Effect of Winter Road Maintenance on the Asphalt Road Surface—Experience in Slovakia and the Czech Republic

Abstract

:1. Introduction

2. Materials and Methods

2.1. Legislation and De-Icing Operations

2.2. Experimental Methods

2.2.1. Bituminous Binders

2.2.2. Asphalt Mixtures

2.2.3. Saline Solution

3. Results

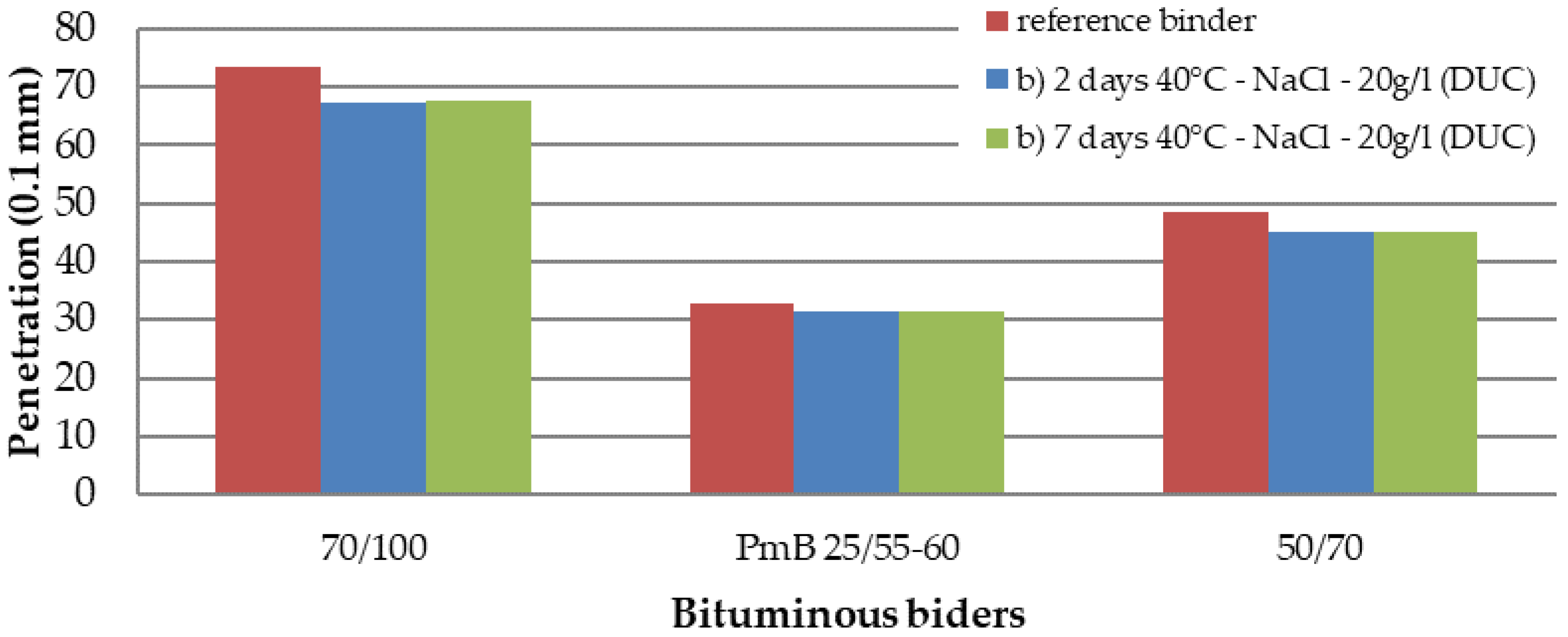

3.1. Asphalt Binder Properties

3.2. Strength and Deformation Characteristics of Asphalt Mixtures

3.3. Application of Results—Pavement Assessment

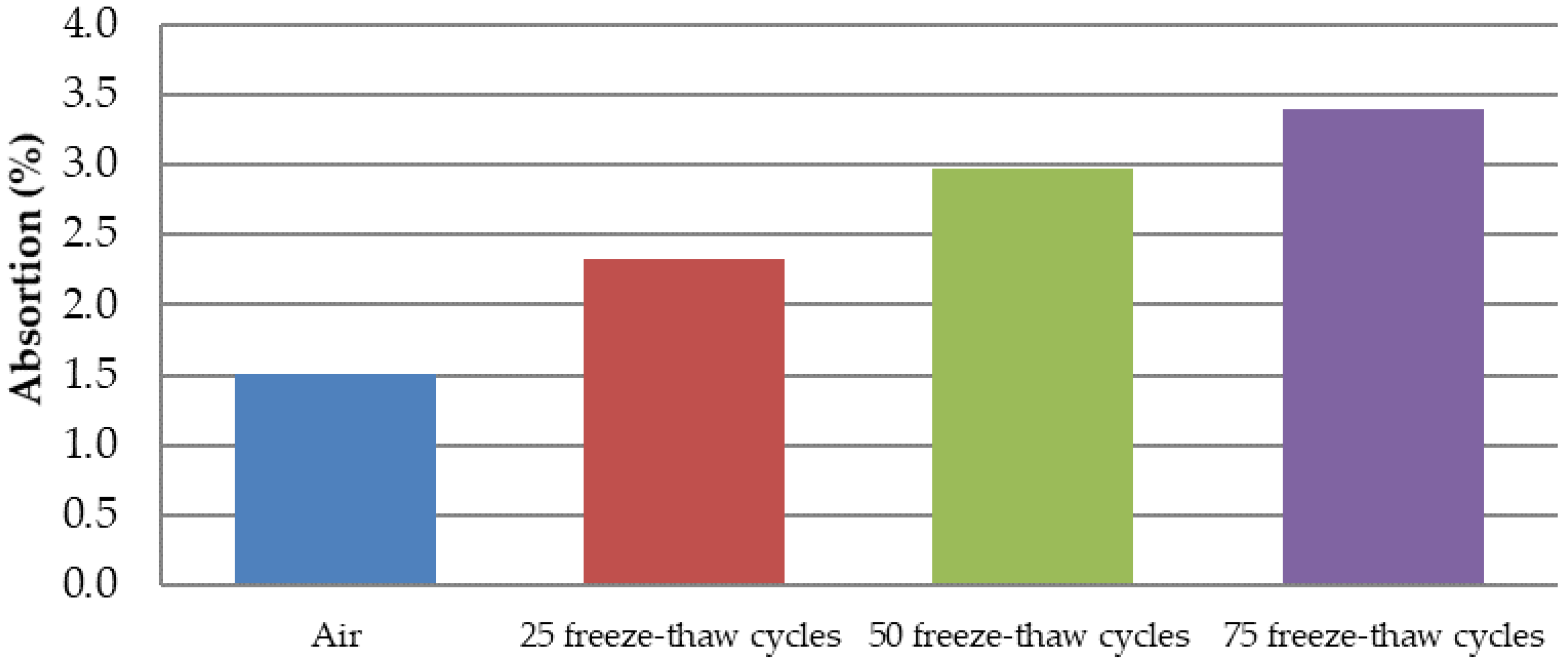

- The length of the assessed period was eight years, and it corresponds to the average durability of the wearing course, which is stressed by 75 freeze–thaw cycles;

- The use of chemical de-icing salt causes a decrease in the stiffness modulus of the wearing course, and the service life of road structures is shortened;

- The service life of the road structure 1 is shorter by 5% for the asphalt-bonded critical layer during the eight-year design period, and by 11% for the subsoil; with a traffic intensity of 10,000 design trucks in 24 h, this is a reduction in the number of design trucks crossings for the assessed period of 8 years in the number of 1,460,000 HGVs for asphalt layers and 3,212,000 for subsoil;

- The service life of the road structure 2 is shorter by 7% for the asphalt-bonded critical layer during the eight-year design period, and by 12% for the subsoil; with a traffic intensity of 440 design trucks in 24 h, this is a reduction in the number of design trucks crossings for the assessed period of 8 years in the number of 89,936 design trucks for asphalt layers and 154,176 for subsoil.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dašek, O.; Stoklásek, S.; Coufalík, P.; Hýzl, P.; Varaus, M. Thermooxidative properties of bituminous binders in relation to their inner chemical compatibility determined by single point precipitation titration. Road Mater. Pavement Des. 2017, 2017 (Suppl. 2), 118–130. [Google Scholar] [CrossRef]

- The Global Risk Report 2021. Available online: https://www.weforum.org/reports/the-global-risks-report-2021 (accessed on 19 January 2021).

- Hodáková, D. Hodnotenie Spoľahlivosti Letiskových Vozoviek. Ph.D. Thesis, Faculty of Civil Engineering, Slovak University of Technology in Bratislava, Bratislava, Slovakia, 2019; p. 132. (In Slovak). [Google Scholar]

- Climatological Information. Available online: https://www.shmu.sk/sk/?page=1&id=klimat_operativneudaje1 (accessed on 1 January 2022).

- Forging a Climate-Resilient Europe—The New EU Strategy on Adaptation to Climate Change. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:52021DC0082&from=EN (accessed on 24 February 2021).

- Climate Change Adaptation Strategy of the Slovak Republic. Available online: https://www.minzp.sk/files/odbor-politiky-zmeny-klimy/strategia-adaptacie-sr-zmenu-klimy-aktualizacia.pdf (accessed on 1 October 2018).

- Adaptation Strategy of the Slovak Republic on Adverse Impacts of Climate Change. Available online: https://climate-adapt.eea.europa.eu/repository/11273729.pdf (accessed on 1 December 2014).

- Strategy on Adaptation to Climate Change in the Czech Republic. Available online: https://www.preventionweb.net/files/58333_oeokadaptationstrategy20171003.pdf (accessed on 26 October 2015).

- Chen, J.; Dan, H.; Ding, Y.; Gao, Y.; Guo, M.; Guo, S.; Han, B.; Hong, B.; Hou, Y.; Hu, C.; et al. New innovations in pavement materials and engineering: A review on pavement engineering research 2021. J. Traffic Transp. Eng. 2021, 8, 815–999. [Google Scholar] [CrossRef]

- Cheng, Y.; Yu, D.; Tan, G.; Zhu, C. Low-Temperature Performance and Damage Constitutive Model of Eco-Friendly Basalt Fiber–Diatomite-Modified Asphalt Mixture under Freeze–Thaw Cycles. Materials 2018, 11, 2148. [Google Scholar] [CrossRef] [PubMed]

- Huang, T.; Qi, S.; Yang, M.; Lv, S.; Liu, H.; Zheng, J. Strength Criterion of Asphalt Mixtures in Three-Dimensional Stress States under Freeze-Thaw Conditions. Appl. Sci. 2018, 8, 1302. [Google Scholar] [CrossRef]

- Sakib, N.; Bhasin, A.; Islam, K.; Khan, K.; Khan, M.I. A review of the evolution of technologies to use sulphur as a pavement construction material. Int. J. Pavement Eng. 2019, 22, 392–403. [Google Scholar] [CrossRef]

- Guo, Z.; Wang, L.; Feng, L.; Guo, Y. Research on fatigue performance of composite crumb rubber modified asphalt mixture under freeze thaw cycles. Constr. Build. Mater. 2022, 323, 126603. [Google Scholar] [CrossRef]

- Lachance-Tremblay, É.; Perraton, D.; Vaillancourt, M.; Di Benedetto, H. Effect of hydrated lime on linear viscoelastic properties of asphalt mixtures with glass aggregates subjected to freeze-thaw cycles. Constr. Build. Mater. 2018, 184, 58–67. [Google Scholar] [CrossRef]

- Remišová, E.; Holý, M. Changes of Properties of Bitumen Binders by Additives Application. In Book Series: IOP Conference Series-Materials Science and Engineering, Proceedings of the WMCAUS 2017, World Multidisciplinary Civil Engineering-Architecture-Urban Planning Symposium, Prague, Czech Republic, 12–16 June 2017; IOP: London, UK, 2017; Volume 245. [Google Scholar]

- Kavussi, A.; Azarnia, M.; Ayar, P.; Pedram, M. The fatigue behavior of polymeric sulfur-modified asphalt mixtures subjected to freeze-thaw conditioning. J. Thermoplast. Compos. Mater. 2019, 35, 467–486. [Google Scholar] [CrossRef]

- Büchner, J.; Wistuba, M.P.; Dasek, O.; Staschkiewicz, M.; Soenen, H.; Zofka, A.; Remmler, T. Interlaboratory study on low temperature asphalt binder testing using Dynamic Shear Rheometer with 4 mm diameter parallel plate geometry. Road Mater. Pavement Des. 2020, 23, 890–906. [Google Scholar] [CrossRef]

- Alisov, A.; Riccardi, C.; Schrader, J.; Cannone Falchetto, A.; Wistuba, M.P. A novel method to characterize asphalt binder at high temperature. Road Mater. Pavement Des. 2020, 21, 143–155. [Google Scholar] [CrossRef]

- Bäckström, M.; Karlsson, S.; Bäckman, L.; Folkeson, L.; Lind, B. Mobilisation of heavy metals by deicing salts in a roadside environment. Water Res. 2004, 38, 720–732. [Google Scholar] [CrossRef] [PubMed]

- Norrström, A.C. Metal mobility by de-icing salt from an infiltration trench for highway runoff. Appl. Geochem. 2005, 20, 1907–1919. [Google Scholar] [CrossRef]

- Rivett, M.O.; Cuthbert, M.O.; Gamble, R.; Connon, L.E.; Pearson, A.; Shepley, M.G.; Davis, J. Highway deicing salt dynamic runoff to surface water and subsequent infiltration to groundwater during severe UK winters. Sci. Total Environ. 2016, 565, 324–338. [Google Scholar] [CrossRef] [PubMed]

- Szklarek, S.; Górecka, A.; Wojtal-Frankiewicz, A. The effects of road salt on freshwater ecosystems and solutions for mitigating chloride pollution—A review. Sci. Total Environ. 2022, 805, 150289. [Google Scholar] [CrossRef] [PubMed]

- Vega-Zamanillo, Á.; Juli-Gándara, L.; Calzada-Pérez, M.; Teijón-López-Zuazo, E. Impact of Temperature Changes and Freeze—Thaw Cycles on the Behaviour of Asphalt Concrete Submerged in Water with Sodium Chloride. Appl. Sci. 2020, 10, 1241. [Google Scholar] [CrossRef]

- Ondrejka, R. (VUD-Transport Research Institute, Zilina, Slovakia). Personal Communication, 2022. [Google Scholar]

- Ikiz, N.; Galip, E. Computerized decision tree for anti-icing/pretreatment applications as a result of laboratory and field testings. Cold Reg. Sci. Technol. 2016, 126, 90–108. [Google Scholar] [CrossRef]

- Kováč, P. Protinámrazová Úprava Asfaltových Vozoviek, 1st ed.; EDIS—University of Žilina: Žilina, Slovakia, 2003; p. 101. (In Slovak) [Google Scholar]

- Technical Conditions TP 039 Používanie Posypových Materiálov na Zimnú Údržbu Pozemných Komunikácií. Available online: https://www.ssc.sk/files/documents/technicke-predpisy/tp/tp-039-2022.pdf (accessed on 7 January 2022). (In Slovak).

- Slovak Road Administration. Maintenance and Repair. Available online: https://www.cdb.sk/files/documents/cestna-databanka/vystupy-cdb/2022/kniha_celkovy-prehlad-stavu-vozoviek_01-01-2022.pdf (accessed on 7 April 2022). (In Slovak).

- ČSN 73 6161; Stanovení Přilnavosti Asfaltových Pojiv ke Kamenivu. Czech Office for Standards, Metrology and Testing: Prague, Czech Republic, 2013. (In Czech)

- Technical Conditions TP 170 Navrhování Vozovek Pozemních Komunikací. Available online: http://www.pjpk.cz/data/USR_001_2_8_TP/TP_170.pdf (accessed on 1 December 2004). (In Czech).

- Valentin, J.; (Czech Technical University in Prague, Faculty of civil engineering, Prague, Czech Republic). Personal communication, 2019.

- Kajaba, P.; (Slovak Hydrometeorological Institute, Bratislava, Slovakia). Personal communication, 2022.

- Results of VaV SP/1a6/108/07 Project. Available online: http://portal.chmi.cz/historicka-data/pocasi/zmena-klimatu/projekt-vav-2007-2011# (accessed on 1 January 2012).

- EN 1426; Bitumen and Bituminous Binders. Determination of Needle Penetration. European Committee for Standardization: Brussels, Belgium, 1999.

- EN 13398; Bitumen and Bituminous Binders. Determination of the Elastic Recovery of Modified Bitumen. European Committee for Standardization: Brussels, Belgium, 2003.

- EN 1427; Bitumen and Bituminous Binders. Determination of the Softening Point. Ring and Ball Method. European Committee for Standardization: Brussels, Belgium, 2015.

- Safety Data Sheet According to Article 31 and Annex II of Regulation (EC) No. 1907/2006—REACH and No. 1272/2008; Date of Issue 6 February 2018, Product Name: Sodium Chloride, CAS Number: 7647-14-5.

- EN 12697-26; Bituminous Mixtures. Test Methods. Part 26: Stiffness. European Committee for Standardization: Brussels, Belgium, 2019.

- EN 12697-34; Bituminous Mixtures. Test Methods. Part 34: Marshall Test. European Committee for Standardization: Brussels, Belgium, 2022.

- Zichner, G. Über die Wirkung von Tausalzen und Spikes-Reifen auf bituminöse Straßendecken. Bitumen 1967, 6, 160–165. (In German) [Google Scholar]

| Conditions | Until June 2022 | From July 2022 | ||||

|---|---|---|---|---|---|---|

| Dosage (g/m2) | NaCl | CaCl2 | Dosage (g/m2) | NaCl | CaCl2 | |

| Icing up to 2 mm | 20 | to −5 °C | to −15 °C | 20 | to −7 °C | to −15 °C |

| Snow layer up to 3 mm | 20 | 20–40 | ||||

| Icing over 2 mm | 40 | 40 | ||||

| Extraordinary conditions | 40–60 | 40–60 | ||||

| Conditions | Dosage (g/m2) | NaCl | CaCl2 |

|---|---|---|---|

| Icing up to 2 mm | 20 | to −5 °C | to −15 °C |

| Snow layer up to 3 mm | 20 | ||

| cing over 2 mm | 40 | ||

| Extraordinary conditions | 40–60 |

| Parameter | Slovakia | Czech Republic |

|---|---|---|

| The concentration of solution in chemical spreading (%) | 20–25 | 18–21 |

| Content of active solvent (%) | 98 | 96 |

| Content of dust particles (%) | max. 15 | max. 5 |

| Water content (%) | max. 2 | max. 2 |

| The proportion of anti-caking agent (g/kg) | 10 to 200 | - |

| Physical and Chemical Properties | Value |

|---|---|

| NaCl | ≥97% |

| pH value at 20 °C (solution 100 g/1 L H2O) | 7.5–8.5 |

| Density | 21,615 kg/dm3 |

| Solubility (at 20 °C) in fats | 360 g/L |

| Solubility (at 20 °C) in water | not soluble |

| Melting point (°C) | 801 °C |

| Boiling point (°C) | 1460 °C |

| Flash point (°C) | - |

| Pavement Structure No. 1 | Pavement Structure No. 2 | ||||

|---|---|---|---|---|---|

| DO-N-1-PIII | D1-N-2-PIII | ||||

| Traffic load class | S | Traffic load class | III | ||

| Pavement structure layer | wearing course | ACO 11 S | 40 mm | ACO 11 + | 40 mm |

| binder course | ACL 22 S | 80 mm | ACL 16 + | 60 mm | |

| base course | ACP 22 S | 150 mm | ACP 16 + | 50 mm | |

| Unbound gravel | 200 mm | Unbound gravel | 150 mm | ||

| subbase course | Unbound gravel | 250 mm | Unbound gravel | 150 mm | |

| Total | 620 mm | Total | 450 mm | ||

| Number of Freeze–thaw Cycles | 0 | 25 | 50 | 75 | |

|---|---|---|---|---|---|

| Design Period (Years) | 2 | 4 | 6 | 8 | |

| Reference pavement structure | Relative failure of the asphalt-bonded critical layer | 0.015 | 0.030 | 0.045 | 0.060 |

| Relative failure of the subsoil | 0.016 | 0.032 | 0.048 | 0.064 | |

| Pavement structure No. 1 | Relative failure of the asphalt-bonded critical layer | 0.015 | 0.030 | 0.046 | 0.063 |

| Relative failure of the subsoil | 0.016 | 0.033 | 0.052 | 0.072 | |

| Number of Freeze–thaw Cycles | 0 | 25 | 50 | 75 | |

|---|---|---|---|---|---|

| Design Period (Years) | 2 | 4 | 6 | 8 | |

| Reference pavement structure | Relative failure of the asphalt-bonded critical layer | 0.026 | 0.052 | 0.078 | 0.104 |

| Relative failure of the subsoil | 0.034 | 0.064 | 0.096 | 0.136 | |

| Pavement structure No. 2 | Relative failure of the asphalt-bonded critical layer | 0.026 | 0.053 | 0.082 | 0.112 |

| Relative failure of the subsoil | 0.034 | 0.070 | 0.111 | 0.155 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Capayova, S.; Cihlarova, D.; Mondschein, P. Effect of Winter Road Maintenance on the Asphalt Road Surface—Experience in Slovakia and the Czech Republic. Materials 2022, 15, 5618. https://doi.org/10.3390/ma15165618

Capayova S, Cihlarova D, Mondschein P. Effect of Winter Road Maintenance on the Asphalt Road Surface—Experience in Slovakia and the Czech Republic. Materials. 2022; 15(16):5618. https://doi.org/10.3390/ma15165618

Chicago/Turabian StyleCapayova, Silvia, Denisa Cihlarova, and Petr Mondschein. 2022. "Effect of Winter Road Maintenance on the Asphalt Road Surface—Experience in Slovakia and the Czech Republic" Materials 15, no. 16: 5618. https://doi.org/10.3390/ma15165618

APA StyleCapayova, S., Cihlarova, D., & Mondschein, P. (2022). Effect of Winter Road Maintenance on the Asphalt Road Surface—Experience in Slovakia and the Czech Republic. Materials, 15(16), 5618. https://doi.org/10.3390/ma15165618