Highly Adhesive and Sustainable UV/Heat Dual-Curable Adhesives Embedded with Reactive Core-Shell Polymer Nanoparticles for Super-Narrow Bezel Display

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

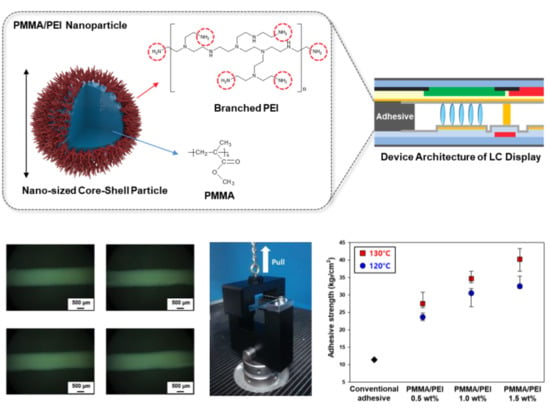

2.2. Synthesis of Multifunctional PMMA/PEI Core-Shell Nanoparticle

2.3. Preparation of UV/Heat Dual-Curable Adhesives Embedded with PMMA/PEI Nanoparticles

2.4. Characterization

3. Results and Discussion

3.1. Synthesis of Multifunctional PMMA/PEI Core-shell Nanoparticles

3.2. Curing and Narrow Drawing Characteristics of New UV/Heat Dual-Curable Adhesives

3.3. Adhesive Strength and Elongation Property of New UV/Heat Dual-Curable Adhesives

3.4. Contact Contamination Characteristics of New UV/Heat Dual-Curable Adhesives

4. Conclusions

Funding

Conflicts of Interest

References

- Shin, J.; Matsushima, H.; Chan, J.W.; Hoyle, C.E. Segmented polythiourethane elastomers through sequential thiol-ene and thiol-isocyanate reactions. Macromolecules 2009, 42, 3294–3301. [Google Scholar] [CrossRef]

- Yin, Q.; Yang, W.; Sun, C.; Di, M. Preparation and properties of lignin-epoxy resin composite. BioResources 2012, 7, 5737–5748. [Google Scholar] [CrossRef]

- Chae, K.H.; Lee, C.S.; Kim, J.H. One component photo-curing agent for epoxy resins based on multifunctional photobase generators containing oxime-urethane groups. Polym. Adv. Technol. 2011, 22, 1427–1433. [Google Scholar] [CrossRef]

- Park, Y.J.; Lim, D.H.; Kim, H.J.; Park, D.S.; Sung, I.K. UV- and thermal-curing behaviors of dual-curable adhesives based on epoxy acrylate oligomers. Int. J. Adhes. Adhes. 2009, 29, 710–717. [Google Scholar] [CrossRef]

- Bayramoglu, G.; Kahraman, M.V.; Kayaman-Apohan, N.; Gungor, A. Synthesis and characterization of UV-curable dual hybrid oligomers based on epoxy acrylate containing pendant alkoxysilane groups. Prog. Org. Coat. 2006, 57, 50–55. [Google Scholar] [CrossRef]

- Thomas, R.; Yumei, D.; Yuelong, H.; Le, Y.; Moldenaers, P.; Weimin, Y.; Czigancy, T.; Thomas, S. Miscibility, morphology, thermal, and mechanical properties of a DGEBA based epoxy resin toughened with a liquid rubber. Polymer 2008, 49, 278–294. [Google Scholar] [CrossRef]

- Jain, R.; Narula, A.K.; Chouldhary, V. Studies on epoxy/carbonate nanocomposites. J. Appl. Polym. Sci. 2009, 114, 2161–2168. [Google Scholar] [CrossRef]

- Petrie, E.M. Epoxy Adhesive Formulations, 1st ed.; McGraw-Hill Book Company: New York, NY, USA, 2005; pp. 1–24. [Google Scholar]

- Wang, Y.T.; Wang, C.S.; Yin, H.Y.; Wang, L.L.; Xie, H.F.; Cheng, R.S. Carboxyl-terminated butadiene-acrylonitrile-toughened epoxy/carboxyl-modified carbon nanotube nanocomposites: Thermal and mechanical properties. Express Polym. Lett. 2012, 6, 719–728. [Google Scholar] [CrossRef]

- Hong, S.; Chung, S.Y.; Neilson, C.; Fedors, R.F. Carboxyl-terminated butadiene-acrylonitrile-modified epoxy resin and its graphite fiber-reinforced composite morphology and dynamic mechanical properties. ACS Symp. Ser. 1984, 243, 91–108. [Google Scholar]

- Nguyen, F.N.; Berg, J.C. Novel core-shell (dendrimer) epoxy tougheners: Processing and hot-wet performance. Compos. Part A-Appl. S. 2008, 39, 1007–1011. [Google Scholar] [CrossRef]

- Lin, K.; Shien, Y. Core-shell particles designed for toughening epoxy resins.1. preparation and characterization of core-shell particles. J. Appl. Polym. Sci. 1998, 69, 2069–2078. [Google Scholar] [CrossRef]

- Giannakopoulos, G.; Masania, K.; Taylor, A.C. Toughening of epoxy using core-shell particles. J. Mater. Sci. 2011, 46, 327–338. [Google Scholar] [CrossRef]

- Jingqiang, S.; Yafeng, Z.; Jindong, Q.; Jianzheng, K. Core-shell particles with an acrylate polyurethane core as tougheners for epoxy resins. J. Mater. Sci. 2004, 39, 6383–6384. [Google Scholar] [CrossRef]

- Wu, X.; Rahman, A.; Zhou, Z.; Pelot, D.D.; Sinha-Ray, S.; Chen, B.; Payne, S.; Yarin, A.L. Electrospinning core-shell nanofibers for interfacial toughening and self-healing of carbon-fiber/epoxy composites. J. Appl. Polym. Sci. 2013, 129, 1383–1393. [Google Scholar] [CrossRef]

- Frohlich, J.; Kautz, H.; Thomann, R.; Frey, H.; Mulhaupt, R. Reactive core/shell type hyperbranched blockcopolyethers as new liquid rubbers for epoxy toughening. Polymer 2004, 45, 2155–2164. [Google Scholar] [CrossRef]

- Qian, J.Y.; Pearson, R.A.; Dimonie, Y.L.; El-Aasser, M.S. Synthesis and application of core-shell particles as toughening agents for epoxies. J. Appl. Polym. Sci. 1995, 58, 439–448. [Google Scholar] [CrossRef]

- Day, R.J.; Lovell, P.A.; Wazzan, A.A. Toughened carbon/epoxy composites made by using core/shell particles. Compos. Sci. Technol. 2001, 61, 41–56. [Google Scholar] [CrossRef]

- Ho, K.M.; Mao, X.; Gu, L.; Li, P. Facile route to enzyme immobilization: Core-shell nanoenzyme particles consisting of well-defined poly(methyl methacrylate) cores and cellulose shells. Langmuir 2008, 24, 11036–11042. [Google Scholar] [CrossRef]

- Lee, B.; Son, I.; Kim, J.H.; Kim, C.; Yoo, J.Y.; Choi, S.S.; Lee, J.H. A simple approach for the preparation of fluorescent poly(methyl methacrylate)-polyethyleneimine nanoparticles containing biomolecular curcumin. J. Nanosci. Nanotechnol. 2016, 16, 10874–10880. [Google Scholar] [CrossRef]

- Fu, S.Y.; Feng, X.Q.; Lauke, B.; Mai, Y.W. Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate–polymer composites. Compos. Part B Eng. 2008, 39, 933–961. [Google Scholar] [CrossRef]

- Ataberk, N. The effect of Cu nanoparticle adding on to epoxy-based adhesive and adhesion properties. Sci. Rep. 2020, 10, 11038. [Google Scholar] [CrossRef] [PubMed]

- Leite, F.L.; Bueno, C.C.; Da Róz, A.L.; Ziemath, E.C.; Oliveira, O.N., Jr. Theoretical models for surface forces and adhesion and their measurement using atomic force microscopy. Int. J. Mol. Sci. 2012, 13, 12773–12856. [Google Scholar] [CrossRef] [PubMed]

- Miao, X.; Meng, Y.; Li, X. A novel all-purpose epoxy-terminated hyperbranched polyether sulphone toughener for an epoxy/amine system. Polymer 2015, 60, 88–95. [Google Scholar] [CrossRef]

| Composition (wt%) | Conventional Adhesive | New Adhesives Embedded with PMMA/PEI Nanoparticles | |||

|---|---|---|---|---|---|

| Resin | YD-128 | 40 | 40 | 40 | 40 |

| BisGMA | 40 | 40 | 40 | 40 | |

| Filler | Fumed silica | 16 | 17 | 16.5 | 16 |

| Hardener | ADH | 1.5 | - | - | - |

| PMMA/PEI | - | 0.5 | 1.0 | 1.5 | |

| Photoinitiator | Irgacure 651 | 2.5 | 2.5 | 2.5 | 2.5 |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.H. Highly Adhesive and Sustainable UV/Heat Dual-Curable Adhesives Embedded with Reactive Core-Shell Polymer Nanoparticles for Super-Narrow Bezel Display. Materials 2020, 13, 3492. https://doi.org/10.3390/ma13163492

Lee JH. Highly Adhesive and Sustainable UV/Heat Dual-Curable Adhesives Embedded with Reactive Core-Shell Polymer Nanoparticles for Super-Narrow Bezel Display. Materials. 2020; 13(16):3492. https://doi.org/10.3390/ma13163492

Chicago/Turabian StyleLee, Jun Hyup. 2020. "Highly Adhesive and Sustainable UV/Heat Dual-Curable Adhesives Embedded with Reactive Core-Shell Polymer Nanoparticles for Super-Narrow Bezel Display" Materials 13, no. 16: 3492. https://doi.org/10.3390/ma13163492

APA StyleLee, J. H. (2020). Highly Adhesive and Sustainable UV/Heat Dual-Curable Adhesives Embedded with Reactive Core-Shell Polymer Nanoparticles for Super-Narrow Bezel Display. Materials, 13(16), 3492. https://doi.org/10.3390/ma13163492