Navigating the Intersection of Microgrids and Hydrogen: Evolutionary Trends, Challenges, and Future Strategies

Abstract

1. Introduction

- An updated review of microgrid definitions, microgrid classifications, hydrogen production techniques, hydrogen storage techniques, and hydrogen utilization techniques.

- Different microgrid applications are matched with potential hydrogen production, storage, and utilization techniques.

2. Microgrids: Definitions, Characteristics and Issues

2.1. Microgrid Definitions

2.2. Microgrid Characteristics and Issues

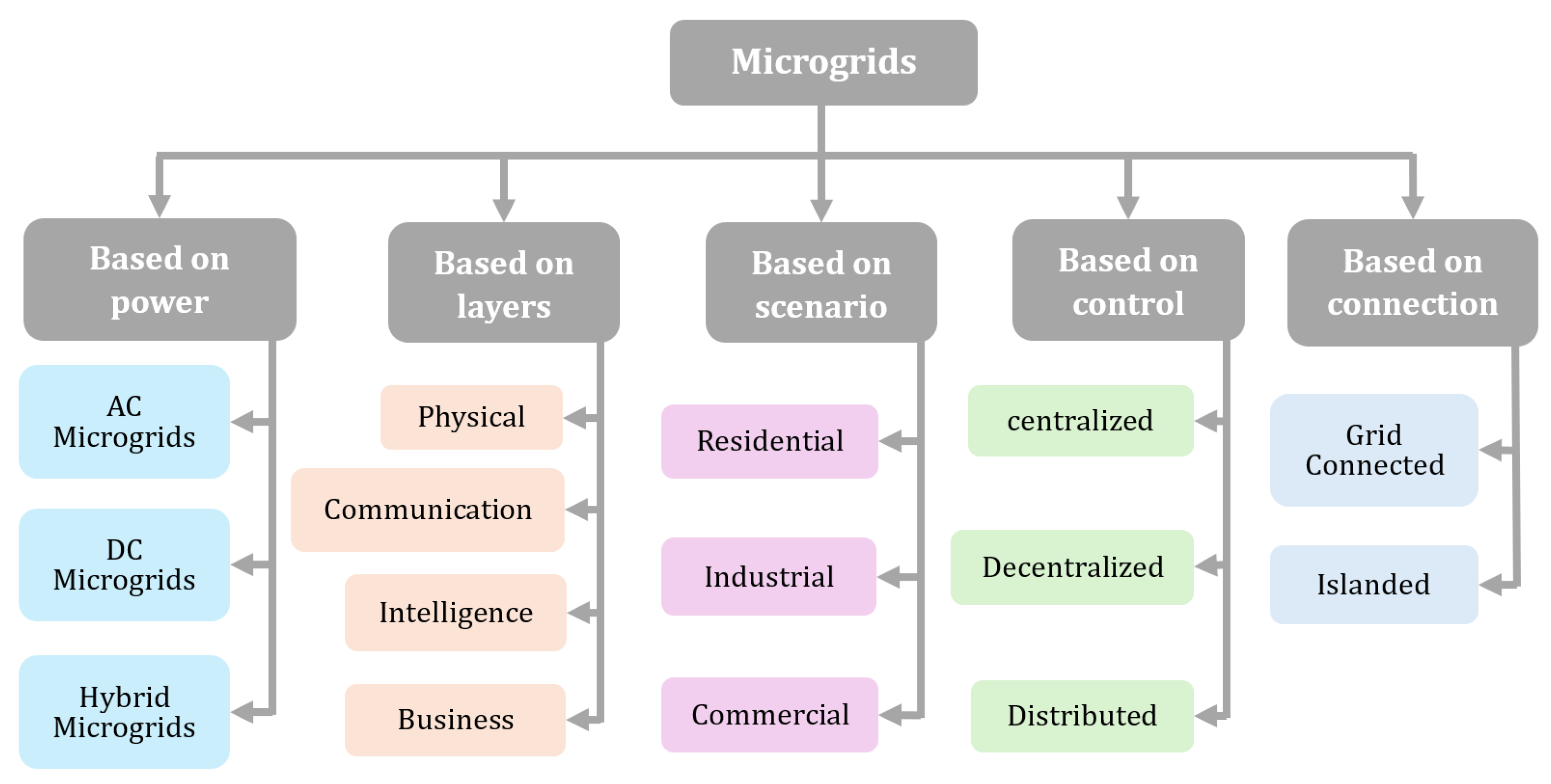

2.3. Microgrid Classification Based on Topology

2.3.1. AC Microgrids

- Interoperability: Can easily interconnect with existing power systems without requiring separate converter controllers.

- Standardization and Compatibility: Well-established worldwide, with standardized norms for power, voltage, and frequency variations. These standards are applicable to AC microgrids, facilitating easy integration into industry.

- Resiliency: Capability to transition from grid-connected to standalone mode. Capability to power the local loads even at main grid outages, providing stable operations.

2.3.2. DC Microgrids

- Easy integration of RESs, ESSs, and loads: Technologies such as PV operate on DC power, and several studies aim to improve their efficiency and power levels. ESS-like batteries also operate on DC power. Most consumer electronic devices, such as PC systems, mobile devices, laptops, printers, and lighting, are powered using DC.

- Elimination of AC-related issues, synchronization, frequency control, reactive power, and harmonics: Issues such as frequency control and harmonic distortion arise with the introduction of frequency in an AC system.

- Reduced conversion stage/improved efficiency: Since most residential and industrial loads operate on DC power, selecting an appropriate DC voltage level minimizes the need for power conversions. Minimal conversion increases system efficiency.

- Reduced cost of the system: DC systems can operate with thinner conductors with reduced cost. Reduced conversion stages increase efficiency with a reduced cost.

2.3.3. Hybrid Microgrids

- Seamless integration: Can incorporate both AC and DC components, leveraging each type’s unique benefits.

- Increased efficiency: Reduce the need for heavy conversion infrastructure by only converting when necessary

- Optimal renewable and ESS usage: Enable optimized integration of renewable energy and storage by leveraging each energy form’s strengths.

2.4. Classification of Microgrids Based on Functional Layers

2.4.1. Physical Layer

2.4.2. Communication Layer

2.4.3. Intelligence Layer

3. Role of Hydrogen in Microgrids as an Energy Storage Solution

3.1. Hydrogen Storage Techniques

3.2. Hydrogen Generation Techniques

3.2.1. Electrolysis Techniques

3.2.2. Other Techniques

3.3. Hydrogen Utilization Techniques

3.3.1. Fuel Cells

3.3.2. Hydrogen-Based Combined Heat and Power (CHP)

3.3.3. Hydrogen Microturbines

3.3.4. Hydrogen for Industries

3.4. Comparision of Cost, Associated Emissions, and Technology Readiness Level (TRL)

4. Potential Hydrogen Applications on Future Microgrids

4.1. Commercial Microgrids

4.2. Industrial Microgrids

4.3. Residential Microgrids

4.4. Remote and Island Microgrids

4.5. Urban Microgrids

5. Discussion and Future Directions

- Future studies should focus on improving the overall efficiency of hydrogen generation, storage, and utilization techniques. Although some of these techniques are environmentally friendly, their operational efficiency remains low.

- Reducing the costs associated with hydrogen technologies will also be crucial in future studies. This reduction will be helpful for the commercial integration of hydrogen.

- Scaling up production levels will also be essential for future research. Increased production capacity can, in turn, help reduce costs.

- The design and investigation of advanced material types for electrolyzers and fuel cell components are critical for improving efficiency, and cost-effectiveness. Suggestions such as high-performance catalysts, corrosion-resistant components, and low-cost membranes could significantly increase the application of hydrogen technologies.

- Furthermore, efficient and accurate modeling and control developments are essential for optimizing hydrogen production, storage, and utilization within microgrids. Advanced algorithms and modules for real-time monitoring and control can ensure system stability and the seamless integration of hydrogen technologies with RESs.

- The Internet of Things (IoT) and digital twin technologies also have huge potential for enabling hydrogen microgrids. IoT systems can enable real-time data collection and remote monitoring, while digital twins support predictive modeling and dynamic optimization of microgrid operations.

- Machine learning algorithms and AI-driven optimization techniques can forecast energy demand, optimize hydrogen production schedules, and reduce operational costs. AI can also assist in anomaly detection, fault diagnosis, and adaptive system management, ensuring high efficiency and minimal downtime.

- Advancements in electrolysis technologies, such as high-temperature and hybrid systems, can improve efficiency and integration with RESs.

- In terms of storage, innovations in advanced materials for metal hydrides, complex hydrides, and chemical hydrogen storage could provide safer, more compact, and cost-effective solutions for various applications.

- Optimizing fuel cells, CHP systems, and hydrogen-compatible turbines will be critical in expanding hydrogen’s role in transportation, industrial processes, and residential energy systems.

- Expanding hydrogen infrastructure, such as centralized storage hubs and distribution networks, particularly in urban areas, is essential for supporting large-scale adoption.

- Policymakers and industry stakeholders are encouraged to prioritize investment in research, pilot projects, and standardization to address challenges such as energy losses, safety concerns, and lifecycle emissions.

6. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Voropai, N. Electric Power System Transformations: A Review of Main Prospects and Challenges. Energies 2020, 13, 5639. [Google Scholar] [CrossRef]

- Short, T.A. Electric Power Distribution Handbook; CRC Press: New York, NY, USA, 2003. [Google Scholar] [CrossRef]

- Breidenich, C.; Magraw, D.; Rowley, A.; Rubin, J.W. The Kyoto Protocol to the United Nations Framework Convention on Climate Change. Am. J. Int. Law 1998, 92, 315–331. [Google Scholar] [CrossRef]

- Renewables 2024 Global Status Report. Available online: https://www.ren21.net/gsr-2024/ (accessed on 7 November 2024).

- McDermott, T.E.; Dugan, R.C. Distributed generation impact on reliability and power quality indices. In Proceedings of the 2002 Rural Electric Power Conference, Papers Presented at the 46th Annual Conference (Cat. No. 02CH37360), Colorado Springs, CO, USA, 5–7 May 2002; IEEE: New York, NY, USA, 2002; p. D3-1. [Google Scholar] [CrossRef]

- Hernández-Mayoral, E.; Madrigal-Martínez, M.; Mina-Antonio, J.D.; Iracheta-Cortez, R.; Enríquez-Santiago, J.A.; Rodríguez-Rivera, O.; Martínez-Reyes, G.; Mendoza-Santos, E. A Comprehensive Review on Power-Quality Issues, Optimization Techniques, and Control Strategies of Microgrid Based on Renewable Energy Sources. Sustainability 2023, 15, 9847. [Google Scholar] [CrossRef]

- Uddin, M.; Mo, H.; Dong, D.; Elsawah, S.; Zhu, J.; Guerrero, J.M. Microgrids: A review, outstanding issues and future trends. Energy Strategy Rev. 2023, 49, 101127. [Google Scholar] [CrossRef]

- Yue, M.; Lambert, H.; Pahon, E.; Roche, R.; Jemei, S.; Hissel, D. Hydrogen energy systems: A critical review of technologies, applications, trends and challenges. Renew. Sustain. Energy Rev. 2021, 146, 111180. [Google Scholar] [CrossRef]

- Goal 7|Department of Economic and Social Affairs. Available online: https://sdgs.un.org/goals/goal7 (accessed on 10 January 2025).

- Boretti, A.; Pollet, B.G. Hydrogen economy: Paving the path to a sustainable, low-carbon future. Int. J. Hydrogen Energy 2024, 93, 307–319. [Google Scholar] [CrossRef]

- Growing Australia’s Hydrogen Industry—DCCEEW. Available online: https://www.dcceew.gov.au/energy/hydrogen (accessed on 10 January 2025).

- Abbasi, M.; Abbasi, E.; Li, L.; Aguilera, R.P.; Lu, D.; Wang, F. Review on the Microgrid Concept, Structures, Components, Communication Systems, and Control Methods. Energies 2023, 16, 484. [Google Scholar] [CrossRef]

- Microgrids & Stand-alone Power Systems: An Explainer, Optimal Group. Available online: https://optimalgroup.com.au/news/microgrids-stand-alone-power-systems-an-explainer (accessed on 7 November 2024).

- Eto, J.H.; Lasseter, R.; Klapp, D.; Khalsa, A.; Schenkman, B.; Illindala, M.; Baktiono, S. The CERTS Microgrid Concept, as Demonstrated at the CERTS/AEP Microgrid Test Bed. US Dep. Energy 2018, 53. Available online: https://www.researchgate.net/publication/328600356_The_CERTS_Microgrid_Concept_as_Demonstrated_at_the_CERTSAEP_Microgrid_Test_Bed (accessed on 20 November 2024).

- Dimeas, A.L.; Hatziargyriou, N.D. Operation of a multiagent system for microgrid control. IEEE Trans. Power Syst. 2005, 20, 1447–1455. [Google Scholar] [CrossRef]

- Using Its Own Technology for Electric Microgrids. CORDIS|European Commission. Available online: https://cordis.europa.eu/article/id/123412-using-its-own-technology-for-electric-microgrids (accessed on 7 November 2024).

- Martin-Martínez, F.; Sánchez-Miralles, A.; Rivier, M. A literature review of Microgrids: A functional layer based classification. Renew. Sustain. Energy Rev. 2016, 62, 1133–1153. [Google Scholar] [CrossRef]

- Aghmadi, A.; Hussein, H.; Polara, K.H.; Mohammed, O. A Comprehensive Review of Architecture, Communication, and Cybersecurity in Networked Microgrid Systems. Inventions 2023, 8, 84. [Google Scholar] [CrossRef]

- Control of Power Converters in AC Microgrids|IEEE Journals & Magazine|IEEE Xplore. Available online: https://ieeexplore-ieee-org.ezproxy.lib.uts.edu.au/document/6200347 (accessed on 7 November 2024).

- Gomez-Redondo, M.; Rivera, M.; Muñoz, J.; Wheeler, P. A Systematic Literature Review on AC Microgrids. Designs 2024, 8, 77. [Google Scholar] [CrossRef]

- Elsayed, A.T.; Mohamed, A.A.; Mohammed, O.A. DC microgrids and distribution systems: An overview. Electr. Power Syst. Res. 2015, 119, 407–417. [Google Scholar] [CrossRef]

- Pires, V.F.; Pires, A.; Cordeiro, A. DC Microgrids: Benefits, Architectures, Perspectives and Challenges. Energies 2023, 16, 1217. [Google Scholar] [CrossRef]

- Saponara, S.; Saletti, R.; Mihet-Popa, L. Hybrid Micro-Grids Exploiting Renewables Sources, Battery Energy Storages, and Bi-Directional Converters. Appl. Sci. 2019, 9, 4973. [Google Scholar] [CrossRef]

- Nejabatkhah, F.; Li, Y.W. Overview of Power Management Strategies of Hybrid AC/DC Microgrid. IEEE Trans. Power Electron. 2014, 30, 7072–7089. [Google Scholar] [CrossRef]

- Yadav, M.; Pal, N.; Saini, D.K. Microgrid Control, Storage, and Communication Strategies to Enhance Resiliency for Survival of Critical Load. IEEE Access 2020, 8, 169047–169069. [Google Scholar] [CrossRef]

- Bastidas, A.J.C.; Méndez, G.L.A.; Revelo-Fuelagán, J.; Candelo-Becerra, J.E. Performance evaluation of modbus and DNP3 protocols in the communication network of a university campus microgrid. Results Eng. 2024, 24, 103656. [Google Scholar] [CrossRef]

- Yoo, B.; Yang, H.-S.; Yang, S.; Jeong, Y.; Kim, W. CAN to IEC 61850 for microgrid system. In Proceedings of the 2011 International Conference on Advanced Power System Automation and Protection, Beijing, China, 16–20 October 2011; pp. 1219–1224. [Google Scholar] [CrossRef]

- Zerk, A.E.L.; Ouassaid, M.; Zidani, Y. Development of a real-time framework between MATLAB and PLC through OPC-UA: A case study of a microgrid energy management system. Sci. Afr. 2023, 21, e01846. [Google Scholar] [CrossRef]

- Bani-Ahmed, A.; Weber, L.; Nasiri, A.; Hosseini, H. Microgrid communications: State of the art and future trends. In Proceedings of the 2014 International Conference on Renewable Energy Research and Application (ICRERA), Milwaukee, WI, USA, 19–22 October 2014; pp. 780–785. [Google Scholar] [CrossRef]

- Ancillotti, E.; Bruno, R.; Conti, M. The role of communication systems in smart grids: Architectures, technical solutions and research challenges. Comput. Commun. 2013, 36, 1665–1697. [Google Scholar] [CrossRef]

- Soroudi, A.; Ehsan, M. A distribution network expansion planning model considering distributed generation options and techo-economical issues. Energy 2010, 35, 3364–3374. [Google Scholar] [CrossRef]

- Evaluation and Optimal Scaling of Distributed Generation Systems in A Smart City. Available online: https://www.witpress.com/elibrary/wit-transactions-on-ecology-and-the-environment/179/25263 (accessed on 7 November 2024).

- Calvillo, C.F.; Sánchez-Miralles, A.; Villar, J. Assessing low voltage network constraints in distributed energy resources planning. Energy 2015, 84, 783–793. [Google Scholar] [CrossRef]

- Thirunavukkarasu, G.S.; Seyedmahmoudian, M.; Jamei, E.; Horan, B.; Mekhilef, S.; Stojcevski, A. Role of optimization techniques in microgrid energy management systems—A review. Energy Strategy Rev. 2022, 43, 100899. [Google Scholar] [CrossRef]

- Hossain, M.A.; Pota, H.R.; Hossain, M.J.; Blaabjerg, F. Evolution of microgrids with converter-interfaced generations: Challenges and opportunities. Int. J. Electr. Power Energy Syst. 2019, 109, 160–186. [Google Scholar] [CrossRef]

- Kanakadhurga, D.; Prabaharan, N. Demand side management in microgrid: A critical review of key issues and recent trends. Renew. Sustain. Energy Rev. 2022, 156, 111915. [Google Scholar] [CrossRef]

- Tripling Renewables by 2030 Requires a Minimum of 16.4% Annual Growth Rate. Available online: https://www.irena.org/News/pressreleases/2024/Jul/Tripling-Renewables-by-2030-Requires-a-Minimum-of-16-point-4-pc-Annual-Growth-Rate (accessed on 7 November 2024).

- CSIRO. Energy storage in Australia. Available online: https://www.csiro.au/en/research/technology-space/energy/Energy-storage/Energy-storage-in-Australia (accessed on 17 July 2024).

- Choudhury, S. Review of energy storage system technologies integration to microgrid: Types, control strategies, issues, and future prospects. J. Energy Storage 2022, 48, 103966. [Google Scholar] [CrossRef]

- Olabi, A.G.; Wilberforce, T.; Abdelkareem, M.A.; Ramadan, M. Critical Review of Flywheel Energy Storage System. Energies 2021, 14, 2159. [Google Scholar] [CrossRef]

- Oliveira, D.Q.; Saavedra, O.R.; Santos-Pereira, K.; Pereira, J.D.F.; Cosme, D.S.; Veras, L.S.; Bento, R.G.; Riboldi, V.B. A critical review of energy storage technologies for microgrids. Energy Syst. 2021, 29, 1–30. [Google Scholar] [CrossRef]

- Cheng, Q.; Zhang, R.; Shi, Z.; Lin, J. Review of common hydrogen storage tanks and current manufacturing methods for aluminium alloy tank liners. Int. J. Lightweight Mater. Manuf. 2024, 7, 269–284. [Google Scholar] [CrossRef]

- Usman, M.R. Hydrogen storage methods: Review and current status. Renew. Sustain. Energy Rev. 2022, 167, 112743. [Google Scholar] [CrossRef]

- Vidas, L.; Castro, R. Recent Developments on Hydrogen Production Technologies: State-of-the-Art Review with a Focus on Green-Electrolysis. Appl. Sci. 2021, 11, 11363. [Google Scholar] [CrossRef]

- Kumar, S.S.; Lim, H. An overview of water electrolysis technologies for green hydrogen production. Energy Rep. 2022, 8, 13793–13813. [Google Scholar] [CrossRef]

- Arsad, A.; Hannan, M.; Al-Shetwi, A.Q.; Begum, R.; Hossain, M.; Ker, P.J.; Mahlia, T.I. Hydrogen electrolyser technologies and their modelling for sustainable energy production: A comprehensive review and suggestions. Int. J. Hydrogen Energy 2023, 48, 27841–27871. [Google Scholar] [CrossRef]

- Ahmad, S.; Ullah, A.; Samreen, A.; Qasim, M.; Nawaz, K.; Ahmad, W.; Alnaser, A.; Kannan, A.M.; Egilmez, M. Hydrogen production, storage, transportation and utilization for energy sector: A current status review. J. Energy Storage 2024, 101, 113733. [Google Scholar] [CrossRef]

- Hassan, Q.; Sameen, A.Z.; Salman, H.M.; Jaszczur, M.; Al-Jiboory, A.K. Hydrogen energy future: Advancements in storage technologies and implications for sustainability. J. Energy Storage 2023, 72, 108404. [Google Scholar] [CrossRef]

- Kumar, N.; Lee, S.-Y.; Park, S.-J. Advancements in hydrogen storage technologies: A comprehensive review of materials, methods, and economic policy. Nano Today 2024, 56, 102302. [Google Scholar] [CrossRef]

- Ansari, S.A.; Khalid, M.; Kamal, K.; Ratlamwala, T.A.H.; Hussain, G.; Alkahtani, M. Modeling and Simulation of a Proton Exchange Membrane Fuel Cell Alongside a Waste Heat Recovery System Based on the Organic Rankine Cycle in MATLAB/SIMULINK Environment. Sustainability 2021, 13, 1218. [Google Scholar] [CrossRef]

- Sharaf, O.Z.; Orhan, M.F. An overview of fuel cell technology: Fundamentals and applications. Renew. Sustain. Energy Rev. 2014, 32, 810–853. [Google Scholar] [CrossRef]

- Uses of Hydrogen in Industry—Features—The Chemical Engineer. Available online: https://www.thechemicalengineer.com/features/uses-of-hydrogen-in-industry/ (accessed on 7 November 2024).

- The Future of Hydrogen—Analysis. IEA. Available online: https://www.iea.org/reports/the-future-of-hydrogen (accessed on 17 August 2023).

- Hydrogen in Industrial Application. FCHEA. Available online: https://fchea.org/learning-center/hydrogen-in-industrial-application/ (accessed on 7 November 2024).

- Li, Y.; Lin, R.; O’Shea, R.; Thaore, V.; Wall, D.; Murphy, J.D. A perspective on three sustainable hydrogen production technologies with a focus on technology readiness level, cost of production and life cycle environmental impacts. Heliyon 2024, 10, e26637. [Google Scholar] [CrossRef]

- Nguyen, T.; Abdin, Z.; Holm, T.; Mérida, W. Grid-connected hydrogen production via large-scale water electrolysis. Energy Convers. Manag. 2019, 200, 112108. [Google Scholar] [CrossRef]

- Sebastian, S.; Wijewardane, S.; Srinivasan, S. Recent advances in hydrogen production, storage, and fuel cell Technologies with an emphasis on inventions, innovations, and commercialization. Sol. Compass 2023, 8, 100065. [Google Scholar] [CrossRef]

- Boretti, A. Technology readiness level of hydrogen storage technologies for transport. Energy Storage 2024, 6, e546. [Google Scholar] [CrossRef]

- Green Hydrogen Cost Reduction. Available online: https://www.irena.org/publications/2020/Dec/Green-hydrogen-cost-reduction (accessed on 10 January 2025).

- Chapter 6: Energy Systems. Available online: https://www.ipcc.ch/report/ar6/wg3/chapter/chapter-6/ (accessed on 10 January 2025).

- Global Hydrogen Review 2024—Analysis. IEA. Available online: https://www.iea.org/reports/global-hydrogen-review-2024 (accessed on 10 January 2025).

- Hydrogen roadmap—European Commission. Available online: https://commission.europa.eu/projects/hydrogen-roadmap_en (accessed on 10 January 2025).

- Commercial & Industrial (C&I) Microgrids—VECKTA Insights. Available online: https://veckta.com/2021/02/09/commercial-and-industrial-microgrids/ (accessed on 30 October 2024).

- A Review of the State of the Art of Industrial Microgrids Based on Renewable Energy. Available online: https://www.mdpi.com/2079-9292/11/7/1002 (accessed on 12 November 2024).

- Residential Microgrids Market Share &. Market New Trends Analysis Report By Type. By Application, By End-use. By Region. And Segment Forecasts. 202|LinkedIn. Available online: https://www.linkedin.com/pulse/residential-microgrids-market-share-amp-new-trends-analysis-mmwte/ (accessed on 30 October 2024).

- Ma, Z.; Santos, A.Q.; Gamborg, F.; Nielsen, J.F.; Johannesen, J.M.; Dahl, M.; Jensen, H.; Pedersen, M.R.; Jorgensen, B.N. Solutions for Remote Island Microgrids: Discussion and analysis of Indonesia’s remote island energy system. In Proceedings of the 2018 IEEE Innovative Smart Grid Technologies—Asia (ISGT Asia), Singapore, 22–25 May 2018; pp. 493–498. [Google Scholar] [CrossRef]

- Gunawardane, K. Chapter 1—Evolution of hydrogen energy and its potential opportunities around the globe. In Hydrogen Energy Conversion and Management; Khan, M.M.K., Azad, A.K., Oo, A.M.T., Eds.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 3–33. [Google Scholar] [CrossRef]

- Padmawansa, N.; Gunawardane, K.; Kularatna, N. PEM Fuel Cell Equivalent Circuit Estimation Using Current Switching Techniques. In Proceedings of the 2023 IEEE International Conference on Energy Technologies for Future Grids (ETFG), Wollongong, Australia, 3–6 December 2023; pp. 1–7. [Google Scholar] [CrossRef]

- Jayasinghe, H.; Gunawardane, K. Unlocking Untapped Solar PV Energy in DC Microgrids Through Hydrogen Energy Storage Solutions. In Proceedings of the 2023 IEEE Fifth International Conference on DC Microgrids (ICDCM), Auckland, New Zealand, 5–17 November 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Indrajith, B.; Gunawardane, K. Performance Analysis of Proton Exchange Membrane (PEM) Electrolyser-Fuel Cell Setup Using Simulink Model. In Proceedings of the 2023 IEEE Fifth International Conference on DC Microgrids (ICDCM), Auckland, New Zealand, 5–17 November 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Supercapacitor-Assisted Energy Harvesting Systems. Available online: https://www.mdpi.com/1996-1073/17/15/3853 (accessed on 17 January 2025).

| Type | Connection Scope | Microgrid Operations |

|---|---|---|

| WAN | Multiple microgrids or microgrid with a central power grid | Data exchange for regional monitoring, control, and coordination. Real-time data transfer across microgrids for operations including balancing supply and demand, managing power fluctuations |

| FAN | Covers specific field equipment like substations | Integrates field devices for centralized monitoring and control within a microgrid. Rapidly collects and transfers data on grid conditions such as faults. Ensures resilience by quickly detecting and addressing issues at critical points |

| NAN | Links buildings or distributed resources in defined area | Supports local load balancing and demand response within community microgrids; gather energy data from multiple residences, optimize energy use, and implement demand responses |

| BAN | Operates within individual area in a microgrid | Transfers data among energy management systems, adjusting usage based on occupancy, time, and temperature. Reduces peak load contributions to the microgrid using building-level energy management |

| HAN | Serves individual homes in a microgrid setup | Connects individual components, enabling energy adjustments according to pricing signals and energy availability. Facilitates integration of PV and EV, allowing residents to control energy use and peak load reduction |

| Storage Method | Description | Benefits | Drawbacks |

|---|---|---|---|

| Compressed Hydrogen Gas Storage | Hydrogen stored in high-pressure tanks (up to 700 bar). Compression consumes about 13–18% of hydrogen’s Lower Heating Value (LHV) |

|

|

| Liquid Hydrogen Storage | Requires very low temperatures (−252.8 °C). High-density results in volumetric energy density of around 8 MJ/L |

|

|

| Metal Hydride Storage | Hydrogen reacts chemically with metals or metal alloys, expanding volume by 20–30%. External energy is required to release stored hydrogen |

|

|

| Complex Hydride Storage | Hydrogen bonds with metal atoms to form stable complex anions, allowing dense atomic-level storage. Holds up to 10–15% hydrogen by weight. |

|

|

| Physical Adsorption | Hydrogen adsorbs onto solid surfaces via van der Waals forces, using microporous carbon structures, metal–organic frameworks, or zeolites |

|

|

| Chemical Hydrogen Storage | Hydrogen stored in liquid organic carriers, which release hydrogen through dehydrogenation. Hydrogenated part can be reused to load hydrogen. |

|

|

| Type | Alkaline | PEM | Solid Oxide |

|---|---|---|---|

| Technical State | Commercial | Commercial | Experimental |

| Electrolyte | KOH solution | Nafion membrane | ZrO2 doped with Y2O3 |

| Temperature (°C) | 40–90 | 20–10 | 650–1000 |

| Pressure (bar) | <30 | <200 | <20 |

| Efficiency (%) | 55–75 | 45–60 | 75–85 |

| Gas purity (%) | >99.50 | >99.99 | >99.90 |

| Application | Hydrogen production applications | Portable applications Power to gas applications | R&D studies |

| Advantages | Stable operation Long term operations Low-cost production | Fast response times High purity Dynamic operations | High efficiency Low energy consumption No noble metal catalyst |

| Challenges | Low-purity Low current densities Corrosive system | High cost Low durability High pressure | Not well established High temperature Low durability |

| Method | Description | Key Factors |

|---|---|---|

| Steam Methane Reforming | Produces hydrogen via natural gas, ethanol, and methanol as feedstocks. Synthesis gas mixture (hydrogen, CO2, CO) is generated using methanol and steam. The process operates at 200–300 °C and pressures around 20–30 atm.

Endothermic: CH3OH → CO + 2H2

Exothermic: CO + H2O → CO2 + H2

|

|

| Partial Oxidation | Utilizes thermal or catalytic oxidation of natural gas or coal under high temperature (1200–5000 °C) and high pressure (3–10 MPa). Syngas produced via Fischer-Tropsch synthesis. TPOX produces more CO; CPOX, with lower temperature, achieves higher H2 ratio.

TPOX: CnHm + nH2O → nCO + (n+½m)H2

CPOX: CnHm + ½ nO2 → nCO + ½ mH2

|

|

| Autothermal Reforming (ATR) | Combines POX and SMR to yield high H2 ratios. Operates in an adiabatic reactor with steam and oxygen, initiating oxidation and reforming simultaneously.

CnHm + ½ nH2O + ¼ nO2 → nCO + ½ (n+m)H2

|

|

| Plasma Reforming (PR) | High-efficiency process utilizing thermal or non-thermal plasma (glow discharge, dielectric barrier discharge) to produce syngas at high temperatures with controlled energy input.

Similar reaction to SR and POX, with plasma providing energy

|

|

| Biomass gassification | Converts coal or biomass into hydrogen, with byproducts like CO, CO2, and H2O. Coal partially oxidized with steam and oxygen, then syngas undergoes a water-gas shift reaction to maximize H2. Biomass gasification also produces CO and CO2, with steam injected to convert CO to H2.

Similar to coal gasification, CO + H2O → H2 + CO2

|

|

| Biohydrogen Production | Biological methods utilizing algae/bacteria for hydrogen production from organic wastes. Processes include photolysis, photo and dark fermentation, and metabolic processing. Direct photolysis splits water using sunlight, while indirect photolysis involves CO2 fixation and H2 production via fermentation.

Direct: 2H2O + light energy → 2H2 + O2

Indirect: C6H12O6 + 12H2O + light energy → 12H2 + 6CO2

|

|

| Photocatalytic Water Splitting | Directly splits water using light energy and semiconductor materials, generating electron and hole pairs that oxidize water to form H+ ions, which then combine to form hydrogen.

2H2O + hv → 2H2 + O2

|

|

| Type | Alkaline | PEM | Solid Oxide | Molten Carbonate |

|---|---|---|---|---|

| Electrolyte | alkaline polymer membrane | Perfluorosulfonic acid | Yttria stabilized zirconia | Molten lithium, sodium, potassium carbonates |

| Temperature | 40–90 °C | 40–100 °C | 600–1000 °C | 600–700 °C |

| Efficiency (%) | 45–60 | 55–65 | 55–60 | 50–60 |

| Fuel Type | H2 | H2 | Natural, biogas | Natural, biogas |

| Oxidant | O2/Air | O2/Air | O2/Air | CO2/O2/Air |

| Application | Space systems Backup power transportation | RES integrations Portable power applications Transportation Backup power systems | Auxiliary power RES integrations Power system applications | Auxiliary power systems Electric utility RES integrations |

| Advantages | Lower costs Fast response Flexibility Low temperature | Reduced corrosion and maintenance Fast response time Low temperature | High efficiency Flexible fuel supply Gas turbine cycle applications | Fuel flexibility High efficiency Solid electrolyte CHP integrations |

| Challenges | High costs Impurity sensitivity | High sensitivity to impurities High cost | High temperature Slow response | High temperature, High corrosion maintenance |

| Category | Technology | Cost (USD) | Associated Emissions (kg CO2/kg H2 or kg CO2/kWh) | TRL | |

|---|---|---|---|---|---|

| Hydrogen Generation | Electrolysis | Alkaline | USD3.00–USD6.00/kg H2 | 0–1.5 (based on energy source) | 8–9 |

| PEM | USD4.00–USD7.00/kg H2 | 0–1.8 (based on energy source) | 8–9 | ||

| Solid Oxide | USD5.00–USD8.00/kg H2 | Near zero (based energy on source) | 6–7 | ||

| Steam Methane Reforming (SMR) | USD1.50–USD2.50/kg H2 | 9–12 (without CCS) 2–4 (with CCS) | 9 | ||

| Partial Oxidation (POX) | USD1.80–USD3.00/kg H2 | 8–10 (depends on feedstock and CCS) | 8 | ||

| Autothermal Reforming (ATR) | USD2.00–USD3.00/kg H2 | 2–4 (with CCS) 8–11 (without CCS) | 7–8 | ||

| Plasma Reforming (PR) | USD5.00–USD10.00/kg H2 | Near zero (based energy on source) | 4–6 | ||

| Biomass Gasification | USD1.50–USD3.00/kg H2 | Near zero (with CCS) | 6–7 | ||

| Biohydrogen Production | USD2.00–USD4.50/kg H2 | Near zero | 4–5 | ||

| Photocatalytic Water Splitting | >USD10.00/kg H2 | Near zero | 3–5 | ||

| Hydrogen Storage | Compressed Hydrogen Gas Storage | USD0.50–USD1.50/kWh | Near zero | 8–9 | |

| Liquid Hydrogen Storage | USD1.00–USD2.50/kWh | Near zero | 7–8 | ||

| Metal Hydride Storage | USD5.00–USD10.00/kWh | Near zero | 4–6 | ||

| Complex Hydride Storage | USD6.00–USD12.00/kWh | Near zero | 3–5 | ||

| Physical Adsorption | USD2.00–USD6.00/kWh | Near zero | 4–6 | ||

| Chemical Hydrogen Storage | USD3.00–USD7.00/kWh | Near zero | 4–6 | ||

| Hydrogen Consumption | Fuel Cells | Alkaline | USD1000–USD2000/kW | Near zero (using green hydrogen) | 8 |

| PEM | USD2000–USD3000/kW | Near zero (using green hydrogen) | 8–9 | ||

| Solid Oxide | USD3000–USD5000/kW | Near zero (using green hydrogen) | 6–7 | ||

| Molten Carbonate | USD2500–USD4000/kW | Near zero (using green hydrogen) | 6–7 | ||

| Combined Heat and Power (CHP) | USD1000–USD5000/kW | Near zero (using green hydrogen) | 8 | ||

| Microturbines | USD700–USD1500/kW | Near zero (if using green hydrogen) | 8 | ||

| Type | Potential Hydrogen Techniques | Analysis | ||

|---|---|---|---|---|

| Generation | Storage | Utilization | ||

| Commercial |

|

|

| Serve as a clean backup energy source and assist with heating/cooling, reducing emissions and reliance on grid power in commercial buildings |

| Industrial |

|

|

| Hydrogen can support high-energy-demand processes, reducing carbon emissions in industrial settings and providing energy security |

| Residential |

|

|

| Can enhance energy independence and provide clean energy for heating, especially in remote residential areas |

| Remote |

|

|

| Enables off-grid, stable power supply in remote locations, improving energy security and reducing the need for fossil fuels |

| Urban |

|

|

| Supports urban energy systems by providing fuel for transport, reducing urban emissions, and stabilizing grid demand through decentralized power sources |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Indrajith, B.; Gunawardane, K. Navigating the Intersection of Microgrids and Hydrogen: Evolutionary Trends, Challenges, and Future Strategies. Energies 2025, 18, 614. https://doi.org/10.3390/en18030614

Indrajith B, Gunawardane K. Navigating the Intersection of Microgrids and Hydrogen: Evolutionary Trends, Challenges, and Future Strategies. Energies. 2025; 18(3):614. https://doi.org/10.3390/en18030614

Chicago/Turabian StyleIndrajith, Bawantha, and Kosala Gunawardane. 2025. "Navigating the Intersection of Microgrids and Hydrogen: Evolutionary Trends, Challenges, and Future Strategies" Energies 18, no. 3: 614. https://doi.org/10.3390/en18030614

APA StyleIndrajith, B., & Gunawardane, K. (2025). Navigating the Intersection of Microgrids and Hydrogen: Evolutionary Trends, Challenges, and Future Strategies. Energies, 18(3), 614. https://doi.org/10.3390/en18030614