Effects of Pulse Parameters on Weld Microstructure and Mechanical Properties of Extra Pulse Current Aided Laser Welded 2219 Aluminum Alloy Joints

Abstract

:1. Introduction

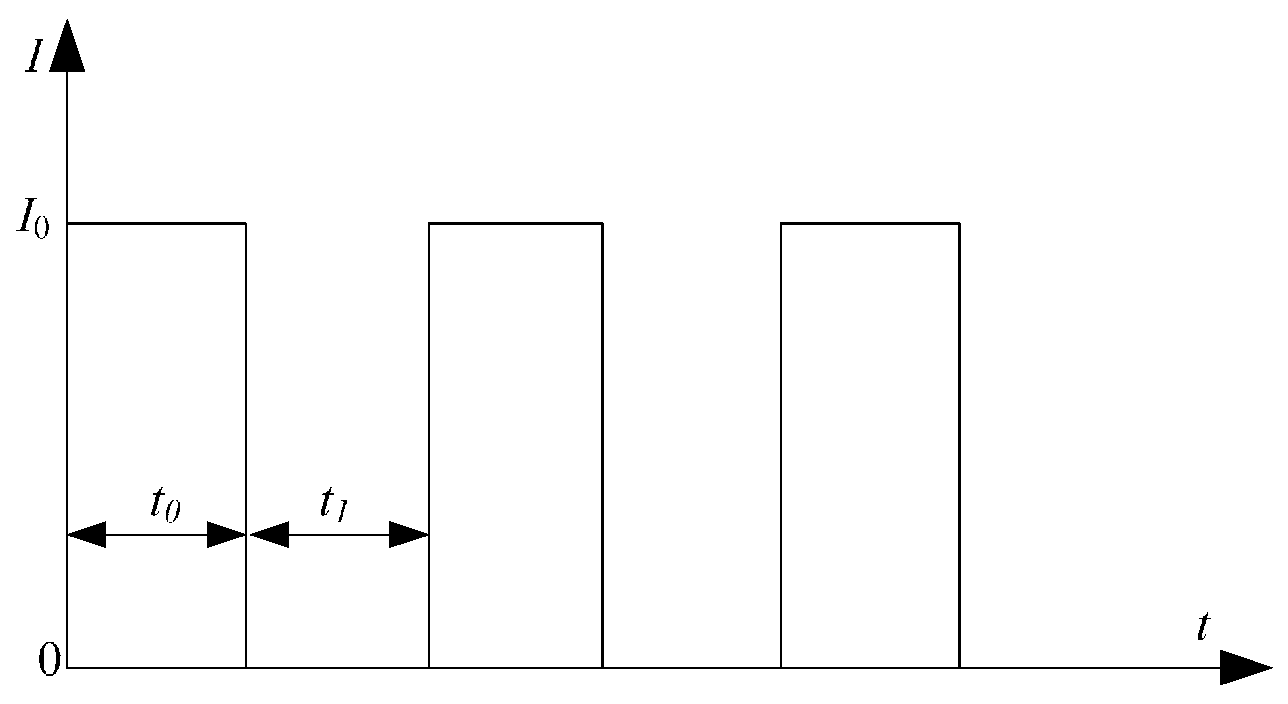

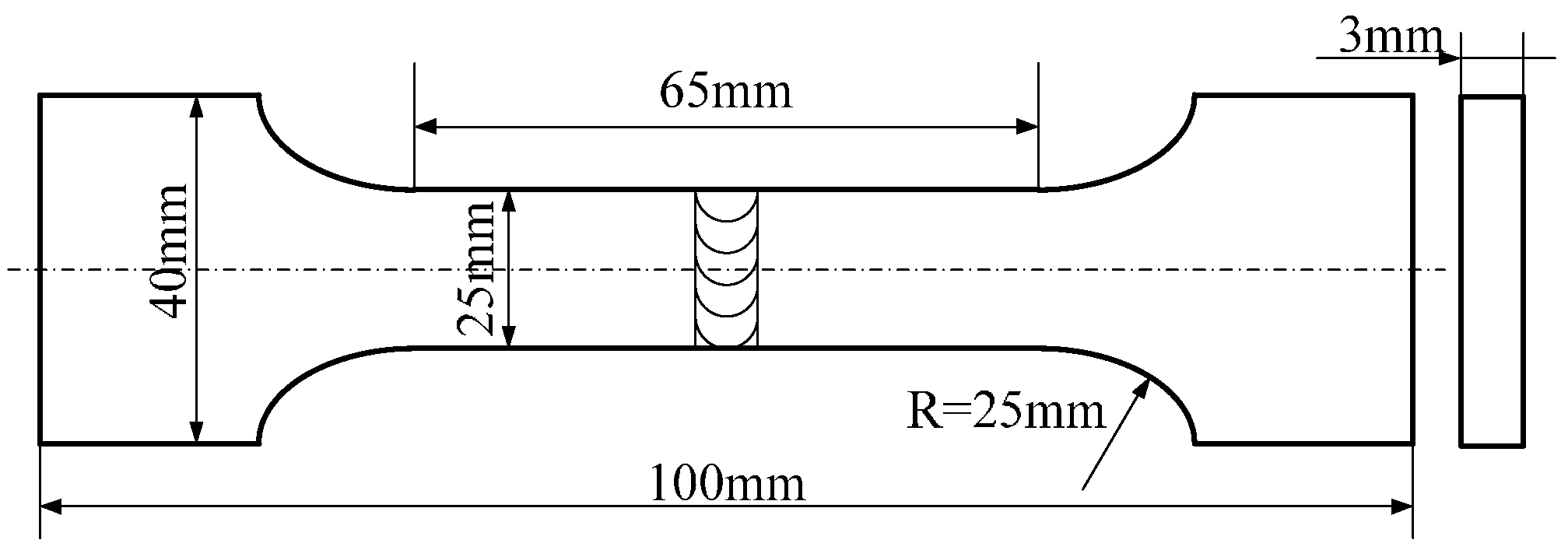

2. Materials and Methods

3. Results and Discussion

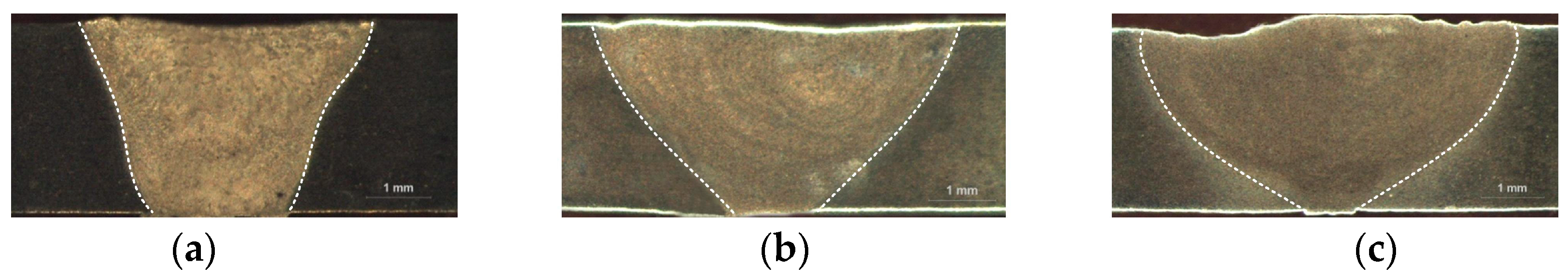

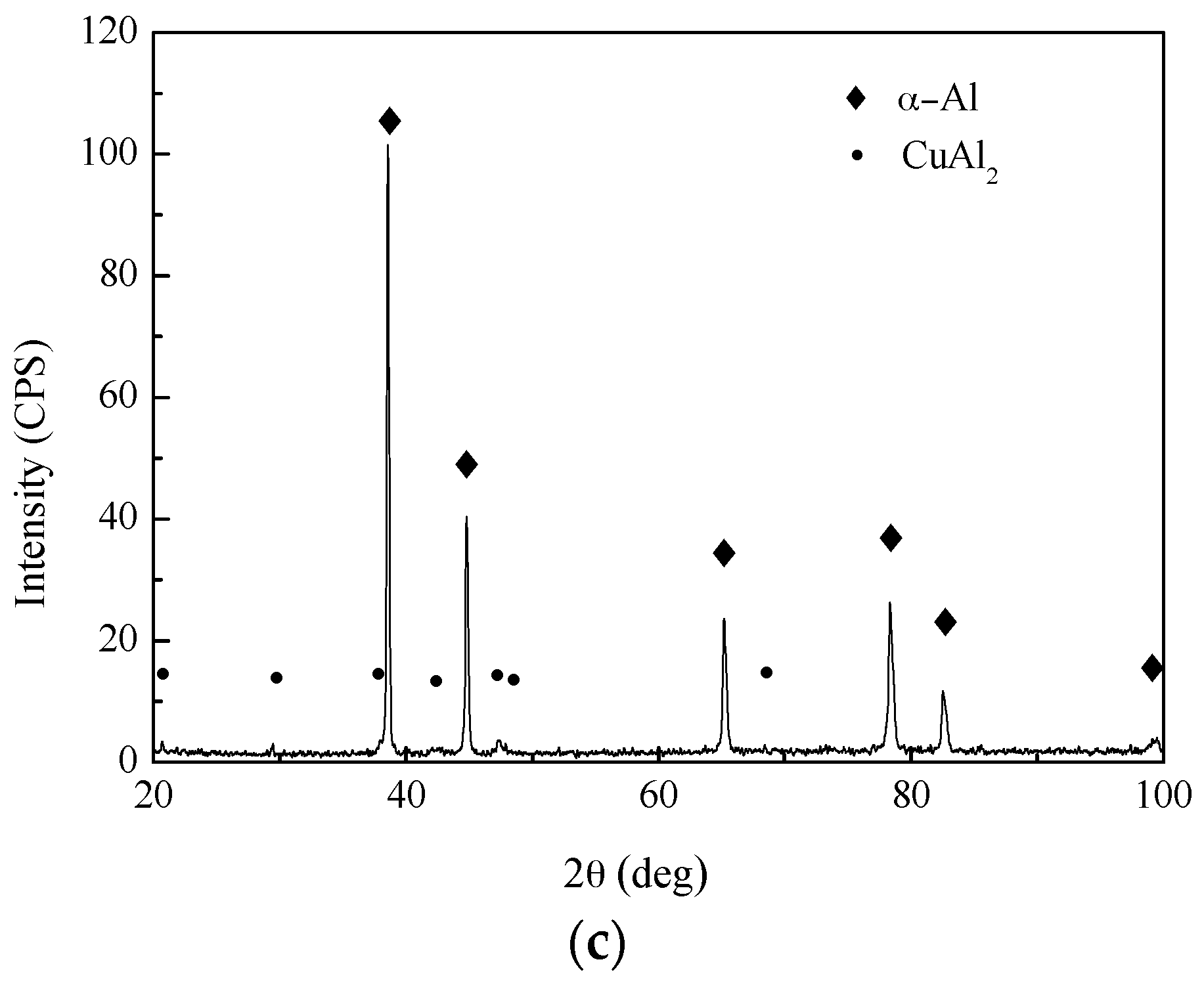

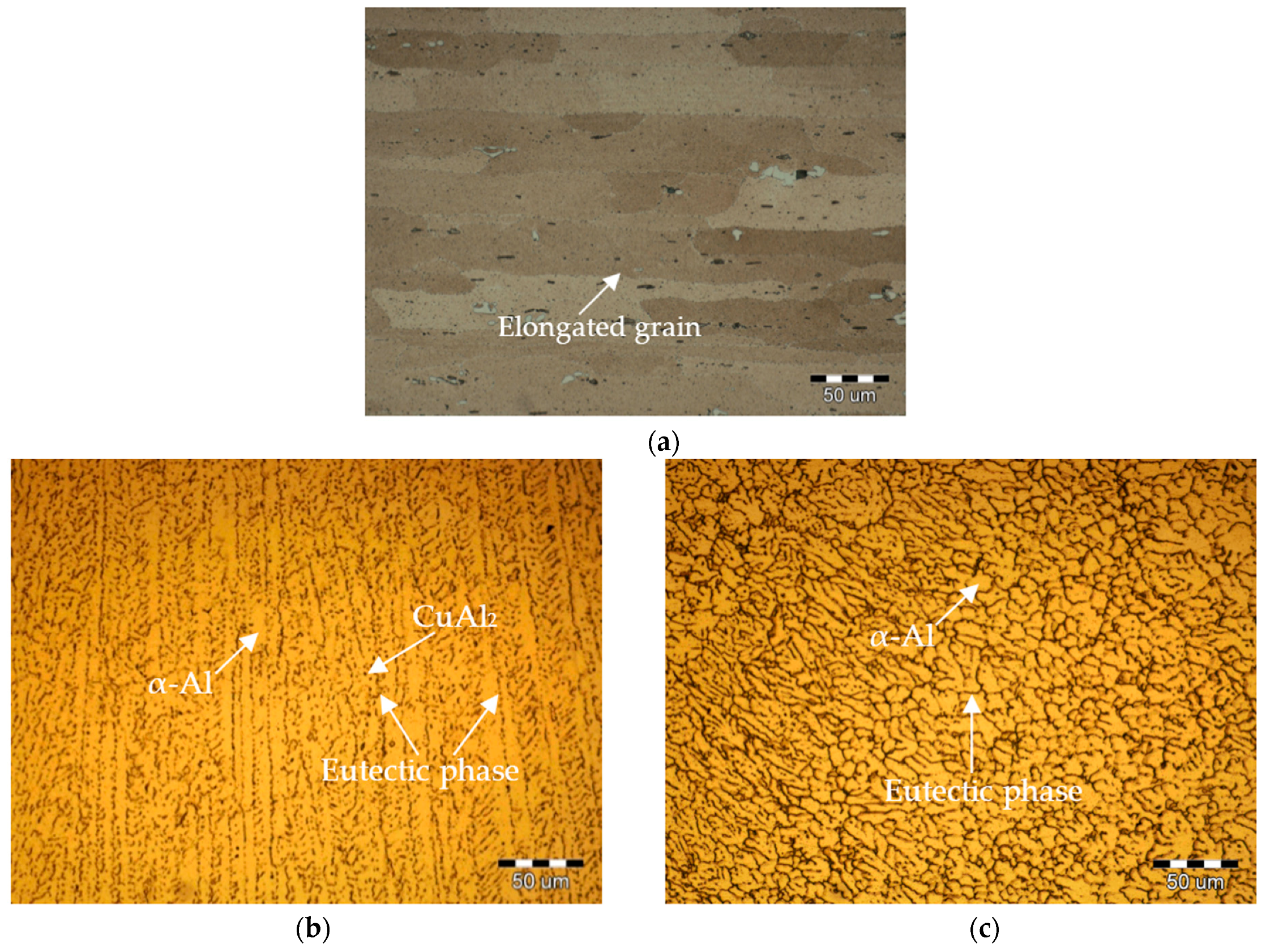

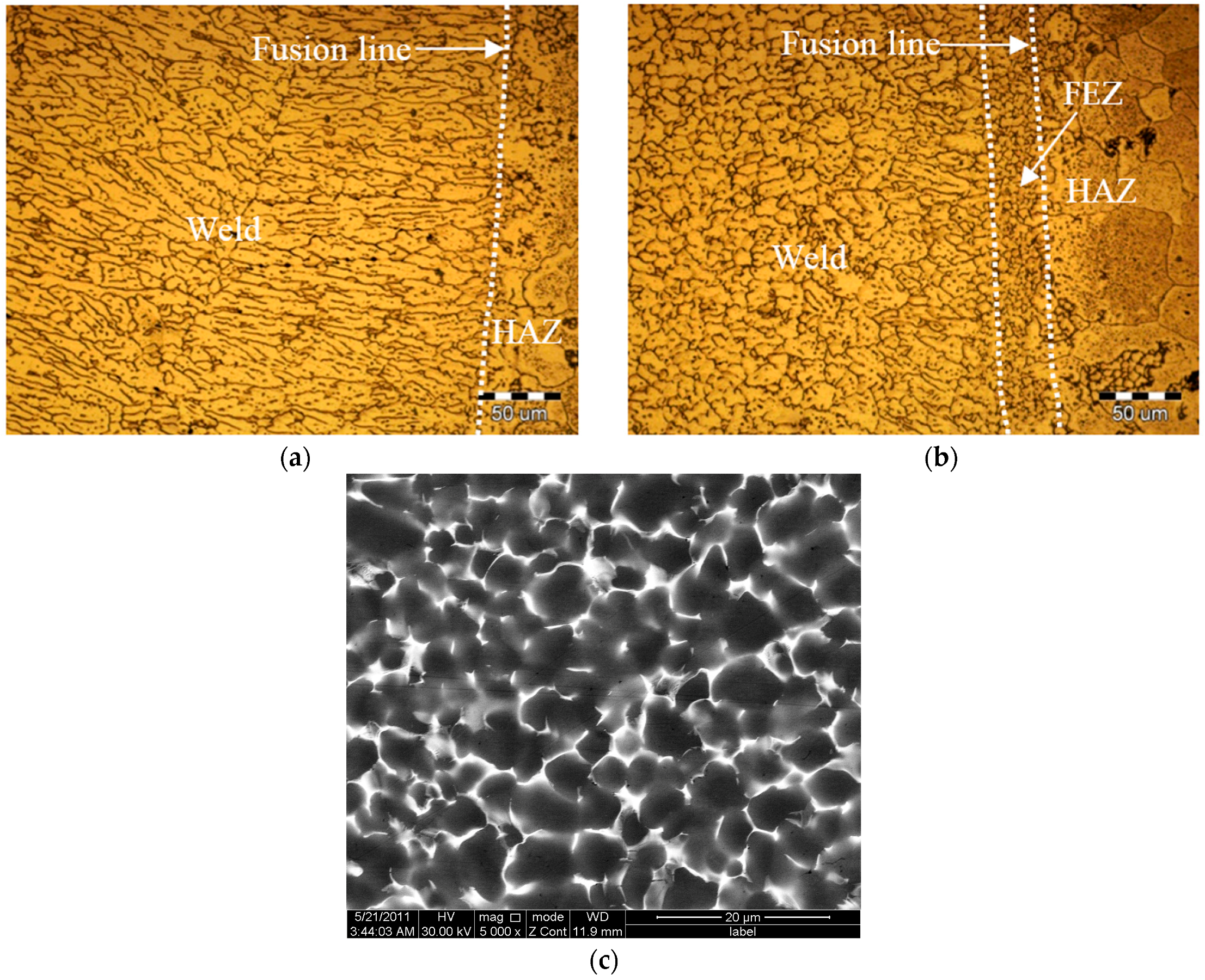

3.1. Effect of Extra Current onthe Weld Zone

3.2. Effect of Extra Pulse Current Parametersonthe Weld Microstructure

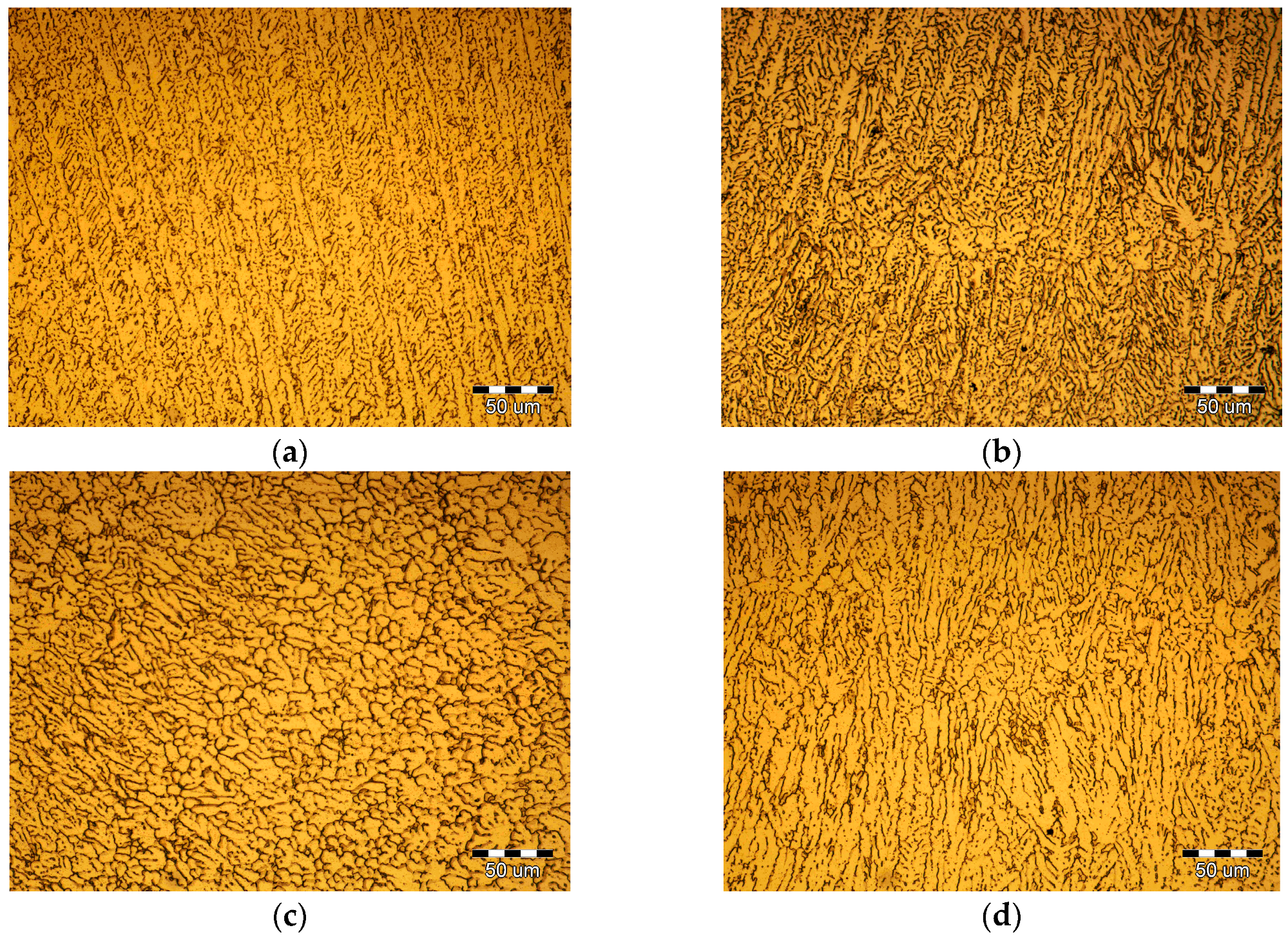

3.2.1. Effect of Peak Current I0 on the Weld Microstructure

3.2.2. Effect of the Pulse Frequency fH on the Weld Microstructure

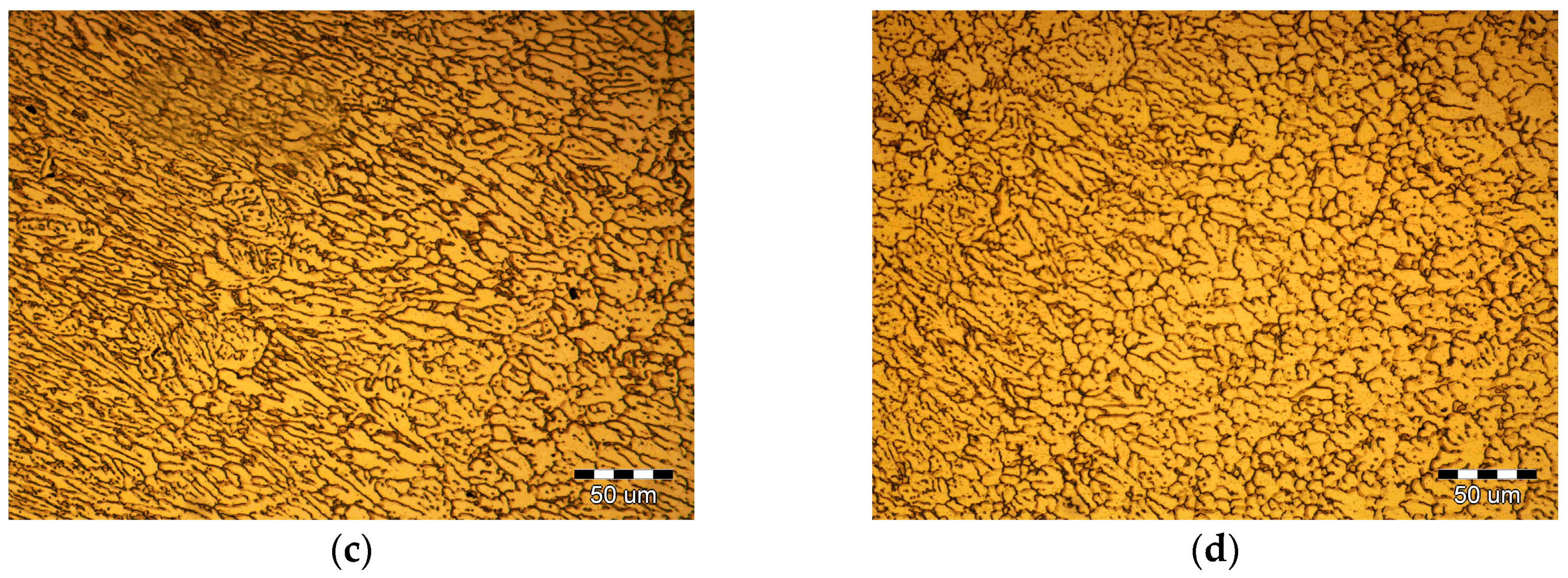

3.2.3. Effect of the Pulse Duty Ratio δ on the Weld Microstructure

3.3. Discussion of Effect Mechanism of the Extra Pulse Current

3.3.1. Magnetic Pinch Effect

3.3.2. Thermal Effect

3.3.3. Electromigration Effect

3.4. Mechanical Properties

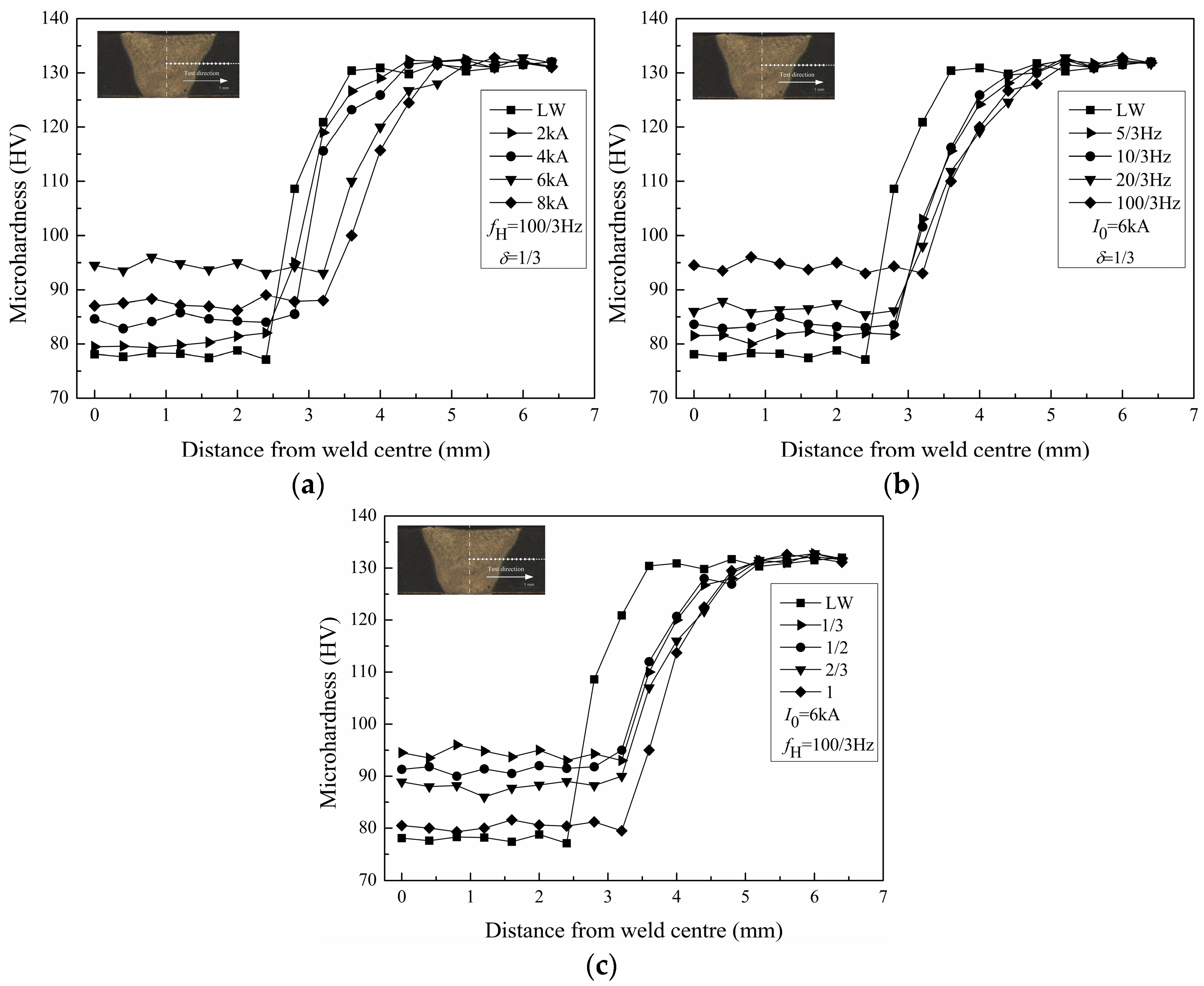

3.4.1. Microhardness Distribution

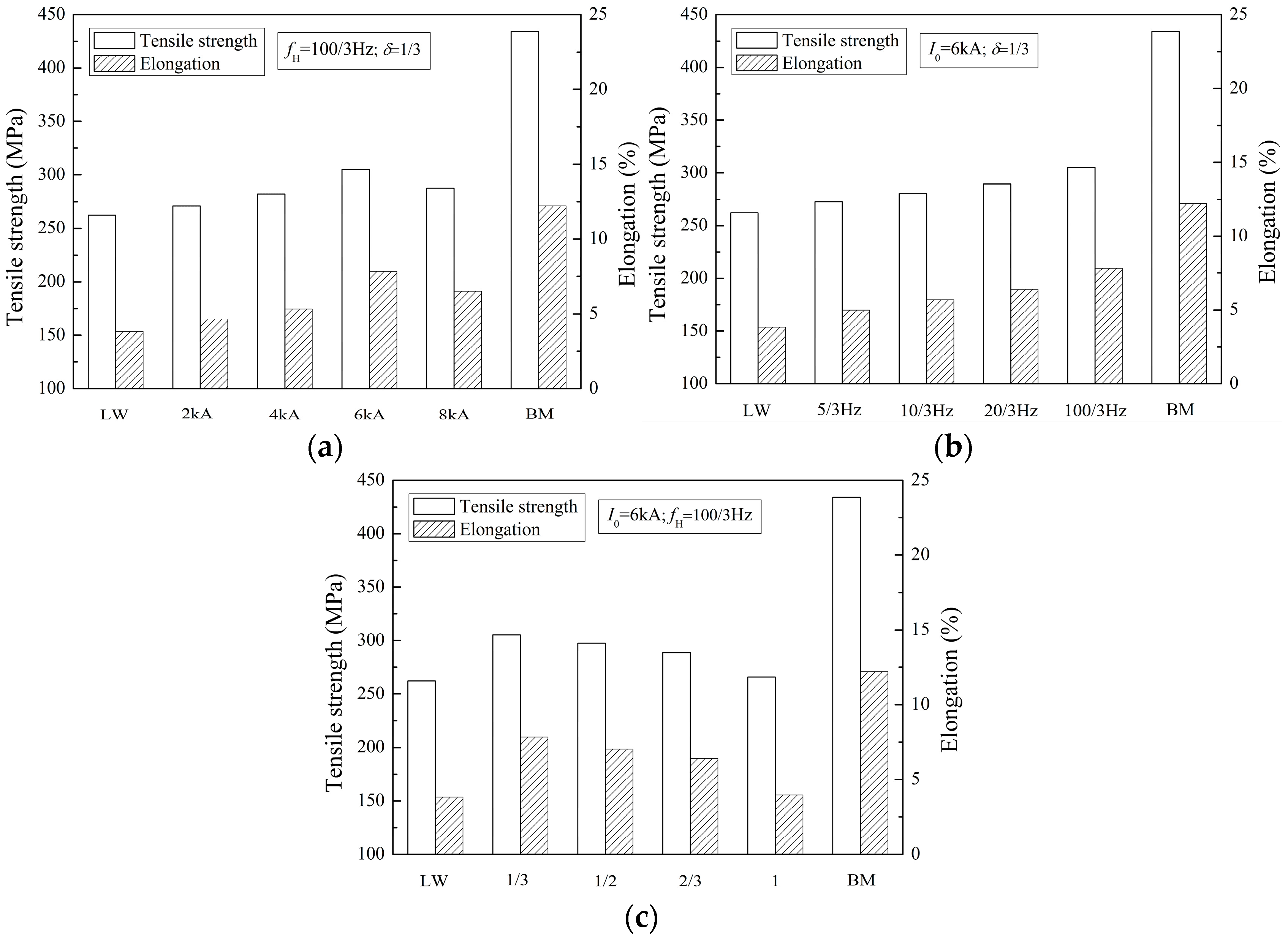

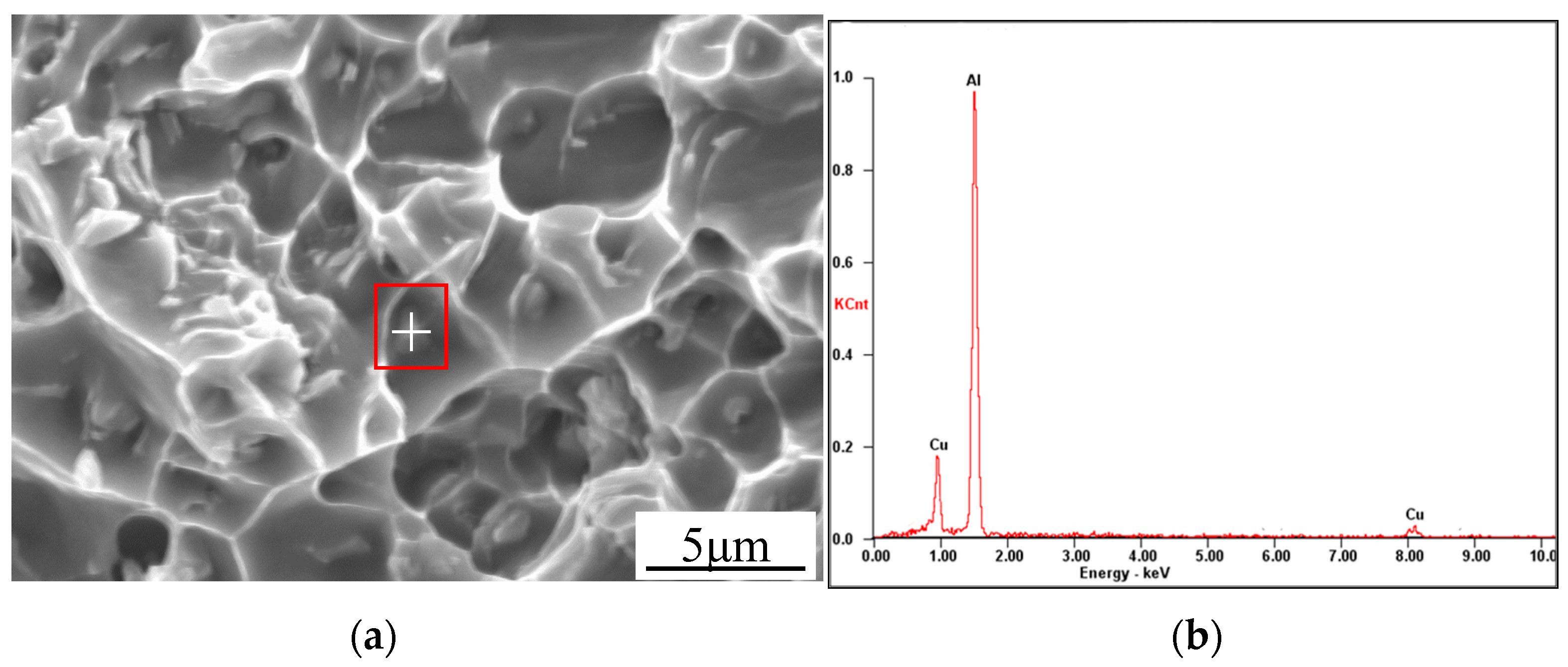

3.4.2. Tensile Properties

4. Conclusions

- (1)

- Using extra pulse current-aided laser welding, the coarse dendritic structure in the weld zone changed to the fine equiaxed structure, and the α + θ eutectic phase homogeneously distributed along the grain boundaries. A fine equiaxed zone existed in the PCALW joint in the vicinity of the fusion line, where the columnar dendritic structure grew perpendicularly for the autogenous laser welded joint.

- (2)

- The favorable extra pulse current parameters, including medium peak current I0, relatively high pulse frequency fH, and low pulse duty ratio δ, can be chosen to refine the weld structure. The effective mechanisms of the extra pulse current are mainly ascribed to the magnetic pinch effect, thermal effect, and electromigration effect caused by the pulse current.

- (3)

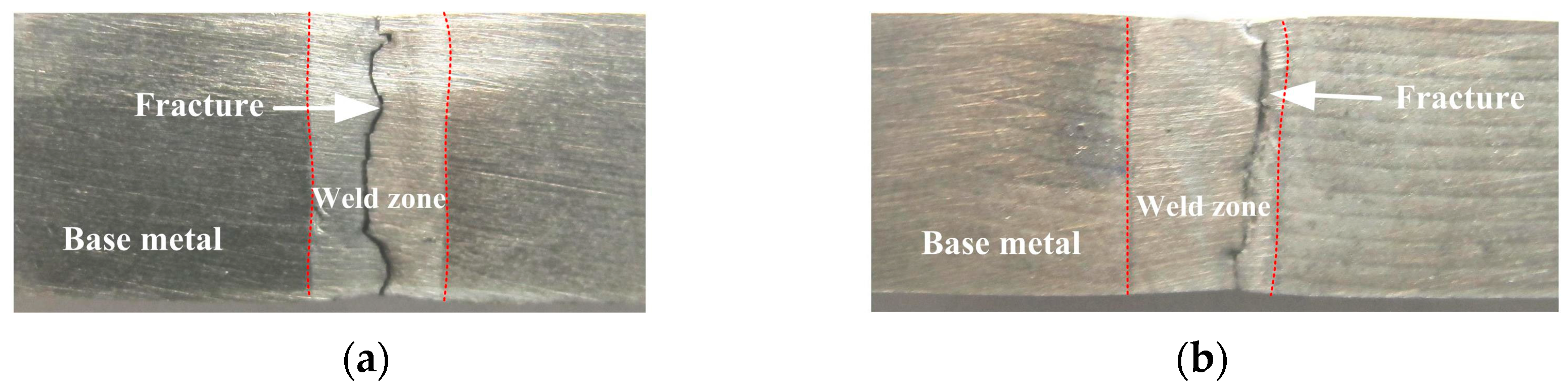

- The effect of pulse parameters on the mechanical properties of the welded joints were consistent with that of the weld microstructure. The microhardness in the weld zone was the lowest, and the laser-welded joint ruptured in the middle of weld zone, then, the PCALW welded joint with a maximum tensile strength ruptured in the weld zone adjacent to the fine equiaxed zone. The tensile strength and elongation of the optimal PCALW welded joint increased by 16.4% and 105% compared with autogenous laser welding.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Duley, W.W. Laser Welding, 1st ed.; John Wiley and Sons Ltd.: New York, NY, USA, 1998; pp. 1–9. [Google Scholar]

- Chen, Y.B.; Miao, Y.G.; Li, L.Q.; Wu, L. Joint performance of laser-TIG double-side welded 5A06 aluminum alloy. Trans. Nonferrous Met. Soc. China 2009, 19, 26–31. [Google Scholar] [CrossRef]

- Wang, X.; Luo, Y.; Huang, T.; Liu, H. Experimental investigation on laser impact welding of Fe-Based amorphous alloys to crystalline copper. Materials 2017, 10, 523. [Google Scholar] [CrossRef] [PubMed]

- Kern, M.; Berger, P.; Hügel, H. Magneto-fluid dynamic control of seam quality in CO2 laser beam welding. Weld. J. 2000, 3, 72–78. [Google Scholar]

- Lindenau, D.; Ambrosy, G.; Berger, P. Effects of magnetically supported laser beam welding of aluminum alloys. In Proceedings of the 20th International Congress on Application of Lasers and Electro-Optics (ICALEO), Jacksonville, FL, USA, 15–18 October 2001; pp. 308–318. [Google Scholar]

- Vollertsen, F.; Thomy, C. Magnetic stirring during laser welding of aluminum. J. Laser Appl. 2005, 18, 28–34. [Google Scholar] [CrossRef]

- Xiao, R.S.; Ambrosy, G.; Zuo, T.C. New approach to improve the laser welding process of aluminum by using an external electrical current. J. Mater. Sci. Lett. 2001, 20, 2163–2165. [Google Scholar] [CrossRef]

- Xiao, R.S.; Zuo, T.C.; Ambrosy, G. Investigation on current enhanced CO2 laser welding of aluminum. Chin. J. Lasers 2004, 31, 359–362. [Google Scholar]

- Xiao, R.S.; Zuo, T.C.; Ambrosy, G. CO2 laser beam welding of aluminum alloy with additional current via filler wire. Trans. China Weld. Inst. 2006, 27, 9–12. [Google Scholar]

- Crossley, F.; Fisher, R.D.; Metcalfe, A.G. Viscous shear as an agent for grain refinement in cast metal. Trans. Metall. Soc. AIME 1961, 221, 19–420. [Google Scholar]

- Zi, B.T.; Cui, J.Z.; Ba, Q.X. Solidification structure of LY12 alloy under pulse electric current with high density. Spec. Cast. Nonferrous Alloys 2000, 114, 4–6. [Google Scholar]

- Karunakaran, N.; Balasubramanian, V. Effect of pulsed current on temperature distribution, weld bead profiles and characteristics of gas tungsten arc welded aluminum alloy joints. Trans. Nonferrous Met. Soc. China 2011, 21, 278–286. [Google Scholar] [CrossRef]

- Cong, B.Q.; Qi, B.J.; Zhou, X.G.; Luo, J. Influences of ultrasonic pulse square-wave current parameters on microstructures and mechanical properties of 2219 aluminum alloy weld joints. Acta Metall. Sin. 2009, 45, 1057–1062. [Google Scholar]

- Potluri, N.B.; Ghosh, P.K.; Gupta, P.C.; Reddy, Y.S. Studies on weld metal characteristics and their influence on tensile and fatigue properties of pulsed-current GMA welded Al-Zn-Mg alloy. Weld. J. 1996, 75, 62–70. [Google Scholar]

- Balasubramanian, V.; Ravisankar, V.; Madhusudhan, R.G. Effect of pulsed current welding on mechanical properties of high strength aluminum alloy. Inter. J. Adv. Manuf. Technol. 2008, 36, 254–262. [Google Scholar] [CrossRef]

- Tan, J.; Zhan, L.; Zhang, J.; Yang, Z.; Ma, Z. Effects of stress relaxation aging with electrical pulses on microstructures and properties of 2219 aluminum alloy. Materials 2016, 9, 538. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Huang, Y.; Xiao, Z.; Jia, G. First principles study of adsorption of hydrogen on typical alloying elements and inclusions in molten 2219 Al alloy. Materials 2017, 10, 816. [Google Scholar] [CrossRef] [PubMed]

- Zhan, L.; Li, W.; Ma, Q.; Liu, L. The influence of different external fields on aging kinetics of 2219 aluminum alloy. Metals 2016, 6, 201. [Google Scholar] [CrossRef]

- Koteswara, R.S.R.; Madhusudhan, R.G.; Prasad, R.K. Effects of thermo-mechanical treatments on mechanical properties of AA2219 gas tungsten arc welds. J. Mater. Process. Technol. 2008, 202, 283–289. [Google Scholar]

- Xu, W.L.; Li, Q.F.; Meng, Q.G. Microstructures of 2219 twin wire welded joints. China Weld. 2005, 114, 101–104. [Google Scholar]

- Nair, B.S.; Rakesh, S.; Phanikumar, G.; Rao, K.P.; Sinha, P.P. Fracture toughness (J1C) of electron beam welded AA2219 alloy. Mater. Des. 2011, 32, 1205–1214. [Google Scholar] [CrossRef]

- Liu, H.J.; Zhang, H.J.; Yu, L. Effect of welding speed on microstructures and mechanical properties of underwater friction stir welded 2219 aluminum alloy. Mater. Des. 2011, 32, 1548–1553. [Google Scholar] [CrossRef]

- Yang, C.L.; Guo, L.J.; Lin, S.B. Mechanical properties of welded joints in vertical-up variable polarity plasma arc welding of 2219 aluminum alloy. Trans. Nonferrous Met. Soc. China 2005, 15, 83–86. [Google Scholar]

- Yan, H.C.; He, G.H.; Zhou, B.L.; Qin, R.S.; Guo, J.D.; Shen, Y.F. The influence of pulse electric discharging on solidified structure of Sn-10% Pb slloy. Acta Metall. Sin. 1997, 33, 352–358. [Google Scholar]

- Hunt, J.D. Steady state columnar and equiaxed growth of dendrites and eutectic. Mater. Sci. Eng. 1984, 65, 75–83. [Google Scholar] [CrossRef]

- Coriell, S.R.; Mcfadden, G.B.; Wheeler, A.A.; Hurle, D.T.J. The effect of an electric field on themorphological stability of the crystal-melt interface of a binary alloy: II. Joule heating and thermoelectric effects. J. Cryst. Growth 1989, 94, 334–346. [Google Scholar] [CrossRef]

- Qin, R.S.; Yan, H.C.; He, G.H.; Zhou, B.L. Exploration on the fabrication of bulk nanocrystalline materials by direct-nanocrystallizing method I. nucleation in disordered metallic media by electropusing. Chin. J. Mater. Res. 1995, 9, 219–222. [Google Scholar]

| Component | Cu | Si | Mn | Fe | Zr | Ti | Al |

|---|---|---|---|---|---|---|---|

| wt % | 6.48 | 0.49 | 0.32 | 0.23 | 0.2 | 0.06 | Balance |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Li, L.; Chen, Y.; Yang, Z.; Chen, Y.; Guo, X. Effects of Pulse Parameters on Weld Microstructure and Mechanical Properties of Extra Pulse Current Aided Laser Welded 2219 Aluminum Alloy Joints. Materials 2017, 10, 1091. https://doi.org/10.3390/ma10091091

Zhang X, Li L, Chen Y, Yang Z, Chen Y, Guo X. Effects of Pulse Parameters on Weld Microstructure and Mechanical Properties of Extra Pulse Current Aided Laser Welded 2219 Aluminum Alloy Joints. Materials. 2017; 10(9):1091. https://doi.org/10.3390/ma10091091

Chicago/Turabian StyleZhang, Xinge, Liqun Li, Yanbin Chen, Zhaojun Yang, Yanli Chen, and Xinjian Guo. 2017. "Effects of Pulse Parameters on Weld Microstructure and Mechanical Properties of Extra Pulse Current Aided Laser Welded 2219 Aluminum Alloy Joints" Materials 10, no. 9: 1091. https://doi.org/10.3390/ma10091091

APA StyleZhang, X., Li, L., Chen, Y., Yang, Z., Chen, Y., & Guo, X. (2017). Effects of Pulse Parameters on Weld Microstructure and Mechanical Properties of Extra Pulse Current Aided Laser Welded 2219 Aluminum Alloy Joints. Materials, 10(9), 1091. https://doi.org/10.3390/ma10091091