Replication of Micro- and Nanofeatures in Injection Molding of Two PLA Grades with Rapid Surface-Temperature Modulation

Abstract

1. Introduction

2. Materials and Methods

3. Results

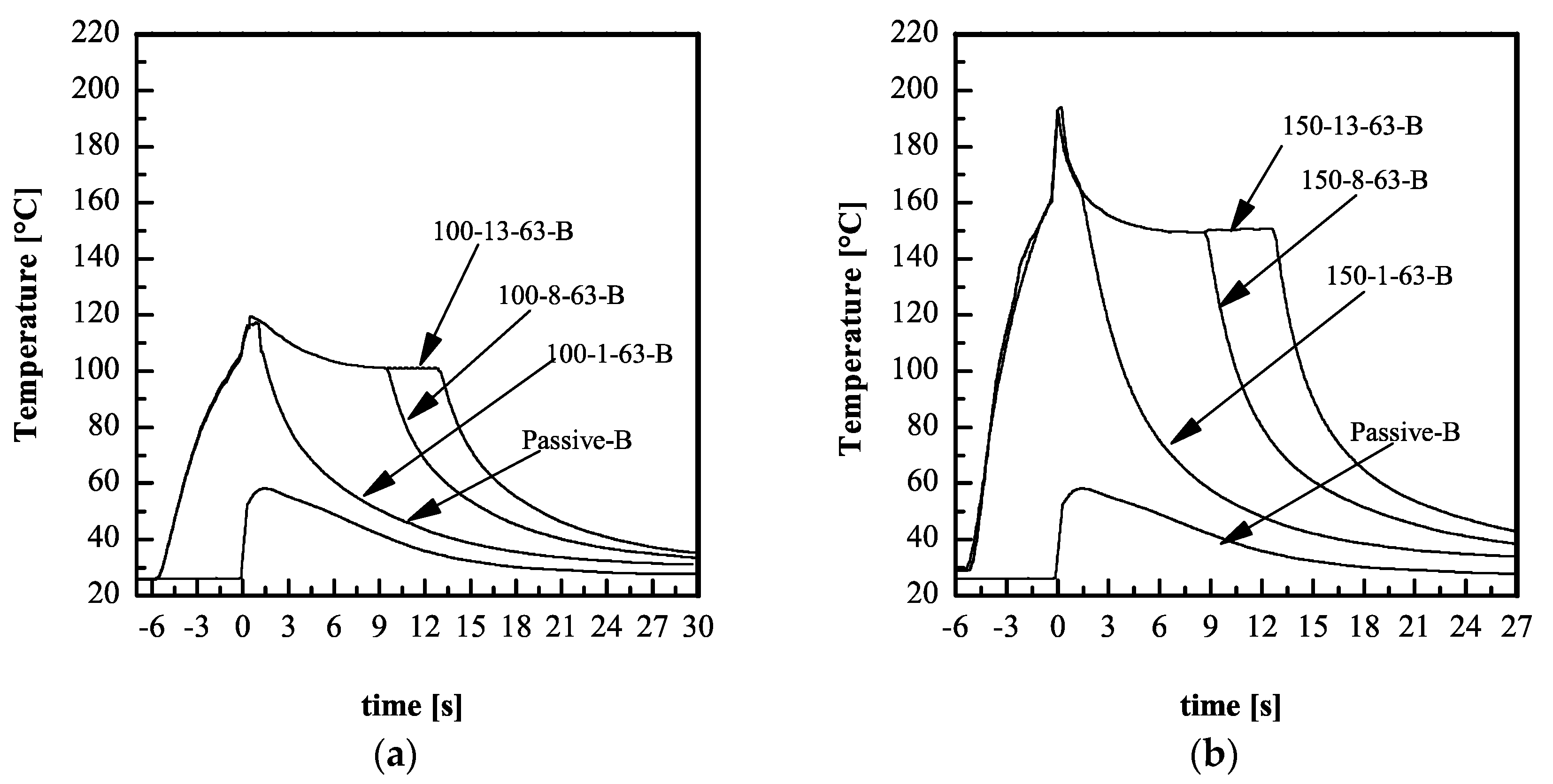

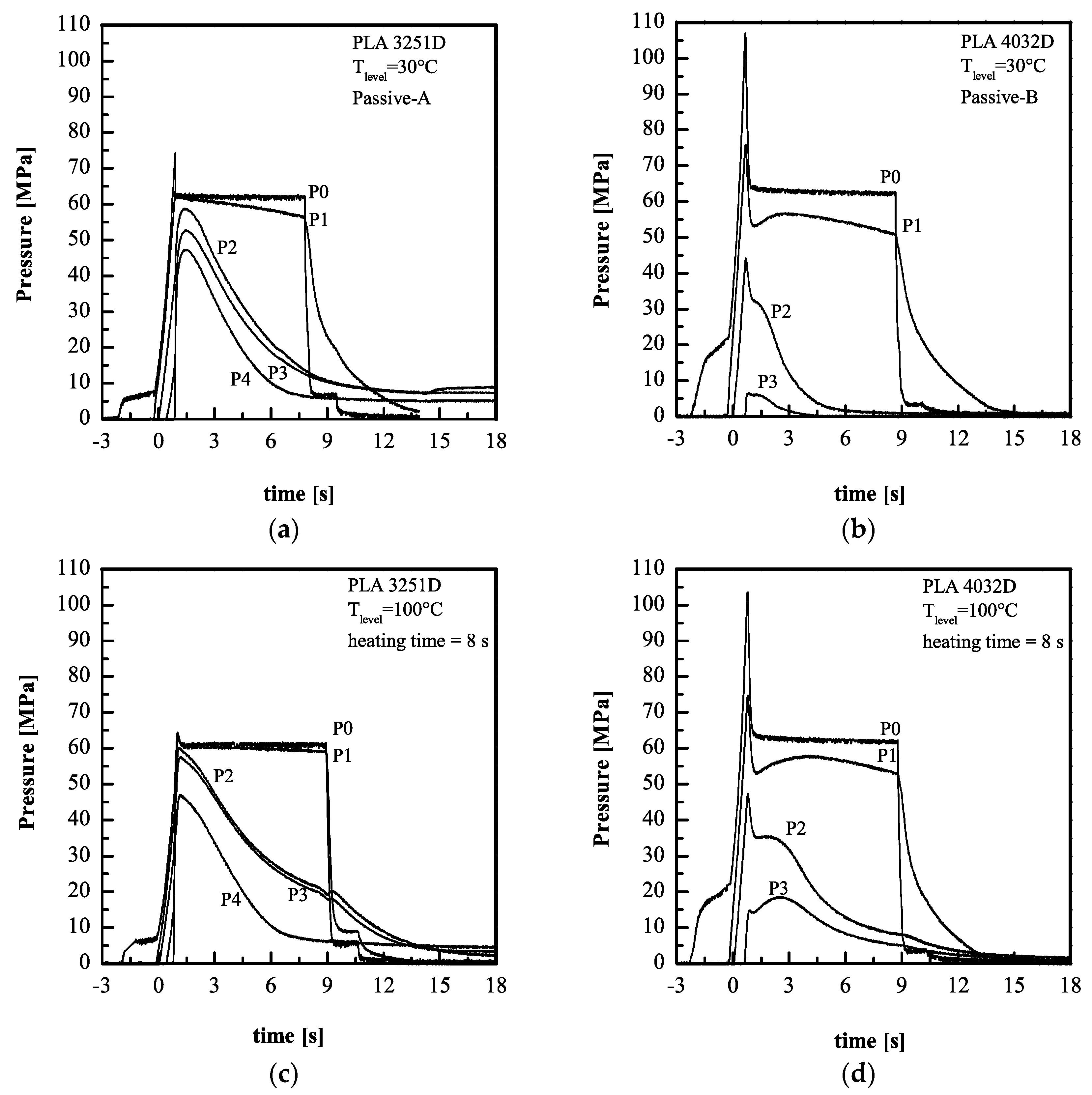

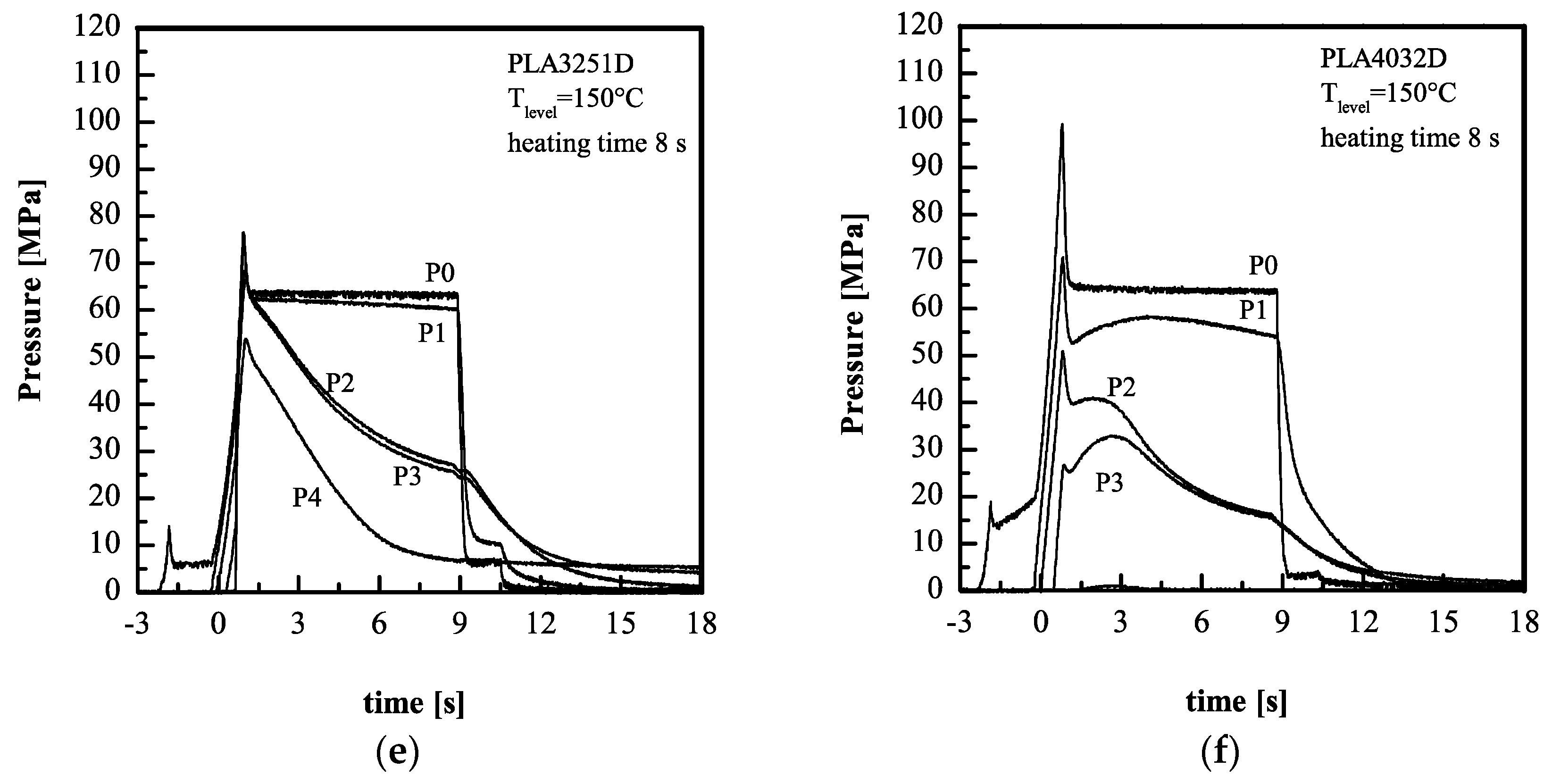

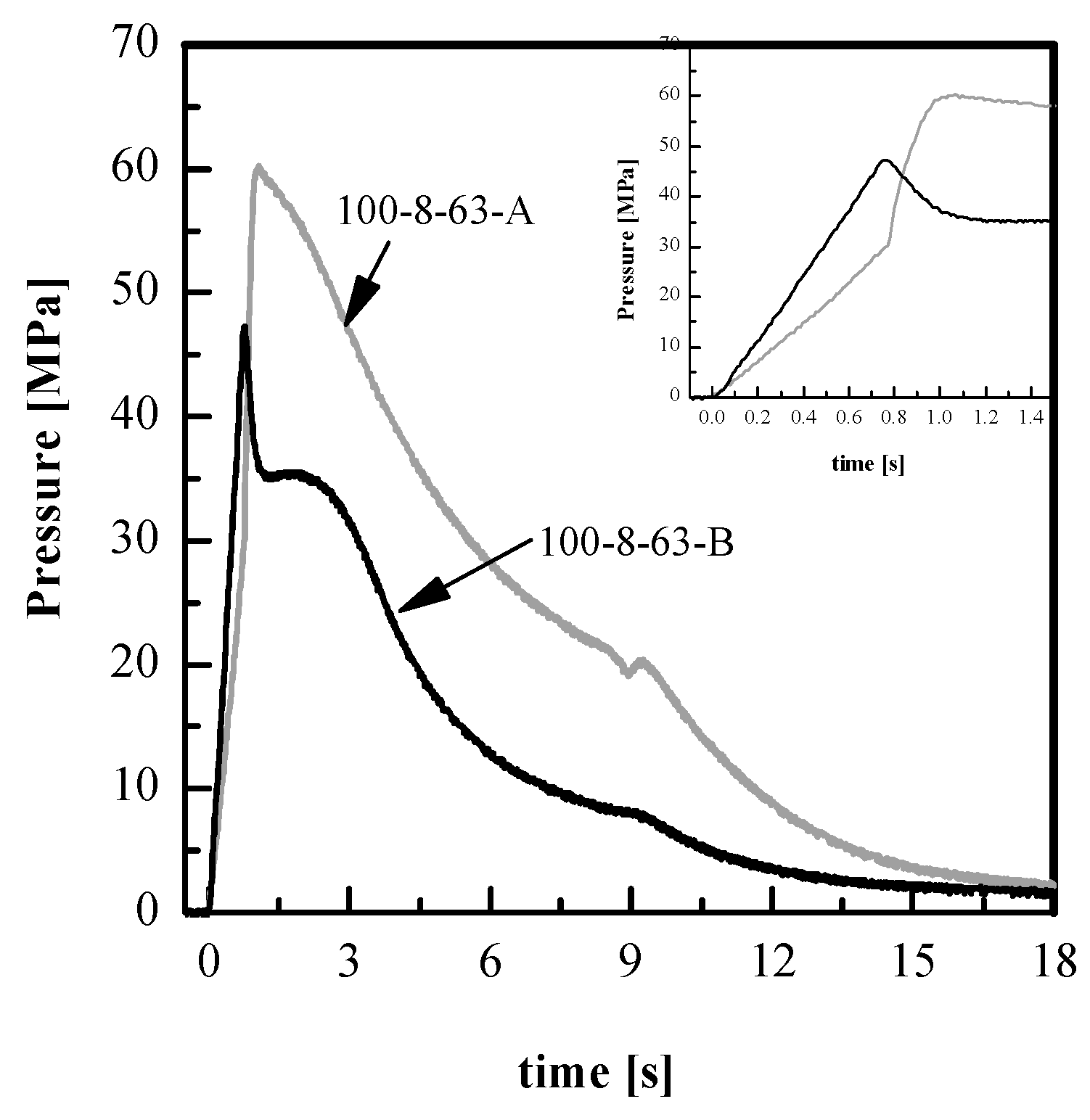

3.1. Temperature and Pressure Evolutions

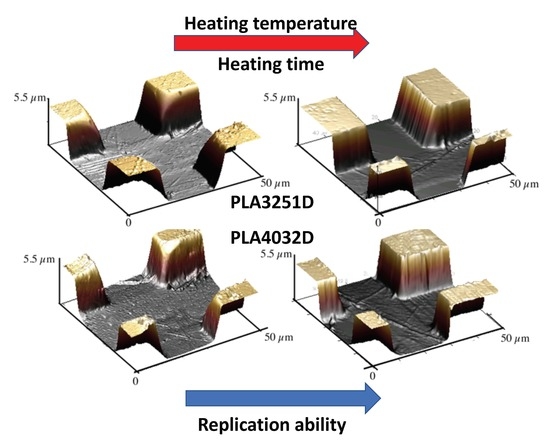

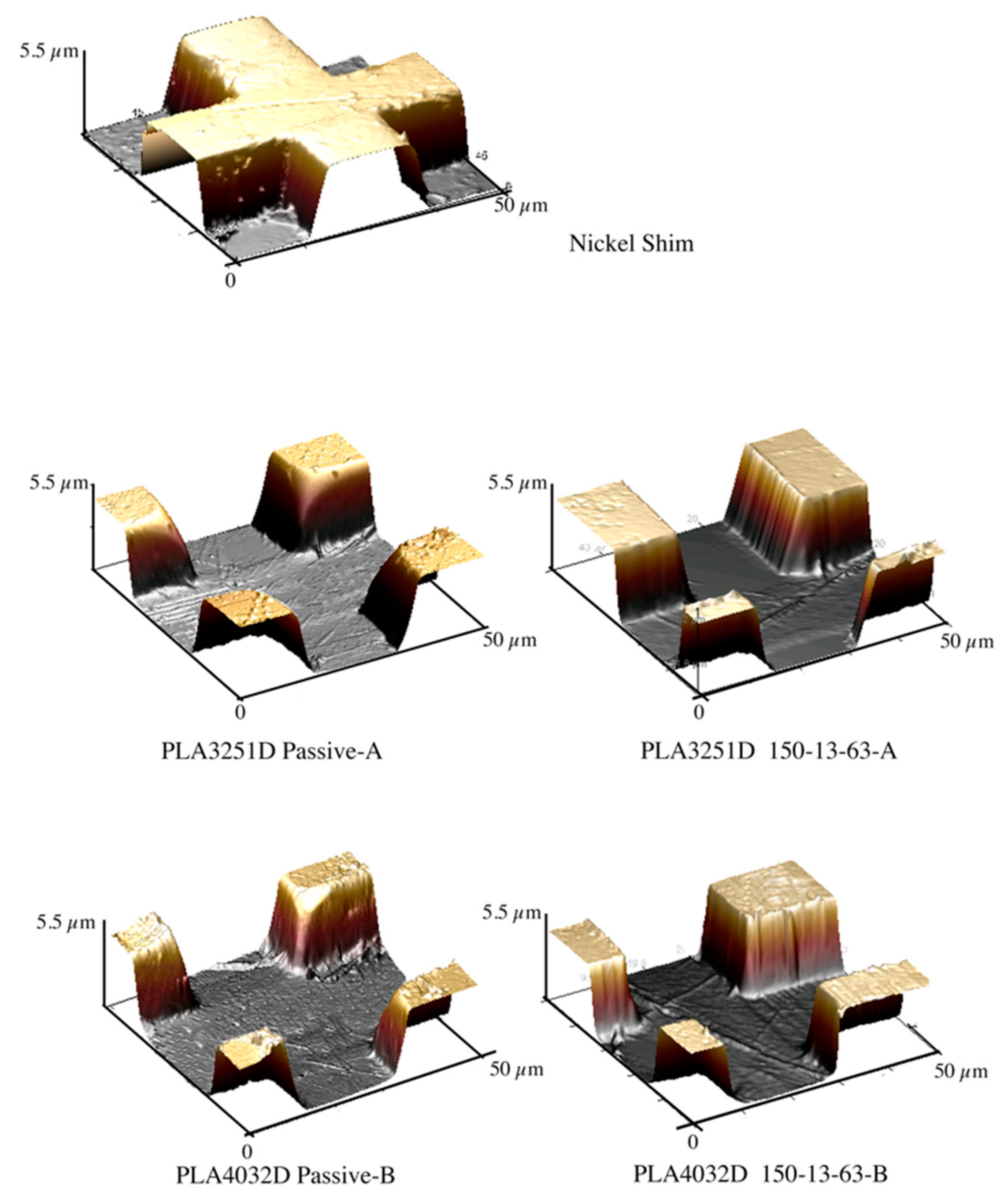

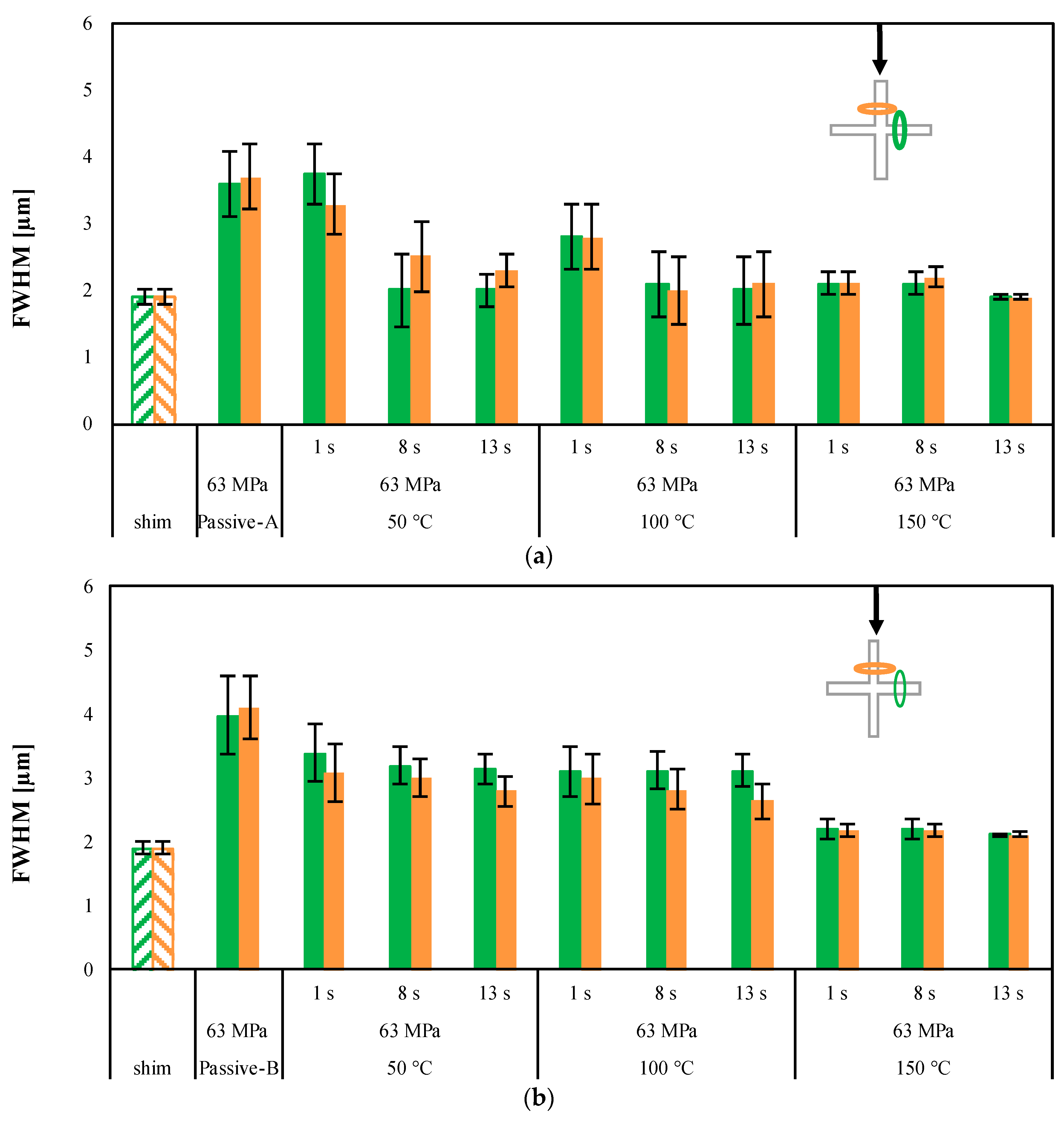

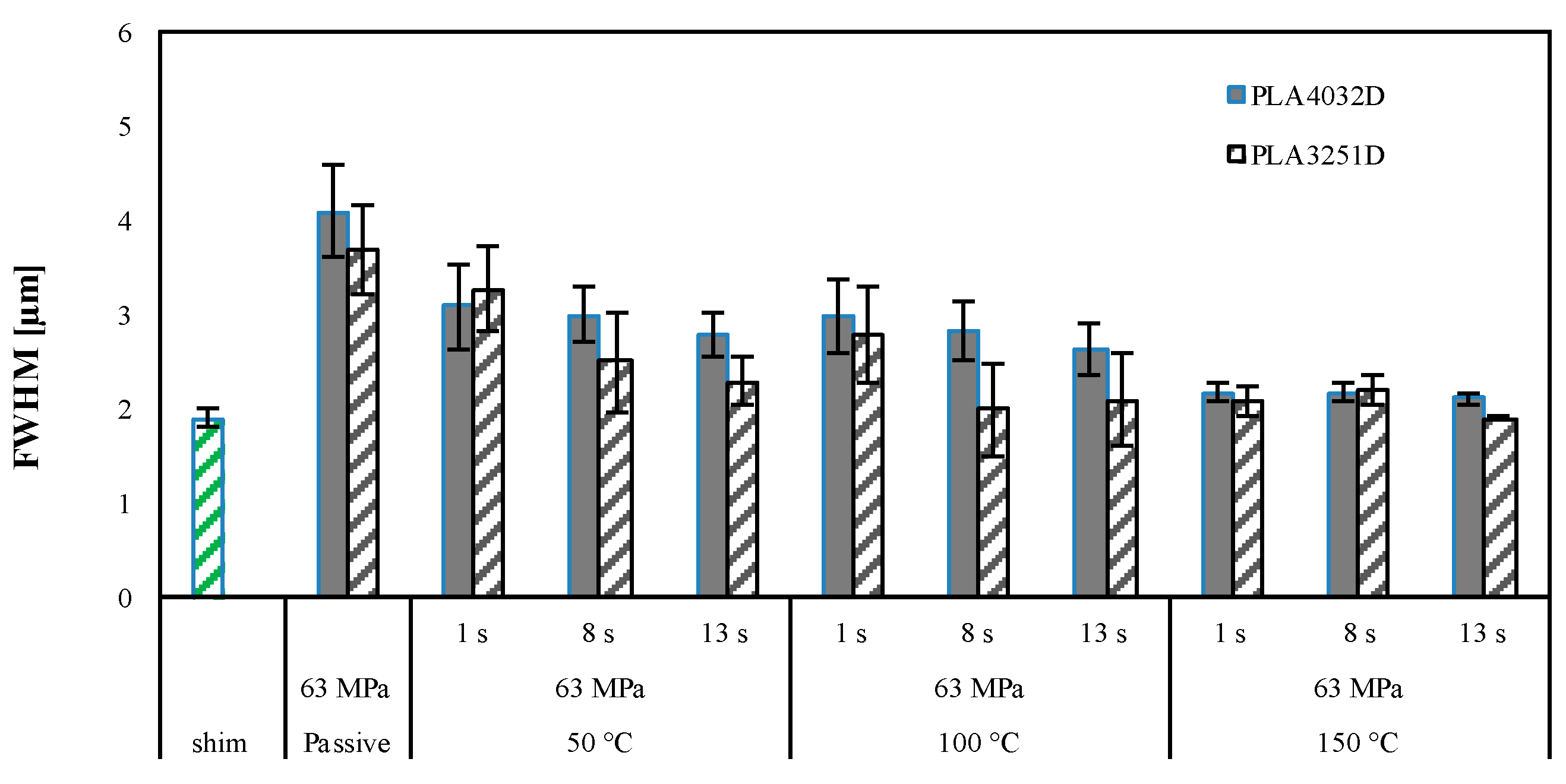

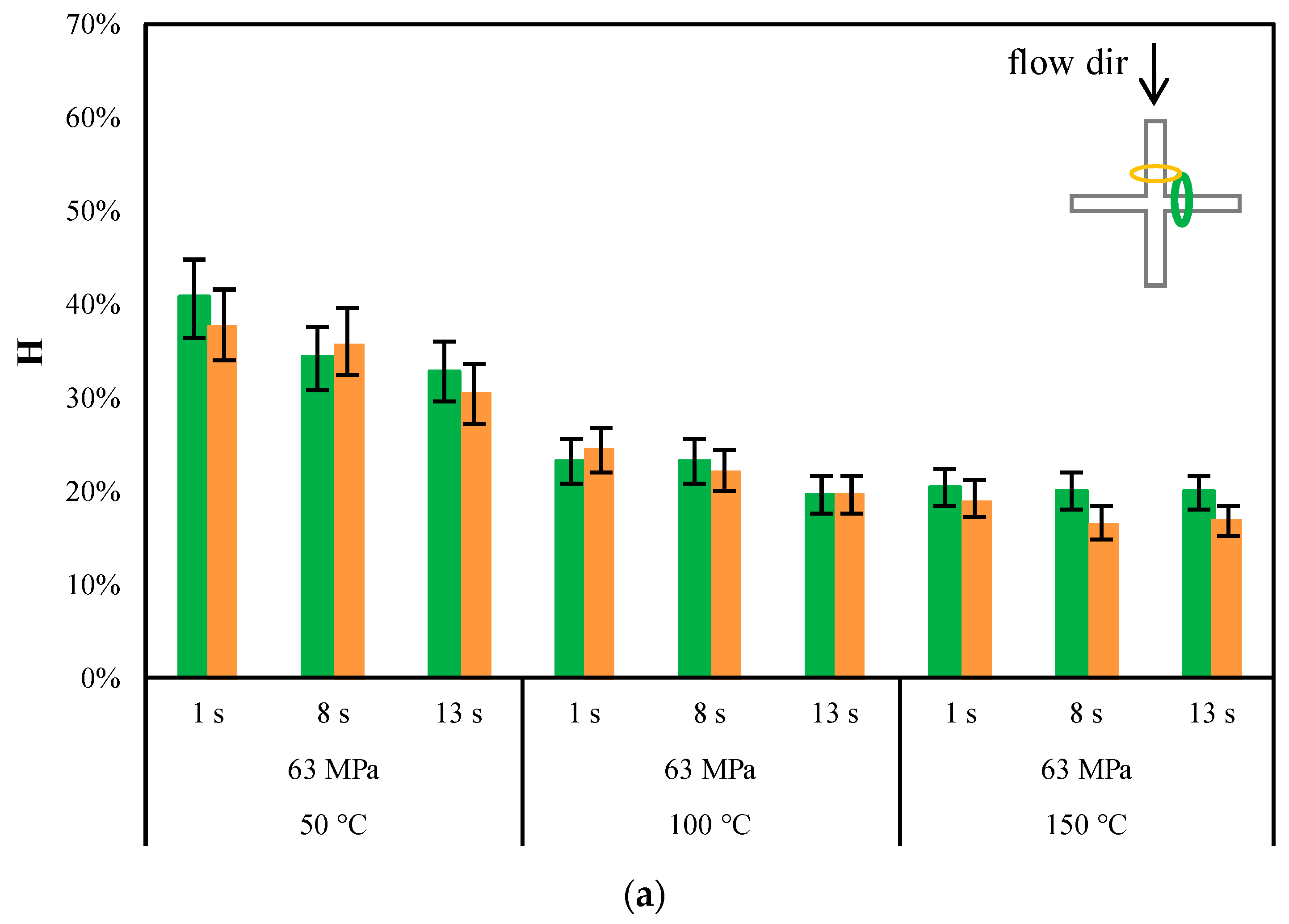

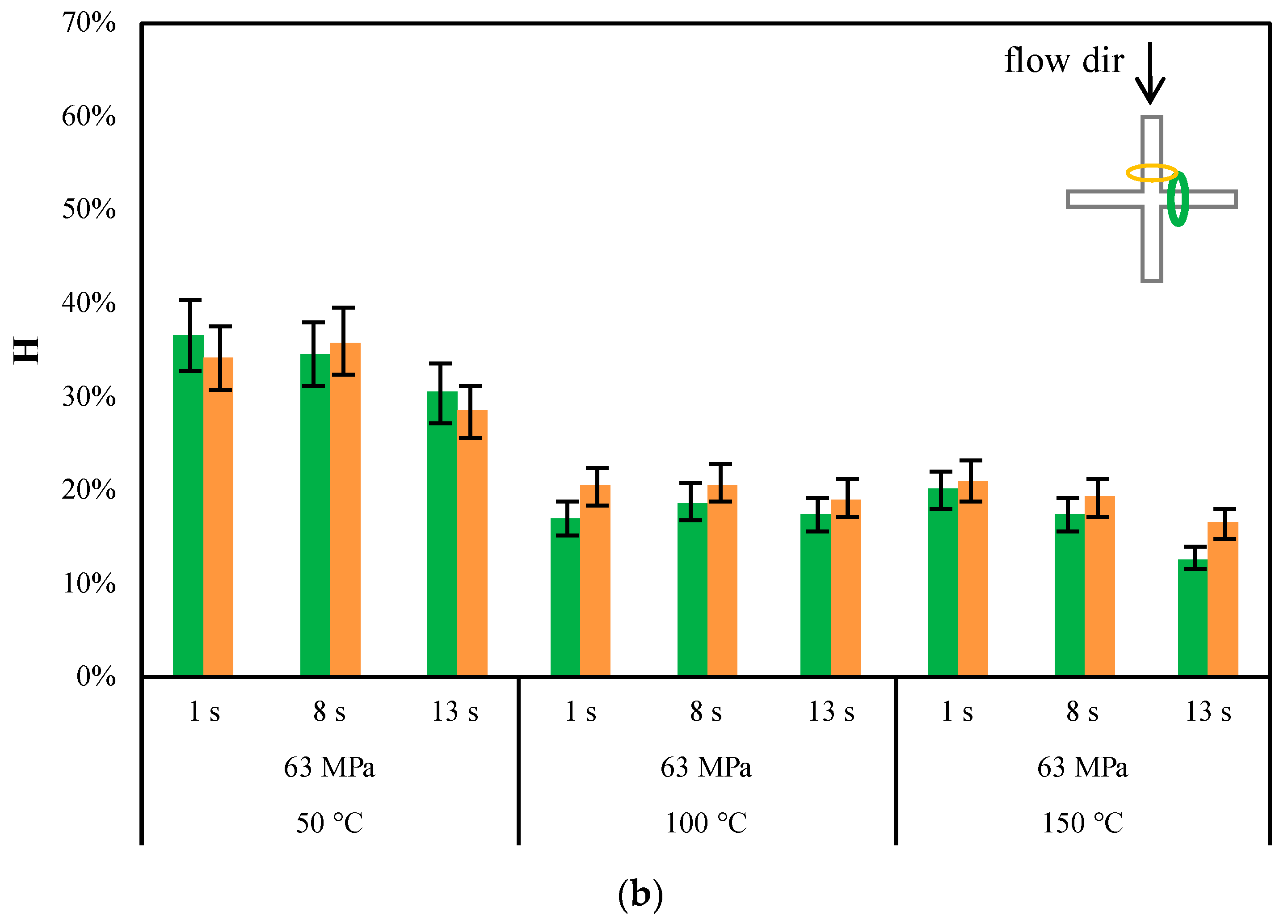

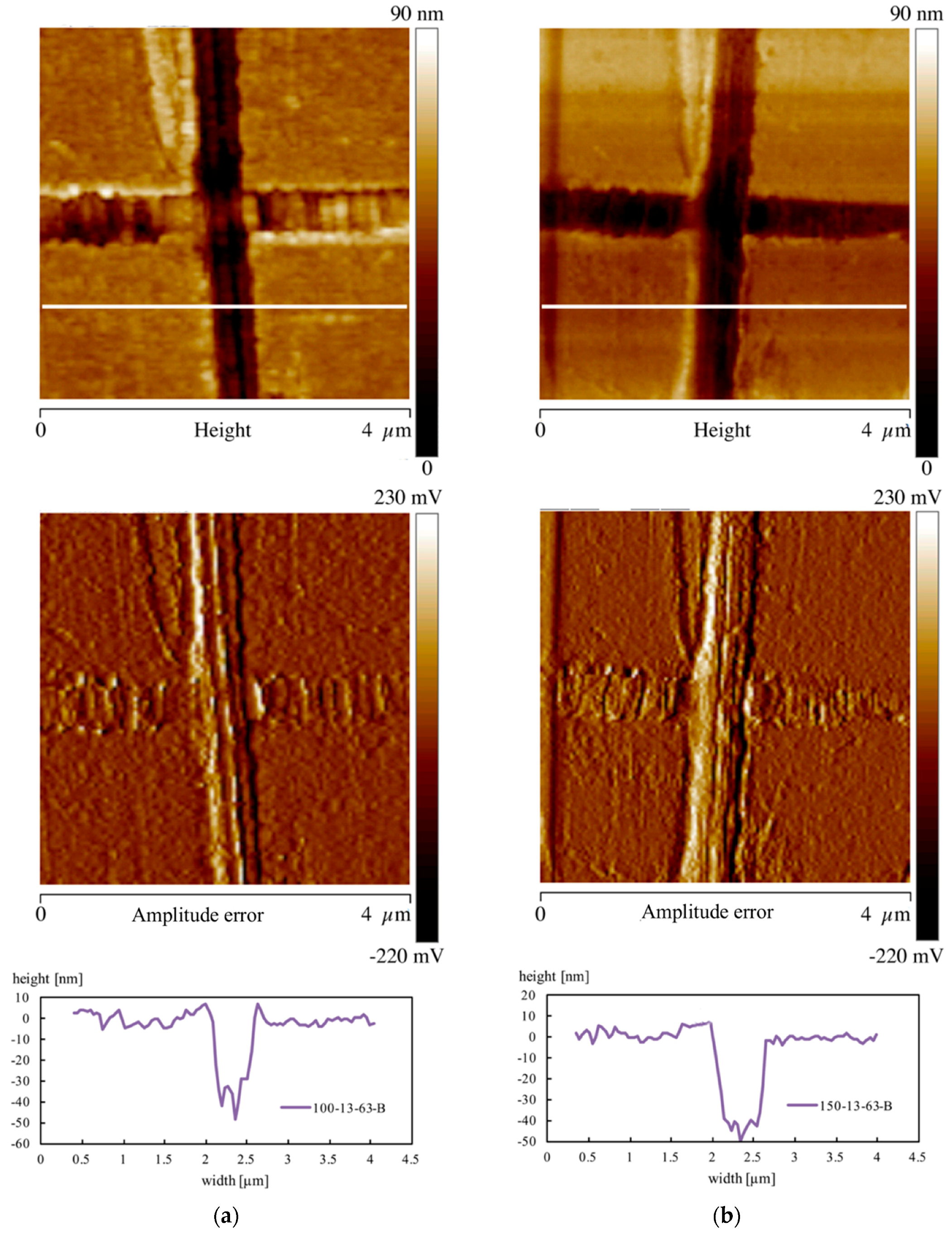

3.2. Replication of Microfeatures

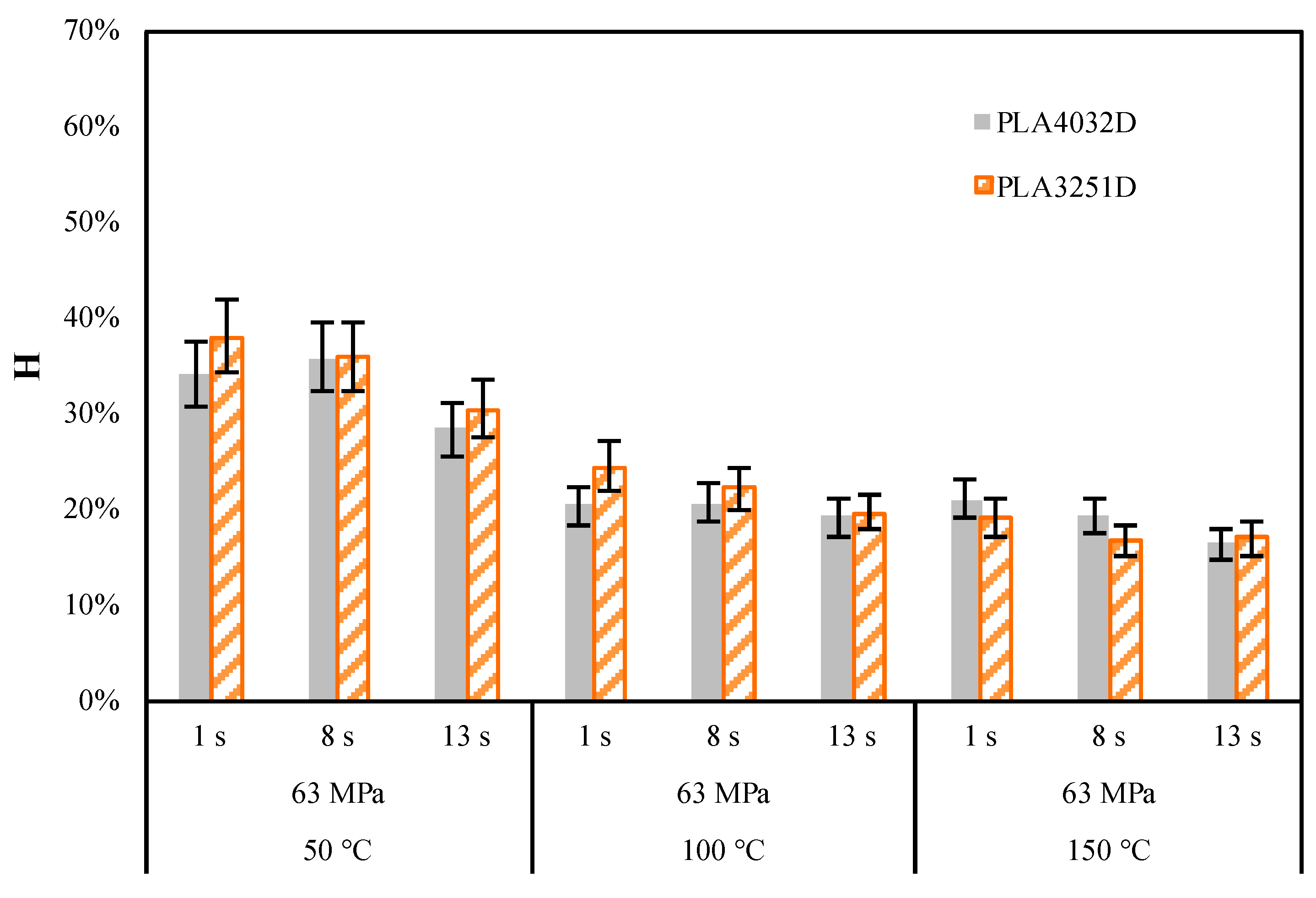

3.3. Replication of Nanofeatures

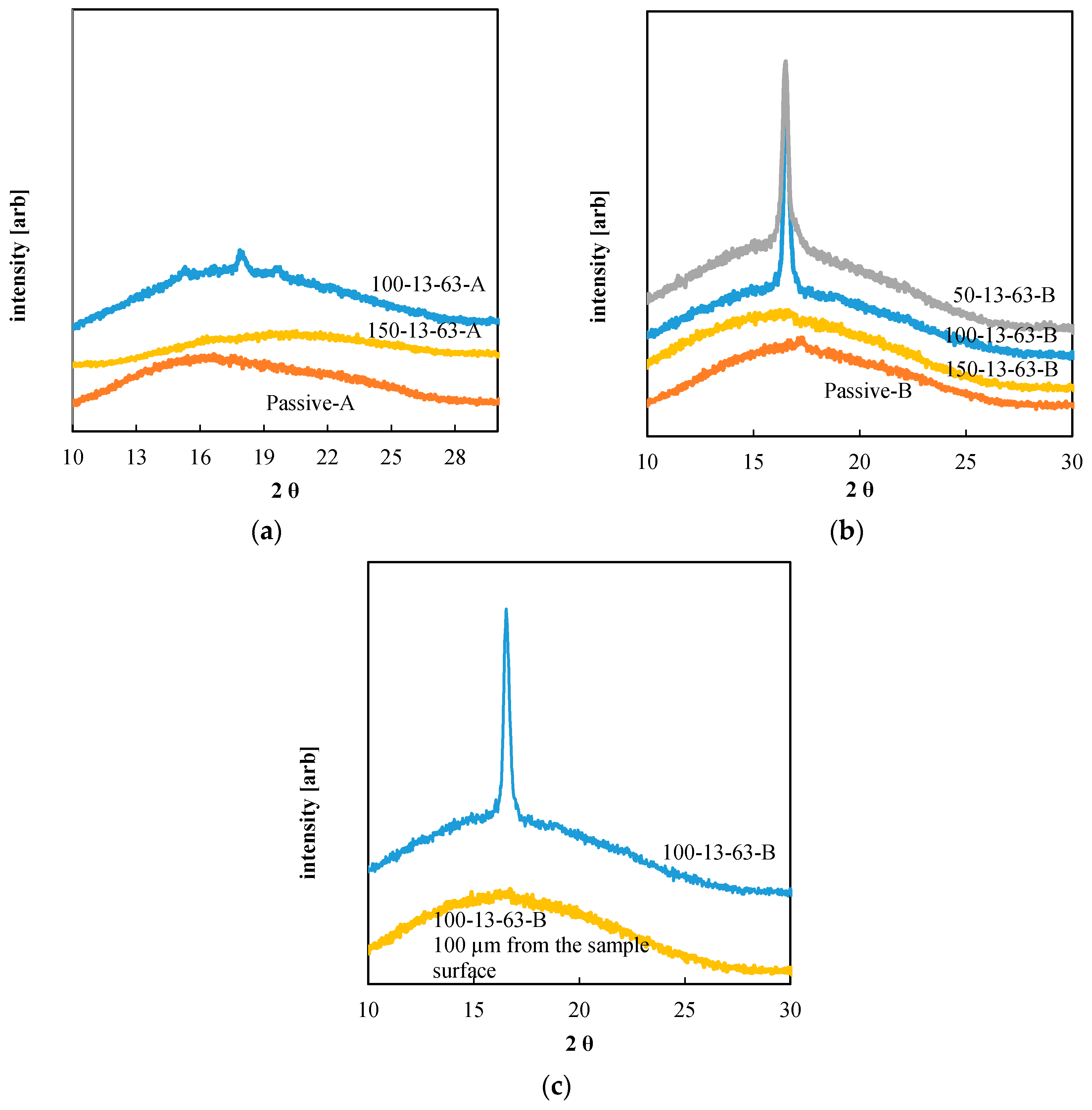

3.4. Analysis of Morphology

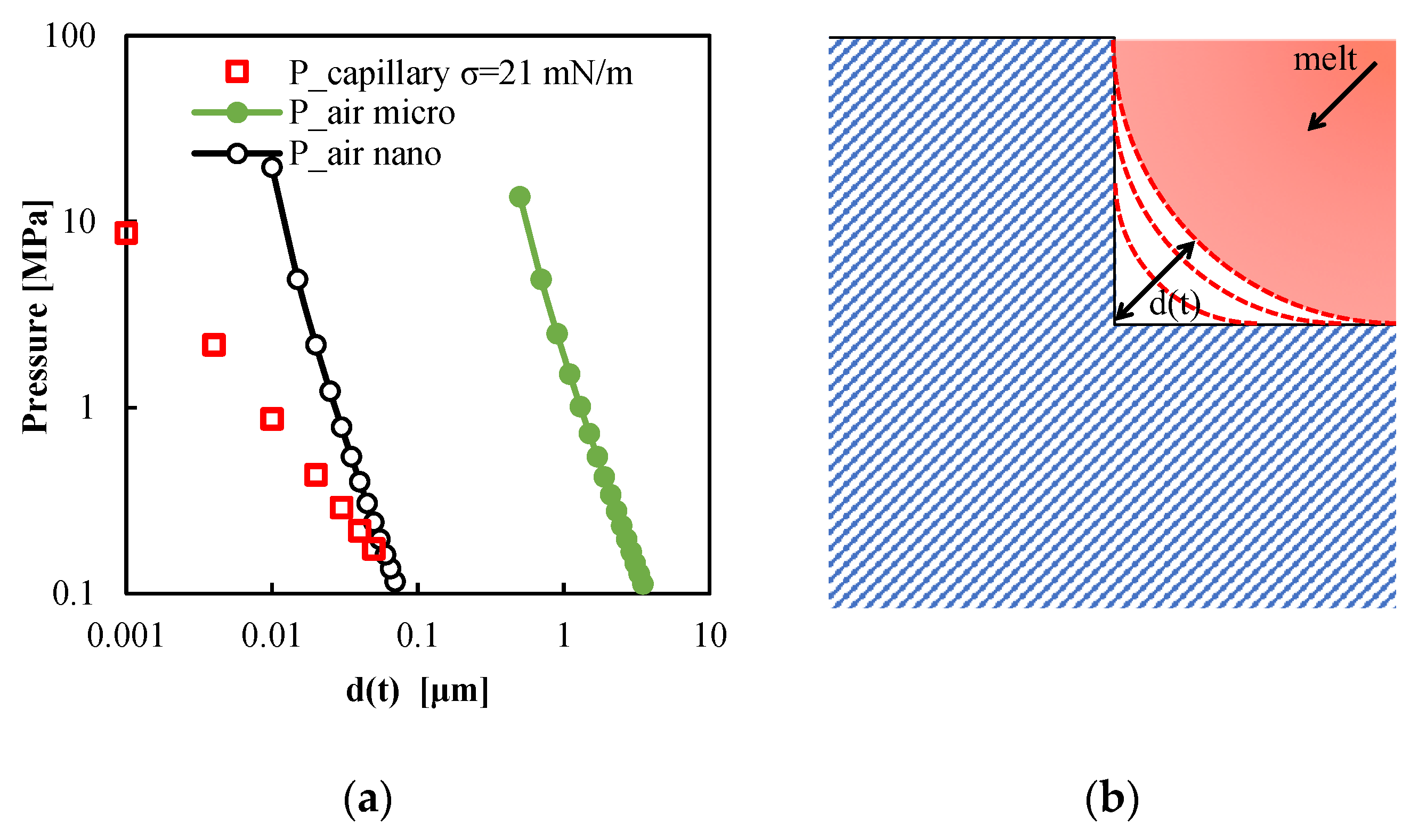

4. Discussion

Supplementary Materials

Supplementary File 1Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cesca, F.; Limongi, T.; Accardo, A.; Rocchi, A.; Orlando, M.; Shalabaeva, V.; Di Fabrizio, E.; Benfenati, F. Fabrication of biocompatible free-standing nanopatterned films for primary neuronal cultures. RSC Adv. 2014, 4, 45696–45702. [Google Scholar] [CrossRef]

- Limongi, T.; Schipani, R.; Di Vito, A.; Giugni, A.; Francardi, M.; Torre, B.; Allione, M.; Miele, E.; Malara, N.; Alrasheed, S.; et al. Photolithography and micromolding techniques for the realization of 3D polycaprolactone scaffolds for tissue engineering applications. Microelectron. Eng. 2015, 141, 135–139. [Google Scholar] [CrossRef]

- Rahim, K.; Mian, A. A review on laser processing in electronic and MEMS packaging. J. Electron. Packag. 2017, 139, 030801. [Google Scholar] [CrossRef]

- Nihtianov, S.; Luque, A. Smart Sensors and MEMS: Intelligent Devices and Microsystems for Industrial Applications; Woodhead Publishing Limited: Cambridge, UK, 2014. [Google Scholar]

- Nuxoll, E. BioMEMS in drug delivery. Adv. Drug Deliv. Rev. 2013, 65, 1611–1625. [Google Scholar] [CrossRef] [PubMed]

- Ranella, A.; Barberoglou, M.; Bakogianni, S.; Fotakis, C.; Stratakis, E. Tuning cell adhesion by controlling the roughness and wettability of 3D micro/nano silicon structures. Acta Biomater. 2010, 6, 2711–2720. [Google Scholar] [CrossRef] [PubMed]

- Sorkin, J.A.; Hughes, S.; Soares, P.; Popat, K.C. Titania nanotube arrays as interfaces for neural prostheses. Mater. Sci. Eng. C 2015, 49, 735–745. [Google Scholar] [CrossRef] [PubMed]

- Weng, C.; Wang, F.; Zhou, M.; Yang, D.; Jiang, B. Fabrication of hierarchical polymer surfaces with superhydrophobicity by injection molding from nature and function-oriented design. Appl. Surf. Sci. 2018, 436, 224–233. [Google Scholar] [CrossRef]

- Liparoti, S.; Pantani, R.; Sorrentino, A.; Speranza, V.; Titomanlio, G. Hydrophobicity tuning by the fast evolution of mold temperature during injection molding. Polymers 2018, 10, 322. [Google Scholar] [CrossRef]

- Eigenfeld, N.T.; Gray, J.M.; Brown, J.J.; Skidmore, G.D.; George, S.M.; Bright, V.M. Ultra-thin 3D nano-devices from atomic layer deposition on polyimide. Adv. Mater. 2014, 26, 3962–3967. [Google Scholar] [CrossRef] [PubMed]

- Kustra, J.; Martin, E.; Chateau, D.; Lerouge, F.; Monnereau, C.; Andraud, C.; Sitarz, M.; Baldeck, P.L.; Parola, S. Two-photon controlled sol–gel condensation for the microfabrication of silica based microstructures. The role of photoacids and photobases. RSC Adv. 2017, 7, 46615–46620. [Google Scholar] [CrossRef]

- Borges, J.; Mano, J.F. Molecular interactions driving the layer-by-layer assembly of multilayers. Chem. Rev. 2014, 114, 8883–8942. [Google Scholar] [CrossRef] [PubMed]

- Rogers, J.A.; Lee, H.H. Unconventional Nanopatterning Techniques and Applications; John Wiley & Sons, Inc.: New York, NY, USA, 2008. [Google Scholar]

- Mogi, K.; Sugii, Y.; Yamamoto, T.; Fujii, T. Rapid fabrication technique of nano/microfluidic device with high mechanical stability utilizing two-step soft lithography. Sens. Actuators B Chem. 2014, 201, 407–412. [Google Scholar] [CrossRef]

- Pinto, E.; Faustino, V.; Rodrigues, R.; Pinho, D.; Garcia, V.; Miranda, J.M.; Lima, R. A rapid and low-cost nonlithographic method to fabricate biomedical microdevices for blood flow analysis. Micromachines 2014, 6, 121–135. [Google Scholar] [CrossRef]

- Tan, G.; Inoue, N.; Funabasama, T.; Mita, M.; Okuda, N.; Mori, J.; Koyama, K.; Kaneko, S.; Nakagawa, M.; Matsuda, A.; et al. Formation of 0.3-nm-high stepped polymer surface by thermal nanoimprinting. Appl. Phys. Express 2014, 7, 055202. [Google Scholar] [CrossRef]

- Kooy, N.; Mohamed, K.; Pin, L.T.; Guan, O.S. A review of roll-to-roll nanoimprint lithography. Nanoscale Res. Lett. 2014, 9, 320. [Google Scholar] [CrossRef] [PubMed]

- Mitra, J.; Tripathi, G.; Sharma, A.; Basu, B. Scaffolds for bone tissue engineering: Role of surface patterning on osteoblast response. RSC Adv. 2013, 3, 11073–11094. [Google Scholar] [CrossRef]

- Masato, D.; Sorgato, M.; Lucchetta, G. Analysis of the influence of part thickness on the replication of micro-structured surfaces by injection molding. Mater. Des. 2016, 95, 219–224. [Google Scholar] [CrossRef]

- Lucchetta, G.; Fiorotto, M.; Bariani, P.F. Influence of rapid mold temperature variation on surface topography replication and appearance of injection-molded parts. CIRP Ann. Manuf. Technol. 2012, 61, 539–542. [Google Scholar] [CrossRef]

- Kuo, C.-C.; Wang, Y.-J. Development of a micro-hot-embossing mold with high replication fidelity using surface modification. Mater. Manuf. Process. 2014, 29, 1101–1110. [Google Scholar] [CrossRef]

- Pantani, R.; Volpe, V.; Titomanlio, G. Foam injection molding of poly(lactic acid) with environmentally friendly physical blowing agents. J. Mater. Process. Technol. 2014, 214, 3098–3107. [Google Scholar] [CrossRef]

- Feldmann, M.; Fuchs, J. Specialized Injection Molding Techniques; Heim, H.P., Ed.; William Andrew Publishing: Oxford, UK, 2016. [Google Scholar]

- Pan, Y.; Liu, X.; Shi, S.; Liu, C.; Dai, K.; Yin, R.; Schubert, D.W.; Zheng, G.; Shen, C. Annealing induced mechanical reinforcement of injection molded iPP parts. Macromol. Mater. Eng. 2016, 301, 1468–1472. [Google Scholar] [CrossRef]

- Jiang, J.; Liu, X.; Lian, M.; Pan, Y.; Chen, Q.; Liu, H.; Zheng, G.; Guo, Z.; Schubert, D.W.; Shen, C.; et al. Self-reinforcing and toughening isotactic polypropylene via melt sequential injection molding. Polym. Test. 2018, 67, 183–189. [Google Scholar] [CrossRef]

- Guerrier, P.; Tosello, G.; Nielsen, K.K.; Hattel, J.H. Three-dimensional numerical modeling of an induction heated injection molding tool with flow visualization. Int. J. Adv. Manuf. Technol. 2016, 85, 643–660. [Google Scholar] [CrossRef]

- Yao, D.; Kimerling, T.E.; Kim, B. High-frequency proximity heating for injection molding applications. Polym. Eng. Sci. 2006, 46, 938–945. [Google Scholar] [CrossRef]

- Yu, M.C.; Young, W.B.; Hsu, P.M. Micro-injection molding with the infrared assisted mold heating system. Mater. Sci. Eng. A 2007, 460–461, 288–295. [Google Scholar] [CrossRef]

- De Santis, F.; Pantani, R. Development of a rapid surface temperature variation system and application to micro-injection molding. J. Mater. Process. Technol. 2016, 237, 1–11. [Google Scholar] [CrossRef]

- Liparoti, S.; Sorrentino, A.; Titomanlio, G. Fast cavity surface temperature evolution in injection molding: Control of cooling stage and final morphology analysis. RSC Adv. 2016, 6, 99274–99281. [Google Scholar] [CrossRef]

- Liparoti, S.; Sorrentino, A.; Guzman, G.; Cakmak, M.; Titomanlio, G. Fast mold surface temperature evolution: Relevance of asymmetric surface heating for morphology of iPP molded samples. RSC Adv. 2015, 5, 36434–36448. [Google Scholar] [CrossRef]

- Liparoti, S.; Titomanlio, G.; Sorrentino, A. Analysis of asymmetric morphology evolutions in iPP molded samples induced by uneven temperature field. AIChE J. 2016, 62, 2699–2712. [Google Scholar] [CrossRef]

- Jansen, K.M.B.; Flaman, A.A.M. Construction of fast-response heating elements for injection molding applications. Polym. Eng. Sci. 1994, 34, 894–897. [Google Scholar] [CrossRef]

- Speranza, V.; Liparoti, S.; Calaon, M.; Tosello, G.; Pantani, R.; Titomanlio, G. Replication of micro and nano-features on iPP by injection molding with fast cavity surface temperature evolution. Mater. Des. 2017, 133, 559–569. [Google Scholar] [CrossRef]

- Volpe, V.; De Filitto, M.; Klofacova, V.; De Santis, F.; Pantani, R. Effect of mold opening on the properties of PLA samples obtained by foam injection molding. Polym. Eng. Sci. 2017, 58, 475–484. [Google Scholar] [CrossRef]

- Liparoti, S.; Landi, G.; Sorrentino, A.; Speranza, V.; Cakmak, M.; Neitzert, H.C. Flexible poly(amide-imide)-carbon black based microheater with high-temperature capability and an extremely low temperature coefficient. Adv. Electron. Mater. 2016, 2, 1600126. [Google Scholar] [CrossRef]

- Calaon, M.; Hansen, H.N.; Tosello, G.; Garnaes, J.; Nørregaard, J.; Li, W. Microfluidic chip designs process optimization and dimensional quality control. Microsyst. Technol. 2013, 21, 561–570. [Google Scholar] [CrossRef]

- Hansen, H.N.; Hocken, R.J.; Tosello, G. Replication of micro and nano surface geometries. CIRP Ann. Manuf. Technol. 2011, 60, 695–714. [Google Scholar] [CrossRef]

- Pantani, R.; Coccorullo, I.; Speranza, V.; Titomanlio, G. Modeling of morphology evolution in the injection molding process of thermoplastic Polymers. Prog. Polym. Sci. 2005, 30, 1185–1222. [Google Scholar] [CrossRef]

- Pantani, R.; De Santis, F.; Brucato, V.; Titomanlio, G. Analysis of gate freeze-off time in injection molding. Polym. Eng. Sci. 2004, 44, 1–17. [Google Scholar] [CrossRef]

- Zhang, N.; Browne, D.J.; Gilchrist, M.D. Characterization of micro injection molding process for the replication of micro/nano features using bulk metallic glass insert. Int. J. Eng. Technol. 2013, 198–201. [Google Scholar] [CrossRef]

- Lu, Z.; Zhang, K.F. Morphology and mechanical properties of polypropylene micro-arrays by micro-injection molding. Int. J. Adv. Manuf. Technol. 2009, 40, 490–496. [Google Scholar] [CrossRef]

- Theilade, U.A.; Hansen, H.N. Surface microstructure replication in injection molding. Int. J. Adv. Manuf. Technol. 2007, 33, 157–166. [Google Scholar] [CrossRef]

- Sarikhani, K.; Jeddi, K.; Thompson, R.B.; Park, C.B.; Chen, P. Effect of pressure and temperature on interfacial tension of poly lactic acid melt in supercritical carbon dioxide. Thermochim. Acta 2015, 609, 1–6. [Google Scholar] [CrossRef]

- Refaa, Z.; Boutaous, M.; Xin, S.; Siginer, D.A. Thermophysical analysis and modeling of the crystallization and melting behavior of PLA with talc: Kinetics and crystalline structures. J. Therm. Anal. Calorim. 2017, 128, 687–698. [Google Scholar] [CrossRef]

- Tsuji, H.; Nakano, M.; Hashimoto, M.; Takashima, K.; Katsura, S.; Mizuno, A. Electrospinning of poly(lactic acid) stereocomplex nanofibers. Biomacromolecules 2006, 7, 3316–3320. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.; Li, H.; Jiang, S.; Chen, X.; An, L. Crystal structure and morphology influenced by shear effect of poly(l-lactide) and its melting behavior revealed by WAXD, DSC and in-situ POM. Polymer 2011, 52, 3478–3487. [Google Scholar] [CrossRef]

- De Santis, F.; Pantani, R.; Titomanlio, G. Nucleation and crystallization kinetics of poly(lactic acid). Thermochim. Acta 2011, 522, 128–134. [Google Scholar] [CrossRef]

- Jalali, A.; Shahbikian, S.; Huneault, M.A.; Elkoun, S. Effect of molecular weight on the shear-induced crystallization of poly(lactic acid). Polymer 2017, 112, 393–401. [Google Scholar] [CrossRef]

- De Meo, A.; De Santis, F.; Pantani, R. Dynamic local temperature control in micro-injection molding: Effects on poly(lactic acid) morphology. Polym. Eng. Sci. 2018, 58, 586–591. [Google Scholar] [CrossRef]

| Test Name | Polylactic Acid (PLA) Grade | Holding Pressure [MPa] | Electrical Power [W/cm2] | Tlevel [°C] | Heating Time [s] |

|---|---|---|---|---|---|

| Passive-A | 3251D | 63 | 0 | 30 | 0 |

| Passive-B | 4032D | 63 | 0 | 30 | 0 |

| 100-1-30-A | 3251D | 30 | 5 | 100 | 1 |

| 100-8-30-A | 3251D | 30 | 5 | 100 | 8 |

| 100-13-30-A | 3251D | 30 | 5 | 100 | 13 |

| 50-1-63-A | 3251D | 63 | 2 | 50 | 1 |

| 50-8-63-A | 3251D | 63 | 2 | 50 | 8 |

| 50-13-63-A | 3251D | 63 | 2 | 50 | 13 |

| 100-1-63-A | 3251D | 63 | 5 | 100 | 1 |

| 100-8-63-A | 3251D | 63 | 5 | 100 | 8 |

| 100-13-63-A | 3251D | 63 | 5 | 100 | 13 |

| 150-1-63-A | 3251D | 63 | 10 | 150 | 1 |

| 150-8-63-A | 3251D | 63 | 10 | 150 | 8 |

| 150-13-63-A | 3251D | 63 | 10 | 150 | 13 |

| 50-1-63-B | 4032D | 63 | 2 | 50 | 1 |

| 50-8-63-B | 4032D | 63 | 2 | 50 | 8 |

| 50-13-63-B | 4032D | 63 | 2 | 50 | 13 |

| 100-1-63-B | 4032D | 63 | 5 | 100 | 1 |

| 100-8-63-B | 4032D | 63 | 5 | 100 | 8 |

| 100-13-63-B | 4032D | 63 | 5 | 100 | 13 |

| 150-1-63-B | 4032D | 63 | 10 | 150 | 1 |

| 150-8-63-B | 4032D | 63 | 10 | 150 | 8 |

| 150-13-63-B | 4032D | 63 | 10 | 150 | 13 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liparoti, S.; Speranza, V.; Pantani, R. Replication of Micro- and Nanofeatures in Injection Molding of Two PLA Grades with Rapid Surface-Temperature Modulation. Materials 2018, 11, 1442. https://doi.org/10.3390/ma11081442

Liparoti S, Speranza V, Pantani R. Replication of Micro- and Nanofeatures in Injection Molding of Two PLA Grades with Rapid Surface-Temperature Modulation. Materials. 2018; 11(8):1442. https://doi.org/10.3390/ma11081442

Chicago/Turabian StyleLiparoti, Sara, Vito Speranza, and Roberto Pantani. 2018. "Replication of Micro- and Nanofeatures in Injection Molding of Two PLA Grades with Rapid Surface-Temperature Modulation" Materials 11, no. 8: 1442. https://doi.org/10.3390/ma11081442

APA StyleLiparoti, S., Speranza, V., & Pantani, R. (2018). Replication of Micro- and Nanofeatures in Injection Molding of Two PLA Grades with Rapid Surface-Temperature Modulation. Materials, 11(8), 1442. https://doi.org/10.3390/ma11081442