Characterisation of a High-Performance Al–Zn–Mg–Cu Alloy Designed for Wire Arc Additive Manufacturing

Abstract

1. Introduction

2. Materials and Methods

2.1. Alloy Composition and Material Processing

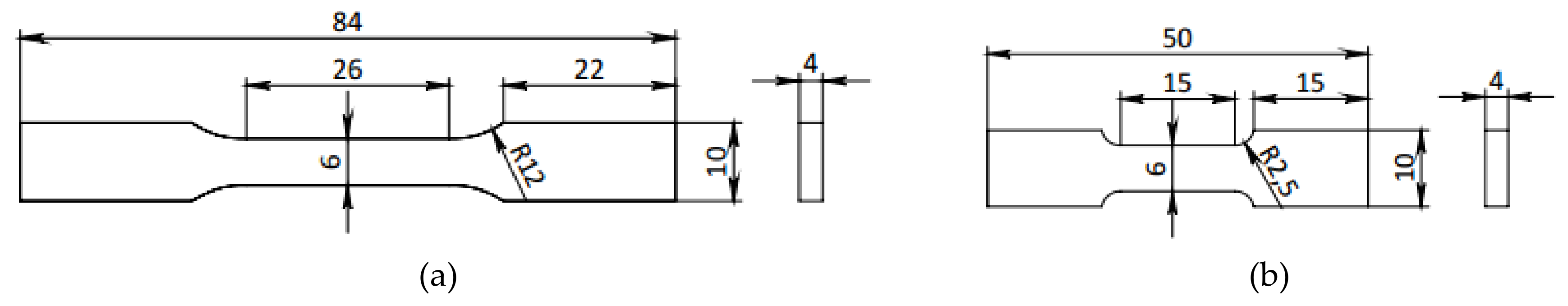

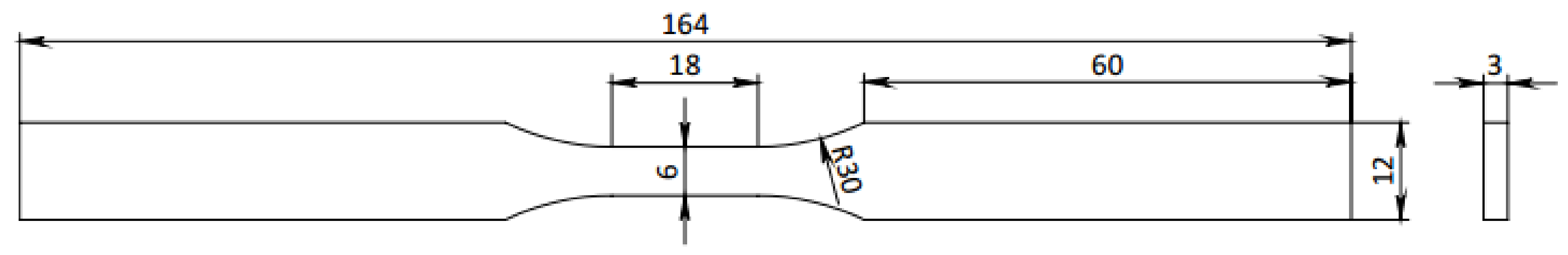

2.2. Characterisation Techniques

2.3. Simulation of the Ageing Response

3. Results and Discussion

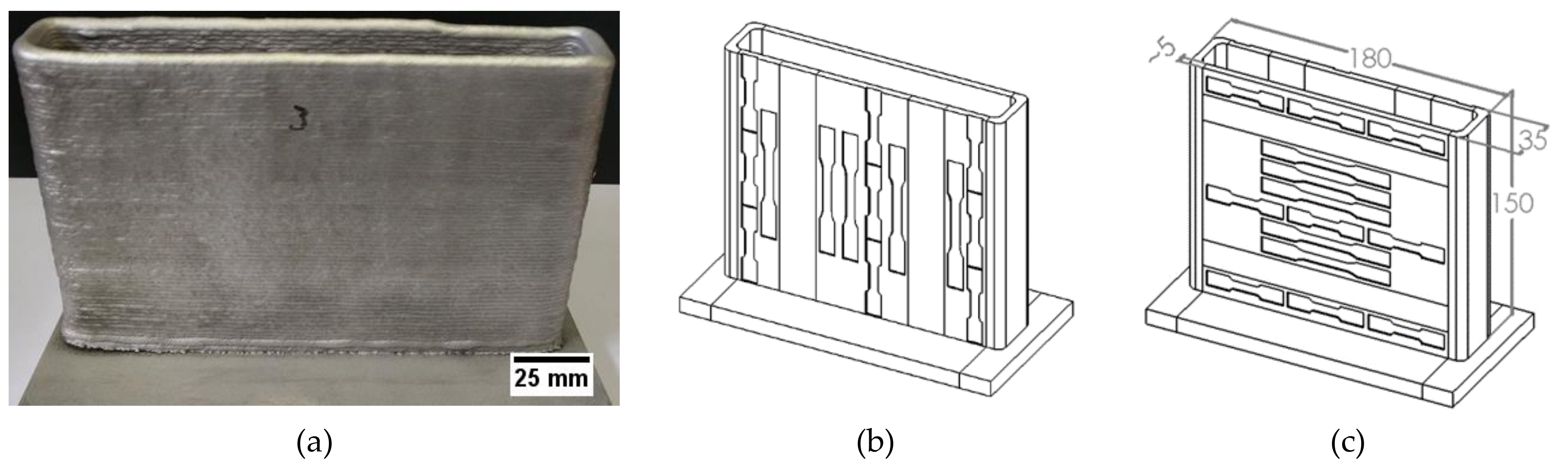

3.1. Wire Arc Deposition

3.2. Microstructure Characterisation

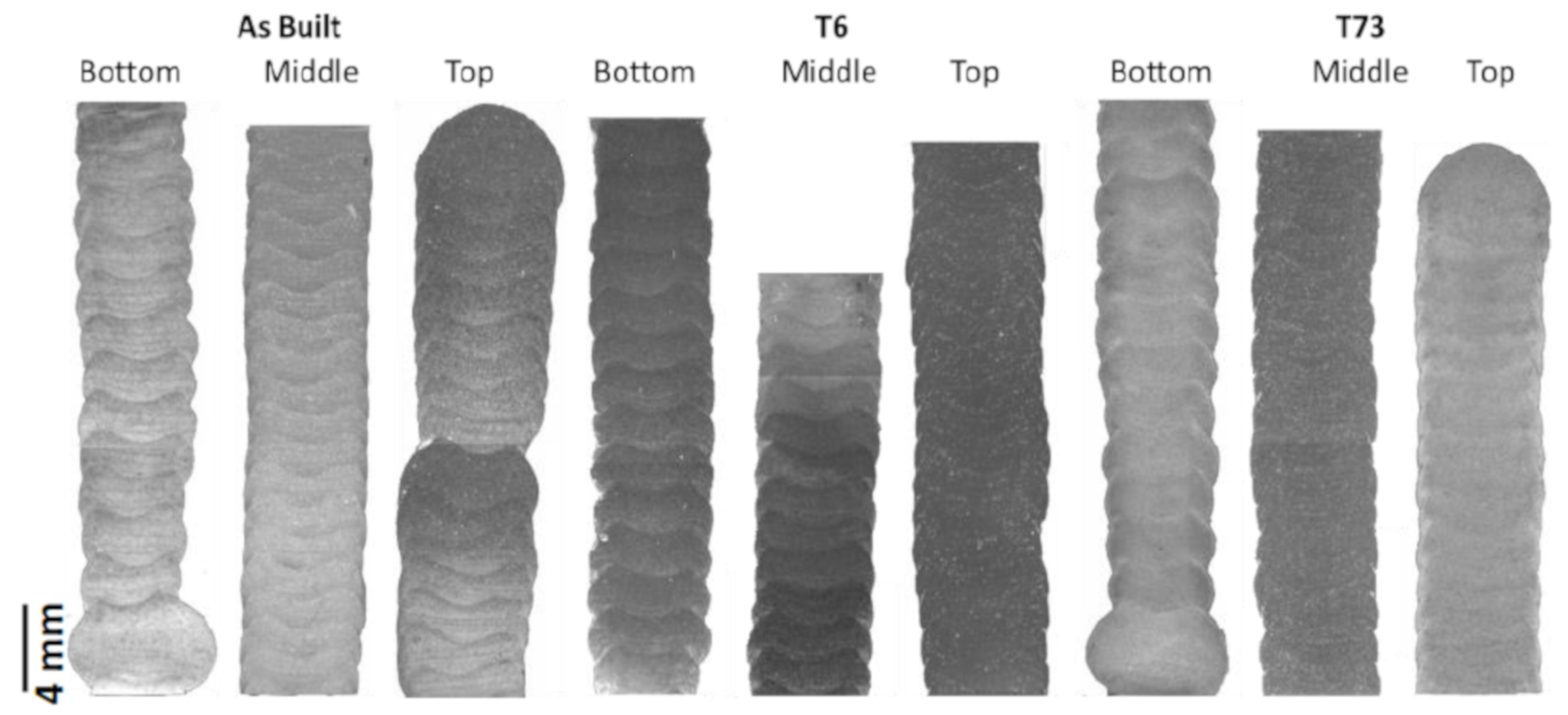

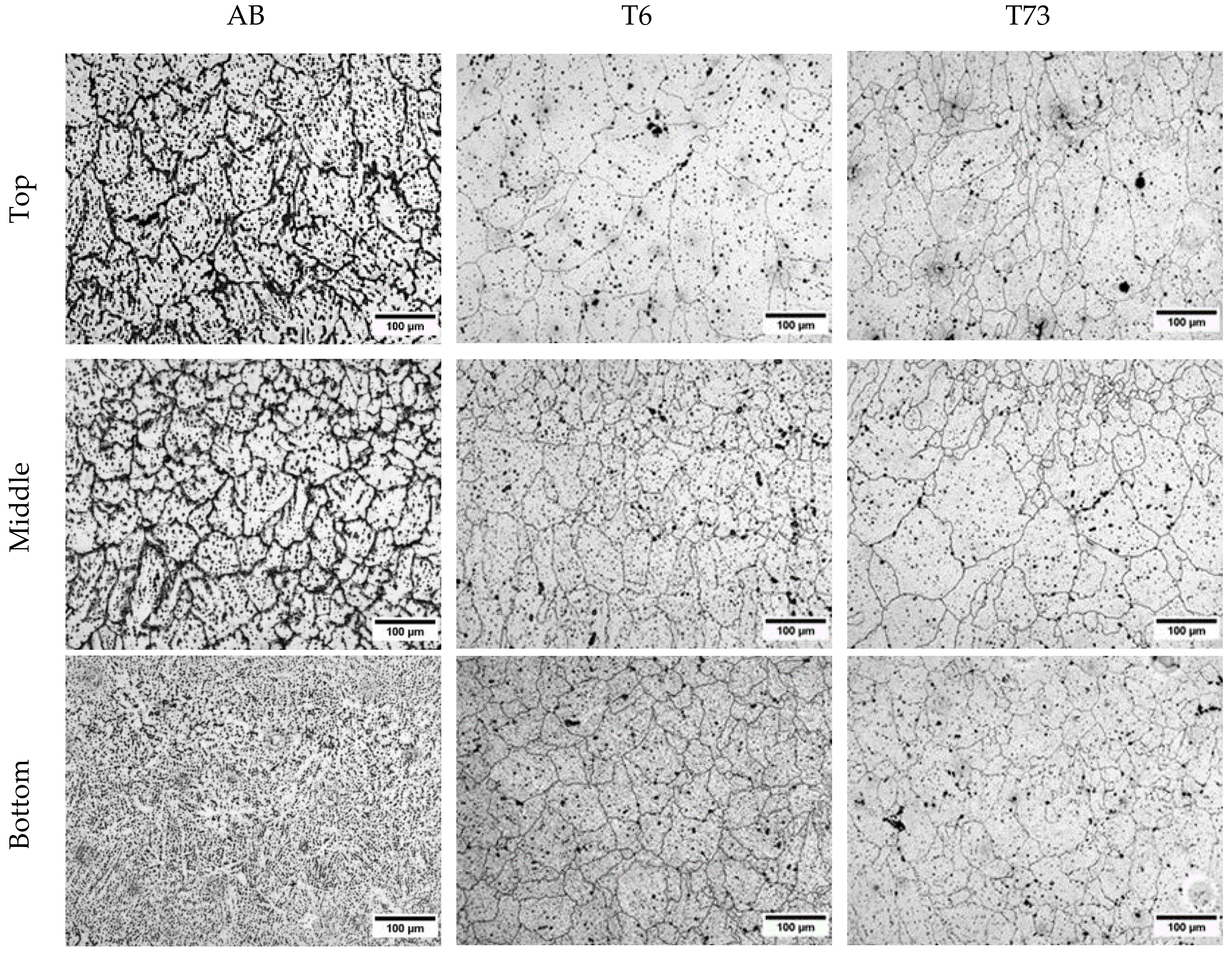

3.2.1. Microstructure Evolution

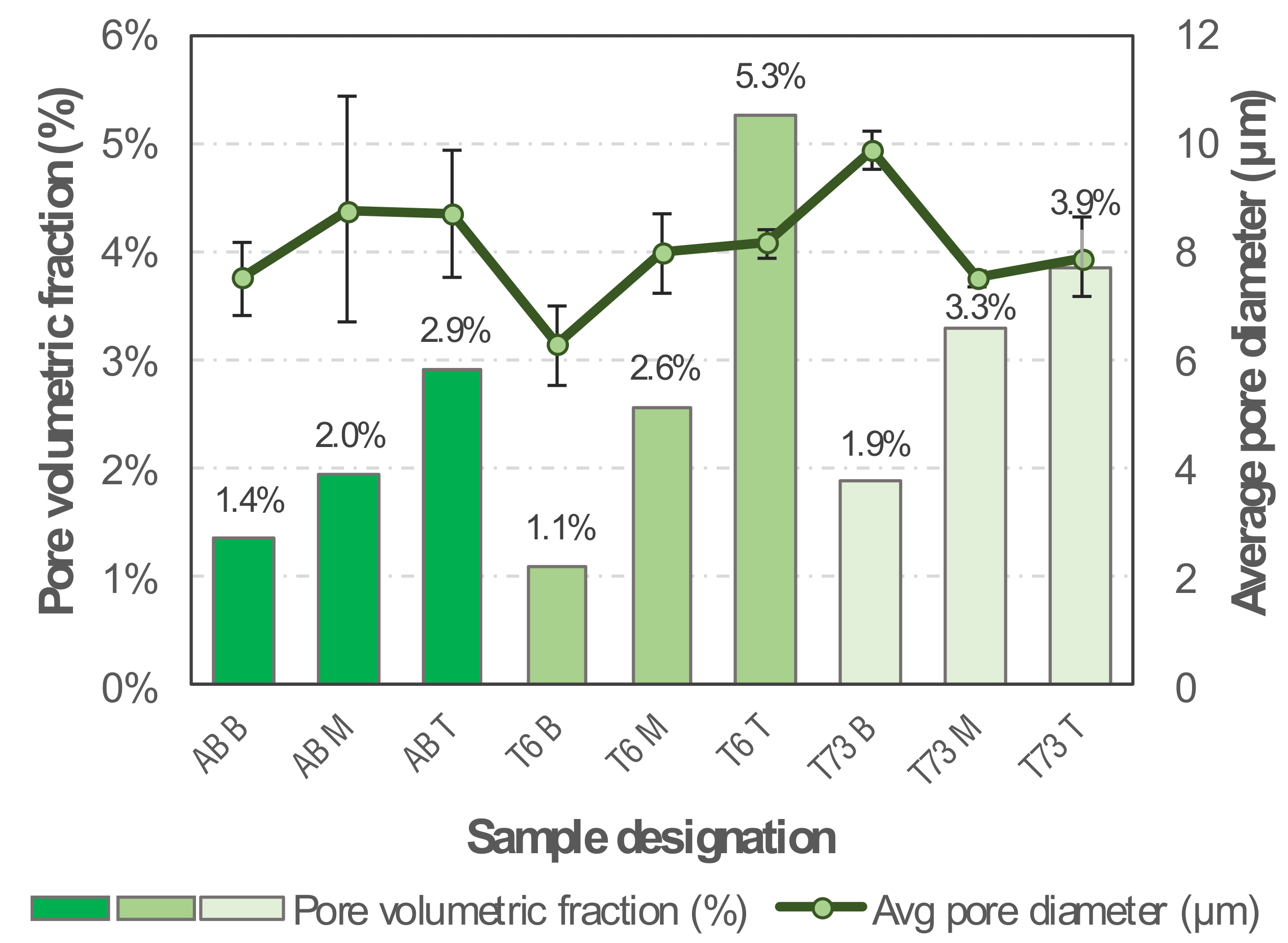

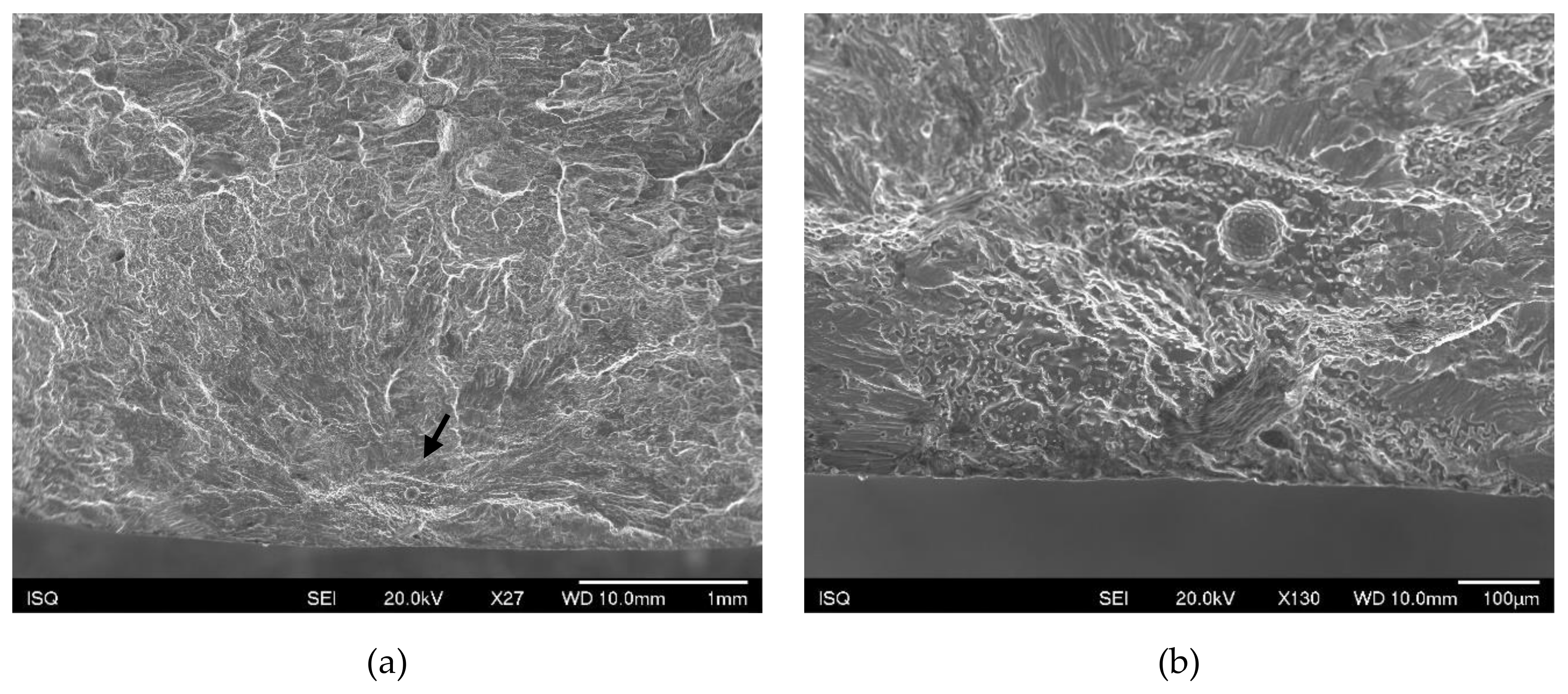

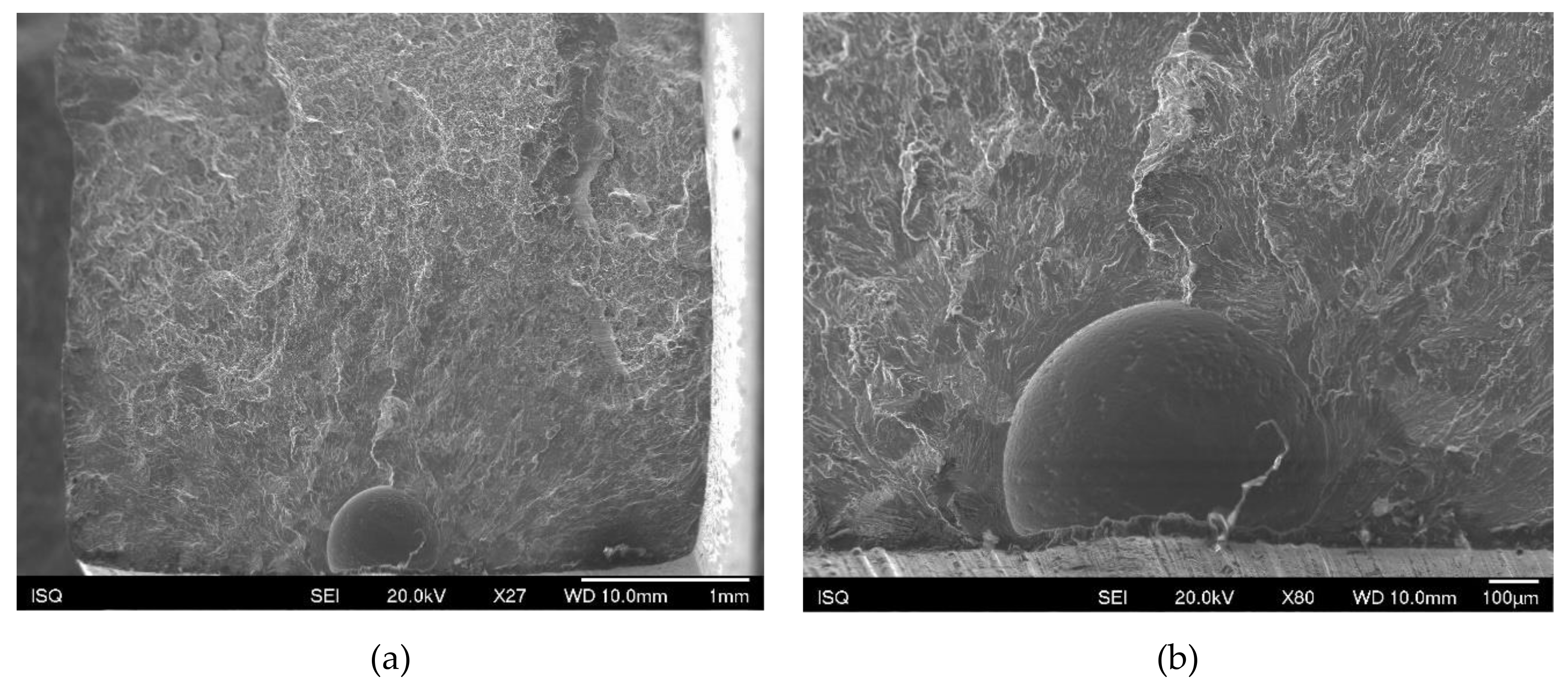

3.2.2. Porosity Evaluation

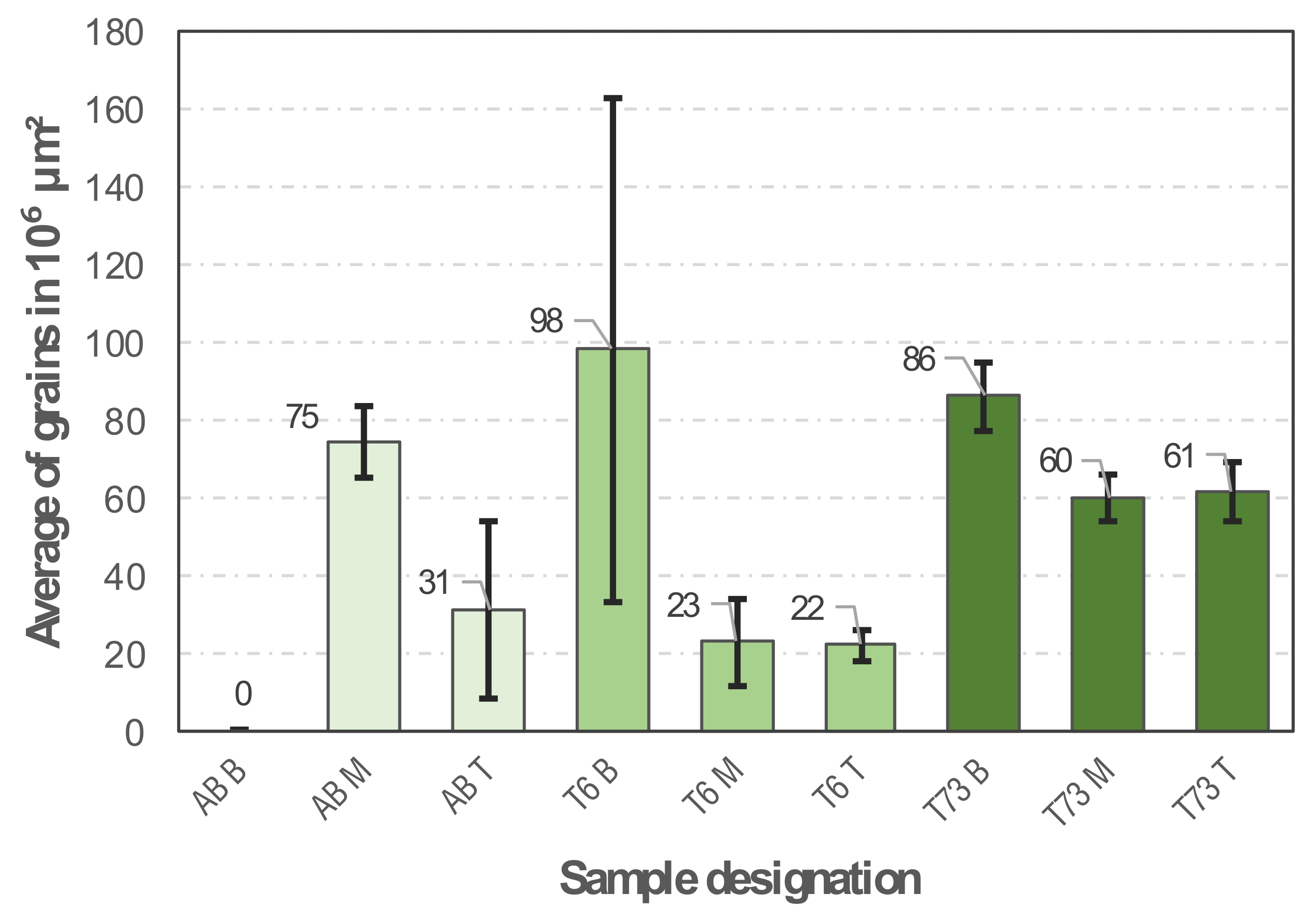

3.2.3. Grain Number

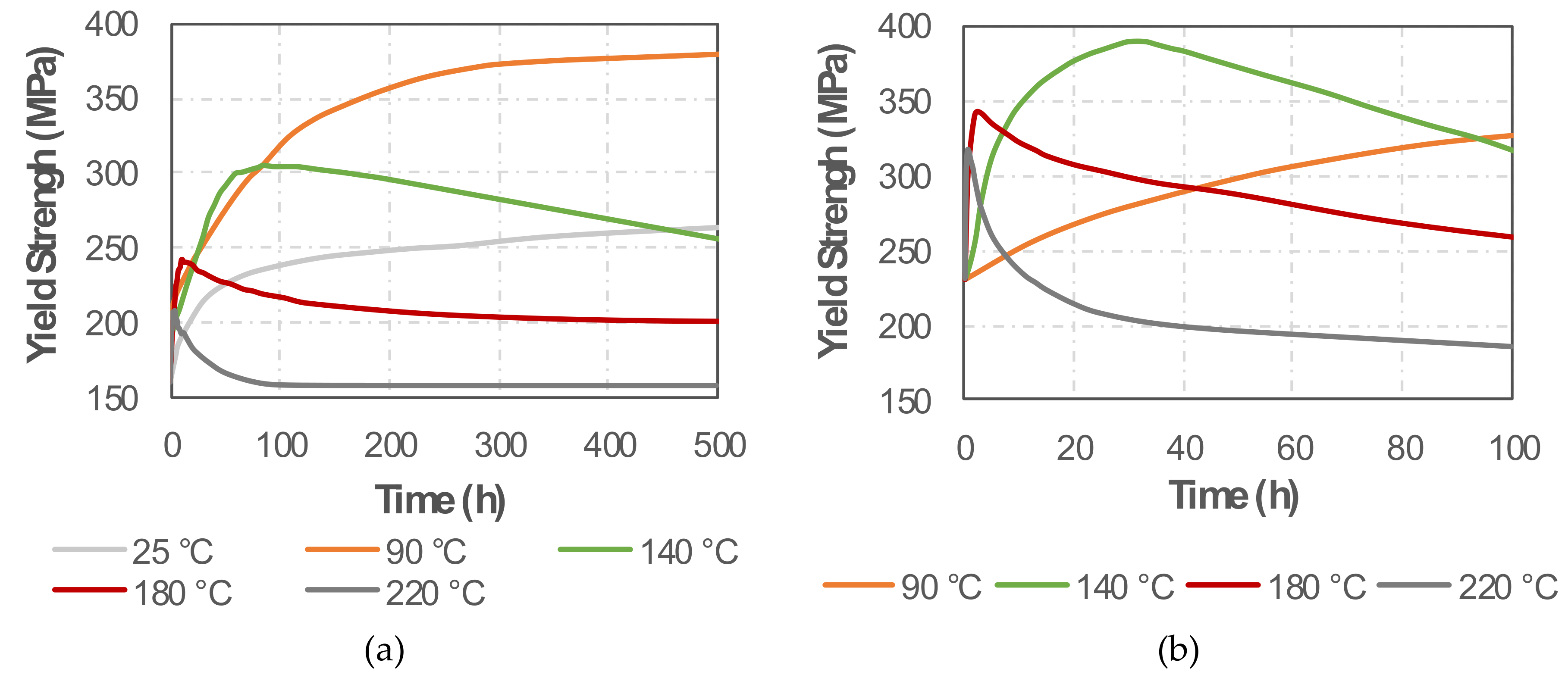

3.3. Heat Treatment Simulation

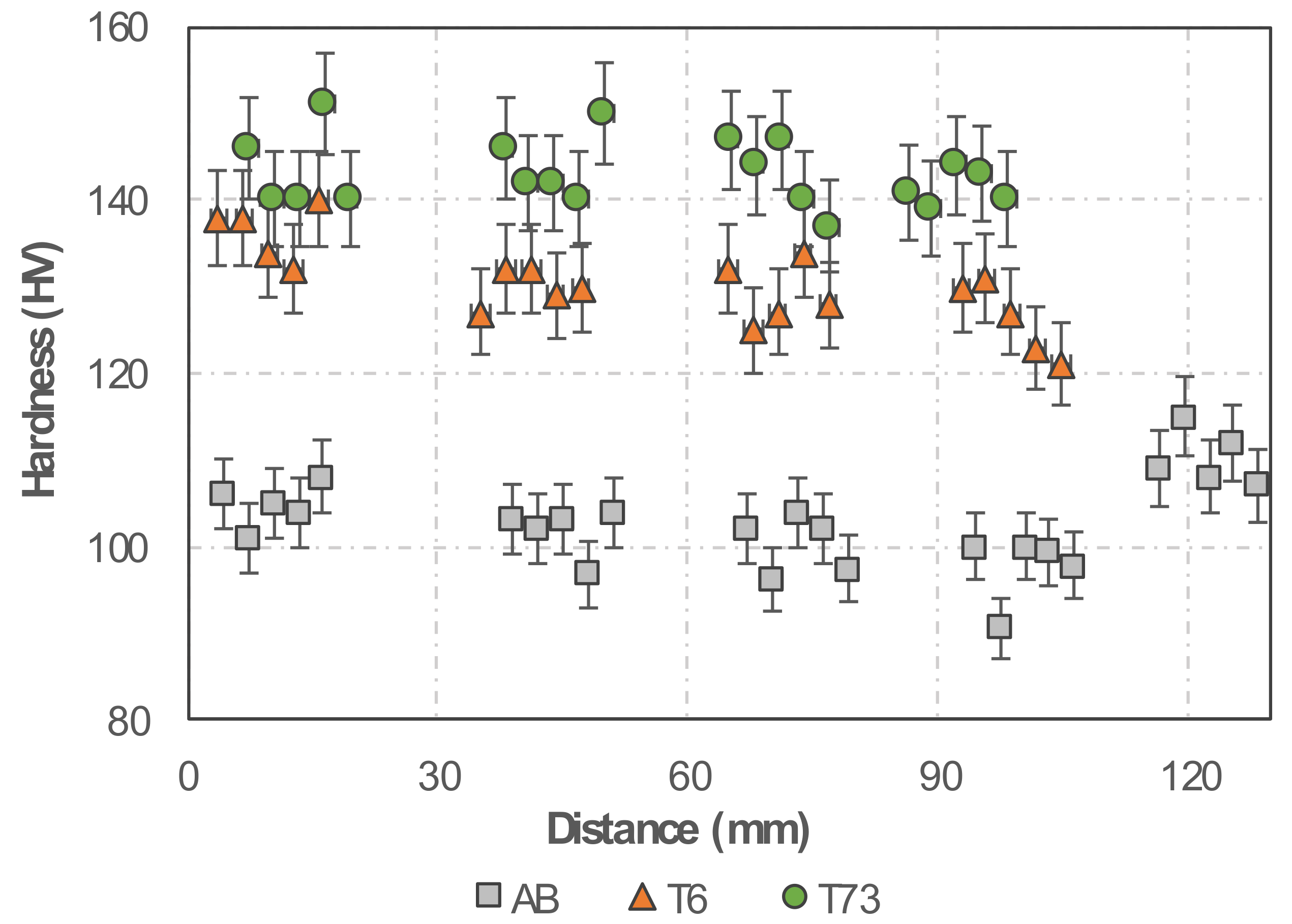

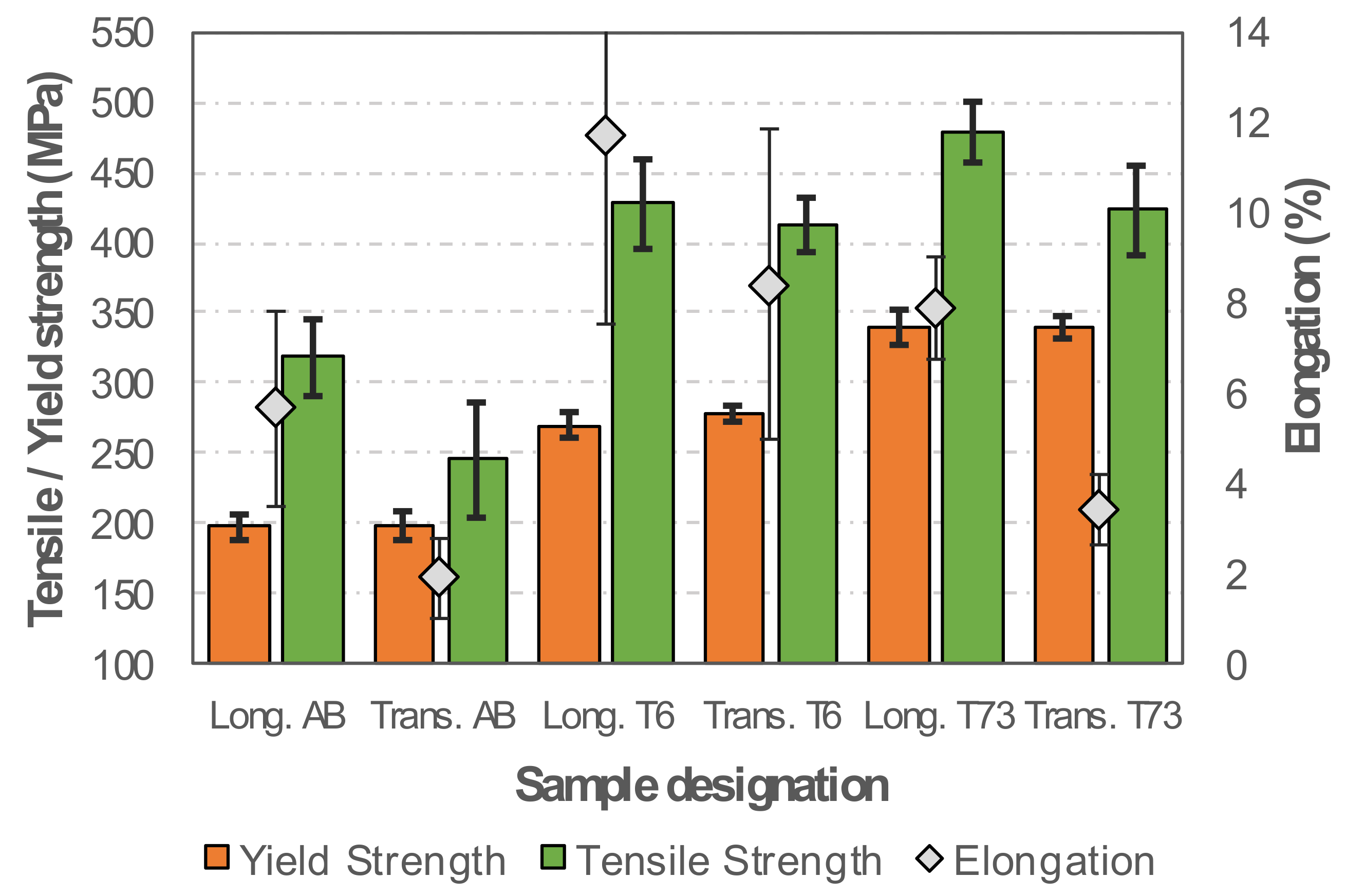

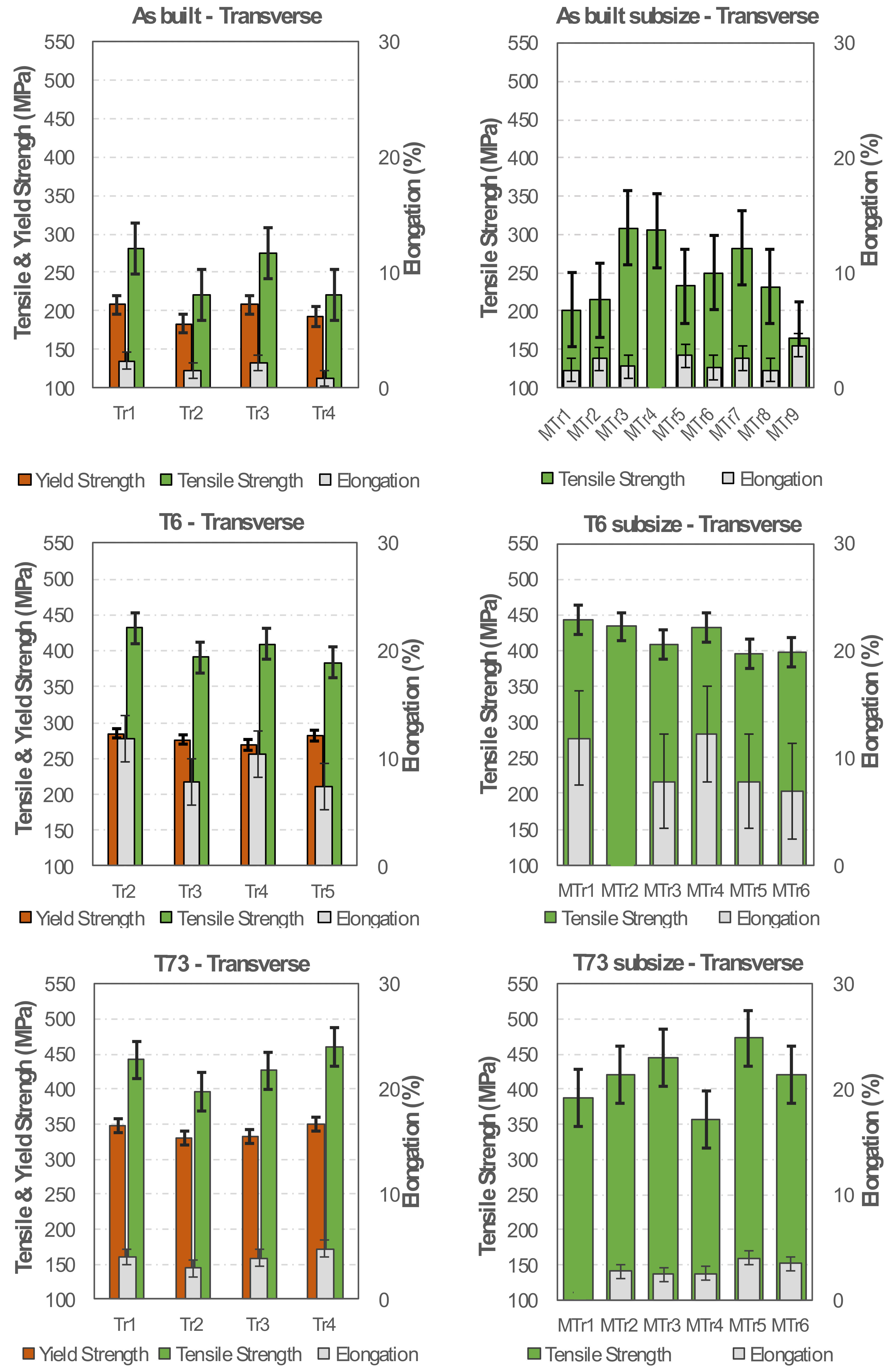

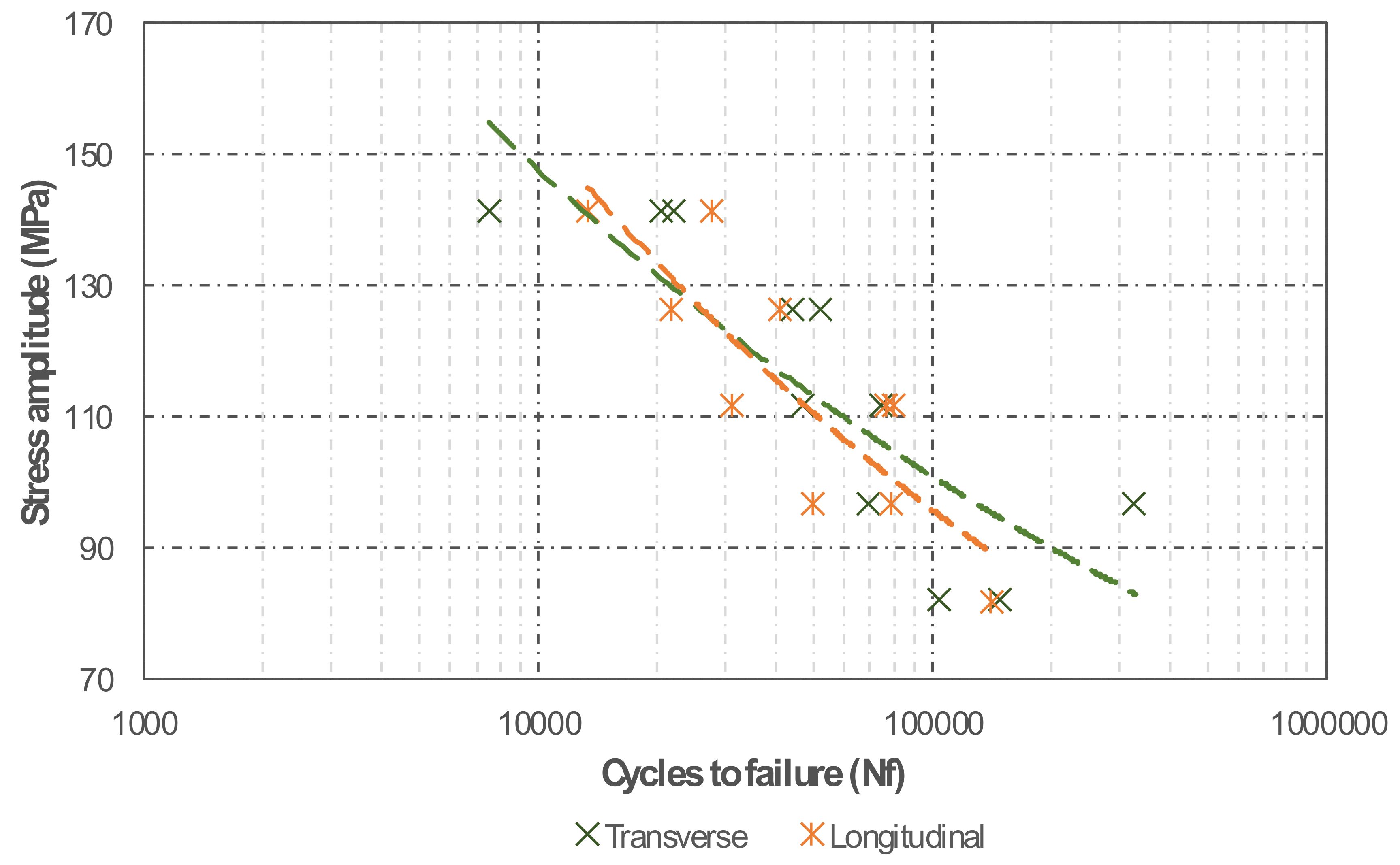

3.4. Mechanical Properties

4. Conclusions

- Wire arc additive manufacturing of the Al5–Mg3–Zn–Cu alloy resulted in a component with exceptionally high mechanical strength when compared to other Al alloys. In fact, the achieved mechanical properties are even superior to the values available for many commercial 7xxx alloys. Furthermore, the heat treatment simulations indicate that even higher mechanical properties can be achieved using optimised ageing treatments.

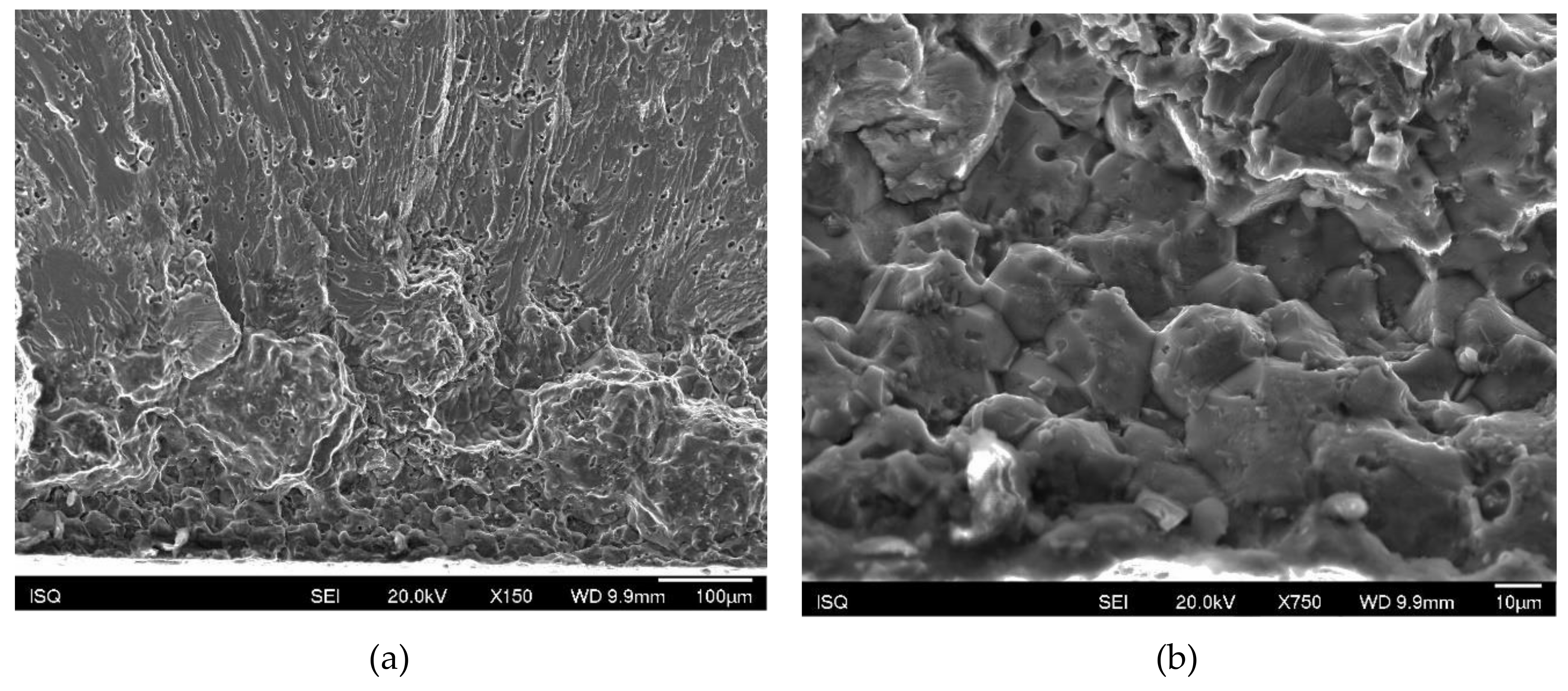

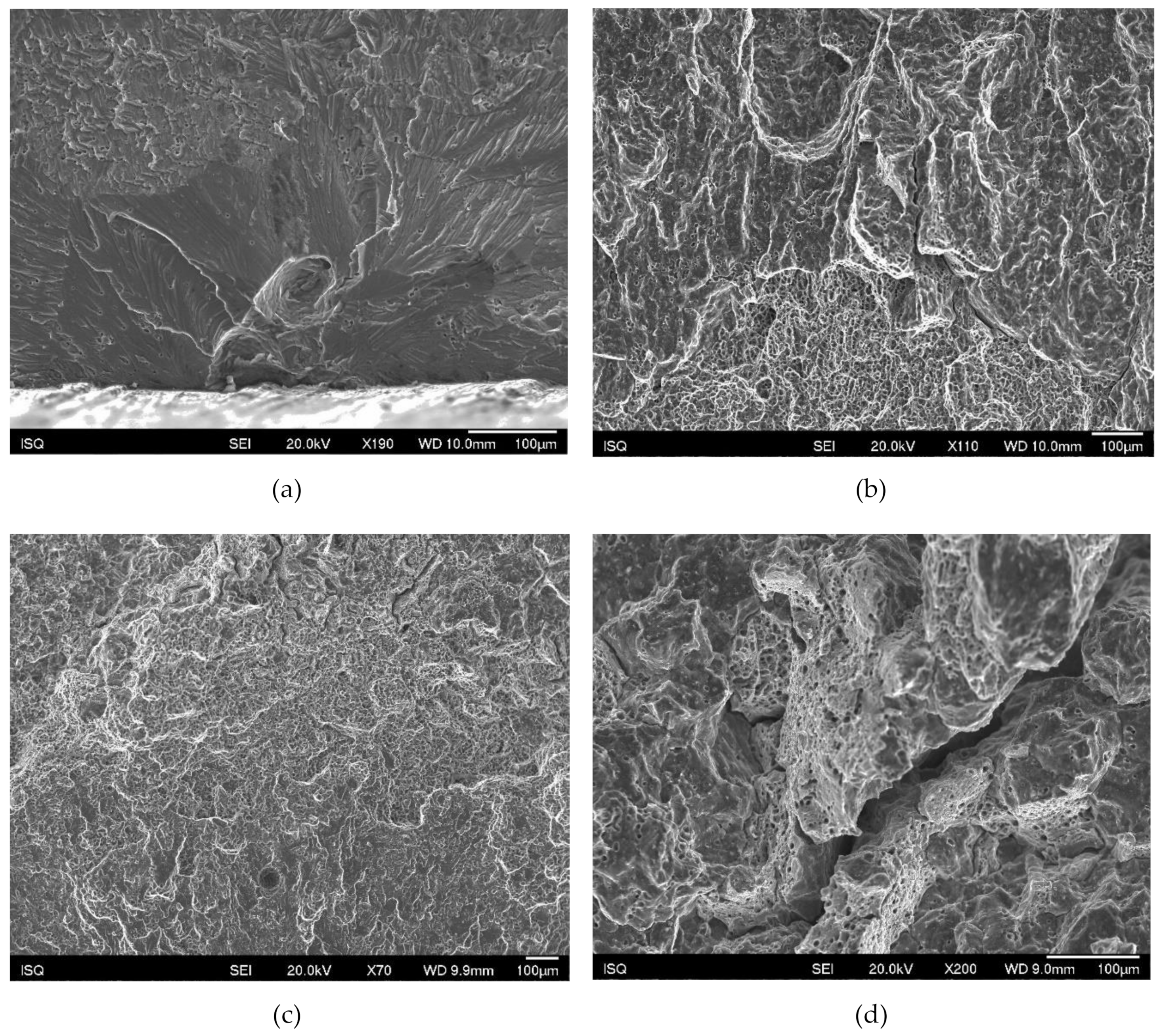

- Concerning defects, the manufactured parts only exhibit few dispersed porosities and volumetric pore fraction changes along the height of the sample. The volumetric pore fraction is smaller in the bottom and bigger in the top region, while the grains are smaller in the bottom and bigger in the upper region. Both observations are in line with an increasing mean component temperature with an increasing height. Equiaxed and elongated grains are seen along the sample—a typical feature of wire arc processed aluminium. It can be noted that smaller equiaxed grains are seen in the interlayer region, followed by elongated grains and a zone of coarser grains with mostly equiaxed grains.

- The fatigue results showed a high scatter caused mainly by residual porosity, which was the main feature associated with failure initiation and eventual risk of intergranular brittleness.

- The high strength reached under 60 h of ageing time can be attributed to the two-stage ageing treatment, which promoted full formation of precipitation and growth of very fine precipitates of the η′ or T′-phase (semi-coherent, metastable precursors of the equilibrium MgZn2 or T (Al2Mg3Zn3) phases, respectively) from GP zones.

- The hardness measurements performed on the aged samples deposited by the wire arc process confirmed the simulation trends and the advantages of the two-stage ageing treatment as a processing method for this material.

Author Contributions

Funding

Conflicts of Interest

References

- Azam, F.I.; Rani, A.M.A.; Altaf, K.; Rao, T.V.V.L.N.; Zaharin, H.A. An In-Depth Review on Direct Additive Manufacturing of Metals. IOP Conf. Ser. Mater. Sci. Eng. 2018, 328, 012005. [Google Scholar] [CrossRef]

- Abdulhameed, O.; Al-Ahmari, A.; Ameen, W.; Mian, S.H. Additive manufacturing: Challenges, trends, and applications. Adv. Mech. Eng. 2019, 11, 1687814018822880. [Google Scholar] [CrossRef]

- Mukherjee, T.; Zuback, J.S.; De, A.; DebRoy, T. Printability of alloys for additive manufacturing. Sci. Rep. 2016, 6, 19717. [Google Scholar] [CrossRef] [PubMed]

- Hirsch, J. Aluminium in Innovative Light-Weight Car Design. Mater. Trans. 2011, 52, 818–824. [Google Scholar] [CrossRef]

- Gloria, A.; Montanari, R.; Richetta, M.; Varone, A. Alloys for aeronautic applications: State of the art and perspectives. Metals 2019, 9, 662. [Google Scholar] [CrossRef]

- Staley, J.; Lege, D. Advances in aluminium alloy products for structural applications in transportation. J. Phys. IV 1993, 3, C7–C179. [Google Scholar] [CrossRef]

- Lumley, R. Fundamentals of Aluminium Metallurgy: Recent Advances; Woodhead Publishing: Sawston, UK, 2018; ISBN 0-08-102064-3. [Google Scholar]

- Ringer, S.; Hono, K. Microstructural evolution and age hardening in aluminium alloys: Atom probe field-ion microscopy and transmission electron microscopy studies. Mater. Charact. 2000, 44, 101–131. [Google Scholar] [CrossRef]

- Stemper, L.; Mitas, B.; Kremmer, T.; Otterbach, S.; Uggowitzer, P.; Pogatscher, S. Age-hardening of high pressure die casting AlMg alloys with Zn and combined Zn and Cu additions. Mater. Des. 2019, 181, 107927. [Google Scholar] [CrossRef]

- Ditta, A.; Wei, L.; Xu, Y.; Wu, S. Microstructural characteristics and properties of spray formed Zn-rich Al-Zn-Mg-Cu alloy under various aging conditions. Mater. Charact. 2020, 110133. [Google Scholar] [CrossRef]

- Mondolfo, L. Aluminum Alloys Structure and Properties; Elsevier: Amsterdam, The Netherlands, 1976. [Google Scholar]

- Strawbridge, D.; Hume-Rothery, W.; Little, A. The Constitution of Al-Mg-Zn Alloys at 460 °C. J. Inst. Met. 1948, 74, 191–225. [Google Scholar]

- Polmear, I.; StJohn, D.; Nie, J.-F.; Qian, M. Light Alloys: Metallurgy of the Light Metals; Butterworth-Heinemann: Oxford, UK, 2017; ISBN 0-08-099430-X. [Google Scholar]

- Davis, J.R. Alloying: Understanding the basics; ASM international: Materials Park, OH, USA, 2001; ISBN 1-61503-063-8. [Google Scholar]

- Ostermann, F. Anwendungstechnologie Aluminium; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Murayama, M.; Hono, K. Three dimensional atom probe analysis of pre-precipitate clustering in an Al-Cu-Mg-Ag alloy. Scr. Mater. 1998, 38, 1315. [Google Scholar] [CrossRef]

- Dos Santos, J.F.; Staron, P.; Fischer, T.; Robson, J.D.; Kostka, A.; Colegrove, P.; Wang, H.; Hilgert, J.; Bergmann, L.; Hütsch, L.L. Understanding precipitate evolution during friction stir welding of Al-Zn-Mg-Cu alloy through in-situ measurement coupled with simulation. Acta Mater. 2018, 148, 163–172. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D printing of high-strength aluminium alloys. Nature 2017, 549, 365. [Google Scholar] [CrossRef]

- Montero-Sistiaga, M.L.; Mertens, R.; Vrancken, B.; Wang, X.; Van Hooreweder, B.; Kruth, J.-P.; Van Humbeeck, J. Changing the alloy composition of Al7075 for better processability by selective laser melting. J. Mater. Process. Technol. 2016, 238, 437–445. [Google Scholar] [CrossRef]

- Casati, R.; Coduri, M.; Riccio, M.; Rizzi, A.; Vedani, M. Development of a high strength Al–Zn–Si–Mg–Cu alloy for selective laser melting. J. Alloys Compd. 2019, 801, 243–253. [Google Scholar] [CrossRef]

- Taylor, J.A. Iron-containing intermetallic phases in Al-Si based casting alloys. Procedia Mater. Sci. 2012, 1, 19–33. [Google Scholar] [CrossRef]

- Couture, A. Iron in aluminum casting alloys-a literature survey. Int. Cast Met. J. 1981, 6, 9–17. [Google Scholar]

- Dinnis, C.; Taylor, J. Manganese as a" neutraliser" of iron-related porosity in Al-Si foundry alloys. Appl. Catal. B Environ. 2007, 101, 388–396. [Google Scholar]

- Eskin, D.G.; Suyitno; Katgerman, L. Mechanical properties in the semi-solid state and hot tearing of aluminium alloys. Prog. Mater. Sci. 2004, 49, 629–711. [Google Scholar] [CrossRef]

- Fukuda, T. Weldability of 7000 series aluminium alloy materials. Weld. Int. 2012, 26, 256–269. [Google Scholar] [CrossRef]

- Cao, C.; Zhang, D.; Wang, X.; Ma, Q.; Zhuang, L.; Zhang, J. Effects of Cu addition on the precipitation hardening response and intergranular corrosion of Al-5.2 Mg-2.0 Zn (wt.%) alloy. Mater. Charact. 2016, 122, 177–182. [Google Scholar] [CrossRef]

- Williams, S.W.; Martina, F.; Addison, A.C.; Ding, J.; Pardal, G.; Colegrove, P. Wire+ arc additive manufacturing. Mater. Sci. Technol. 2016, 32, 641–647. [Google Scholar] [CrossRef]

- Almeida, P.S. Process Control and Development in Wire and Arc Additive Manufacturing. PhD Thesis, Cranfield University, Cranfield, UK, 2012. [Google Scholar]

- Schmidt, M.; Merklein, M.; Bourell, D.; Dimitrov, D.; Hausotte, T.; Wegener, K.; Overmeyer, L.; Vollertsen, F.; Levy, G.N. Laser based additive manufacturing in industry and academia. CIRP Ann. 2017, 66, 561–583. [Google Scholar] [CrossRef]

- Plangger, J.; Schabhüttl, P.; Vuherer, T.; Enzinger, N. CMT additive manufacturing of a high strength steel alloy for application in crane construction. Metals 2019, 9, 650. [Google Scholar] [CrossRef]

- Rodrigues, T.A.; Duarte, V.; Miranda, R.; Santos, T.G.; Oliveira, J. Current status and perspectives on wire and arc additive manufacturing (WAAM). Materials 2019, 12, 1121. [Google Scholar] [CrossRef]

- Köhler, M.; Fiebig, S.; Hensel, J.; Dilger, K. Wire and Arc Additive Manufacturing of Aluminum Components. Metals 2019, 9, 608. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. A multi-bead overlapping model for robotic wire and arc additive manufacturing (WAAM). Robot. Comput.-Integr. Manuf. 2015, 31, 101–110. [Google Scholar] [CrossRef]

- Cunningham, C.; Wikshåland, S.; Xu, F.; Kemakolam, N.; Shokrani, A.; Dhokia, V.; Newman, S. Cost modelling and sensitivity analysis of wire and arc additive manufacturing. Procedia Manuf. 2017, 11, 650–657. [Google Scholar] [CrossRef]

- Ryan, E.; Sabin, T.; Watts, J.; Whiting, M. The influence of build parameters and wire batch on porosity of wire and arc additive manufactured aluminium alloy 2319. J. Mater. Process. Technol. 2018, 262, 577–584. [Google Scholar] [CrossRef]

- Cong, B.; Qi, Z.; Qi, B.; Sun, H.; Zhao, G.; Ding, J. A comparative study of additively manufactured thin wall and block structure with Al-6.3% Cu alloy using cold metal transfer process. Appl. Sci. 2017, 7, 275. [Google Scholar] [CrossRef]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef] [PubMed]

- Schnall, M.; Bozorgi, S.; Klein, T.; Gradinger, R.; Birgmann, A.; Morais, P.; Warzok, P. Sonder-Aluminium-Schweißzusätze optimiert für die Verarbeitung im Wire-Arc Additive Manufacturing-Prozess. In DVS Congress; DVS Media GmbH: Dusseldorf, Germany, 2019. [Google Scholar]

- Geng, H.; Li, J.; Xiong, J.; Lin, X. Optimisation of interpass temperature and heat input for wire and arc additive manufacturing 5A06 aluminium alloy. Sci. Technol. Weld. Join. 2016, 22, 1–12. [Google Scholar] [CrossRef]

- Froend, M.; Ventzke, V.; Dorn, F.; Kashaev, N.; Klusemann, B.; Enz, J. Microstructure by design: An approach of grain refinement and isotropy improvement in multi-layer wire-based laser metal deposition. Mater. Sci. Eng. A 2020, 772, 138635. [Google Scholar] [CrossRef]

- Talbot, D.; Granger, D. Secondary hydrogen porosity in aluminium. J. Inst. Met. 1964, 92, 290. [Google Scholar]

- Gu, J.; Yang, S.; Gao, M.; Bai, J.; Zhai, Y.; Ding, J. Micropore evolution in additively manufactured aluminum alloys under heat treatment and inter-layer rolling. Mater. Des. 2020, 186, 108288. [Google Scholar] [CrossRef]

- Toda, H.; Hidaka, T.; Kobayashi, M.; Uesugi, K.; Takeuchi, A.; Horikawa, K. Growth behavior of hydrogen micropores in aluminum alloys during high-temperature exposure. Acta Mater. 2009, 57, 2277–2290. [Google Scholar] [CrossRef]

- Anyalebechi, P.N.; Hogarth, J. Effect of supereutectic homogenization on incidence of porosity in aluminum alloy 2014 ingot. Metall. Mater. Trans. B 1994, 25, 111–122. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashcroft, I.; Tuck, C.; Hague, R. 3D printing of Aluminium alloys: Additive Manufacturing of Aluminium alloys using selective laser melting. Prog. Mater. Sci. 2019, 106, 100578. [Google Scholar] [CrossRef]

- Zhao, T.; Jiang, Y. Fatigue of 7075-T651 aluminum alloy. Int. J. Fatigue 2008, 30, 834–849. [Google Scholar] [CrossRef]

- Vu, C.; Wern, C.; Kim, B.H.; Kim, S.K.; Choi, H.J.; Yi, S. Fatigue Behaviour of New Eco-7175 Extruded Aluminium Alloy. In Proceedings of the 8th European Conference for Aeronautics and Space Sciences (EUCASS), Madrid, Spain, 1–4 July 2019. [Google Scholar] [CrossRef]

- Ozdes, H. The Relationship between High-Cycle Fatigue and Tensile Properties in Cast Aluminum Alloys. Master’s Thesis, University of North Florida, Jacksonville, FL, USA, 2016. [Google Scholar]

| As-cast (OES) | Al | Mg | Zn | Mn | Si | Cu | Fe | Cr | Ti | Zr |

|---|---|---|---|---|---|---|---|---|---|---|

| wt.% | 89.30 | 5.87 | 3.58 | 0.49 | 0.07 | 0.33 | 0.11 | 0.04 | 0.05 | 0.12 |

| As-built (OES) | Al | Mg | Zn | Mn | Si | Cu | Fe | Cr | Ti | Zr |

|---|---|---|---|---|---|---|---|---|---|---|

| wt.% | 90.00 | 5.33 | 3.44 | 0.49 | 0.07 | 0.31 | 0.11 | 0.04 | 0.06 | 0.12 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morais, P.J.; Gomes, B.; Santos, P.; Gomes, M.; Gradinger, R.; Schnall, M.; Bozorgi, S.; Klein, T.; Fleischhacker, D.; Warczok, P.; et al. Characterisation of a High-Performance Al–Zn–Mg–Cu Alloy Designed for Wire Arc Additive Manufacturing. Materials 2020, 13, 1610. https://doi.org/10.3390/ma13071610

Morais PJ, Gomes B, Santos P, Gomes M, Gradinger R, Schnall M, Bozorgi S, Klein T, Fleischhacker D, Warczok P, et al. Characterisation of a High-Performance Al–Zn–Mg–Cu Alloy Designed for Wire Arc Additive Manufacturing. Materials. 2020; 13(7):1610. https://doi.org/10.3390/ma13071610

Chicago/Turabian StyleMorais, Paulo J., Bianca Gomes, Pedro Santos, Manuel Gomes, Rudolf Gradinger, Martin Schnall, Salar Bozorgi, Thomas Klein, Dominik Fleischhacker, Piotr Warczok, and et al. 2020. "Characterisation of a High-Performance Al–Zn–Mg–Cu Alloy Designed for Wire Arc Additive Manufacturing" Materials 13, no. 7: 1610. https://doi.org/10.3390/ma13071610

APA StyleMorais, P. J., Gomes, B., Santos, P., Gomes, M., Gradinger, R., Schnall, M., Bozorgi, S., Klein, T., Fleischhacker, D., Warczok, P., Falahati, A., & Kozeschnik, E. (2020). Characterisation of a High-Performance Al–Zn–Mg–Cu Alloy Designed for Wire Arc Additive Manufacturing. Materials, 13(7), 1610. https://doi.org/10.3390/ma13071610