Abstract

Doping of nitrogen is a promising approach to improve the electrical conductivity of 3C-SiC and allow its application in various fields. N-doped, <110>-oriented 3C-SiC bulks with different doping concentrations were prepared via halide laser chemical vapour deposition (HLCVD) using tetrachlorosilane (SiCl4) and methane (CH4) as precursors, along with nitrogen (N2) as a dopant. We investigated the effect of the volume fraction of nitrogen (ϕN2) on the preferred orientation, microstructure, electrical conductivity (σ), deposition rate (Rdep), and optical transmittance. The preference of 3C-SiC for the <110> orientation increased with increasing ϕN2. The σ value of the N-doped 3C-SiC bulk substrates first increased and then decreased with increasing ϕN2, reaching a maximum value of 7.4 × 102 S/m at ϕN2 = 20%. Rdep showed its highest value (3000 μm/h) for the undoped sample and decreased with increasing ϕN2, reaching 1437 μm/h at ϕN2 = 30%. The transmittance of the N-doped 3C-SiC bulks decreased with ϕN2 and showed a declining trend at wavelengths longer than 1000 nm. Compared with the previously prepared <111>-oriented N-doped 3C-SiC, the high-speed preparation of <110>-oriented N-doped 3C-SiC bulks further broadens its application field.

1. Introduction

Silicon carbide (SiC) is a promising electronic material, which has been applied in various fields due to its excellent mechanical properties, chemical stability, and high durability [1,2]. Although SiC is an intrinsic semiconductor, a high electrical conductivity (σ) is a necessary requirement for certain applications, such as solar cells [3], electromagnetic shielding materials [4], pressure sensors [5], and electro-discharge machining [6]. In situ doping via chemical vapour deposition (CVD) is a common method to improve the electrical conductivity of intrinsic semiconductors and allow its application in various fields, such as diamond, ZnO, TiO2, etc. [7,8,9]. In recent decades, a great deal of work has been focused on the preparation of N-doped SiC by adding NH3 [5,10] or N2 [11,12] during CVD, achieving σ values from 0.1 to 103 S/m. However, the deposition rates (Rdep) were limited to values between 0.1 and 10 μm/h [10,11,12,13,14]. Due to the low deposition rate, conventional CVD is usually effective for preparing SiC films but not bulk crystals, which greatly limits the applications of doped SiC.

Our research group has recently developed an efficient halide laser CVD (HLCVD) process to fabricate dense and pure 3C-SiC bulks with high Rdep, including transparent 3C-SiC bulks with low defect density and highly preferred orientations [15,16,17]. The maximum Rdep of 3C-SiC prepared by HLCVD reached 3600 μm/h, which is 10 to 103 times greater than that of conventional CVD. Preferred orientation has a great influence on the properties of corresponding crystals, for example, <111>-oriented 3C-SiC has higher hardness than that of <110>- and <111> co-oriented [15], <110>- 3C-SiC can be used in biosensors by modifying it using an organic molecule [18]. Although 3C-SiC prepared by CVD usually exhibit <111> and <110> preferred orientations, the doped 3C-SiC obtained in previous studies showed an almost exclusively <111> orientation. Nevertheless, the <110>-oriented 3C-SiC may be a more sensitive structural material and could be applied to pressure sensors in microelectromechanical systems (MEMS) [19], due to its lower Young’s modulus (about 350 GPa) than that of the <111>-oriented 3C-SiC (about 500 GPa).

NH3 is an effective and widely used precursor in N-doped SiC, but in the chloride precursor system, especially when the flow rate of the precursor is large, NH3 reacts violently with chloride to form ultra-fine powdery by-products and easily block the pipeline and vacuum pump. In addition, large amounts of Si-N bonds are easily generated due to the high reactivity of NH3. On the contrary, although the reaction activity of nitrogen is low, N2 is often used as the precursor of semiconductor doping because of its good safety and large flow regulation range. In our previous study, we showed that laser CVD can rapidly produce highly <110>-oriented 3C-SiC at a relatively low temperature (approximately 1523 K) [15]. To obtain a <110>-oriented 3C-SiC bulk with high electrical conductivity at high Rdep, in situ nitrogen doping was conducted by adding nitrogen during the preparation of 3C-SiC via HLCVD. In this study, we prepared thick, conductive, and N-doped <110>-oriented 3C-SiC bulks and investigated the effect of the volume fraction of N2 (ϕN2) on their preferred orientation, deposition rate, electrical conductivity, and optical transmittance. This study provides a new promising route for the rapid fabrication of various doped bulk semiconductors with specific preferred orientation.

2. Experimental

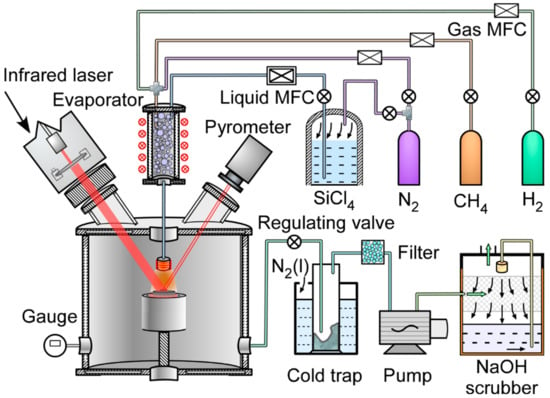

A cold wall HLCVD apparatus was developed to fabricate N-doped 3C-SiC bulks. Figure 1 shows the diagram of the HLCVD apparatus. Graphite discs (IGS-743, ϕ = 15 mm × 1 mm, Sankyo Carbon, Tokyo, Japan) were used as substrates and heated on a heating stage at a temperature of 773 K before deposition. A diode laser beam (InGaAlAs, λ = 1060 nm, BEIJING ZK Laser Co., Ltd., Beijing, China) was introduced into the chamber through a quartz window and its diameter was enlarged to 20 mm by a lens to cover the entire substrate. The deposition temperature (Tdep) was measured with a pyrometer (2MH-CF4, Optris GmbH, Berlin, Germany) and automatically controlled at 1623 K by a computer. The error in the surface temperature of the entire graphite substrate was ±5 K. SiCl4 and CH4 were used as precursors and N2 as dopant. Liquid SiCl4 was evaporated into a gas by an evaporator at a temperature of 353 K before being carried into the CVD chamber. The flow rates of SiCl4, CH4, and H2 were fixed at 600, 200, and 1200 sccm, respectively (the flow rate of SiCl4 was converted from liquid to gas units), whereas the flow rate of N2 was controlled to 5% to 30% of the total gas. The total pressure (Ptot) and deposition time were set to 4 kPa and 15 min, respectively. The distance between the graphite substrate and the nozzle was 30 mm. The nozzle temperature was set to 473 K. An exhaust gas treatment system composed of a cold trap filled with liquid nitrogen, an activated carbon filter, and an NaOH spray scrubber was used for the disposal of the harmful acidic intermediates. Table 1 summarises the main deposition parameters used for the preparation of N-doped 3C-SiC bulks.

Figure 1.

Schematic illustration of the HLCVD apparatus.

Table 1.

Deposition parameters.

The crystalline phases of the deposited samples were analysed by θ-2θ X-ray diffraction (XRD) with Cu Kα radiation at 40 kV and 40 mA (Ultima III, Rigaku, Tokyo, Japan). The microstructure and thickness of the deposits were inspected by field emission scanning electron microscopy (FESEM, Quanta-250, FEI, 20 kV, Houston, TX, USA). Raman spectra were measured by a LabRam HR800 Ev (Horiba, Tokyo, Japan) spectrometer equipped with a 532 nm He-Ne laser. The transmittance was measured in the wavelength range of 250 to 2000 nm using a UV-Vis-near infrared (NIR) spectrophotometer (Lambda 750 S, PerkinElmer, Waltham, MA, USA). Before testing the optical transmittance of 3C-SiC, the thick deposits were removed from the graphite substrate by a diamond grinding disc and polished into a mirror surface on both sides using diamond slurries of diameters 9, 3, and 1 μm. The final thicknesses of the 3C-SiC bulks were approximately 250 μm. The electrical conductivity and Hall coefficient of the 3C-SiC bulks were measured by a self-assembled electric and magnetic performance testing system. The elemental composition of the N-doped 3C-SiC bulks was analysed by X-ray photoelectron spectroscopy (XPS, ESCALAB 250Xi, Thermo Fisher Scientific, MA, USA). To prevent surface contamination from affecting the results, all samples were argon-etched prior to testing. The Seebeck coefficients were determined using a portable tester (PTM-3, Jouleyacht, Wuhan, China).

3. Results and Discussion

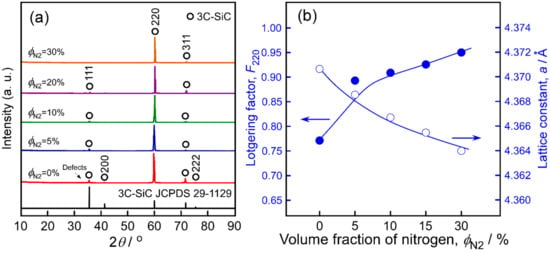

Figure 2a shows typical XRD patterns of the 3C-SiC bulks prepared by HLCVD with ϕN2 values up to 30%. No traces of second phases were detected in the XRD patterns. A small shoulder observed at 2θ ~ 33.8° could be attributed to planar defects [20,21,22]. All specimens deposited at Tdep = 1623 K and Ptot = 4 kPa exhibited a <110> preferred orientation. Figure 2b shows the Lotgering factors (Fhkl) and lattice constants (a) of the N-doped 3C-SiC samples. Fhkl was calculated from Equation (1) [23]:

where Phkl and P0 are the ratios of the peak intensity of the (hkl) planes to the sum of the intensities of all peaks for the films (Phkl) and powders (P0), respectively. The values of Fhkl range from negative (orientation along the other axes) to 0 (random) to 1 (perfect orientation). The F110 value of undoped 3C-SiC was 0.774 and increased with increasing ϕN2, reaching 0.945 at ϕN2 = 30%. To the best of our knowledge, this is the first report of N-doped 3C-SiC with <110> orientation. According to Refs. [24,25], <111>-oriented 3C-SiC shows a polar crystal structure containing Si {111} and C {-1-1-1} planes. The substituted N atoms mostly occupy the C sites in the SiC lattice. However, the adsorption of C or N on Si atoms along the Si-terminated surface of <111>-oriented 3C-SiC grains during the growth is relatively weak. With increasing ϕN2, the site competition between C and N atoms becomes more intense, which may reduce the growth rate of the <111> orientation and result in the increase of F110. The lattice constant (a) of 3C-SiC decreased from 4.3707 Å for the undoped sample to 4.3640 Å at ϕN2 = 30%. Nitrogen doping usually results in the shrinkage of the SiC lattice, due to the substitution of N atoms at the C sites and the smaller covalent radius of N (0.70 Å) than that of C (0.77 Å) [13].

Figure 2.

Crystallographic properties of N-doped 3C-SiC prepared with different ϕN2 values. (a) XRD patterns; (b) Lotgering factors F110 and corresponding lattice constants.

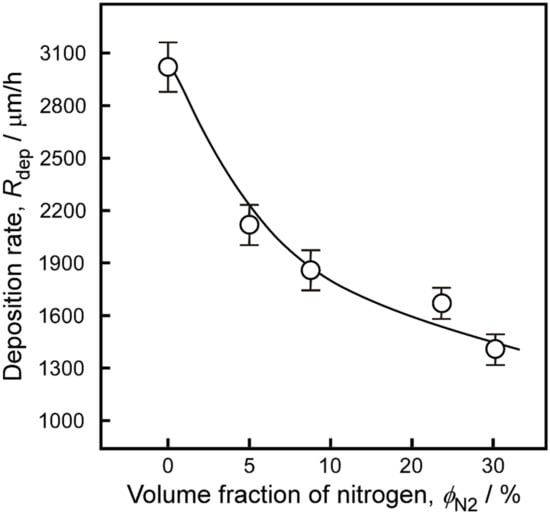

Figure 3 displays the surface (a–e) and cross-sectional (f–j) morphologies of 3C-SiC bulks prepared with various ϕN2 values. The undoped 3C-SiC bulk sample shows a cauliflower-like surface structure (Figure 3a) and a columnar cross section (Figure 3f). The cross-sectional morphology of the N-doped 3C-SiC samples are still columnar (Figure 3g–j), while the surface morphology (Figure 3b–e) changed with increasing ϕN2. The aggregate particle size decreased from approximately 250 μm (undoped sample) to 60 μm (ϕN2 = 30%), and the morphology gradually changed from cauliflower to fourfold-symmetric pyramid microstructure. The pyramidal grains were considered to be the final stage of the twin-plane propagation model previously proposed for fully <110>-oriented 3C-SiC [26]. The change of morphology indicates the enhancement of <110>-orientation. However, it is not a complete pyramid structure in Figure 3e, indicating that 3C-SiC is still not completely <110>-oriented when nitrogen volume fraction reaches 30%, which is consistent with the XRD results. Figure 4 shows the dependence of the deposition rate on ϕN2. The Rdep values were calculated from the deposition time and film thickness. With increasing ϕN2, Rdep decreased from 3000 μm/h for the undoped sample to 1437 μm/h at ϕN2 = 30%. As the substitution of N atoms mostly occurs at the C sites in the SiC lattice, the dopant may occupy the surface sites of the carbon-containing group, leading to a decrease in the deposition rate [27].

Figure 3.

Surface and cross-sectional microstructure of N-doped 3C-SiC bulks obtained at Tdep = 1623 K and Ptot = 4 kPa, with ϕN2 = 0% (a,f), 5% (b,g), 10% (c,h), 20% (d,i), and 30% (e,j).

Figure 4.

Rdep values of N-doped 3C-SiC bulks prepared with different ϕN2 parameters.

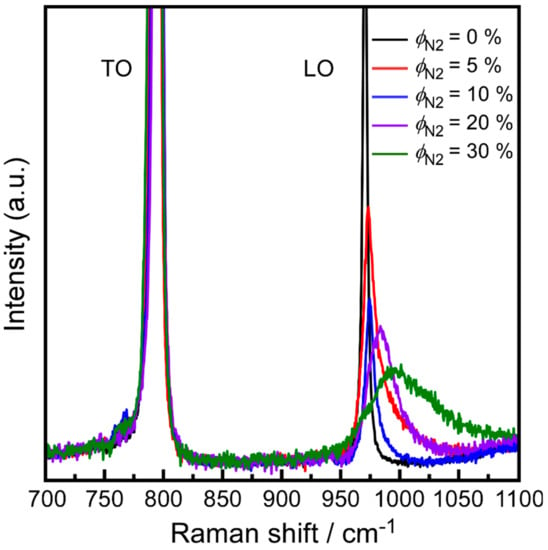

Figure 5 shows the Raman scattering spectra of N-doped 3C-SiC bulks deposited at Tdep = 1623 K with different ϕN2 values. The characteristic Raman modes of pure 3C-SiC primarily consisted of transverse optical (TO) and longitudinal optical (LO) phonons at 796 and 972 cm−1, respectively [28]. This is consistent with the Raman characteristics of the undoped 3C-SiC bulk. However, for ϕN2 > 5%, the shape of the LO peak of the 3C-SiC bulks showed a marked change, due to Raman scattering from LO phonon-plasmon coupled (LOPC) modes. In a polar semiconductor, the free carrier plasma interacts with the LO lattice vibrations (phonons) via macroscopic electric fields. As a result of this interaction, instead of a pure plasmon and a pure LO phonon, a coupled plasmon-phonon mode appears in the spectrum [29,30]. Yugami et al. studied the appearance of the TO and LO peaks in N-doped 3C-SiC, and suggested that the increase in carrier concentration due to the incorporation of N was closely related to the LO peak. The LO peak shifted toward high frequencies and became broader with the decrease in peak intensity as the carrier concentration increased. In contrast, the frequency and full width at half maximum (FWHM) of the TO peaks did not change with the carrier concentration [31]. In this study, the frequency of the LO peak gradually shifted from 972 cm−1 to higher frequencies with increasing ϕN2. In particular, the frequency of the LO peak reached 997 cm−1 for ϕN2 = 30%.

Figure 5.

Raman spectra of N-doped 3C-SiC bulks grown with different ϕN2 values.

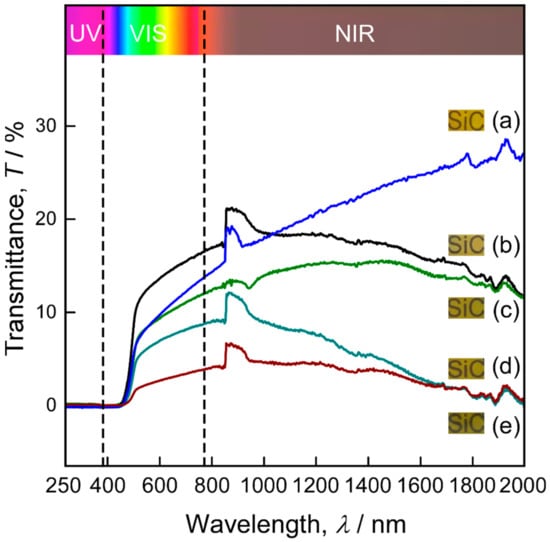

Figure 6 displays the transmittance in the UV-Vis-NIR range of N-doped 3C-SiC bulks prepared at Tdep = 1623 K and Ptot = 4 kPa, with different ϕN2 values. The photographs of the bulks, also shown in Figure 6, reveal that they had a translucent appearance. The differences in the transmittance characteristics of the undoped and N-doped 3C-SiC bulks can be divided into three regions [32,33]. In the low-wavelength region (below 500 nm), the fundamental absorption (FA) of N-doped 3C-SiC shifted to high wavelengths; in other words, the bandgap of these samples was shifted to lower energies (“bandgap shrinkage”). In the visible region, the slope of the transmittance curve of N-doped 3C-SiC was lower than that of undoped 3C-SiC, which caused the apparent colour of the doped SiC to change from yellow to green. The overall transmittance decreased with increasing ϕN2, resulting in a darker apparent colour of the bulks. In addition, no absorption bands in the below-bandgap region (BGGA), which are usually present in the transmittance spectrum of N-doped α-SiC, were observed for N-doped 3C-SiC, because of the absence of nitrogen donors at inequivalent lattice sites in 3C-SiC [34]. In the NIR region, the transmittance of undoped 3C-SiC increased with increasing wavelength, whereas that of N-doped 3C-SiC decreased; this may be due to free carrier absorption (FCA) and is considered to be an intravalence band transition. The peaks between 850 and 950 nm are generated by the switch between the detector and the light source in the spectrophotometer [35].

Figure 6.

Photograph and optical transmission curves of mirror-polished N-doped 3C-SiC bulks.

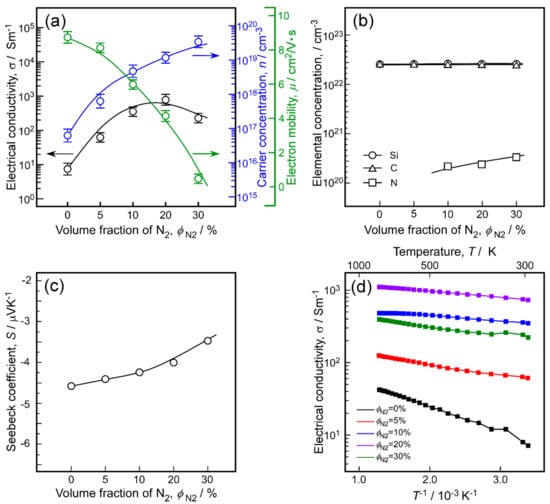

Figure 7a shows the electrical conductivity (σ), carrier concentration (n), and electron mobility (μ) of the N-doped 3C-SiC bulks. The σ value of the undoped 3C-SiC sample was 7.1 Sm−1, and the corresponding intrinsic carrier concentration was 5.7 × 1016 cm−3, which is higher than that reported in the literature (~1015 cm−3) [13,31]. This means the undoped 3C-SiC may be an unintentionally N-doped sample. The σ value of the N-doped 3C-SiC bulks first increased and then decreased with increasing ϕN2, reaching a maximum of 740.7 Sm−1 at ϕN2 = 20%. When ϕN2 was further increased, the conductivity showed a slight decrease. Simultaneously, the μ value of the 3C-SiC bulks decreased from 8.37 to 0.39 cm2/V⋅s with increasing ϕN2. The decrease in mobility may be attributed to the decrease in crystallinity or the formation of amorphous Si3N4 in the 3C-SiC bulks at high ϕN2 [10]. The corresponding n values increased with increasing ϕN2, and the highest n of 3.3 × 1019 cm−3 was obtained for the N-doped 3C-SiC bulk deposited at a ϕN2 = 30%. Figure 7b displays the elemental compositions of the 3C-SiC bulks. A stoichiometric 3C-SiC composition was obtained for the undoped sample, and the concentration of C atoms decreased slightly as ϕN2 increased. In addition, the nitrogen concentration was two to three orders of magnitudes higher than the carrier concentration. This indicates that most nitrogen atoms are not activated and may be incorporated into the grain boundaries in the form of amorphous nitrogen complexes [13]. Figure 7c shows the Seebeck coefficient of the 3C-SiC bulks at room temperature. All 3C-SiC bulks investigated in this study showed a negative Seebeck coefficient, implying n-type conduction. In addition, the absolute value of the Seebeck coefficient decreased with increasing ϕN2. The Seebeck coefficient and electrical conductivity usually follow an opposite trend as a function of the carrier concentration [36,37]. Figure 7d illustrates the temperature dependence of the electrical conductivity. The σ values of all 3C-SiC bulks increased with increasing temperature in the range of 295 to 775 K. The activation energy of σ was 0.08 eV for the undoped 3C-SiC and decreased to 0.03 eV at ϕN2 = 30%, indicating the presence of a shallow donor level below the conduction band (with energy EN = 0.03–0.08 eV) in the 3C-SiC bulks [38]. The slight decrease in activation energy with increasing ϕN2 has been reported in several studies [5,13,39], and is generally attributed to the decrease in average potential energy of an electron [40].

Figure 7.

Effect of ϕN2 on electrical conductivity, carrier concentration, and mobility (a), elemental compositions (b), and Seebeck coefficient (c) of N-doped 3C-SiC bulks. (d) Temperature dependence of electrical conductivities of N-doped 3C-SiC bulks.

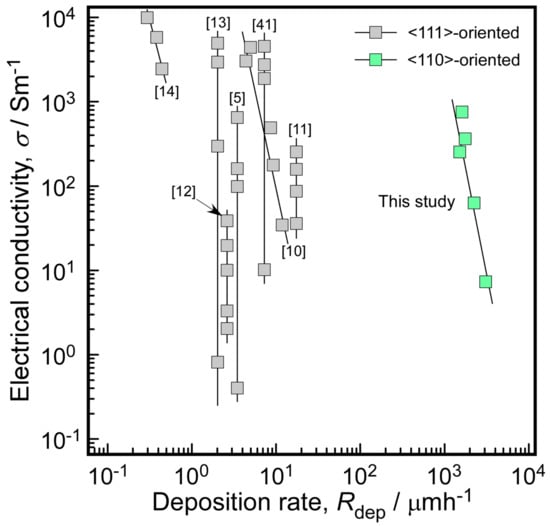

Figure 8 compares the electrical conductivity and deposition rate of the N-doped 3C-SiC samples prepared in this study with those reported in the literature [5,10,11,12,13,14,41]. Since most previous studies only provide approximate deposition rates, we assume that they involve a constant deposition rate. Most doped 3C-SiC samples were prepared via conventional CVD using NH3 as dopant, and exhibited <111> but not <110> orientation. The electrical conductivities varied between 33 and 1 × 104 Sm−1 while the deposition rates were in the 0.4–18 μmh−1 range. The N-doped 3C-SiC bulks prepared via HLCVD in this study exhibited predominant <110> orientation, high deposition rates (1430 to 1670 μmh−1, between 80 and 4000 times higher than those reported in the literature), and high electrical conductivities (7.4 × 102 Sm−1).

Figure 8.

Comparison of electrical conductivities and deposition rates of N-doped 3C-SiC samples prepared via CVD.

4. Conclusions

Halide laser chemical vapour deposition is a promising method for obtaining 3C-SiC bulks with predominant <110> orientation and high electrical conductivity at high deposition rates. The degree of <110> orientation of 3C-SiC increased with increasing nitrogen content and became nearly complete at ϕN2 = 30%, with a Lotgering factor (F220) of 0.945. Upon increasing ϕN2 to 30%, the electrical conductivity and carrier concentration of the N-doped 3C-SiC bulks increased from 7.1 to 740 Sm−1 and from 5.7 × 1016 to 3.3 × 1019 cm−3, respectively. While the <110>-oriented 3C-SiC bulks were translucent, upon nitrogen doping their transmittance decreased with increasing ϕN2 and also with increasing wavelength. Finally, the Rdep value decreased with increasing ϕN2, reaching 1437 μmh−1 at ϕN2 = 30%, which is 80 to 4276 times higher than that of reported in other studies.

Author Contributions

Conceptualization, Y.L.; Data curation, Y.L.; Formal analysis, L.X., Q.X., K.L., M.Y., S.Z., M.H., T.G. and L.Z.; Funding acquisition, Y.L.; Resources, Q.L.; Writing—original draft, Y.L.; Writing—review & editing, R.T. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by National Natural Science Foundation of China, No. 51372188, No. 51521001, No. 51872212, No. 51861145306 and the 111 Project (B13035). This research was also supported by the International Science & Technology Cooperation Program of China (2014DFA53090) and the Natural Science Foundation of Hubei Province, China (2016CFA006), and the Fundamental Research Funds for the Central Universities (WUT: 2017-YB-004, 2018III016), and Science Challenge Project (No. TZ2016001), and the State Key Laboratory of Advanced Technology for Materials Synthesis and Processing (WUT, Grant No. 2019-KF-12).

Acknowledgments

We would like to acknowledge support from the center for materials research and analysis of Wuhan University of Technology.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lee, T.H.; Bhunia, S.; Mehregany, M. Electromechanical computing at 500 °C with silicon carbide. Science 2010, 5997, 1316–1318. [Google Scholar] [CrossRef] [PubMed]

- Barringer, E.; Faiztompkins, Z.; Feinroth, H. Corrosion of CVD silicon carbide in 500°C supercritical water. J. Am. Ceram. Soc. 2007, 1, 315–318. [Google Scholar] [CrossRef]

- Cho, J.S.; Jang, E.; Lim, D.; Ahn, S.; Yoo, J.; Cho, A.; Park, J.H.; Kim, K.; Choi, B.H. Wide-bandgap nanocrystalline silicon-carbon alloys for photovoltaic applications. Sol. Energy Mater. Sol. Cells 2018, 182, 220–227. [Google Scholar] [CrossRef]

- Li, Q.; Yin, X.; Duan, W.; Kong, L.; Liu, X.; Cheng, L.; Zhang, L. Improved dielectric and electromagnetic interference shielding properties of ferrocene-modified polycarbosilane derived SiC/C composite ceramics. J. Eur. Ceram. Soc. 2014, 10, 2187–2201. [Google Scholar] [CrossRef]

- Latha, H.K.E.; Udayakumar, A.; Prasad, V.S. Microstructure and electrical properties of nitrogen doped 3C -SiC thin films deposited using methyltrichlorosilane. Mater. Sci. Semicond. Process. 2015, 29, 117–123. [Google Scholar] [CrossRef]

- Kim, Y.W.; Kim, K.J.; Kim, H.C.; Cho, N.H.; Lim, K.Y. Electrodischarge-machinable silicon carbide ceramics sintered with Yttrium Nitrate. J. Am. Ceram. Soc. 2011, 4, 991–993. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, C.; Liu, J.L.; An, K.; Yan, X.B.; Hei, L.F. The interface and mechanical properties of a CVD single crystal diamond produced by multilayered nitrogen doping epitaxial growth. Materials 2019, 15, 2492. [Google Scholar] [CrossRef]

- Chen, C.C.; Wang, F.H.; Chang, S.C.; Yang, C.F. Using oxygen plasma pretreatment to enhance the properties of F-Doped ZnO films prepared on polyimide substrates. Materials 2018, 9, 1501. [Google Scholar] [CrossRef]

- Lu, N.; Quan, X.; Li, J.Y.; Chen, X.; Yu, H.T.; Chen, G.H. Fabrication of boron-doped TiO2 nanotube array electrode and investigation of its photoelectrochemical capability. J. Phys. Chem. C 2007, 32, 11836–11842. [Google Scholar] [CrossRef]

- Wijesundara, M.B.J.; Stoldt, C.R.; Carraro, C.; Howe, R.T.; Maboudian, R. Nitrogen doping of polycrystalline 3C–SiC films grown by single-source chemical vapor deposition. Thin Solid Films 2002, 419, 69–75. [Google Scholar] [CrossRef]

- Chen, J.; Steckl, A.J.; Loboda, M.J. In situ N2 -doping of SiC films grown on Si (111) by chemical vapor deposition from organosilanes. J. Electrochem. Soc. 2000, 6, 2324–2327. [Google Scholar] [CrossRef]

- Hoshide, Y.; Tabata, A.; Kitagawa, A.; Kondo, A. Preparation of n-type nanocrystalline 3C-SiC films by hot-wire CVD using N2 as doping gas. Thin Solid Films 2009, 12, 3524–3527. [Google Scholar] [CrossRef]

- Zhang, J.; Carraro, C. Electrical, mechanical and metal contact properties of polycrystalline 3C-SiC films for MEMS in harsh environments. Surf. Coat. Technol. 2007, 22–23, 8893–8898. [Google Scholar] [CrossRef]

- Trevino, J.; Fu, X.; Mehregany, M.; Zorman, C. Low-Stress, heavily-doped polycrystalline silicon carbide for MEMS application. In Proceedings of the 18th IEEE International Conference on Micro Electro Mechanical Systems (MEMS 2005), Miami Beach, FL, USA, 30 January–3 February 2005. [Google Scholar]

- Cheng, H.; Tu, R.; Zhang, S.; Han, M.X.; Goto, T.; Zhang, L.M. Preparation of highly oriented beta SiC bulks by halide laser chemical vapor deposition. J. Eur. Ceram. Soc. 2017, 2, 509–515. [Google Scholar] [CrossRef]

- Cheng, H.; Yang, M.J.; Lai, Y.F.; Hu, M.W.; Li, Q.Z.; Tu, R.; Zhang, S. Transparent highly oriented 3C-SiC bulks by halide laser CVD. J. Eur. Ceram. Soc. 2018, 9, 3057–3063. [Google Scholar] [CrossRef]

- Lai, Y.F.; Cheng, H. Fine-grained 3C-SiC thick films prepared via hybrid laser chemical vapor deposition. J. Am. Ceram. Soc. 2019, 102, 1–11. [Google Scholar] [CrossRef]

- Catellani, A.; Calzolari, A. Functionalization of SiC (110) surfaces via porphyrin adsorption: Ab initio results. J. Phys. Chem. C 2012, 116, 886–892. [Google Scholar] [CrossRef]

- Roy, S.; Zorman, C.; Mehregany, M.; Deanna, R.; Deeb, C. The mechanical properties of polycrystalline 3C-SiC films grown on polysilicon substrates by atmospheric pressure chemical-vapor deposition. J. Appl. Phys. 2006, 4, 11–12. [Google Scholar] [CrossRef]

- Jha, H.S.; Agarwal, P. Highly crystalline silicon carbide thin films grown at low substrate temperature by HWCVD technique. J. Mater. Sci. Mater. Electron. 2015, 3, 1381–1388. [Google Scholar] [CrossRef]

- Carduner, K.R.; Shinozaki, S.S.; Rokosz, M.J.; Peters, C.R.; Whalen, T.J. Characterization of beta-Silicon Carbide by Silicon-29 Solid-State NMR, Transmission Electron Microscopy, and Powder X-ray Diffraction. J. Am. Ceram. Soc. 1990, 8, 2281–2286. [Google Scholar] [CrossRef]

- Koumoto, K.; Takeda, S. High-resolution electron microscopy observations of stacking faults in beta-SiC. J. Am. Ceram. Soc. 1989, 10, 1985–1987. [Google Scholar] [CrossRef]

- Lotgering, F. K Topotactical reactions with ferrimagnetic oxides having hexagonal crystal structures-I. J. Inorg. Nucl. Chem. 1959, 9, 113–123. [Google Scholar] [CrossRef]

- Ferro, G.; Chaussende, D. A new model for in situ nitrogen incorporation into 4H-SiC during epitaxy. Sci. Rep. 2017, 7, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Larkin, D.J.; Neudeck, P.G.; Powell, J.A.; Matus, L.J. Site-competition epitaxy for superior silicon carbide electronics. Appl. Phys. Lett. 1994, 13, 1659–1661. [Google Scholar] [CrossRef]

- Tu, R.; Zheng, D.H.; Cheng, H.; Hu, M.W.; Zhang, S.; Han, M.X.; Goto, T.; Zhang, L.M. Effect of CH4/SiCl4ratio on the composition and microstructure of <110>-oriented beta-SiC bulks by halide CVD. J. Eur. Ceram. Soc. 2017, 4, 1217–1223. [Google Scholar] [CrossRef]

- Ohshita, Y.; Kitajima, H. In situ doped polycrystalline silicon selective growth using the SiH2Cl2/H2/HCl/PH3 gas system. J. Appl. Phys. 2014, 3, 1989–1992. [Google Scholar]

- Feldman, D.W.; Parker, J.H. Phonon Dispersion Curves by Raman Scattering in SiC, Polytypes 3C, 4H, 6H, 15R, and 21R. Phys. Rev. 1968, 3, 787–793. [Google Scholar] [CrossRef]

- Klein, M.V.; Ganguly, B.N. Theoretical and Experimental Study of Raman Scattering from Coupled LO-Phonon-Plasmon Modes in Silicon Carbide. Phys. Rev. B 1972, 6, 2380–2388. [Google Scholar] [CrossRef]

- Irmer, G. Determination of the Charge Carrier Concentration and Mobility in n-GaP by Raman Spectroscopy. Phys. Status Solidi 1983, 2, 595–603. [Google Scholar] [CrossRef]

- Yugami, H.; Nakashima, S.; Mitsuishi, A.; Uemoto, A.; Shigeta, M. Characterization of the freecarrier concentrations in doped β SiC crystals by Raman scattering. J. Appl. Phys. 1987, 61, 354–358. [Google Scholar] [CrossRef]

- Wellmann, P.J.; Weinga, R. Determination of doping levels and their distribution in SiC by optical techniques. Mater. Sci. Eng. B 2003, 1–3, 262–268. [Google Scholar] [CrossRef]

- Weingärtner, R.; Wellmann, P.J.; Bickermann, M.; Hofmann, D.; Straubinger, T.L.; Winnacker, A. Determination of charge carrier concentration in n- and p-doped SiC based on optical absorption measurements. Appl. Phys. Lett. 2012, 80, 70–72. [Google Scholar] [CrossRef]

- Weingärtner, R.; Wellmann, P.J. On the Origin of the Below Band-Gap Absorption Bands in n-Type (N) 4H- and 6H-SiC. Mater. Sci. Forum 2004, 457, 645–648. [Google Scholar] [CrossRef]

- Hellmann, B.A.R. SiC absorption of near-infrared laser radiation at high temperatures. Appl. Phys. A 2016, 7, 642. [Google Scholar]

- Shi, X.; Chen, L.; Uher, C. Recent advances in high-performance bulk thermoelectric materials. Int. Mater. Rev. 2016, 6, 379–415. [Google Scholar] [CrossRef]

- Tan, G.; Zhao, L.D.; Kanatzidis, M.G. Rationally designing high-performance bulk thermoelectric materials. Chem. Rev. 2016, 19, 12123–12149. [Google Scholar] [CrossRef]

- Sonntag, H.; Kalbitzer, S. Ion-implantation doping of crystalline 6H-SiC. Appl. Phys. A Mater. Sci. Process. 1995, 4, 363–367. [Google Scholar] [CrossRef]

- Yukina, T.; Yukina, T.; Mettaya, K.; Hirokazu, K.; Takashi, G. Electrical and thermal properties of nitrogen-doped SiC sintered body. J. Jpn. Soc. Powder Powder Metall. 2018, 8, 508–512. [Google Scholar]

- Pearson, G.L.; Bardeen, J. Electrical properties of pure silicon and silicon alloys containing boron and phosphorus. Phys. Rev. 1949, 5, 865–883. [Google Scholar] [CrossRef]

- Wijesundara, M.B.J.; Gao, D.; Carraro, C.; Howe, R.T.; Maboudian, R. Nitrogen doping of polycrystalline 3C-SiC films grown using 1, 3-disilabutane in a conventional LPCVD reactor. J. Cryst. Growth 2003, 259, 18–25. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).