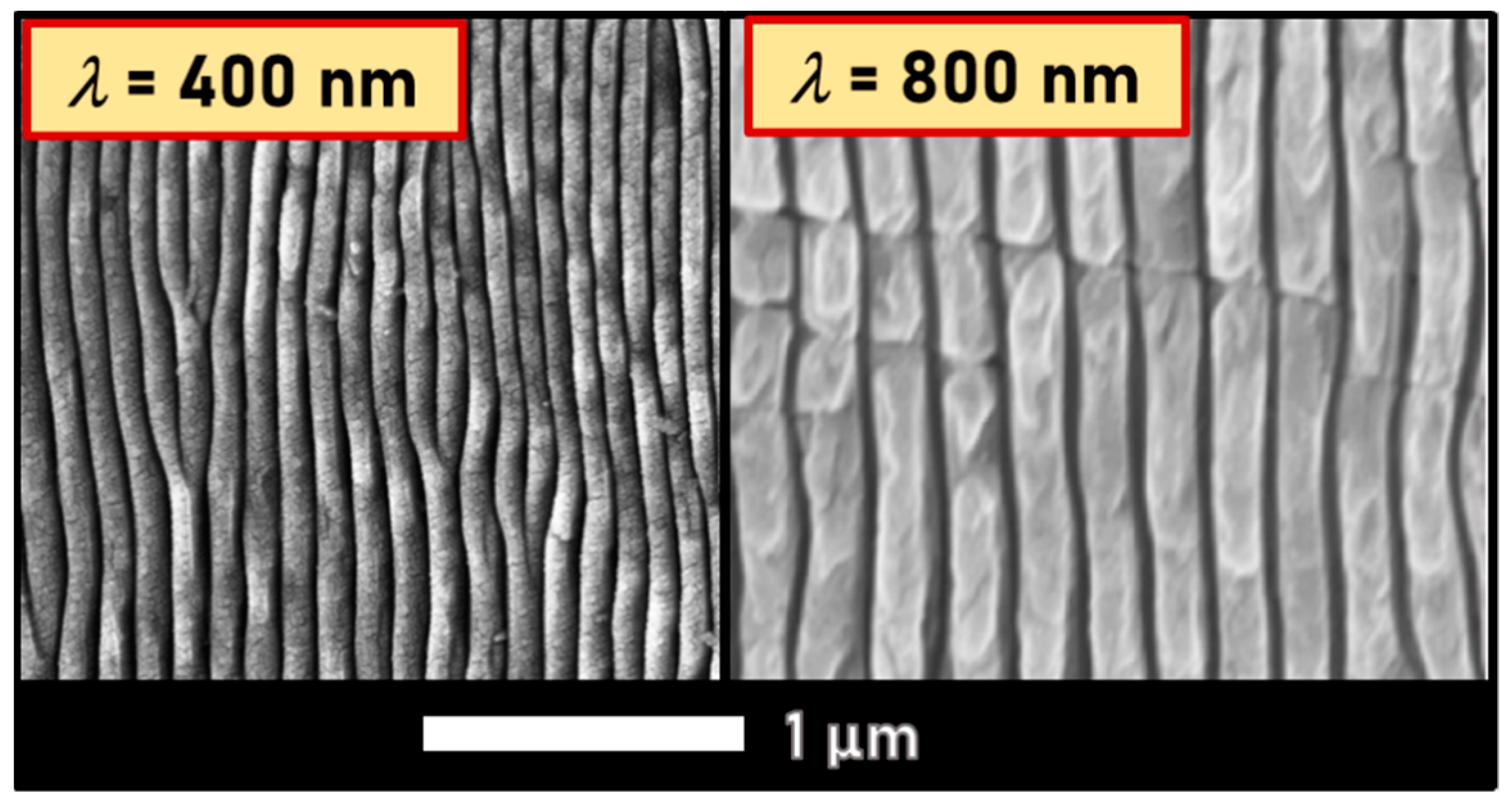

- Girolami, M.; Bellucci, A.; Mastellone, M.; Orlando, S.; Valentini, V.; Montereali, R.M.; Vincenti, M.A.; Polini, R.; Trucchi, D.M. Impact of laser wavelength on the optical and electronic properties of black diamond. Phys. Status Solidi 2017, 214, 1700250. [Google Scholar] [CrossRef]

- Granados, E.; Calderon, M.M.; Krzywinski, J.; Wörner, E.; Rodriguez, A.; Aranzadi, M.G.; Olaizola, S.M. Enhancement of surface area and wettability properties of boron doped diamond by femtosecond laser-induced periodic surface structuring. Opt. Mater. Express 2017, 7, 3389. [Google Scholar] [CrossRef]

- Sartori, A.F.; Orlando, S.; Bellucci, A.; Trucchi, D.M.; Abrahami, S.; Boehme, T.; Hantschel, T.; Vandervorst, W.; Buijnsters, J.G. Laser-induced periodic surface structures (LIPSS) on heavily boron-doped diamond for electrode applications. ACS Appl. Mater. Interfaces 2018, 10, 43236–43251. [Google Scholar] [CrossRef]

- Amoruso, S.; Andreone, A.; Bellucci, A.; Koral, C.; Girolami, M.; Mastellone, M.; Mou, S.; Orlando, S.; Papari, G.P.; Paparo, D.; et al. All-carbon THz components based on laser-treated diamond. Carbon N. Y. 2020, 163, 197–201. [Google Scholar] [CrossRef]

- Girolami, M.; Criante, L.; Di Fonzo, F.; Lo Turco, S.; Mezzetti, A.; Notargiacomo, A.; Pea, M.; Bellucci, A.; Calvani, P.; Valentini, V.; et al. Graphite distributed electrodes for diamond-based photon-enhanced thermionic emission solar cells. Carbon N. Y. 2017, 111, 48–53. [Google Scholar] [CrossRef]

- Beltaos, A.; Kovačević, A.G.; Matković, A.; Ralević, U.; Savić-Šević, S.; Jovanović, D.; Jelenković, B.M.; Gajić, R. Femtosecond laser induced periodic surface structures on multi-layer graphene. J. Appl. Phys. 2014, 116, 204306. [Google Scholar] [CrossRef]

- Mehregany, M.; Zorman, C.A.; Rajan, N.; Wu, C.H. Silicon carbide MEMS for Harsh environments. Proc. IEEE 1998, 86, 1594–1609. [Google Scholar] [CrossRef]

- Liu, G.; Tuttle, B.R.; Dhar, S. Silicon carbide: A unique platform for metal-oxide-semiconductor physics. Appl. Phys. Rev. 2015, 2, 021307. [Google Scholar] [CrossRef]

- Salvatori, S.; Ponticelli, G.S.; Pettinato, S.; Genna, S.; Guarino, S. High-pressure sensors based on laser-manufactured sintered silicon carbide. Appl. Sci. 2020, 10, 7095. [Google Scholar] [CrossRef]

- Zhao, Q.Z.; Ciobanu, F.; Malzer, S.; Wang, L.J. Enhancement of optical absorption and photocurrent of 6H-SiC by laser surface nanostructuring. Appl. Phys. Lett. 2007, 91, 121107. [Google Scholar] [CrossRef]

- Song, J.; Dai, Y.; Tao, W.; Gong, M.; Ma, G.; Zhao, Q.; Qiu, J. Surface birefringence of self-assembly periodic nanostructures induced on 6H-SiC surface by femtosecond laser. Appl. Surf. Sci. 2016, 363, 664–669. [Google Scholar] [CrossRef]

- Mastellone, M.; Bellucci, A.; Girolami, M.; Montereali, R.M.; Orlando, S.; Polini, R.; Serpente, V.; Sani, E.; Valentini, V.; Vincenti, M.A.; et al. Enhanced selective solar absorption of surface nanotextured semi-insulating 6H–SiC. Opt. Mater. 2020, 107, 109967. [Google Scholar] [CrossRef]

- Sciti, D.; Silvestroni, L.; Mercatelli, L.; Sans, J.-L.; Sani, E. Suitability of ultra-refractory diboride ceramics as absorbers for solar energy applications. Sol. Energy Mater. Sol. Cells 2013, 109, 8–16. [Google Scholar] [CrossRef]

- Sani, E.; Mercatelli, L.; Meucci, M.; Balbo, A.; Silvestroni, L.; Sciti, D. Compositional dependence of optical properties of zirconium, hafnium and tantalum carbides for solar absorber applications. Sol. Energy 2016, 131, 199–207. [Google Scholar] [CrossRef]

- Kunz, C.; Engel, S.; Müller, F.A.; Gräf, S. Large-area fabrication of laser-induced periodic surface structures on fused silica using thin gold layers. Nanomaterials 2020, 10, 1187. [Google Scholar] [CrossRef]

- Žemaitis, A.; Mimidis, A.; Papadopoulos, A.; Gečys, P.; Račiukaitis, G.; Stratakis, E.; Gedvilas, M. Controlling the wettability of stainless steel from highly-hydrophilic to super-hydrophobic by femtosecond laser-induced ripples and nanospikes. RSC Adv. 2020, 10, 37956–37961. [Google Scholar] [CrossRef]

- Schwarz, S. Two-dimensional low spatial frequency laser-induced periodic surface structuring of sapphire. J. Laser Micro Nanoeng. 2017, 12, 67–71. [Google Scholar] [CrossRef][Green Version]

- Cappelli, E.; Orlando, S.; Sciti, D.; Bellucci, A.; Lettino, A.; Trucchi, D.M. Improving solar radiation absorbance of high refractory sintered ceramics by Fs Ti: Sapphire laser surface treatment. In Applied Surface Science; Elsevier B.V.: Amsterdam, The Netherlands, 2014; Volume 302, pp. 177–183. [Google Scholar]

- Trucchi, D.M.; Bellucci, A.; Girolami, M.; Calvani, P.; Cappelli, E.; Orlando, S.; Polini, R.; Silvestroni, L.; Sciti, D.; Kribus, A. Solar thermionic-thermoelectric generator (ST2G): Concept, materials engineering, and prototype demonstration. Adv. Energy Mater. 2018, 8, 1802310. [Google Scholar] [CrossRef]

- Cappelli, E.; Orlando, S.; Sciti, D.; Bellucci, A.; Lettino, A.; Trucchi, D.M. Fs Laser surface nano-structuring of high refractory ceramics to enhance solar radiation absorbance. Appl. Phys. A Mater. Sci. Process. 2014, 117, 243–251. [Google Scholar] [CrossRef]

- Sciti, D.; Trucchi, D.M.; Bellucci, A.; Orlando, S.; Zoli, L.; Sani, E. Effect of surface texturing by femtosecond laser on tantalum carbide ceramics for solar receiver applications. Sol. Energy Mater. Sol. Cells 2017, 161, 1–6. [Google Scholar] [CrossRef]

- Sani, E.; Sciti, D.; Silvestroni, L.; Bellucci, A.; Orlando, S.; Trucchi, D.M. Tailoring optical properties of surfaces in wide spectral ranges by multi-scale femtosecond-laser texturing: A case-study for TaB2 ceramics. Opt. Mater. 2020, 109, 110347. [Google Scholar] [CrossRef]

- Rohloff, M.; Das, S.K.; Höhm, S.; Grunwald, R.; Rosenfeld, A.; Krüger, J.; Bonse, J. Formation of laser-induced periodic surface structures on fused silica upon multiple cross-polarized double-femtosecond-laser-pulse irradiation sequences. J. Appl. Phys. 2011, 110, 014910. [Google Scholar] [CrossRef]

- Höhm, S.; Herzlieb, M.; Rosenfeld, A.; Krüger, J.; Bonse, J. Dynamics of the formation of laser-induced periodic surface structures (LIPSS) upon femtosecond two-color double-pulse irradiation of metals, semiconductors, and dielectrics. Appl. Surf. Sci. 2016, 374, 331–338. [Google Scholar] [CrossRef]

- Höhm, S.; Rosenfeld, A.; Krüger, J.; Bonse, J. Femtosecond diffraction dynamics of laser-induced periodic surface structures on fused silica. Appl. Phys. Lett. 2013, 102, 054102. [Google Scholar] [CrossRef]

- Cong, J.; Yang, J.; Zhao, B.; Xu, X. Fabricating subwavelength dot-matrix surface structures of molybdenum by transient correlated actions of two-color femtosecond laser beams. Opt. Express 2015, 23, 5357. [Google Scholar] [CrossRef] [PubMed]

- Qiao, H.; Yang, J.; Li, J.; Liu, Q.; Liu, J.; Guo, C. Formation of subwavelength periodic triangular arrays on tungsten through double-pulsed femtosecond laser irradiation. Materials 2018, 11, 2380. [Google Scholar] [CrossRef] [PubMed]

- Romano, J.M.; Garcia-Giron, A.; Penchev, P.; Dimov, S. Triangular laser-induced submicron textures for functionalising stainless steel surfaces. Appl. Surf. Sci. 2018, 440, 162–169. [Google Scholar] [CrossRef]

- Fraggelakis, F.; Mincuzzi, G.; Lopez, J.; Manek-Hönninger, I.; Kling, R. Controlling 2D laser nano structuring over large area with double femtosecond pulses. Appl. Surf. Sci. 2019, 470, 677–686. [Google Scholar] [CrossRef]

- Jalil, S.A.; Yang, J.; Elkabbash, M.; Cong, C.; Guo, C. Formation of controllable 1D and 2D periodic surface structures on cobalt by femtosecond double pulse laser irradiation. Appl. Phys. Lett. 2019, 115, 031601. [Google Scholar] [CrossRef]

- Mastellone, M.; Bellucci, A.; Girolami, M.; Serpente, V.; Polini, R.; Orlando, S.; Santagata, A.; Sani, E.; Hitzel, F.; Trucchi, D.M. Deep-subwavelength 2D periodic surface nanostructures on diamond by double-pulse femtosecond laser irradiation. Nano Lett. 2021, 21, 4477–4483. [Google Scholar] [CrossRef]

- Girolami, M.; Bellucci, A.; Mastellone, M.; Orlando, S.; Valentini, V.; Montereali, R.M.; Vincenti, M.A.; Polini, R.; Trucchi, D.M. Optical characterization of double-nanotextured black diamond films. Carbon N. Y. 2018, 138, 384–389. [Google Scholar] [CrossRef]

- Bellucci, A.; Calvani, P.; Girolami, M.; Orlando, S.; Polini, R.; Trucchi, D.M. Optimization of black diamond films for solar energy conversion. Appl. Surf. Sci. 2016, 380, 8–11. [Google Scholar] [CrossRef]

- Anoop, K.K.; Rubano, A.; Fittipaldi, R.; Wang, X.; Paparo, D.; Vecchione, A.; Marrucci, L.; Bruzzese, R.; Amoruso, S. Femtosecond laser surface structuring of silicon using optical vortex beams generated by a Q-plate. Appl. Phys. Lett. 2014, 104, 241604. [Google Scholar] [CrossRef]

- Nivas, J.J.; He, S.; Rubano, A.; Vecchione, A.; Paparo, D.; Marrucci, L.; Bruzzese, R.; Amoruso, S. Direct femtosecond laser surface structuring with optical vortex beams generated by a Q-plate. Sci. Rep. 2015, 5, 17929. [Google Scholar] [CrossRef] [PubMed]

- Lasagni, A.F.; Gachot, C.; Trinh, K.E.; Hans, M.; Rosenkranz, A.; Roch, T.; Eckhardt, S.; Kunze, T.; Bieda, M.; Günther, D.; et al. Direct laser interference patterning, 20 years of development: From the basics to industrial applications. In Laser-Based Micro-and Nanoprocessing XI; Klotzbach, U., Washio, K., Kling, R., Eds.; SPIE: Institute for Manufacturing Technology, Technische Universität Dresden: Dresden, Germany, 2017; Volume 10092, p. 1009211. [Google Scholar]

- Wang, Y.-R.; Olaizola, S.M.; Han, I.S.; Jin, C.-Y.; Hopkinson, M. Direct patterning of periodic semiconductor nanostructures using single-pulse nanosecond laser interference. Opt. Express 2020, 28, 32529. [Google Scholar] [CrossRef] [PubMed]

- Hauschwitz, P.; Jochcová, D.; Jagdheesh, R.; Rostohar, D.; Brajer, J.; Kopeček, J.; Cimrman, M.; Smrž, M.; Mocek, T.; Lucianetti, A. Towards rapid large-scale LIPSS fabrication by 4-beam Ps DLIP. Opt. Laser Technol. 2021, 133, 106532. [Google Scholar] [CrossRef]

- Rodriguez, A.; Echeverría, M.; Ellman, M.; Perez, N.; Verevkin, Y.K.; Peng, C.S.; Berthou, T.; Wang, Z.; Ayerdi, I.; Savall, J.; et al. Laser interference lithography for nanoscale structuring of materials: From laboratory to industry. Microelectron. Eng. 2009, 86, 937–940. [Google Scholar] [CrossRef]

- Lu, C.; Lipson, R.H. Interference lithography: A powerful tool for fabricating periodic structures. Laser Photon. Rev. 2010, 4, 568–580. [Google Scholar] [CrossRef]

- Knittel, P.; Buchner, F.; Hadzifejzovic, E.; Giese, C.; Quellmalz, P.; Seidel, R.; Petit, T.; Iliev, B.; Schubert, T.J.S.; Nebel, C.E.; et al. Nanostructured boron doped diamond electrodes with increased reactivity for solar-driven CO2 reduction in room temperature ionic liquids. ChemCatChem 2020, 12, 5548–5557. [Google Scholar] [CrossRef]

- Zehetner, J.; Kraus, S.; Lucki, M.; Vanko, G.; Dzuba, J.; Lalinsky, T. Manufacturing of membranes by laser ablation in SiC, sapphire, glass and ceramic for GaN/Ferroelectric thin film MEMS and pressure sensors. Microsyst. Technol. 2016, 22, 1883–1892. [Google Scholar] [CrossRef]

- Slepička, P.; Siegel, J.; Lyutakov, O.; Slepičková Kasálková, N.; Kolská, Z.; Bačáková, L.; Švorčík, V. Polymer nanostructures for bioapplications induced by laser treatment. Biotechnol. Adv. 2018, 36, 839–855. [Google Scholar] [CrossRef]

- Bellucci, A.; Girolami, M.; Mastellone, M.; Orlando, S.; Polini, R.; Santagata, A.; Serpente, V.; Valentini, V.; Trucchi, D.M. Novel concepts and nanostructured materials for thermionic-based solar and thermal energy converters. Nanotechnology 2021, 32, 24002. [Google Scholar] [CrossRef]

- Bialuschewski, D.; Hoppius, J.S.; Frohnhoven, R.; Deo, M.; Gönüllü, Y.; Fischer, T.; Gurevich, E.L.; Mathur, S. Laser-textured metal substrates as photoanodes for enhanced PEC water splitting reactions. Adv. Eng. Mater. 2018, 20, 1800167. [Google Scholar] [CrossRef]

- Lin, B.; Song, Q.; Pang, D.; Liu, B.; Kong, W.; Li, Z.; Qin, Y.; Hu, M. Optical grating and THz polarizer based on normal grade single crystal diamond fast fabricated by Fs laser. Infrared Phys. Technol. 2021, 115, 103703. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mastellone, M.; Pace, M.L.; Curcio, M.; Caggiano, N.; De Bonis, A.; Teghil, R.; Dolce, P.; Mollica, D.; Orlando, S.; Santagata, A.; et al. LIPSS Applied to Wide Bandgap Semiconductors and Dielectrics: Assessment and Future Perspectives. Materials 2022, 15, 1378. https://doi.org/10.3390/ma15041378

Mastellone M, Pace ML, Curcio M, Caggiano N, De Bonis A, Teghil R, Dolce P, Mollica D, Orlando S, Santagata A, et al. LIPSS Applied to Wide Bandgap Semiconductors and Dielectrics: Assessment and Future Perspectives. Materials. 2022; 15(4):1378. https://doi.org/10.3390/ma15041378

Chicago/Turabian StyleMastellone, Matteo, Maria Lucia Pace, Mariangela Curcio, Nicola Caggiano, Angela De Bonis, Roberto Teghil, Patrizia Dolce, Donato Mollica, Stefano Orlando, Antonio Santagata, and et al. 2022. "LIPSS Applied to Wide Bandgap Semiconductors and Dielectrics: Assessment and Future Perspectives" Materials 15, no. 4: 1378. https://doi.org/10.3390/ma15041378

APA StyleMastellone, M., Pace, M. L., Curcio, M., Caggiano, N., De Bonis, A., Teghil, R., Dolce, P., Mollica, D., Orlando, S., Santagata, A., Serpente, V., Bellucci, A., Girolami, M., Polini, R., & Trucchi, D. M. (2022). LIPSS Applied to Wide Bandgap Semiconductors and Dielectrics: Assessment and Future Perspectives. Materials, 15(4), 1378. https://doi.org/10.3390/ma15041378