Review of Formation Mechanisms, Localization Methods, and Enhanced Oil Recovery Technologies for Residual Oil in Terrigenous Reservoirs

Abstract

1. Introduction

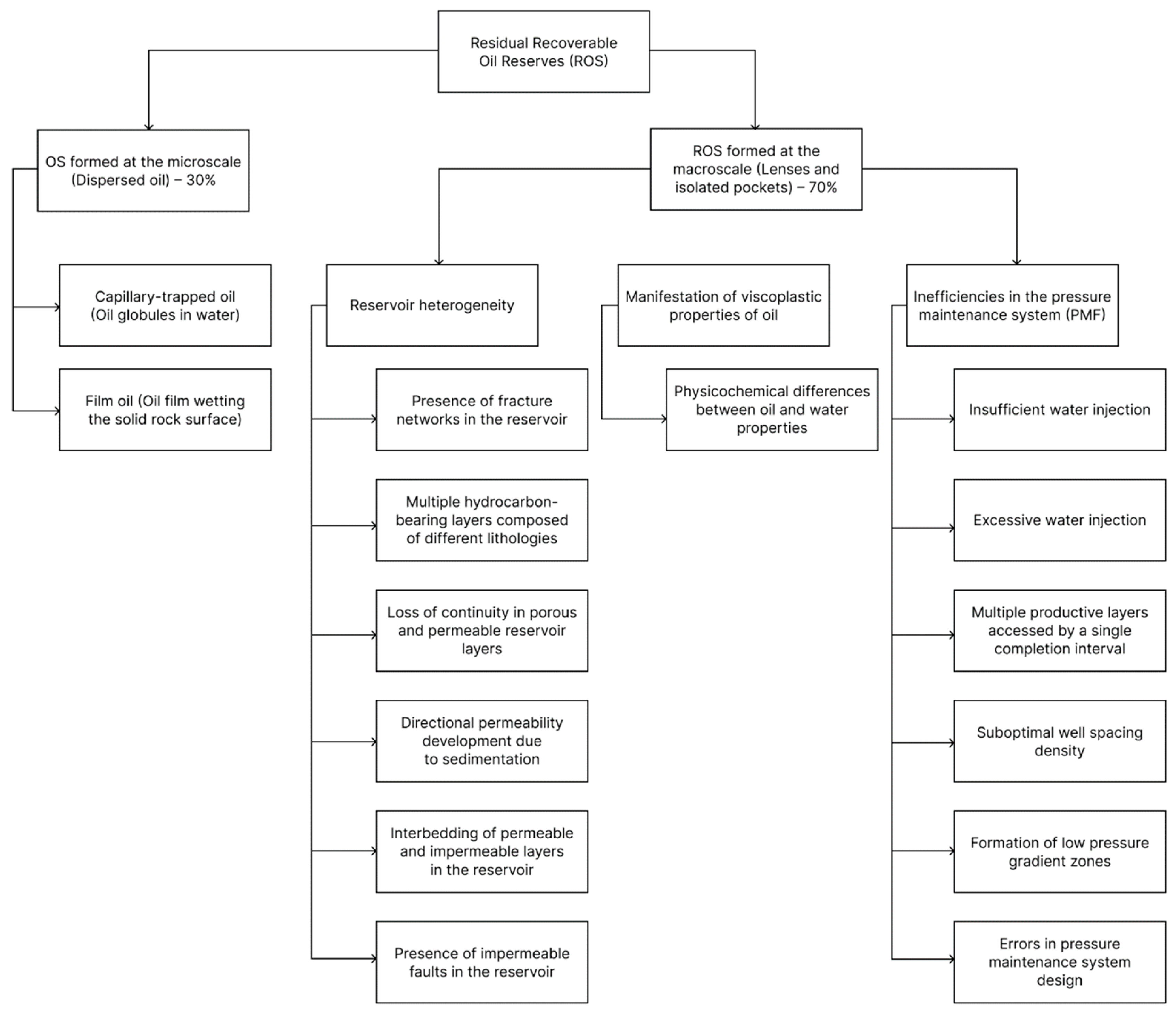

2. Classification and Formation of Residual Oil

- Oil remaining in interlayer low-permeability zones not affected by waterflooding;

- Oil located in lenses isolated from the productive reservoir by impermeable barriers or baffles and not penetrated by wells;

- Oil migrating into dead-end zones of homogeneous reservoirs.

2.1. Formation of RRR at the Microscale

2.2. Formation of RRR at the Macroscale

- Oil-saturated pillars formed as a result of high heterogeneity of the reservoir in terms of geological and physical properties;

- Oil-saturated pillars formed due to the manifestation of the viscoplastic properties of oil;

- Oil-saturated pillars formed as a result of an imperfect well pattern or other technological factors.

- The presence of multiple hydrocarbon-bearing interlayers composed of rocks with significantly different properties, such as sandstones interbedded with carbonates;

- Variations in the continuity, interconnection, and areal distribution of porous and permeable layers within the reservoir;

- The presence of a natural fracture system in the formation, resulting from regional tectonic stresses in the rock;

- Directional development of permeability caused by depositional conditions or diagenetic alterations;

- The presence of faults that affect the connectivity between parts of the reservoir and adjacent zones, either acting as barriers or enabling unrestricted fluid flow along the fault plane;

- Interbedding of permeable and porous reservoir layers with nearly or completely impermeable layers of anhydrite, shale, or other minerals.

- —flow velocity (averaged over the gap thickness);

- b—gap between the plates;

- —fluid viscosity;

- p—pressure.

- Insufficient water injection—when the injection rate lags behind oil production, it leads to pressure decline, resulting in a reduced pressure gradient. According to Poiseuille’s law [52], water begins to preferentially flow through the most permeable zones toward the nearest wells, bypassing distant areas and leaving them unswept. Prolonged exposure to such conditions results in the formation of stable streamlines from injection to production wells, leading to the development of so-called “dead zones.”

- High-intensity reservoir flooding—when the injection rate significantly exceeds the oil production rate. On the one hand, this causes water to push oil through high-permeability channels, forming dominant filtration pathways. On the other hand, it may lead to the formation of auto-hydraulic fracturing (auto-HF) channels—high-permeability paths from the RPM well—into which the injected water escapes. It is important to note the difference in RRR formation in this case compared to point 1: here, the pressure is sufficient to reach remote zones of the reservoir, but water bypasses large volumes due to high filtration velocity. In other words, the reservoir’s filtration capacity was not properly accounted for during RPM system design.

- The presence of multiple productive horizons within a reservoir, differing in filtration and storage properties (FSP), penetrated by a common wellbore filter. When an impermeable barrier exists between them, water injection occurs predominantly into the most permeable intervals, leaving other layers almost or entirely unaffected. If there is some degree of hydrodynamic communication between the layers (i.e., crossflows), along with lateral variability in reservoir properties, situations may arise in which the injected water enters one formation and then flows into another, more permeable one, forming filtration channels and bypassing other portions of the reserves. For example, analysis of low-permeability formations in China has shown that after 20 years of waterflooding, approximately one-third of the layers in the section had never been swept by water; it is precisely in these layers that residual oil is concentrated [53]. The cause was the absence of an effective layer-by-layer RPM system during the early years of development. A similar issue is observed at mature fields: due to wear and damage of casing strings in old wells, it becomes difficult to implement proper zonal injection across the formations, which complicates the alignment of the water front.

- The distance between injection and production wells, as well as the density of the well pattern, is another common cause of RRR formation. Large spacing between injection and production wells can lead to low sweep efficiency—the water front may not reach the production wells or may arrive in a weakened state. However, this relationship is most relevant for heterogeneous reservoirs with variable filtration and storage properties (FSP). It has been demonstrated repeatedly—mainly in fields in the western part of Texas, developed in carbonate reservoirs—that in isotropic formations with a high degree of continuity, reducing the spacing between wells did not lead to a significant increase in development efficiency and had little effect on the ultimate oil recovery factor. The optimal well pattern density depends on several factors, including permeability; for example, low-permeability reservoirs require denser well spacing. In practice, most fields started with sparse well patterns, gradually increasing density. At the Romashkinskoye field, well spacing was reduced in 1968, and the development system was switched from a linear to a block-pattern waterflood. In 1976, the grid was further densified by implementing a 3:1 well ratio. It should be noted that well pattern design is a complex task influenced by numerous factors [54].

- Formation of zones with reduced pressure gradient between wells, where oil remains in an almost immobile state. During waterflooding, a specific pressure distribution is established in the inter-well space. The farther a given point is from the production well, the lower the filtration velocity in that zone, as it is directly proportional to the pressure gradient. High pressure gradients are established near the wellbore, while with increasing distance, the gradients decrease accordingly.

- Another cause of RRR formation is design errors in the waterflooding system with respect to geological structures within the reservoir. For example, when there is strong hydrodynamic communication between the outer and near-boundary zones and an active aquifer, an improperly designed RPM system may lead to water bypassing into the near-boundary zone. This, in turn, promotes the formation of zones with unswept oil in the central part of the reservoir [55].

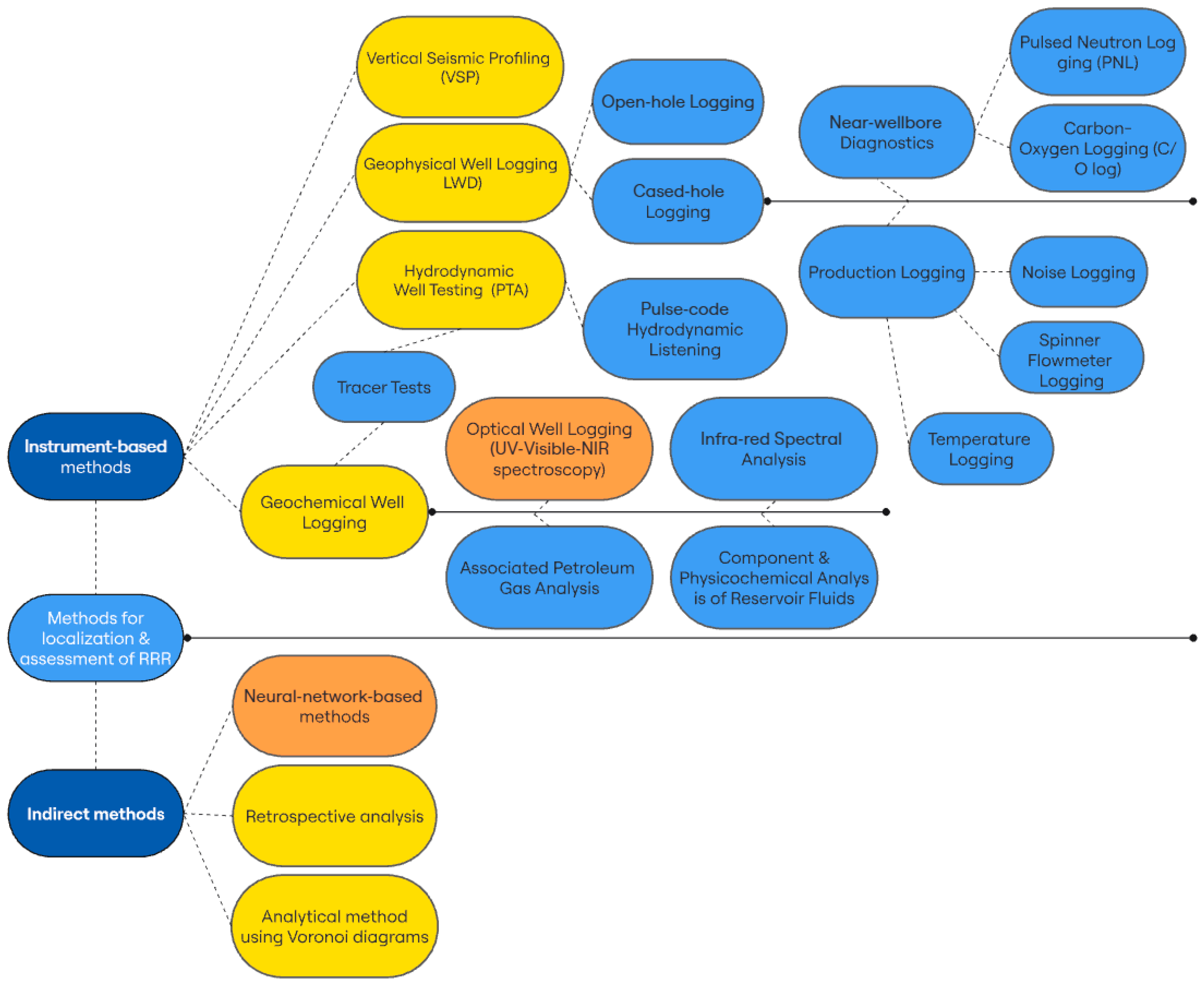

3. Methods for Localizing Residual Recoverable Reserves

- Seismic technologies, such as Vertical Seismic Profiling. This is a high-resolution seismic exploration method in which geophones are placed along the wellbore, while the seismic source is located on the surface—or vice versa. VSP provides higher accuracy compared to conventional 3D surface seismic surveys. It is used both in single-well mode for detailed examination of a local zone and in multi-offset mode (e.g., walkaway VSP, where the seismic source is moved along a profile) [56,57].

- 2.

- Well Logging. This group of instrument-based methods includes both open-hole logging, i.e., conducted during drilling, and cased-hole logging. The fundamental difference lies in the objectives of these investigations. Open-hole logging is aimed at recording the initial parameters of the wellbore. Cased-hole logging—commonly referred to in modern literature as production geophysical investigations —is considered a separate category and focuses on recording parameters during field development.

- 3.

- Hydrodynamic well testing is another group of instrument-based investigation method. Special attention should be given to the modern impulse-coded hydrodynamic listening (ICHL) method and tracer studies. ICHL is an advanced version of inter-well hydrodynamic listening. Instead of continuous excitation, it uses a series of short pulses delivered into one or several excitation wells. The reception of the coded signal in the observation well eliminates the need to shut down surrounding wells, making the method highly resistant to various types of interference. The method allows for the identification of stagnant oil zones based on the intensity of the received signal.

- 4.

- Geochemical well investigations, when applied to the task of localization, represent a group of methods based on the detection of anomalies and deviations from natural background values during oil field development. Methods that are actively used in practice include sampling of formation water and gas, determination of the component composition of formation gas, determination of the physico-chemical properties of formation fluids, optical studies (in the UV–visible–NIR spectral range), infrared (IR) spectral analysis, and luminescent-bituminological analysis of cuttings and core samples. Unlike the previous groups of methods, this group is less labor-intensive and does not require the suspension of production well operations.

- Kac—absorption coefficient,

- D—optical density of the analyzed solution,

- C—concentration of the solution,

- l—path length (thickness of the solution layer).

- Methods based on neural network algorithms represent a rapidly developing set of approaches for localizing residual recoverable reserves. Neural network algorithms apply machine learning (ML) techniques to analyze large volumes of heterogeneous field data and generate distribution forecasts. The main objective of using neural networks is to identify hidden nonlinear relationships that are not detectable through manual analysis. A key advantage of these methods lies in their ability to automatically account for massive datasets, including development history, well logging, hydrodynamic studies, and geochemical investigations. It is important to emphasize that neural network models are most effective at fields with a large, accumulated data base and a sufficient number of examples for training. For example, in a large producing field where RRR has been assessed in several pilot zones, a neural network can be trained on those data and then applied to the rest of the area [65,66]. The application of neural network algorithms is especially justified in multilayered and highly heterogeneous systems, where traditional methods struggle to generalize information—neural networks can independently uncover complex dependencies. They are also well suited for real-time forecast updates as new data become available: the model can be retrained using fresh inputs. In small or poorly studied fields, neural network methods are less reliable due to the scarcity of training data; in such cases, they are more appropriate when combined with physical models—as part of history matching or for hypothesis validation. Thus, the application of neural network algorithms can be viewed as an integration of data from all types of investigations into a unified base for further analysis and pattern discovery. The authors further propose to explore the combined use of ML and optical oil analysis for RRR localization.

- 2.

- Retrospective analysis is a method for identifying undeveloped or poorly developed reservoir zones based on the analysis of field development over the entire production history. Essentially, it is a search for missed oil-bearing intervals using development data. Within this approach, all available information is collected: initial reserves, inflow profiles for each reservoir object, well logging results, monthly production reports (MPR), workover histories, well reassignments to other horizons, and so on. Then, using a decision-making algorithm, potential zones containing RRR are identified, along with applicable geological and technical measures for their recovery.

- 3.

- Voronoi diagrams, or analysis of specific production reserves by well. This method is based on dividing the field area into so-called Voronoi polygons—filtration zones in the form of polygons that are closer to a given well than to any other. Each such polygon is considered the “zone of responsibility” of the corresponding well, from which it is expected to extract oil. The initial oil reserves within each polygon are then compared with the actual cumulative production. The difference is considered the residual reserve associated with the well. The method is simple and visually intuitive; however, it relies on a simplified model of streamlines, assuming that the entire selected area is hydraulically connected to a single well—an assumption that often does not reflect reality. The method requires highly reliable input data, as errors in the initial reserves map will directly affect the accuracy of residual reserve estimates. The approach is compatible with retrospective analysis—in fact, the Voronoi diagram method is a formalized version of well-by-well retrospective analysis. It also integrates well with categorical classification, allowing polygons to be classified as fully depleted or underdeveloped.

4. Chemical Methods for Enhanced Oil Recovery at the Macroscale

4.1. Gel-Forming Systems

4.2. Other Methods for Selective Permeability Reduction

- Mobility control agent during steam injection into the reservoir;

- Mobility control agent during CO2 injection;

- Gas-blocking agent around production wells.

- Thermal stabilizers—chemical additives that prevent the degradation of chemical systems under high-temperature conditions;

- Catalysts—substances that accelerate chemical reactions within the reservoir, for example, external and internal catalysts used in inorganic gel systems;

- Stabilizers—compounds that ensure the integrity and functional performance of gel systems over time by providing resistance to salinity, pH fluctuations, shear stress, and filtration effects;

- Fillers—solid particles introduced into the dispersed phase to increase mechanical strength and plugging capability. They enhance the mechanical properties of the system and may provide additional filtration resistance. For instance, the combined addition of wood flour and clay powder significantly increases resistance to flow in water-swept zones: wood flour swells on contact with water, while clay flocculates with the polymer, forming a strong structural framework. Another example is the use of rubber crumb, where shredded recycled rubber is mixed with sodium silicate or bitumen; the crumb swells, blocking fractures and flow channels.

5. Results and Discussion

6. Conclusions

- At large oil fields in Russia, up to 62.5% of oil reserves remain unrecovered in the reservoir, of which 30% correspond to oil retained at the microscale and 70% to oil accumulated at the macroscale.

- The formation of macroscale residual oil is caused by various types of reservoir heterogeneity, differences in oil and water properties, and imperfections in the pressure maintenance system.

- A wide range of monitoring methods is used in the field to control reservoir development. These include both instrumental and indirect (analytical) methods. The key distinction between them lies in the manner of acquiring information about the reservoir.

- A promising direction is the integration of optical well investigation methods in the UV–visible–NIR spectrum with neural network algorithms operating in situ. The combined implementation of these methods will improve mapping by enabling the localization of residual oil that differs significantly in its optical properties. However, the question of the feasibility and necessity of large-scale pilot projects for integrating neural network algorithms in field operations remains relevant.

- Chemical methods for residual oil recovery based on selective permeability reduction have proven effective. These include gel-forming, precipitate-forming, curable, and surfactant–foam systems for creating blocking barriers. Gel systems, in particular, offer the highest degree of tunability.

- A promising direction in the field of flow-diverting technologies is the use of waste products from various industries, including pulp and paper, agricultural, metallurgical, and petroleum refining sectors. These recycled materials may contain useful components such as crosslinking agents, gel-forming substances, and thermal stabilizers.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ministry of Natural Resources and Environment of the Russian Federation, Federal Agency for Subsoil Use. State Report on the Condition and Use of Mineral Resources of the Russian Federation in 2022; Ministry of Natural Resources and Environment of the Russian Federation: Moscow, Russia, 2023; 626p. Available online: http://rosnedra.gov.ru/ (accessed on 1 June 2025). (In Russian)

- PJSC “LUKOIL”. Key Trends in the Global Liquid Hydrocarbon Market Development up to 2035; PJSC “LUKOIL”: Moscow, Russia, 2019; 110p, Available online: https://lukoil.ru/Business/Futuremarkettrends (accessed on 1 June 2025). (In Russian)

- Litvinenko, V.S.; Petrov, E.I.; Vasilevskaya, D.V.; Yakovenko, A.V.; Naumov, I.A.; Ratnikov, M.A. Assessment of the role of the state in the management of mineral resources. J. Min. Inst. 2023, 259, 95–111. [Google Scholar] [CrossRef]

- FGBU “VSEGEI”. Report on the State and Prospects for the Use of the Mineral Resource Base of the Republic of Tatarstan as of 15.03.2021; Federal State Budgetary Institution “VSEGEI”: Saint Petersburg, Russia, 2021. Available online: https://rosnedra.gov.ru/data/Fast/Files/202104/0d7902ff118308f4bc272cdb94c47d02.pdf (accessed on 1 June 2025). (In Russian)

- Dvoynikov, M.V.; Minaev, Y.D. Mathematical Model of Non-Pressurized Flow for Calculating Killing of Gas Wells with Abnormally Low Reservoir Pressures. Int. J. Eng. 2025, 38, 1677–1684. [Google Scholar] [CrossRef]

- Melnikov, П.H.; Varlamov, A.I.; Fortunatova, N.; Poroskun, B.И.; Soloviev, A.V.; Skvortsov, M.B.; Kravchenko, M.N.; Kanev, A.S.; Sotnikova, A.G. Results of Quantitative Estimation of Unconventional Oil Resources of the Russian Federation. Geol. Geophys. 2024, 65, 8–25. [Google Scholar] [CrossRef]

- Wang, L.; Zhu, L.; Cao, Z.; Liu, J.; Xue, Y.; Wang, P.; Cao, X.; Liu, Y. Thermo-Mechanical Degradation and Fracture Evolution in Low-Permeability Coal Subjected to Cyclic Heating–Cryogenic Cooling. Phys. Fluids 2025, 37, 086617. [Google Scholar] [CrossRef]

- Wang, L.; Zhu, L.; Xue, Y.; Cao, X.; Liu, G. Multiphysics Modeling of Thermal–Fluid–Solid Interactions in Coalbed Methane Reservoirs: Simulations and Optimization Strategies. Phys. Fluids 2025, 37, 076649. [Google Scholar] [CrossRef]

- Shishlyannikov, D.; Zvonarev, I.; Rybin, A.; Zverev, V.; Ivanchenko, A. Assessment of Changes in the Abrasiveness of Solid Particles in Hydraulic Mixtures Pumped with ESPs. Appl. Sci. 2023, 13, 1885. [Google Scholar] [CrossRef]

- Burkhanov, R.N.; Lutfullin, A.A.; Raupov, I.R.; Maksyutin, A.V.; Valiullin, I.V.; Farrakhov, I.M.; Shvydenko, M.V. Localization and Involvement in Development of Residual Recoverable Reserves of a Multilayer Oil Field. J. Min. Inst. 2024, 268, 599–612, EDN DKXZSP. Available online: https://pmi.spmi.ru/pmi/article/view/15996 (accessed on 1 June 2025).

- Burkhanov, R.N.; Lutfullin, A.A.; Ibragimov, I.I.; Maksyutin, A.V. Estimation and Localization of Residual Recoverable Oil Reserves by the Complex of Filtration, Optical and Field Research. In Proceedings of the Society of Petroleum Engineers—SPE Russian Petroleum Technology Conference 2020, RPTC 2020, Virtual, 26–29 October 2020. [Google Scholar] [CrossRef]

- Pshenin, V.; Sleptsov, A.; Dukhnevich, L. Prospects of Improving the Vibroacoustic Method for Locating Buried Non-Metallic Pipelines. Eng 2025, 6, 121. [Google Scholar] [CrossRef]

- Surguchev, M.L. Methods of Monitoring and Regulating the Oil Field Development Process; Nedra: Moscow, Russia, 1968; Available online: https://www.geokniga.org/books/33112 (accessed on 1 June 2025). (In Russian)

- Zheltov, Y.V.; Surguchev, M.L.; Simkin, E.M. Physicochemical Microprocesses in Oil and Gas Reservoirs; Nedra: Moscow, Russia, 1984; Available online: https://www.geokniga.org/books/32008 (accessed on 1 June 2025). (In Russian)

- Gazizov, A.A. Enhanced Oil Recovery from Heterogeneous Reservoirs at the Late Stage of Development; Nedra-Businesscenter LLC.: Moscow, Russia, 2002; ISBN 5-8365-0119-X. Available online: https://www.geokniga.org/books/2656 (accessed on 1 June 2025). (In Russian)

- Gazizov, A.S.; Gazizov, A.A. Improving the Efficiency of Oil Field Development Based on Water Movement Control in Reservoirs; Nedra-Businesscenter LLC.: Moscow, Russia, 1999; ISBN 5-8365-0022-3. Available online: https://www.geokniga.org/bookfiles/geokniga-povyshenieeffektivnostirazrabotki.pdf (accessed on 1 June 2025). (In Russian)

- Devlikamov, V.V.; Kabirov, M.M.; Khabibullin, Z.A. Anomalous Oils; Nedra: Moscow, Russia, 1975; Available online: https://www.geokniga.org/books/16600 (accessed on 1 June 2025). (In Russian)

- Craig, F.F. The Reservoir Engineering Aspects of Waterflooding; SPE: Richardson, TX, USA, 1980; ISBN 0-89520-202-6. Available online: https://www.google.nl/books/edition/The_Reservoir_Engineering_Aspects_of_Wat/aThQAQAAIAAJ?hl=ru&gbpv=0&bsq=TheReservoirEngineeringAspectsof WaterfloodingcraigF.F (accessed on 1 June 2025).

- Willhite, G.P. Waterflooding: Textbook 3 (Spe Textbook Series); Society of Petroleum Engineers: Houston, TX, USA, 2011; ISBN 978-1-55563-005-8. Available online: https://www.google.ru/books/edition/Waterflooding/AVpQAQAAIAAJ?hl=ru&gbpv=0&bsq=Waterflooding:%20Textbook%203%20(Spe%20Textbook%20Series)%20-%20Softcover (accessed on 1 June 2025).

- Rose, S.C.; Buckwalter, J.F.; Woodhall, R.J. The Design Engineering Aspects of Waterflooding; Society of Petroleum Engineers: Houston, TX, USA, 1989; ISBN 978-1-55563-016-4. Available online: https://www.google.nl/books/edition/The_Design_Engineering_Aspects_of_Waterf/KzlQAQAAIAAJ?hl=ru&gbpv=0&bsq=design engineeringaspectsofwaterflooding (accessed on 1 June 2025).

- Lake, W.L. Enhanced Oil Recovery; Prentice Hall: Saddle River, NJ, USA, 2010; Available online: https://books.google.ru/books/about/Enhanced_Oil_Recovery.html?id=oERUDQEACAAJ&redir_esc=y (accessed on 1 June 2025).

- Putilov, I.S.; Chizhov, D.B.; Kochergin, E.A. Appearance of Capillary End Effects in Filtration Studies. Perm J. Pet. Min. Eng. 2021, 21, 23–27. [Google Scholar] [CrossRef]

- Morenov, V.A.; Shchigolev, K. Assessment of the Possibility of Carbon Dioxide Utilization for Enhanced Oil Recovery in Oil Field Conditions. Neft. Khozyaystvo Oil Ind. 2025. [Google Scholar] [CrossRef]

- Gabrielyants, G.A. Geology of Oil and Gas Fields, 2nd ed.; Nedra: Moscow, Russia, 1979; Available online: https://www.geokniga.org/books/16574 (accessed on 1 June 2025). (In Russian)

- Ghanbarian, B.; Liang, F.; Liu, H. Unconventional Reservoirs. In Physics of Fluid Flow and Transport in Unconventional Reservoir Rocks; John Wiley & Sons: Hoboken, NJ, USA, 2023; pp. 1–14. [Google Scholar] [CrossRef]

- Wu, J.; Ansari, U. From CO2 Sequestration to Hydrogen Storage: Further Utilization of Depleted Gas Reservoirs. Reserv. Sci. 2025, 1, 19–35. [Google Scholar] [CrossRef]

- Wang, F.; Kobina, F. The Influence of Geological Factors and Transmission Fluids on the Exploitation of Reservoir Geothermal Resources: Factor Discussion and Mechanism Analysis. Reserv. Sci. 2025, 1, 3–18. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, K.; Zhang, C.; Yan, H.; Yu, J.; Yu, B.; Liu, J.; Jiang, T.; Dan, W.; Hu, C. Integral Effects of Porosity, Permeability, and Wettability on Oil–Water Displacement in Low-Permeability Sandstone Reservoirs—Insights from X-Ray CT-Monitored Core Flooding Experiments. Processes 2023, 11, 2786. [Google Scholar] [CrossRef]

- GB/T 29172-2012; Practices for Core Analysis. China Standards Press: Beijing, China, 2012.

- ASTM D4520-18; Standard Practice for Determining Water Injectivity Through the Use of On-Site Floods. ASTM International: West Conshohocken, PA, USA, 2018.

- GOST 26450.1-85; Rocks. Method for Determination of Open Porosity Coefficient by Fluid Saturation. Publishing House of Standards: Moscow, USSR, 1985.

- GOST 26450.2-85; Rocks. Method for Determination of Absolute Gas Permeability Coefficient by Steady and Unsteady Filtration. Publishing House of Standards: Moscow, USSR, 1985.

- Fan, H.; Liu, X.; Li, G.; Li, X.; Radwan, A.E.; Yin, S. Study on Characteristics, Efficiency, and Variations of Water Flooding in Different Stages for Low Permeability Oil Sandstone. Energy Sci. Eng. 2024, 12, 5245–5265. [Google Scholar] [CrossRef]

- Zhou, Y.; Yang, W.; Yin, D. Experimental Investigation on Reservoir Damage Caused by Clay Minerals after Water Injection in Low Permeability Sandstone Reservoirs. J. Pet. Explor. Prod. Technol. 2022, 12, 915–924. [Google Scholar] [CrossRef]

- He, J.; Liu, X.; Zhu, X.; Jiang, T.; He, H.; Zhou, L.; Liu, Q.; Zhu, Y.; Liu, L. Water-Flooding Characteristics of Lithologic Reservoir in Ordos Basin. Sci. Rep. 2021, 11, 2503. [Google Scholar] [CrossRef]

- Sun, X.; Suo, L.; Huang, Y.; Wang, H.; Yu, H.; Xu, C.; Xu, J.; Qin, X.; Sun, W.; Cao, Y.; et al. Study on the Occurrence Characteristics of the Remaining Oil in Sandstone Reservoirs with Different Permeability after Polymer Flooding. Polymers 2024, 16, 1902. [Google Scholar] [CrossRef]

- Liu, Y.; Ge, L.; Ma, K.; Chen, X.; Zhu, Z.; Hou, J. Study on Surfactant–Polymer Flooding after Polymer Flooding in High-Permeability Heterogeneous Offshore Oilfields: A Case Study of Bohai S Oilfield. Polymers 2024, 16, 2004. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, Z.; Liu, Q.; Sun, L.; Xiao, H.; Gao, J.; Kang, H. Physical Modeling of Development Adjustment Mechanism for Heterogeneous Thick Oil Reservoir. Front. Energy Res. 2023, 10, 1094697. [Google Scholar] [CrossRef]

- Wang, H.; Torabi, F.; Zeng, F.; Xiao, H. A Novel Visualization Approach for Foamy Oil Non-Equilibrium Phase Behavior Study of Solvent/Live Heavy Oil Systems. Fuel 2020, 272, 117648. [Google Scholar] [CrossRef]

- Lee, J.; Babadagli, T. Comprehensive Review on Heavy-Oil Emulsions: Colloid Science and Practical Applications. Chem. Eng. Sci. 2020, 228, 115962. [Google Scholar] [CrossRef]

- Zheng, Z. Hydraulic Fractures of the Cusp Shape in a Hele-Shaw Cell. J. Fluid Mech. 2024, 995, A17. [Google Scholar] [CrossRef]

- Howison, S. Practical Applied Mathematics Modelling, Analysis, Approximation; Cambridge University Press: Cambridge, UK, 2005; ISBN 978-0-521-84274-7. Available online: https://www.google.ru/books/edition/Practical_Applied_Mathematics/A2Hy_54Y1MsC?hl=ru&gbpv=0 (accessed on 1 June 2025).

- Aime, S.; Sabato, M.; Xiao, L.; Weitz, D.A. Dynamic Speckle Holography. Phys. Rev. Lett. 2021, 127, 088003. [Google Scholar] [CrossRef]

- Yadali Jamaloei, B. Effect of Wettability on Immiscible Viscous Fingering: Part I. Mechanisms. Fuel 2021, 304, 120726. [Google Scholar] [CrossRef]

- Singh, A.; Pandey, K.M.; Singh, Y. Numerical Investigation of Immiscible Liquid-Liquid Displacement in Hele-Shaw Cell. Mater. Today Proc. 2020, 45, 7151–7155. [Google Scholar] [CrossRef]

- Guerrero, F.; Bryan, J.; Kantzas, A. Visualization of Chemical Heavy Oil Eor Displacement Mechanisms in a 2d System. Energies 2021, 14, 950. [Google Scholar] [CrossRef]

- Raza, S.; Gates, I.D. Effect of Cellulose Nanocrystal Nanofluid on Displacement of Oil in a Hele-Shaw Cell. J. Pet. Sci. Eng. 2021, 196, 108068. [Google Scholar] [CrossRef]

- An, B.; Solorzano, D.; Yuan, Q. Viscous Fingering Dynamics and Flow Regimes of Miscible Displacements in a Sealed Hele-Shaw Cell. Energies 2022, 15, 5798. [Google Scholar] [CrossRef]

- Ratanpara, A.; Kim, M. Wettability Alteration Mechanisms in Enhanced Oil Recovery with Surfactants and Nanofluids: A Review with Microfluidic Applications. Energies 2023, 16, 8003. [Google Scholar] [CrossRef]

- Dvoynikov, M.V.; Nikitin, V.I.; Kopteva, A.I. Analysis of Methodology for Selecting Rheological Model of Cement Slurry for Determining Technological Parameters of Well Casing. Int. J. Eng. 2024, 37, 2042–2050. [Google Scholar] [CrossRef]

- Savenok, O.V.; Chuikova, E.P.; Agaguena, A. Justification of Waterless Hydraulic Fracturing Methods. Int. J. Eng. 2025, 38, 1462–1475. [Google Scholar] [CrossRef]

- Kang, H.; Li, G.; Gao, J. Study on Permeability Characteristics of Tight Oil Reservoir through High-Pressure Mercury Injection. Front. Energy Res. 2023, 10, 1023099. [Google Scholar] [CrossRef]

- Jia, D.; Zhang, J.; Li, Y.; Wu, L.; Qiao, M. Recent Development of Smart Field Deployment for Mature Waterflood Reservoirs. Sustainability 2023, 15, 784. [Google Scholar] [CrossRef]

- Jia, D.; Zhang, J.; Sun, Y.; Wang, S.; Gao, S.; Qiao, M.; Li, Y.; Qu, R. Collaboration between Oil Development and Water/Power Consumption in High-Water-Cut Oilfields. Sustainability 2023, 15, 11405. [Google Scholar] [CrossRef]

- Smirnova, E.; Saychenko, L. Hydrodynamic Modeling and Evaluation of Partial Substitution of Cushion Gas During Creation of Temporary Underground Gas Storage in an Aquifer. Int. J. Eng. 2024, 37, 1221–1230. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, Y.; Chang, X. VSP Imaging Using Free-Surface Multiples with Wavefield Decomposition: Synthetic and Field Data Examples. Front. Earth Sci. 2021, 9, 730184. [Google Scholar] [CrossRef]

- Isaenkov, R.; Tertyshnikov, K.; Yurikov, A.; Shashkin, P.; Pevzner, R. Effect of Source Mispositioning on the Repeatability of 4D Vertical Seismic Profiling Acquired with Distributed Acoustic Sensors. Sensors 2022, 22, 9742. [Google Scholar] [CrossRef]

- Bayamirova, R.; Togasheva, A.; Saduakasov, D.; Zholbasarova, A.; Tabylganov, M.; Gusmanova, A.; Sarbopeeva, M.; Nauyryzova, B.; Nugumarov, S. Reservoir Development and Well Operation Control Methods: Practical Application. Processes 2025, 13, 1541. [Google Scholar] [CrossRef]

- Zhou, W.; Lin, Y.; Gao, G.; Wang, P. Enhanced Carbon/Oxygen Ratio Logging Interpretation Methods and Applications in Offshore Oilfields. Processes 2024, 12, 2301. [Google Scholar] [CrossRef]

- Luo, R.; Liu, J.; Yang, D.; Deng, Q. Application and Analysis of Array Production Logging Technology for Multiphase Flow in Horizontal Wells. Processes 2023, 11, 3421. [Google Scholar] [CrossRef]

- Gao, J.; Wang, X.; Zhang, D.; Wang, J. The Formation Mechanism of Residual Oil and Methods of Enhanced Oil Recovery in a Fractured Low-Permeability Metamorphic Rock Reservoir in Bohai Bay. Processes 2024, 12, 2281. [Google Scholar] [CrossRef]

- Patidar, A.K.; Joshi, D.; Dristant, U.; Choudhury, T. A Review of Tracer Testing Techniques in Porous Media Specially Attributed to the Oil and Gas Industry. J. Pet. Explor. Prod. Technol. 2022, 12, 3339–3356. [Google Scholar] [CrossRef]

- Yang, H.; Guo, K.; Lin, L.; Zhang, S.; Wang, Y. Application of Micro-Substance Tracer Test in Fractured Horizontal Wells. J. Pet. Explor. Prod. Technol. 2024, 14, 1235–1246. [Google Scholar] [CrossRef]

- Bouguer, P. Essay on Optics on the Gradation of Light; Claude Jombert: Paris, France, 1729; Available online: https://archive.org/details/UFIE003101_TO0324_PNI-2703_000000/page/74/mode/2up (accessed on 1 June 2025).

- Gomaa, S.; Soliman, A.A.; Mansour, M.; El Salamony, F.A.; Salem, K.G. Machine Learning Models for Estimating the Overall Oil Recovery of Waterflooding Operations in Heterogenous Reservoirs. Sci. Rep. 2025, 15, 14619. [Google Scholar] [CrossRef]

- Maghsoudian, A.; Izadpanahi, A.; Bahmani, Z.; Avvali, A.H.; Esfandiarian, A. Utilizing Deterministic Smart Tools to Predict Recovery Factor Performance of Smart Water Injection in Carbonate Reservoirs. Sci. Rep. 2025, 15, 537. [Google Scholar] [CrossRef]

- Sudakov, V.A.; Safuanov, R.I.; Kozlov, A.N.; Porivaev, T.M.; Zaikin, A.A.; Zinykov, R.A.; Lutfullin, A.A.; Farhutdinov, I.Z.; Tylyakov, I.Z. Localization and Development of Residual Oil Reserves Using Geochemical Studies Based on Neural Network Algorithms. Georesursy 2022, 24, 50–64. [Google Scholar] [CrossRef]

- Galkin, S.; Krivoshchekov, S.; Kozyrev, N.; Kochnev, A.; Mengaliev, A. Accounting of Geomechanical Layer Properties in Multi-Layer Oil Field Development. J. Min. Inst. 2020, 244, 408–417. [Google Scholar] [CrossRef]

- Gruenenfelde, M.A.; Zaitoun, A.; Kohler, N.; Ali, S.A.; Linser, T.M. Implementing New Permeability Selective Water Shutoff Polymer Technology in Offshore, Gravel-Packed Wells; Society of Petroleum Engineers: Tulsa, OK, USA, 1994. [Google Scholar]

- Stanley, F.O.; Tanggu, P.S.; Marnoch, E. Amphoteric Polymer Improves Hydrocarbon/Water Ratios in Producing Wells—An Indonesian Case Study. SPE Prod. Facil. 1997, 12, 181–186. [Google Scholar] [CrossRef]

- Malozyomov, B.V.; Martyushev, N.V.; Kukartsev, V.V.; Tynchenko, V.S.; Bukhtoyarov, V.V.; Wu, X.; Tyncheko, Y.A.; Kukartsev, V.A. Overview of Methods for Enhanced Oil Recovery from Conventional and Unconventional Reservoirs. Energies 2023, 16, 4907. [Google Scholar] [CrossRef]

- Kashirina, K.O.; Elov, I.N. Review of Domestic and Foreign Applications of Conformance Control Technologies. Nat. Sci. 2016, 85, 10. Available online: https://www.elibrary.ru/item.asp?id=26361702 (accessed on 1 June 2025). (In Russian).

- Ketova, Y.; Bai, B.; Khizhnyak, G.; Gladkikh, Y.; Galkin, S. Testing of Preformed Particles Polymer Gel Technology on Core Filtration Models to Limit Water Inflows. J. Min. Inst. 2020, 241, 91. [Google Scholar] [CrossRef]

- Pu, J.; Bai, B.; Schuman, T. Systematic Evaluation of a Novel Self-Healing Poly(Acrylamide-Co-Vinyl Acetate)/Alginate Polymer Gel for Fluid Flow Control in High Temperature and High Salinity Reservoirs. Polymers 2021, 13, 3616. [Google Scholar] [CrossRef]

- Kawai, K.; Zhao, W.; Nishimura, S.; Yamada, A. High-Voltage Cr 4+/Cr 3+ Redox Couple in Polyanion Compounds. ACS Appl. Energy Mater. 2018, 1, 928–931. [Google Scholar] [CrossRef]

- Neto, V.J.S.; Dores, F.G.L.; Oliveira, P.F.; Mansur, C.R.E. Evaluation of the Influence of Adding Clay in Polymeric Hydrogels Based on Partially Hydrolyzed Polyacrylamide and Aluminum Citrate. J. Appl. Polym. Sci. 2023, 141, e55019. [Google Scholar] [CrossRef]

- Shamlooh, M.; Hussein, I.; Nasser, M.; Magzoub, M.; Salehi, S. Development of pH-Controlled Aluminum-Based Polymeric Gel for Conformance Control in Sour Gas Reservoirs. ACS Omega 2020, 5, 24504–24512. [Google Scholar] [CrossRef] [PubMed]

- Galkin, S.V.; Rozhkova, Y.A. Analysis of Experience in the Use of Preformed Particle Polymer Gels in the Development of High-Water-Cut Production Facilities in Low-Temperature Oil Reservoirs. J. Min. Inst. 2024, 265, 55–64, EDN 20CNCFIW. Available online: https://pmi.spmi.ru/pmi/article/view/14686 (accessed on 1 June 2025). (In Russian).

- Rátzsch, M.; Schade, H.; Pabst, P. The Conversion of Ethylene–Vinyl Acetate Copolymers with Aluminum Alcoholates. J. Appl. Polym. Sci. 1971, 15, 589–595. [Google Scholar] [CrossRef]

- Song, T.; Bai, B.; Eriyagama, Y.; Schuman, T. Lysine Crosslinked Polyacrylamide—A Novel Green Polymer Gel for Preferential Flow Control. ACS Appl. Mater. Interfaces 2023, 15, 4419–4429. [Google Scholar] [CrossRef]

- Nimir, H.; Hamza, A.; Hussein, I. Development of Greener D-Metal Inorganic Crosslinkers for Polymeric Gels Used in Water Control in Oil and Gas Applications. Energies 2020, 13, 4262. [Google Scholar] [CrossRef]

- Mao, J.; Mao, J.; Liu, B.; Xiao, Y.; Yang, X.; Lin, C.; Zhang, Y.; Wang, Q.; Zhang, Q. Study of Crosslinker Size on the Rheological Properties of Borate Crosslinked Guar Gum. Int. J. Biol. Macromol. 2023, 231, 123284. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, F.; Wang, H.; He, J.; Luo, M.; Chen, H.; Zhong, C. Starch Microsphere Silicon-Boron Crosslinker for Low Concentration Hydroxypropyl Guar Gum Based Fracturing Fluid. Int. J. Biol. Macromol. 2024, 264, 130575. [Google Scholar] [CrossRef]

- Gao, X.; Huang, L.; Xiu, J.; Yi, L.; Zhao, Y. Evaluation of Viscosity Changes and Rheological Properties of Diutan Gum, Xanthan Gum, and Scleroglucan in Extreme Reservoirs. Polymers 2023, 15, 4338. [Google Scholar] [CrossRef] [PubMed]

- Afdhol, M.K.; Hidayat, F.; Erfando, T.; Purnama, D.P. Pectin Extraction of Jackfruit Peel as a Biopolymer Potential with Microwave Assisted Extraction Method. Sci. Contrib. Oil Gas 2024, 47, 125–133. [Google Scholar] [CrossRef]

- Ezeh, O.S.; Ikiensikimama, S.S.; Akaranta, O. Comparative Analysis of the Effects of Monovalent and Divalent Ions on Imported Biopolymer-Xanthan Gum and Locally Formulated Biopolymers-Gum Arabic and Terminalia Mantaly. J. Energy Res. Rev. 2021, 9, 33–46. [Google Scholar] [CrossRef]

- Abou-alfitooh, S.A.M.; El-hoshoudy, A. Eco-Friendly Modified Biopolymers for Enhancing Oil Production: A Review. J. Polym. Environ. 2023, 32, 2457–2483. [Google Scholar] [CrossRef]

- Medvedeva, V.V.; Myasnikova, L.; Semchikov, Y.; Rogovina, L. Kinetics of Coordination Networks in the Sodium Carboxymethyl Cellulose-Cr3+ Salt System. Polym. Sci. Ser. B 1998, 40, 80–84. Available online: https://www.researchgate.net/publication/286654559_Kinetics_of_coordination_networks_in_the_sodium_carboxymethyl_cellulose-Cr3_salt_system?_tp=eyJjb250ZXh0Ijp7ImZpcnN0UGFnZSI6InB1YmxpY2F0aW9uIiwicGFnZSI6InNjaWVudGlmaWNDb250cmlidXRpb25zIiwicHJldmlvdXNQYWdlIjoicHVibGljYXRpb24ifX0 (accessed on 1 June 2025).

- Medvedeva, V.V.; Semchikov, Y. Effect of pH on Gelation in the Sodium Carboxymethyl Cellulose-Cr3+ Salt System. Polym. Sci. Ser. B 2001, 43, 162–165. Available online: https://www.researchgate.net/publication/288978541_Effect_of_pH_on_Gelation_in_the_Sodium_Carboxymethyl_Cellulose-Cr3_Salt_System (accessed on 1 June 2025).

- Abbas, A.H.; Moslemizadeh, A.; Sulaiman, W.; Jaafar, M.; Pourafshary, P. Lignin Adsorption in Sandpacks during Horizontal Flow Using UV–Vis Spectrometry as a Quantification Tool. Arab. J. Geosci. 2022, 15, 501. [Google Scholar] [CrossRef]

- Cui, S.; Qi, B.; Liu, H.; Sun, X.; He, R.; Lian, J.; Li, Y.; Lu, J.; Bao, M. Aluminum Soap Nanoparticles-Lignin Powder Form Phase-Selective Gelator as an Efficient Sorbent for Oils/Water Separation. Chemosphere 2023, 340, 139803. [Google Scholar] [CrossRef]

- Yang, Z.; Gao, F.; Guo, J.; Gao, Q.-Y.; Xu, Y.-Y.; Yang, H.; Xu, Z.-X.; Leng, L. Improving Temperature and Salinity Tolerance of Polymer Gels by Modifying with Lignin-Containing Nanocellulose. Fuel 2025, 384, 134019. [Google Scholar] [CrossRef]

- Saghafi, H.; Naderifar, A.; Gerami, S.; Emadi, M. Improvement in Thermo-chemical Stability of Nanocomposite Preformed Particle Gels for Conformance Control in Harsh Oil Reservoir Conditions. Can. J. Chem. Eng. 2016, 94, 1880–1890. [Google Scholar] [CrossRef]

- AlSofi, A.; Dokhon, W. Toward Deep Diversion for Waterflooding and EOR: From Representative Delayed Gelation to Practical Field-Trial Design. In Proceedings of the SPE Improved Oil Recovery Conference, Virtual, 25 April 2022. [Google Scholar] [CrossRef]

- Amir, Z.; Saaid, I.; Jan, B.M.; Patah, M.F.A.; Khalil, M.; Bakar, W.Z.W. PAM/PEI Polymer Gel for Water Control in High-Temperature and High-Pressure Conditions: Core Flooding with Crossflow Effect. Korean J. Chem. Eng. 2022, 39, 605–615. [Google Scholar] [CrossRef]

- Wang, K.; Guo, Y.; Wen, J.; Yang, H.; Zhang, H. Magnetic Smart Polymer Gel with Directional Plugging for Conformance Control in Oil Reservoirs. J. Mol. Liq. 2024, 405, 125046. [Google Scholar] [CrossRef]

- Zhao, Y.; Leng, J.; Lin, B.; Wei, M.; Bai, B. Experimental Study of Microgel Conformance-Control Treatment for a Polymer-Flooding Reservoir Containing Superpermeable Channels. SPE J. 2021, 26, 2305–2317. [Google Scholar] [CrossRef]

- Cao, W.; Xie, K.; Cao, B.; Lu, X.; Tian, Z. Inorganic Gel Enhanced Oil Recovery in High Temperature Reservoir. J. Pet. Sci. Eng. 2021, 196, 107691. [Google Scholar] [CrossRef]

- Tang, X.; Yang, L.; Liu, Y.; Li, Z.; Chang, Z.; Li, Y.; Wei, F. A New In-Depth Fluid Diverting Agent of Inorganic Gel Coating. Pet. Explor. Dev. 2012, 39, 82–87. [Google Scholar] [CrossRef]

- Zulkifli, N.; Hendraningrat, L.; Razali, N.; Bakri, C.N.; Zainal, S.; Kechut, N.I. Evaluation of Flow Diverter Chemical to Improve Waterflood Performance as Conformance Control for Heterogeneous Reservoir and High-Temperature Field Application: An Innovative Experimental Design. In Proceedings of the International Petroleum Technology Conference, Bangkok, Thailand, 1 November 2022. [Google Scholar] [CrossRef]

- Portwood, J.T.; Romero, J.L. Waterflood Conformance Improvement—Practical Considerations & Lessons Learned. Rev. Fuentes El Reventón Energético 2018, 16, 7–21. Available online: https://revistas.uis.edu.co/index.php/revistafuentes/article/view/9156/8998 (accessed on 1 June 2025).

- Al Brahim, A.; Bai, B.; Schuman, T. Comprehensive Review of Polymer and Polymer Gel Treatments for Natural Gas-Related Conformance Control. Gels 2022, 8, 353. [Google Scholar] [CrossRef]

- Zemtsov, Y.V.; Mazaev, V.V. Current State of Physicochemical Methods for Enhanced Oil Recovery: A Literature and Patent Review; Publishing Solutions LLC.: Yekaterinburg, Russia, 2021; Available online: http://eues.ru/sites/default/files/2022-02/%D0%9C%D0%BE%D0%BD%D0%BE%D0%B3%D1%80%D0%B0%D1%84%D0%B8%D1%8F%20%D0%A4%D0%A5%20%D0%9C%D0%A3%D0%9D_2021_%D0%97%D0%B5%D0%BC%D1%86%D0%BE%D0%B2-%D0%9C%D0%B0%D0%B7%D0%B0%D0%B5%D0%B2.pdf (accessed on 1 June 2025). (In Russian)

- Al-Muntasheri, G.A.; Nasr-El-Din, H.A.; Zitha, P.L.J. Gelation Kinetics and Performance Evaluation of an Organically Crosslinked Gel at High Temperature and Pressure. SPE J. 2008, 13, 337–345. [Google Scholar] [CrossRef]

- Dastjani-Farahani, R.; Asadzadeh, N.; Jafari, A.; Vafaie-Sefti, M.; Baghban-Salehi, M. Enhancing Xanthan Hydrogels for Water Shutoff Treatment in Sandstone Oil Reservoirs through Core Flooding and CCD Approach. Sci. Rep. 2025, 15, 14016. [Google Scholar] [CrossRef]

- Han, J.; Sun, J.; Lv, K.; Yang, J.; Li, Y. Polymer Gels Used in Oil–Gas Drilling and Production Engineering. Gels 2022, 8, 637. [Google Scholar] [CrossRef]

- Pi, Y.; Liu, J.; Cao, R.; Liu, L.; Ma, Y.; Gu, X.; Li, X.; Fan, X.; Zhao, M. Visualized Study on a New Preformed Particle Gels (PPG) + Polymer System to Enhance Oil Recovery by Oil Saturation Monitoring Online Flooding Experiment. Gels 2023, 9, 81. [Google Scholar] [CrossRef]

- Liu, H.; Han, H.; Li, Z.; Wang, B. Granular-Polymer-Gel Treatment Successful in the Daqing Oil Field. SPE Prod. Oper. 2006, 21, 142–145. [Google Scholar] [CrossRef]

- Duryagin, V.; Nguyen Van, T.; Onegov, N.; Shamsutdinova, G. Investigation of the Selectivity of the Water Shutoff Technology. Energies 2023, 16, 366. [Google Scholar] [CrossRef]

- Telin, A.; Vezhnin, S.; Safarov, F.E.; Lenchenkova, L.; Yakubov, R.N.; Safuanova, R.M. Application of Hydrogels for Conformance Control and Flow Diversion. Pet. Eng. 2023, 21, 58–77. [Google Scholar] [CrossRef]

- Meng, X.; Zhang, G.; Wu, J.; Zhao, X.; Wang, L.; Zhang, F. Experimental Study on Phenol-Formaldehyde Resin Aggregates as In-Depth Conformance Control Agents Stabilized by Polymer. Polymers 2022, 14, 3159. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; Ge, J.; Ding, L.; Wei, K.; Deng, X.; Liu, Y. Identification and Characterization of a Proper Gel System for Large-Volume Conformance Control Treatments in a Fractured Tight Reservoir: From Lab to Field. J. Pet. Sci. Eng. 2020, 198, 108199. [Google Scholar] [CrossRef]

- Liu, Y.; Bai, B.; Wang, Y. Applied Technologies and Prospects of Conformance Control Treatments in China. Oil Gas Sci. Technol.—Rev. IFP Energ. Nouv. 2010, 65, 859–878. [Google Scholar] [CrossRef]

- Xu, C.; Bi, W.; Li, X.; Yang, H.; Xue, F.; Yi, P. Application Prospects for Harmless Treatments of Oily Sludge in Changqing Oilfield; National Engineering Laboratory for Exploration and Development of Low Permeability Oil and Gas Field, Oil & Gas Technology Research Institute of Changqing Oilfield Company: Xi’an, China, 2015; Available online: https://www.atlantis-press.com/article/19576.pdf (accessed on 1 June 2025).

- Meshalkin, V.; Akhmetov, A.; Lenchenkova, L.; Nzioka, A.; Politov, A.; Strizhnev, V.; Telin, A.; Fakhreeva, A. Application of Renewable Natural Materials for Gas and Water Shutoff Processes in Oil Wells. Energies 2022, 15, 9216. [Google Scholar] [CrossRef]

- Farid Alfredovich, G.; Kashayev, R.A. Cellulose Flour for Isolation of Water-Bearing or Watered Formations for Enhanced Oil Recovery and Method of Its Production. RU2575488C2, 20 February 2016. Available online: https://patents.google.com/patent/RU2575488C2/ru (accessed on 1 June 2025).

- Liu, M.; Wu, B.; Du, Y.; Leng, Q.; Gong, J. Oil and Water Well Plugging Agent and Its Producing Process. CN1335348A, 15 November 2006. Available online: https://patents.google.com/patent/CN1335348A/en (accessed on 1 June 2025).

- Pan, J.; Deng, W.; Li, Y. Slag Plugging Agent for Heavy Oil Thermal Recovery Steam Injection Well. CN101353570A, 28 January 2009. Available online: https://eureka.patsnap.com/patent-CN101353570A (accessed on 1 June 2025).

- Lv, B.; Sun, P.; Wu, Y.; Yang, Z.; Liu, P.; Wang, C.; Liu, Q. Study and Application of Oily Sludge Profile Control Technology in Heavy Oil Reservoir. Energies 2023, 16, 5064. [Google Scholar] [CrossRef]

- Lu, X. Use of Modified Flyash as Profile Control Agent. CN1317481C, 23 May 2007. Available online: https://patents.google.com/patent/CN1317481C/en?oq=CN1317481C (accessed on 1 June 2025).

- Prischepa, O.M.; Nefedov, Y.V.; Kochneva, O.E. Raw Material Base of Hard-to-Extract Oil Reserves of Russia. Periódico Tchê Química 2020, 17, 915–924. [Google Scholar] [CrossRef]

| Gel Type | Reservoir Type | Residual Oil | Effect | Limitations | Country of Application |

|---|---|---|---|---|---|

| Cr(III)–carboxylate/acrylamide gel | Sandstone, 2 D | RO zones with 100% water cut | Oil production increased from 9.2 to 20 m3/day; water cut decreased to 60–70% | Applicable up to ~80–90 °C; sensitive to hard water (Ca2+/Mg2+); possible rock adsorption; requires gelation control using retarders (malonate, glycolates). Gelation accelerates at higher temperatures. Suitable for low- to medium-temperature reservoirs. | China |

| Al(III)–crosslinked gel | Carbonate, moderate T | RO in water-bearing intervals | Moderate water cut reduction; production rate increase (limited data) | Thermal stability up to 90 °C; sensitive to salt ions; difficult to control gelation time without retarders; crosslinking may occur too rapidly. Limited use under high-temperature conditions. Less toxic than Cr-based gels. | Iran |

| Organically crosslinked gel | Carbonate, 2–3 mD | RO in fractured zones | Water cut decreased by 42%; gas rate increased by 7.7 times. | Stable at T > 120 °C due to covalent bonds; thermally resistant up to 150 °C; effective in fractured and tight reservoirs. Requires shut-in period for gelation; inhibitors needed at high T. Chemically complex and costly. | China |

| Biopolymer gel | Sandstone, heterogeneous | RO in swept zones | Oil increase ≈ 3 t/day; water cut ↓ | Thermal stability up to ~90 °C; insensitive to Ca2+/Mg2+; biodegradable (biocides required); high viscosity; stable under pH and salinity variations. Applicable in fresh and saline waters; environmentally friendly and low-corrosive. | Russia |

| Monomer-based gel | Various, high permeability | RO in deep zones | Historical success; increased oil recovery | Highly sensitive to temperature and oxygen; difficult to control free-radical polymerization. Acrylamide is toxic and requires degassing. Thermal stability up to 93 °C with composition modification. Largely replaced by pre-crosslinked gels. | USA |

| Synthetic polymer gel (PPG) | Sandstone/carbonate, >0.5 D | RO between interbeds | Oil rate increase up to 10 t/day; water cut reduction by 5–10% | Operable up to 140 °C; requires sufficient pore or fracture width (>0.1 mm); unsuitable for fine-pore rocks. Applicable in highly heterogeneous formations. Provides long-term effect; available in various particle sizes. | USA, China |

| Inorganic (silicate) gel | Carbonate, fractures >1 D | RO in matrix zones | Significant water reduction; oil production increase | Temperature range 20–120 °C; high salinity resistance; inexpensive and readily available; non-selective—may block oil-saturated zones. Brittle; possible breakthrough under pressure variation. Requires precise placement. | Russia |

| Gel Type | Composition | Country | Reservoir Type | Temperature, °C | Pressure, MPa | Permeability, mD | Water Salinity, g/L | Application Effect | Source |

|---|---|---|---|---|---|---|---|---|---|

| Cr(III)- carboxylate/PAM gel | Partially hydrolyzed polyacrylamide (PHPA) + Cr(III) acetate | USA Field (multiple applications) | Fractured formation | up to 124 (H2S-resistant) | Not available | Not available | High (salt-tolerant) | Widely implemented: ~700 treatments, reduced water cut, increased oil recovery | [101,102] |

| Al(III)- crosslinked gel | PAM + Al(III)-citrate complex (molar ratio ~2:1) | Not specified Laboratory tests | Porous (low- permeability) | ~60–90 (moderate) | Not available | Not available | Depends on salinity (citrate selection at higher mineralization) | Effectively gels and blocks water at moderate temps | [103] |

| Organically crosslinked gel | PHPA (or AM/AMPS copolymer) + organic crosslinker (e.g., PEI) | Saudi Arabia (lab) Laboratory (core flooding) | Porous (sandstone) | up to 130 (stable ≥ 8 weeks) | 3 | Not available | Stable in salts/acids (no ionic precipitates) | At 90 °C and ΔP = 6.89 MPa, complete water shutoff for 3 weeks | [104] |

| Biopolymer gel | Polysaccharide (xanthan) + Cr(III) crosslinker + nano-silica | Iran (lab) Laboratory (bottle and core tests | Porous (sandstone) | 60 (tested); stable at 80 (with 170 g/L salinity) | Not available | 42.6 | 6.8 (simulated formation water); high salt tolerance | ~72% water cut reduction after gel injection; high water selectivity | [102,105] |

| Monomer-based gel | In situ free-radical polymerization of acrylamide/acrylate monomers (initiator + crosslinker) | China | Matrix (perforated intervals) | up to ~93 (controlled gelation); at 149 (stable for a year) | Not available | Not available | Insensitive (inorganic monomers) | Forms rigid gel-plug | [106] |

| Synthetic polymer gel | Pre-crosslinked gel (PPG) based on PHPA, particles 1.5–5 mm | China (Daqing, field) Field (pilot injections) | Porous (heterogeneous sandstone) | ~37 | ~10 (est.) | up to ~1200 mD | ~6.8 (low salinity) | In pilot: oil recovery ↑ by ~8% (after polymer flooding), water cut ↓ | [107,108] |

| Inorganic gel | Water glass (Na2SiO3) + Cr(III) salt (e.g., alum) + polyol (glycerin) | Russia (lab) Laboratory (fracture simulation) | Fractured/fractured-porous | ≥100 (thermally stable) | Not specified (thermo-barostable) | Not available | Insensitive to salinity (no organics) | In core: RRF_water ≈ 180, RRF_oil ≈ 1.2—high water selectivity (>150) | [109] |

| Waste Type | Composition | Country | Project Status | Reservoir Type | Reservoir Temperature, °C | Result | Source |

|---|---|---|---|---|---|---|---|

| Oil sludge (bottom sediment from oil storage tanks) | ~40% oil, ~7% water, ~52% solids (silt, sand, etc.) | China | Field (injection into 15 injection wells) | Porous (sandstone, multilayered) | Not specified (effective at high temps) | Positive: after treatment, injection pressure increased, injection profile redistributed (absorption share in high-perm layer decreased from 71.3% to 44.5%; increased in low-perm layer from 9.7% to 45.5%). Additional oil recovery: ~12,186 tons from 15 wells; oil recovery factor increased by ~4.1%. | [113,114] |

| Wood flour (finely ground sawdust; pulp and paper industry waste) | Cellulose and hemicellulose fibers, high lignin content (typical lignocellulosic material); possible additives (clay, reagents) | Russia | Field (pilot field trials) | Not specified (used in heterogeneous reservoir) | Not specified | Positive: field trials of wood flour-based system showed improved oil recovery and isolation of formation water influx | [115] |

| Cellulose flour (from agricultural waste, e.g., straw) | ~40–58% microcellulose (from annual plants), ~40–60% fine hydromuscovite (clay filler), 1.5–5% thermally and salt-resistant polymer | Russia | Laboratory (patented formulation, tested on samples) | Not specified | Not specified (formulation stable at high temperatures) | Positive: the composition increases oil production and reduces water cut by selectively blocking water-bearing layers | [116] |

| Metallurgical sludge + ash and slag waste (blast furnace slag and thermal power plant ash in plugging formulation) | Mixture of powdered solid waste: granulated blast furnace slag, fly ash, clay component, perlite (total 50–85 wt.%); binder—phenol-formaldehyde resin (~10–45%); hardener—hexamethylenetetramine + benzoic acid (0.5–5%) | China | Laboratory (development and testing, patented) | Not specified | Not specified | Positive: composition is easy to prepare, reliably solidifies in formation, forms a durable long-term blocking barrier; low cost | [117] |

| Blast furnace slag (metallurgical slag containing aluminum) | CaO (~39–41%), SiO2 (~36%), Al2O3 (~10–13%) | China | Field | Fractured | High (≈80–150 °C) | Formation of a strong sealing structure; effective blocking of water-bearing fractures/channels (100% success in trials) | [118] |

| Oil sludge (from separators at TPPs, heavy oil) | ~60–70% water, 10–15% oil, 15–30% solids (sand/clay; d ≈ 10–50 µm) | China | Laboratory + field (150 wells) | Porous | Not specified | After injection and solidification, sludge cemented large pores, redirecting flow to fine-pore zones; cumulative effect: +10,756 tons of additional oil recovered | [119] |

| Ground fly ash (coal) | Mainly SiO2 (~92%) and Al2O3 (mullite ~8%) | China | Laboratory (patented) | Porous | Not specified | Mechanical “bridging” of pore channels; strong adhesion in pores, high thickening strength, low cost, long-term effect | [120] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Raupov, I.; Rogachev, M.; Shevaldin, E. Review of Formation Mechanisms, Localization Methods, and Enhanced Oil Recovery Technologies for Residual Oil in Terrigenous Reservoirs. Energies 2025, 18, 5649. https://doi.org/10.3390/en18215649

Raupov I, Rogachev M, Shevaldin E. Review of Formation Mechanisms, Localization Methods, and Enhanced Oil Recovery Technologies for Residual Oil in Terrigenous Reservoirs. Energies. 2025; 18(21):5649. https://doi.org/10.3390/en18215649

Chicago/Turabian StyleRaupov, Inzir, Mikhail Rogachev, and Egor Shevaldin. 2025. "Review of Formation Mechanisms, Localization Methods, and Enhanced Oil Recovery Technologies for Residual Oil in Terrigenous Reservoirs" Energies 18, no. 21: 5649. https://doi.org/10.3390/en18215649

APA StyleRaupov, I., Rogachev, M., & Shevaldin, E. (2025). Review of Formation Mechanisms, Localization Methods, and Enhanced Oil Recovery Technologies for Residual Oil in Terrigenous Reservoirs. Energies, 18(21), 5649. https://doi.org/10.3390/en18215649