Effect of Environmental Exposure on the Pore Structure and Transport Properties of Carbon Nanotube-Modified Mortars

Abstract

1. Introduction

2. Materials and Methods

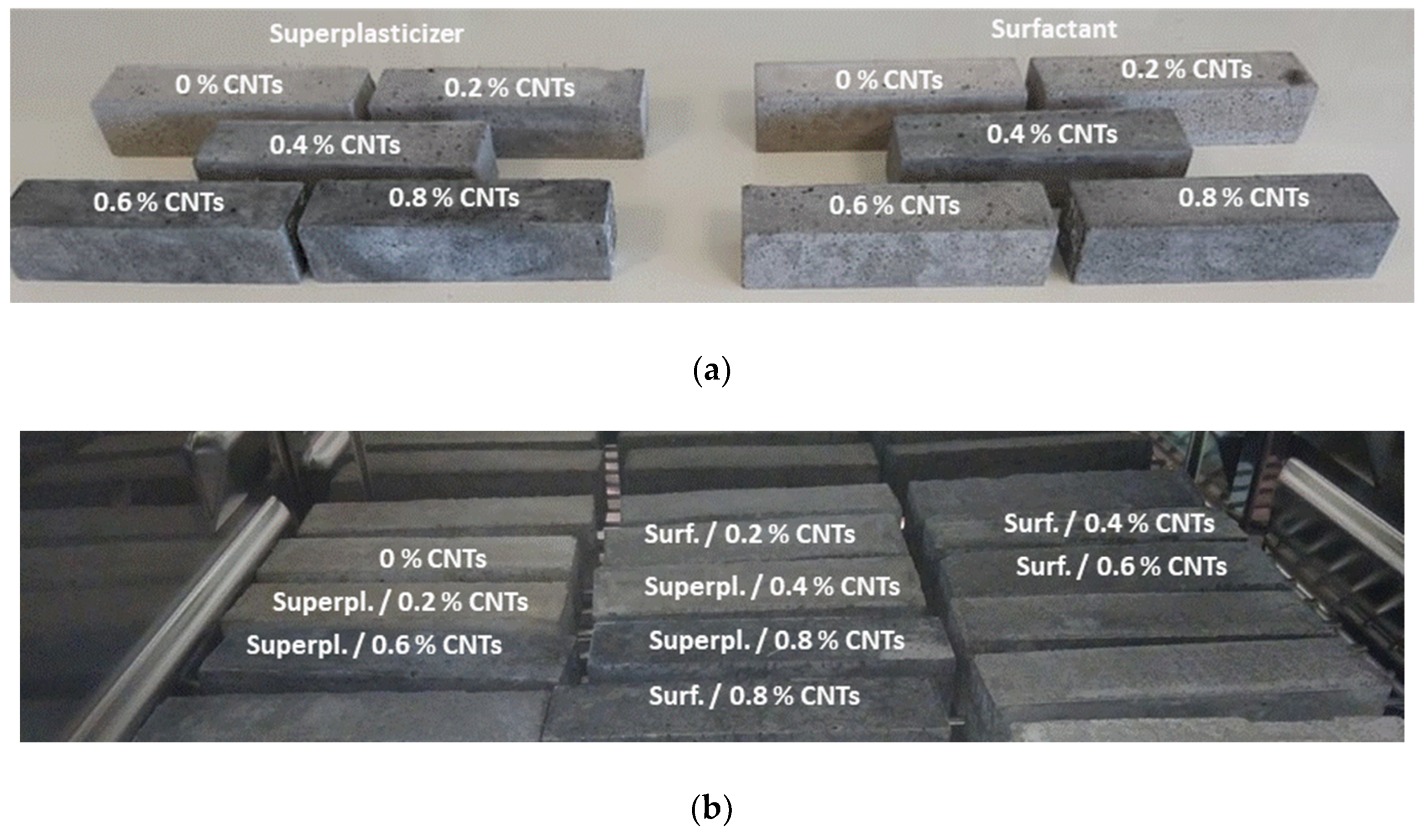

2.1. Materials and Specimen’s Preparation

2.2. Environmental Exposure and Characterization

3. Results

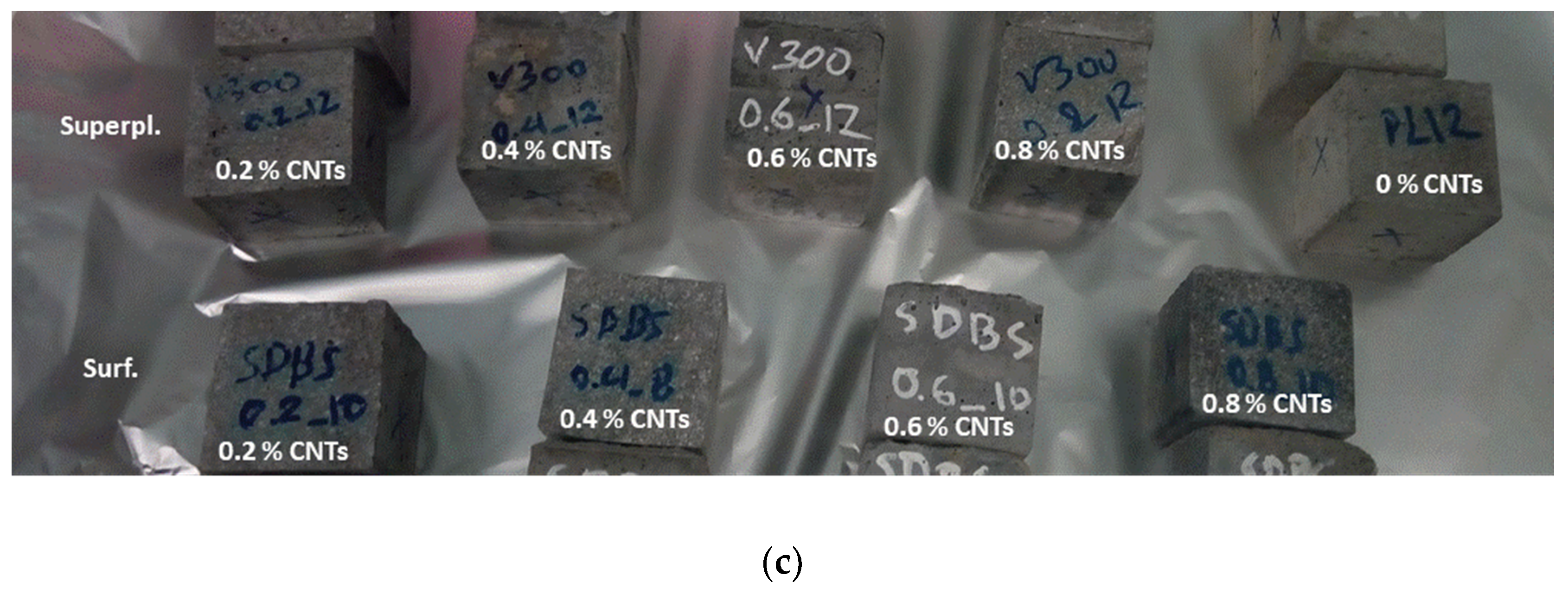

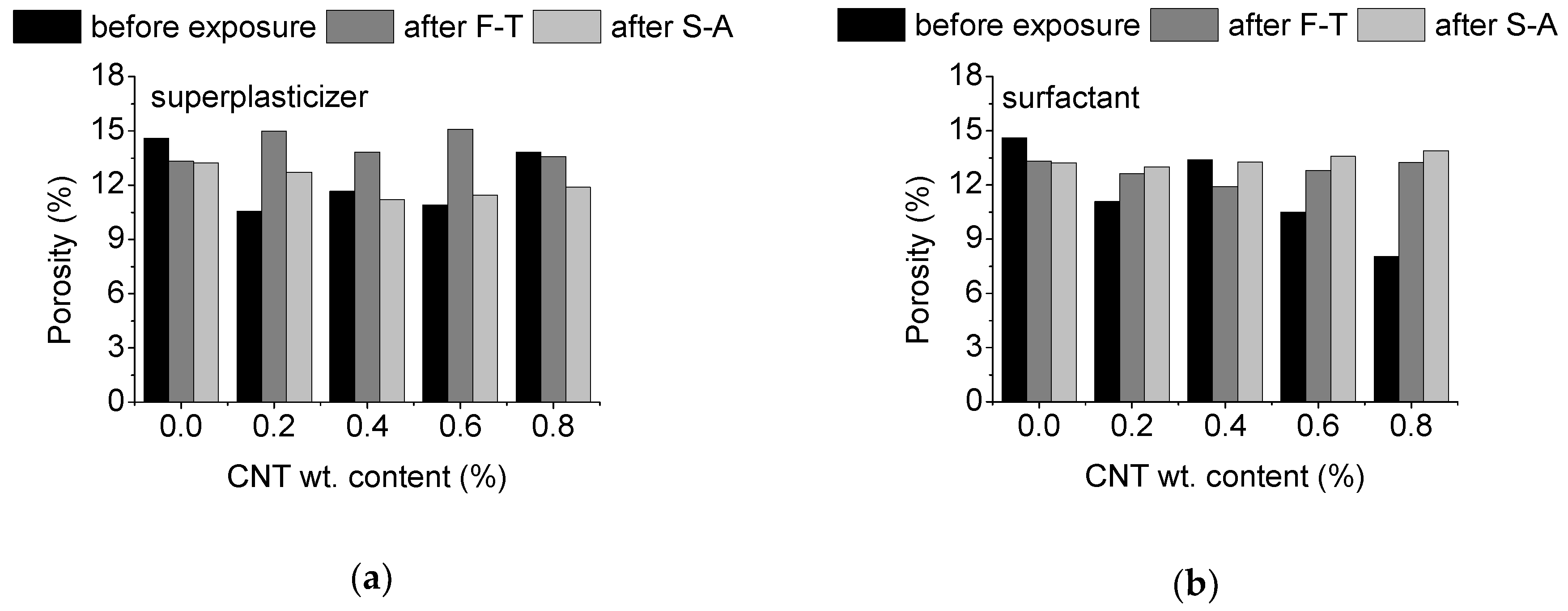

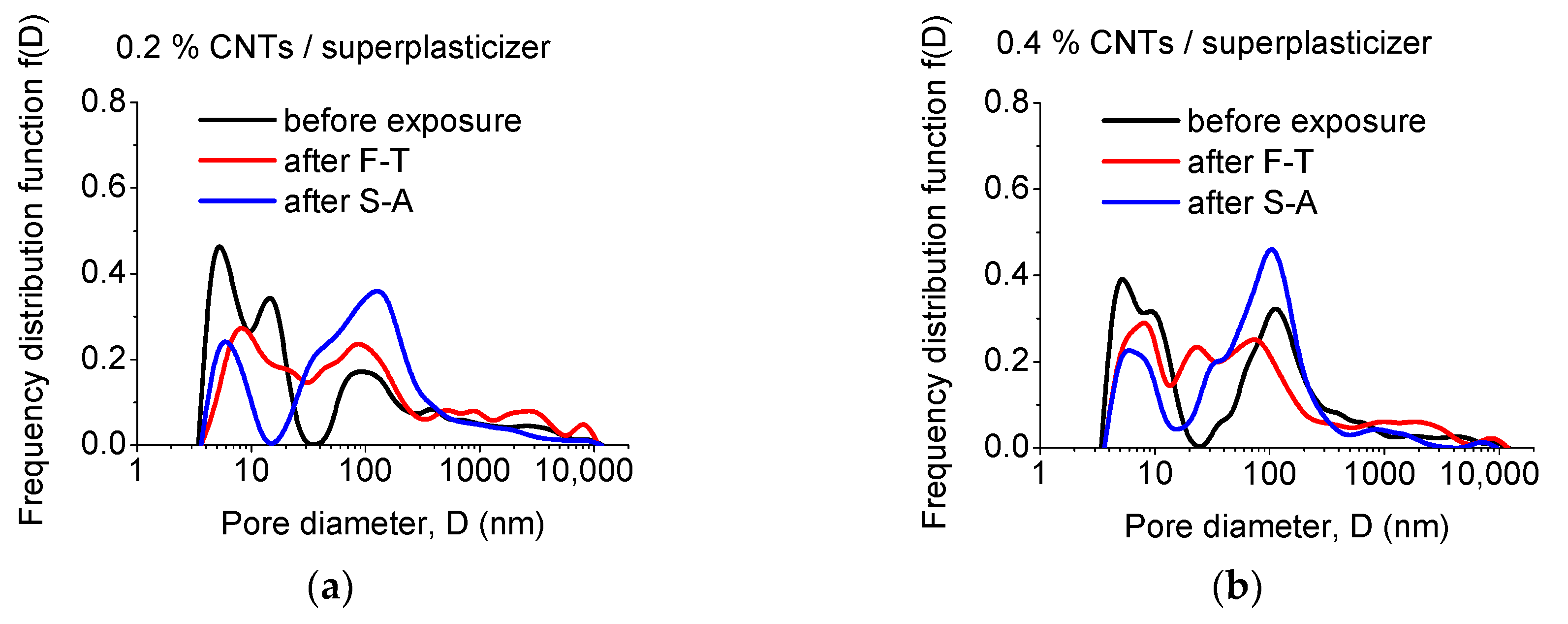

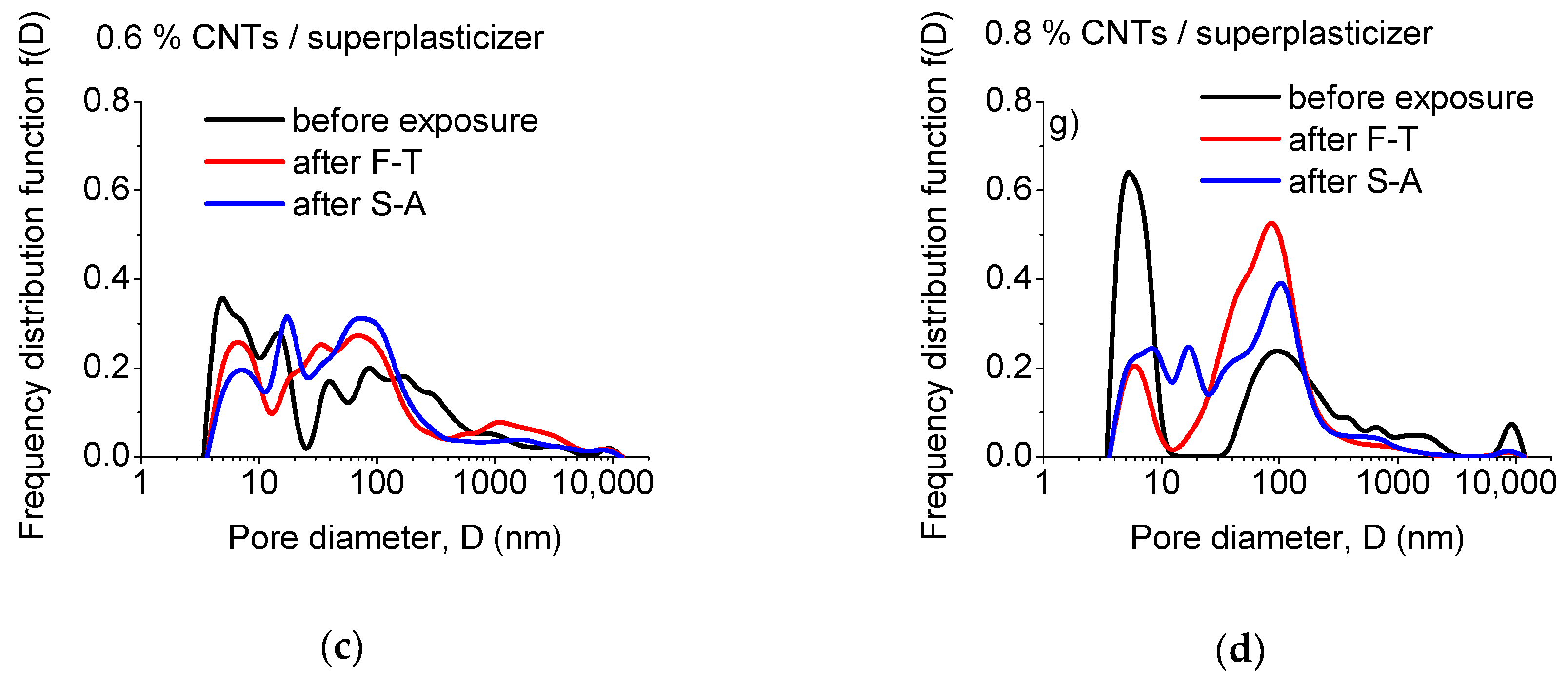

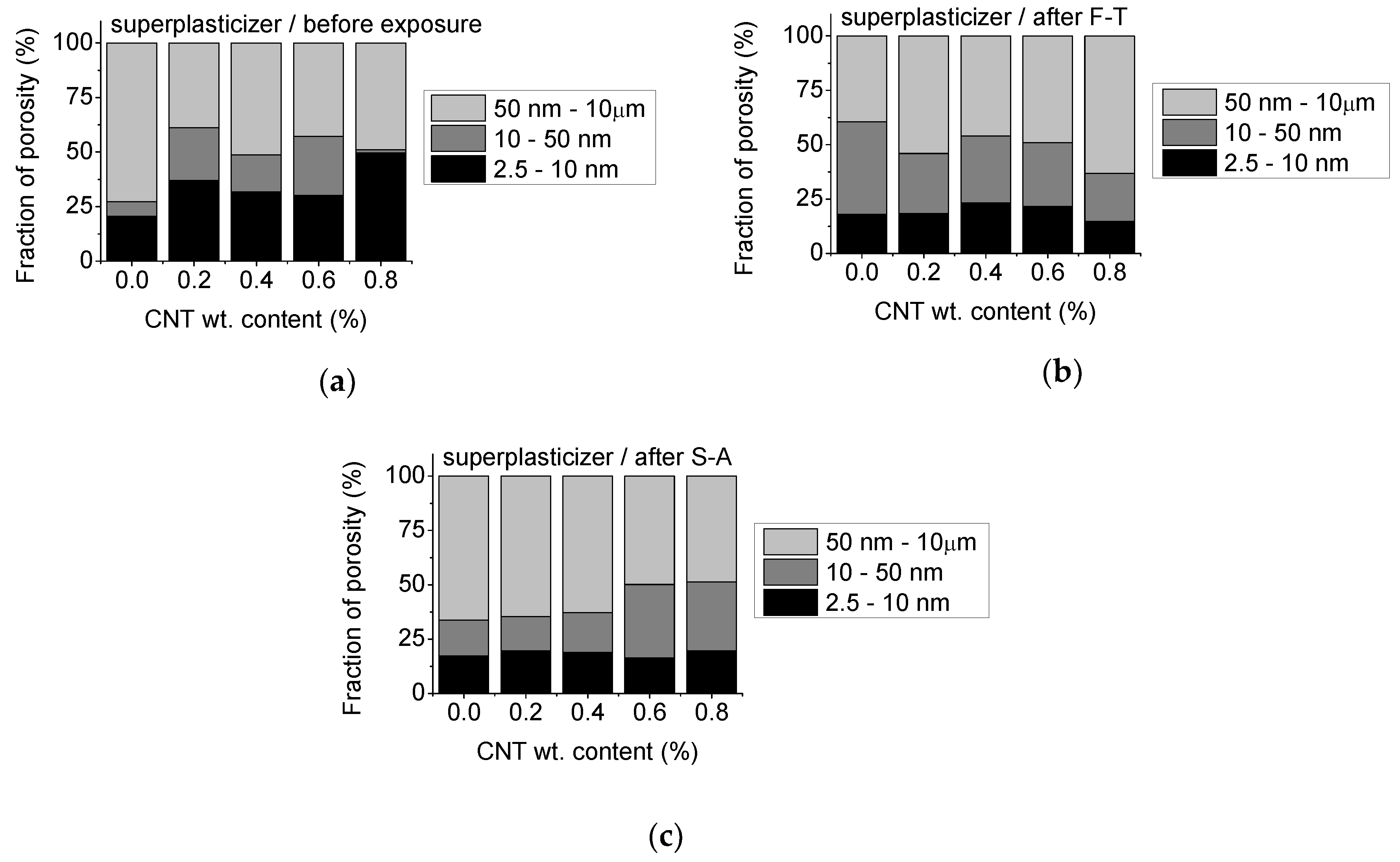

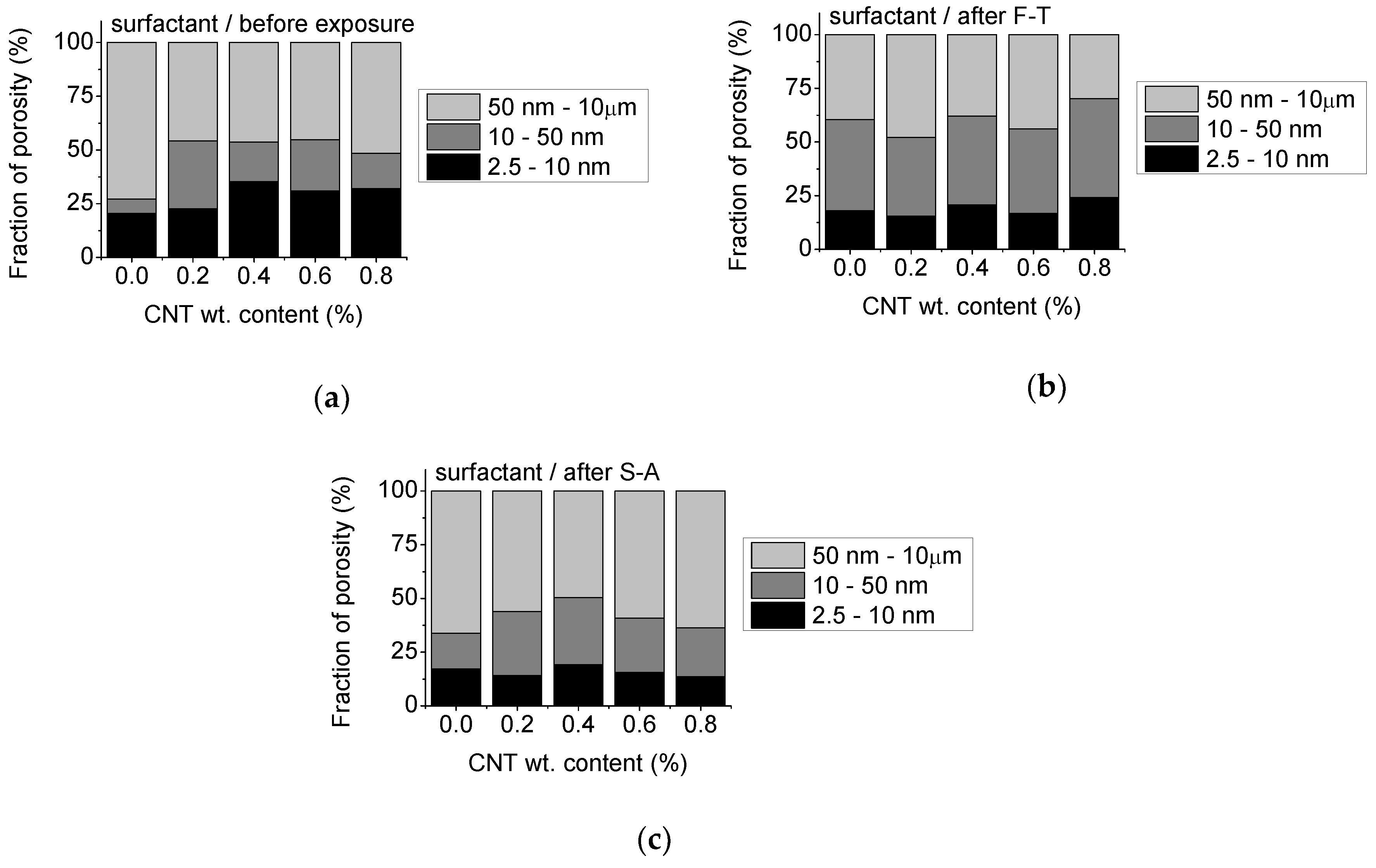

3.1. Pore Structure

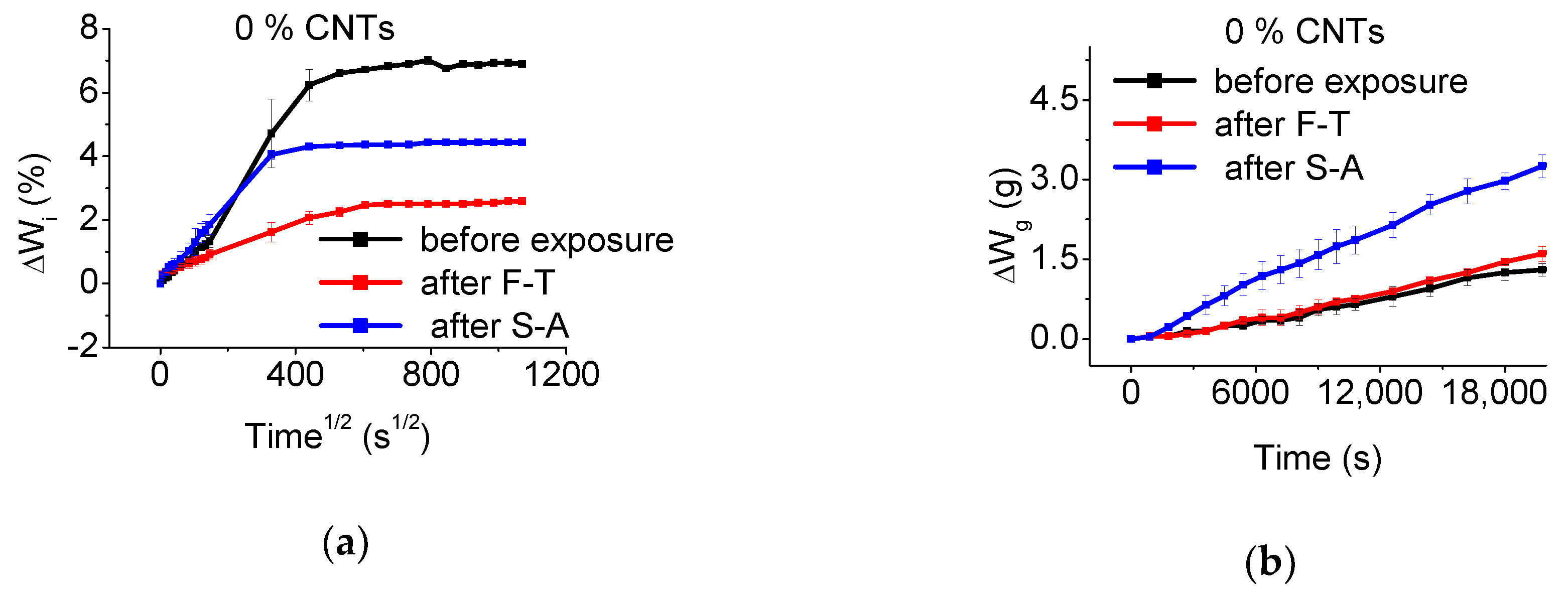

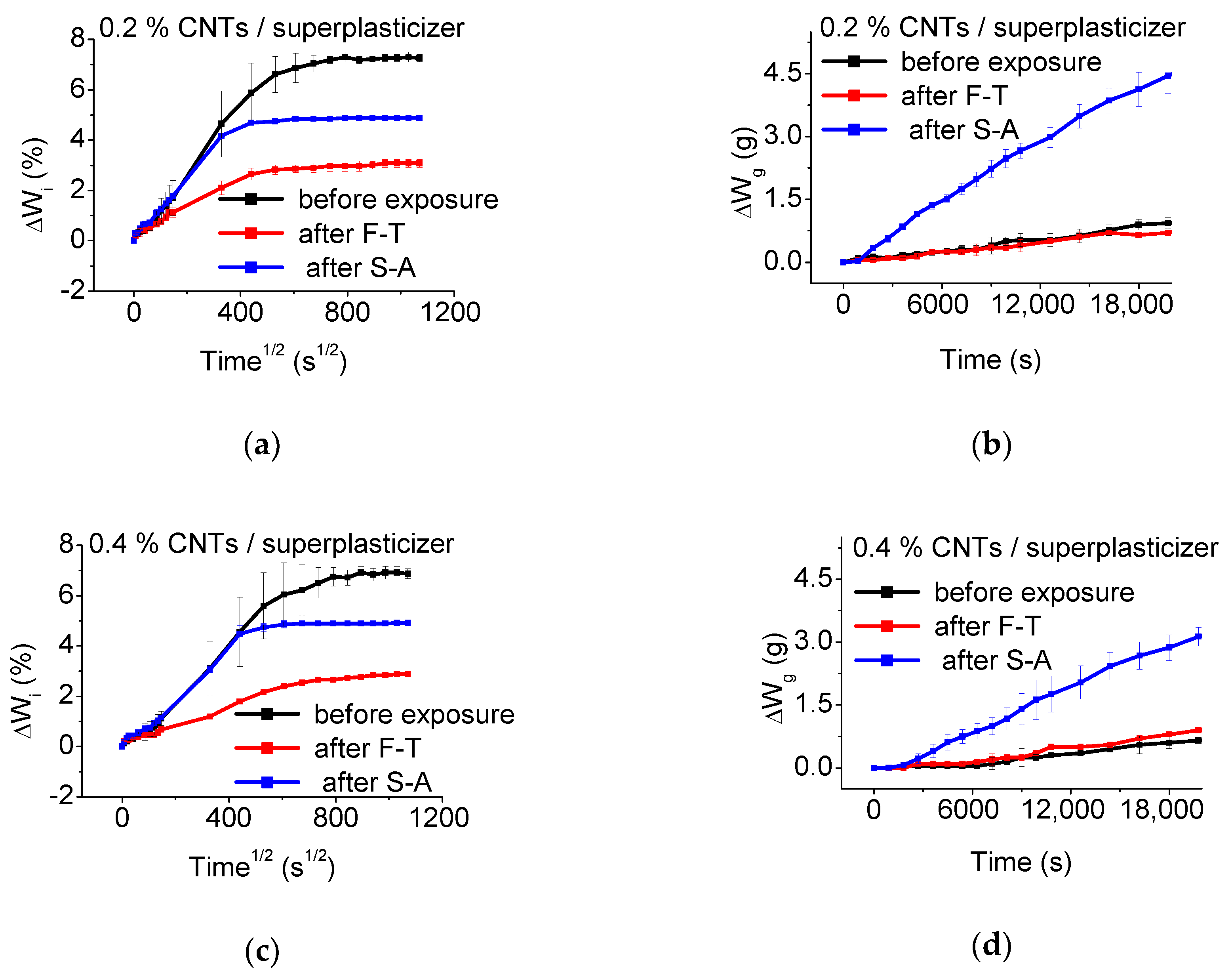

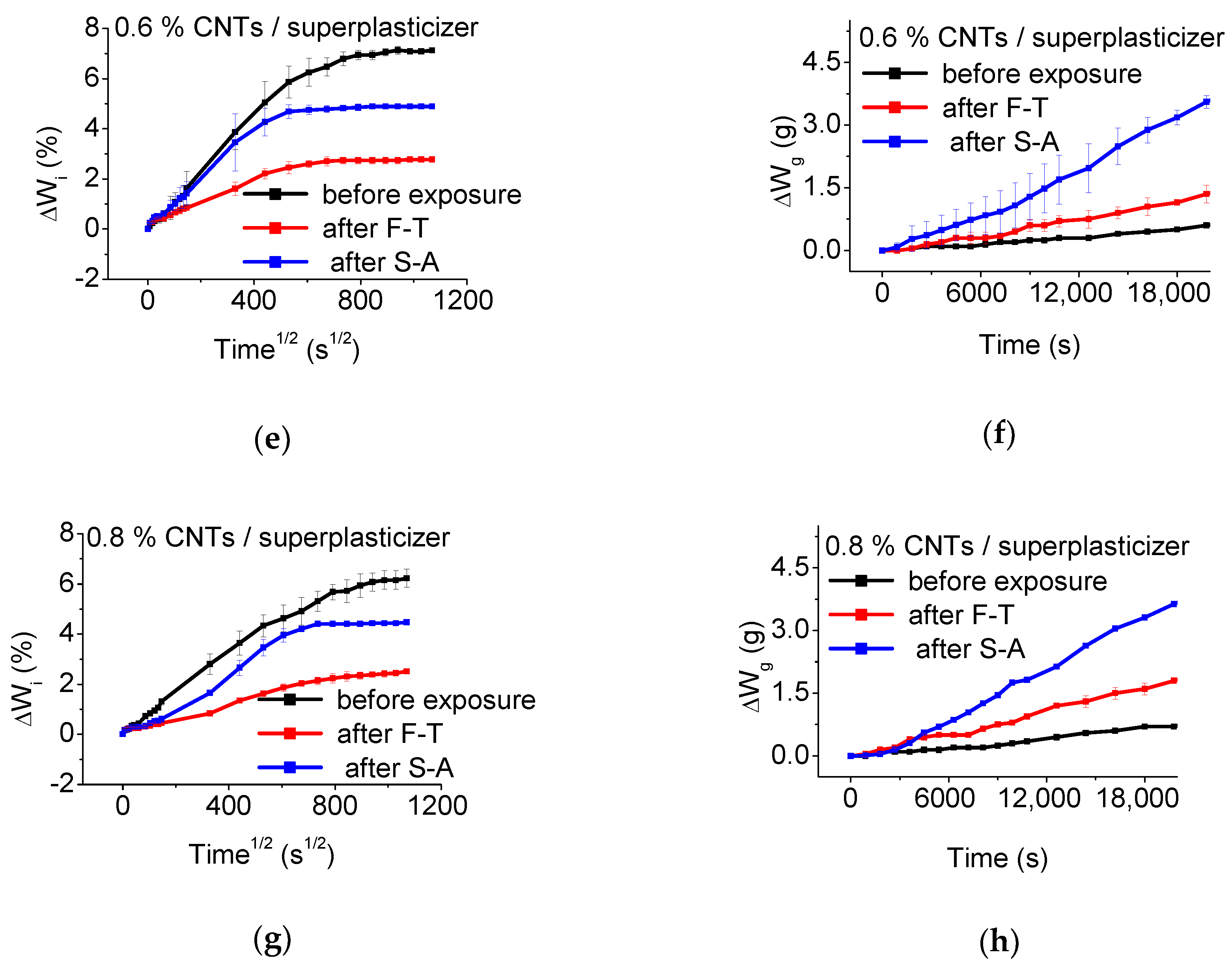

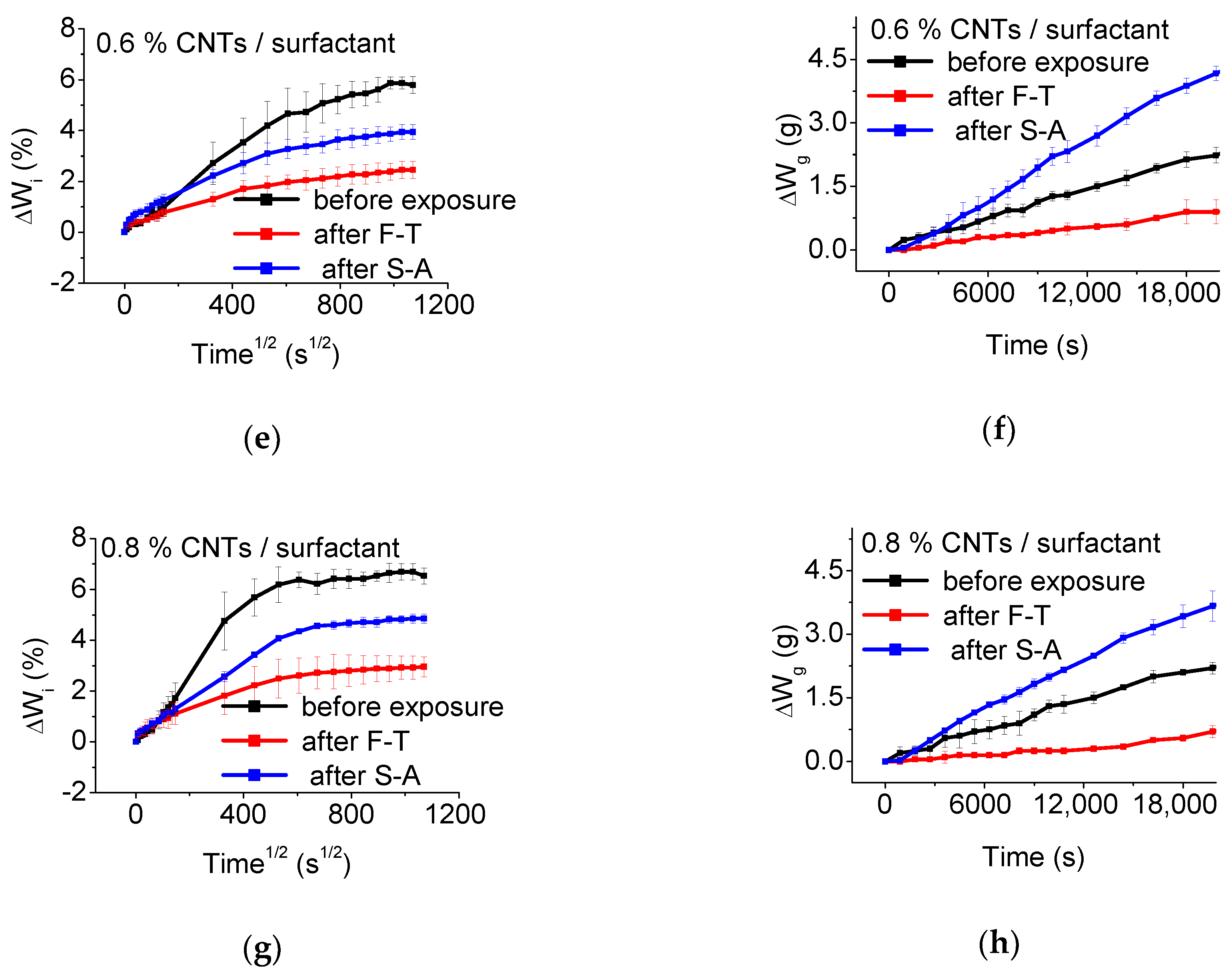

3.2. Transport Properties

4. Discussion

5. Conclusions

- CNT inclusion results in a considerable drop of the total porosity and a respective enhancement of the amount of the gel and medium-sized pores in the un-exposed state.

- F-T and S-A lead to a slight reduction of the fraction of gel pores and an enhancement of medium sized ones before nano-modification.

- Nano-modified specimens present a substantial decrease of the fraction of gel pores after F-T and S-A exposure. Large-sized capillaries dominate over medium-sized ones when superplasticizer is used as dispersant. Surfactant-based mortars follow this trend after S-A, while after F-T, medium-sized capillaries dominate.

- Water absorption is reduced in both un-modified and nano-modified mortars after F-T and S-A. Nano-modification is beneficial for the diffusion coefficient however the total amount of absorbed water is overall slightly higher in CNT-containing specimens both in the un-exposed and the exposed state. The only exception is observed in surfactant-based specimens after S-A.

- Gas permeability is worsened after F-T and S-A in un-modified and CNT-modified specimens with superplasticizer. Surfactant-based specimens show an improvement after F-T with very low gas flow rate values compared to the un-exposed state.

- Transport properties cannot be directly connected with the microstructural properties expressed by the porosity of the prepared specimens. Both the presence of nano-fillers and the nature of the dispersant influence the resultant properties.

Author Contributions

Funding

Conflicts of Interest

References

- Basheer, L.; Kropp, J.; Cleland, D.J. Assessment of the durability of concrete from its permeation properties: A review. Constr. Build. Mater. 2001, 15, 93–103. [Google Scholar] [CrossRef]

- He, B.; Xie, M.; Jiang, Z.; Zhang, C.; Zhu, X. Temperature field distribution and microstructure of cement-based materials under cryogenic freeze-thaw cycles. Constr. Build. Mater. 2020, 243, 118256. [Google Scholar] [CrossRef]

- Grubeša, I.N.; Markovic, B.; Vracevic, M.; Tunkiewicz, M.; Szenti, I.; Kukovecz, A. Pore structure as a response to the freeze/thaw resistance of mortars. Materials 2019, 12, 3196. [Google Scholar] [CrossRef] [PubMed]

- Mao, M.; Zhang, D.; Yang, Q.; Zhang, W. Study of Durability of Concrete with Fly Ash as Fine Aggregate under Alternative Interactions of Freeze-Thaw and Carbonation. Adv. Civ. Eng. 2019, 2019, 4693893. [Google Scholar] [CrossRef]

- Ebrahimi, K.; Daiezadeh, M.J.; Zakertabrizi, M.; Zahmatkesh, F.; Habibnejad Korayem, A. A review of the impact of micro- and nanoparticles on freeze-thaw durability of hardened concrete: Mechanism perspective. Constr. Build. Mater. 2018, 186, 1105–1113. [Google Scholar] [CrossRef]

- Huang, Q.; Zhu, X.; Zhao, L.; Zhao, M.; Liu, Y.; Zeng, X. Effect of nanosilica on sulfate resistance of cement mortar under partial immersion. Constr. Build. Mater. 2020, 231, 117180. [Google Scholar] [CrossRef]

- Cheng, S.; Shui, Z.; Gao, X.; Yu, R.; Sun, T.; Guo, C.; Huang, Y. Degradation mechanisms of Portland cement mortar under seawater attack and drying-wetting cycles. Constr. Build. Mater. 2020, 230, 116934. [Google Scholar] [CrossRef]

- Qudoos, A.; Kim, H.G.; Ryou, J.-S. Influence of titanium dioxide nanoparticles on the sulfate attack upon ordinary Portland cement and slag-blended mortars. Materials 2018, 11, 356. [Google Scholar]

- Brown, L.; Sanchez, F. Influence of carbon nanofiber clustering in cement pastes exposed to sulfate attack. Constr. Build. Mater. 2018, 166, 181–187. [Google Scholar] [CrossRef]

- Zhang, P.; Wittmann, F.H.; Vogel, M.; Müller, H.S.; Zhao, T. Influence of freeze-thaw cycles on capillary absorption and chloride penetration into concrete. Cem. Concr. Res. 2017, 100, 60–67. [Google Scholar] [CrossRef]

- Wieczorek, A.; Koniorczyk, M.; Bednarska, D.; Grabowska, K. The transport properties of cement mortars subjected to freeze-thaw cycles. E3S Web Conf. 2018, 49, 128. [Google Scholar] [CrossRef]

- Jo, B.W.; Sikandar, M.A.; Chakraborty, S.; Baloch, Z. Investigation of the acid and sulfate resistance performances of hydrogen-rich water based mortars. Constr. Build. Mater. 2017, 137, 1–11. [Google Scholar] [CrossRef]

- Han, B.; Wang, Y.; Dong, S.; Zhang, L.; Ding, S.; Yu, X.; Ou, J. Smart concretes and structures: A review. J. Intell. Mater. Syst. Struct. 2015, 26, 1303–1345. [Google Scholar] [CrossRef]

- Han, B.; Sun, S.; Ding, S.; Zhang, L.; Yu, X.; Ou, J. Review of nanocarbon-engineered multifunctional cementitious composites. Compos. Part A Appl. Sci. Manuf. 2015, 70, 69–81. [Google Scholar] [CrossRef]

- Manzur, T.; Yazdani, N.; Emon, M.A.B. Potential of carbon nanotube reinforced cement composites as concrete repair material. J. Nanomater. 2016, 2016, 1421959. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, Y.; Zhao, X.; Hai, R. Mechanical and strain-sensing properties of cement-matrix composite containing nano-sized carbon black. Key Eng. Mater. 2019, 815, 203–209. [Google Scholar] [CrossRef]

- Han, B.; Zhang, L.; Sun, S.; Yu, X.; Dong, X.; Wu, T.; Ou, J. Electrostatic self-assembled carbon nanotube/nano carbon black composite fillers reinforced cement-based materials with multifunctionality. Compos. Part A Appl. Sci. Manuf. 2015, 79, 103–115. [Google Scholar] [CrossRef]

- Parveen, S.; Rana, S.; Fangueiro, R. A review on nanomaterial dispersion, microstructure, and mechanical properties of carbon nanotube and nanofiber reinforced cementitious composites. J. Nanomater. 2013, 2013, 710175. [Google Scholar] [CrossRef]

- Nochaiya, T.; Chaipanich, A. Behavior of multi-walled carbon nanotubes on the porosity and microstructure of cement-based materials. Appl. Surf. Sci. 2011, 257, 1941–1945. [Google Scholar] [CrossRef]

- Ghahari, S.A.; Ghafari, E.; Assi, L. Pore structure of cementitious material enhanced by graphitic nanomaterial: A critical review. Front. Struct. Civ. Eng. 2018, 12, 137–147. [Google Scholar] [CrossRef]

- Guan, X.; Bai, S.; Li, H.; Ou, J. Mechanical properties and microstructure of multi-walled carbon nanotube-reinforced cementitious composites under the early-age freezing conditions. Constr. Build. Mater. 2020, 233, 117317. [Google Scholar] [CrossRef]

- Kaur, R.; Kothiyal, N.C. Positive synergistic effect of superplasticizer stabilized graphene oxide and functionalized carbon nanotubes as a 3-D hybrid reinforcing phase on the mechanical properties and pore structure refinement of cement nanocomposites. Constr. Build. Mater. 2019, 222, 358–370. [Google Scholar] [CrossRef]

- Parveen, S.; Rana, S.; Fangueiro, R.; Paiva, M.C. Microstructure and mechanical properties of carbon nanotube reinforced cementitious composites developed using a novel dispersion technique. Cem. Concr. Res. 2015, 73, 215–227. [Google Scholar] [CrossRef]

- Hu, S.; Xu, Y.; Wang, J.; Zhang, P.; Guo, J. Modification effects of carbon nanotube dispersion on the mechanical properties, pore structure, and microstructure of cement mortar. Materials 2020, 13, 1101. [Google Scholar] [CrossRef]

- Salemi, N.; Behfarnia, K. Effect of nano-particles on durability of fiber-reinforced concrete pavement. Constr. Build. Mater. 2013, 48, 934–941. [Google Scholar] [CrossRef]

- Shao, H.; Chen, B.; Li, B.; Tang, S.; Li, Z. Influence of dispersants on the properties of CNTs reinforced cement-based materials. Constr. Build. Mater. 2017, 131, 186–194. [Google Scholar] [CrossRef]

- Musso, S.; Tulliani, J.-M.; Ferro, G.; Tagliaferro, A. Influence of carbon nanotubes structure on the mechanical behavior of cement composites. Compos. Sci. Technol. 2009, 69, 1985–1990. [Google Scholar] [CrossRef]

- Sobolkina, A.; Mechtcherine, V.; Khavrus, V.; Maier, D.; Mende, M.; Ritschel, M.; Leonhardt, A. Dispersion of carbon nanotubes and its influence on the mechanical properties of the cement matrix. Cem. Concr. Compos. 2012, 34, 1104–1113. [Google Scholar] [CrossRef]

- Alafogianni, P.; Dassios, K.; Tsakiroglou, C.D.; Matikas, T.E.; Barkoula, N.M. Effect of CNT addition and dispersive agents on the transport properties and microstructure of cement mortars. Constr. Build. Mater. 2019, 197, 251–261. [Google Scholar] [CrossRef]

- Alafogianni, P.; Tragazikis, I.; Balaskas, A.; Barkoula, N.-M. Structural properties and damage detection capability of carbon nanotube modified mortars after freeze-thaw. Materials 2019, 12, 1747. [Google Scholar] [CrossRef]

- BS EN 196-1:2016. Methods of Testing Cement. Determination of Strength; BSI: London, UK, 2016. [Google Scholar] [CrossRef]

- ASTM C666/C666M-15. Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM C1012/C1012M-18b. Standard Test Method for Length Change of Hydraulic-Cement Mortars Exposed to a Sulfate Solution; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Alshamsi, A.M.; Imran, H.D.A. Development of a permeability apparatus for concrete and mortar. Cem. Concr. Res. 2002, 32, 923–929. [Google Scholar] [CrossRef]

- Bágel’, L’.; Živica, V. Relationship between pore structure and permeability of hardened cement mortars: On the choice of effective pore structure parameter. Cem. Concr. Res. 1997, 27, 1225–1235. [Google Scholar]

- Pipilikaki, P.; Beazi-Katsioti, M. The assessment of porosity and pore size distribution of limestone Portland cement pastes. Constr. Build. Mater. 2009, 23, 1966–1970. [Google Scholar] [CrossRef]

- Zhao, H.; Xiao, Q.; Huang, D.; Zhang, S. Influence of pore structure on compressive strength of cement mortar. Sci. World J. 2014, 2014, 247058. [Google Scholar] [CrossRef]

- Ouyang, X.; Guo, Y.; Qiu, X. The feasibility of synthetic surfactant as an air entraining agent for the cement matrix. Constr. Build. Mater. 2008, 22, 1774–1779. [Google Scholar] [CrossRef]

- Han, S.; Plank, J. Mechanistic study on the effect of sulfate ions on polycarboxylate superplasticisers in cement. Adv. Cem. Res. 2013, 25, 200–207. [Google Scholar] [CrossRef]

- Plank, J.; Sakai, E.; Miao, C.W.; Yu, C.; Hong, J.X. Chemical admixtures—Chemistry, applications and their impact on concrete microstructure and durability. Cem. Concr. Res. 2015, 78, 81–99. [Google Scholar] [CrossRef]

- Marchon, D.; Sulser, U.; Eberhardt, A.; Flatt, R.J. Molecular design of comb-shaped polycarboxylate dispersants for environmentally friendly concrete. Soft Matter 2013, 9, 10719–10728. [Google Scholar] [CrossRef]

| CNT Content % | CNT Content g | Dispersive Medium | Dispersant g | Anti-Foaming Agent g | Workability Modifier g |

|---|---|---|---|---|---|

| 0 | 0 | - | 0 | 0 | 1.5 |

| 0.2 | 0.9 | Superpl. | 1.4 | 0 | 1.7 |

| 0.4 | 1.8 | 2.7 | 0 | 0.9 | |

| 0.6 | 2.7 | 4.1 | 0 | 0.5 | |

| 0.8 | 3.6 | 6.8 | 0 | 0.1 | |

| 0.2 | 0.9 | Surf. | 0.5 | 0.7 | 0.9 |

| 0.4 | 1.8 | 0.9 | 0.7 | 1.8 | |

| 0.6 | 2.7 | 1.4 | 0.7 | 1.9 | |

| 0.8 | 3.6 | 1.8 | 0.7 | 2.1 |

| CNT Content % | Dispersive Medium | Dm B-E 1 10−3 mm2/s | ΔWs B-E 1 % | Dm F-T 1 10−3 mm2/s | ΔWs F-T 1 % | Dm S-A 1 10−3 mm2/s | ΔWs S-A 1 % |

|---|---|---|---|---|---|---|---|

| 0 | - | 1.62 ± 0.07 | 6.91 ± 0.03 | 1.22 ± 0.02 | 2.57 ± 0.03 | 2.66 ± 0.05 | 4.44 ± 0.00 |

| 0.,2 | Superpl. | 1.08 ± 0.03 | 7.25 ± 0.03 | 1.18 ± 0.02 | 3.08 ± 0.00 | 2.51 ± 0.05 | 4.88 ± 0.00 |

| 0.4 | 0.80 ± 0.04 | 6.89 ± 0.04 | 0.30 ± 0.01 | 2.87 ± 0.03 | 1.28 ± 0.03 | 4.91 ± 0.02 | |

| 0.6 | 0.58 ± 0.03 | 7.10 ± 0.03 | 0.77 ± 0.02 | 2.77 ± 0.02 | 0.95 ± 0.02 | 4.89 ± 0.00 | |

| 0.8 | 0.58 ± 0.04 | 6.11 ± 0.11 | 0.22 ± 0.00 | 2.45 ± 0.06 | 0.51 ± 0.01 | 4.45 ± 0.02 | |

| 0,2 | Surf. | 0.57 ±0.04 | 5.60 ± 0.08 | 2.87 ± 0.06 | 3.42 ± 0.00 | 0.69 ± 0.01 | 3.97 ± 0.03 |

| 0,4 | 0.71 ± 0.05 | 6.17 ± 0.04 | 1.75 ± 0.04 | 3.13 ± 0.03 | 0.62 ± 0.01 | 3.98 ± 0.02 | |

| 0,6 | 0.81 ± 0.02 | 5.72 ± 0.18 | 0.77 ± 0.02 | 2.42 ± 0.05 | 0.59 ± 0.01 | 3.91 ± 0.06 | |

| 0,8 | 1.05 ± 0.01 | 6.62 ± 0.08 | 1.43 ± 0.03 | 2.93 ± 0.03 | 0.81 ± 0.02 | 4.84 ± 0.02 |

| CNT Content % | Dispersive Medium | ΔŴg B-E 1 g/h | Adj. R-Square | ΔŴg F-T 1 g/h | Adj. R-Square | ΔŴg S-A 1 g/h | Adj. R-Square |

|---|---|---|---|---|---|---|---|

| 0 | - | 0.23 | 0.99 | 0.27 | 0.99 | 0.61 | 1.00 |

| 0.2 | Superplast. | 0.17 | 0.99 | 0.14 | 0.99 | 0.84 | 1.00 |

| 0.4 | 0.11 | 0.96 | 0.15 | 0.97 | 0.57 | 1.00 | |

| 0.6 | 0.10 | 0.99 | 0.23 | 0.99 | 0.61 | 0.99 | |

| 0.8 | 0.13 | 0.98 | 0.32 | 1.00 | 0.63 | 0.99 | |

| 0.2 | Surf. | 0.15 | 0.96 | 0.15 | 0.99 | 0.53 | 1.00 |

| 0.4 | 0.19 | 0.98 | 0.13 | 0.99 | 0.67 | 1.00 | |

| 0.6 | 0.43 | 1.00 | 0.16 | 1.00 | 0.76 | 1.00 | |

| 0.8 | 0.42 | 1.00 | 0.11 | 0.96 | 0.69 | 1.00 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alafogianni, P.; Dassios, K.; Tsakiroglou, C.D.; Matikas, T.E.; Barkoula, N.-M. Effect of Environmental Exposure on the Pore Structure and Transport Properties of Carbon Nanotube-Modified Mortars. Materials 2020, 13, 4543. https://doi.org/10.3390/ma13204543

Alafogianni P, Dassios K, Tsakiroglou CD, Matikas TE, Barkoula N-M. Effect of Environmental Exposure on the Pore Structure and Transport Properties of Carbon Nanotube-Modified Mortars. Materials. 2020; 13(20):4543. https://doi.org/10.3390/ma13204543

Chicago/Turabian StyleAlafogianni, Panagiota, Konstantinos Dassios, Christos D. Tsakiroglou, Theodore E. Matikas, and Nektaria-Marianthi Barkoula. 2020. "Effect of Environmental Exposure on the Pore Structure and Transport Properties of Carbon Nanotube-Modified Mortars" Materials 13, no. 20: 4543. https://doi.org/10.3390/ma13204543

APA StyleAlafogianni, P., Dassios, K., Tsakiroglou, C. D., Matikas, T. E., & Barkoula, N.-M. (2020). Effect of Environmental Exposure on the Pore Structure and Transport Properties of Carbon Nanotube-Modified Mortars. Materials, 13(20), 4543. https://doi.org/10.3390/ma13204543