Phase Studies of Additively Manufactured Near Beta Titanium Alloy-Ti55511

Abstract

1. Introduction

2. Materials and Methods

2.1. Powders

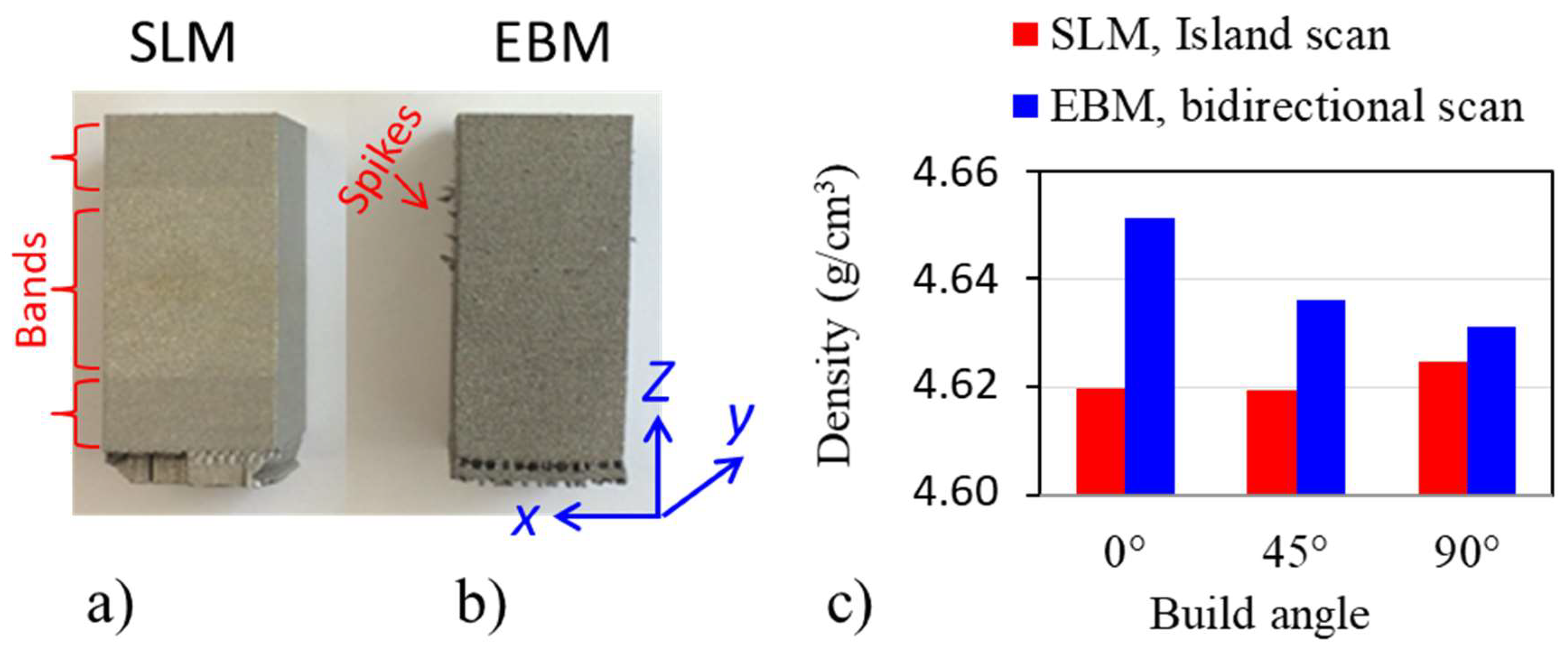

2.2. Sample Build Processes

2.3. Characterization Methods

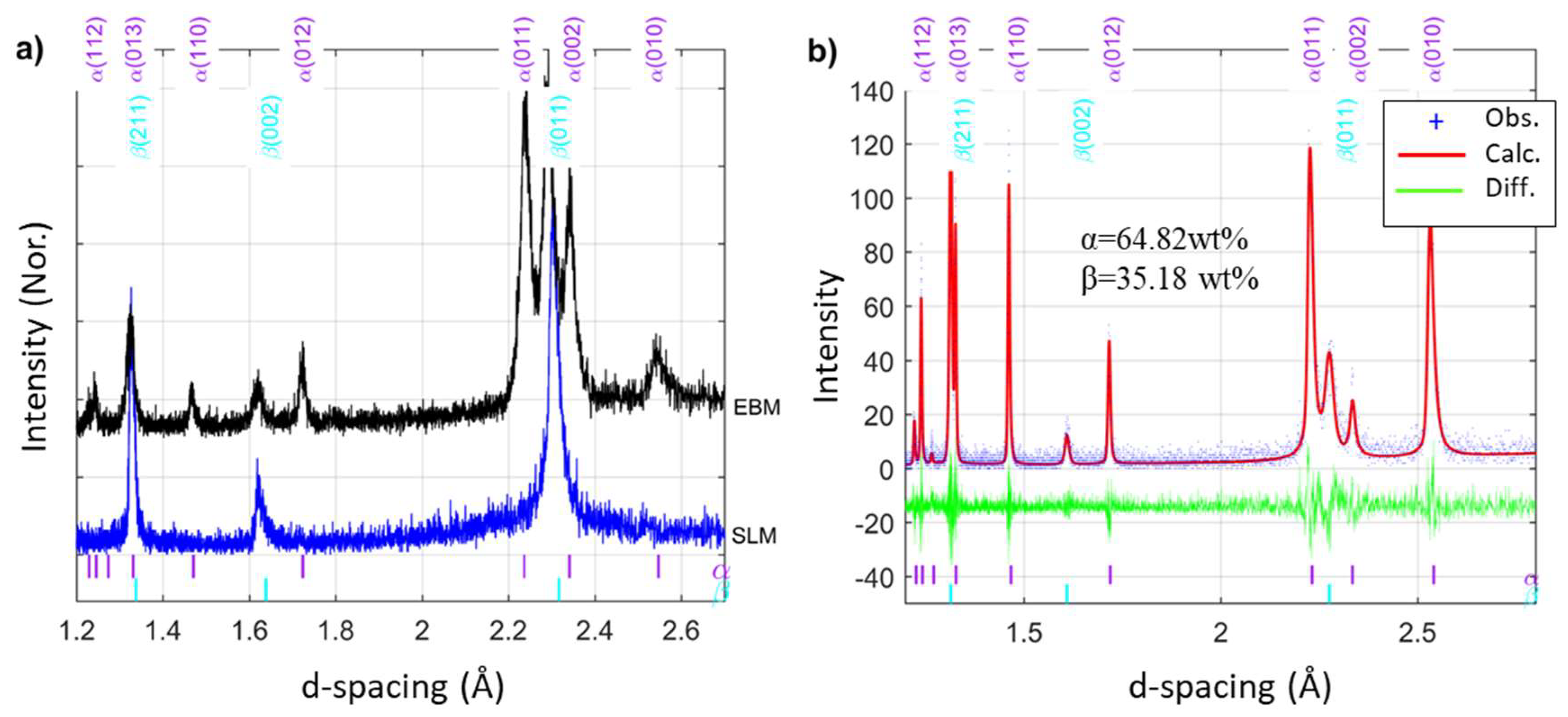

3. Results and Discussions

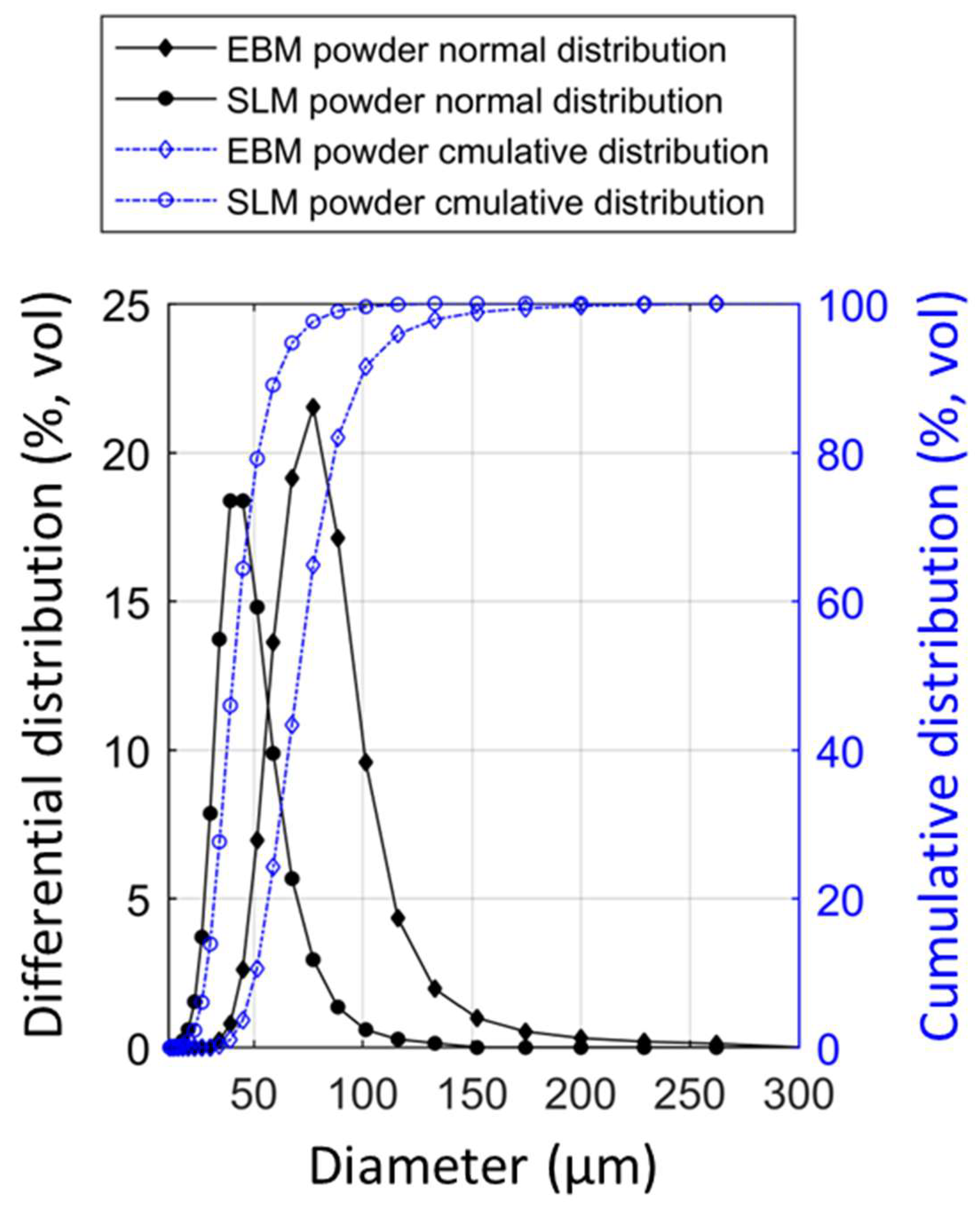

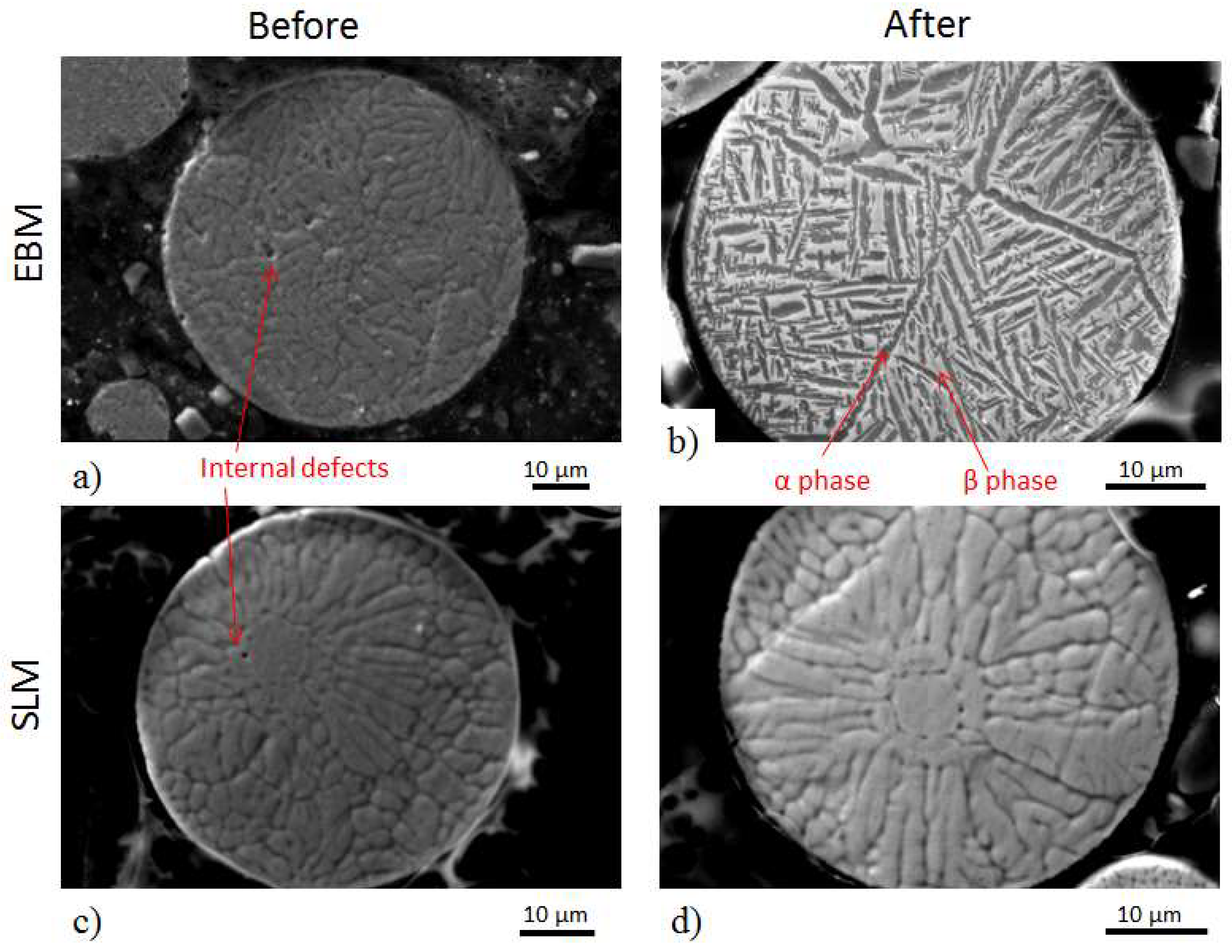

3.1. Powder Characterization

3.2. Surface Roughness

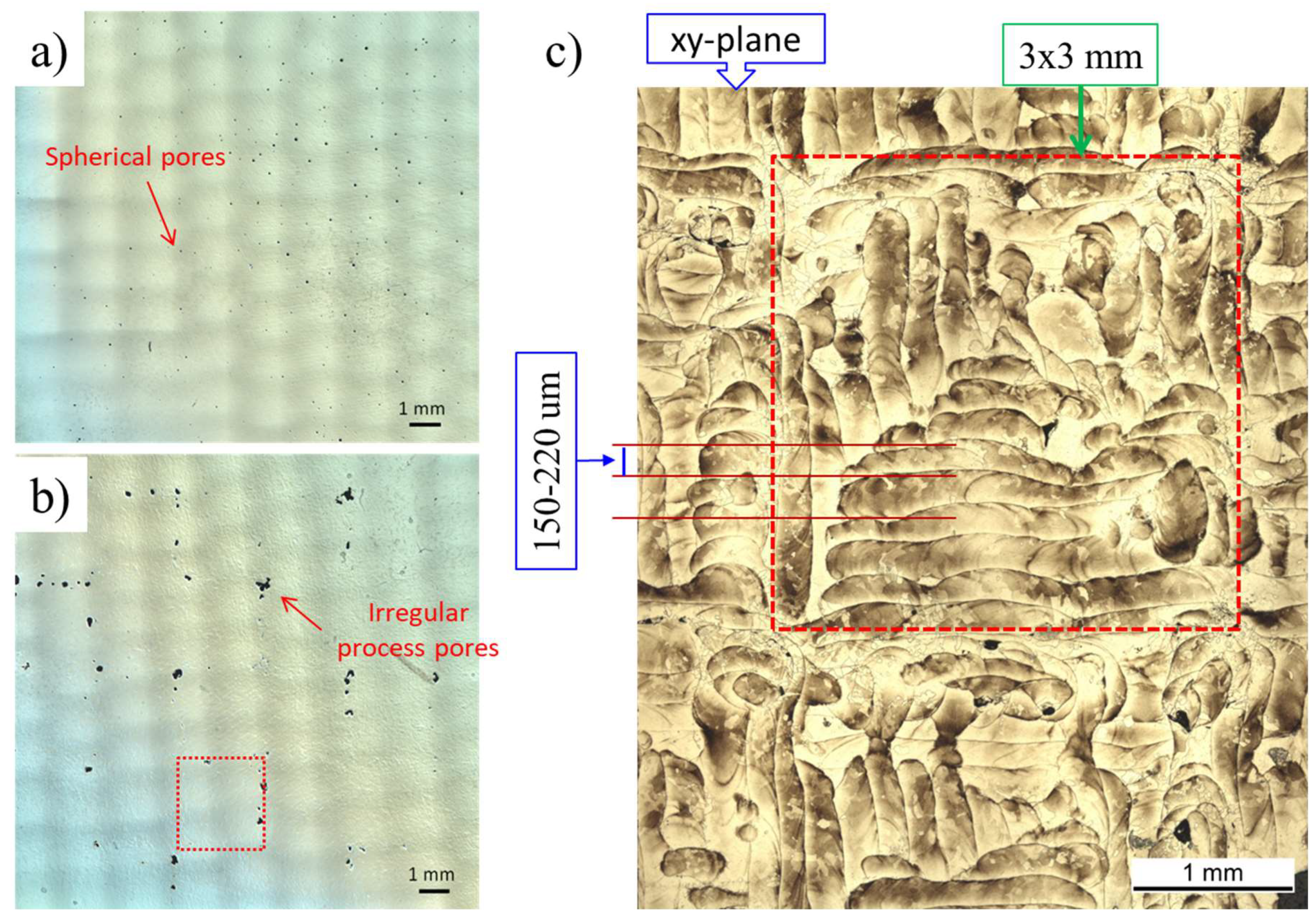

3.3. Porosity

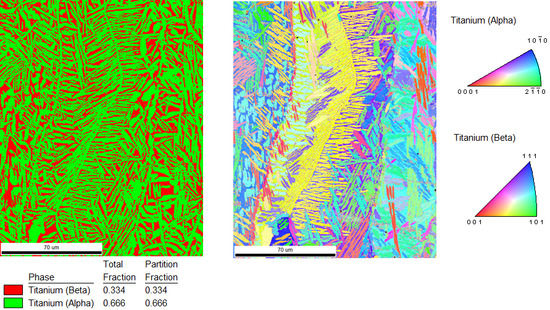

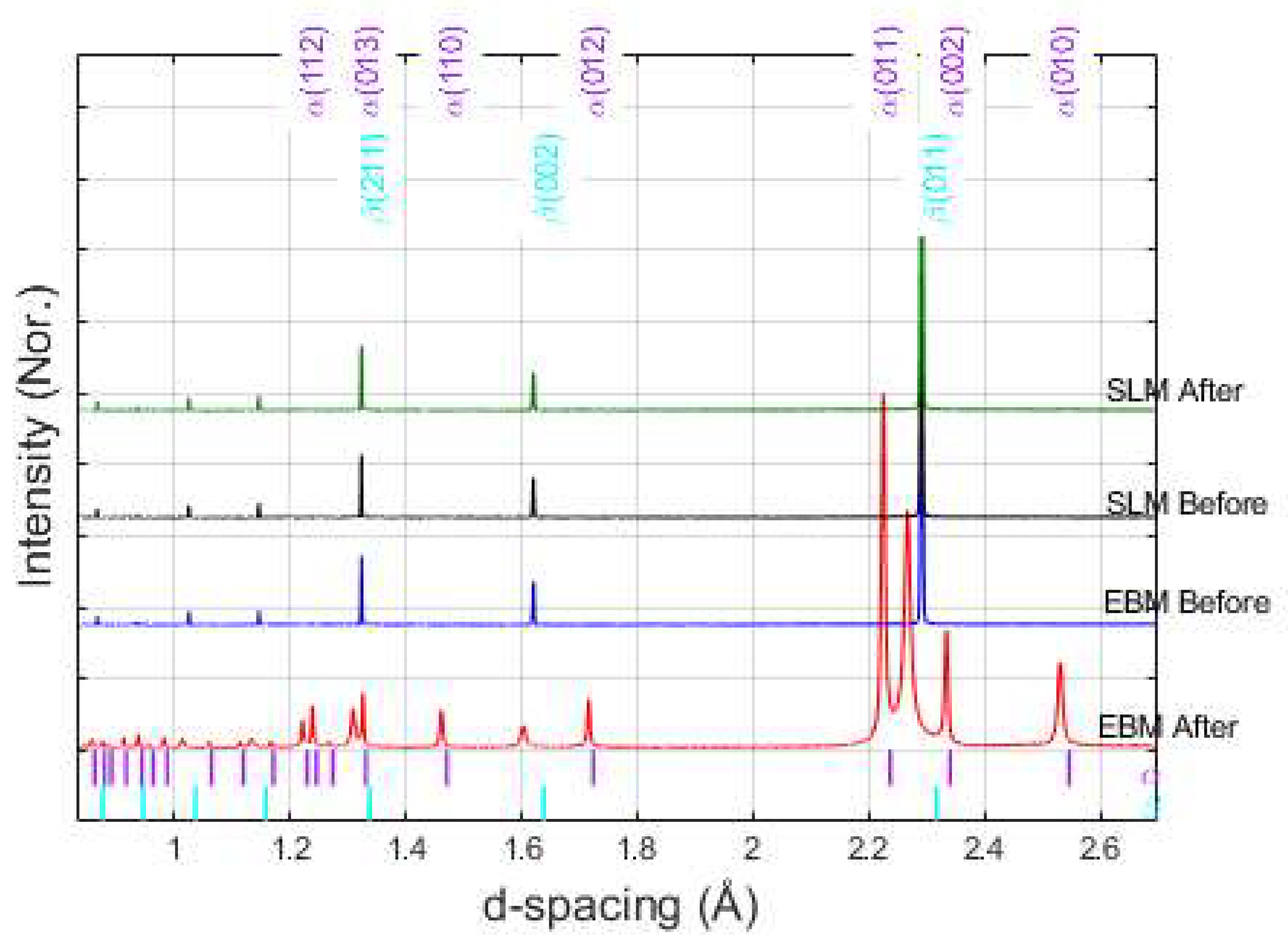

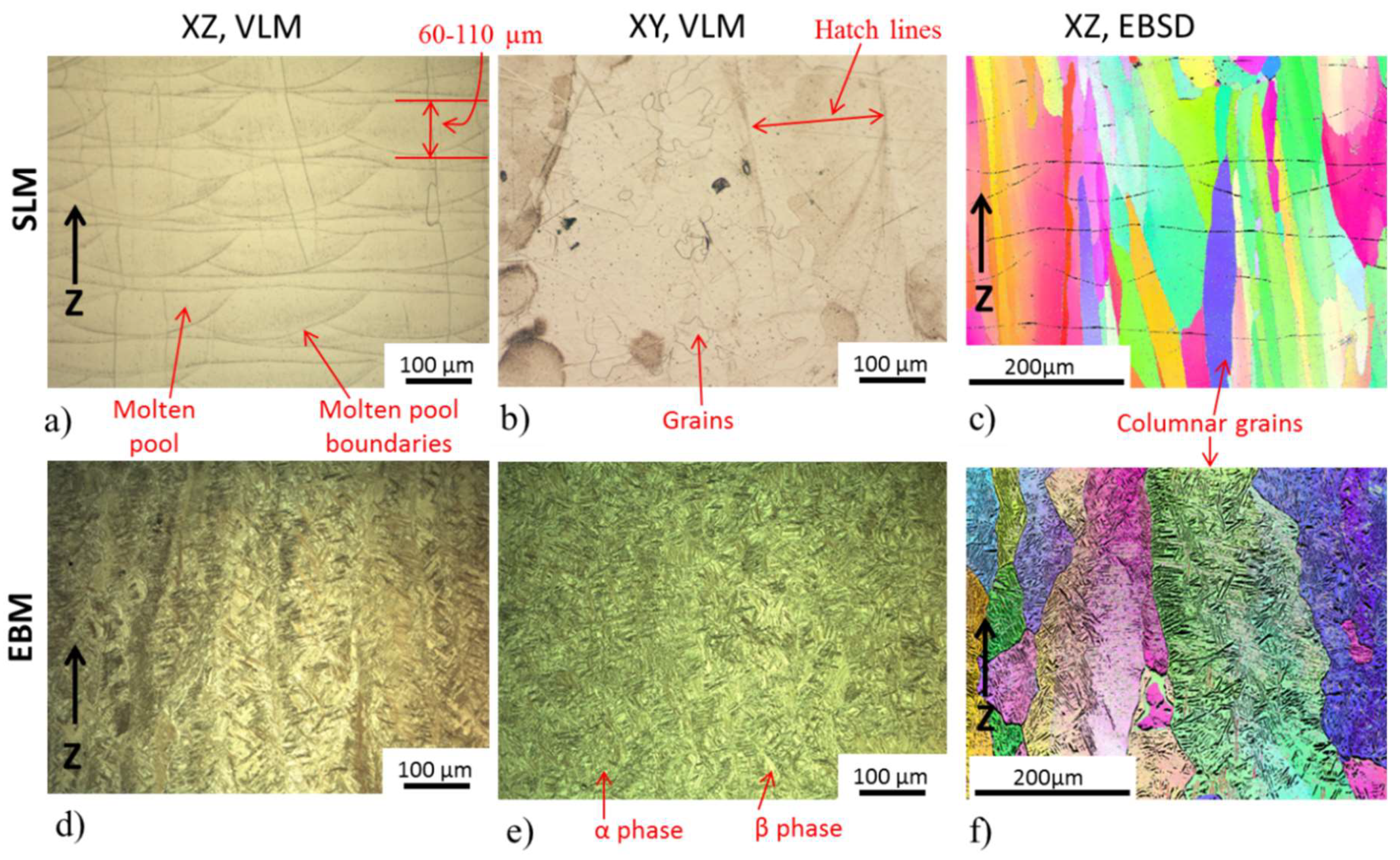

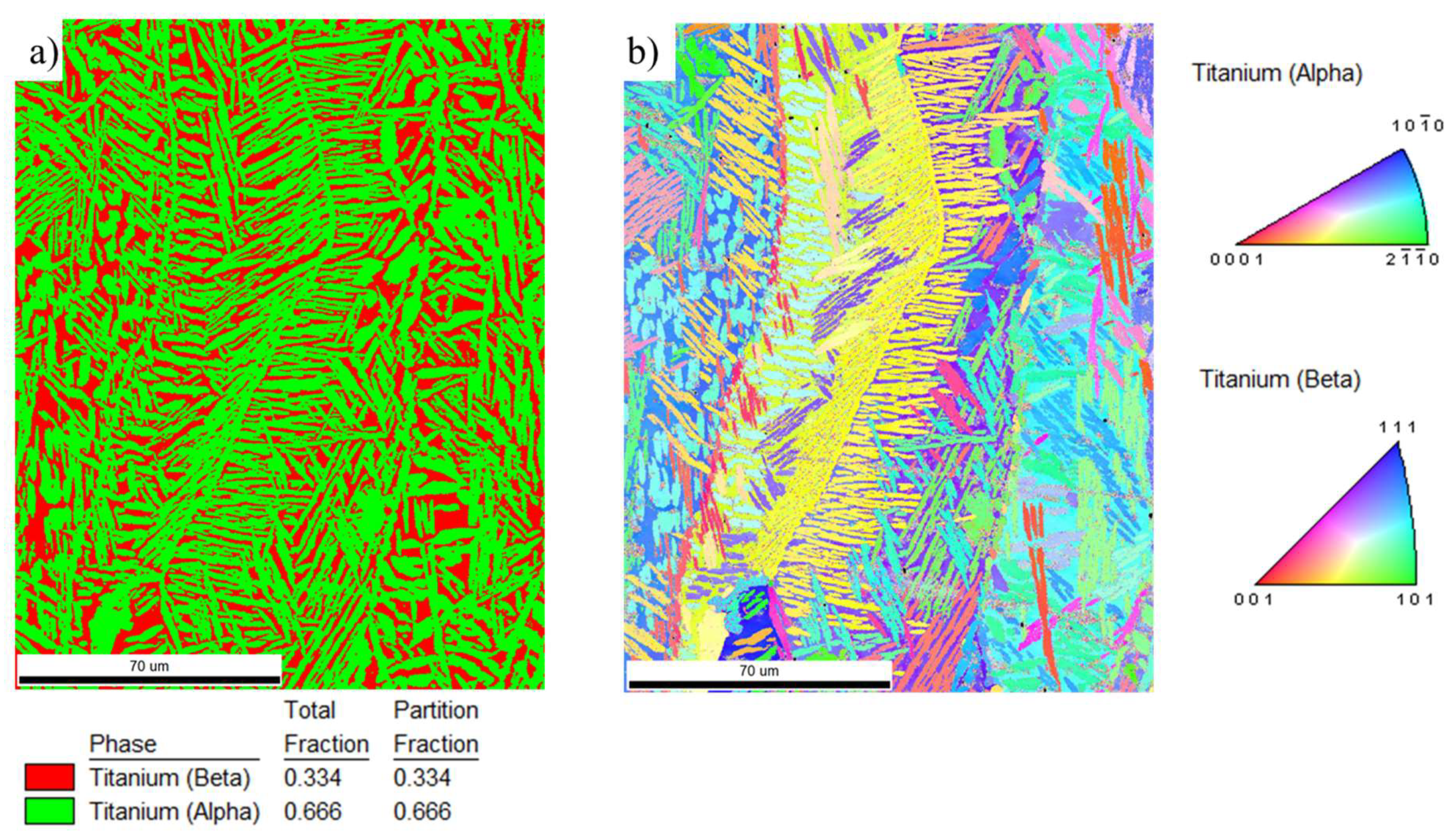

3.4. Microstructures of the Build Material

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hocine, S.; Swygenhoven, H.V.; Petegem, S.V.; Chang, C.S.T.; Maimaitiyili, T.; Tinti, G.; Sanchez, D.F.; Grolimund, D.; Casati, N. Operando X-ray diffraction during laser 3D printing. Mater. Today 2019. [Google Scholar] [CrossRef]

- Maimaitiyili, T.; Woracek, R.; Neikter, M.; Boin, M.; Wimpory, R.C.; Pederson, R.; Strobl, M.; Drakopoulos, M.; Schafer, N.; Bjerken, C. Residual Lattice Strain and Phase Distribution in Ti-6Al-4V Produced by Electron Beam Melting. Materials 2019, 12, 667. [Google Scholar] [CrossRef] [PubMed]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Murr, L.E.; Esquivel, E.V.; Quinones, S.A.; Gaytan, S.M.; Lopez, M.I.; Martinez, E.Y.; Medina, F.; Hernandez, D.H.; Martinez, E.; Martinez, J.L.; et al. Microstructures and mechanical properties of electron beam-Rapid manufactured Ti–6Al–4V biomedical prototypes compared to wrought Ti–6Al–4V. Mater. Charact. 2009, 60, 96–105. [Google Scholar] [CrossRef]

- Harun, W.S.W.; Manam, N.S.; Kamariah, M.S.I.N.; Sharif, S.; Zulkifly, A.H.; Ahmad, I.; Miura, H. A review of powdered additive manufacturing techniques for Ti-6al-4v biomedical applications. Powder Technol. 2018, 331, 74–97. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Al-Bermani, S.S.; Blackmore, M.L.; Zhang, W.; Todd, I. The Origin of Microstructural Diversity, Texture, and Mechanical Properties in Electron Beam Melted Ti-6Al-4V. Metall. Mater. Trans. A 2010, 41, 3422–3434. [Google Scholar] [CrossRef]

- Kenel, C.; Grolimund, D.; Li, X.; Panepucci, E.; Samson, V.A.; Sanchez, D.F.; Marone, F.; Leinenbach, C. In situ investigation of phase transformations in Ti-6Al-4V under additive manufacturing conditions combining laser melting and high-Speed micro-X-Ray diffraction. Sci. Rep. 2017, 7, 16358. [Google Scholar] [CrossRef]

- Neikter, M.; Woracek, R.; Maimaitiyili, T.; Scheffzük, C.; Strobl, M.; Antti, M.-L.; Åkerfeldt, P.; Pederson, R.; Bjerkén, C. Alpha texture variations in additive manufactured Ti-6Al-4V investigated with neutron diffraction. Addit. Manuf. 2018, 23, 225–234. [Google Scholar] [CrossRef]

- Safdar, A.; He, H.Z.; Wei, L.; Snis, A.; Chavez, D.P. Effect of process parameters settings and thickness on surface roughness of EBM produced Ti-6Al-4V. Rapid Prototyp. J. 2012, 18, 401–408. [Google Scholar] [CrossRef]

- Phutela, C.; Aboulkhair, T.N.; Tuck, J.C.; Ashcroft, I. The Effects of Feature Sizes in Selectively Laser Melted Ti-6Al-4V Parts on the Validity of Optimised Process Parameters. Materials 2019, 13, 117. [Google Scholar] [CrossRef] [PubMed]

- Kurzynowski, T.; Madeja, M.; Dziedzic, R.; Kobiela, K. The Effect of EBM Process Parameters on Porosity and Microstructure of Ti-5Al-5Mo-5V-1Cr-1Fe Alloy. Scanning 2019, 2019, 2903920. [Google Scholar] [CrossRef] [PubMed]

- Neikter, M.; Colliander, M.; Schwerz, C.d.A.; Hansson, T.; Ãkerfeldt, P.; Pederson, R.; Antti, M.-L. Fatigue Crack Growth of Electron Beam Melted Ti-6Al-4V in High-Pressure Hydrogen. Materials 2020, 13, 1287. [Google Scholar] [CrossRef]

- Xie, Z.; Dai, Y.; Ou, X.; Ni, S.; Song, M. Effects of selective laser melting build orientations on the microstructure and tensile performance of Ti-6Al-4V alloy. Mater. Sci. Eng. A 2020, 776, 139001. [Google Scholar] [CrossRef]

- Shipley, H.; McDonnell, D.; Culleton, M.; Coull, R.; Lupoi, R.; O′Donnell, G.; Trimble, D. Optimisation of process parameters to address fundamental challenges during selective laser melting of Ti-6Al-4V: A review. Int. J. Mach. Tools Manuf. 2018, 128, 1–20. [Google Scholar] [CrossRef]

- Gerd, L.; James, C.W. Titanium, 2nd ed.; Springer: Heidelberg, Germany, 2007. [Google Scholar]

- Polmear, I.; StJohn, D.; Nie, J.; Qian, M. Light Alloys: Metallurgy of the Light Metals, Chapter 7-Titanium Alloys. In Light Alloys: Metallurgy of the Light Metals, 5th ed.; Butterworth-Heinemann: Boston, MA, USA, 2017; pp. 369–460. [Google Scholar] [CrossRef]

- Tan, X.; Kok, Y.; Toh, W.Q.; Tan, Y.J.; Descoins, M.; Mangelinck, D.; Tor, S.B.; Leong, K.F.; Chua, C.K. Revealing martensitic transformation and α/β interface evolution in electron beam melting three-Dimensional-Printed Ti-6Al-4V. Sci. Rep. 2016, 6, 26039. [Google Scholar] [CrossRef]

- Zhao, C.; Fezzaa, K.; Cunningham, R.W.; Wen, H.; De Carlo, F.; Chen, L.; Rollett, A.D.; Sun, T. Real-Time monitoring of laser powder bed fusion process using high-Speed X-Ray imaging and diffraction. Sci. Rep. 2017, 7, 3602. [Google Scholar] [CrossRef]

- Wang, K.; Bao, R.; Zhang, T.; Liu, B.; Yang, Z.; Jiang, B. Fatigue crack branching in laser melting deposited Ti55511 alloy. Int. J. Fatigue 2019, 124, 217. [Google Scholar] [CrossRef]

- Boyer, R.R.; Briggs, R.D. The use of beta titanium alloys in the aerospace industry. J. Mater. Eng. Perform. 2005, 14, 681–685. [Google Scholar] [CrossRef]

- Ahmed, M.; Savvakin, D.G.; Ivasishin, O.M.; Pereloma, E.V. The effect of cooling rates on the microstructure and mechanical properties of thermo-Mechanically processed Ti–Al–Mo–V–Cr–Fe alloys. Mater. Sci. Eng. A 2013, 576, 167–177. [Google Scholar] [CrossRef]

- Ran, C.; Chen, P.; Li, L.; Zhang, W. Dynamic shear deformation and failure of Ti-5Al-5Mo-5V-1Cr-1Fe titanium alloy. Mater. Sci. Eng. A 2017, 694, 41–47. [Google Scholar] [CrossRef]

- Levy, G.; Herres, N.; Spierings, A.B. Influence of the particle size distribution on surface quality and mechanical properties in AM steel parts. Rapid Prototyp. J. 2011, 17, 195–202. [Google Scholar] [CrossRef]

- Li, C.; Zhang, X.; Zhou, K.; Peng, C. Relationship between lamellar α evolution and flow behavior during isothermal deformation of Ti–5Al–5Mo–5V–1Cr–1Fe near β titanium alloy. Mater. Sci. Eng. A 2012, 558, 668–674. [Google Scholar] [CrossRef]

- Belsky, A.; Hellenbrandt, M.; Karen, V.L.; Luksch, P. New developments in the Inorganic Crystal Structure Database (ICSD): Accessibility in support of materials research and design. Acta Crystallogr. Sect. B 2002, 58, 364–369. [Google Scholar] [CrossRef] [PubMed]

- Santos, E.C.; Shiomi, M.; Osakada, K.; Laoui, T. Rapid manufacturing of metal components by laser forming. Int. J. Mach. Tools Manuf. 2006, 46, 1459–1468. [Google Scholar] [CrossRef]

- Algardh, J.K.; Horn, T.; West, H.; Aman, R.; Snis, A.; Engqvist, H.; Lausmaa, J.; Harrysson, O. Thickness dependency of mechanical properties for thin-Walled titanium parts manufactured by Electron Beam Melting (EBM)®. Addit. Manuf. 2016, 12 Pt A, 45–50. [Google Scholar] [CrossRef]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Nan, Y.; Ning, Y.; Liang, H.; Guo, H.; Yao, Z.; Fu, M.W. Work-Hardening effect and strain-Rate sensitivity behavior during hot deformation of Ti–5Al–5Mo–5V–1Cr–1Fe alloy. Mater. Des. 2015, 82, 84–90. [Google Scholar] [CrossRef]

- Neikter, M.; Åkerfeldt, P.; Pederson, R.; Antti, M.-L.; Sandell, V. Microstructural characterization and comparison of Ti-6Al-4V manufactured with different additive manufacturing processes. Mater. Charact. 2018, 143, 68–75. [Google Scholar] [CrossRef]

| Ti55511 | ||||||

|---|---|---|---|---|---|---|

| SLM | EBM | |||||

| Before | After | % Change | Before | After | % Change | |

| D10 (µm) | 27.96 | 30.42 | 8.80 | 50.88 | 59.74 | 17.41 |

| D50 (µm) | 40.42 | 44.82 | 10.89 | 70.41 | 85.32 | 21.18 |

| D90 (µm) | 60.32 | 68.58 | 13.68 | 99.23 | 127 | 28.02 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maimaitiyili, T.; Mosur, K.; Kurzynowski, T.; Casati, N.; Van Swygenhoven, H. Phase Studies of Additively Manufactured Near Beta Titanium Alloy-Ti55511. Materials 2020, 13, 1723. https://doi.org/10.3390/ma13071723

Maimaitiyili T, Mosur K, Kurzynowski T, Casati N, Van Swygenhoven H. Phase Studies of Additively Manufactured Near Beta Titanium Alloy-Ti55511. Materials. 2020; 13(7):1723. https://doi.org/10.3390/ma13071723

Chicago/Turabian StyleMaimaitiyili, Tuerdi, Krystian Mosur, Tomasz Kurzynowski, Nicola Casati, and Helena Van Swygenhoven. 2020. "Phase Studies of Additively Manufactured Near Beta Titanium Alloy-Ti55511" Materials 13, no. 7: 1723. https://doi.org/10.3390/ma13071723

APA StyleMaimaitiyili, T., Mosur, K., Kurzynowski, T., Casati, N., & Van Swygenhoven, H. (2020). Phase Studies of Additively Manufactured Near Beta Titanium Alloy-Ti55511. Materials, 13(7), 1723. https://doi.org/10.3390/ma13071723