Thermomechanical Response of Polycarbonate/Aluminum Nitride Nanocomposites in Material Extrusion Additive Manufacturing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Nanocomposites

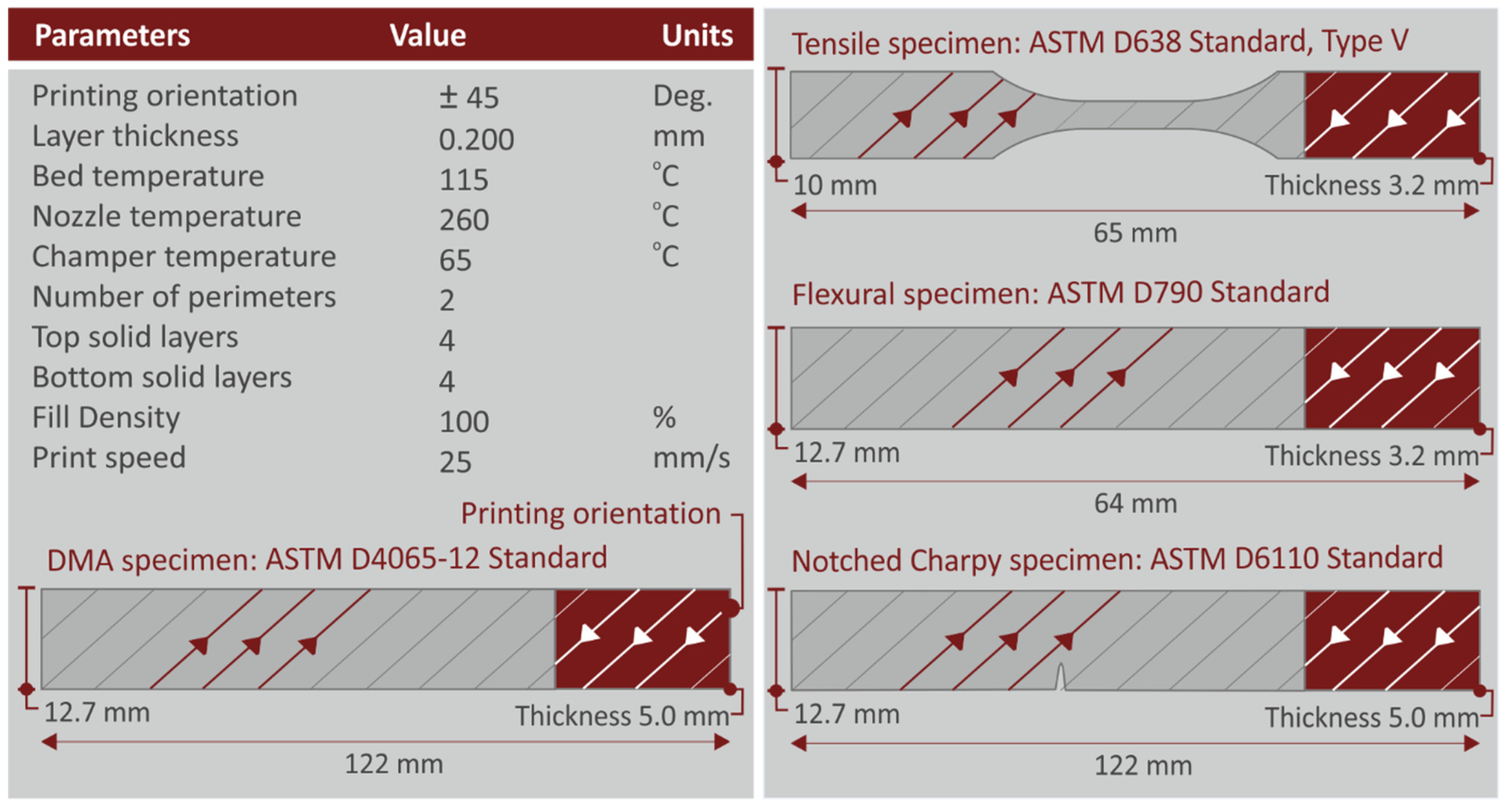

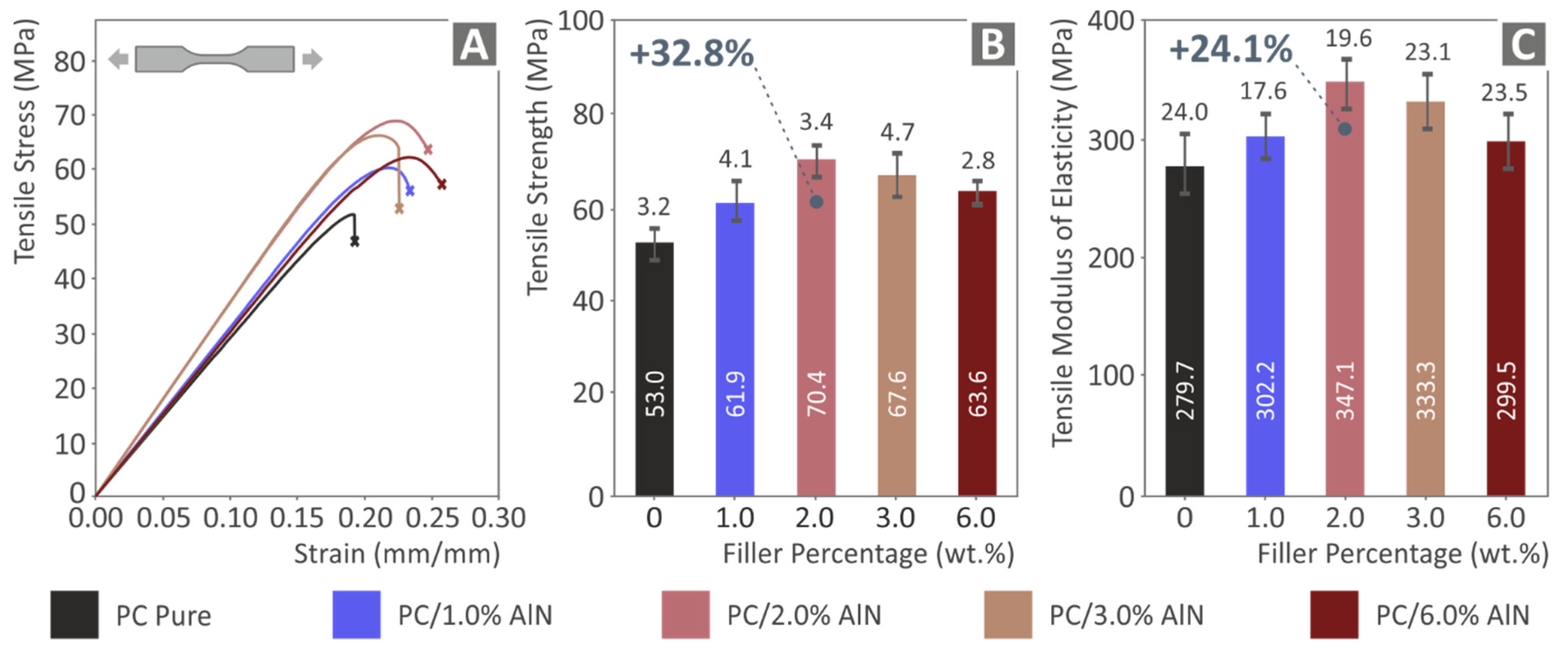

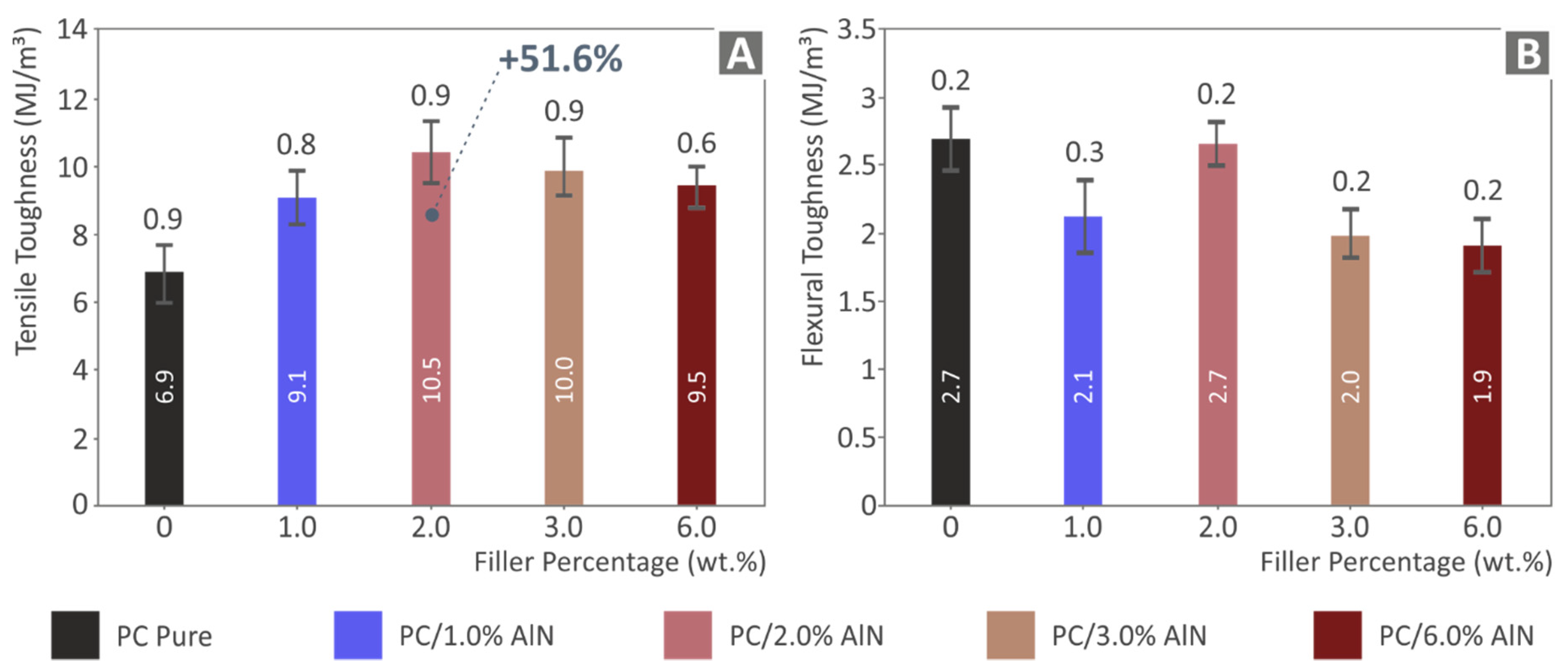

2.3. Specimens Fabrication

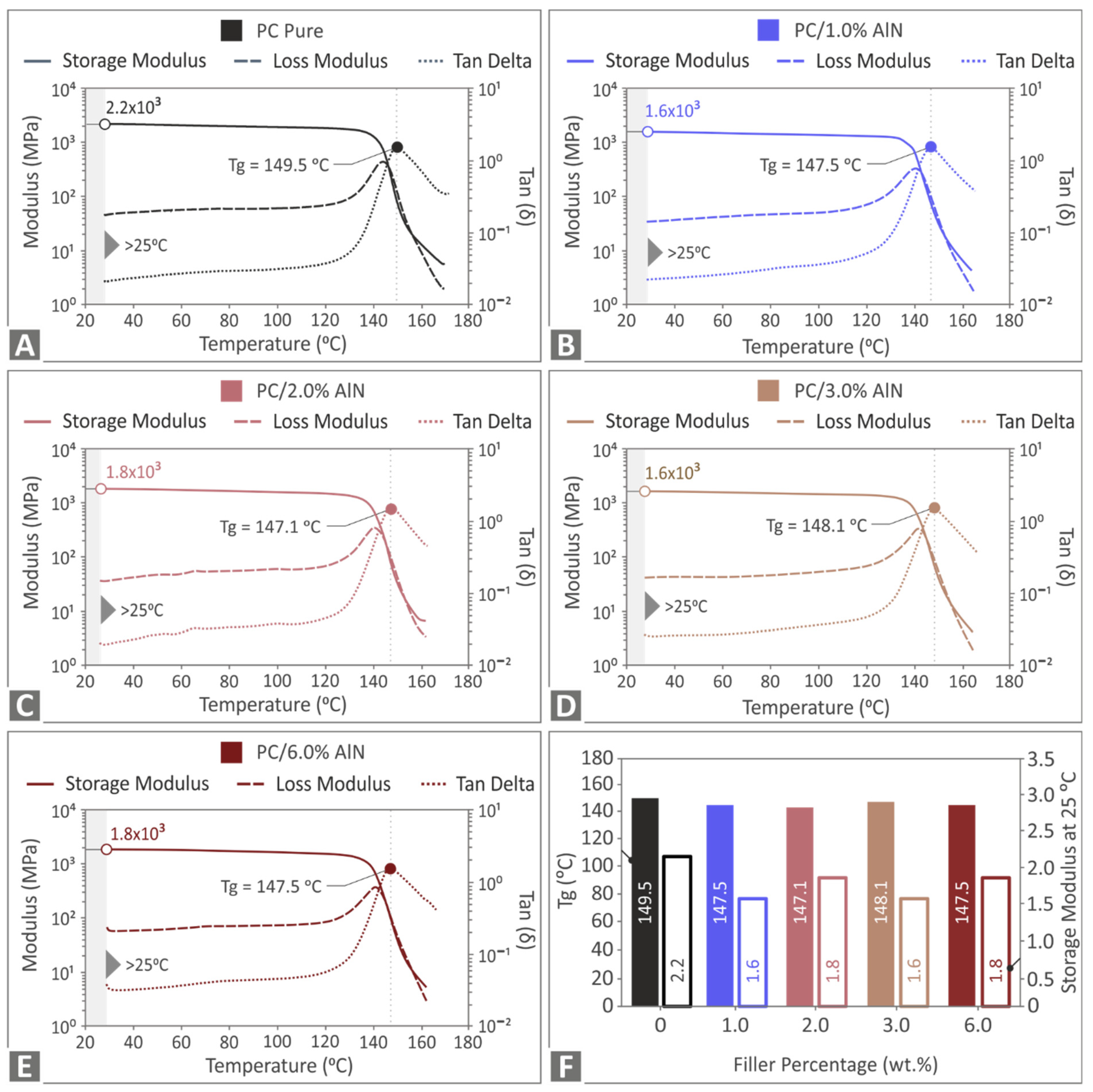

2.4. Thermal Analysis and Raman Spectroscopy

2.5. Filament Evaluation

2.6. Mechanical Tests

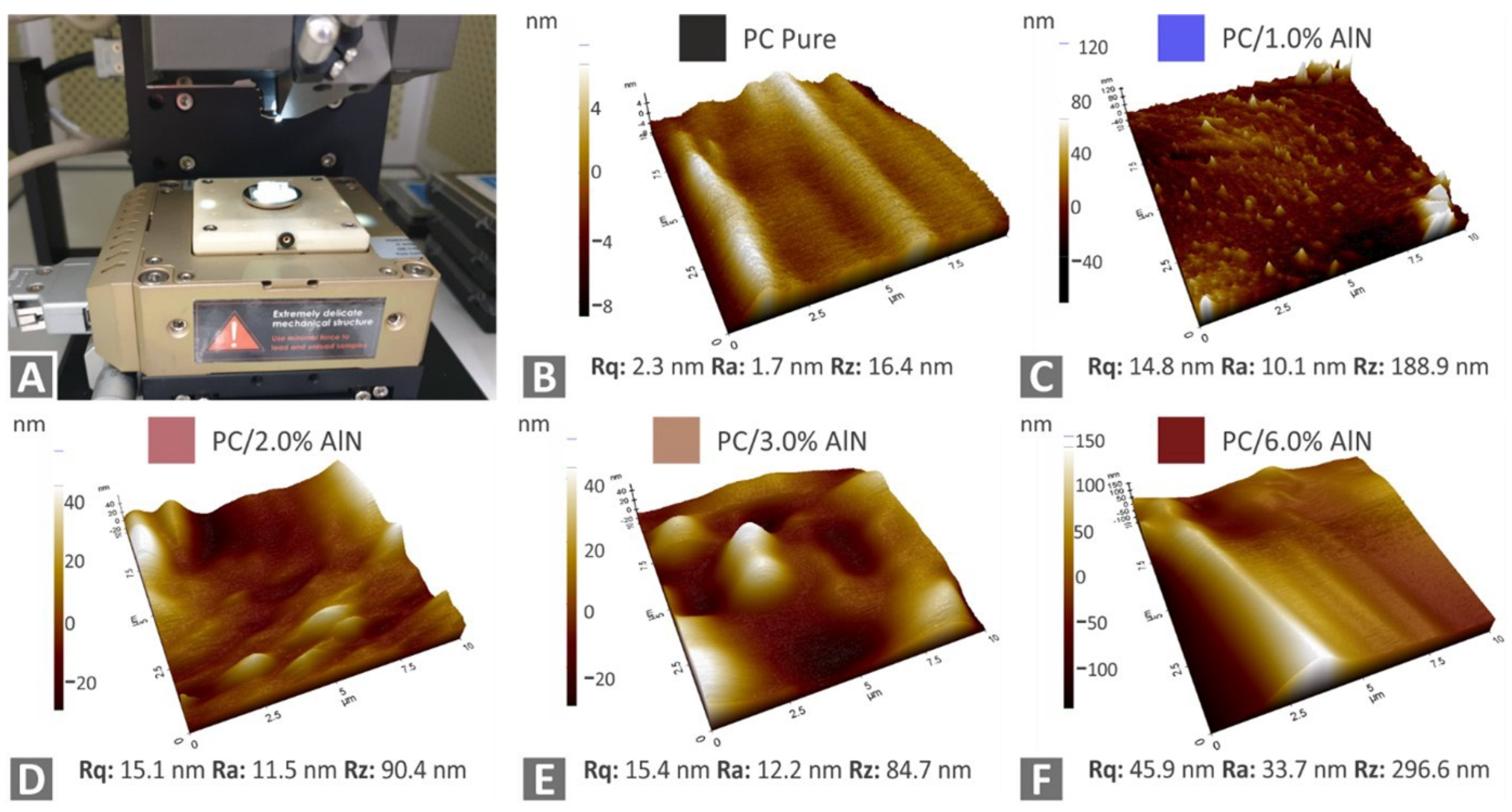

2.7. Morphology Characterization of Specimens

3. Results

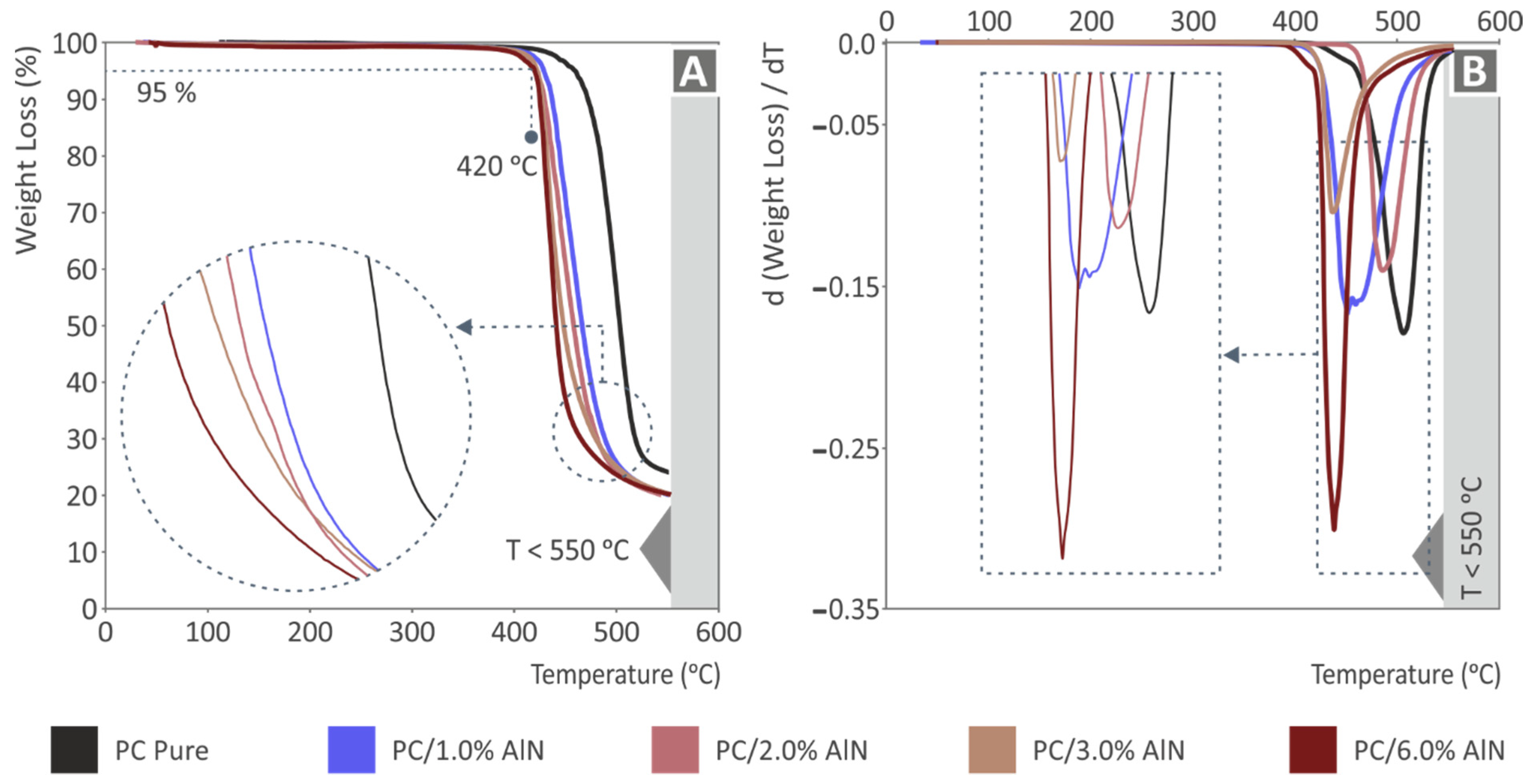

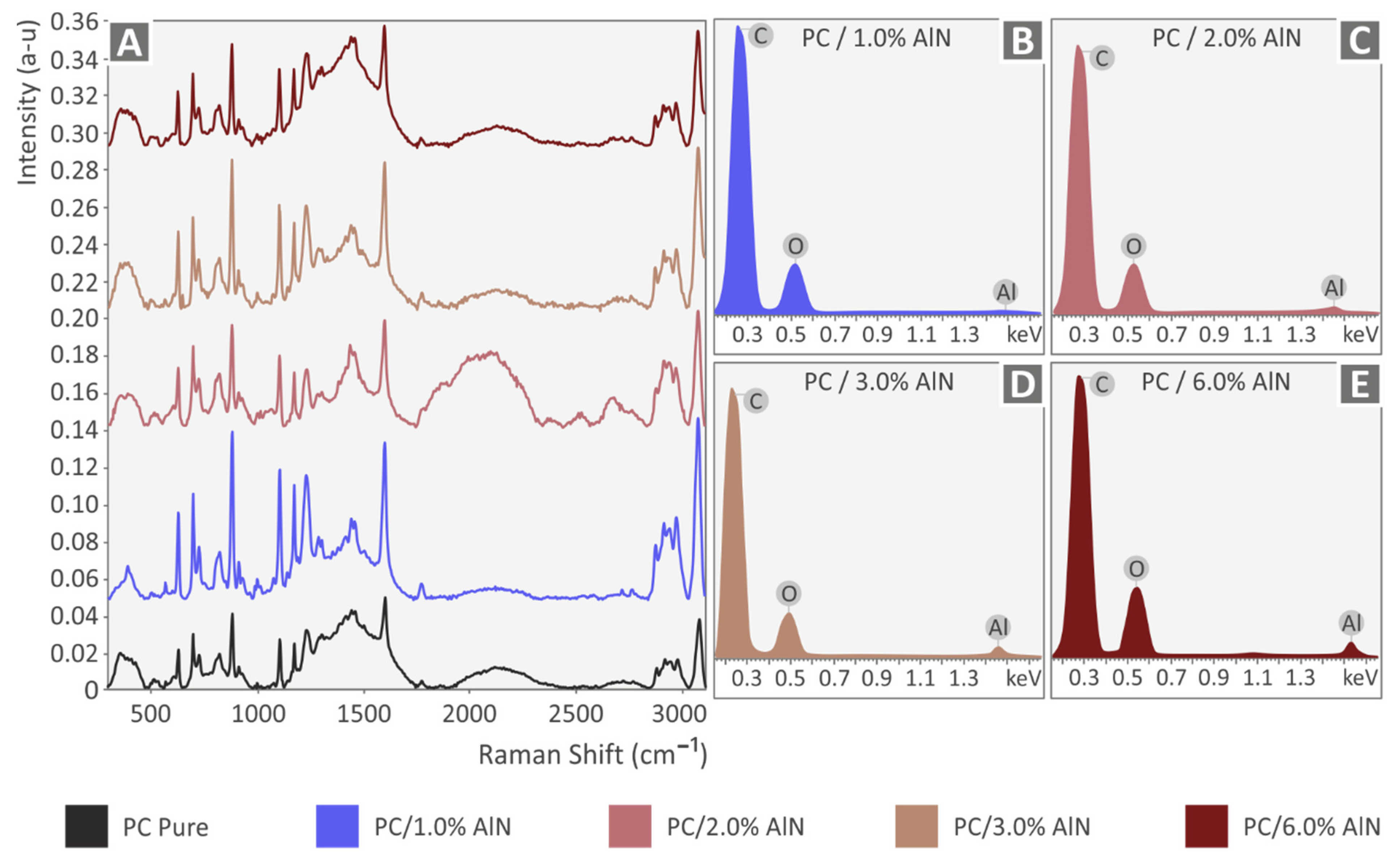

3.1. Thermal Analysis and Raman Spectroscopy

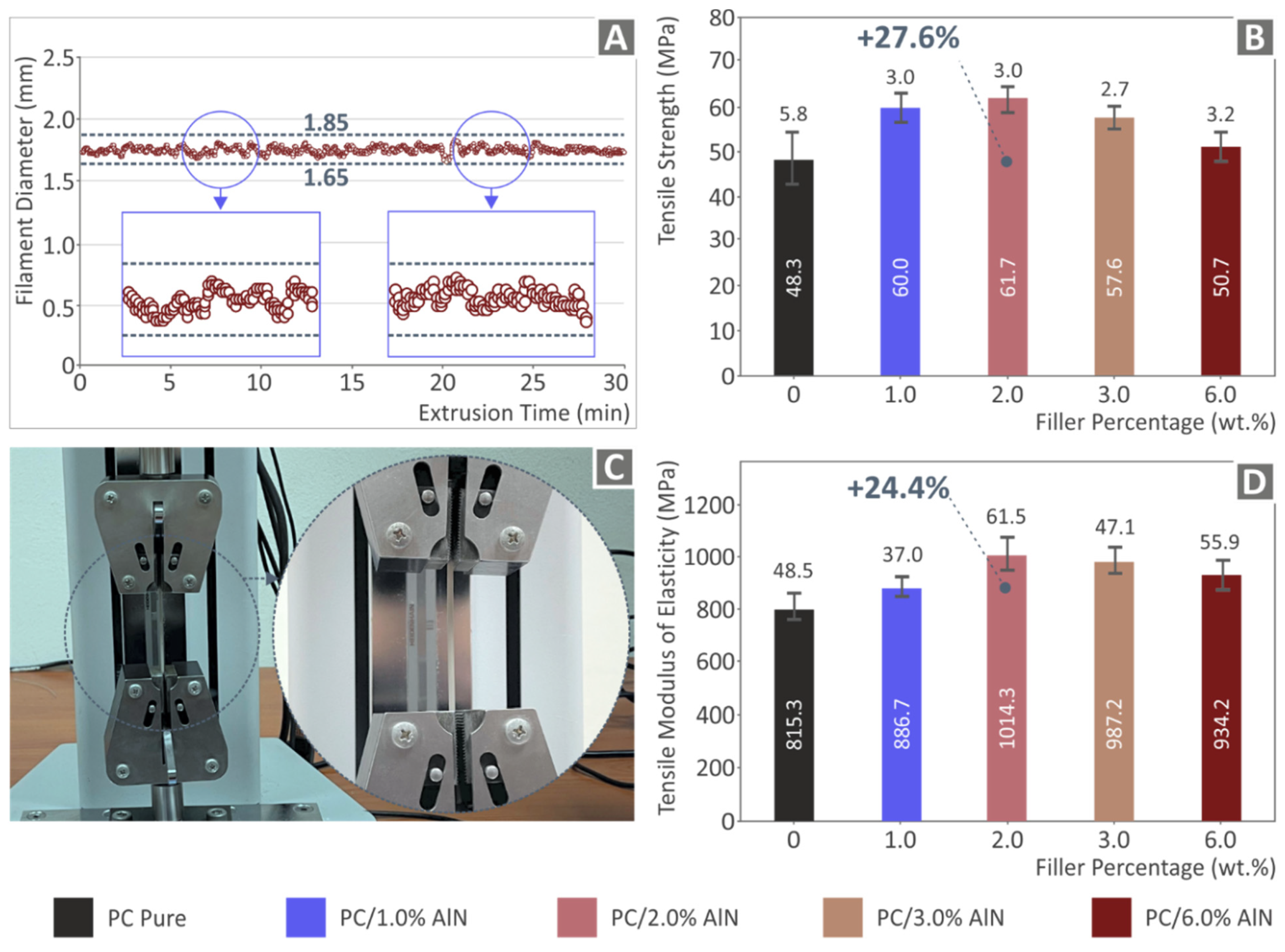

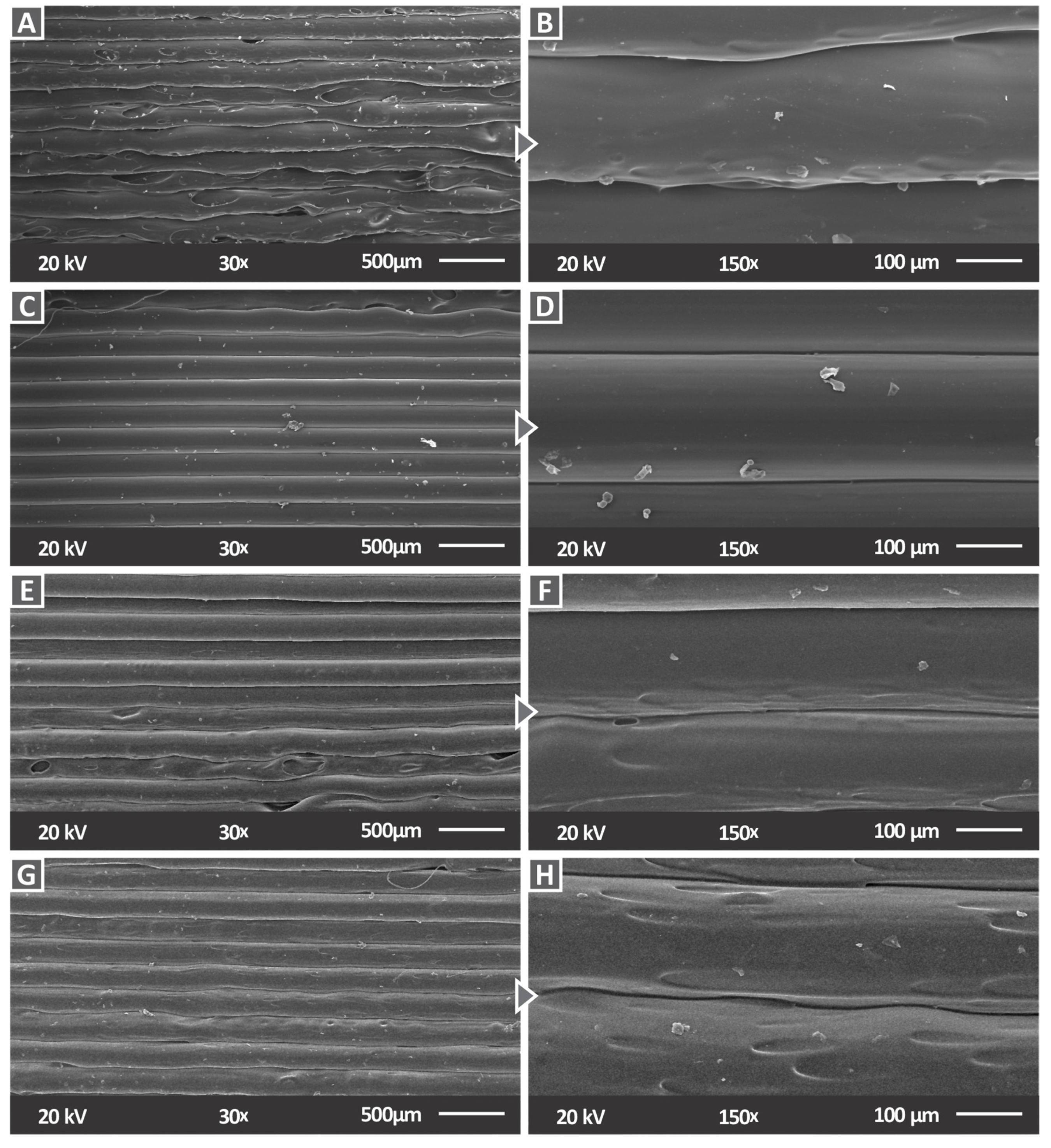

3.2. Filament Characterization

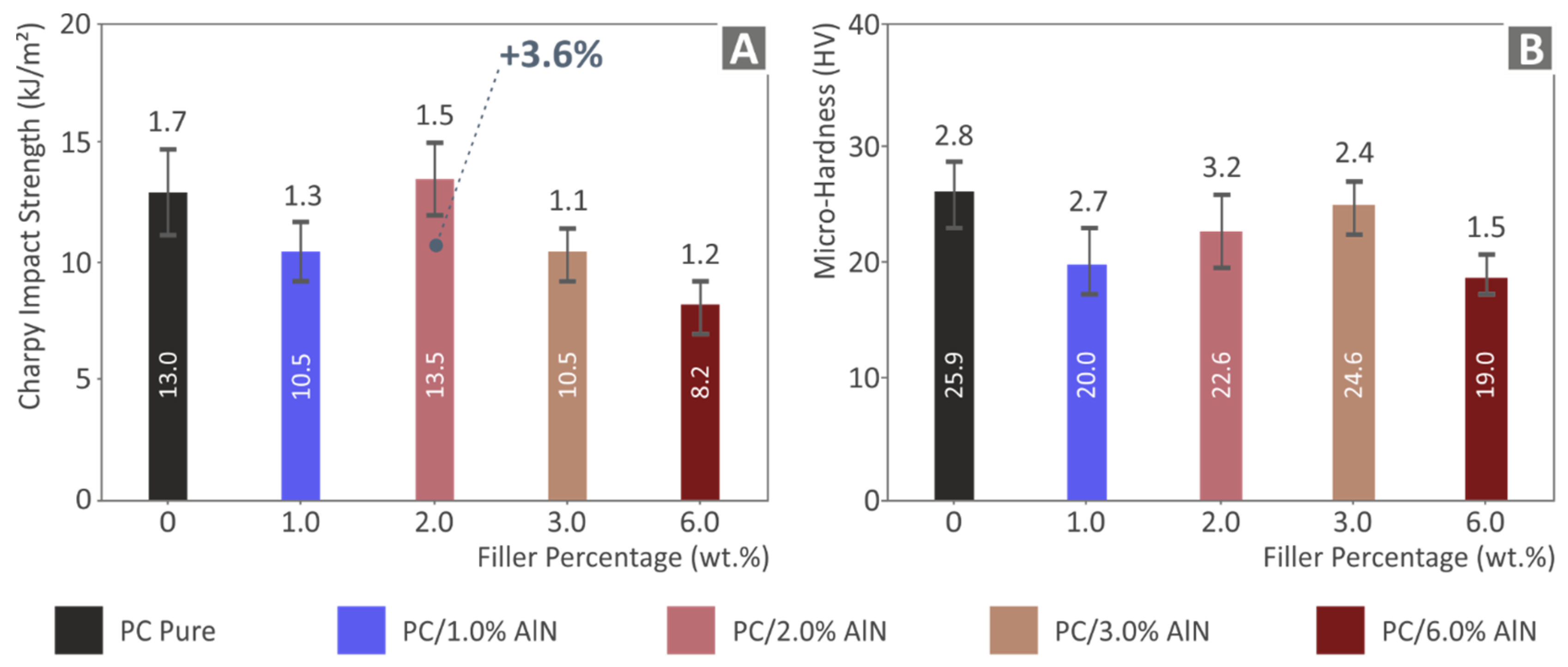

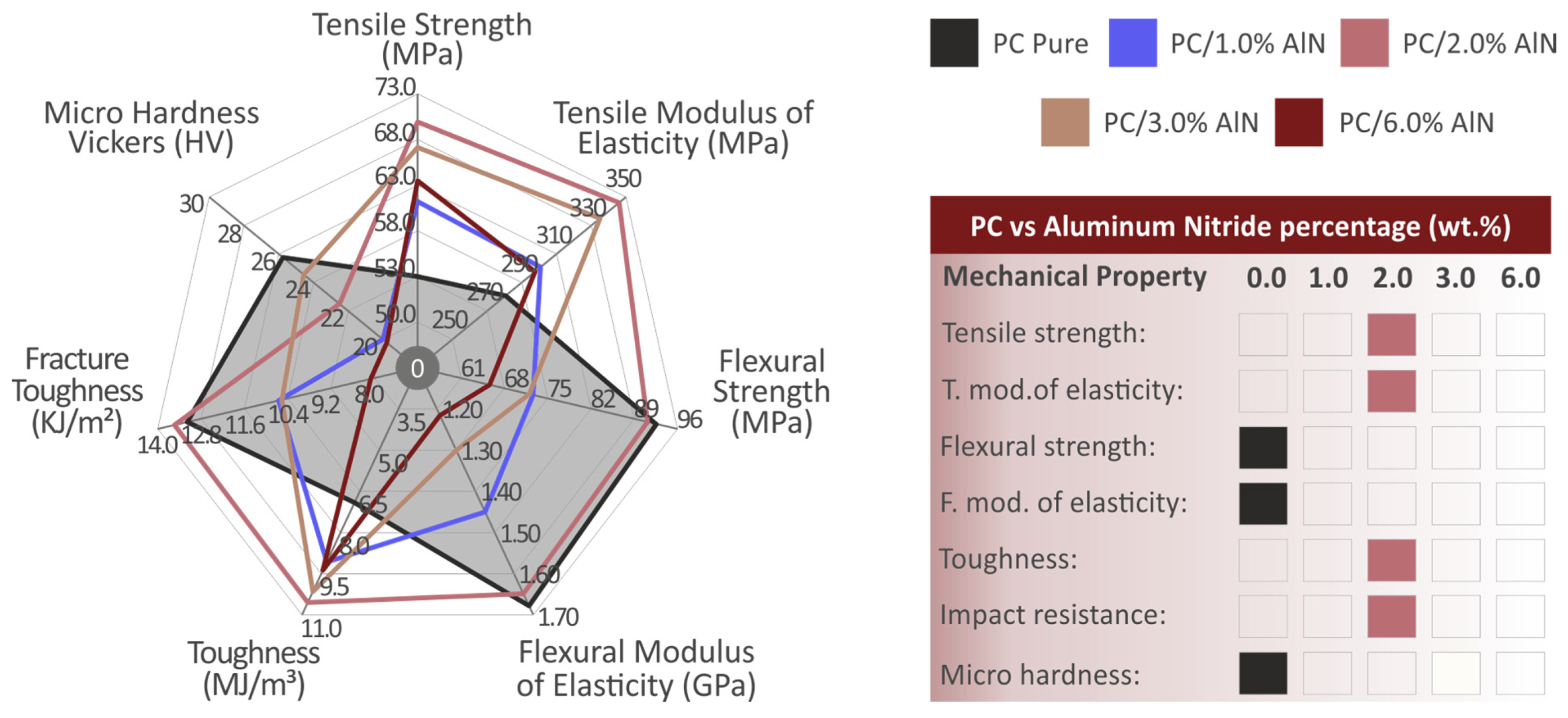

3.3. Mechanical Characterization of the Fabricated Specimens

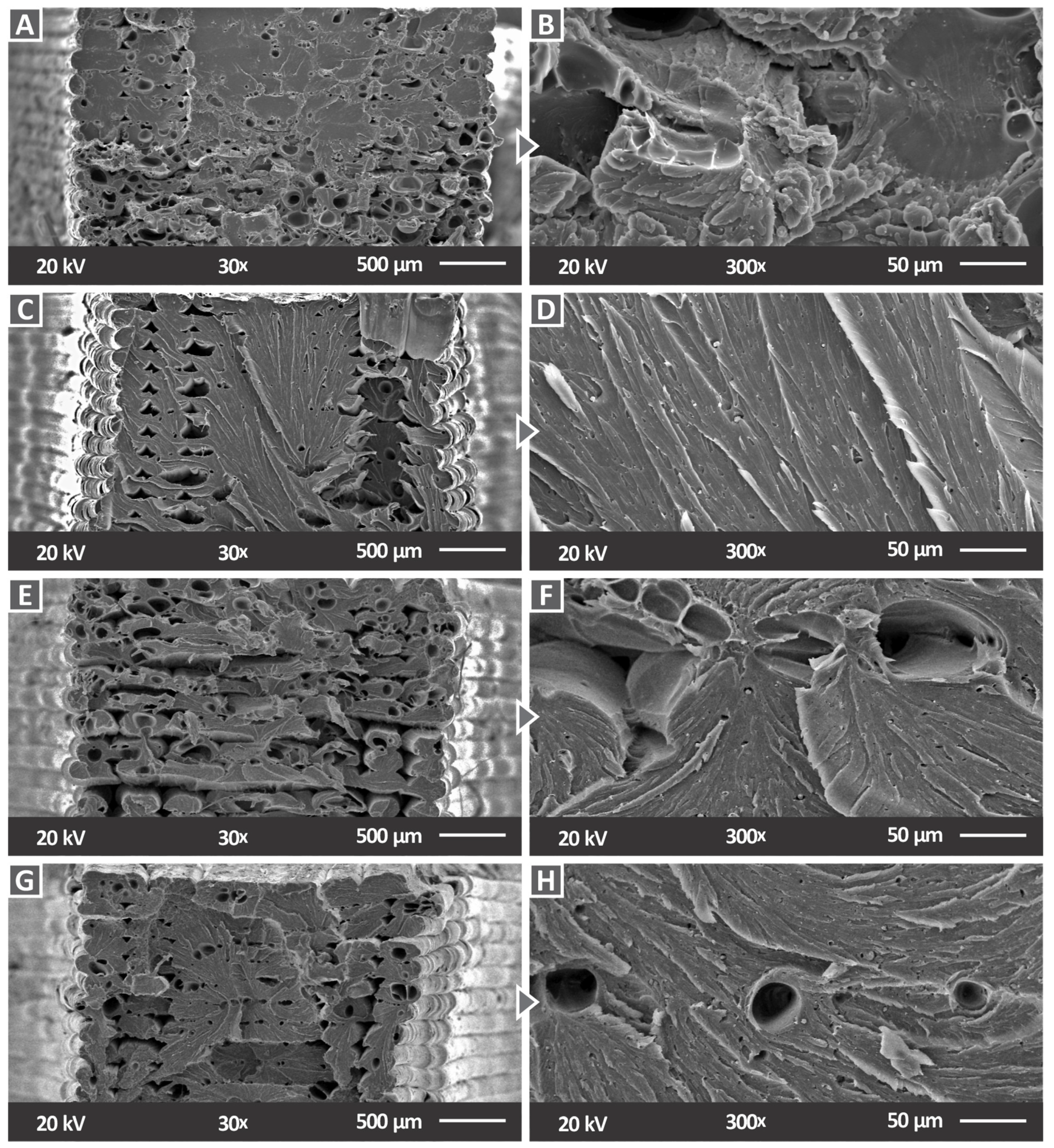

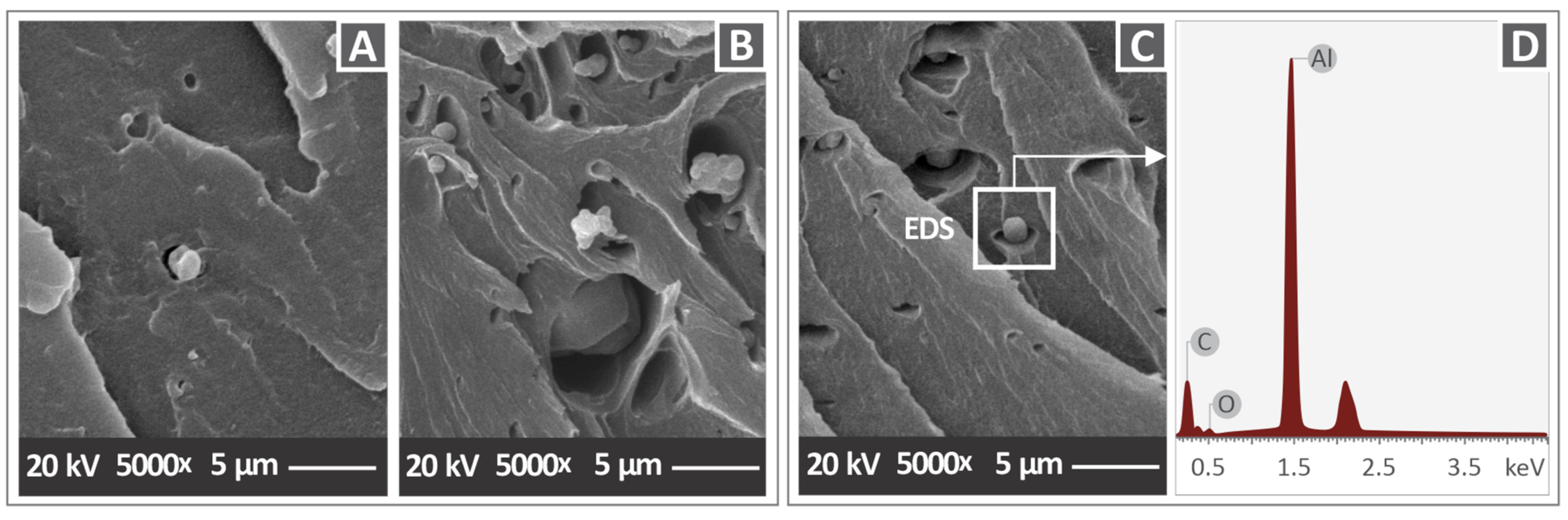

3.4. Morphology Characterization of Fabricated Specimens

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tao, W.; Lin, Z.; Yuan, Q.; Gong, P. Estimation of Effective Thickness of Cyclopore Polycarbonate Membrane by Scanning Electrochemical Impedance Microscopy. J. Electroanal. Chem. 2022, 905, 115974. [Google Scholar] [CrossRef]

- Budiman, A.S.; Illya, G.; Anbazhagan, S.; Tippabhotla, S.K.; Song, W.J.; Sahay, R.; Tay, A.A.O. Enabling Lightweight Polycarbonate-Polycarbonate (PC-PC) Photovoltaics Module Technology–Enhancing Integration of Silicon Solar Cells into Aesthetic Design for Greener Building and Urban Structures. Solar Energy 2022, 235, 129–139. [Google Scholar] [CrossRef]

- Quereda, J.; Kuriakose, S.; Munuera, C.; Mompean, F.J.; Al-Enizi, A.M.; Nafady, A.; Diez, E.; Frisenda, R.; Castellanos-Gomez, A. Scalable and Low-Cost Fabrication of Flexible WS2 Photodetectors on Polycarbonate. Npj Flex Electron. 2022, 6, 23. [Google Scholar] [CrossRef]

- Pan, K.; Li, X.; Shi, H.; Dai, M.; Yang, Z.; Chen, M.; Wei, W.; Liu, X.; Zheng, Y. Preparation of Photo-Crosslinked Aliphatic Polycarbonate Coatings with Predictable Degradation Behavior on Magnesium-Alloy Stents by Electrophoretic Deposition. Chem. Eng. J. 2022, 427, 131596. [Google Scholar] [CrossRef]

- Mu, X.; Jin, Z.; Chu, F.; Cai, W.; Zhu, Y.; Yu, B.; Song, L.; Hu, Y. High-Performance Flame-Retardant Polycarbonate Composites: Mechanisms Investigation and Fire-Safety Evaluation Systems Establishment. Compos. Part B: Eng. 2022, 238, 109873. [Google Scholar] [CrossRef]

- Pérez, J.M.; Vilas, J.L.; Laza, J.M.; Arnáiz, S.; Mijangos, F.; Bilbao, E.; Rodríguez, M.; León, L.M. Effect of Reprocessing and Accelerated Ageing on Thermal and Mechanical Polycarbonate Properties. J. Mater. Process. Technol. 2010, 210, 727–733. [Google Scholar] [CrossRef]

- Aden, M.; Roesner, A.; Olowinsky, A. Optical Characterization of Polycarbonate: Influence of Additives on Optical Properties. J. Polym. Sci. Part B Polym. Phys. 2010, 48, 451–455. [Google Scholar] [CrossRef]

- Maqsood, N.; Rimašauskas, M. Characterization of Carbon Fiber Reinforced PLA Composites Manufactured by Fused Deposition Modeling. Compos. Part C Open Access 2021, 4, 100112. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Liebscher, M.; Tzounis, L. Three-Dimensional Printed Antimicrobial Objects of Polylactic Acid (PLA)-Silver Nanoparticle Nanocomposite Filaments Produced by an In-Situ Reduction Reactive Melt Mixing Process. Biomimetics 2020, 5, 42. [Google Scholar] [CrossRef]

- Zakaria, M.R.; Md Akil, H.; Omar, M.F.; Abdul Kudus, M.H.; Mohd Sabri, F.N.A.; Abdullah, M.M.A.B. Enhancement of Mechanical and Thermal Properties of Carbon Fiber Epoxy Composite Laminates Reinforced with Carbon Nanotubes Interlayer Using Electrospray Deposition. Compos. Part C: Open Access 2020, 3, 100075. [Google Scholar] [CrossRef]

- Krausz, T.; Serban, D.A.; Negru, R.M.; Radu, A.G.; Marsavina, L. The Effect of Strain Rate and Temperature on the Mechanical Properties of Polycarbonate Composites. Mater. Today Proc. 2021, 45, 4211–4215. [Google Scholar] [CrossRef]

- Eitan, A.; Fisher, F.T.; Andrews, R.; Brinson, L.C.; Schadler, L.S. Reinforcement Mechanisms in MWCNT-Filled Polycarbonate. Compos. Sci. Technol. 2006, 66, 1162–1173. [Google Scholar] [CrossRef]

- Krausz, T.; Ailinei, I.; Galatanu, S.V.; Marsavina, L. Charpy Impact Properties and Numerical Modeling of Polycarbonate Composites. Mat. Des. Process Comms. 2021, 3, e260. [Google Scholar] [CrossRef]

- Kodali, D.; Umerah, C.O.; Idrees, M.O.; Jeelani, S.; Rangari, V.K. Fabrication and Characterization of Polycarbonate-Silica Filaments for 3D Printing Applications. J. Compos. Mater. 2021, 55, 4575–4584. [Google Scholar] [CrossRef]

- Biswal, M.; Mohanty, S.; Nayak, S.K.; Kumar, P.S. Effect of Functionalized Nanosilica on the Mechanical, Dynamic-Mechanical, and Morphological Performance of Polycarbonate/Nanosilica Nanocomposites. Polym. Eng. Sci. 2013, 53, 1287–1296. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Grammatikos, S.; Papadakis, V.; Korlos, A.; Mountakis, N. High Performance Polycarbonate Nanocomposites Mechanically Boosted with Titanium Carbide in Material Extrusion Additive Manufacturing. Nanomaterials 2022, 12, 1068. [Google Scholar] [CrossRef]

- Moreno, I.; Navascues, N.; Arruebo, M.; Irusta, S.; Santamaria, J. Facile Preparation of Transparent and Conductive Polymer Films Based on Silver Nanowire/Polycarbonate Nanocomposites. Nanotechnology 2013, 24, 275603. [Google Scholar] [CrossRef] [PubMed]

- Khan, A.; Puttegowda, M.; Jagadeesh, P.; Marwani, H.M.; Asiri, A.M.; Manikandan, A.; Parwaz Khan, A.A.; Ashraf, G.M.; Rangappa, S.M.; Siengchin, S. Review on Nitride Compounds and Its Polymer Composites: A Multifunctional Material. J. Mater. Res. Technol. 2022, 18, 2175–2193. [Google Scholar] [CrossRef]

- Guan, J.; Derdouri, A.; Ashrafi, B.; Benhalima, A.; Kim, K.S.; Daroszewska, M.; Simard, B. Boron Nitride Nanotubes Reinforced Polycarbonate Nanocomposites. Mater. Today Commun. 2019, 20, 100586. [Google Scholar] [CrossRef]

- Iqbal, A.; Mohd-Yasin, F. Reactive Sputtering of Aluminum Nitride (002) Thin Films for Piezoelectric Applications: A Review. Sensors 2018, 18, 1797. [Google Scholar] [CrossRef]

- Pinto, R.M.R.; Gund, V.; Calaza, C.; Nagaraja, K.K.; Vinayakumar, K.B. Piezoelectric Aluminum Nitride Thin-Films: A Review of Wet and Dry Etching Techniques. Microelectron. Eng. 2022, 257, 111753. [Google Scholar] [CrossRef]

- Piazza, G.; Felmetsger, V.; Muralt, P.; Olsson III, R.H.; Ruby, R. Piezoelectric Aluminum Nitride Thin Films for Microelectromechanical Systems. MRS Bull. 2012, 37, 1051–1061. [Google Scholar] [CrossRef]

- Jia, L.; Shi, L.; Liu, C.; Yao, Y.; Sun, C.; Wu, G. Design and Characterization of an Aluminum Nitride-Based MEMS Hydrophone With Biologically Honeycomb Architecture. IEEE Trans. Electron Devices 2021, 68, 4656–4663. [Google Scholar] [CrossRef]

- Jiang, W.; Dong, L.; Liu, S.; Ai, B.; Zhao, S.; Zhang, W.; Pan, K.; Zhang, L. Improvement of the Interface between the Lithium Anode and a Garnet-Type Solid Electrolyte of Lithium Batteries Using an Aluminum-Nitride Layer. Nanomaterials 2022, 12, 2023. [Google Scholar] [CrossRef] [PubMed]

- Hao, S.; Zhang, L.; Wang, X.; Zhao, G.; Hou, P.; Xu, X. Design of Multilayered Porous Aluminum Nitride for Supercapacitor Applications. Energy Fuels 2021, 35, 12628–12636. [Google Scholar] [CrossRef]

- Wu, Q.; Hu, Z.; Wang, X.; Chen, Y.; Lu, Y. Synthesis and Optical Characterization of Aluminum Nitride Nanobelts. J. Phys. Chem. B 2003, 107, 9726–9729. [Google Scholar] [CrossRef]

- Liu, X.; Gong, Z.; Bruch, A.W.; Surya, J.B.; Lu, J.; Tang, H.X. Aluminum Nitride Nanophotonics for Beyond-Octave Soliton Microcomb Generation and Self-Referencing. Nat. Commun. 2021, 12, 5428. [Google Scholar] [CrossRef] [PubMed]

- Bishop, S.G.; Hadden, J.P.; Alzahrani, F.D.; Hekmati, R.; Huffaker, D.L.; Langbein, W.W.; Bennett, A.J. Room-Temperature Quantum Emitter in Aluminum Nitride. ACS Photonics 2020, 7, 1636–1641. [Google Scholar] [CrossRef]

- Hickman, A.L.; Chaudhuri, R.; Bader, S.J.; Nomoto, K.; Li, L.; Hwang, J.C.M.; Grace Xing, H.; Jena, D. Next Generation Electronics on the Ultrawide-Bandgap Aluminum Nitride Platform. Semicond. Sci. Technol. 2021, 36, 044001. [Google Scholar] [CrossRef]

- Fichtner, S.; Wolff, N.; Lofink, F.; Kienle, L.; Wagner, B. AlScN: A III-V Semiconductor Based Ferroelectric. J. Appl. Phys. 2019, 125, 114103. [Google Scholar] [CrossRef]

- Hayden, J.; Hossain, M.D.; Xiong, Y.; Ferri, K.; Zhu, W.; Imperatore, M.V.; Giebink, N.; Trolier-McKinstry, S.; Dabo, I.; Maria, J.-P. Ferroelectricity in Boron-Substituted Aluminum Nitride Thin Films. Phys. Rev. Mater. 2021, 5, 044412. [Google Scholar] [CrossRef]

- Srinivasan, D.; Meignanamoorthy, M.; Gacem, A.; Vinayagam, M.; Sathish, T.; Ravichandran, M.; Srinivasan, S.K.; Abdellattif, M.H.; Allasi, H.L. Tribological Behavior of Al/Nanomagnesium/Aluminum Nitride Composite Synthesized through Liquid Metallurgy Technique. J. Nanomater. 2022, 2022, 7840939. [Google Scholar] [CrossRef]

- Hoque, M.S.B.; Koh, Y.R.; Braun, J.L.; Mamun, A.; Liu, Z.; Huynh, K.; Liao, M.E.; Hussain, K.; Cheng, Z.; Hoglund, E.R.; et al. High In-Plane Thermal Conductivity of Aluminum Nitride Thin Films. ACS Nano 2021, 15, 9588–9599. [Google Scholar] [CrossRef] [PubMed]

- Kuo, P.K.; Auner, G.W.; Wu, Z.L. Microstructure and Thermal Conductivity of Epitaxial AlN Thin Films. Thin Solid Films 1994, 253, 223–227. [Google Scholar] [CrossRef]

- Pan, C.; Kou, K.; Zhang, Y.; Li, Z.; Wu, G. Enhanced Through-Plane Thermal Conductivity of PTFE Composites with Hybrid Fillers of Hexagonal Boron Nitride Platelets and Aluminum Nitride Particles. Compos. Part B Eng. 2018, 153, 1–8. [Google Scholar] [CrossRef]

- Wu, S.-Y.; Huang, Y.-L.; Ma, C.-C.M.; Yuen, S.-M.; Teng, C.-C.; Yang, S.-Y. Mechanical, Thermal and Electrical Properties of Aluminum Nitride/Polyetherimide Composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1573–1583. [Google Scholar] [CrossRef]

- Lin, L.; Wu, H.; Ni, P.; Chen, Y.; Huang, Z.; Li, Y.; Lin, K.; Sheng, P.; Wu, S. Additive Manufacturing of Complex-Shaped and High-Performance Aluminum Nitride-Based Components for Thermal Management. Addit. Manuf. 2022, 52, 102671. [Google Scholar] [CrossRef]

- Zhang, Z.; Fidan, I.; Allen, M. Detection of Material Extrusion In-Process Failures via Deep Learning. Inventions 2020, 5, 25. [Google Scholar] [CrossRef]

- Koker, B.; Ruckdashel, R.; Abajorga, H.; Curcuru, N.; Pugatch, M.; Dunn, R.; Kazmer, D.O.; Wetzel, E.D.; Park, J.H. Enhanced Interlayer Strength and Thermal Stability via Dual Material Filament for Material Extrusion Additive Manufacturing. Addit. Manuf. 2022, 55, 102807. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Vairis, A.; Savvakis, K.; Maniadi, A. A Parametric Determination of Bending and Charpy’s Impact Strength of ABS and ABS-plus Fused Deposition Modeling Specimens. Prog. Addit. Manuf. 2019, 4, 323–330. [Google Scholar] [CrossRef]

- Vidakis, N.; Maniadi, A.; Petousis, M.; Vamvakaki, M.; Kenanakis, G.; Koudoumas, E. Mechanical and Electrical Properties Investigation of 3D-Printed Acrylonitrile–Butadiene–Styrene Graphene and Carbon Nanocomposites. J. Mater. Eng. Perform. 2020, 29, 1909–1918. [Google Scholar] [CrossRef]

- Ai, J.-R.; Vogt, B.D. Size and Print Path Effects on Mechanical Properties of Material Extrusion 3D Printed Plastics. Prog. Addit. Manuf. 2022, 7, 1009–1021. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Kechagias, J.D. A Comprehensive Investigation of the 3D Printing Parameters’ Effects on the Mechanical Response of Polycarbonate in Fused Filament Fabrication. Prog. Addit. Manuf. 2022, 7, 713–722. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Korlos, A.; Velidakis, E.; Mountakis, N.; Charou, C.; Myftari, A. Strain Rate Sensitivity of Polycarbonate and Thermoplastic Polyurethane for Various 3D Printing Temperatures and Layer Heights. Polymers 2021, 13, 2752. [Google Scholar] [CrossRef] [PubMed]

- Arai, T.; Kawaji, M. Thermal Performance and Flow Characteristics in Additive Manufactured Polycarbonate Pulsating Heat Pipes with Novec 7000. Appl. Therm. Eng. 2021, 197, 117273. [Google Scholar] [CrossRef]

- Dialami, N.; Rivet, I.; Cervera, M.; Chiumenti, M. Computational Characterization of Polymeric Materials 3D-Printed via Fused Filament Fabrication. Mech. Adv. Mater. Struct. 2022, 1–11. [Google Scholar] [CrossRef]

- Somireddy, M.; Czekanski, A. Computational Modeling of Constitutive Behaviour of 3D Printed Composite Structures. J. Mater. Res. Technol. 2021, 11, 1710–1718. [Google Scholar] [CrossRef]

- Nasirov, A.; Fidan, I. Prediction of Mechanical Properties of Fused Filament Fabricated Structures via Asymptotic Homogenization. Mech. Mater. 2020, 145, 103372. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Savvakis, K.; Maniadi, A.; Koudoumas, E. A Comprehensive Investigation of the Mechanical Behavior and the Dielectrics of Pure Polylactic Acid (PLA) and PLA with Graphene (GnP) in Fused Deposition Modeling (FDM). Int. J. Plast. Technol. 2019, 23, 195–206. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Mountakis, N.; Fischer-Griffiths, P.E.; Grammatikos, S.A.; Tzounis, L. Mechanical Reinforcement Course of 3D Printed Polypropylene–Antimony Doped Tin Oxide Nanocomposites versus Filler Loading. Adv. Compos. Mater. 2022, 31, 235–256. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Mountakis, N.; Korlos, A.; Papadakis, V.; Moutsopoulou, A. Trilateral Multi-Functional Polyamide 12 Nanocomposites with Binary Inclusions for Medical Grade Material Extrusion 3D Printing: The Effect of Titanium Nitride in Mechanical Reinforcement and Copper/Cuprous Oxide as Antibacterial Agents. J. Funct. Biomater. 2022, 13, 115. [Google Scholar] [CrossRef]

- Pazhamannil, R.V.; Edacherian, A. Property Enhancement Approaches of Fused Filament Fabrication Technology: A Review. Polym. Eng. Sci. 2022, 62, 1356–1376. [Google Scholar] [CrossRef]

- Yang, L.; Chen, Y.; Wang, M.; Shi, S.; Jing, J. Fused Deposition Modeling 3D Printing of Novel Poly(Vinyl Alcohol)/Graphene Nanocomposite with Enhanced Mechanical and Electromagnetic Interference Shielding Properties. Ind. Eng. Chem. Res. 2020, 59, 8066–8077. [Google Scholar] [CrossRef]

- Lee, J.; Lee, H.; Cheon, K.-H.; Park, C.; Jang, T.-S.; Kim, H.-E.; Jung, H.-D. Fabrication of Poly(Lactic Acid)/Ti Composite Scaffolds with Enhanced Mechanical Properties and Biocompatibility via Fused Filament Fabrication (FFF)–Based 3D Printing. Addit. Manuf. 2019, 30, 100883. [Google Scholar] [CrossRef]

- Dickson, A.N.; Abourayana, H.M.; Dowling, D.P. 3D Printing of Fibre-Reinforced Thermoplastic Composites Using Fused Filament Fabrication—A Review. Polymers 2020, 12, 2188. [Google Scholar] [CrossRef]

- Ambone, T.; Torris, A.; Shanmuganathan, K. Enhancing the Mechanical Properties of 3D Printed Polylactic Acid Using Nanocellulose. Polym. Eng. Sci. 2020, 60, 1842–1855. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Spiridaki, M.; Kechagias, J.D. Mechanical Performance of Fused Filament Fabricated and 3D-Printed Polycarbonate Polymer and Polycarbonate/Cellulose Nanofiber Nanocomposites. Fibers 2021, 9, 74. [Google Scholar] [CrossRef]

- Jahangir, M.N.; Billah, K.M.M.; Lin, Y.; Roberson, D.A.; Wicker, R.B.; Espalin, D. Reinforcement of Material Extrusion 3D Printed Polycarbonate Using Continuous Carbon Fiber. Addit. Manuf. 2019, 28, 354–364. [Google Scholar] [CrossRef]

- Gupta, A.; Fidan, I.; Hasanov, S.; Nasirov, A. Processing, Mechanical Characterization, and Micrography of 3D-Printed Short Carbon Fiber Reinforced Polycarbonate Polymer Matrix Composite Material. Int. J. Adv. Manuf. Technol. 2020, 107, 3185–3205. [Google Scholar] [CrossRef]

- Kumar, M.N.V.R.L.; Ramakrishnan, R. Optimization of Fused Deposition Modeling Process Parameters and Dynamic Mechanical Analysis of 3D Printed Polycarbonate/Acrylonitrile-Butadiene-Styrene Composite Loaded with Tetrabromobiphenol-A and Microcrystalline Cellulose. J. Mater. Eng. Perform. 2022, 31, 10071–10080. [Google Scholar] [CrossRef]

- Kannan, S.; Ramamoorthy, M. Mechanical Characterization and Experimental Modal Analysis of 3D Printed ABS, PC and PC-ABS Materials. Mater. Res. Express 2020, 7, 015341. [Google Scholar] [CrossRef]

- Kumar, M.; Ramakrishnan, R.; Omarbekova, A. 3D Printed Polycarbonate Reinforced Acrylonitrile–Butadiene–Styrene Composites: Composition Effects on Mechanical Properties, Micro-Structure and Void Formation Study. J. Mech. Sci. Technol. 2019, 33, 5219–5226. [Google Scholar] [CrossRef]

- Antoniadis, A.; Vidakis, N.; Bilalis, N. Fatigue Fracture Investigation of Cemented Carbide Tools in Gear Hobbing, Part 2: The Effect of Cutting Parameters on the Level of Tool Stresses—A Quantitative Parametric Analysis. J. Manuf. Sci. Eng. 2002, 124, 792–798. [Google Scholar] [CrossRef]

- Petousis, M.; Vidakis, N.; Mountakis, N.; Grammatikos, S.; Papadakis, V.; David, C.N.; Moutsopoulou, A.; Das, S.C. Silicon Carbide Nanoparticles as a Mechanical Boosting Agent in Material Extrusion 3D-Printed Polycarbonate. Polymers 2022, 14, 3492. [Google Scholar] [CrossRef] [PubMed]

- Vidakis, N.; Petousis, M.; Mountakis, N.; Grammatikos, S.; Papadakis, V.; Kechagias, J.D.; Das, S.C. On the Thermal and Mechanical Performance of Polycarbonate / Titanium Nitride Nanocomposites in Material Extrusion Additive Manufacturing. Compos. Part C Open Access 2022, 8, 100291. [Google Scholar] [CrossRef]

- Kechagias, J.D.; Ninikas, K.; Petousis, M.; Vidakis, N.; Vaxevanidis, N. An Investigation of Surface Quality Characteristics of 3D Printed PLA Plates Cut by CO2 Laser Using Experimental Design. Mater. Manuf. Process. 2021, 36, 1544–1553. [Google Scholar] [CrossRef]

- Liravi, F.; Toyserkani, E. A Hybrid Additive Manufacturing Method for the Fabrication of Silicone Bio-Structures: 3D Printing Optimization and Surface Characterization. Mater. Des. 2018, 138, 46–61. [Google Scholar] [CrossRef]

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. Current Trends and Research Opportunities in Hybrid Additive Manufacturing. Int. J. Adv. Manuf. Technol. 2021, 113, 623–648. [Google Scholar] [CrossRef]

- Moetazedian, A.; Allum, J.; Gleadall, A.; Mele, E.; Silberschmidt, V.V. MaTrEx AM: A New Hybrid Additive Manufacturing Process to Selectively Control Mechanical Properties. Addit. Manuf. 2021, 47, 102337. [Google Scholar] [CrossRef]

- Andreu, A.; Kim, S.; Dittus, J.; Friedmann, M.; Fleischer, J.; Yoon, Y.-J. Hybrid Material Extrusion 3D Printing to Strengthen Interlayer Adhesion through Hot Rolling. Addit. Manuf. 2022, 55, 102773. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Reinicke, T. On the Environmental Impacts of 3D Printing Technology. Appl. Mater. Today 2020, 20, 100689. [Google Scholar] [CrossRef]

- Annibaldi, M.V. Rotilio Energy Consumption Consideration of 3D Printing. In Proceedings of the 2019 II Workshop on Metrology for Industry 4.0 and IoT (MetroInd4.0&IoT), Naples, Italy, 4 June 2019; pp. 243–248. [Google Scholar]

- Vidakis, N.; Kechagias, J.D.; Petousis, M.; Vakouftsi, F.; Mountakis, N. The Effects of FFF 3D Printing Parameters on Energy Consumption. Mater. Manuf. Process. 2022, 1–18. [Google Scholar] [CrossRef]

- Peng, T. Analysis of Energy Utilization in 3D Printing Processes. Procedia CIRP 2016, 40, 62–67. [Google Scholar] [CrossRef]

- Resta, V.; Quarta, G.; Lomascolo, M.; Maruccio, L.; Calcagnile, L. Raman and Photoluminescence Spectroscopy of Polycarbonate Matrices Irradiated with Different Energy 28Si+ Ions. Vacuum 2015, 116, 82–89. [Google Scholar] [CrossRef]

- Stuart, B.H. Temperature Studies of Polycarbonate Using Fourier Transform Raman Spectroscopy. Polym. Bull. 1996, 36, 341–346. [Google Scholar] [CrossRef]

- Zimmerer, C.; Matulaitiene, I.; Niaura, G.; Reuter, U.; Janke, A.; Boldt, R.; Sablinskas, V.; Steiner, G. Nondestructive Characterization of the Polycarbonate-Octadecylamine Interface by Surface Enhanced Raman Spectroscopy. Polym. Test. 2019, 73, 152–158. [Google Scholar] [CrossRef]

- Yavas, D.; Zhang, Z.; Liu, Q.; Wu, D. Fracture Behavior of 3D Printed Carbon Fiber-Reinforced Polymer Composites. Compos. Sci. Technol. 2021, 208, 108741. [Google Scholar] [CrossRef]

- Song, Y.; Li, Y.; Song, W.; Yee, K.; Lee, K.Y.; Tagarielli, V.L. Measurements of the Mechanical Response of Unidirectional 3D-Printed PLA. Mater. Des. 2017, 123, 154–164. [Google Scholar] [CrossRef]

- Srinivasan, R.; Ruban, W.; Deepanraj, A.; Bhuvanesh, R.; Bhuvanesh, T. Effect on Infill Density on Mechanical Properties of PETG Part Fabricated by Fused Deposition Modelling. Mater. Today: Proc. 2020, 27, 1838–1842. [Google Scholar] [CrossRef]

- Gunasekaran, K.N.; Aravinth, V.; Muthu Kumaran, C.B.; Madhankumar, K.; Pradeep Kumar, S. Investigation of Mechanical Properties of PLA Printed Materials under Varying Infill Density. Mater. Today: Proc. 2021, 45, 1849–1856. [Google Scholar] [CrossRef]

- Akhoundi, B.; Behravesh, A.H. Effect of Filling Pattern on the Tensile and Flexural Mechanical Properties of FDM 3D Printed Products. Exp. Mech. 2019, 59, 883–897. [Google Scholar] [CrossRef]

- Tymrak, B.M.; Kreiger, M.; Pearce, J.M. Mechanical Properties of Components Fabricated with Open-Source 3-D Printers under Realistic Environmental Conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef]

- Galeja, M.; Hejna, A.; Kosmela, P.; Kulawik, A. Static and Dynamic Mechanical Properties of 3D Printed ABS as a Function of Raster Angle. Materials 2020, 13, 297. [Google Scholar] [CrossRef] [PubMed]

- Yao, T.; Deng, Z.; Zhang, K.; Li, S. A Method to Predict the Ultimate Tensile Strength of 3D Printing Polylactic Acid (PLA) Materials with Different Printing Orientations. Compos. Part B Eng. 2019, 163, 393–402. [Google Scholar] [CrossRef]

- Decuir, K.F.; Phelan, B.C. Hollins Mechanical Strength of 3-D Printed Filaments. In Proceedings of the 2016 32nd Southern Biomedical Engineering Conference (SBEC), Shreveport, LA, USA, 11 March 2016; pp. 47–48. [Google Scholar]

- Doshi, M.; Mahale, A.; Kumar Singh, S.; Deshmukh, S. Printing Parameters and Materials Affecting Mechanical Properties of FDM-3D Printed Parts: Perspective and Prospects. Mater. Today: Proc. 2022, 50, 2269–2275. [Google Scholar] [CrossRef]

- Yan, M.; Ying, H.G.; Ma, T.Y. Improved Microhardness and Wear Resistance of the As-Deposited Electroless Ni–P Coating. Surf. Coat. Technol. 2008, 202, 5909–5913. [Google Scholar] [CrossRef]

- Dayan, C.; Kiseri, B.; Gencel, B.; Kurt, H.; Tuncer, N. Wear Resistance and Microhardness of Various Interim Fixed Prosthesis Materials. J. Oral Sci. 2019, 61, 447–453. [Google Scholar] [CrossRef]

- Li, Y.; Shi, Y. Microhardness, Wear Resistance, and Corrosion Resistance of AlxCrFeCoNiCu High-Entropy Alloy Coatings on Aluminum by Laser Cladding. Opt. Laser Technol. 2021, 134, 106632. [Google Scholar] [CrossRef]

| DMA | |

| Test | Three-point bending |

| Temperature Range | 30–200 °C |

| Temperature Rate | 5 °C/min |

| Oscillation Magnitude | 30 μm |

| Frequency | 1 Hz |

| Preload | 0.1 N |

| Standard | ASTM D4065—12 |

| Device | DHR 20 of TA Instruments (TA Instruments, New Castle, DE, USA) |

| Tensile | |

| Sample | Type V with a thickness of 3.2 mm |

| Strain rate | 10 mm/min |

| Standard | ASTM D638—02a |

| Device | Imada MX2 (Northbrook, IL, USA) |

| Flexural | |

| Test Type | Three-point bending |

| Span length | 52 mm |

| Strain rate | 10 mm/min |

| Standard | ASTM D790 |

| Device | Imada MX2 (Northbrook, IL, USA) |

| Impact | |

| Test Type | Charpy |

| Samples | Notched |

| Release height | 367 mm |

| Standard | ASTM D6110 |

| Device | Terco MT 220 (Kungens Kurva, Sweden) |

| Microhardness | |

| Method | Vickers |

| Applied load | 200 gF |

| Indentations’ duration | 10 s |

| Standard | ASTM E384—17 |

| Device | 300 Innova Test (Maastricht, The Netherlands) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vidakis, N.; Petousis, M.; Mangelis, P.; Maravelakis, E.; Mountakis, N.; Papadakis, V.; Neonaki, M.; Thomadaki, G. Thermomechanical Response of Polycarbonate/Aluminum Nitride Nanocomposites in Material Extrusion Additive Manufacturing. Materials 2022, 15, 8806. https://doi.org/10.3390/ma15248806

Vidakis N, Petousis M, Mangelis P, Maravelakis E, Mountakis N, Papadakis V, Neonaki M, Thomadaki G. Thermomechanical Response of Polycarbonate/Aluminum Nitride Nanocomposites in Material Extrusion Additive Manufacturing. Materials. 2022; 15(24):8806. https://doi.org/10.3390/ma15248806

Chicago/Turabian StyleVidakis, Nectarios, Markos Petousis, Panagiotis Mangelis, Emmanuel Maravelakis, Nikolaos Mountakis, Vassilis Papadakis, Maria Neonaki, and Georgia Thomadaki. 2022. "Thermomechanical Response of Polycarbonate/Aluminum Nitride Nanocomposites in Material Extrusion Additive Manufacturing" Materials 15, no. 24: 8806. https://doi.org/10.3390/ma15248806

APA StyleVidakis, N., Petousis, M., Mangelis, P., Maravelakis, E., Mountakis, N., Papadakis, V., Neonaki, M., & Thomadaki, G. (2022). Thermomechanical Response of Polycarbonate/Aluminum Nitride Nanocomposites in Material Extrusion Additive Manufacturing. Materials, 15(24), 8806. https://doi.org/10.3390/ma15248806