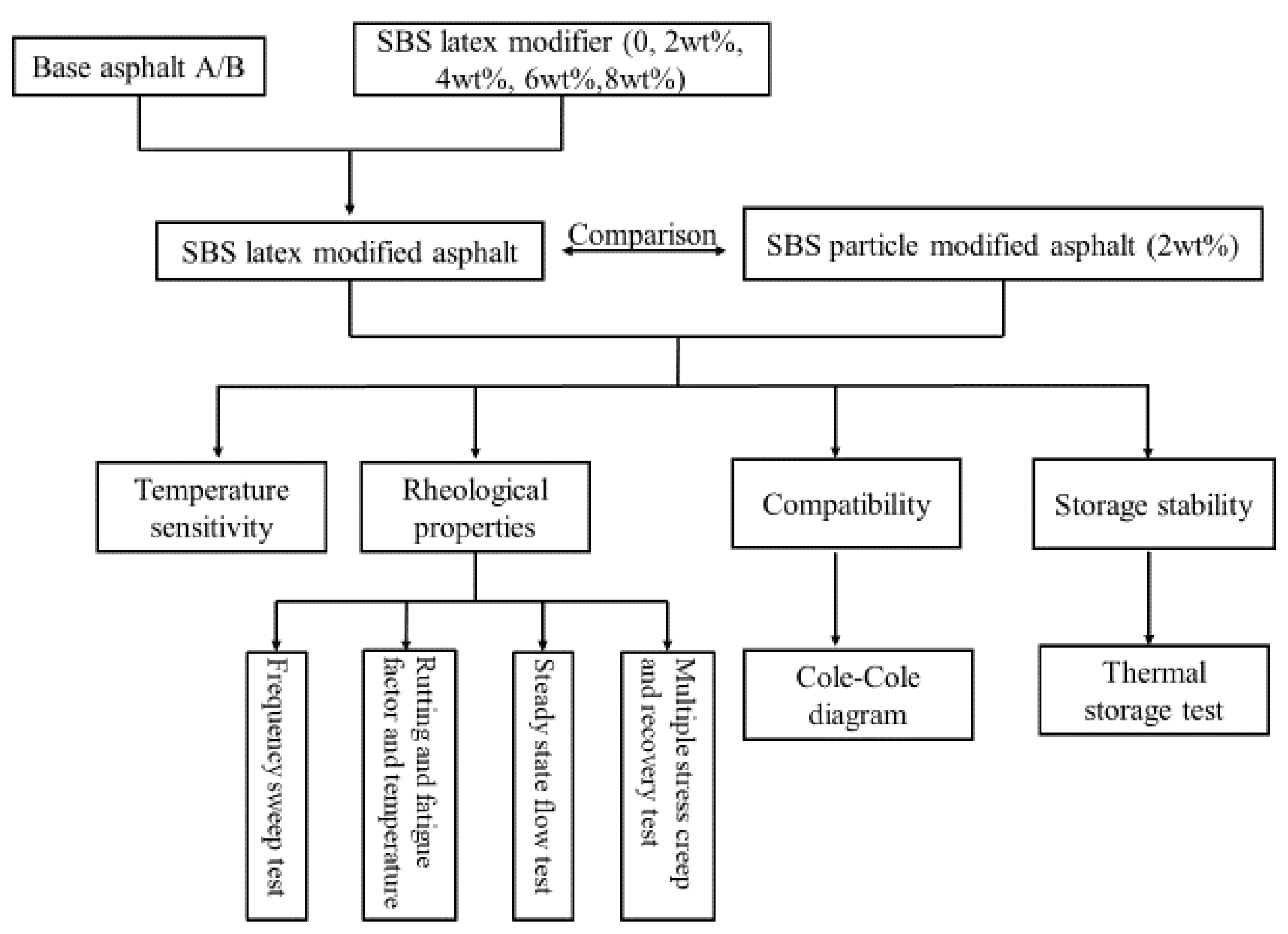

3.1. Frequency Sweep Tests

It is clear that road performance depends, to some extent, on the viscoelastic and mechanical properties of asphalt binder [

30,

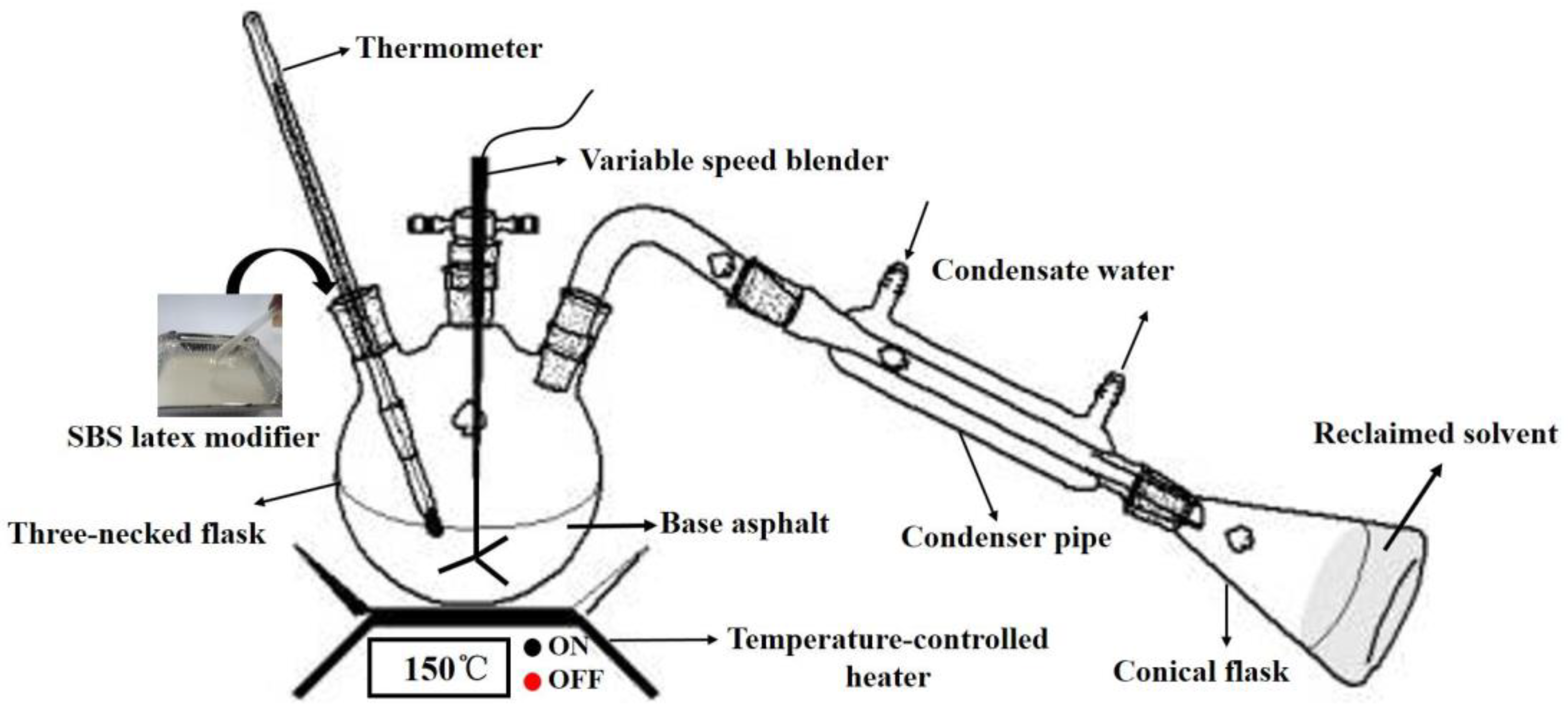

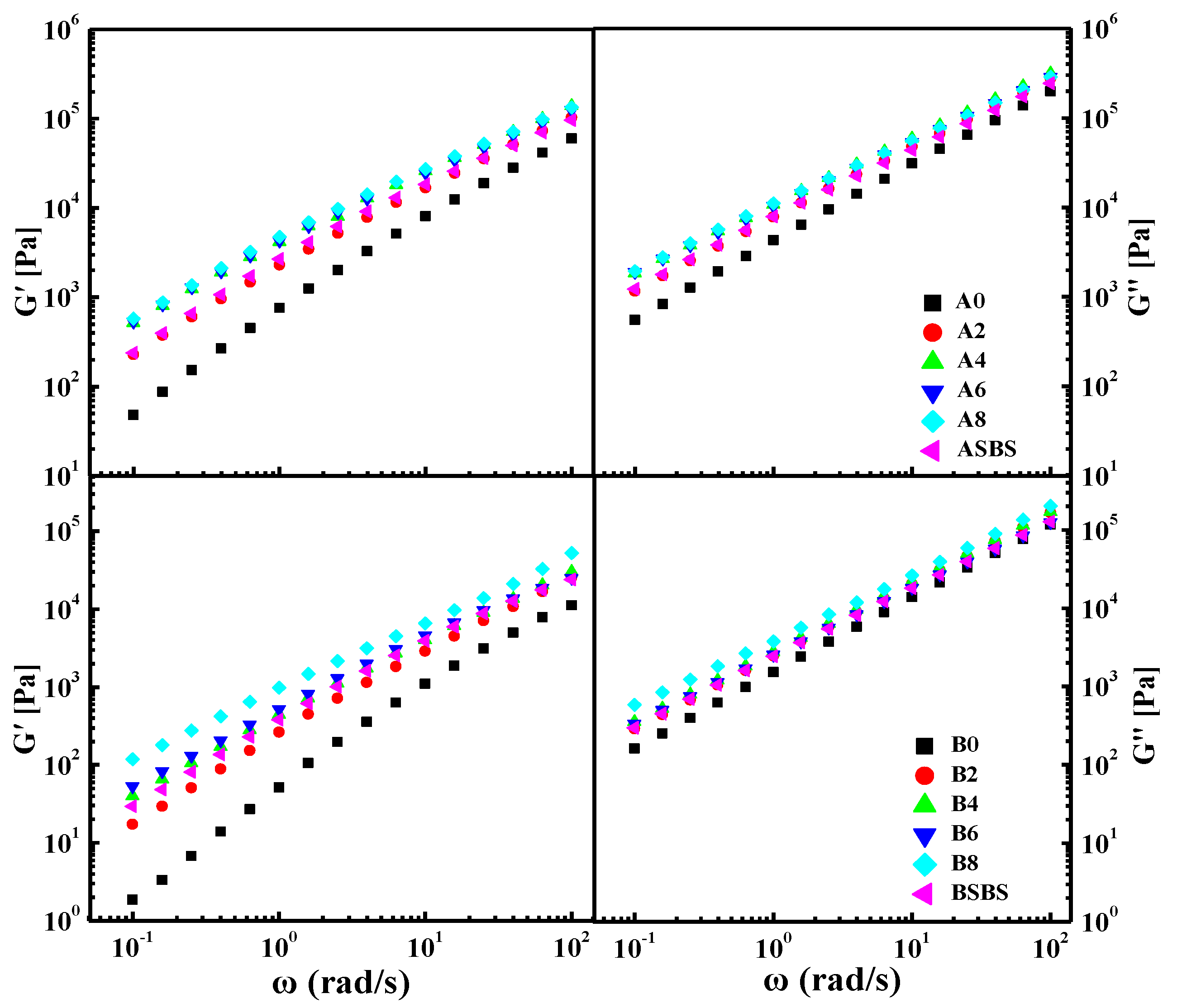

31]. Characterization of the linear viscoelastic behavior of the asphalt binder was performed to evaluate the effect of the SBS latex dosage on the rheology of the modified asphalts. Asphalt is a viscoelastic material that behaves very differently with various temperature and loading times. Therefore, a frequency sweep test was performed in the frequency region of 0.1–100 rad/s at 60 °C, and the experimental results are shown in

Figure 3.

From

Figure 3, clear increasing trends in the storage modulus G’ and loss modulus G” can be seen with the frequency increasing gradually. It is well known that storage modulus G’ represents the energy recovery and elastic section of asphalt, while loss modulus G” shows the energy loss and viscous part. However, the increasing trends of the two moduli were very heterogeneous. With regard to all asphalt samples, storage modulus G’ showed lower values than loss modulus G” in the whole testing frequency region, indicating that the viscoelastic performance of the base and modified asphalts were primarily dominated by viscous properties.

This phenomenon was more obvious in the case of neat asphalt which is attributed to its poor viscoelastic properties at high temperature. Meanwhile, the gap between G’ and G” became smaller as the frequency declined. After adding SBS latex, the G’ and G” values of the modified asphalt both underwent an increasing trend compared with the neat asphalt. With the increase in the SBS latex dosage, the G’ and G” values of asphalt samples both continued to increased, while the increasing trend weakened when the SBS latex content exceeds 6 wt%. The results also reveal that adding SBS latex increased the proportion of elastic components in the binder, which contributes to improving the stiffness of asphalt at high temperature.

Furthermore, asphalt composition also has a remarkable influence on the modulus and stiffness of SBS latex-modified asphalt. Both the storage and loss modulus of asphalt A were higher than that of asphalt B with the same SBS latex concentration; this is attributed to the differences in asphalt composition. This phenomenon suggests that there was a stronger reaction between the SBS latex modifier and base asphalt A with a higher asphaltenes content. As a consequence, asphalt type and composition are very crucial for SBS latex modification, and a relatively high asphaltenes dosage is beneficial to obtaining a satisfactory modification result. Additionally, the SBS latex-modified asphalt had better moduli than that of the conventional SBS particle-modified asphalt when the SBS concentration was the same, indicating that the SBS latex-modified asphalt possessed better deformation resistance performance. In addition, the moduli difference between the SBS latex-modified asphalt and the conventional SBS particle-modified asphalt was more distinct for asphalt A.

3.2. Temperature Sweep Tests

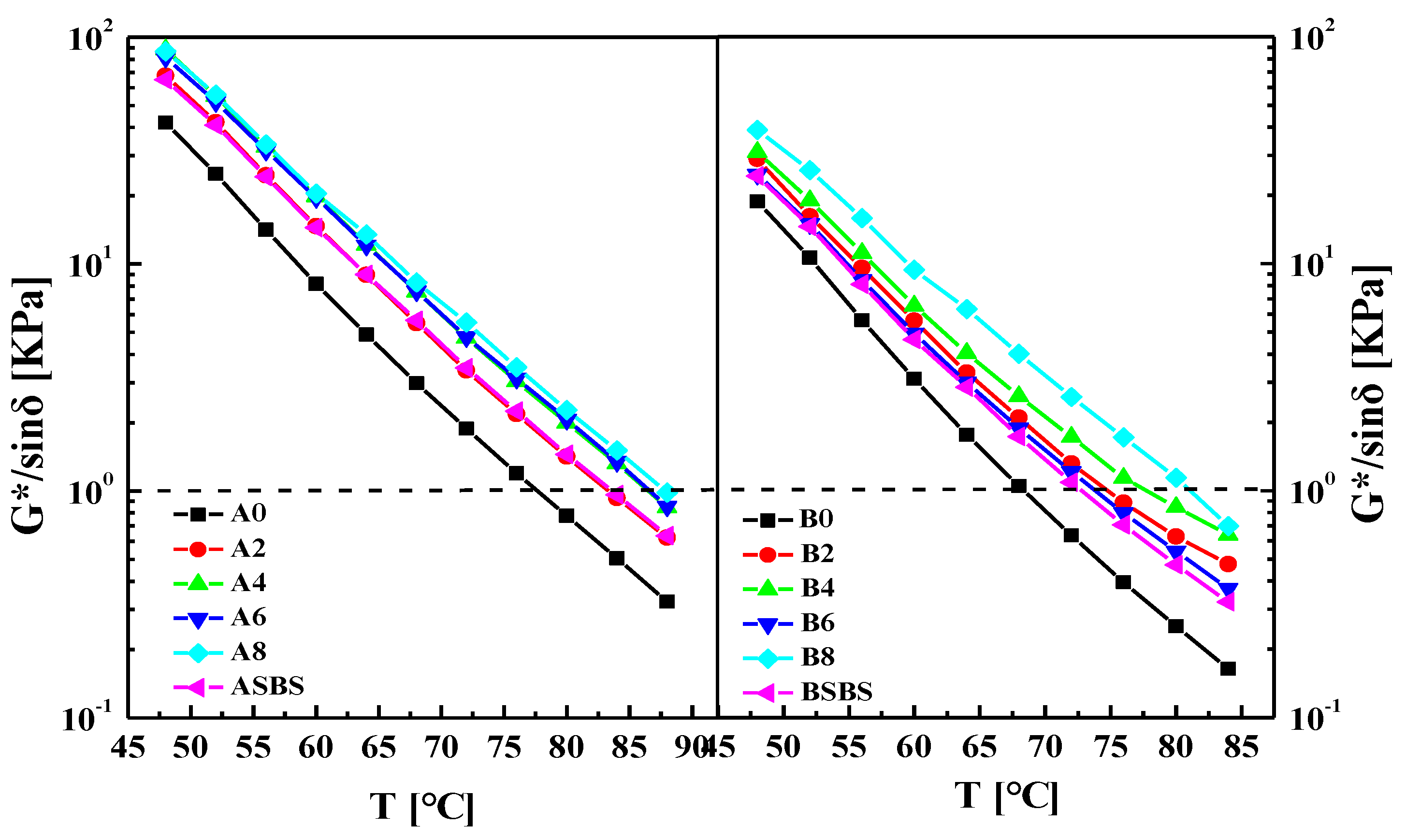

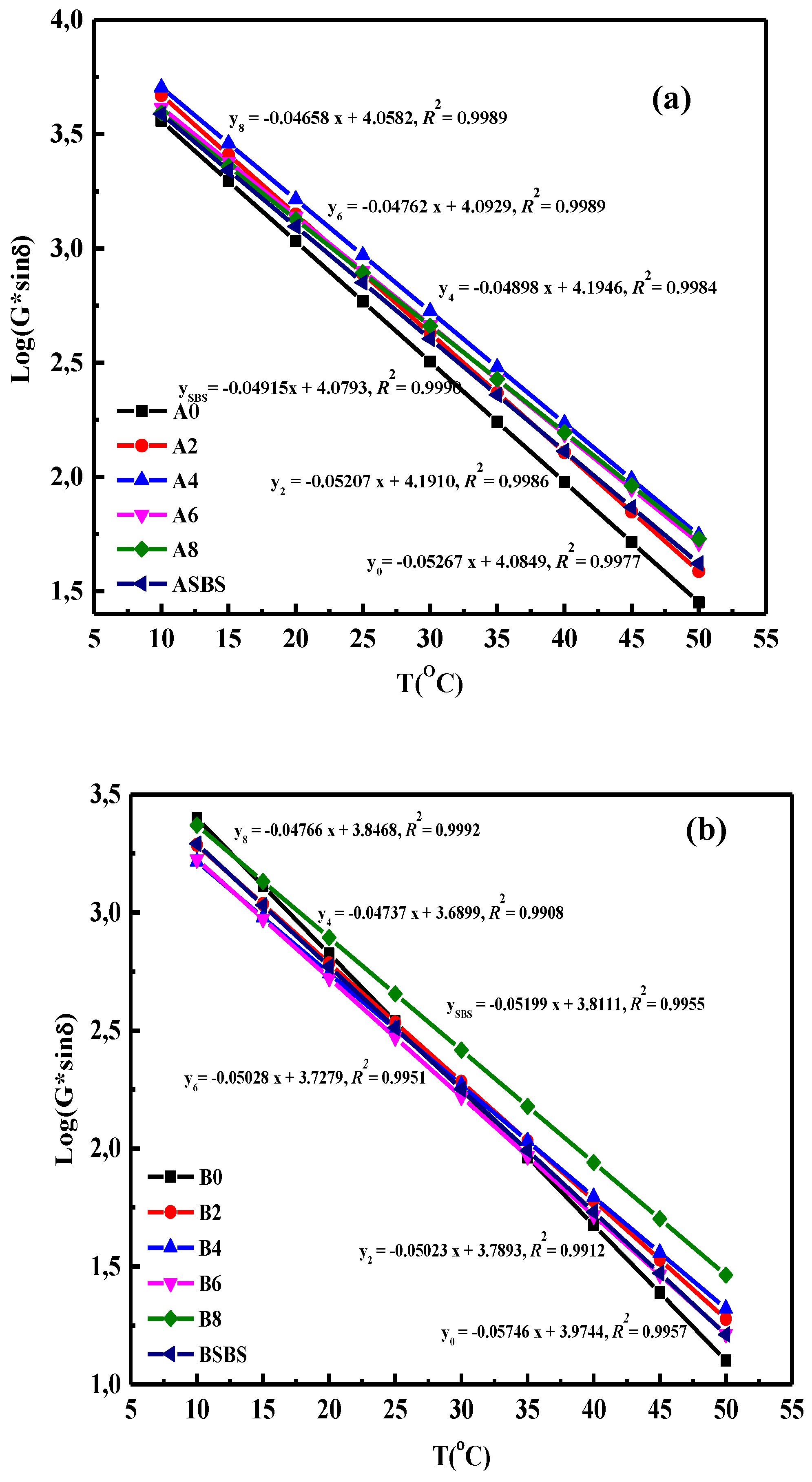

It is well known that rutting resistance factor G*/sinδ is an important index to evaluate the high-temperature stability of asphalt. The rutting resistance factor G*/sinδ of asphalt was obtained by temperature sweep tests with the temperature increasing from 48 °C to 84 °C and with a frequency of 10 rad/s. The rutting resistance factors G*/sinδ of the base and modified asphalts with various SBS latex dosages are presented in

Figure 4. There was an obvious linear relationship between the testing temperature and rutting resistance factors of the asphalts. In order to evaluate the impact of SBS latex content on the anti-rutting properties of the modified asphalts, the linear fitting formula was used and the failure temperatures of the asphalts were calculated when the rutting resistance factor G*/sinδ was equal to 1.0 KPa.

Table 2 shows the failure temperatures of the base and modified asphalts. It can be seen that the addition of SBS latex increased the failure temperature of the base asphalt dramatically, indicating SBS latex can improve the anti-rutting ability of asphalt. However, the SBS latex dosage had a different effect on the improvement of the failure temperature of the asphalts. For asphalt A, the failure temperature increased by 7.01%, 10.74%, 10.79%, and 12.25% when the SBS latex content was 2 wt%, 4 wt%, 6 wt%, and 8 wt%, respectively, while the failure temperature of asphalt B increased by 9.15%, 14.28%, 15.27%, and 18.42%. Clearly, the greater influence of the SBS latex concentration on asphalt B over asphalt A is obvious. Meanwhile, the degree of influence became smaller when the SBS latex dosage exceeded 4 wt%.

In addition, the failure temperature of the SBS latex-modified asphalt was higher than that of the SBS particle-modified asphalt with the same SBS solid content. That is to say, SBS latex-modified asphalt had a better anti-rutting ability than the SBS particle-modified asphalt which is the main binder used in pavement construction. Moreover, for asphalt A, the failure temperature of the SBS latex-modified asphalt was 2.67 °C larger than that of the SBS particle-modified asphalt, while the difference for asphalt B was 6.15 °C. Meanwhile, the failure temperature values of the modified asphalts A were all higher than that of asphalts B, showing that the SBS latex-modified asphalt A had greater rutting and deformation resistance because of the higher asphaltenes concentration.

Fatigue cracking is another defect of asphalt pavement, thus the fatigue resistance factor is an important and essential index to evaluate the long-term pavement performance and service life of asphalt roads which has been receiving increasing attention [

32,

33]. In this study, temperature sweep tests were performed with temperature changes from 10 °C to 50 °C with 5 °C increments to investigate the effect of SBS latex dosage on the fatigue resistance of modified asphalt. The relationship between testing temperature and fatigue factors G*sinδ in SBS-latex-modified asphalt is plotted in

Figure 5. It was found that the fatigue resistance factor of modified asphalt increased as the temperature gradually increased, illustrating that a high-temperature environment has an adverse effect on the fatigue resistance performance of SBS latex-modified asphalt.

In order to assess the fatigue property of modified asphalt intuitively, the ultimate fatigue temperature was calculated and used for analysis [

34]. The relationship between the temperature and fatigue resistance of asphalt can be demonstrated by a linear formula, which is also shown in

Figure 5. There was a clear linear relationship between the temperature and fatigue factor of asphalt, and the correlation coefficient values

R2 were all more than 0.99. Besides, the fatigue temperature of of base and modified asphalts with various SBS latex concentrations are displayed in

Table 2. The SBS latex dosage has great influence on the fatigue property of modified asphalt. The addition of SBS latex remarkably decreased the fatigue temperature of base asphalt, showing the positive effect of SBS latex on improving the fatigue resistance of asphalt. However, as SBS latex dosage increased, the fatigue temperature of modified asphalt first declined and then increased, indicating that a higher SBS latex dosage leads to a loss in fatigue resistance for SBS latex-modified asphalt, and that there exists an optimal SBS latex content to ensure the best fatigue resistance performance. Regardless of the asphalt components, the modified asphalt with an SBS latex content of 4 wt% had the lowest fatigue temperature and best fatigue resistance ability. That is to say, the optimal dosage of SBS latex in this study was 4 wt% when considering the anti-fatigue performance of modified asphalt.

Furthermore, asphalt type and chemical composition also affected the fatigue resistance of SBS-latex-modified asphalt dramatically [

35,

36]. It was found that, with the same SBS latex dosage, the fatigue temperature values of modified asphalts A were all higher than that of modified asphalts B, indicating that modified asphalts B had better fatigue resistance performance. This is due to the difference in asphalt composition, and the lower asphaltene concentration of asphalt B contributed to the improvement of fatigue resistance performance. It is interesting that the SBS latex-modified asphalt had a lower fatigue temperature than the SBS particle-modified asphalt, indicating that the SBS latex-modified asphalt had better fatigue resistance. Thus, in regard to the fatigue resistance properties, it is feasible and superior to use SBS latex as a modifier of asphalt to enhance its properties.

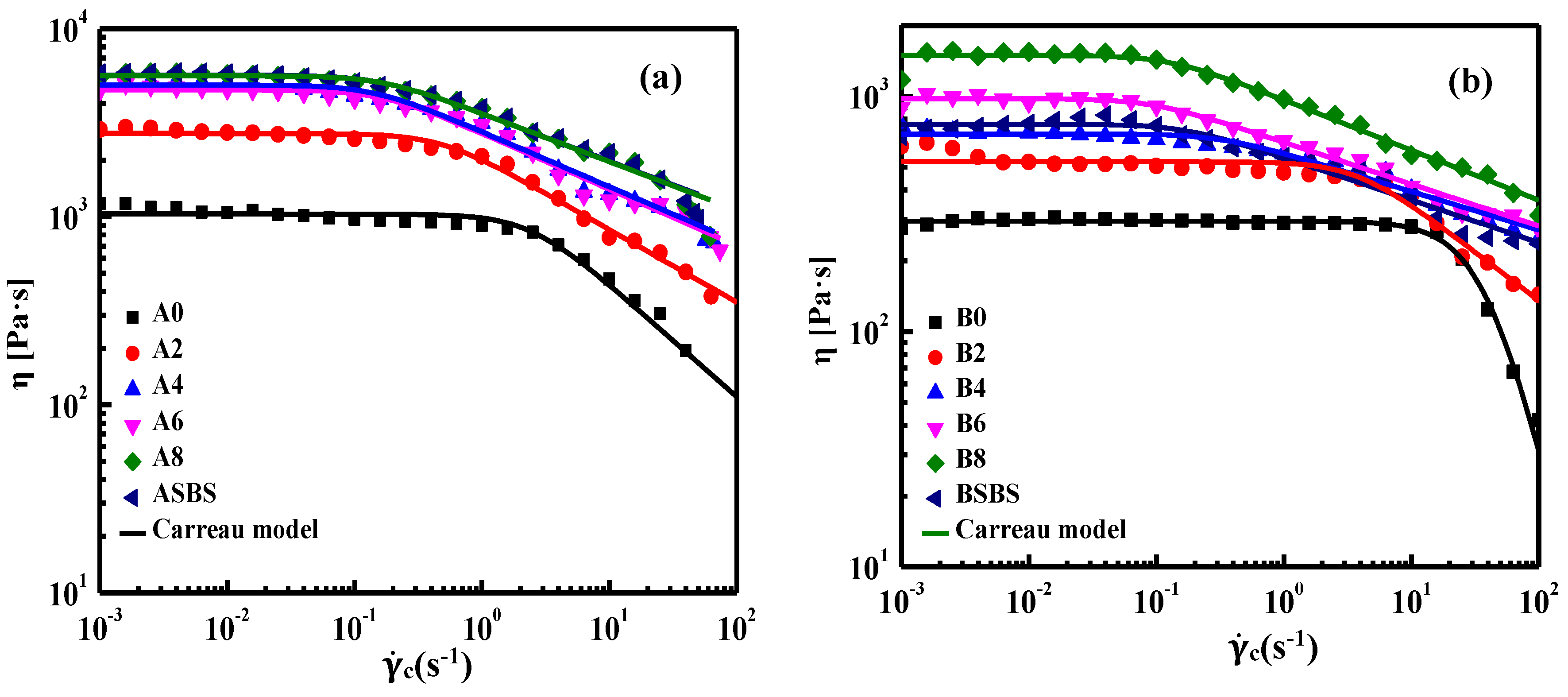

3.3. Steady-State Flow Tests

Characterization under large deformation always gives a very distinct viscoelastic response in comparison with those in small deformation, especially for polymer-modified asphalt [

37,

38]. Thus, the 60 °C flow behavior of asphalt was characterized by steady-state flow tests with the shear rate increasing from 10

−3 s

−1 to 10

2 s

−1. The flow curves of base and SBS-latex-modified asphalts are plotted in

Figure 6. On the whole, the viscous flow behavior of asphalt shows a dependence on shear rate, which is extraordinarily distinct for modified asphalt. The shear viscosity of asphalt keeps constant when the shear rate is in the low range, representing the typical Newtonian fluid characteristic [

39]. When the shear rate exceeds this value, the shear viscosity of the asphalt decreases remarkably which presents an apparent shear-thinning behavior. Neat asphalt has the widest Newtonian behavior region, which is shortened after adding SBS latex. The non-Newtonian fluid characteristics of asphalt with a higher SBS latex dosage were more obvious, which is attributed to the complicated entanglement between asphalt and polymer. On the other hand, the viscosity of the base asphalt was the lowest, increasing gradually with the increase in SBS latex content, indicating that adding SBS latex can improve the flow resistance of asphalt dramatically. Overall, base asphalt presented primarily Newtonian fluid characteristics, while SBS latex-modified asphalts showed non-Newtonian behavior in the studied region of shear rates. In addition, it is clear that the type and composition of base asphalt had great influence on the flow behavior of SBS-latex-modified asphalt. The Newtonian fluid region of asphalt B was larger than that of asphalt B, which is attributed to the lower amount of asphaltenes in asphalt B. Meanwhile, it was found that the viscosity values of SBS-latex-modified asphalt B were all lower than that of modified asphalt A. That is to say, asphalt B with lower asphaltenes had the advantages of workability and inferior flow resistance ability.

In order to evaluate the effects of SBS latex dosage on the viscous properties of asphalt quantitatively, the relationship between shear rates and viscosity of asphalt can be fitted using Carreau model [

8], which is as follows:

where η shows the viscosity of asphalt, η

0 is the ultimate viscosity when the shear viscosity approaches zero which is also called the zero-shear viscosity (ZSV), s represents the slope of the fitting curve in the non-Newtonian region, while

is shear rate, and

c represents the critical shear rate value when the viscoelastic characteristic of asphalt binder changes from Newtonian behavior to the non-Newtonian region [

40,

41]. From

Figure 6, the flow curve of asphalt fits the Carreau model fairly well, showing the parameters obtained from the Carreau model are very reliable.

Table 3 shows the results of all the studied samples calculated from the Carreau model including zero-shear viscosity η

0, critical shear rate value

c, and fitting curve slope s. It is clear that the neat asphalt has the lowest η

0 value (ZSV), showing the poor flow resistance ability of the base asphalt at high temperature. From

Table 3, it can be seen that the zero-shear viscosity of asphalt B was lower than that of asphalt A, while the

c value of asphalt B was much higher than asphalt A. The results show that compared to asphalt A, asphalt B had a wider Newtonian fuild range and better workability, which is attributed to its higher content of light oil fractions and lower dosage asphaltenes. Meanwhile, it can also be found that the s value of asphalt B is higher than asphalt A, which means asphalt B has higher shear susceptibility than asphalt B, which is also connected to its chemical component characteristics.

Meanwhile, SBS latex can remarkably enhance the ZSV value of asphalt and this improvement was more obvious for modified asphalt A. Interestingly, the zero shear viscosity value of modified asphalt A was higher than that of modified asphalt B, indicating the viscous flow behavior was also significantly affected by the chemical composition of base asphalt. In terms of viscoelastic properties, high aromatic content and moderate asphaltenes dosage were beneficial for enhancing the flow resistance of asphalt. Furthermore, SBS particle-modified asphalt A had a higher η0 value than that of SBS-latex-modified asphalt A, even though the SBS latex content increased to 8 wt%, while the η0 value of SBS particle-modified asphalt B was lower than that of 6 wt% SBS particle-modified asphalt B. On the other hand, adding SBS latex results in a decrease in the critical shear rate c of the asphalt, indicating that the shear-thinning behavior of modified asphalt became more distinct. This is related to the presence of macro-molecules due to the incorporation of polymers and the complicated structure of modified asphalt being prone to disruption by shear stress. Moreover, the addition of SBS latex decreases the s value and improves the resistance to shear thinning of the modified asphalt.

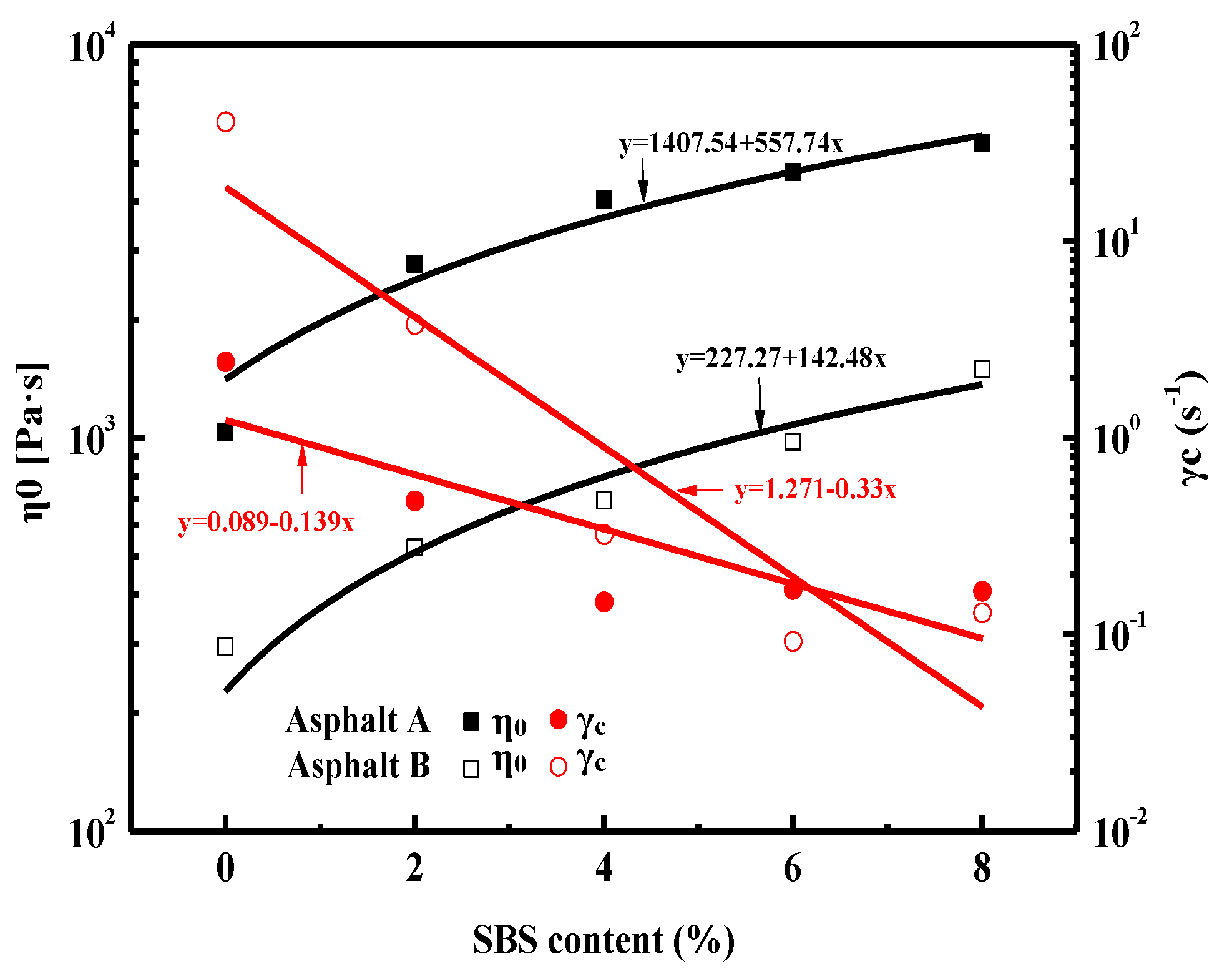

The relationship between the SBS latex dosage and η

0 value as well as the critical shear rate

c was fitted by a linear formula as shown in

Figure 7. With the increase in SBS latex, the η

0 value of modified asphalt increased dramatically, while the critical shear rate

c decreased, showing that SBS latex can improve the deformation resistance and shear-thinning behavior of asphalt. However, the influence of SBS latex content on the ZSV value of modified asphalt A was more obvious than that of modified asphalt B, while the effect on the

c value of modified asphalt B was more distinct than that of modified asphalt B. Furthermore, the asphalt component can also affect the ZSV and

c values of modified asphalt. It was found that the ZSV value of modified asphalt A was higher than that of modified asphalt B, while the

c value of modified asphalt A was lower than that of modified asphalts B, indicating that asphalt A had better deformation resistance ability and was closer to the non-Newtonian fluid characteristic.

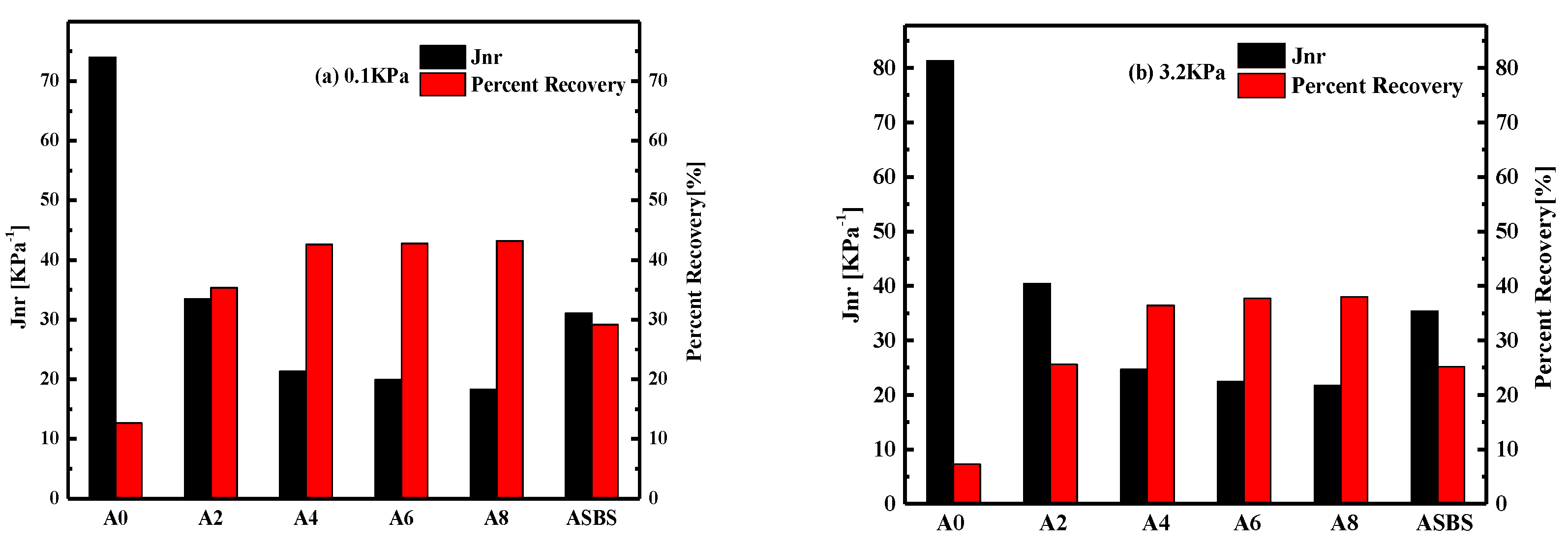

3.4. Creep and Recovery Behavior

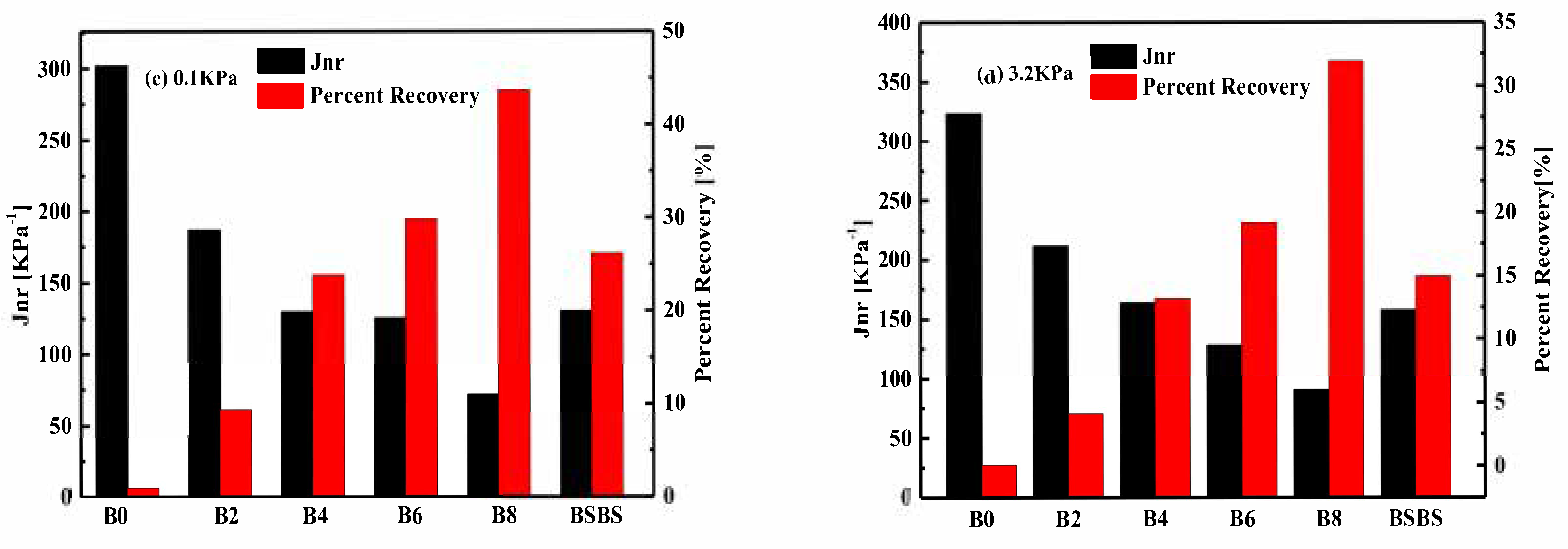

In order to further evaluate the effects of SBS latex dosage on the high-temperature properties and recovery behavior of modified asphalt, MSCR tests were conducted with respect to AASHTO TP70 [

25].

Figure 8 shows the MSCR results of asphalt samples at stress levels of 0.1 KPa and 3.2 KPa, respectively. It is well known that the percent recovery (R%) is an elastic response indicator of asphalt, and the increased value of R% indicates the improvement in the elastic component in asphalt. Meanwhile, non-recoverable creep compliance (Jnr) is well related to the rutting performance of asphalt, and the lower Jnr value represents the better resistance to permanent deformation of binder.

As expected, base asphalt had the lowest R% value and highest Jnr value regardless of the loading stress level. The R% value of asphalt was damaged when the loading stress increased from 0.1 KPa to 3.2 KPa, while the non-recoverable creep compliance Jnr increased dramatically. Meanwhile, adding SBS latex can remarkably increase the R% value and decrease the Jnr value of asphalt. The R% and Jnr value of modified asphalt increased and declined with the increase in SBS latex dosage, respectively. That is to say, SBS latex can improve the elastic recovery and deformation resistance of asphalt. However, the degree of influence of SBS latex content on the R% and Jnr value of modified asphalt depends on the chemical composition of the base asphalt. The effect of SBS latex dosage on the elastic properties of asphalt B was more obvious than that of asphalt A, which means the positive effect of SBS latex on the resistance to permanent deformation was more significant for asphalt B.

Additionally, modified asphalt A always had a higher R% and lower Jnr value than those of modified asphalt B, indicating modified asphalt A had better elastic response and deformation resistance performance than asphalt B. On the other hand, it was found that the R% value of SBS latex-modified asphalt was higher than that of SBS particle-modified asphalt, while the Jnr value of the former was lower than the latter, regardless of loading stress level when the SBS particle content was the same as the latex. Obviously, the SBS latex-modified asphalt possessed better elastic properties and anti-deformation abilities than conventional SBS particle-modified asphalt. As to asphalt A, both R% and Jnr values of SBS particle-modified asphalt were similar to that of 2 wt% SBS latex-modified asphalt, while SBS particle-modified asphalt B had the same grade of anti-rutting and elastic response performance with 4 wt% SBS latex-modified asphalt B. Furthermore, it can be found that the influence of SBS latex dosage on improving the permanent deformation resistance of asphalt A became less obvious when the SBS latex dosage exceeded to 4 wt%. However, the influence of SBS latex dosage on the recovery and creep compliance of asphalt B was more obvious. Therefore, asphalt B was more suitable to be modified with SBS latex which is consistent with the above results.

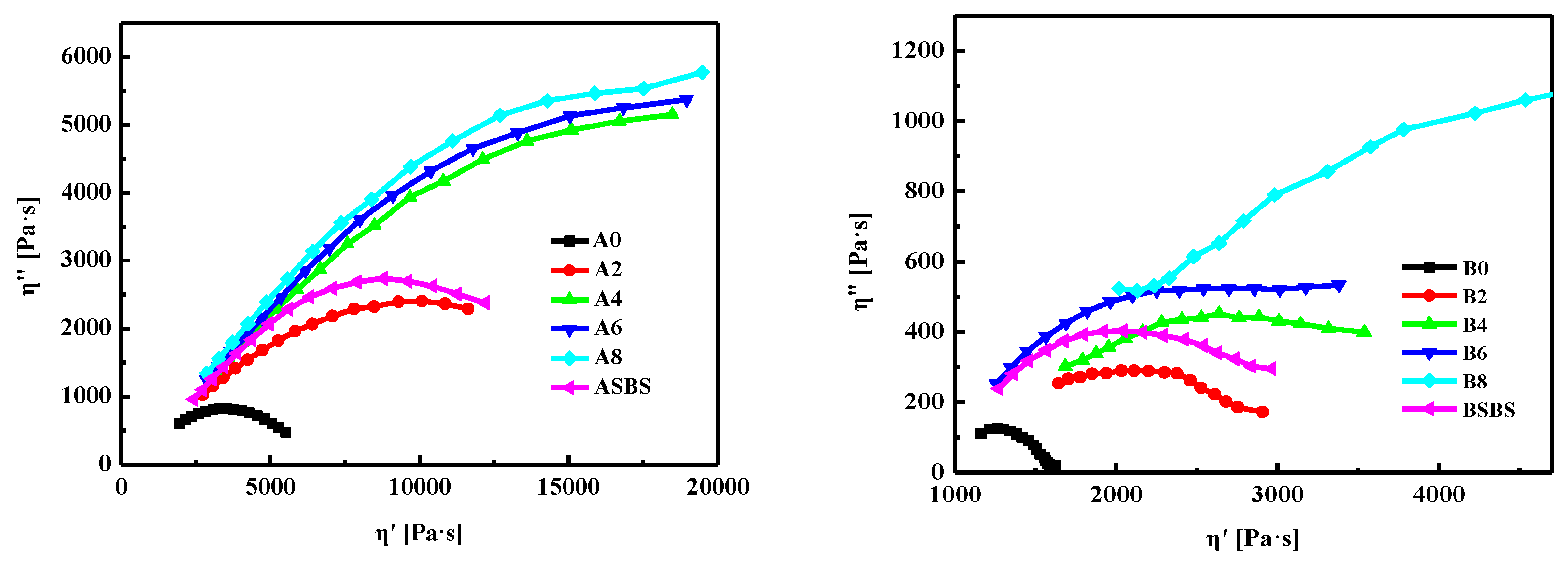

3.5. Compatibility

As is well known, compatibility between polymer and base asphalt is very essential, which can result in phase separation and performance inhomogeneity of polymer-modified asphalt [

12]. According to previous studies [

9,

22,

42], a Cole-Cole diagram is the most efficient method to investigate the compatibility of polymer-modified asphalts. In this study, the Cole-Cole plot was selected to assess the compatibility differences during the preparation of the SBS latex-modified asphalts. It is well known that the compatibility of modified asphalt is related to the shape of Cole-Cole diagrams, and a symmetrical parabola shows great compatibility, while a conclusion of incompatibility between the asphalt and modifier is drawn when the shape deviates from symmetry [

12].

Figure 9 displays the Cole-Cole diagrams of the base asphalt and the SBS latex-modified asphalts at 60 °C. For modified asphalt A, when the SBS latex dosage was lower than 4 wt%, the η” value first increased and then descended with the increase in η’. However, when the SBS latex dosage was larger than 4 wt%, the η” value of the modified asphalt rapidly increased with the increase in η’. This means that the compatibility of SBS latex-modified asphalt A became worse with the increase in the SBS latex dose; this is attributed to the concentretion limitation of resin in asphalt A. On the other hand, Cole-Cole plots of modified asphalt B present symmetrical parabolas when the SBS latex dosage was less than 8 wt%. With the increase in the SBS latex modifier, the shape of the Cole-Cole diagram deviated from this symmetry gradually, indicating the SBS latex dosage had a passive influence on the compatibility of modified asphalt.

Furthermore, the compatibility between asphalt and polymer also depended on the composition of the base asphalt. It was clear that the shape of the Cole-Cole plot for modified asphalt B was closer to symmetrical parabolas than that of modified asphalt A under the same SBS latex dosage [

42,

43,

44]. This result showed that SBS latex-modified asphalt B had better compatibility than asphalt A, which is attributed to the composition differences of the base asphalt. From

Table 1, it can be seen that asphalt B had more resins and a lower asphaltene concentration than asphalt A which is beneficial to the formation of a stable colloid structure and enhanced the compatibility between asphalt and SBS latex modifier. In conclusion, neat asphalt with a higher resins dosage and lower asphaltenes content is suitable to be used to prepare stable SBS latex-modified asphalt with satisfactory compatibility. Furthermore, it was found that the shape of the Cole-Cole plot for the SBS particle-modified asphalt trended to symmetrical parabolas better than that of the SBS latex-modified asphalt, regardless of the type and composition of the base asphalt. This indicates that the SBS latex-modified asphalt had worse compatibility than the conventional SBS particle-modified asphalt.

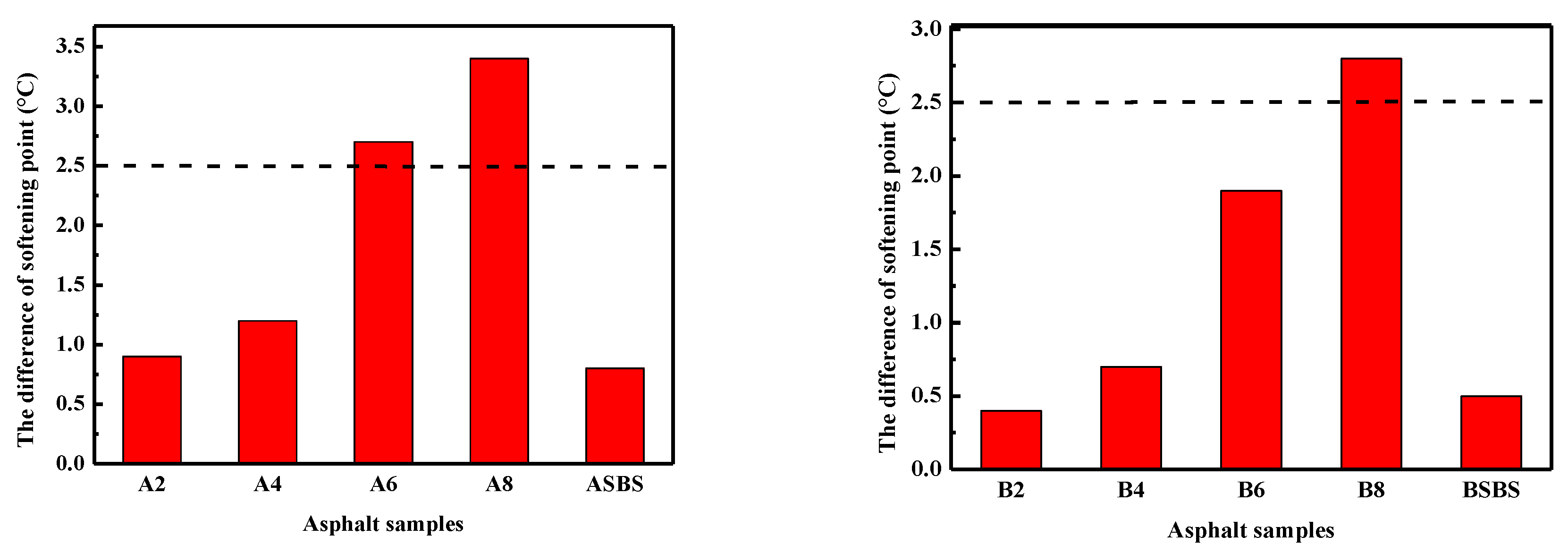

3.6. Storage Stability

Polymer-modified asphalts are multiphase systems and the difference in the solubility and density between polymer and asphalt can result in phase separation of the modified asphalt during high-temperature storage processes [

45]. On the basis of this, a storage stability test was performed on SBS latex-modified asphalt according to the aforementioned testing method. To reveal the effect of SBS latex dosage on storage stability, thermal storage tests were conducted for all modified asphalts at 163 °C for 2 d.

Figure 10 shows the results of storage stability tests for the SBS latex-modified asphalts. The results indicate that, with the increase in the SBS latex dosage, the softening point difference of the modified asphalts became gradually larger, showing that the higher SBS latex content had a passive influence on the storage stability and compatibility of modified asphalt. Meanwhile, the softening point difference value of modified asphalt B was lower than that of modified asphalt A. Hence, it was concluded that all SBS latex-modified asphalts suffered from phase separation during thermal storage, and the storage stability of modified asphalt was associated with the base asphalt composition as well as the SBS latex dosage.

It was found that the softening point difference of the modified asphalt increased as the SBS latex dosage increased. When the SBS dosage content reached 8 wt%, the softening point difference of modified asphalt A and B increased to 3.4 °C and 2.7 °C, respectively, which obviously exceeded the specification that polymer-modified asphalt is storage-stable with a softening point difference lower than 2.5 °C. These results demonstrate that a high SBS latex dosage has an adverse effect on the storage stability of modified asphalt. Furthermore, the thermal stability of modified asphalt also depends on the components of the base asphalt. It was clear that SBS latex-modified asphalt B had a smaller softening point difference value and greater storage stability than modified asphalt A which is associated with the asphalt components. From

Table 1, asphalt A contained more asphaltenes and a lower amount of resins than asphalt B. Therefore, the difference in storage stability can be interpreted by the difference in asphalt compositions. Furthermore, the softening point difference of SBS latex-modified asphalt A was 1.9 °C larger than that of SBS particle-modified asphalt, while modified asphalt B had a 1.4 °C higher softening point difference. That is to say, SBS latex-modified asphalt had worse storage stability than conventional SBS particle-modified asphalt. Thus, it can be concluded that SBS latex-modified asphalt is suitable to be prepared and used at the construction site immediately. Certainly, SBS latex-modified asphalt with a lower content SBS latex can be prepared by the asphalt industry and transported to the site of the construction of an asphalt road.