Thickness-Dependence Electrical Characterization of the One-Dimensional van der Waals TaSe3 Crystal

Abstract

:1. Introduction

2. Materials and Methods

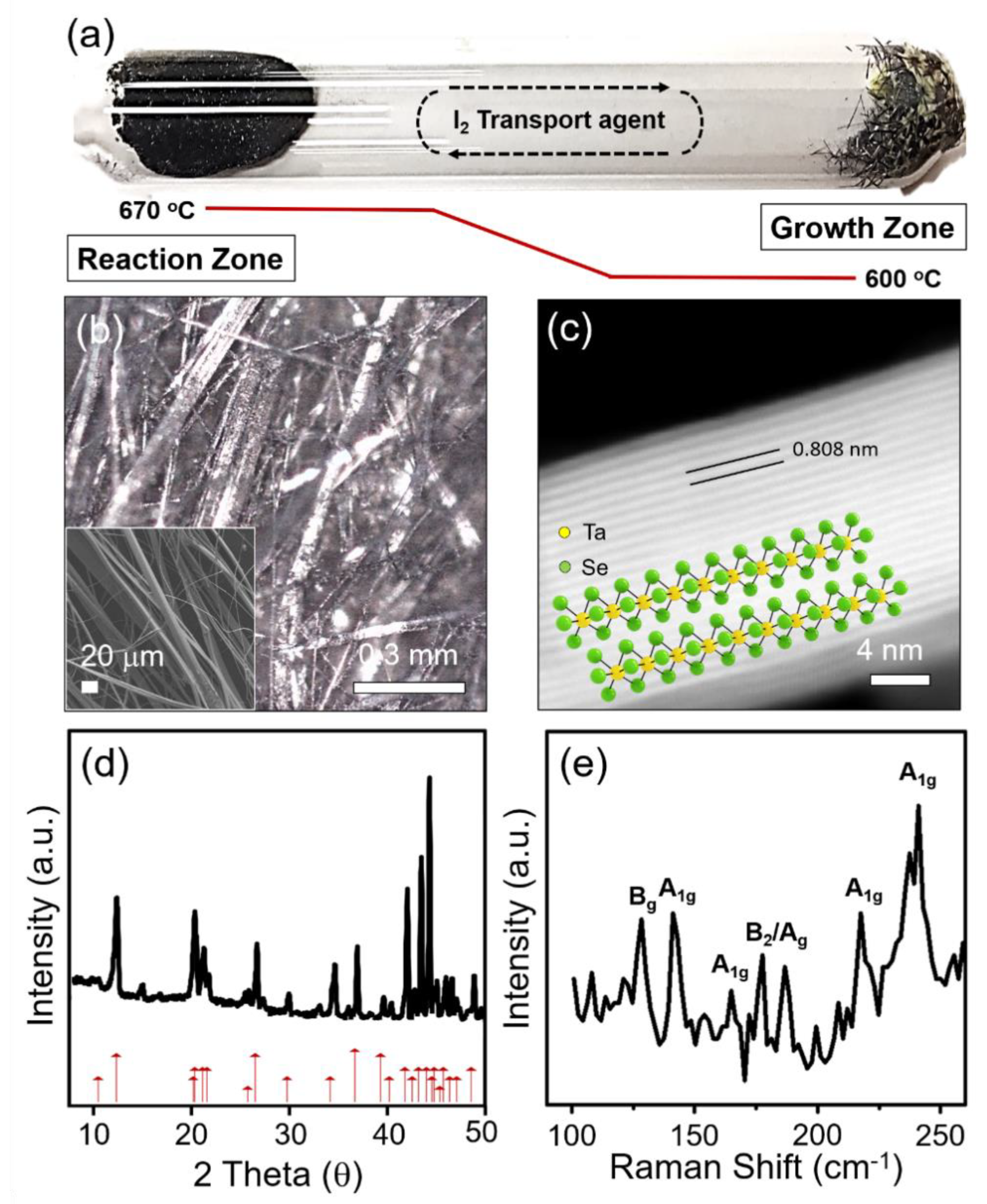

2.1. Synthesis

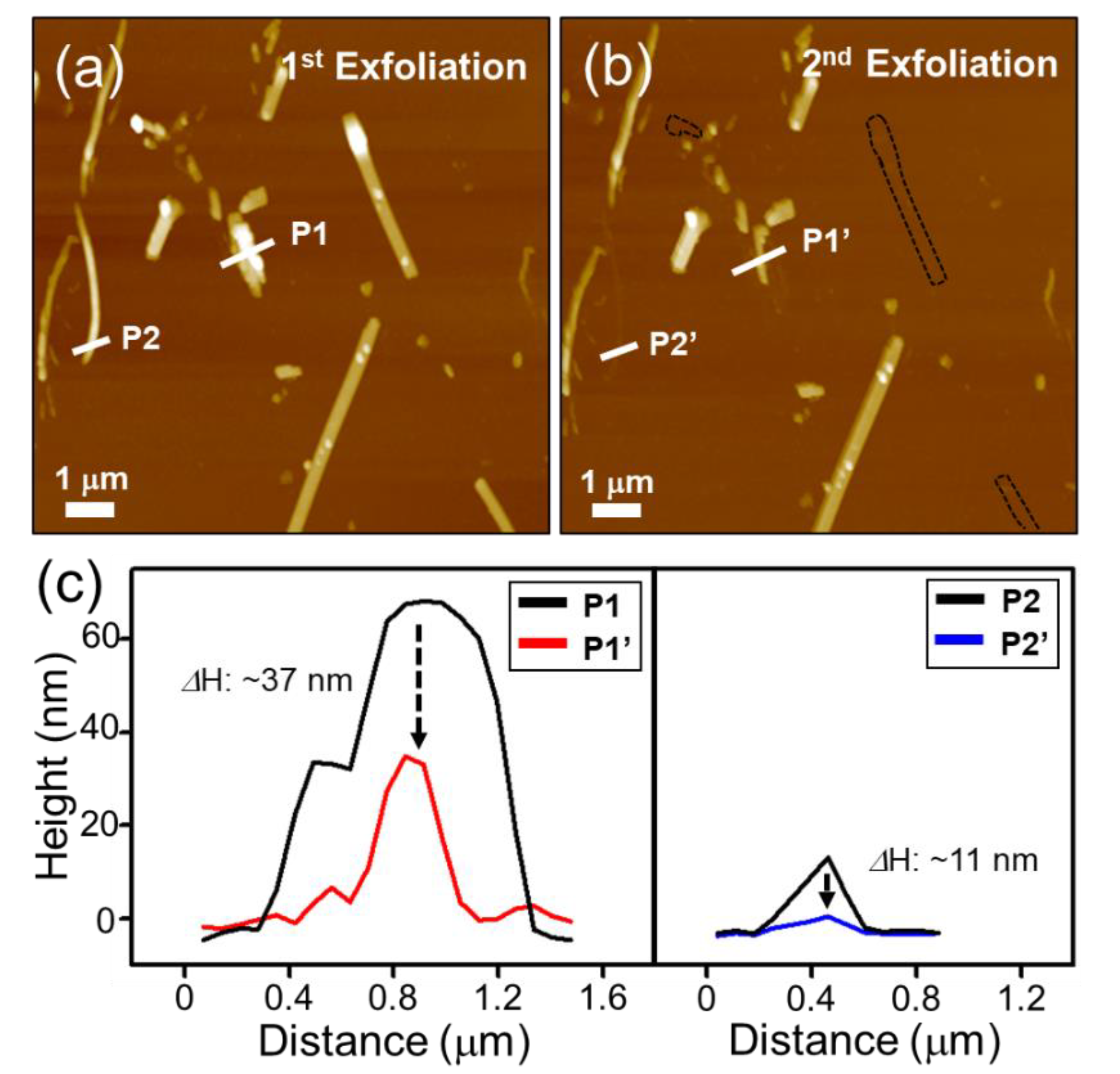

2.2. Mechanical Exfoliation

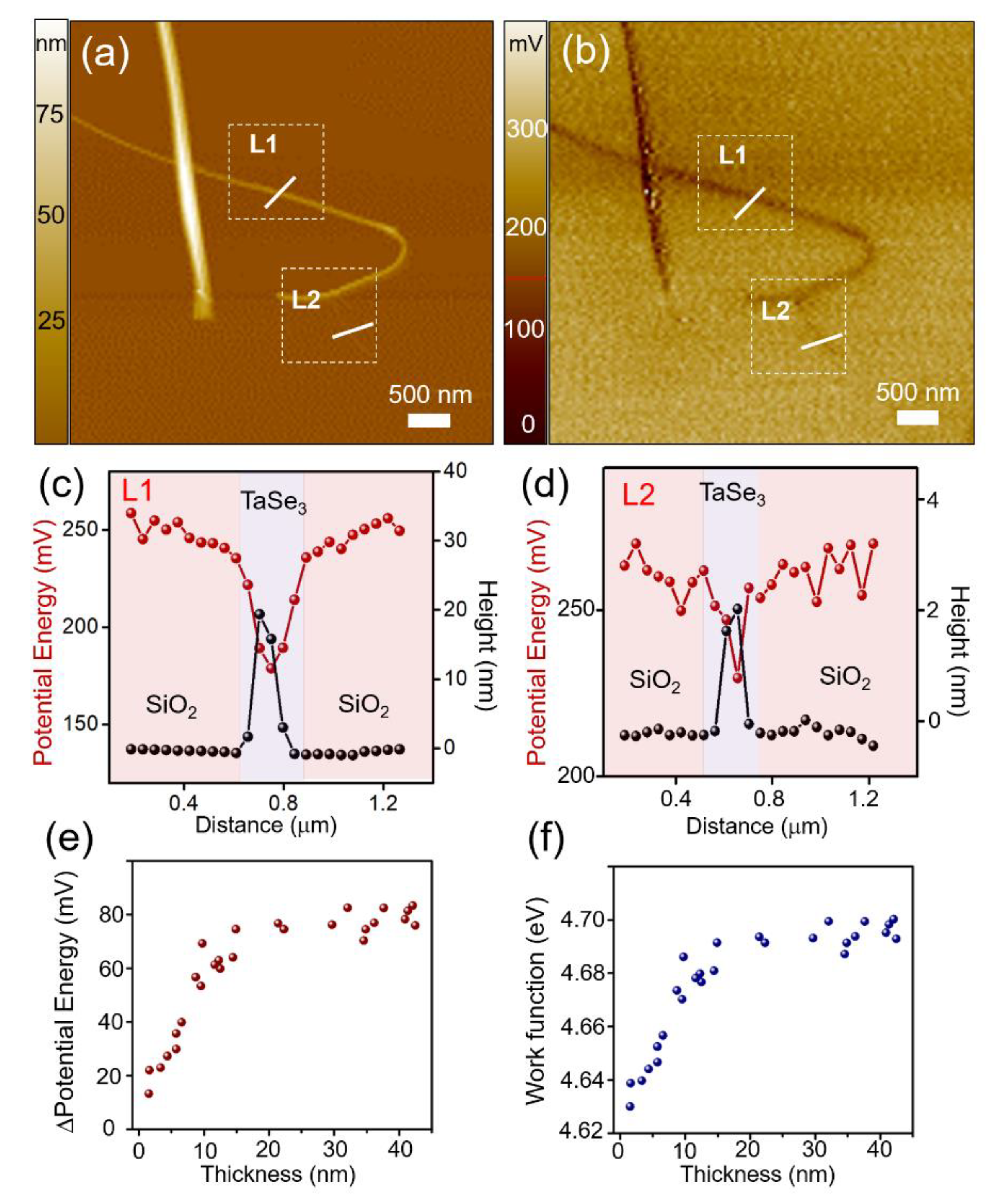

2.3. Characterization

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Huang, X.J.; Lee, W.-C.; Kuo, C.; Hisamoto, D.; Chang, L.; Kedzierski, J.; Anderson, E.; Takeuchi, H.; Choi, Y.-K.; Asano, K.; et al. Sub-50 nm p-channel FinFET. IEEE Trans. Electron Dev. 2001, 48, 880–886. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.; Jiang, D.; Katsnelson, M.I.; Grigorieva, I.; Dubonos, S.V.; Firsov, A.A. Two-dimensional gas of massless Dirac fermions in graphene. Nature 2005, 438, 197–200. [Google Scholar] [CrossRef] [PubMed]

- Radisavljevic, B.; Radenovic, A.; Brivio, J.; Giacometti, V.; Kis, A. Single-layer MoS2 transistors. Nat. Nanotechnol. 2011, 6, 147–150. [Google Scholar] [CrossRef] [PubMed]

- Geim, A.K.; Grigorieva, I.V. Van der Waals heterostructures. Nature 2013, 499, 419–425. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Lee, W.C.; Kuo, C.; Hisamoto, D.; Chang, L.; Kedzierski, J.; Anderson, E.; Takeuchi, H.; Choi, Y.-K.; Asano, K.; et al. Sub-50 nm FinFET: PMOS. In Proceedings of the International Electron Devices Meeting, Washington, DC, USA, 5–8 December 1999; pp. 67–70. [Google Scholar]

- Pal, R.S.; Sharma, S.; Dasgupta, S. Recent trend of FinFET devices and its challenges: A review. In Proceedings of the 2017 Conference on Emerging Devices and Smart Systems, Tiruchengode, India, 3–4 March 2017; pp. 150–154. [Google Scholar]

- Zhang, P.; Wang, F.; Yu, M.; Zhuang, X.; Feng, X. Two-dimensional materials for miniaturized energy storage devices: from individual devices to smart integrated systems. Chem. Soc. Rev. 2018, 47, 7426–7451. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, S.; Shi, Q.; Lee, C. From flexible electronics technology in the era of IoT and artificial intelligence toward future implanted body sensor networks. APL Mater. 2019, 7, 031302. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.H.; Kim, B.S.; Choi, S.H.; Jang, Y.; Hwang, S.W.; Whang, D. A facile route to Si nanowire gate-all-around field effect transistors with a steep subthreshold slope. Nanoscale 2013, 5, 8968–8972. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Hone Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef]

- Schwierz, F. Graphene transistors. Nat. Nanotechnol. 2010, 5, 487–496. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Mishchenko, A.; Carvalho, A.; Neto, A.C. 2D materials and van der Waals heterostructures. Science 2016, 353, aac9439. [Google Scholar] [CrossRef] [Green Version]

- Cao, Y.; Fatemi, V.; Fang, S.; Watanabe, K.; Taniguchi, T.; Kaxiras, E.; Jarillo-Herrero, P. Unconventional superconductivity in magic-angle graphene superlattices. Nature 2018, 556, 43–50. [Google Scholar] [CrossRef] [PubMed]

- Stolyarov, M.A.; Liu, G.; Bloodgood, M.A.; Aytan, E.; Jiang, C.; Samnakay, R.; Salguero, T.T.; Nika, D.L.; Rumyantsev, S.L.; Shur, M.S.; et al. Breakdown current density in h-BN-capped quasi-1D TaSe3 metallic nanowires: prospects of interconnect applications. Nanoscale 2016, 8, 15774–15782. [Google Scholar] [CrossRef] [PubMed]

- Meden, A.; Kodre, A.; Gomilsek, J.P.; Arcon, I.; Vilfan, I.; Vrbanic, D.; Mrzel, A.; Mihailovic, D. Atomic and electronic structure of Mo6S9−xIx nanowires. Nanotechnology 2005, 16, 1578–1583. [Google Scholar] [CrossRef]

- Kim, B.J.; Jeong, B.J.; Oh, S.; Chae, S.; Choi, K.H.; Nasir, T.; Lee, S.H.; Kim, K.W.; Lim, H.K.; Choi, I.J.; et al. Choi Mechanical exfoliation and electrical characterization of a one-dimensional Nb2Se9 atomic crystal. RSC Adv. 2018, 8, 37724–37728. [Google Scholar] [CrossRef]

- Oh, S.; Chae, S.; Kim, B.J.; Siddiqa, A.J.; Choi, K.H.; Jang, W.S.; Lee, K.H.; Kim, H.Y.; Lee, D.K.; Kim, Y.M.; et al. Inorganic Molecular Chain Nb2Se9: Synthesis of Bulk Crystal and One-Atom-Thick Level Exfoliation. Phys. Status Solidi RRL 2018, 12, 1800451. [Google Scholar] [CrossRef]

- Chae, S.; Siddiqa, A.J.; Oh, S.; Kim, B.J.; Choi, K.H.; Jang, W.S.; Kim, Y.M.; Yu, H.K.; Choi, J.Y. Isolation of Nb2Se9 Molecular Chain from Bulk One-Dimensional Crystal by Liquid Exfoliation. Nanomaterials 2018, 8, 794. [Google Scholar] [CrossRef] [PubMed]

- Oh, S.; Chae, S.; Kim, B.J.; Choi, K.H.; Jang, W.S.; Jang, J.M.; Hussain, Y.; Lee, D.K.; Kim, Y.M.; Yu, H.K.; et al. Synthesis of a one-dimensional atomic crystal of vanadium selenide (V2Se9). RSC Adv. 2018, 8, 33980–33984. [Google Scholar] [CrossRef]

- Chae, S.; Siddiqa, A.J.; Kim, B.J.; Oh, S.; Choi, K.H.; Lee, K.H.; Kim, H.Y.; Yu, H.K.; Choi, J.Y. Isolation of inorganic molecular chains from rod-like bulk V2Se9 crystal by liquid exfoliation. RSC Adv. 2018, 8, 35348–35352. [Google Scholar] [CrossRef]

- Kim, B.J.; Jeong, B.J.; Oh, S.; Chae, S.; Choi, K.H.; Nasir, T.; Lee, S.H.; Kim, K.W.; Lim, H.K.; Choi, I.J.; et al. Exfoliation and Characterization of V2Se9 Atomic Crystals. Nanomaterials 2018, 8, 737. [Google Scholar] [CrossRef]

- Chae, S.; Siddiqa, A.J.; Kim, B.J.; Oh, S.; Choi, K.H.; Kim, H.Y.; Lee, K.H.; Yu, H.K.; Choi, J.Y. Design of dispersant structures for preparing highly concentrated one-dimensional inorganic molecular chains from V2Se9 crystals. Chem. Commun. 2018, 54, 12190–12193. [Google Scholar] [CrossRef]

- Nie, S.; Xing, L.; Jin, R.; Xie, W.; Wang, Z.; Prinz, F. Topological phases in the TaSe3 compound. Phys. Rev. B 2018, 98, 125143. [Google Scholar] [CrossRef]

- Kumagai, G.; Matsuura, T.; Ichimura, K.; Yamaya, K.; Inagaki, K.; Tanda, S. Topological effects of the superconducting vortex state in a TaSe3 ring crystal: Observation of magnetic torque oscillations. Phys. Rev. B 2010, 81, 184506. [Google Scholar] [CrossRef]

- Matsuura, T.; Tanda, S.; Asada, K.; Sakai, Y.; Tsuneta, T.; Inagaki, K.; Yamaya, K. Structural and electrical properties of TaSe3 ring crystals. Physica B 2003, 329, 1550–1551. [Google Scholar] [CrossRef]

- Kumagai, G.; Matsuura, T.; Ichimura, K.; Tanda, S. Discovery of new vortex state in TaSe3 topological ring crystals. Physica B 2010, 405, S284–S287. [Google Scholar] [CrossRef]

- Liu, G.; Rumyantsev, S.; Bloodgood, M.A.; Salguero, T.T.; Shur, M.; Balandin, A.A. Low-Frequency Electronic Noise in Quasi-1D TaSe3 van der Waals Nanowires. Nano Lett. 2017, 17, 377–383. [Google Scholar] [CrossRef]

- Tanda, S.; Kawamoto, H.; Shiobara, M.; Okajima, Y.; Yamaya, K. Ring-shaped crystals of NbSe3 and TaSe3. J. Phys. IV 1999, 9, 379–381. [Google Scholar] [CrossRef]

- Geremew, A.; Bloodgood, M.A.; Aytan, E.; Woo, B.W.K.; Corber, S.R.; Liu, G.; Bozhilov, K.; Salguero, T.T.; Rumyantsev, S.; Rao, M.; et al. Current Carrying Capacity of Quasi-1D ZrTe3 Van Der Waals Nanoribbons. IEEE Electron Dev. Lett. 2018, 39, 735–738. [Google Scholar] [CrossRef]

- Perucchi, A.; Sondergaard, C.; Mitrovic, S.; Grioni, M.; Barisic, N.; Berger, H.; Forro, L.; Degiorgi, L. Spectroscopic and dc-transport investigations of the electronic properties of TaSe3. Eur. Phys. J. B 2004, 39, 433–440. [Google Scholar] [CrossRef]

- Nomura, A.; Yamaya, K.; Takayanagi, S.; Ichimura, K.; Matsuura, T.; Tanda, S. Emergence of a resistance anomaly by Cu-doping in TaSe3. EPL 2017, 119, 17005. [Google Scholar] [CrossRef]

- Nomura, A.; Yamaya, K.; Takayanaci, S.; Ichimura, K.; Tanda, S. Effect of Cu doping on superconductivity in TaSe3: Relationship between superconductivity and induced charge density wave. EPL 2018, 124, 67001. [Google Scholar] [CrossRef]

- Bjerkelund, E.; Kjekshus, A. On the Crystal Structure of TaSe3. Acta Chem. Scand. 1965, 19, 701–710. [Google Scholar] [CrossRef]

- Bjerkelund, E.; Fermor, J.H.; Kjekshus, A. On the properties of TaS3 and TaSe3. Acta Chem. Scand. 1966, 20, 1836–1842. [Google Scholar] [CrossRef]

- Lee, N.J.; Yoo, J.W.; Choi, Y.J.; Kang, C.J.; Jeon, D.Y.; Kim, D.C.; Seo, S.; Chung, H.J. The interlayer screening effect of graphene sheets investigated by Kelvin probe force microscopy. Appl. Phys. Lett. 2009, 95, 222107. [Google Scholar] [CrossRef]

- Golla, D.; Chattrakun, K.; Watanabe, K.; Taniguchi, T.; LeRoy, B.J.; Sandhu, A. Optical thickness determination of hexagonal boron nitride flakes. Appl. Phys. Lett. 2013, 102, 191606. [Google Scholar] [CrossRef]

- Choi, S.; Shaolin, Z.; Yang, W. Layer-number-dependent work function of MoS2 nanoflakes. J. Korean Phys. Soc. 2014, 64, 1550–1555. [Google Scholar] [CrossRef]

- Li, Y.; Xu, C.Y.; Zhen, L. Surface potential and interlayer screening effects of few-layer MoS2 nanoflakes. Appl. Phys. Lett. 2013, 102, 143110. [Google Scholar] [CrossRef]

- Hao, G.L.; Huang, Z.Y.; Liu, Y.D.; Qi, X.; Ren, L.; Peng, X.Y.; Yang, L.W.; Wei, X.L.; Zhong, J.X. Electrostatic properties of few-layer MoS2 films. AIP Adv. 2013, 3, 042125. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, B.J.; Jeong, B.J.; Oh, S.; Chae, S.; Choi, K.H.; Nasir, T.; Lee, S.H.; Lim, H.K.; Choi, I.J.; Hong, M.-K.; et al. Thickness-Dependence Electrical Characterization of the One-Dimensional van der Waals TaSe3 Crystal. Materials 2019, 12, 2462. https://doi.org/10.3390/ma12152462

Kim BJ, Jeong BJ, Oh S, Chae S, Choi KH, Nasir T, Lee SH, Lim HK, Choi IJ, Hong M-K, et al. Thickness-Dependence Electrical Characterization of the One-Dimensional van der Waals TaSe3 Crystal. Materials. 2019; 12(15):2462. https://doi.org/10.3390/ma12152462

Chicago/Turabian StyleKim, Bum Jun, Byung Joo Jeong, Seungbae Oh, Sudong Chae, Kyung Hwan Choi, Tuqeer Nasir, Sang Hoon Lee, Hyung Kyu Lim, Ik Jun Choi, Min-Ki Hong, and et al. 2019. "Thickness-Dependence Electrical Characterization of the One-Dimensional van der Waals TaSe3 Crystal" Materials 12, no. 15: 2462. https://doi.org/10.3390/ma12152462

APA StyleKim, B. J., Jeong, B. J., Oh, S., Chae, S., Choi, K. H., Nasir, T., Lee, S. H., Lim, H. K., Choi, I. J., Hong, M.-K., Yu, H. K., Lee, J.-H., & Choi, J.-Y. (2019). Thickness-Dependence Electrical Characterization of the One-Dimensional van der Waals TaSe3 Crystal. Materials, 12(15), 2462. https://doi.org/10.3390/ma12152462