Study on the Effect of Microwave Processing on Asphalt-Rubber

Abstract

1. Introduction

- (1)

- To measure the effects of microwave processing on CR swelling and dissolution;

- (2)

- To evaluate the viscosity and storage stability of AR binders after microwave processing;

- (3)

- To study the rheologic properties of AR binders after microwave processing.

2. Materials and Methods

2.1. Materials, Microwave Processing Method and Preparation of AR Binders

2.1.1. Materials

2.1.2. The Microwave Processing

2.1.3. Preparation of Asphalt-Rubber Binders

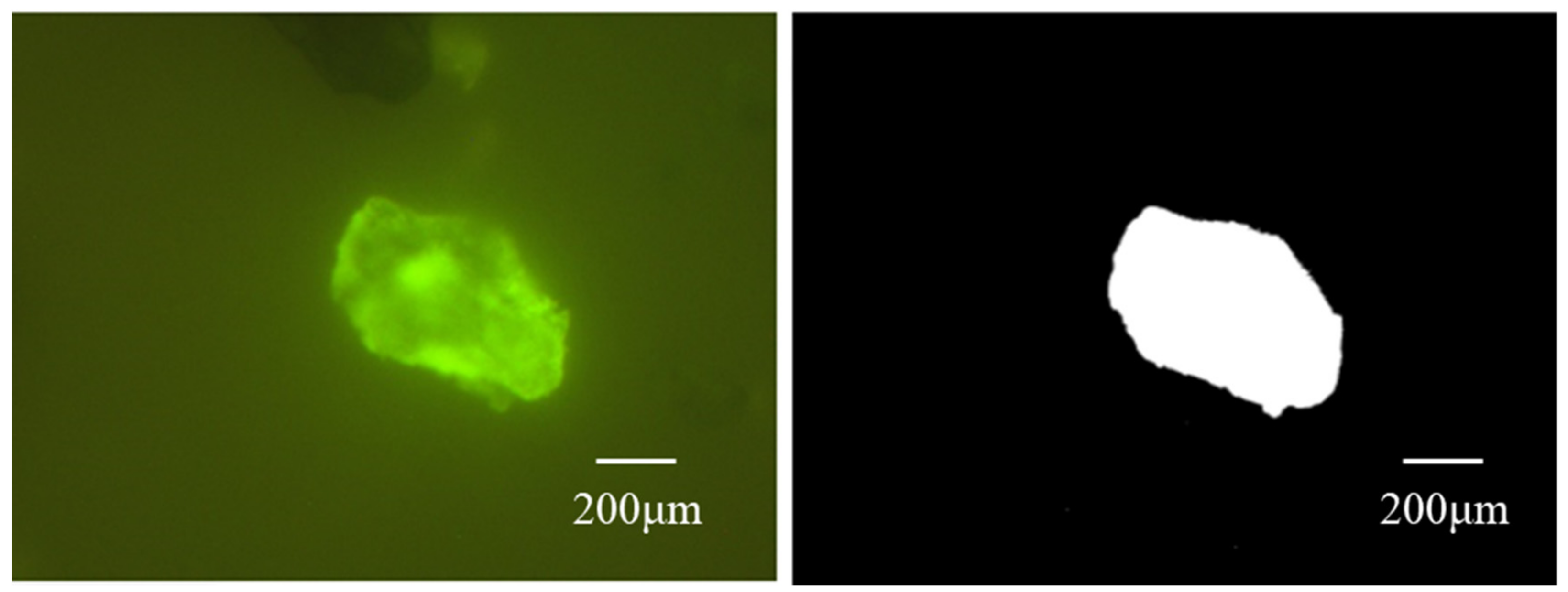

2.2. Fluorescence Microscope and Extraction Experiments

2.2.1. Fluorescence Microscope Scanning

2.2.2. Extraction Tests

2.3. Viscosity and Storage Stability Experiments

2.3.1. Viscosity Tests

2.3.2. Stability Tests

2.4. DSR and BBR Experiments

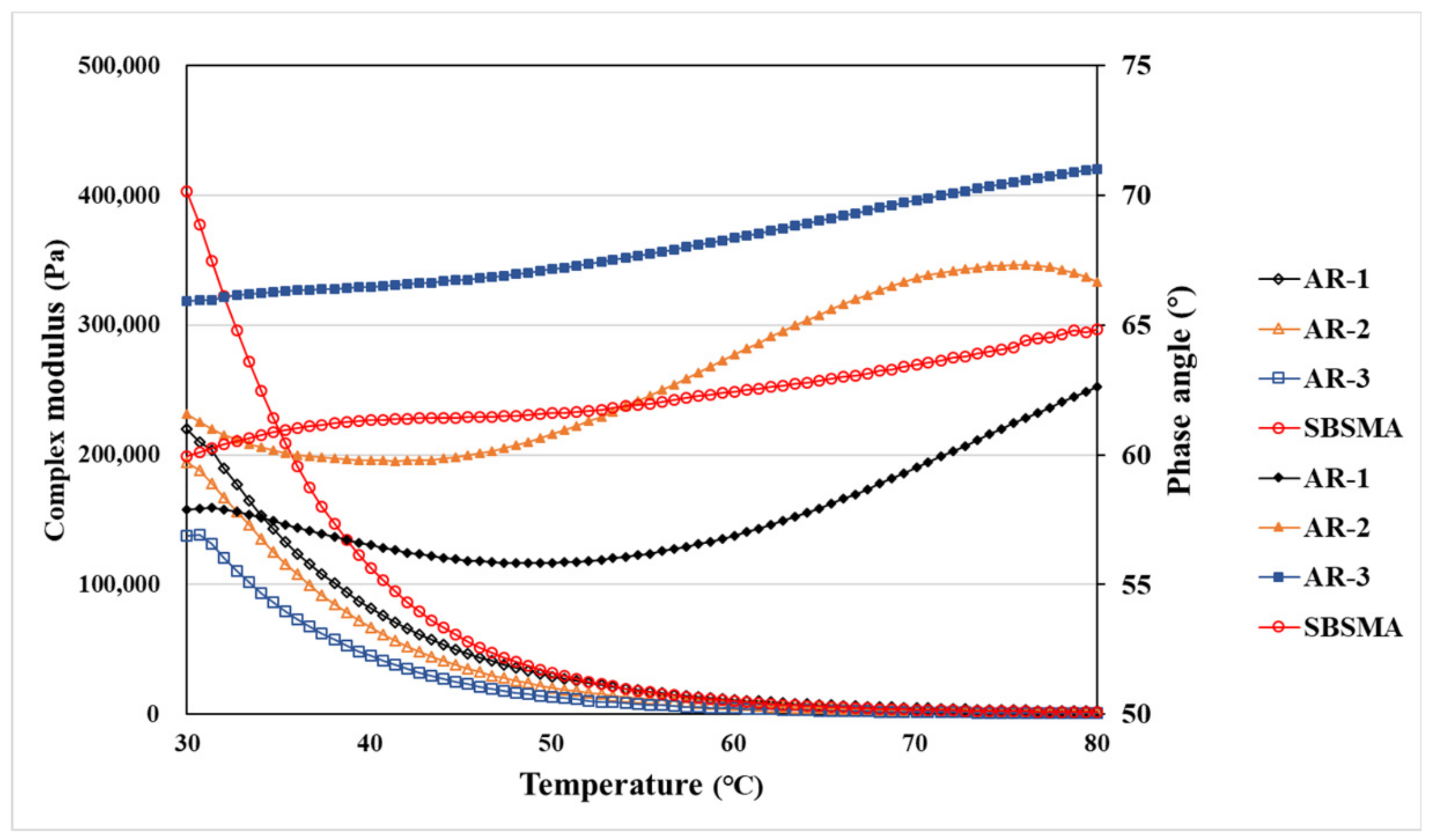

2.4.1. Temperature Sweep Tests

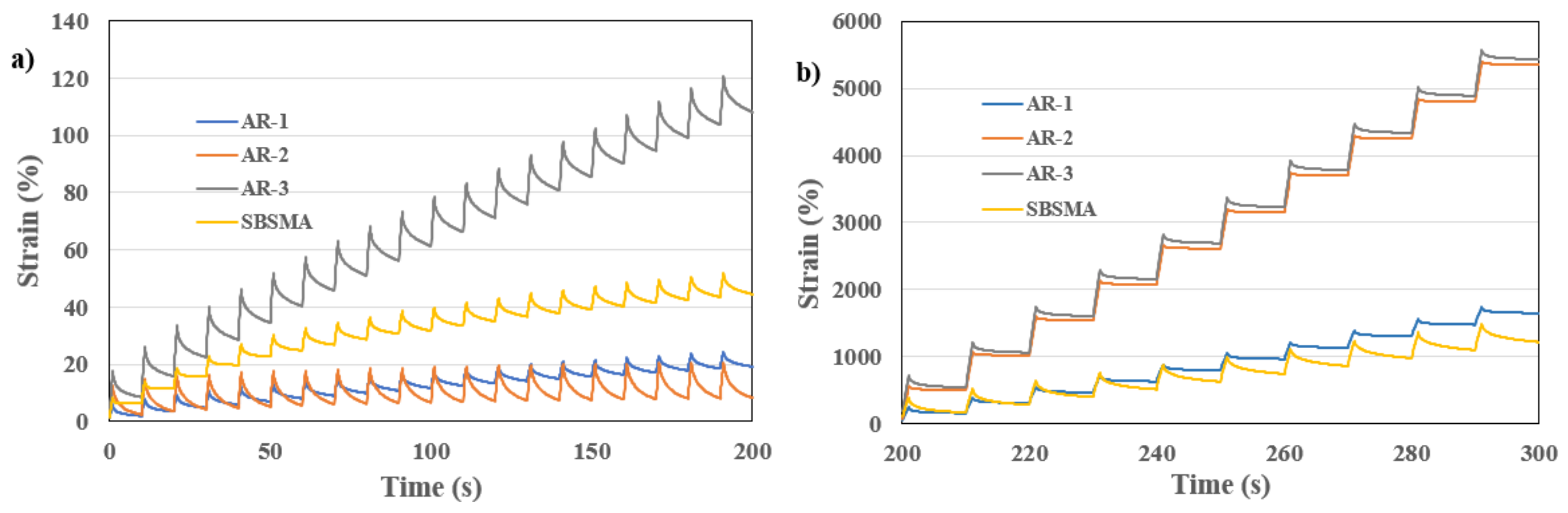

2.4.2. Multiple Stress Creep and Recovery Tests

2.4.3. BBR Tests

3. Results and Discussions

3.1. The Effects of Microwave Processing on the Swelling and Dissolution of CR

3.2. The Fundamental Properties and Storage Stability

3.2.1. The Fundamental Properties

3.2.2. Storage Stability

3.3. Rheological Performance

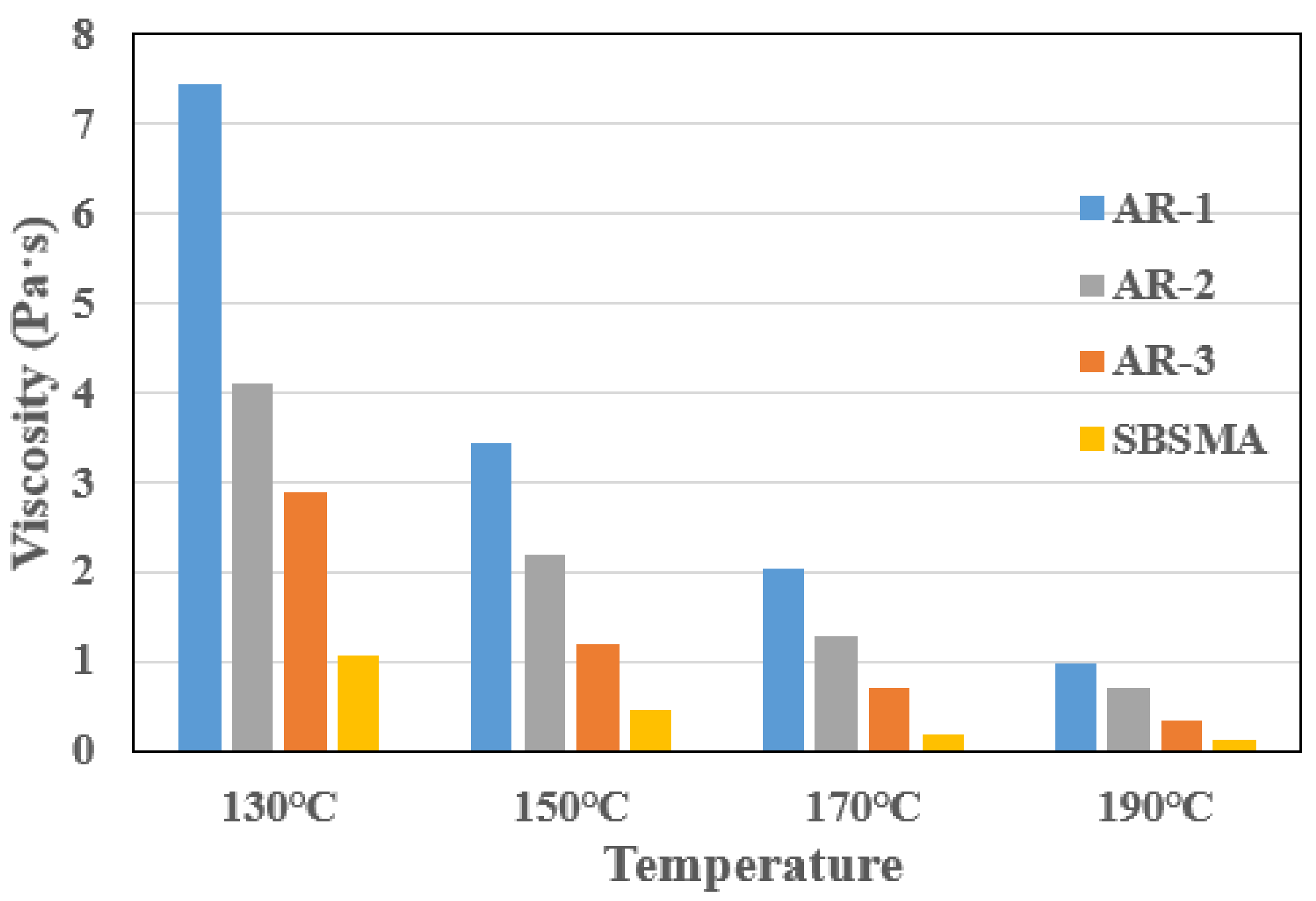

3.3.1. Viscosity

3.3.2. The Results of Temperature Sweep Tests

3.3.3. High-Temperature Resistance to Permanent Deformation

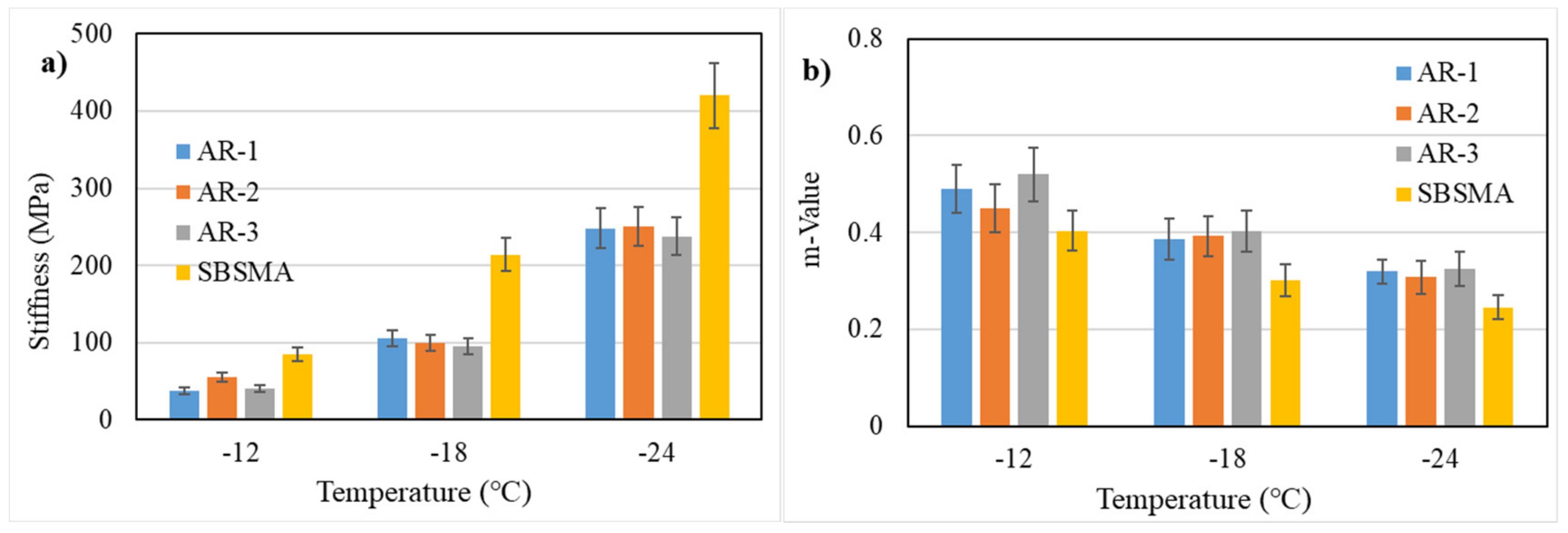

3.3.4. Low-Temperature Performance

4. Conclusions

- (1)

- The swelling results showed that the swelling rate of CR-3, processed by microwave, was two times as high as CR-1’s (without processing). Meanwhile, the sizes of CR-1 and CR-2 particles were close. Considering the extraction test results, the dissolving rate in the base binder of CR-3 increased more than two times as compared with CR-1, and the dissolution rate of CR-2 was also one time bigger than CR-1’s. So, the substance exchange between CR and the base asphalt could be accelerated by desulphurization, especially by microwave processing.

- (2)

- The viscosity results showed that the viscosity of CR samples after desulphurization was consistently lower than CR-1’s at all temperatures and, especially, microwave processing had a noticeable effect of reducing viscosity (a viscosity decrease of 65% occurred at 190 °C). The storage stability result showed that the storage stability would be negatively affected by desulphurization, but it was still better than that of SBS-modified asphalt.

- (3)

- The high-temperature performance results showed that the high temperature PG grade decreased from 88 °C to 76 °C and the Jnr parameters of 0.1 and 3.2 kPa increased more than fivefold and threefold, respectively, after microwave processing, indicating that the microwave processing CR would exert a negative impact on the high-temperature anti-rutting performance of AR binders. Additionally, BBR results showed that the stiffness and m-value decreased and increased slightly at all temperatures, respectively, after microwave processing, indicating the low-temperature anti-cracking performance is improved. Also, low-temperature results of all AR binder samples performed better than SBS modified asphalt.

Author Contributions

Funding

Conflicts of Interest

References

- Presti, D.L. Recycled tyre rubber modified bitumens for road asphalt mixtures: a literature review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Ali, A.H.; Karim, M.R.; Abdelaziz, M. A review on using crumb rubber in reinforcement of asphalt pavement. Sci. World J. 2014, 2014. [Google Scholar] [CrossRef]

- Heitzman, M. Design and construction of asphalt paving materials with crumb-rubber modifier. Transport. Res. Rec. 1992, 47, 171–174. [Google Scholar]

- Xiao, F.P.; Amirkhanian, S.N. HP-GPC Approach to evaluating laboratory prepared long-term aged rubberized asphalt binders. In Proceedings of the Geohunan International Conference, Changsha, Hunan, China, 3–6 August 2009. [Google Scholar]

- Xiao, F.; Zhao, P.E.W.; Amirkhanian, S.N. Fatigue behavior of rubberized asphalt concrete mixtures containing warm asphalt additives. Constr. Build. Mater. 2009, 23, 3144–3151. [Google Scholar] [CrossRef]

- Kim, H.H.; Mithil, M.; Soon-Jae, L.; Moon-Sup, L. Characterization of recycled crumb rubber modified binders containing wax warm additives. J. Traffic Transp. Eng. 2018, 5, 197–206. [Google Scholar] [CrossRef]

- Li, R.; Wang, C.; Wang, P.; Pei, J. Preparation of a novel flow improver and its viscosity-reducing effect on bitumen. FUEL 2016, 181, 935–941. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, Z.; Xu, G.; Shi, C. Evaluation of aging behaviors of asphalt binders through different rheological indices. Fuel 2018, 221, 78–88. [Google Scholar] [CrossRef]

- Putman, B.J.; Amirkhanian, S.N. Rubberized asphalt mixtures: a novel approach to pavement noise reduction. Urban Transp. 2005, 77, 541–549. [Google Scholar]

- Singh, D.; Ashish, P.; Jagadeesh, A. Influence of particle and interaction effects of different sizes of crumb rubber on rheological performance parameters of binders. J. Mater. Civ. Eng. 2018, 30. [Google Scholar] [CrossRef]

- Putman, B.J.; Amirkhanian, S.N. Characterization of the interaction effect of crumb rubber modified binders using HP-GPC. J. Mater. Civ. Eng. 2010, 22, 153–159. [Google Scholar] [CrossRef]

- Putman, B.J.; Amirkhanian, S.N. Crumb rubber modification of binders: interaction and particle effects. In Proceedings of the Asphalt Rubber 2006 Conference, Palm Springs, CA, USA, October 2006. [Google Scholar]

- Lougheed, T.J.; Papagiannakis, A.T. Viscosity characteristics of rubber-modified asphalts. J. Mater. Civ. Eng. 1996, 8, 153–156. [Google Scholar] [CrossRef]

- Frantzis, P. Crumb rubber-bitumen interactions: diffusion of bitumen into rubber. J. Mater. Civ. Eng. 2004, 16, 387–390. [Google Scholar] [CrossRef]

- Shatanawi, K.; Thodesen, C.; Amirkhanian, S. Effects of crumb rubber variability on failure temperature of crumb rubber modified binders. Road Mater. Pavement. 2008, 9, 291–309. [Google Scholar]

- Bahia, H.U.; Davies, R. Effect of crumb rubber modifiers (CRM) on performance-related properties of asphalt binders. Asphalt Paving Technol. 1994, 414–438. [Google Scholar]

- Wang, S.; Wang, Q.; Li, S. Thermooxidative aging mechanism of crumb-rubber-modified asphalt. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Chipps, J.F.; Davison, R.R.; Glover, C.J. A model for oxidative aging of rubber-modified asphalts and implications to performance analysis. Energy Fuels 2001, 15, 637–647. [Google Scholar] [CrossRef]

- Presti, D.L.; Izquierdo, M.A.; Carrión, A.J.D.B. Towards storage-stable high-content recycled tyre rubber modified bitumen. Constr. Build. Mater. 2018, 172, 106–111. [Google Scholar] [CrossRef]

- Zhang, J.; Fan, Z.; Hu, D.; Hu, Z.; Pei, J.; Kong, W. Evaluation of asphalt–aggregate interaction based on the rheological properties. Int. J. Pavement Eng. 2018, 19, 586–592. [Google Scholar] [CrossRef]

- Shen, J.; Amirkhanian, S.; Xiao, F. High-pressure gel permeation chromatography of aging of recycled crumb rubber-modified binders with rejuvenating agents. Transp. Res. Rec. 2006, 1962, 21–27. [Google Scholar] [CrossRef]

- Shen, J.; Amirkhanian, S.; Xiao, F.; Tang, B. Influence of surface area and size of crumb rubber on high temperature properties of crumb rubber modified binders. Constr. Build. Mater. 2009, 23, 304–310. [Google Scholar] [CrossRef]

- Abdelrahman, M.; Carpenter, S. Mechanism of interaction of asphalt cement with crumb rubber modifier. Transpor. Res. Rec. 1999, 1661, 106–113. [Google Scholar] [CrossRef]

- Sun, D.Q.; Li, L.H. Factors Affecting the viscosity of crumb rubber-modified asphalt. Liq. Fuels Technol. 2010, 28, 1555–1566. [Google Scholar] [CrossRef]

- Yu, G.X.; Li, Z.M.; Zhou, X.L.; Li, C.L. Crumb rubber-modified asphalt: microwave treatment effects. Petrol. Sci. Technol. 2011, 29, 411–417. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Karim, M.R. Investigating the rheological properties of crumb rubber modified bitumen and its correlation with temperature susceptibility. Mater. Res. 2013, 16, 116–127. [Google Scholar] [CrossRef]

- Jeong, K.D.; Lee, S.J.; Amirkhanian, S.N.; Kim, K.W. Interaction effects of crumb rubber modified asphalt binders. Constr. Build. Mater. 2010, 24, 824–831. [Google Scholar] [CrossRef]

- Aflaki, S.; Memarzadeh, M. Using two-way anova and hypothesis test in evaluating crumb rubber modification (CRM) agitation effects on rheological properties of bitumen. Constr. Build. Mater. 2011, 25, 2094–2106. [Google Scholar] [CrossRef]

- Wang, T.; Xiao, F.; Amirkhanian, S.; Huang, W.; Zheng, M. A review on low temperature performances of rubberized asphalt materials. Constr. Build. Mater. 2017, 145, 483–505. [Google Scholar] [CrossRef]

- Lee, S.J.; Amirkhanian, S.N. Effects of reaction time on physical and chemical properties of rubber-modified binders. In Proceedings of the International Rubber Conference, Lyon, France, 16–18 May 2006. [Google Scholar]

- Mashaan, N.S.; Ali, A.H.; Karim, M.R.; Abdelaziz, M. Effect of blending time and crumb rubber content on properties of crumb rubber modified asphalt binder. Int. J. Phys. Sci. 2011, 6, 2189–2193. [Google Scholar]

- Zhu, J.; Birgisson, B.; Kringos, N. Polymer modification of bitumen: advances and challenges. Eur. Polym. J. 2014, 54, 18–38. [Google Scholar] [CrossRef]

| Items | Specifications | Measured Values |

|---|---|---|

| Penetration (25 °C, 0.1 mm) | ASTM D5 | 89.8 |

| Penetration index PI | ASTM D5 | −0.5 |

| Softening point ( , °C) | ASTM D36 | 44.6 |

| Ductility (15 °C, cm) | ASTM D113 | 165 |

| Kinematic Viscosity (135 °C, Pa·s) | ASTM D4402 | 0.413 |

| Density (15 °C, g/cm3) | ASTM D70 | 1.025 |

| Samples | Measured Value (%) | Average Value (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| CR-1 | 5.88 | 3.73 | 7.56 | 5.27 | 5.75 | 6.01 | 9.53 | 3.66 | 5.71 | 5.96 | 5.91 |

| CR-2 | 8.23 | 3.8 | 9.84 | 6.18 | 5.92 | 5.02 | 4.93 | 5.12 | 4.17 | 4.01 | 5.72 |

| CR-3 | 12.113 | 12.51 | 9.46 | 9.16 | 10.46 | 7.75 | 9.39 | 14.21 | 9.89 | 9.36 | 10.43 |

| Samples | Toluene (%) | Base Asphalt (%) |

|---|---|---|

| CR-1 | 6.2 | 12.2 |

| CR-2 | 5.0 | 27.0 |

| CR-3 | 5.7 | 39.4 |

| Items | Specifications | Samples | |||

|---|---|---|---|---|---|

| AR-1 | AR-2 | AR-3 | SBSMA | ||

| Penetration (15 °C, 0.1 mm) | ASTM D5 | 23.5 | 24.7 | 20.9 | 24.5 |

| Penetration (25 °C, 0.1 mm) | 55.4 | 58.3 | 52.8 | 58.6 | |

| Penetration (30 °C, 0.1 mm) | 78.4 | 78.7 | 79.6 | 90.6 | |

| Penetration Index | 0.8696 | 1.0906 | 0.1868 | 0.3627 | |

| Ductility (5 °C, cm) | ASTM D113 | 9.5 | 9.0 | 6.4 | 24.2 |

| Softening point (°C) | ASTM D36 | 62.5 | 61.6 | 56.9 | 83.0 |

| Elastic recovery rate (%) | ASTM D6084 | 62.03 | 65.23 | 59.81 | 62.03 |

| Samples | Top (°C) | Bottom (°C) | Difference Value (°C) |

|---|---|---|---|

| AR-1 | 53.2 | 56.3 | 3.1 |

| AR-2 | 52.2 | 58.1 | 5.9 |

| AR-3 | 50.6 | 55.1 | 4.5 |

| SBSMA | 75.4 | 64.8 | 10.6 |

| Samples | G*/sin(δ) (kPa) | PG Grade (°C) | |||||

|---|---|---|---|---|---|---|---|

| 58 °C | 64 °C | 70 °C | 76 °C | 82 °C | 88 °C | ||

| AR-1 | 16.2 | 9.3 | 5.6 | 3.4 | 2.2 | 1.01 | 88 |

| AR-2 | 10.0 | 5.5 | 3.1 | 1.8 | 1.1 | / | 82 |

| AR-3 | 6.0 | 3.3 | 1.9 | 1.1 | 0.7 | / | 82 |

| SBSMA | 14.2 | 7.4 | 4.1 | 2.5 | 1.3 | / | 82 |

| Samples | 0.1 kPa | 3.2 kPa | ||

|---|---|---|---|---|

| R (%) | Jnr (×10−3) | R (%) | Jnr (×10−3) | |

| AR-1 | 84.1 | 9.6 | 34.6 | 51 |

| AR-2 | 96.7 | 4.1 | 8.9 | 167.1 |

| AR-3 | 68.9 | 54.0 | 21.1 | 166.1 |

| SBSMA | 71.6 | 22.2 | 68.0 | 36.7 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Li, R.; Liu, T.; Pei, J.; Li, Y.; Luo, Q. Study on the Effect of Microwave Processing on Asphalt-Rubber. Materials 2020, 13, 411. https://doi.org/10.3390/ma13020411

Xu J, Li R, Liu T, Pei J, Li Y, Luo Q. Study on the Effect of Microwave Processing on Asphalt-Rubber. Materials. 2020; 13(2):411. https://doi.org/10.3390/ma13020411

Chicago/Turabian StyleXu, Jing, Rui Li, Tao Liu, Jianzhong Pei, Yongkang Li, and Qinghui Luo. 2020. "Study on the Effect of Microwave Processing on Asphalt-Rubber" Materials 13, no. 2: 411. https://doi.org/10.3390/ma13020411

APA StyleXu, J., Li, R., Liu, T., Pei, J., Li, Y., & Luo, Q. (2020). Study on the Effect of Microwave Processing on Asphalt-Rubber. Materials, 13(2), 411. https://doi.org/10.3390/ma13020411