Grain Boundary Engineering of an Additively Manufactured AlSi10Mg Alloy for Advanced Energy Systems: Grain Size Effects on He Bubbles Distribution and Evolution

Abstract

1. Introduction

2. Methodology

2.1. Material Fabrication

2.1.1. Laser Powder Bed Fusion (LPBF)

2.1.2. KOBO Extrusion Process

2.1.3. Post-Extrusion Annealing

2.1.4. He Implantation Experiment

2.2. Sample Preparation and Microstructure Analysis

2.2.1. Electron Backscatter Diffraction (EBSD)

2.2.2. Data Processing and Grain Size Quantification

2.2.3. Transmission Electron Microscopy (TEM)

3. Results

3.1. Microstructure Analysis Before He Implantation

3.2. Effect of He Irradiation on Microstructure

4. Discussion

5. Conclusions

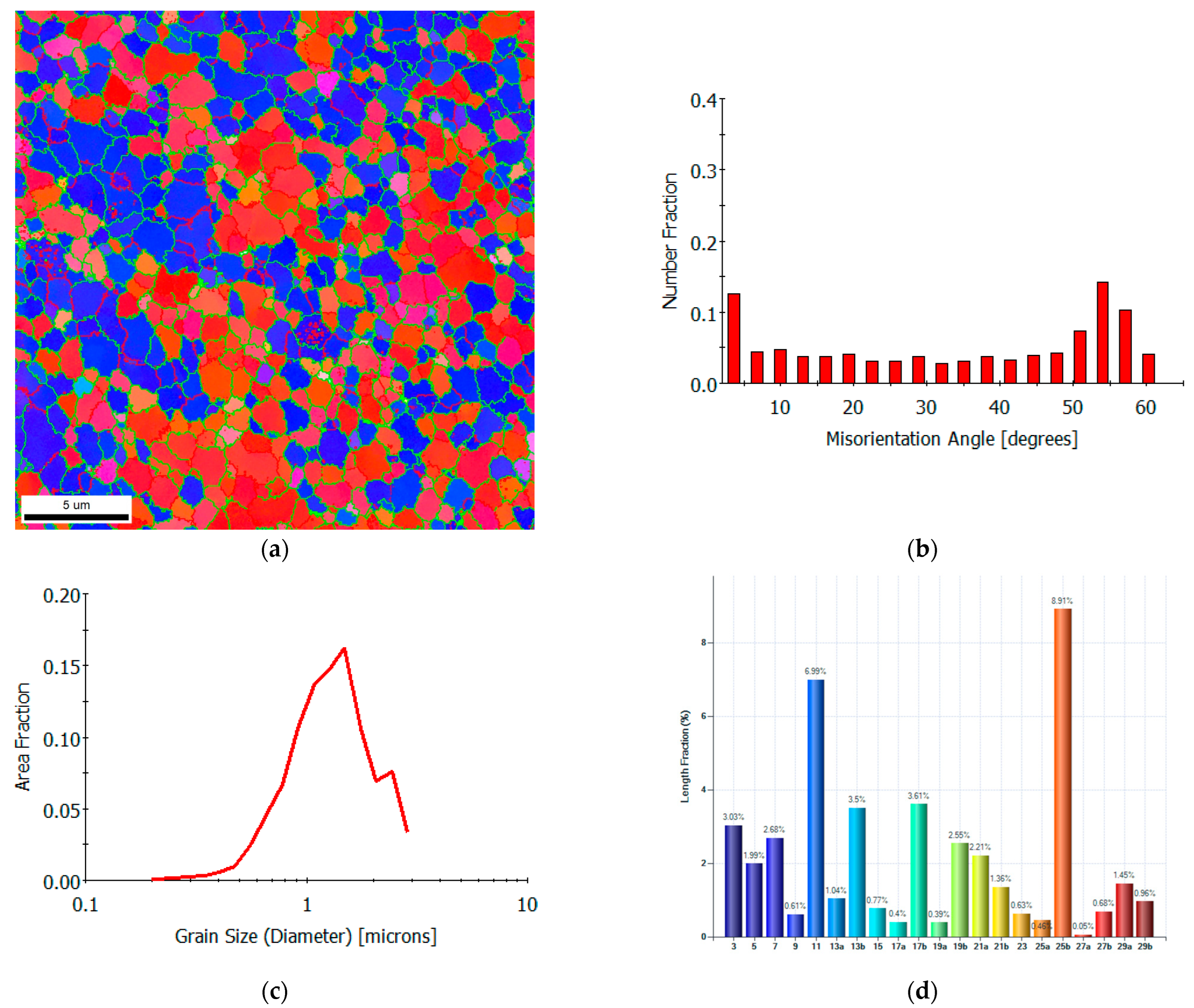

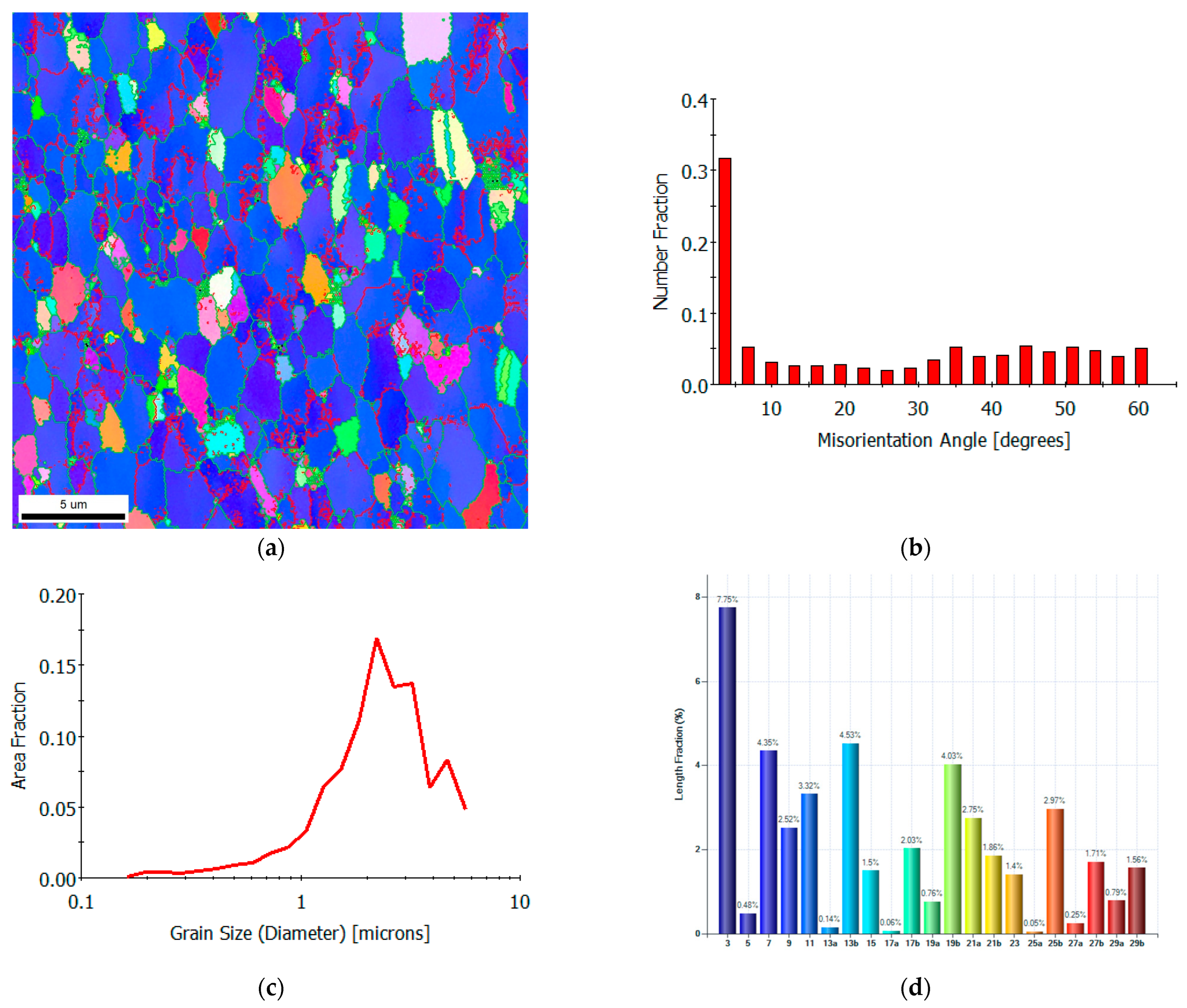

- Analysis by Electron Backscatter Diffraction (EBSD) showed that the KOBO-extruded sample has an average grain size of 0.8 µm and a Coincidence Site Lattice (CSL) boundary fraction of approximately 41%.

- Following annealing, the KOBO-processed sample exhibited a larger average grain size of about 1.2 µm and a higher CSL boundary fraction of approximately 45%.

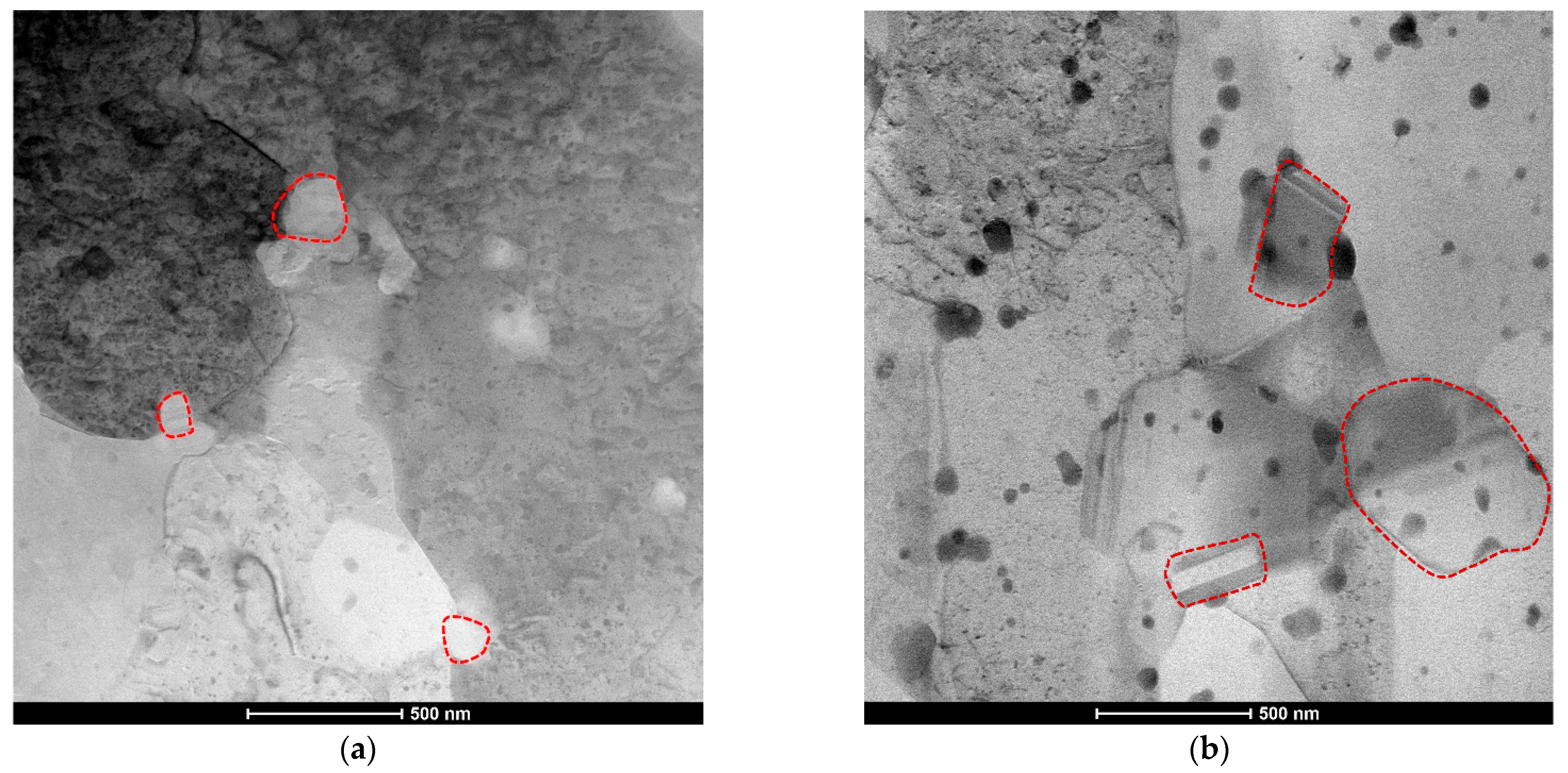

- Helium bubbles formed in both samples because of He ion irradiation, and TEM analysis revealed that grain boundaries are preferential sites for the accumulation and growth of these bubbles.

- The onset of helium bubble formation occurred at a greater depth in the as-extruded sample (~80 nm) compared to the annealed sample (~25 nm). The high density of defect sinks in the as-extruded material suppressed bubble nucleation near the surface, forcing helium to diffuse deeper into the material.

- HRTEM analysis confirmed that ion irradiation induced a high density of nanoscale defects in both material conditions. In the as-extruded sample, these defects included dislocation loops and nanotwins or stacking faults, while the annealed sample showed a high density of dislocation loops.

- The superior performance of the as-extruded sample in suppressing helium bubble growth is attributed to its high density of sinks (grain boundaries and dislocations). These sinks trapped radiation-induced point defects, promoting their annihilation and reducing the vacancy concentration required for bubble formation.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qiu, S.; Liu, H.; Jiang, M.; Min, S.; Gu, Y.; Wang, Q.; Yang, J.; Li, X.; Chen, Z.; Hou, J. A Brief Review on He Ion Irradiation Research of Steel and Iron-Based Alloys in Nuclear Power Plants. Acta Metall. Sin. Engl. Lett. 2023, 36, 529–551. [Google Scholar] [CrossRef]

- Chen, H.; Cheng, Y.; Lin, C.; Peng, J.; Liang, X.; Gao, J.; Liu, W.; Huang, H. In-Situ TEM Observation of Nanobubbles Evolution in Helium-Irradiated Aluminium upon Tensile Stressing. J. Nucl. Mater. 2019, 520, 178–184. [Google Scholar] [CrossRef]

- Zhu, H.; Qin, M.; Wei, T.; Davis, J.; Ionescu, M. Atomic-Scale Study of He Ion Irradiation-Induced Clustering in α-Zirconium. Acta Mater. 2023, 244, 118584. [Google Scholar] [CrossRef]

- Hu, Y.; Peng, L.; Shi, J.; Li, L.; Sun, Y.; Chen, S.; Wan, Y. The Temperature Effect on the Formation and Growth of Helium-Vacancy Clusters in Bcc Iron: A Comprehensive Molecular Dynamics Simulation. J. Nucl. Mater. 2024, 597, 155130. [Google Scholar] [CrossRef]

- Wang, J.; Liu, D.; Dang, W.; Guo, Z.; Song, W. Segregation and Coalescence Behavior of Helium Bubbles in Tungsten. J. Nucl. Mater. 2021, 544, 152732. [Google Scholar] [CrossRef]

- Yoshida, N.; Iwakiri, H.; Tokunaga, K.; Baba, T. Impact of Low Energy Helium Irradiation on Plasma Facing Metals. J. Nucl. Mater. 2005, 337–339, 946–950. [Google Scholar] [CrossRef]

- Li, J.-T.; Beyerlein, I.J.; Han, W.-Z. Helium Irradiation-Induced Ultrahigh Hardening in Niobium. Acta Mater. 2022, 226, 117656. [Google Scholar] [CrossRef]

- Kishimoto, H.; Yutani, K.; Kasada, R.; Kimura, A. Helium Cavity Formation Research on Oxide Dispersed Strengthening (ODS) Ferritic Steels Utilizing Dual-Ion Irradiation Facility. Fusion Eng. Des. 2006, 81, 1045–1049. [Google Scholar] [CrossRef]

- Shang, Z.; Niu, T.; Sun, T.; Xue, S.; Fan, C.; Chen, W.-Y.; Li, M.; Wang, H.; Zhang, X. In Situ Study on Radiation Response of a Nanotwinned Steel. Scr. Mater. 2022, 220, 114920. [Google Scholar] [CrossRef]

- Wang, L.; Yan, S.; Meng, M.; Xue, K.; Li, P. Twin Boundary-Assisted Improvement of Radiation Resistance of Iron: Defect Evolution, Mechanical Properties, and Deformation Mechanism. J. Nucl. Mater. 2022, 567, 153818. [Google Scholar] [CrossRef]

- Cao, P.; So, K.P.; Yang, Y.; Park, J.G.; Li, M.; Yan, L.; Hu, J.; Kirk, M.; Li, M.; Lee, Y.H.; et al. Carbon Nanotube (CNT) Metal Composites Exhibit Greatly Reduced Radiation Damage. Acta Mater. 2021, 203, 116483. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Zinkle, S.J.; Henry, J.; Levine, S.M.; Edmondson, P.D.; Gilbert, M.R.; Tanigawa, H.; Kessel, C.E. Irradiation Damage Concurrent Challenges with RAFM and ODS Steels for Fusion Reactor First-Wall/Blanket: A Review. J. Phys. Energy 2022, 4, 034003. [Google Scholar] [CrossRef]

- Wu, Z.F.; Xu, L.D.; Chen, H.Q.; Liang, Y.X.; Du, J.L.; Wang, Y.F.; Zhang, S.L.; Cai, X.C.; Sun, B.R.; Zhang, J.; et al. Significant Suppression of Void Swelling and Irradiation Hardening in a Nanograined/Nanoprecipitated 14YWT-ODS Steel Irradiated by Helium Ions. J. Nucl. Mater. 2022, 559, 153418. [Google Scholar] [CrossRef]

- Xie, Z.; Guo, L.; Chen, Y.; Long, Y.; Lv, P.; Li, F.; Luo, H.; Lin, W.; Yin, Z.; Cao, J.; et al. Deterioration of Irradiation Resistance of ODS-F/M Steel under High Concentration of Helium. J. Nucl. Mater. 2023, 577, 154293. [Google Scholar] [CrossRef]

- Barr, C.M.; El-Atwani, O.; Kaoumi, D.; Hattar, K. Interplay Between Grain Boundaries and Radiation Damage. JOM 2019, 71, 1233–1244. [Google Scholar] [CrossRef]

- El-Atwani, O.; Nathaniel, J.E.; Leff, A.C.; Muntifering, B.R.; Baldwin, J.K.; Hattar, K.; Taheri, M.L. The Role of Grain Size in He Bubble Formation: Implications for Swelling Resistance. J. Nucl. Mater. 2017, 484, 236–244. [Google Scholar] [CrossRef]

- Nathaniel, J.E.; El-Atwani, O.; Huang, S.; Marian, J.; Leff, A.C.; Baldwin, J.K.; Hattar, K.; Taheri, M.L. Implications of Microstructure in Helium-Implanted Nanocrystalline Metals. Materials 2022, 15, 4092. [Google Scholar] [CrossRef]

- Saeed, A.; Mohamed, R.H.; Abu-Raia, W.A. Nickel-Free Austenitic Stainless Steel Alloys as a Sodium-Cooled Fast Reactor Fuel Cladding. Mater. High Temp. 2022, 39, 380–386. [Google Scholar] [CrossRef]

- Cheng, G.M.; Xu, W.Z.; Wang, Y.Q.; Misra, A.; Zhu, Y.T. Grain Size Effect on Radiation Tolerance of Nanocrystalline Mo. Scr. Mater. 2016, 123, 90–94. [Google Scholar] [CrossRef]

- Chen, Y.; Yu, K.Y.; Liu, Y.; Shao, S.; Wang, H.; Kirk, M.A.; Wang, J.; Zhang, X. Damage-Tolerant Nanotwinned Metals with Nanovoids under Radiation Environments. Nat. Commun. 2015, 6, 7036. [Google Scholar] [CrossRef]

- Manna, M.; Pal, S. Molecular Dynamics Simulation for Radiation Response of Nb Bicrystal Having Σ 13, Σ 29, and Σ 85 Grain Boundary. J. Appl. Phys. 2023, 133, 165902. [Google Scholar] [CrossRef]

- Manna, M.; Pal, S. Improvement in Radiation Resistance of Nanocrystalline Cu Using Grain Boundary Engineering: An Atomistic Simulation Study. J. Mater. Sci. 2022, 57, 19832–19845. [Google Scholar] [CrossRef]

- Han, W.Z.; Demkowicz, M.J.; Fu, E.G.; Wang, Y.Q.; Misra, A. Effect of Grain Boundary Character on Sink Efficiency. Acta Mater. 2012, 60, 6341–6351. [Google Scholar] [CrossRef]

- Snopiński, P.; Matus, K. Characterisation of Microstructure and Special Grain Boundaries in LPBF AlSi10Mg Alloy Subjected to the KoBo Extrusion Process. Symmetry 2023, 15, 1634. [Google Scholar] [CrossRef]

- Snopiński, P.; Liverić, L.; Beniak, J. Annealing Effects on Microstructure and Texture in KOBO-Processed LPBF AlSi10Mg Alloy: Elucidating CSL Boundary Formation. Symmetry 2024, 16, 1663. [Google Scholar] [CrossRef]

- Snopiński, P. Effects of KoBo-Processing and Subsequent Annealing Treatment on Grain Boundary Network and Texture Development in Laser Powder Bed Fusion (LPBF) AlSi10Mg Alloy. Symmetry 2024, 16, 122. [Google Scholar] [CrossRef]

- Bochniak, W.; Ostachowski, P.; Korbel, A.; Łagoda, M. Potential of the KOBO Extrusion Process for Nonferrous Metals in the Form of Solids and Chips. Int. J. Adv. Manuf. Technol. 2023, 127, 733–750. [Google Scholar] [CrossRef]

- Bochniak, W.; Marszowski, K.; Korbel, A. Theoretical and Practical Aspects of the Production of Thin-Walled Tubes by the KOBO Method. J. Mater. Process. Technol. 2005, 169, 44–53. [Google Scholar] [CrossRef]

- Korbel, A.; Bochniak, W.; Ostachowski, P.; Błaż, L. Visco-Plastic Flow of Metal in Dynamic Conditions of Complex Strain Scheme. Metall. Mater. Trans. A 2011, 42, 2881–2897. [Google Scholar] [CrossRef]

- Bochniak, W.; Korbel, A.; Ostachowski, P.; Łagoda, M. Plastic Flow of Metals under Cyclic Change of Deformation Path Conditions. Arch. Civ. Mech. Eng. 2018, 18, 679–686. [Google Scholar] [CrossRef]

- Alghamdi, F.; Song, X.; Hadadzadeh, A.; Shalchi-Amirkhiz, B.; Mohammadi, M.; Haghshenas, M. Post Heat Treatment of Additive Manufactured AlSi10Mg: On Silicon Morphology, Texture and Small-Scale Properties. Mater. Sci. Eng. A 2020, 783, 139296. [Google Scholar] [CrossRef]

- Wang, Y.; Meng, J.; Jia, F.; Cao, F.; Jiang, Y. Effects of Helium and Vacancy in Ni Symmetric Tilt Grain Boundaries by First-Principles. Nucl. Mater. Energy 2024, 40, 101721. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, L.; Zhang, Y.; Zhang, P.; Huang, X.; Huang, S.; Hu, K.; Tang, J.; Deng, L.; Deng, H.; et al. First-Principles Study of the Trapping Behavior of Hydrogen Atoms by Defects in Vanadium Alloys. Int. J. Hydrogen Energy 2025, 128, 425–431. [Google Scholar] [CrossRef]

- Uberuaga, B.P.; Vernon, L.J.; Martinez, E.; Voter, A.F. The Relationship between Grain Boundary Structure, Defect Mobility and Grain Boundary Sink Efficiency. Sci. Rep. 2015, 5, 9095. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, Y.; Cheng, W.; Guo, L.; Jin, S. Study on the Mechanism of He Effect on Dislocation Loop Formation in Three Types of Dual Ion Beam Irradiations. J. Nucl. Mater. 2024, 588, 154782. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, Z.; Huang, J.; Li, J.; Wei, H.; Zhang, T.; Polcar, T.; Daghbouj, N.; Li, B. Damage Behavior of He-Irradiated Sintered SiC at High Temperatures. J. Nucl. Mater. 2025, 612, 155839. [Google Scholar] [CrossRef]

- Li, N.; Fu, E.G.; Wang, H.; Carter, J.J.; Shao, L.; Maloy, S.A.; Misra, A.; Zhang, X. He Ion Irradiation Damage in Fe/W Nanolayer Films. J. Nucl. Mater. 2009, 389, 233–238. [Google Scholar] [CrossRef]

- Edwards, D.J.; Schemer-Kohrn, A.; Olszta, M.; Prabhakaran, R.; Zhu, Y.; Wang, J.; Haag, J.; El Atwani, O.; Lach, T.G.; Toloczko, M. Understanding and Removing FIB Artifacts in Metallic TEM Samples Using Flash Electropolishing. J. Nucl. Mater. 2025, 606, 155618. [Google Scholar] [CrossRef]

- Kohnert, A.A.; Capolungo, L. A Novel Approach to Quantifying the Kinetics of Point Defect Absorption at Dislocations. J. Mech. Phys. Solids 2019, 122, 98–115. [Google Scholar] [CrossRef]

- Edmondson, P.D.; Parish, C.M.; Zhang, Y.; Hallén, A.; Miller, M.K. Helium Entrapment in a Nanostructured Ferritic Alloy. Scr. Mater. 2011, 65, 731–734. [Google Scholar] [CrossRef]

- Wurmshuber, M.; Frazer, D.; Balooch, M.; Issa, I.; Bachmaier, A.; Hosemann, P.; Kiener, D. The Effect of Grain Size on Bubble Formation and Evolution in Helium-Irradiated Cu-Fe-Ag. Mater. Charact. 2021, 171, 110822. [Google Scholar] [CrossRef]

- Nathaniel, J.E.; Suri, P.K.; Hopkins, E.M.; Wen, J.; Baldo, P.; Kirk, M.; Taheri, M.L. Grain Boundary Strain as a Determinant of Localized Sink Efficiency. Acta Mater. 2022, 226, 117624. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, W.Q.; Gokhman, A.; Yang, J.J.; Shi, K.; Luan, J.H.; Cui, Y.; Liaw, P.K.; Liu, C.T.; Zhang, Z.W. Enhanced Irradiation Tolerance of Fe30Cr25Ni20Co15Mn10 High-Entropy Alloy via Nanotwin Boundaries. J. Nucl. Mater. 2021, 557, 153292. [Google Scholar] [CrossRef]

- Bian, Y.-N.; Lu, Y.; Zhang, J.; Gao, B.; Wang, W.-B.; Han, W.-Z. Interaction of Irradiation Defects with Precipitates in CuCrZr and Cu-1Fe Alloys. Acta Mater. 2023, 253, 118964. [Google Scholar] [CrossRef]

- Chai, J.; Zhu, D.; Guo, Z.; Wang, B.; Yan, R.; Ding, R.; Li, C.; Gao, B.; Xuan, C.; Wang, Z.; et al. Microstructure Evolution and Hardening of Helium Ion Irradiated Tungsten. Vacuum 2025, 235, 114153. [Google Scholar] [CrossRef]

- Fan, Y. Atomistic Modeling of Microstructural Defect Evolution in Alloys Under Irradiation: A Comprehensive Review. Appl. Sci. 2025, 15, 9110. [Google Scholar] [CrossRef]

- Cheik Njifon, I.; Torres, E. Effect of Grain Boundaries on the Helium Degradation Mechanisms of Alloy 800H: A Molecular Dynamics Study. J. Nucl. Mater. 2025, 603, 155395. [Google Scholar] [CrossRef]

- Li, B.; Li, H.-Y.; Luo, S.-N. Molecular Dynamics Simulations of Displacement Cascades in Nanotwinned Cu. Comput. Mater. Sci. 2018, 152, 38–42. [Google Scholar] [CrossRef]

- Zhang, L. Understanding the Radiation Resistance Mechanisms of Nanocrystalline Metals from Atomistic Simulation. Metals 2021, 11, 1875. [Google Scholar] [CrossRef]

- Yao, X.; Wen, M.; Xiong, K.; Mao, Y.; Guo, Y.-F. Effect of Elemental Segregation on Grain Boundary Cohesion in Platinum: A First-Principles Study. Philos. Mag. 2025, 105, 895–918. [Google Scholar] [CrossRef]

- Zhang, L.; Fu, C.-C.; Hayward, E.; Lu, G.-H. Properties of He Clustering in α-Fe Grain Boundaries. J. Nucl. Mater. 2015, 459, 247–258. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Snopiński, P.; Barlak, M.; Zagórski, J.; Pagač, M. Grain Boundary Engineering of an Additively Manufactured AlSi10Mg Alloy for Advanced Energy Systems: Grain Size Effects on He Bubbles Distribution and Evolution. Energies 2025, 18, 5445. https://doi.org/10.3390/en18205445

Snopiński P, Barlak M, Zagórski J, Pagač M. Grain Boundary Engineering of an Additively Manufactured AlSi10Mg Alloy for Advanced Energy Systems: Grain Size Effects on He Bubbles Distribution and Evolution. Energies. 2025; 18(20):5445. https://doi.org/10.3390/en18205445

Chicago/Turabian StyleSnopiński, Przemysław, Marek Barlak, Jerzy Zagórski, and Marek Pagač. 2025. "Grain Boundary Engineering of an Additively Manufactured AlSi10Mg Alloy for Advanced Energy Systems: Grain Size Effects on He Bubbles Distribution and Evolution" Energies 18, no. 20: 5445. https://doi.org/10.3390/en18205445

APA StyleSnopiński, P., Barlak, M., Zagórski, J., & Pagač, M. (2025). Grain Boundary Engineering of an Additively Manufactured AlSi10Mg Alloy for Advanced Energy Systems: Grain Size Effects on He Bubbles Distribution and Evolution. Energies, 18(20), 5445. https://doi.org/10.3390/en18205445