Investigation into the Effect of Thermal Treatment on the Obtaining of Magnetic Phases: Fe5Y, Fe23B6, Y2Fe14B and αFe within the Amorphous Matrix of Rapidly-Quenched Fe61+xCo10−xW1Y8B20 Alloys (Where x = 0, 1 or 2)

Abstract

1. Introduction

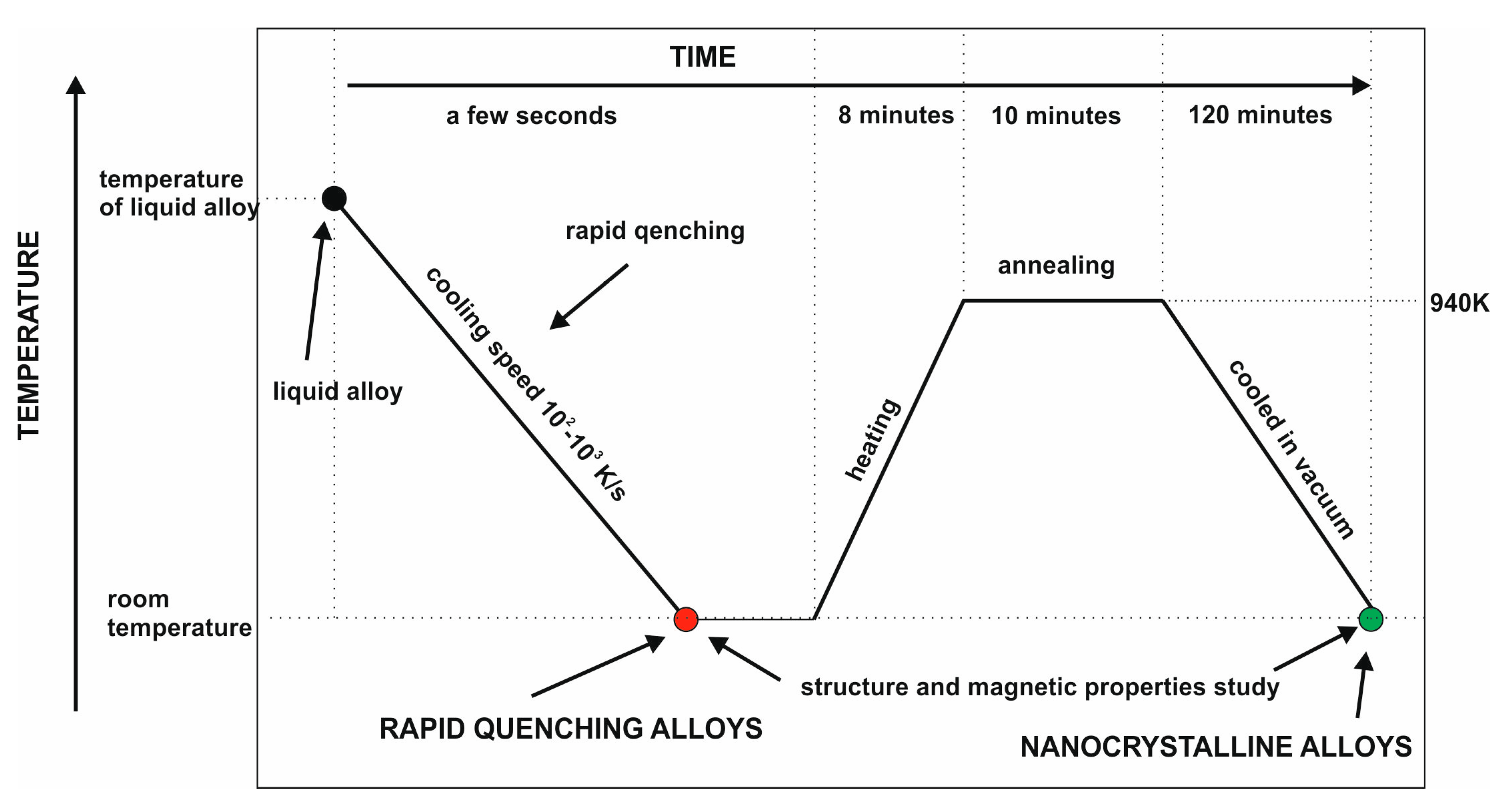

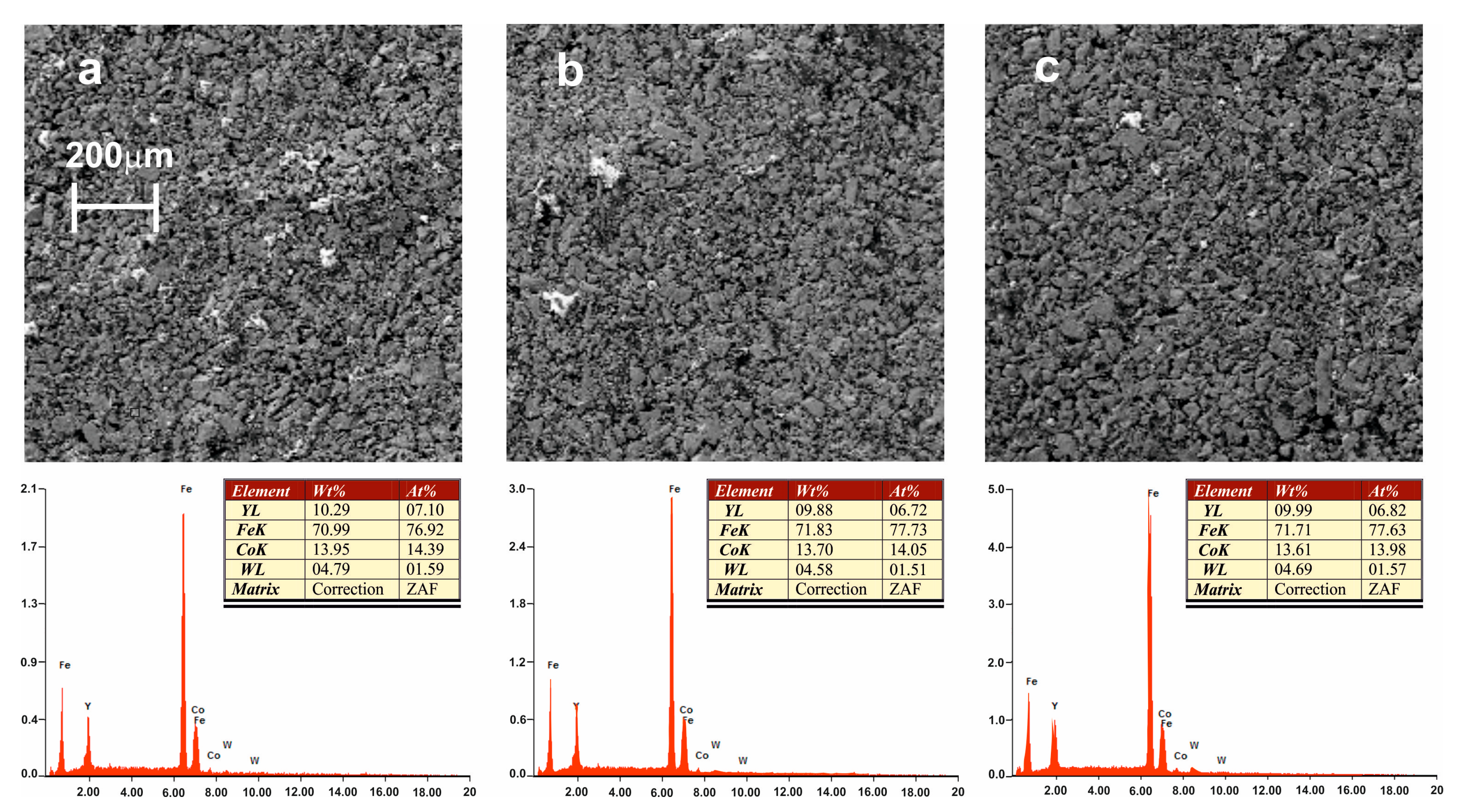

2. Materials and Methods

3. Results

4. Conclusions

- The injection and suction-casting methods (into a copper die) allow the manufacture of bulk amorphous alloys with the chemical composition Fe61+xCo10−xW1Y8B20 (x = 0, 2).

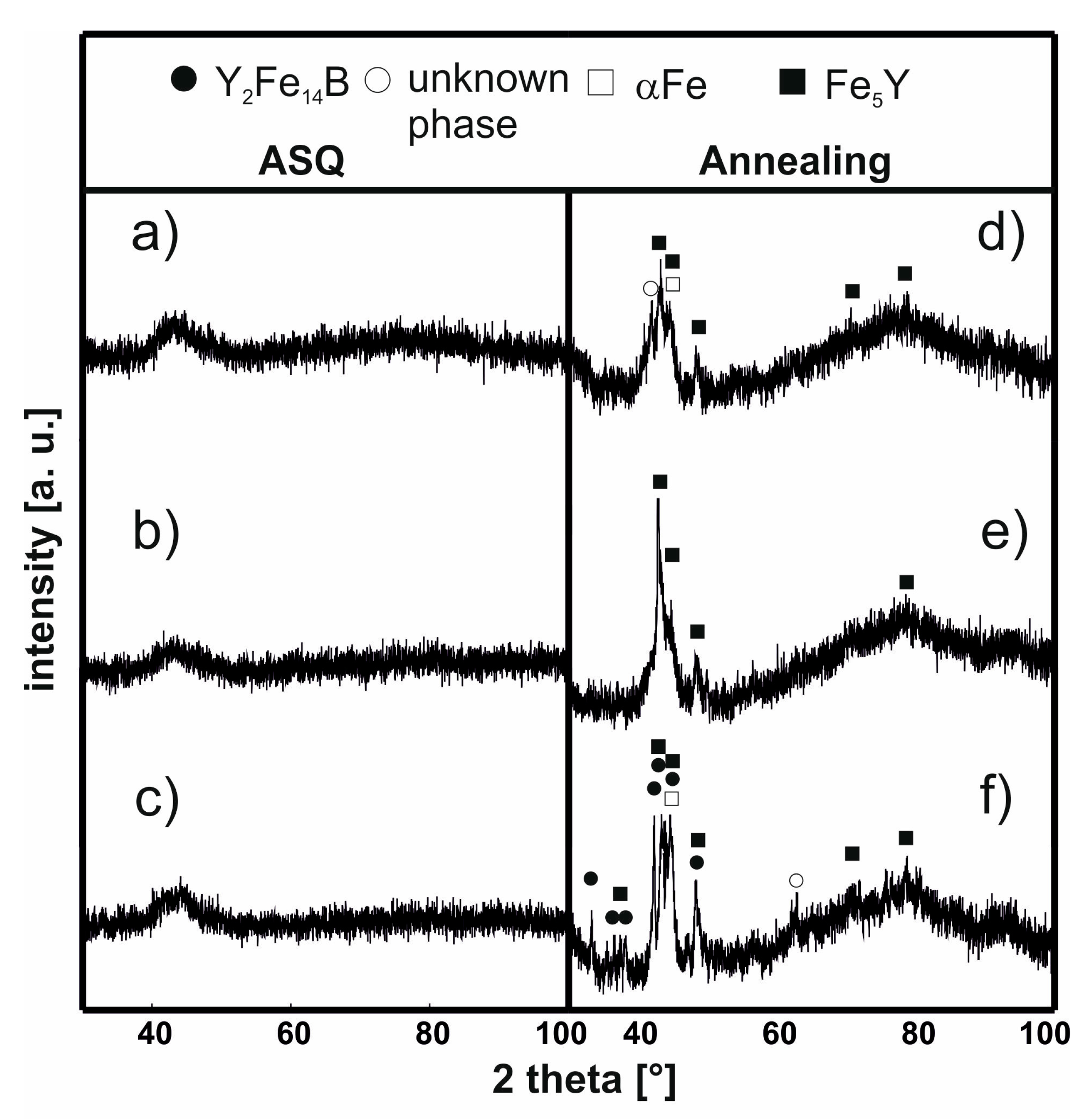

- In the case of the alloy Fe62Co9W1Y8B20 in the as-cast state, the presence of a small amount of the phase Fe5Y was observed; this could be related to the minor difference in the process time between the two production methods: for the injection-casting method, the time is marginally longer, which might lead to the formation of crystallites during the production process.

- The isothermal annealing process, carried out at a temperature close to the crystallization temperature (940 K/10 min), led to the partial crystallization of the alloys.

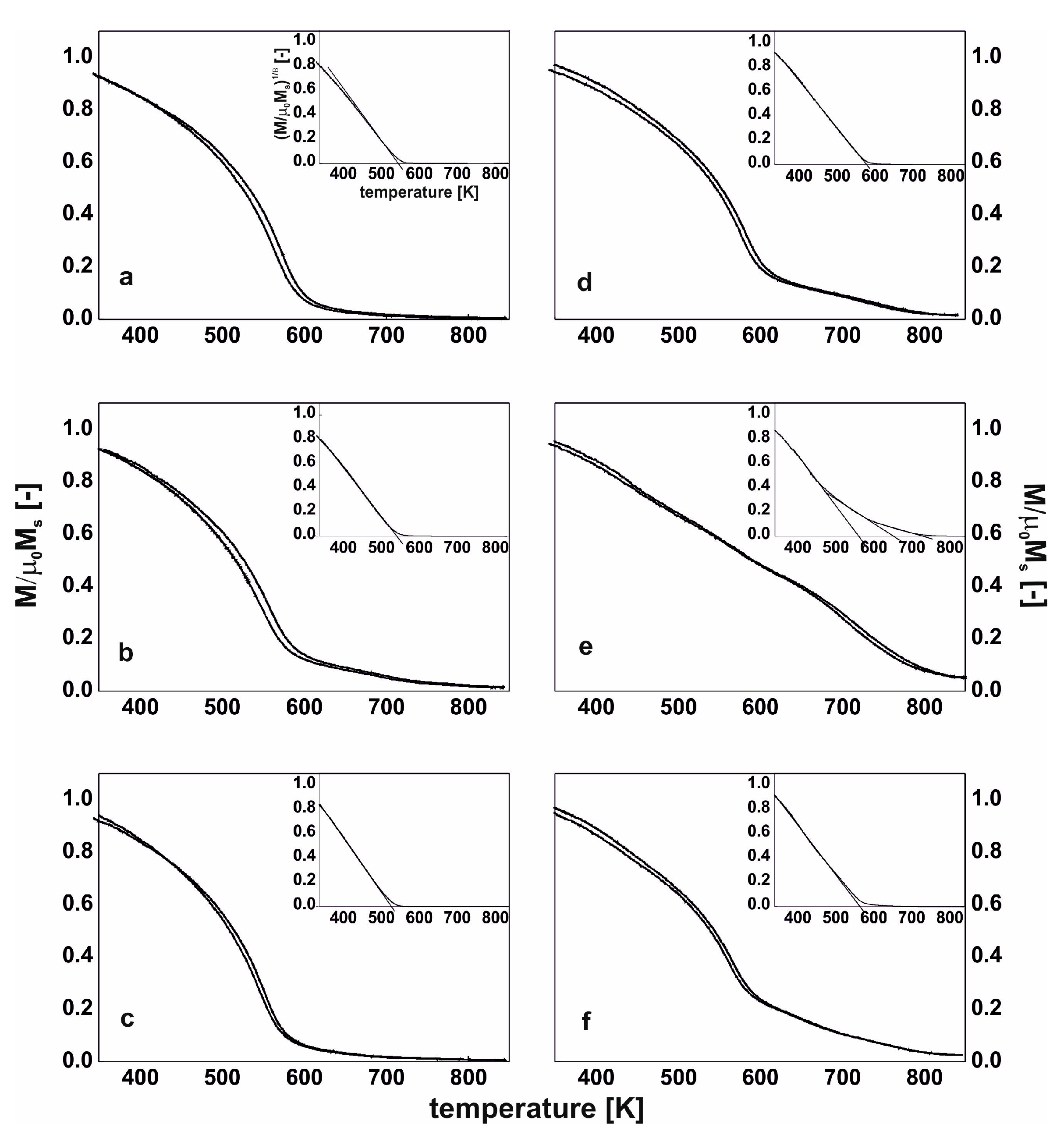

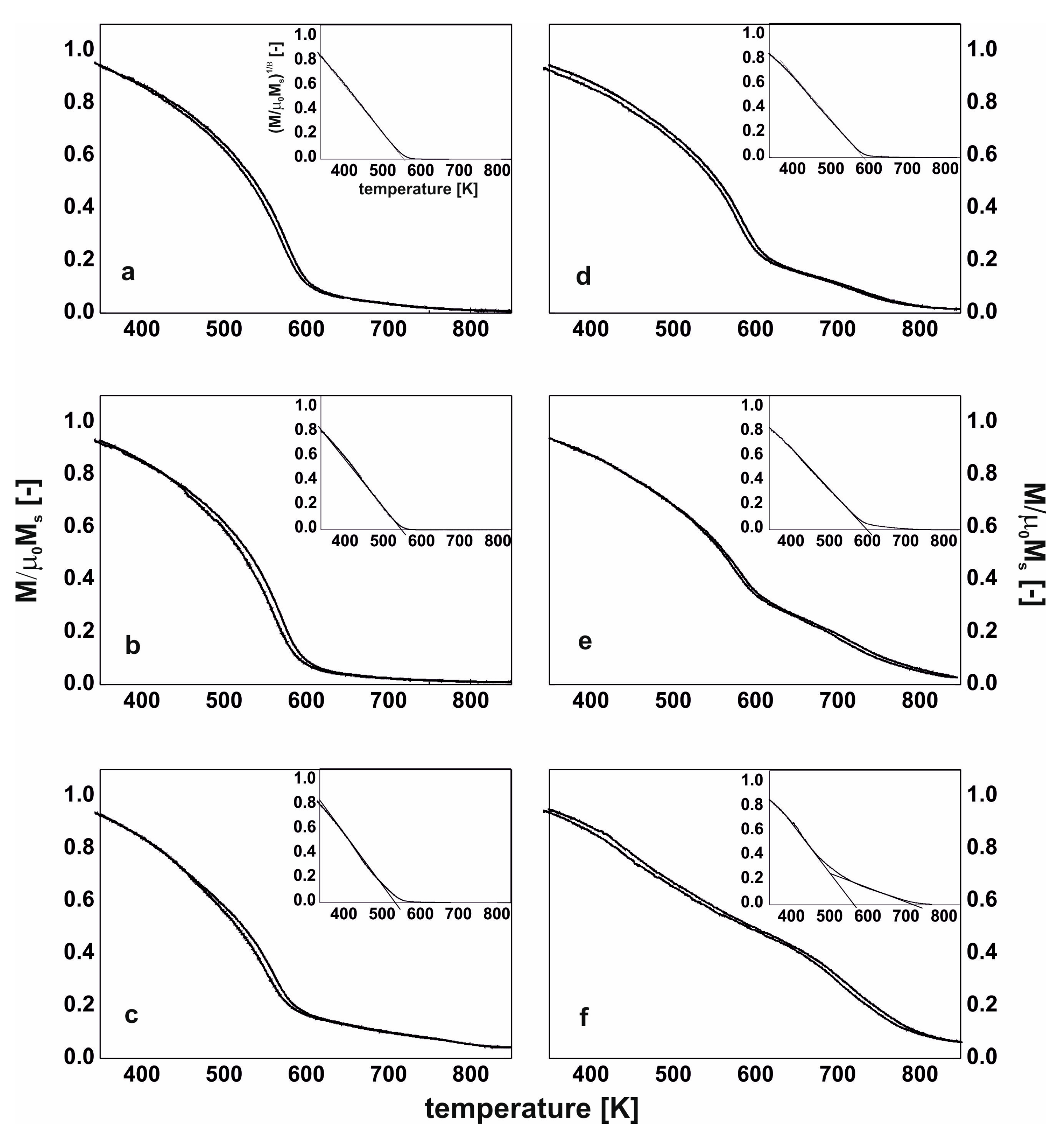

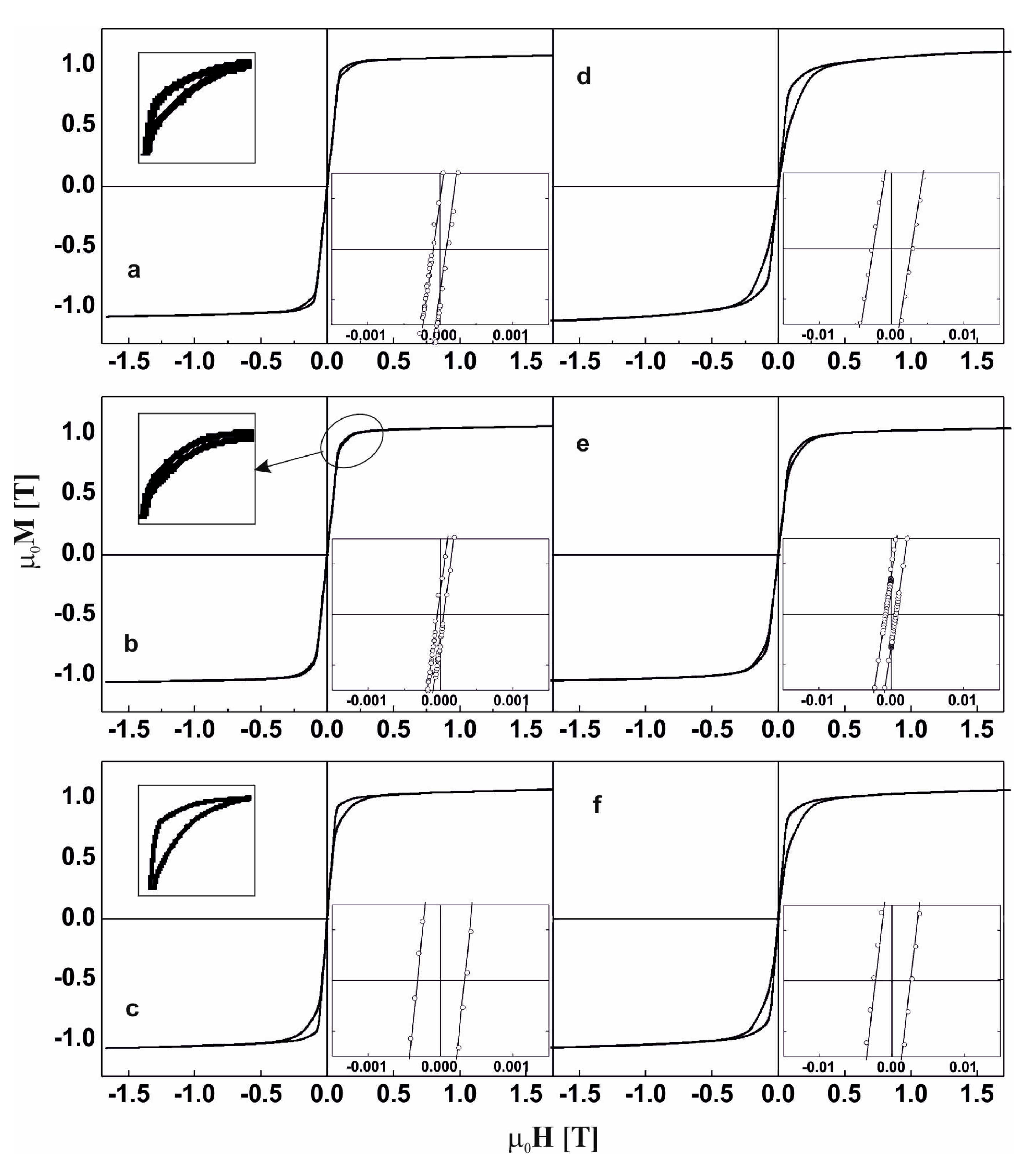

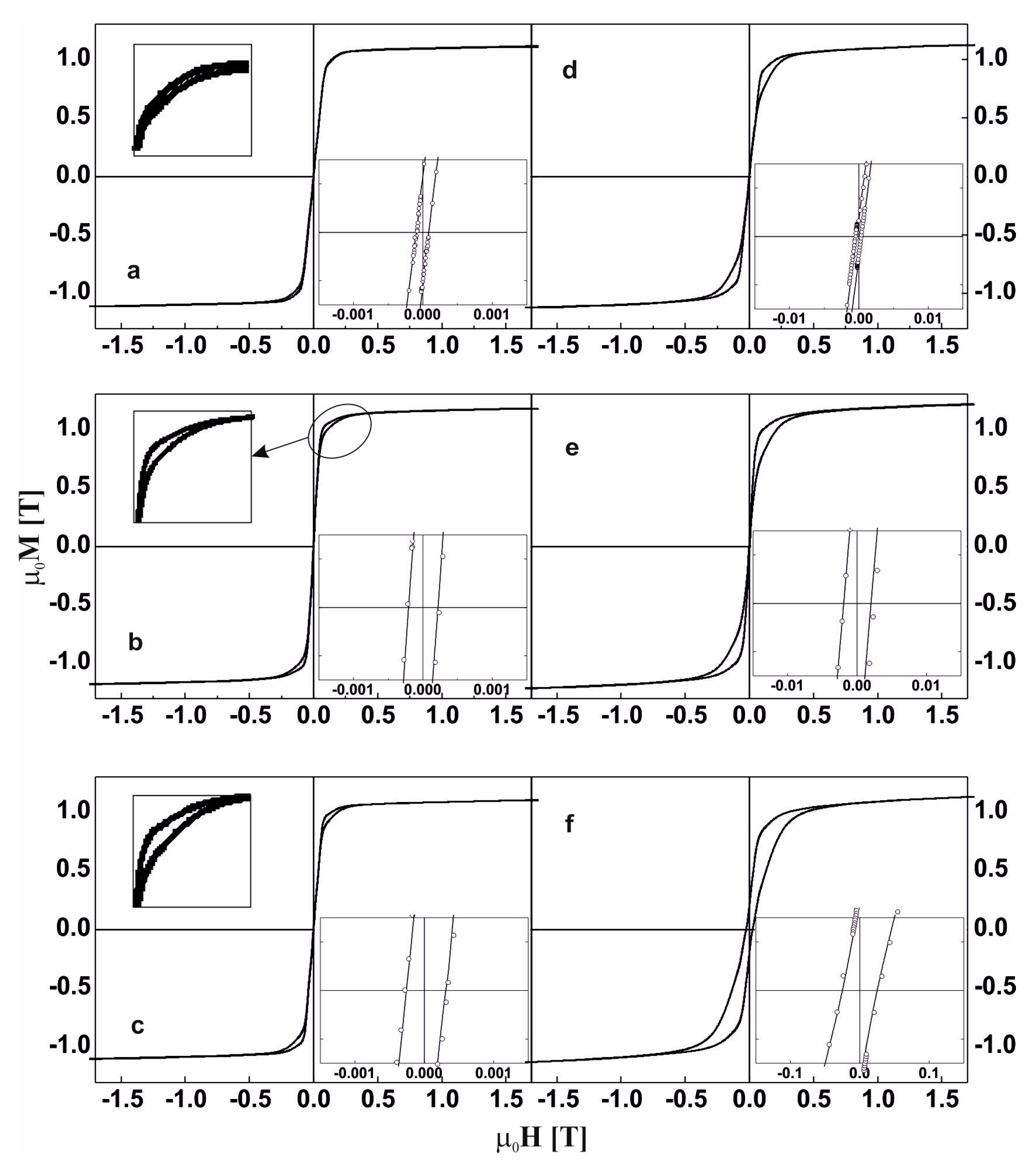

- Based on the obtained magnetic test results—i.e., the thermomagnetic curves and static hysteresis loops—it was found that the tested alloys were magnetically heterogeneous materials.

- The Curie temperature values were found to be slightly higher for the suction-cast alloys, which could be related to the different degrees of disorder in the structure.

- The magnetic properties of the investigated alloys in the as-cast state were found to be similar, regardless of the chosen production method.

- The low value of coercivity for the injection-cast Fe62Co9W1Y8B20 alloy is related to the presence of grains of the Fe5Y crystalline phase.

- The carefully designed parameters of the production process for the rapidly-quenched alloys have an influence on the obtaining of fine grains of crystalline phases within the amorphous matrix during the solidification process.

- An increase in the Fe content, at the expense of the Co content, resulted in a decrease in the Curie temperature.

- The size of the crystalline grains was found to exert a strong influence on the value of the coercive field in terms of an increase in the crystallite size hindering the magnetization process, which was visible from the high coercivity value for the suction-cast Fe63Co8W1Y8B20 alloy. Despite the presence of the Y2Fe14B phase in the volume of the injection-cast Fe62Co9W1Y8B20 alloy, a low coercivity was achieved after annealing. This is connected with the relatively small crystallitesize of this phase and the presence of the Fe23B6 soft magnetic phase.

Author Contributions

Funding

Conflicts of Interest

References

- Geng, Y.; Zhang, Z.; Wang, Z.; Wang, Y.; Qiang, J.; Dong, C.; Wang, H.; Tegus, O. Magnetic properties and a structure model for high Fe-content Fe–B–Si–Zr bulk glassy alloys. J. Non Cryst. Solids 2016, 450, 1–5. [Google Scholar] [CrossRef]

- Jaafari, Z.; Seifoddini, A.; Hasani, S. Enhanced Mechanical and Magnetic Properties of [(Fe0.9Ni0.1)77Mo5P9C7.5B1.5]99.9Cu0.1 Bulk Metallic Glass by Partial Annealing. Metall. Mater. Trans. A 2019, 50, 2875–2885. [Google Scholar] [CrossRef]

- Han, Y.; Ding, J.; Kong, F.L.; Inoue, A.; Zhu, S.L.; Wang, Z.; Shalaan, E.; Al-Marzouki, F. FeCo-based soft magnetic alloys with high Bs approaching 1.75 T and good bending ductility. J. Alloy Compd. 2017, 691, 364–368. [Google Scholar] [CrossRef]

- Han, Y.; Inoue, A.; Kong, F.L.; Chang, C.T.; Shu, S.L.; Shalaan, E.; Al-Marzouki, F. Softening and good ductility for nanocrystal-dispersed amorphous FeCoB alloys with high saturation magnetization above 1.7 T. J. Alloy Compd. 2016, 657, 237–245. [Google Scholar] [CrossRef]

- Wang, J.; Liu, Z.W.; Zheng, Z.G.; Yu, H.Y.; Tang, G.P.; Zeng, D.C. Effect of rare earth additions on microstructure, thermal stability and crystallization behavior of melt spun Fe80.65Cu1.35Si2B14RE2 (RE = Y, Gd, Tb and Dy) soft magnetic alloys. Mater. Lett. 2015, 159, 76–79. [Google Scholar] [CrossRef]

- Ackland, K.; Masood, A.; Kulkarni, S.; Stamenov, P. Ultrasoftmagnetic Co-Fe-B-Si-Nb amorphous alloys for high frequency power applications. AIP Adv. 2018, 8, 056129. [Google Scholar] [CrossRef]

- Inoue, A. Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater. 2000, 48, 279–306. [Google Scholar] [CrossRef]

- McHenry, M.E.; Willard, M.A.; Laughlin, D.E. Amorphous and nanocrystalline materials for applications as soft magnets. Prog. Mater. Sci. 1999, 44, 291–433. [Google Scholar] [CrossRef]

- Li, X.; Wang, Z.; Duan, H. The effect of the minor Al addition on microstructure and soft magnetic properties for (Fe0.5Co0.5)73.5Si13.5Nb3Cu1B9 nanocrystalline alloy. J. NonCryst. Solids 2019, 517, 114–118. [Google Scholar] [CrossRef]

- Nabialek, M.; Jez, B.; Jez, K. The influence of the method of producing massive amorphous materials on the defects of the structure in the alloy Fe61+xCo10-xY8W1B20 where x = 0 or 1. Rev. Chim. 2018, 69, 2545–2549. [Google Scholar] [CrossRef]

- Błoch, K.; Nabiałek, M. Approach to Ferromagnetic Saturation for the Bulk Amorphous Alloy: (Fe0:61Co0:10Zr0:025Hf0:025Ti0:02W0:02B0:20)97Y3. Acta Phys. Pol. A 2015, 127, 413–414. [Google Scholar] [CrossRef]

- Klement, W.; Willens, R.H.; Duwez, P. Non-crystalline structure in solidified Gold-Silicon alloys. Nature 1960, 187, 869–870. [Google Scholar] [CrossRef]

- Duwez, P.; Willens, R.H.; Crewdson, R.C. Amorphous phase in palladium—Silicon alloys. J. Appl. Phys. 1965, 36, 2267–2269. [Google Scholar] [CrossRef]

- Chen, H.S. Thermodynamic considerations on the formation and stability of metallic glasses. Acta Metall. 1974, 22, 1505–1511. [Google Scholar] [CrossRef]

- Wang, A.; Zhao, C.; Men, H.; He, A.; Chang, C.; Wang, X.; Li, R. Fe-based amorphous alloys for wide ribbon production with high Bs and outstanding amorphous forming ability. J. Alloy Compd. 2015, 630, 209–213. [Google Scholar] [CrossRef]

- Han, Y.; Chang, C.T.; Zhu, S.L.; Inoue, A.; Louzguine-Luzgin, D.V.; Shalaan, E.; Al-Marzouki, F. Fe-based soft magnetic amorphous alloys with high saturation magnetization above 1.5 T and high corrosion resistance. Intermetallics 2014, 54, 169–175. [Google Scholar] [CrossRef]

- Li, J.; Liu, X.; Zhao, S.; Ding, H.; Yao, K. Fe-based bulk amorphous alloys with iron contents as high as 82 at%. J. Magn. Magn. Mater. 2015, 386, 107–110. [Google Scholar] [CrossRef]

- Li, W.; Yang, Y.Z.; Xu, J. Crystallization and soft magnetic properties of metalloid-free Fe89Hf7Al3Zr1 amorphous alloy. J. Non Cryst. Solids 2017, 461, 93–97. [Google Scholar] [CrossRef]

- Trexler, M.M.; Thadhani, N.N. Mechanical properties of bulk metallic glasses. Prog. Mater. Sci. 2010, 55, 759–839. [Google Scholar] [CrossRef]

- Ishida, M.; Takeda, H.; Watanabe, D.; Amiya, K.; Nishiyama, N.; Kita, K.; Saotome, Y.; Inoue, A. Fillability and Imprintability of High-strength Ni-based Bulk Metallic Glass Prepared by the Precision Die-casting Technique. Mater. Trans. 2004, 45, 1239–1244. [Google Scholar] [CrossRef][Green Version]

- Narayan, R.L.; Singh, P.S.; Hofmann, D.C.; Hutchinson, N.; Flores, K.M.; Ramamurty, U. On the microstructure–tensile property correlations in bulk metallic glass matrix composites with crystalline dendrites. Acta Mater. 2012, 60, 5089–5100. [Google Scholar] [CrossRef]

- Si, J.; Mei, J.; Wang, R.; Chen, X.; Hui, X. Fe-B-Si-Zr bulk metallic glasses with ultra high compressive strength and excellent soft magnetic properties. Mater. Lett. 2016, 181, 282–284. [Google Scholar] [CrossRef]

- Pietrusiewicz, P. Magnetic Properties of the Rapidly Solidified Bulk Alloy: Fe61Co10B20Y8xWyPtx (where: x = 1; 2; y = 0; 1). Acta Phys. Pol. A 2018, 133, 666–668. [Google Scholar] [CrossRef]

- Liu, T.; Li, F.; Wang, A.; Xie, L.; He, Q.; Luan, J.; He, A.; Wang, X.; Liu, C.T.; Yang, Y. High performance Fe-based nanocrystalline alloys with excellent thermal stability. J. Alloy Compd. 2019, 776, 606–613. [Google Scholar] [CrossRef]

- Jung, H.Y.; Yi, S. Nanocrystallization and soft magnetic properties of Fe23M6 (M:C or B) phase in Fe-based bulk metallic glass. Intermetallics 2014, 49, 18–22. [Google Scholar] [CrossRef]

- Elmanov, G.N.; Chernavskii, P.A.; Kozlov, I.V.; Dzhumaev, P.S.; Kostitsyna, E.V.; Tarasov, V.P.; Ignatov, A.S.; Gudoshnikov, S.A. Effect of heat treatment on phase transformations and magnetization of amorphous Co69Fe4Cr4Si12B11 microwires. J. Alloy Compd. 2018, 741, 648–655. [Google Scholar] [CrossRef]

- Xia, G.T.; Wang, Y.G.; Dai, J.; Dai, Y.D. Effects of Cu cluster evolution on soft magnetic properties of Fe83B10C6Cu1 metallic glass in two-step annealing. J. Alloy Compd. 2017, 690, 281–286. [Google Scholar] [CrossRef]

- Wang, W.H. Roles of minor additions in formation and properties of bulk metallic glasses. Prog. Mater. Sci. 2007, 52, 540–596. [Google Scholar] [CrossRef]

- Nabiałek, M. Soft magnetic and microstructural investigation in Fe-based amorphous alloy. J. Alloy Compd. 2015, 642, 98–103. [Google Scholar] [CrossRef]

- Chen, H.S.; Turnbull, D. Formation, stability and structure of palladium-silicon based alloy glasses. Acta Metall. 1969, 17, 1021–1031. [Google Scholar] [CrossRef]

- Pietrusiewicz, P.; Nabiałek, M. Analysis of the Thermal and Magnetic Properties of Amorphous Ribbons of Fe61Co10B20Y8Me1 (where Me = W, Zr, Nb, Mo). Acta Phys. Pol. A 2017, 131, 678–680. [Google Scholar] [CrossRef]

- Oesterreicher, H.; Abache, C. Fe//1//4R//2B type compounds for magnetic recording applications. J. Phys. Colloq. 1985, 46, 45–48. [Google Scholar] [CrossRef]

- Zhai, X.B.; Wang, Y.G.; Zhu, L.; Cao, C.C.; Dai, Y.D.; Chen, J.K.; Pan, F.M. Effect of heating rate on atom migration, phase structure and magnetic properties of the Fe82Si2B11P4Cu1 alloy. J. Non Cryst. Solids 2018, 499, 337–343. [Google Scholar] [CrossRef]

- Gondro, J.; Błoch, K.; Nabiałek, M.; Walters, K.; Szota, M. Microstructure And Magnetic Properties Of The FeZr (Y) NbCuB Amorphous Alloys. Arch. Metall. Mater. 2015, 60, 1071–1074. [Google Scholar] [CrossRef]

- Nabiałek, M.; Jeż, B.; Błoch, K.; Pietrusiewicz, P.; Gondro, J. The effect of the cobalt-content on the magnetic properties of iron-based amorphous alloys. J. Magn. Magn. Mater. 2019, 477, 214–219. [Google Scholar] [CrossRef]

- Nabiałek, M.; Jeż, K. Approach to the ferromagnetic saturation of the Fe39Co33Y8B20 alloy produced using two methods. Eur. J. Mater. Sci. Eng. 2019, 4, 23–28. [Google Scholar] [CrossRef]

- Imafuku, M.; Sato, S.; Koshiba, H.; Matsubara, E.; Inoue, A. Structural study of Fe-Based glassy alloys with a large super cooled liquid region. Mater. Res. Soc. Symp. Proc. 2001, 644, L1.6.1–L1.6.10. [Google Scholar]

- Martinez-Garcia, J.C.; Garcia, J.C.; Rivas, M. Asymmetric magnetization reversal of partially devitrified Co66Si15B14Fe4Ni1. J. Non Cryst. Solids 2008, 354, 5123–5125. [Google Scholar] [CrossRef]

- Bennet, L.H.; Torre, E.D. Analysis of wasp-waist hysteresis loops. J. Appl. Phys. 2005, 97, 10E502. [Google Scholar] [CrossRef]

- Kulik, T. Soft Magnetic Nanocrystalline Materials Obtained by Crystallization of Metallic Glasses; Warsaw University of Technology Publishing House: Warsaw, Poland, 1998. (In Polish) [Google Scholar]

- Gruszka, K. Properties of Bulk Nanocrystalline Materials Obtained in One-Stage Manufacturing Process and after Isothermal Heating. Ph.D. Thesis, Czestochowa University of Technology, Częstochowa, Poland, 2013. (In Polish). [Google Scholar]

- Nabiałek, M.; Dospiał, M.; Szota, M. Study of the mechanical and magnetic properties of Fe61Co10Zr5-xHfxW2Y2B20 (x = 0 or 3) bulk amorphous and crystalline alloys. Phys. Status Solidi C 2010, 7, 1428–1431. [Google Scholar] [CrossRef]

| Method | Alloy | Average Crystallite Size (nm) | |||

|---|---|---|---|---|---|

| Fe5Y | αFe | Y2Fe14B | Fe23B6 | ||

| Injection | Fe61Co10Y8W1B20 | 15.0 | 19.0 | - | - |

| Fe62Co9Y8W1B20 | 24.2 | 22.5 | 17.0 | 14.0 | |

| ASQ Fe62Co9Y8W1B20 | 8 | 8 | - | - | |

| Fe63Co8Y8W1B20 | 27.3 | 26.5 | - | - | |

| Suction | Fe61Co10Y8W1B20 | 12.0 | 15.0 | - | - |

| Fe62Co9Y8W1B20 | 26.7 | 15.4 | - | - | |

| Fe63Co8Y8W1B20 | 26.8 | 25.6 | 24.8 | - | |

| Method | Injection Casting | Suction Casting | |||||

|---|---|---|---|---|---|---|---|

| Curie Temperature [K] | |||||||

| Alloy | ASQ [35] | 940 K | ASQ [35] | 940 K | |||

| Y2Fe14B | Fe23B6 | amorp. | Y2Fe14B | amorp. | |||

| Fe61Co10Y8W1B20 | 561 | - | - | 595 | 568 | - | 597 |

| Fe62Co9Y8W1B20 | 549 | 580 | 655 | 726 | 557 | - | 600 |

| Fe63Co8Y8W1B20 | 541 | - | - | 570 | 545 | 595 | 710 |

| Method | Alloy | Saturation Magnetic Polarization (T) | Saturation Magnetic Polarization for 0.7 T (T) | Coercive Field (A/m) | |||

|---|---|---|---|---|---|---|---|

| ASQ [35] | 940 K | ASQ [35] | 940 K | ASQ [35] | 940 K | ||

| Injection-casting | Fe61Co10Y8W1B20 | 1.11 | 1.11 | 1.10 | 1.09 | 71 | 2148 |

| Fe62Co9Y8W1B20 | 1.09 | 1.04 | 1.08 | 1.04 | 33 | 495 | |

| Fe63Co8Y8W1B20 | 1.10 | 1.06 | 1.09 | 1.04 | 241 | 1987 | |

| Suction-casting | Fe61Co10Y8W1B20 | 1.14 | 1.12 | 1.13 | 1.12 | 61 | 293 |

| Fe62Co9Y8W1B20 | 1.21 | 1.22 | 1.20 | 1.20 | 159 | 1565 | |

| Fe63Co8Y8W1B20 | 1.13 | 1.13 | 1.12 | 1.11 | 223 | 19820 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vizureanu, P.; Nabiałek, M.; Sandu, A.V.; Jeż, B. Investigation into the Effect of Thermal Treatment on the Obtaining of Magnetic Phases: Fe5Y, Fe23B6, Y2Fe14B and αFe within the Amorphous Matrix of Rapidly-Quenched Fe61+xCo10−xW1Y8B20 Alloys (Where x = 0, 1 or 2). Materials 2020, 13, 835. https://doi.org/10.3390/ma13040835

Vizureanu P, Nabiałek M, Sandu AV, Jeż B. Investigation into the Effect of Thermal Treatment on the Obtaining of Magnetic Phases: Fe5Y, Fe23B6, Y2Fe14B and αFe within the Amorphous Matrix of Rapidly-Quenched Fe61+xCo10−xW1Y8B20 Alloys (Where x = 0, 1 or 2). Materials. 2020; 13(4):835. https://doi.org/10.3390/ma13040835

Chicago/Turabian StyleVizureanu, Petrica, Marcin Nabiałek, Andrei Victor Sandu, and Bartłomiej Jeż. 2020. "Investigation into the Effect of Thermal Treatment on the Obtaining of Magnetic Phases: Fe5Y, Fe23B6, Y2Fe14B and αFe within the Amorphous Matrix of Rapidly-Quenched Fe61+xCo10−xW1Y8B20 Alloys (Where x = 0, 1 or 2)" Materials 13, no. 4: 835. https://doi.org/10.3390/ma13040835

APA StyleVizureanu, P., Nabiałek, M., Sandu, A. V., & Jeż, B. (2020). Investigation into the Effect of Thermal Treatment on the Obtaining of Magnetic Phases: Fe5Y, Fe23B6, Y2Fe14B and αFe within the Amorphous Matrix of Rapidly-Quenched Fe61+xCo10−xW1Y8B20 Alloys (Where x = 0, 1 or 2). Materials, 13(4), 835. https://doi.org/10.3390/ma13040835