Abstract

Transparent conductive aluminum-doped zinc oxide (AZO) films were investigated as potential recombination layers for perovskite/silicon tandem solar cells, comparing the results of atomic layer deposition (ALD) and magnetron sputtering (MS) on vertically aligned silicon nanowire (SiNW) scaffolds. Conformality and thickness control were examined by cross-sectional SEM/TEM and profilometry, revealing fully conformal ALD coatings with tunable thicknesses (40–120 nm) versus tip-capped, semi-uniform MS films (100–120 nm). Optical transmission measurements on glass substrates showed that both 120 nm ALD and MS layers exhibit interference maxima near 450–500 nm and 72–89% transmission across 800–1200 nm; the thinnest ALD films reached up to 86% near-IR transparency. Four-point probe analysis demonstrated that ALD reduces surface resistance from 1150 Ω/□ at 40 nm to 245 Ω/□ at 120 nm, while MS layers achieved 317 Ω/□ at 120 nm. These results delineate the balance between conformality, transparency, and conductivity, providing design guidelines for AZO recombination interfaces in next-generation tandem photovoltaics.

1. Introduction

The conversion of solar energy via photovoltaic (PV) devices offers a compelling pathway to sustainable electricity generation, owing to high power yields, long-term operational stability, minimal user intervention, and versatile installation options on rooftops and façades. Coupled with rapidly declining levelized costs, PV has emerged as a cornerstone of Europe’s clean energy transition. By the end of 2024, the EU surpassed its REPowerEU target—installing approximately 339.4 GW of solar capacity, up from 320 GW—and is on course to achieve 600 GW by 2030, driven by record annual additions of 62.5 GW in 2024, projected to be 70 GW in 2025. Solar power overtook coal in 2024, supplying over 11% of EU electricity, with Central and Eastern European markets such as Poland increasing their capacity from 9 GW in 2019 to 46 GW in 2024 despite regulatory and financial hurdles [1].

Silicon remains the dominant PV technology, accounting for roughly 95% of the global market. Its combination of earth abundance, non-toxicity, and mature manufacturing has led to a record single-junction efficiency of 27.3% (NREL, June 2025) and driven costs downward. However, the theoretical Shockley–Queisser limit for silicon (≈29.4%) has nearly been reached, prompting interest in tandem architectures. Over the past decade, organic–inorganic perovskites have emerged as an ideal high-bandgap top cell material, enabling monolithic silicon/perovskite tandems with demonstrated efficiencies up to 34.9% [2]. By stacking absorbers with complementary bandgaps, tandem cells reduce thermalization losses in the top junction and harvest sub-bandgap photons in the silicon bottom cell, pushing the thermodynamic efficiency limit toward 43% [3,4]. This spectral splitting approach represents a promising strategy for surpassing the intrinsic efficiency ceiling of single-junction devices [5].

Silicon nanowire texturization is well established as an effective surface engineering strategy in photovoltaics, reducing front-surface reflectance and thereby increasing photon absorption within the silicon substrate. By transforming the Si surface from a smooth to a high-aspect-ratio, roughened morphology, nanowire arrays enable enhanced light trapping and improved photovoltaic efficiency [6,7]. Surface texturization via metal-assisted etching (MAE) is highly effective for creating “black silicon” with dramatically reduced reflectivity and near-total solar absorption. Based on extensive experience with the texture of MAE-fabricated nanowire structures, the authors are now investigating vertically aligned silicon nanowires as a scaffold for subsequent functional layers in tandem solar cells. In particular, these high-aspect-ratio textures offer an ideal platform for the conformal deposition of transparent conductive oxides as recombination layers, as well as perovskite absorbers, enabling novel tandem architectures that remain largely unexplored in the current literature [8]. However, literature reports indicate that depositing perovskite onto textured silicon can significantly benefit tandem cell performance by minimizing front-surface reflectance and maximizing photocurrent. To date, most studies have focused on classic pyramidal texturing, where perovskite films conformally coated pyramidal facets to achieve low optical losses and photocurrents exceeding 20 mA cm−2 in each subcell [3]. The benefits of pyramidal fully textured tandems have been demonstrated [9,10,11]. However, conformal perovskite deposition on pyramidal textures requires complex, high-cost techniques that have yet to see widespread industrial adoption, owing to the challenge of uniformly filling pyramidal valleys without material buildup. Wet chemical deposition methods offer a lower-cost alternative but demand a porous scaffold to support uniform perovskite infiltration. Common scaffolds for perovskite cells employ porous Al2O3 or TiO2 matrices [12,13]; for example, TiO2 nanowire arrays (~300 nm tall) have enabled stable perovskite infiltration and enhanced device efficiency [14]. Building on our experience in producing silicon nanowires of comparable dimensions (~300–400 nm height), we explore their use as an innovative porous scaffold for perovskite deposition in tandem solar architectures.

Silicon/perovskite tandem cells represent a promising and innovative direction for next-generation photovoltaics, where two key factors govern the effective interconnection of a tandem cell. Firstly, their architecture necessitates a transparent conductive oxide (TCO) interlayer to provide efficient electrical coupling between the silicon and perovskite subcells to form a monolithic two-terminal (2T) tandem configuration [15], and secondly, the precise current matching between the silicon and perovskite subcells is essential to avoid power losses [5,16,17,18]. The subcells are interconnected by a single recombination layer, requiring only two external contacts—one of which must be semitransparent to allow for light transmission to the bottom junction [19]. This recombination interface must combine low electrical resistance with minimal optical absorption to enable efficient hole–electron recombination between subcells [20,21,22,23,24,25,26]. Moreover, the deposition of the perovskite top cell must not compromise the light harvesting or electrical performance of the textured silicon bottom cell, which further challenges the integration of uniform, high-quality layers on rough, high-aspect-ratio surfaces [4]. Building on our expertise in silicon nanowire texturization and the demonstrated benefits of high-aspect-ratio scaffolds for tandem photovoltaics, we have extended this work to the deposition of recombination layers directly onto SiNW arrays. To date, we have deposited both indium–tin oxide (ITO) and tin dioxide (SnO2) films as interconnecting layers, demonstrating proof of concept for conformal, low-loss contacts in monolithic silicon/perovskite tandem architectures [15,27]. In the paper, the authors extend this approach by implementing aluminum-doped zinc oxide (AZO) films in the same recombination layer role.

The selection of an appropriate recombination layer material is critical, with aluminum-doped zinc oxide (AZO) emerging as an excellent candidate among various transparent conductive oxides [28,29]. As a viable ITO alternative, AZO combines long-term stability with high electrical conductivity and visible-range transparency, making it suitable for applications ranging from touch screens and LEDs to organic photovoltaic devices [30,31,32,33,34,35]. To function effectively as a transparent electrode, TCO films must exhibit low resistivity (≤10−3 Ω·cm) and maintain optical transmittance above 80% at thicknesses below 200 nm while also offering robust mechanical durability and strong substrate adhesion. Magnetron sputtering, a scalable and versatile thin-film deposition technique frequently employed in industry, meets these requirements and supports precise control over film properties [36].

For the deposition of AZO thin films by magnetron sputtering, the most commonly used targets are made of sintered zinc oxide powders and aluminum oxide (ZnO-Al2O3). The optimal percentage of aluminum oxide in such targets is approximately 2% [37,38,39,40,41,42,43,44,45,46,47,48,49]. Studies aiming to minimize AZO resistivity have typically adjusted the Al2O3 fraction within the sputtering target to between 1 and 6 mol% [39,40,43]. The reactive sputtering of a Zn–Al metal target in an Ar/O2 atmosphere has likewise produced low-resistivity films [39,41,43,44,45,50,51,52], and co-sputtering from separate ZnO and Al targets has enabled the fine tuning of composition via independent power control [41,51,52]. In these processes, the target power densities are generally a few W cm−2, and substrates are often maintained at elevated temperatures (~500 °C) to promote film crystallinity. Under such conditions, film resistivities as low as 1 × 10−4 to 1 × 10−3 Ω cm have been reported, alongside visible-range transmittances exceeding 80%. Post-deposition annealing further reduces resistivity and enhances optical transparency.

Beyond magnetron sputtering, a variety of deposition methods—such as pulsed laser deposition, chemical vapor deposition, sol–gel techniques, and atomic layer deposition (ALD)—have been employed to fabricate transparent conductive films. Among these, ALD has gained significant attention for its ability to produce exceptionally uniform coatings at a low cost and low processing temperatures, even on substrates with complex geometries. While pulsed laser deposition can yield films with superior electrical properties, its scalability to industrial scales is limited. Magnetron sputtering remains a practical option for high-throughput production, but ALD stands out for its sub-nanometer thickness control, large-area compatibility, and conformal coverage capabilities [53], making it particularly well suited to textured or high-aspect-ratio surfaces. In ALD, alternating exposures to precursor and reactant gases allow for the sequential formation of single molecular layers, enabling precise thickness and composition control via self-limiting surface reactions [54]. This approach has been successfully used to deposit uniform coatings on nanowire arrays and other nanostructures [55,56,57]. Although several methods have been applied to synthesize transparent Al-doped ZnO films, achieving uniform dopant distribution and stable electrical behavior remains challenging. ALD’s inherent precision in precursor dosing and exposure timing offers a promising route to high-quality AZO films, yet studies on ALD-grown AZO remain relatively scarce [58,59,60].

We report for the first time the integration of an AZO layer in function of a recombination layer on high-aspect-ratio silicon nanowire (SiNW) scaffolds, addressing the critical challenge of conformal coverage on porous, vertically aligned arrays. By comparing AZO films deposited by magnetron sputtering and ALD methods on identical SiNW templates via SEM, TEM, optical transmission, and electrical measurements, we delineate how deposition mechanism and film thickness jointly influence conformality, microstructure, and optoelectronic performance, thereby establishing process guidelines for AZO-based recombination interfaces in next-generation tandem photovoltaics.

2. Materials and Methods

2.1. Materials

This experimental work was conducted using “as-cut”, p-type monocrystalline silicon wafers with a (100) crystallographic orientation and a resistivity in the range of 2.5–6 Ω·cm. The wafers were laser-cut into square samples with an area of 25 cm2 and a thickness of approximately 200 µm. Initial surface preparation involved mechanical cleaning using high-purity isopropanol (99.7%, POCH) and acetone (CHEMPUR), followed by sequential ultrasonic baths in acetone and isopropanol at elevated temperatures to ensure the thorough removal of organic residues.

2.2. Methods

Detailed procedures and reagent specifications for the metal-assisted etching (MAE) of silicon, which was used to form nanowire structures, have been described in earlier publications on this subject [8,61]. For the subsequent processing steps, silicon substrates featuring etched nanowires with lengths ranging from 300 to 500 nm—corresponding to etching durations of approximately 20 s—were utilized.

An AZO layer was deposited via atomic layer deposition (ALD) using a Picosun R-200 reactor (Espoo, Finland). Thin films were deposited using diethylzinc (DEZ) and trimethylaluminum (TMA) as the respective zinc and aluminum precursors. In both cases, deionized water was employed as the oxygen source. Deposition was carried out at temperatures ranging from 200 °C to 300 °C, with precursor and water pulse durations between 0.1 s and 5 s. Nitrogen was used as a purge gas between each pulse to remove excess reactants and by-products from the reaction chamber. The growth of the AZO layer was achieved by alternating ALD sub-cycles: DEZ + H2O for ZnO formation and TMA + H2O for Al2O3 incorporation. The total number of ALD cycles ranged from 100 to 1000, depending on the desired film thickness and doping level.

Magnetron-sputtered AZO thin films were deposited in a WMK-100 circular magnetron (NdFeB magnets, handmade Wroclaw University of Science and Technology, Wroclaw, Poland) equipped with a Zn/Al two-element target (99.999% purity; Al rings in a 100 mm Zn disk). Sputtering was powered by a MSS-10 kW mid-frequency power supply (Dora Power System, Wroclaw, Poland, 100 kHz, 10 µs pulses, 16 A amplitude), with circulating power (Pc) monitored as a process indicator. The vacuum chamber, pumped by a 2000 L/s diffusion pump and 30 m3/h rotary pump, was evacuated to 1.2 × 10−5 Torr. Substrates were mounted 60 mm above the target at a 67 mm radial offset and tilted 45° toward it. The most important process parameters are summarized in a Table 1.

Table 1.

The parameters of the ALD process.

Two processes were implemented. In AZO(MS)-1, Ar (to 9.4 × 10−4 Torr) and O2 (to 1.6 × 10−3 Torr) were introduced, and films were grown for 3.5 min at PE = 200 W, Pc = 100 W. AZO(MS)-2 included an initial 1 min AZO buffer layer at PE = 200 W, Pc = 200 W under identical pressures, followed by a 3.5 min main deposition at PE = 200 W, Pc = 100 W. The ratio of circulating power to effective power was selected based on earlier studies, described in detail in [36]. Process parameters are summarized in Table 2.

Table 2.

The parameters of the magnetron sputtering process.

All samples subjected to characterization were prepared in a single, consistent deposition run to eliminate process-induced variability. Accordingly, each deposition simultaneously coated three substrates: the silicon nanowire scaffold, a microscope glass slide, and a polished silicon wafer. Films deposited on glass and polished silicon were reserved for optical and electrical measurements, respectively, while the nanowire-coated substrates served for microstructural analysis via electron microscopy.

Surface morphology was investigated using FEI Europe B.v. (Eindhoven, The Netherlands) QUANTA 200 3D Dual Beam system scanning electron microscope. High-resolution imaging was performed under high-vacuum conditions with an accelerating voltage of 13 kV and a probe current of 16.00 nA. Secondary electron mode was used to acquire micrographs at magnifications up to 50,000×.

To further analyze the microstructure of the interfacial region between the silicon substrate and the AZO layer, transmission electron microscopy (TEM) was conducted using a FEI Europe B.v. (Eindhoven, The Netherlands) Tecnai G2 F20 microscope (200 kV), equipped with a field-emission gun and a high-angle annular dark-field detector, operating in scanning transmission electron microscopy (STEM) mode.

3. Results

3.1. SEM Analysis of AZO Thin Films on Silicon Nanowire Substrates

The morphological quality and coverage uniformity of AZO layers deposited on silicon nanowire (SiNW) scaffolds play a critical role in determining the overall electrical and optical performance of tandem solar cell architectures. Given the high aspect ratio and porous nature of vertically aligned SiNWs, achieving conformal and continuous AZO coatings presents significant challenges that are highly dependent on the selected deposition method.

To assess the surface topography, film continuity, and penetration depth of the AZO layers within the nanowire matrix, scanning electron microscopy (SEM) was employed. High-resolution SEM imaging enables the direct visualization of the layer morphology on both the cross-sectional profiles of the nanostructured substrate. By comparing coatings obtained via atomic layer deposition and magnetron sputtering, key differences in coverage quality, thickness uniformity, and structural integrity can be elucidated.

Such imaging-based analysis provides critical insights into the interaction between deposition parameters and complex substrate geometry, guiding the optimization of AZO films for enhanced charge transport, light management, and interfacial properties in nanostructured tandem photovoltaic devices.

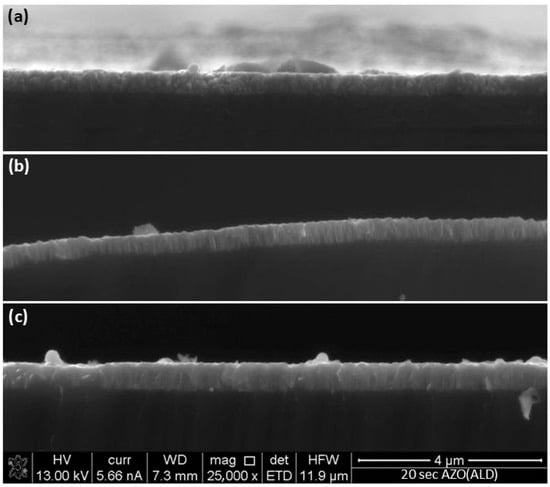

3.1.1. AZO Layer Deposited Using ALD Method

Figure 1a presents a cross-sectional view of an AZO layer deposited onto vertically aligned silicon nanowires, imaged at a magnification of 25,000×. Deposition was conducted after 20 s of silicon nanowire etching (estimated nanowire length ~300–500 nm). The AZO film appears as a bright, conformal layer covering the top surface of the porous scaffold and interwire area. Some surface roughness and agglomerates are visible in the uppermost part of the layer, likely resulting from non-uniform film nucleation or partial densification during growth. Despite the challenging high-aspect-ratio morphology, the coverage suggests effective material penetration, characteristic of a well-optimized atomic layer deposition (ALD) process. No apparent voids or delamination zones are observed between the AZO and the SiNW base layer, indicating good interfacial adhesion.

Figure 1.

SEM micrograph showing (a) AZO(ALD)-1, (b) AZO(ALD)-2, and (c) AZO(ALD)-3 layers deposited on substrate consisting of SiNWs etched in 20 s.

This SEM cross-section in Figure 1b shows silicon nanowires (~300–500 nm long) coated with a thicker AZO film compared to the AZO(ALD)-1 sample. The brighter, continuous AZO layer exhibits improved thickness uniformity and complete top-surface coverage, extending deeper into the porous scaffold. The increased film thickness is caused by a higher number of ALD cycles. The conformal nature of the coating is well preserved despite the higher layer volume, confirming that the ALD process maintains its self-limiting growth behavior and effective precursor infiltration even at advanced deposition stages. No apparent cracks or delamination are visible, which is critical for the structural integrity and optoelectronic performance of nanowire-based tandem solar cells.

Figure 1c shows an AZO layer of increased thickness compared to previous samples. The film remains conformal and continuous along the nanowire scaffold, confirming the trend of uniform layer growth with increasing deposition time. This behavior is consistent with the self-limiting mechanism of the ALD process on high-aspect-ratio structures.

However, there are specific locations in the sample where the AZO overgrowth dramatically alters the nanowire topology; one of these is shown in Figure 2. Here, the ALD-deposited AZO clogged the interwire voids and formed a pronounced “match-head” cap atop individual silicon nanowires. This excessive tip buildup bridges adjacent wires, sealing the scaffold’s porosity and preventing uniform precursor access to deeper regions. Such bulbous capping is detrimental, as it hinders sidewall coverage, disrupts electrical continuity along the wire length, and may introduce mechanical stress or delamination at the AZO/SiNW interface.

Figure 2.

SEM micrograph in high magnification showing local overgrowth of AZO(ALD)-2 layer deposited on substrate consisting of SiNWs etched in 20 s.

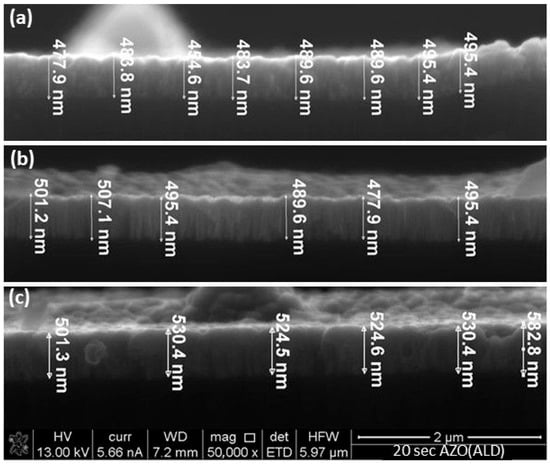

To assess the true thickness of the AZO thin film independently of the underlying silicon nanowire (SiNW) height, a systematic height-profiling analysis on cross-sectional SEM images was performed. After acquiring high-magnification (×50,000) SEM micrographs of each sample (AZO(ALD)-1 in Figure 3a, AZO(ALD)-2 in Figure 3b, AZO(ALD)-3) in Figure 3c), an image analysis software was used to measure the distance from the bottom of SiNW to the outermost AZO surface at multiple locations along the wire array. This approach aids in the AZO contribution by referencing all measurements to an identical height level defined by the bare SiNWs.

Figure 3.

Cross-sectional SEM image of (a) AZO(ALD)-1-, (b) AZO(ALD)-2-, and (c) AZO(ALD)-3-coated silicon nanowires with overlaid markers indicating SiNW bottom and outer AZO surface, used for film thickness measurement.

These values shows relationship between cycle count and film thickness. However, the increased scatter at higher thicknesses reflects the onset of “match-head” overgrowth and surface roughening, as indicated by the larger standard deviation. Ultimately, this approximate height-profiling approach offers a practical, image-based quantification of AZO growth on complex nanostructured substrates, and the average SiNW/AZO structure heights are summarized in Table 3.

Table 3.

Average SiNW/AZO structure heights obtained from SEM height profiling.

The measured average heights of the SiNW/AZO structures, as determined by SEM height profiling, demonstrate a clear increase in total feature height with higher ALD cycle counts. Sample AZO(ALD)-1 exhibits an average height of 464 nm, reflecting a relatively thin and conformal AZO overlayer. AZO(ALD)-2 raises the average height to 481 nm, indicating continued but controlled film growth without significant tip overgrowth. In contrast, AZO-3 shows a pronounced jump to 560 nm, corroborating the SEM observations of frequent “match-head” caps and non-uniform accumulation at the nanowire tips.

These results highlight the trade-off between achieving sufficient AZO thickness for electrical conductivity and maintaining conformal coverage within the nanowire forest. While moderate cycle numbers yield uniform coatings with minimal tip bulking, excessive cycles lead to pore occlusion and tip overgrowth, which can compromise charge transport pathways and introduce mechanical stress. Optimizing ALD parameters to balance thickness against conformality will therefore be critical for the development of efficient, nanostructured tandem solar cells.

Ultimately, this height-profiling methodology provides a reliable, image-based quantification of AZO layer growth on complex nanostructured substrates and underscores the need to balance thickness against conformality for optimal device performance.

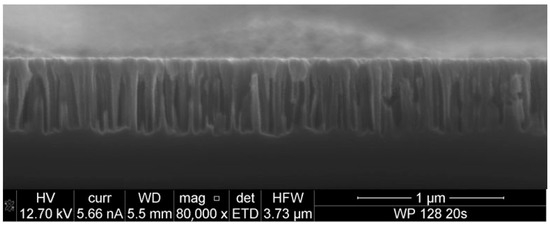

3.1.2. AZO Layer Deposited Using MS Method

In addition to the atomic layer deposition of AZO films, we extended our study to include magnetron sputtering as an alternative deposition technique. While ALD offers unrivaled conformality and thickness control on high-aspect-ratio nanostructures, its inherently low growth rate and complex precursor chemistry can limit throughput and increase process cost. Magnetron sputtering, by contrast, provides higher deposition rates, simpler precursor handling, and proven scalability in industrial thin-film manufacturing. Moreover, the distinct energy and angular distribution of sputtered species can induce different microstructural features—such as columnar grain growth and enhanced optical scattering—that may prove advantageous for light trapping and charge extraction in tandem photovoltaic architectures. By comparing AZO layers grown by both ALD and magnetron sputtering on identical silicon nanowire scaffolds, we aim to elucidate how the deposition method influences film conformality, electrical conductivity, and interfacial quality, thereby informing optimal process selection for high-performance perovskite/silicon tandem solar cells. Cross-sectional SEM analysis at a 25,000× magnification of samples coated by magnetron sputtering reveals a markedly different coverage morphology compared to ALD-grown films. The results are presented in Figure 4.

Figure 4.

SEM micrograph showing (a) AZO(MS)-1 and (b) AZO(MS)-2 layers deposited on substrate consisting of SiNWs etched in 20 s.

The sputtered AZO layer predominantly accumulates at the nanowire tips, forming partial caps while leaving significant gaps along the sidewalls. This non-conformal “line-of-sight” deposition is characterized by shadowing effects and reduced precursor penetration into the porous scaffold. Voids and uncovered regions observed in the lower half of the nanowires suggest that electrical continuity and charge recombination pathways may be compromised. These observations underscore the trade-off inherent in sputtering: while higher deposition rates and industrial scalability are achievable, the directional nature of the process limits uniform film growth on high-aspect-ratio structures and necessitates further optimization—such as substrate rotation or oblique angle sputtering—to improve conformality. To highlight the preferential accumulation of AZO at the nanowire tips, high-magnification SEM images were captured (Figure 5).

Figure 5.

SEM micrograph in high magnification showing overall overgrowth of AZO(MS)-2 layer deposited on substrate consisting of SiNWs etched in 20 s.

Cross-sectional SEM (80,000×, HFW 3.73 µm) of a magnetron-sputtered AZO film on vertically aligned SiNWs reveals a pronounced “cap” of 50–100 nm thickness at the wire apexes, while the sidewalls would seem undercoated, and the lower forest is essentially bare. These results underscore the necessity of adapting sputtering parameters—e.g., substrate rotation or oblique angle deposition—to improve AZO coverage on high-aspect-ratio nanostructures.

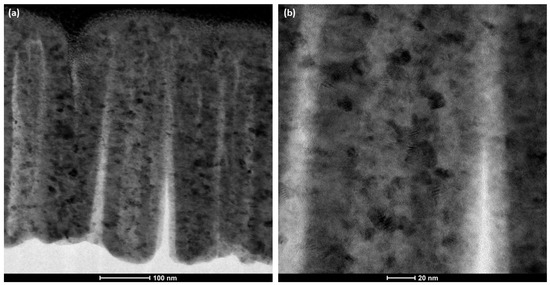

3.2. TEM Analysis of AZO Thin Films on Silicon Nanowire Substrates

To comprehensively evaluate the thickness uniformity of the AZO coating along the full length of the silicon nanowires, transmission electron microscopy (TEM) was employed as a complementary technique to SEM. Whereas high-resolution SEM imaging offers detailed surface and cross-sectional morphology, TEM enables the direct visualization of the AZO/SiNW interface at the nanoscale, providing precise measurements of film continuity, crystallinity, and potential interfacial defects throughout the entire wire height.

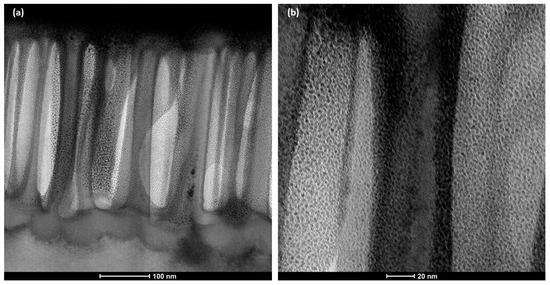

The bright-field TEM micrographs in Figure 6 depict the AZO(ALD)-1 sample—an ALD-deposited Al-doped ZnO layer on silicon nanowire arrays.

Figure 6.

A BF-TEM micrograph of the AZO(ALD)-1 layer deposited on a substrate consisting of wires etched in 20 s. (a) 81,000× magnification; (b) 220,000× magnification.

Figure 6a shows the AZO film which appears as a uniform, conformal shell enveloping each nanowire, with an average thickness of ~40 nm and no observable voids at the interface. Figure 6b offers a closer view of the AZO nanostructure: fine, polycrystalline ZnO grains (~5–10 nm in diameter) are visible, interspersed with darker contrast regions that likely correspond to Al-rich domains or slight amorphous intergranular material. The sharp AZO/Si interface and the homogeneous grain dispersion confirm the effectiveness of the ALD process in achieving continuous coverage and a controlled microstructure—even along high-aspect-ratio SiNWs—critical for ensuring efficient charge transport and minimal recombination losses in tandem solar devices.

The high-resolution TEM (HRTEM) image in Figure 7 provides atomic-scale insight beyond the bright-field overview, revealing the crystallographic quality and defect structure of the ALD-grown AZO layer. Distinct lattice fringes with interplanar spacings of ~0.26 nm are clearly resolved, corresponding to the (002) planes of wurtzite ZnO, which confirms the preferential c-axis orientation of the ZnO crystallites. The uniform fringe contrast across the region indicates consistently sized grains (~5–10 nm) without large amorphous pockets, corroborating the grain size distribution inferred from lower-magnification TEM. At the AZO/Si interface (lower right), no transitional amorphous layer is observed, demonstrating a sharp, defect-free boundary crucial for efficient charge transfer. Occasional fringe disruptions suggest a low density of point defects or dislocations—likely associated with aluminum incorporation—which can modulate carrier concentration without significantly compromising crystal integrity. Overall, this HRTEM analysis validates that the ALD process yields a highly crystalline, uniformly doped AZO layer with excellent interfacial quality.

Figure 7.

An HRTEM micrograph of the AZO(ALD)-1 layer deposited on a substrate consisting of wires etched in 20 s.

STEM–HAADF and the corresponding EDS elemental maps (Si, Zn, Al) provide a definitive, spatially resolved confirmation of both the AZO shell morphology and its compositional uniformity, extending the insights obtained from SEM and bright-field/TEM imaging. In the HAADF image (Figure 8), the high-Z contrast clearly delineates the Si nanowire cores (brightest) from the surrounding AZO coating (intermediate gray) and the vacuum (dark). The Si map (green) precisely traces the nanowire positions, confirming intact wire geometry and revealing that the AZO film does not penetrate between the closely spaced wires. The Zn map (purple) shows a continuous, conformal shell enveloping each nanowire with nearly constant thickness, corroborating the ALD-driven uniformity inferred from TEM thickness profiles. Meanwhile, the Al map (yellow-green) demonstrates homogeneous dopant incorporation throughout the ZnO matrix, without observable clustering or segregation at the interface or within grain boundaries. Together, these data validate that the ALD process produces a uniform, doped ZnO layer on high-aspect-ratio SiNW scaffolds, with a sharp AZO/Si boundary and consistent elemental distribution.

Figure 8.

STEM (SI EDS–HAADF) micrograph of AZO(ALD)-1 layer deposited on substrate consisting of wires etched in 20 s.

An identical TEM characterization workflow was applied to AZO layers deposited by magnetron sputtering, facilitating a direct nanoscale comparison with ALD-grown films. This side-by-side analysis enables the evaluation of coating conformality, grain structure, interface quality, and dopant distribution arising from the distinct deposition mechanisms.

The bright-field TEM images of the magnetron-sputtered AZO layer on SiNWs reveal a markedly different microstructure compared to the ALD sample. In Figure 9a the AZO coating appears as an irregular, discontinuous shell: thick caps at the wire tips contrast with sparse, patchy coverage along the sidewalls, leaving voids at the wire bases. Figure 9b shows that the sputtered film comprises larger, loosely packed ZnO grains (∼10–20 nm) with variable contrast—indicative of uneven Al incorporation and possible amorphous intergranular regions. The lack of a uniform, conformal shell and the presence of grain boundary gaps underscore the limited sidewall penetration characteristic of line-of-sight sputtering, which may hinder charge transport and recombination uniformity in the tandem cell architecture.

Figure 9.

A BF-TEM micrograph of the AZO(MS)-2 layer deposited on a substrate consisting of wires etched in 20 s. (a) 81,000× magnification; (b) 220,000× magnification.

The high-resolution TEM micrograph (Figure 10) of the magnetron-sputtered AZO on SiNWs reveals the fine details underlying the patchy coating observed in lower-magnification images. Here, the ZnO grains appear significantly larger (~10–20 nm) and more irregularly shaped than in the ALD sample, with poorly defined lattice fringes and regions of diffuse contrast that suggest the presence of amorphous or defect-rich intergranular material. Grain boundaries are prominent and unevenly distributed, correlating with the discontinuous sidewall coverage and voids seen in bright-field TEM. The uneven contrast across adjacent nanowire sidewalls confirms that sputtered species did not uniformly infiltrate the scaffold, instead aggregating into isolated columns. This image thus substantiates that magnetron sputtering produces a heterogeneous microstructure.

Figure 10.

An HRTEM micrograph of the AZO(MS)-2 layer deposited on a substrate consisting of wires etched in 20 s.

While magnetron sputtering exhibits limitations in conformally coating highly porous silicon nanowire scaffolds—manifesting as tip-dominant caps and incomplete sidewall coverage—this technique nonetheless offers advantages such as high deposition rates, industrial scalability, and distinct columnar microstructures that could be leveraged for enhanced light scattering or patterned coatings. The observed non-uniformity is therefore not an inherent flaw of sputtering itself but rather a consequence of the challenging high-aspect-ratio geometry; for such applications, atomic layer deposition remains the preferred method for ensuring complete, uniform coverage. However, sputtered AZO films may still prove valuable for complementary roles—such as surface texturing, seed layers for subsequent ALD, or in devices with less demanding conformality requirements.

3.3. Evaluation of AZO Layer Thickness

The accurate determination of AZO layer thickness is essential for optimizing the balance between electrical conductivity and optical transparency in perovskite/silicon tandem solar cells. Film thickness directly influences resistance—thicker films generally reduce resistive losses—and free carrier absorption, which can impair light transmission to the silicon subcell.

Film thickness was measured ex situ by the step height method using a Taylor Hobson CCI Lite optical profilometer. These measurements enable a direct comparison of conformality and growth rate between the two deposition methods and inform the selection of the process parameters (ALD cycle count or sputtering duration) needed to achieve the optimal compromise between optical and electrical performance in tandem device architectures. The results are presented in Table 4.

Table 4.

Thickness of AZO layers obtained by profilometry measurements.

The profilometry results summarized in Table 4 demonstrate the precise, cycle-dependent control of AZO film thickness via ALD, with nominal values of 40 nm (AZO(ALD)-1), 65 nm (AZO(ALD)-2), and 120 nm (AZO(ALD)-3). In contrast, magnetron sputtering yields thicker baseline coatings—100 nm for AZO(MS)-1 and 120 nm for AZO(MS)-2—with less granular control over intermediate thicknesses. Notably, both ALD and sputtering can achieve the target ~120 nm film (AZO(ALD)-3 and AZO(MS)-2), but only ALD offers stepwise fine tuning across a wide thickness range. These findings underline that ALD is better suited when precise thickness adjustment is required, whereas sputtering provides a faster route to moderate-to-thick films when sub-50 nm resolution is not critical.

3.4. Optical Characterization of AZO Layers

In perovskite/silicon tandem solar cells, the optical properties of the intermediate recombination layer are critical: its visible and near-infrared transmission directly governs the fraction of incident sunlight that can penetrate into the underlying silicon subcell. A highly transparent recombination layer maximizes photocurrent in the bottom junction, boosting overall tandem efficiency. However, achieving both high electrical conductivity and excellent optical transmission in a single thin film is inherently challenging. Conductive oxide layers such as AZO must incorporate sufficient free carrier density to facilitate charge transport, yet excessive free carrier absorption and plasma reflection in the near-IR range can severely reduce transmittance. Balancing these competing demands—doping level, film thickness, and microstructure—thus represents a key materials engineering hurdle in the design of efficient recombination layers for perovskite/silicon tandems.

Transmission spectra were acquired with a Lambda 950S Perkin Elmer (Shelton, CT, USA) spectrometer halogen–deuterium light source with an integrating sphere in the wavelength range 300–1200 nm (ALD-deposited layers) and an Ocean Optics QE65000 spectrophotometer (Dunedin, FL, USA) coupled to a DH-BAL 2000 halogen–deuterium light source (Dunedin, FL, USA) over the 250–1000 nm wavelength range (MS-deposited layers).

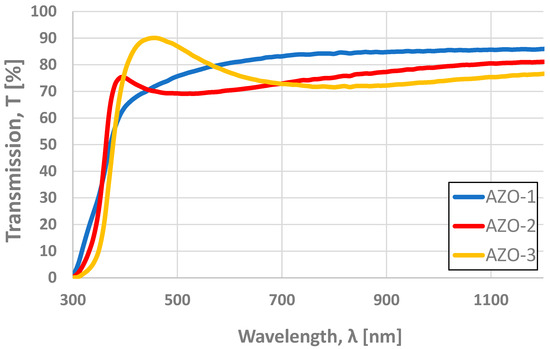

The optical transmission spectra of AZO films deposited by the ALD method on microscope glass (Figure 11) exhibit pronounced thickness-dependent behavior that is critical for their function as recombination layers in perovskite/silicon tandem solar cells. The thinnest film, AZO(ALD)-1, achieves the highest broadband transparency, rising sharply from near zero at the ultraviolet cutoff to approximately 75% at 500 nm and plateauing between 82% and 86% across the 600–1100 nm region. Such high near-infrared transmittance is essential to ensure that sub-bandgap photons efficiently reach the silicon bottom cell. In contrast, the intermediate-thickness sample AZO(ALD)-2 displays a modestly reduced minimum transmission of ~69% at 500 nm and stabilizes around 76–80% in the near-IR range, reflecting increased free carrier absorption and interference effects. The thickest film, AZO-3, features a pronounced interference maximum near 450 nm (~90%), followed by a transmission dip to ~68% at 600 nm and a recovery to ~75–78% in the NIR range. While this visible-range enhancement is beneficial, the concomitant reduction in longer-wavelength transmission may constrain the photocurrent of the silicon subcell. These results underscore that, although thicker AZO layers can improve electrical conductivity, they also introduce optical losses that must be carefully balanced to maximize overall tandem device efficiency.

Figure 11.

Spectral dependence of total transmission for ALD-deposited AZO films of varying thicknesses on glass substrates.

Similarly, the optical transmission of AZO films deposited by magnetron sputtering on glass substrates was evaluated under identical measurement conditions, enabling a direct comparison of the wavelength-dependent transparency and interference behavior imparted by each deposition technique.

The transmission spectra of magnetron-sputtered AZO films (Figure 12) exhibit a different optical signature compared to their ALD-deposited counterparts. Both the AZO(MS)-1 and AZO(MS)-2 samples show a sharp UV cutoff near 350 nm, but the interference peak around 450–500 nm is significantly more pronounced—reaching over 90% for the thicker AZO(MS)-2 film—than in the ALD layers. Beyond this visible-range maximum, the sputtered films settle to a steady 80–85% transmission in the near-IR range (700–1000 nm). This behavior reflects the columnar microstructure and greater thickness of the MS coatings, which enhance constructive interference in the visible band yet incur modest additional free carrier absorption at longer wavelengths.

Figure 12.

Spectral dependence of total transmission for AZO films deposited by magnetron sputtering method with varying thicknesses on glass substrates.

Notably, the transmission spectrum of the ≈120 nm AZO(ALD)-3 film (Figure 11) closely mirrors that of the ≈120 nm AZO(MS)-2 coating (Figure 12), with both exhibiting a pronounced interference maximum around 450–500 nm and settling to comparable near-IR transparencies (~80–85%), underscoring that ALD-grown layers of similar thickness can achieve optical performance on par with magnetron-sputtered films.

3.5. Electrical Characterization of AZO Layers

To evaluate the charge transport properties of the AZO recombination layers, we conducted electrical characterization on films deposited concurrently with those used for optical measurements.

Surface resistance was measured using a Jandel Engineering four-point probe head (Jandel Engineering Ltd., Buzzard, UK) with 1 mm spaced tungsten carbide tips, coupled to a Keithley 2611A source measure unit (Keithley Instruments Inc., Solon, OH, USA). The outer probes supplied the current, while the inner probes recorded the voltage drop.

Four-point probe measurements were performed on AZO coatings deposited on SiO2 dielectric substrates to determine surface resistance as functions of film thickness and deposition method. This electrical parameter is critical for assessing the trade-off between transparency and conductivity in recombination layers: high carrier density and mobility are required to minimize resistive losses, while excessively thick or heavily doped films can compromise optical transmission. By comparing ALD and magnetron-sputtered AZO samples under identical conditions, we establish a comprehensive view of how deposition technique and film thickness influence the electrical performance of tandem solar cell interfaces. The results are presented in Table 5.

Table 5.

Surface resistance of AZO layers on dielectric SiO2 substrates.

The surface resistance data reveal a clear dependence of electrical conductivity on both film thickness and deposition method. For the ALD-grown layers, increasing the cycle count from AZO(ALD)-1 to AZO(ALD)-3 reduces the surface resistance from 1150 Ω/□ to 245 Ω/□, consistent with thicker films supporting higher carrier densities and more continuous conduction pathways. Magnetron-sputtered samples fall between the ALD extremes: AZO(MS)-1 (648 Ω/□) outperforms the thinnest ALD film but underperforms AZO(ALD)-2, whereas AZO(MS)-2 (317 Ω/□) achieves conductivity on par with the thickest ALD coating. Notably, both AZO(MS)-2 and AZO(ALD)-3 share an estimated thickness of approximately 120 nm and exhibit similar electrical parameters, underscoring that similar layer dimensions yield comparable surface resistances regardless of deposition technique. These trends highlight the classic trade-off in recombination layer design: thicker or more heavily doped films improve electrical transport but can introduce optical penalties. The comparable performance of AZO(MS)-2 and AZO(ALD)-3 suggests that sputtering can be a viable route to low-resistance layers—albeit with the conformality limitations noted earlier—while ALD offers superior thickness control and uniformity at the expense of longer processing times.

3.6. A Summary of Optical and Electrical Properties as a Function of AZO Layer Thickness and Deposition Method

To enable a direct comparison of optoelectronic performance across deposition methods and film thicknesses, Table 6 compiles the near-infrared transmission (800–1200 nm), measured layer thickness, and four-point probe surface resistance for all AZO samples.

Table 6.

Summarized values of transmission (800–1200 nm), thickness, and surface resistance of AZO layers.

Table 6 summarizes the key optoelectronic properties of AZO films deposited by ALD and magnetron sputtering. For each sample, the near-infrared transmission range (800–1200 nm) is reported alongside the measured layer thickness and four-point probe surface resistance. The data reveal that thinner ALD films (40–65 nm) offer superior NIR transparency (75–86%) but exhibit higher surface resistance (276–1150 Ω/□), whereas thicker coatings (~120 nm) achieve lower resistances (245–317 Ω/□) at the expense of modestly reduced transmission (72–86%). Magnetron-sputtered layers display comparable transmission and resistance to their ALD counterparts at similar thicknesses, highlighting that both deposition methods can be tuned to balance optical and electrical performance for tandem solar cell recombination layers.

4. Discussion

The comparative evaluation of AZO layers deposited by ALD and magnetron sputtering on silicon nanowire (SiNW) scaffolds reveals a nuanced interplay between deposition method, film morphology, and optoelectronic performance. This relationship is central to the design of efficient perovskite/Si tandem cells. SEM investigations (Figure 1, Figure 2 and Figure 3) show that ALD yields uniformly conformal shells along the wire length—even at 120 nm thickness—whereas magnetron sputtering (Figure 4 and Figure 5) produces pronounced “match-head” caps and undercoated sidewalls. Height profiling (Table 3 and Table 4) quantifies the following: ALD films grow from an average 464 nm total structure height at 40 nm overlayer to 560 nm at 120 nm, with minimal void formation except in localized overgrowth zones. In contrast, sputtered films of comparable thickness (100–120 nm) exhibit non-uniform coverage, leaving voids that may disrupt charge percolation pathways.

Optically (Figure 11 and Figure 12), the thinnest ALD sample achieves 84–86% transmission in the 800–1200 nm window, dropping to 72–77% at 120 nm (AZO-3), while sputtered films maintain 83–89% transmission over the same range. The pronounced interference peaks around 450–500 nm in both AZO(ALD)-3 and AZO(MS)-2 underscore that sufficiently thick films—regardless of method—can enable equivalent light management properties. Electrically (Table 5), surface resistance falls sharply from 1150 Ω/□ at 40 nm to 245 Ω/□ at 120 nm in ALD films; sputtered layers bracket these values at 648 Ω/□ (100 nm) and 317 Ω/□ (120 nm). The direct correspondence between ≈120 nm ALD and sputtered films (245 vs. 317 Ω/□) confirms that similar thicknesses yield comparable conductivity, even though their microstructures differ markedly.

Taken together, these data support several key conclusions. First, ALD is uniquely able to produce defect-free, conformal AZO coatings that minimize interfacial trap sites and ensure continuous recombination pathways—critical for avoiding resistive losses and shunting in tandem architectures. Second, magnetron sputtering, while less conformal on high-aspect-ratio SiNWs, can still deliver low-resistance, highly transparent films when thickness is matched, suggesting a role in hybrid strategies (e.g., as a rapid seed layer prior to ALD overcoat or in planar regions of the device). Third, the clear thickness–performance correlations evident in both optical (transmission vs. free carrier absorption) and electrical (resistance vs. carrier density) metrics point to an optimal AZO window around 100–120 nm for balancing transparency and conductivity.

Looking forward, integrating these AZO variants into fully processed tandem cells will be essential to translate material-level advantages into device efficiency gains. Future work should explore dynamic sputtering geometries (e.g., substrate rotation, glancing incidence). Dopant co-incorporation strategies (e.g., Ga or In) and post-deposition annealing regimes should also be investigated to refine microstructure, enhance dopant activation, and reduce resistive and optical losses. Such efforts will be critical for realizing AZO-based recombination layers that combine the throughput advantages of sputtering with the conformality and uniformity intrinsic to ALD.

5. Conclusions

In this work, we systematically compared AZO films deposited by atomic layer deposition (ALD) and magnetron sputtering (MS) on silicon nanowire scaffolds to evaluate their suitability as recombination layers in perovskite/Si tandem solar cells. SEM and TEM analyses demonstrated that ALD produces fully conformal coatings along the entire nanowire length, whereas sputtering results in tip-capping and incomplete sidewall coverage. Optically, both 120 nm ALD and MS films exhibited similar interference maxima around 450–500 nm and maintained 72–89% transmission in the 800–1200 nm range, while thinner ALD films achieved higher near-infrared transparency. Electrically, surface resistance decreased from 1150 Ω/□ at 40 nm to 245 Ω/□ at 120 nm for ALD and reached 317 Ω/□ for 120 nm MS films. These results highlight that ALD offers superior conformality and uniformity, whereas sputtering enables faster, scalable deposition with comparable optoelectronic performance at matched thickness. Future work will focus on integrating these AZO layers into complete tandem devices and exploring advanced deposition geometries, dopant incorporation strategies, and post-deposition treatments to optimize both coverage and conductivity.

Author Contributions

Conceptualization, G.K.-M. and K.D.; methodology, G.K.-M., M.S., M.M.S., M.K., U.W., A.S., Ł.M. and K.D.; validation, G.K.-M., M.S., M.M.S. and K.D.; formal analysis, G.K.-M.; investigation, G.K.-M., M.S., M.M.S., M.K., U.W., A.S., Ł.M. and K.D.; data curation, G.K.-M.; writing—original draft preparation, G.K.-M., M.S., M.M.S. and M.K.; writing—review and editing, K.D.; visualization, G.K.-M.; supervision, K.D.; project administration, G.K.-M.; funding acquisition, K.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by IMMS PAS as a statutory work. The SEM and TEM examinations were performed in the Accredited Testing Laboratories at the IMMS PAS (ILAC-MRA). Silver nitrate was acquired (at no cost) from Helioenergia Ltd., Czerwionka-Leszczyny, Poland (Silvercon-Silver Smart Solutions).

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| 2T | Two-Terminal Architecture |

| ALD | Atomic Layer Deposition |

| AZO | Aluminum-Doped Zinc Oxide |

| ITO | Indium–Tin Oxide |

| MAE | Metal-Assisted Etching |

| MS | Magnetron Sputtering |

| SEM | Scanning Electron Microscopy |

| SiNWs | Silicon Nanowires |

| STEM | Scanning Transmission Electron Microscopy |

| TCO | Transparent Conductive Oxide |

| TEM | Transmission Electron Microscopy |

References

- Snapshot of Global PV Markets 2025, IEA PVPS, Task 1 Strategic PV Analysis and Outreach, April 2025. Available online: https://iea-pvps.org/wp-content/uploads/2025/04/Snapshot-of-Global-PV-Markets_2025.pdf (accessed on 1 July 2025).

- Available online: https://www.nrel.gov/pv/cell-efficiency.html (accessed on 30 May 2025).

- Werner, J.; Niesen, B.; Ballif, C. Perovskite/Silicon Tandem Solar Cells: Marriage of Convenience or True Love Story?—An Overview. Adv. Mater. Interfaces 2018, 5, 1700731. [Google Scholar] [CrossRef]

- Anaya, M.; Lozano, G.; Calvo, M.E.; Míguez, H. ABX3 Perovskites for Tandem Solar Cells. Joule 2017, 1, 769. [Google Scholar] [CrossRef]

- Jošt, M.; Kegelmann, L.; Korte, L.; Albrecht, S. Monolithic Perovskite Tandem Solar Cells: A Review of the Present Status and Advanced Characterization Methods Toward 30% Efficiency. Adv. Energy Mater. 2020, 10, 1904102. [Google Scholar] [CrossRef]

- Kulesza, G.; Panek, P.; Zięba, P. Silicon solar cells efficiency improvement by the wet chemical texturization in the HF/HNO3/diluent solution. Arch. Metall. Mater. 2013, 58, 291–295. [Google Scholar] [CrossRef]

- Kulesza, G.; Panek, P.; Zięba, P. Time efficient texturization of multicrystalline silicon in the HF/HNO3 solutions and its effect on optoelectronic parameters of solar cells. Arch. Civ. Mech. 2014, 14, 595–601. [Google Scholar] [CrossRef]

- Kulesza-Matlak, G.; Gawlińska, K.; Starowicz, Z.; Sypień, A.; Drabczyk, K.; Drabczyk, B.; Lipiński, M.; Zięba, P. Black silicon obtained in two-step short wet etching as a texture for silicon solar cells—Surface microstructure and optical properties studies. Arch. Metall. Mater. 2018, 63, 1009. [Google Scholar] [CrossRef]

- Sahli, F.; Werner, J.; Kamino, B.A.; Bräuninger, M.; Monnard, R.; Paviet-Salomon, B.; Barraud, L.; Ding, L.; Leon, J.J.D.; Sacchetto, D.; et al. Fully textured monolithic perovskite/silicon tandem solar cells with 25.2% power conversion efficiency. Nat. Mater. 2018, 17, 820–826. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Yu, Z.J.; Manzoor, S.; Wang, S.; Weigand, W.; Yu, Z.; Yang, G.; Ni, Z.; Dai, X.; Holman, Z.C.; et al. Blade-coated perovskites on textured silicon for 26%-efficient monolithic perovskite/silicon tandem solar cells. Joule 2020, 4, 850–864. [Google Scholar] [CrossRef]

- Hou, Y.; Aydin, E.; De Bastiani, M.; Xiao, C.; Isikgor, F.H.; Xue, D.-J.; Chen, B.; Chen, H.; Bahrami, B.; Chowdhury, A.H.; et al. Efficient tandem solar cells with solution-processed perovskite on textured crystalline silicon. Science 2020, 367, 1135–1140. [Google Scholar] [CrossRef]

- Lee, M.M.; Teuscher, J.; Miyasaka, T.; Murakami, T.N.; Snaith, H.J. Efficient Hybrid Solar Cells Based on Meso-Superstructured Organometal Halide Perovskites. Science 2012, 338, 643–647. [Google Scholar] [CrossRef]

- Leijtens, T.; Eperon, G.E.; Pathak, S.; Abate, A.; Lee, M.M.; Snaith, H.J. Overcoming ultraviolet light instability of sensitized TiO2 with meso-superstructured organometal tri-halide perovskite solar cells. Nat. Commun. 2013, 4, 2885. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Q.; Sheng, X.; Shi, B.; Feng, X.; Xu, T. Nickel-Cathoded Perovskite Solar Cells. J. Phys. Chem. C 2014, 118, 25878–25883. [Google Scholar] [CrossRef]

- Kulesza-Matlak, G.; Szindler, M.; Szindlrer, M.M.; Sypień, A.; Major, Ł.; Drabczyk, K. Morphology of an ITO recombination layer deposited on a silicon wire texture for potential silicon/perovskite tandem solar cell applications. Opto Electron. Rev. 2023, 31, e148222. [Google Scholar] [CrossRef]

- Leijtens, T.; Bush, K.A.; Prasanna, R.; McGehee, M.D. Opportunities and challenges for tandem solar cells using metal halide perovskite semiconductors. Nat. Energy 2018, 3, 828–838. [Google Scholar] [CrossRef]

- Hu, Y.; Song, L.; Chen, Y.; Huang, W. Two-Terminal Perovskites Tandem Solar Cells: RecentAdvances and Perspectives. Solar RRL 2019, 3, 1900080. [Google Scholar] [CrossRef]

- Eperon, G.E.; Hörantner, M.T.; Snaith, H.J. Metal halide perovskite tandem and multiple-junction photovoltaics. Nat. Rev. Chem. 2017, 1, 0095. [Google Scholar] [CrossRef]

- Wang, H.; Lin, W.; Wang, Y.; Qiu, K.; Yu, X. Perovskite/silicon tandem solar cells: A comprehensive review of recent strategies and progress. Semicond. Sci. Technol. 2025, 40, 023001. [Google Scholar] [CrossRef]

- Liu, H.; Zhu, Y.; Xiong, W.; Yang, Y.; Li, S.; Bai, S. Transparent Conductive Oxide Films and Their Applications in Silicon Heterojunction and Perovskite/Silicon Tandem Photovoltaics. ACS Appl. Energy Mater. 2025, 8, 4032–4047. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, X.; Lim, E.L.; Shi, L.; Wei, Z. Advancing all-perovskite two-terminal tandem solar cells: Optimization of wide- and narrow-bandgap perovskites and interconnecting layers. Energy Environ. Sci. 2025, 18, 3060–3084. [Google Scholar] [CrossRef]

- Tanko, K.T.; Tian, Z.; Raga, S.; Xie, H.; Katz, E.A.; Lira-Cantu, M. Stability and reliability of perovskite photovoltaics: Are we there yet? MRS Bull. 2025, 50, 512–525. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Q.; Zhou, L.; Zhang, J.; Chen, D.; Zhu, W.; Xi, H.; Zhang, J.; Zhang, C.; Hao, Y. Recent Progress of Wide Bandgap Perovskites towards Two-Terminal Perovskite/Silicon Tandem Solar Cells. Nanomaterials 2024, 14, 202. [Google Scholar] [CrossRef]

- Lin, Y.; Yang, W.; Gu, H.; Du, F.; Liao, J.; Yu, D.; Xia, J.; Wang, H.; Yang, S.; Fang, G.; et al. Transparent Recombination Layers Design and Rational Characterizations for Efficient Two-Terminal Perovskite-Based Tandem Solar Cells. Adv. Mater. 2024, 36, 2405684. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Berry, J.J.; Zhang, F. Perovskite/Silicon Tandem Solar Cells: Insights and Outlooks. ACS Energy Lett. 2024, 9, 1305–1330. [Google Scholar] [CrossRef]

- Li, Y.; Yao, D.S.; Long, F.; Zhang, G.Z.; Yu, F. Interfacial engineering for efficient and stable two-terminal perovskite-based tandem solar cells. Rare Met. 2024, 43, 5573–5624. [Google Scholar] [CrossRef]

- Kulesza-Matlak, G.; Szindler, M.; Szindlrer, M.M.; Sypień, A.; Major, Ł.; Drabczyk, K. Deposition of SnO2 as a functional layer on a porous silicon substrate for potential tandem solar cell application. Opto Electron. Rev. 2025, 33, e152685. [Google Scholar] [CrossRef]

- Cheng, Y.; Liu, X.; Guan, Z.; Li, M.; Zeng, Z.; Li, H.W.; Tsang, S.W.; Aberle, A.G.; Lin, F. Revealing the Degradation and Self-Healing Mechanisms in Perovskite Solar Cells by Sub-Bandgap External Quantum Efficiency Spectroscopy. Adv. Mater. 2020, 33, 2006170. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.; Zeng, Z.; Liu, T.; Wang, Y.; Rodríguez-Gallegos, C.D.; Liu, H.; Liu, X.; Thway, M.; Khup, D.; Khaing, A.M.; et al. Amorphous CdO-In2O3 Electrode for Perovskite-Based Bifacial and Tandem Photovoltaic Technologies with High Energy Production. Solar RRL 2022, 6, 2100809. [Google Scholar] [CrossRef]

- Sun, L.; Grant, J.T.; Jones, J.G.; Murphy, N.R. Tailoring electrical and optical properties of Al-doped ZnO thin films grown at room temperature by reactive magnetron co-sputtering: From band gap to near infrared. Opt. Mater. 2018, 84, 146–157. [Google Scholar] [CrossRef]

- Nomoto, J.; Hirano, T.; Miyata, T.; Minami, T. Preparation of Al-doped ZnO transparent electrodes suitable for thin-film solar cell applications by various types of magnetron sputtering depositions. Thin Solid Films 2011, 520, 1400–1406. [Google Scholar] [CrossRef]

- Yamamoto, N.; Makino, H.; Osone, S.; Ujihara, A.; Ito, T.; Hokari, H.; Maruyama, T.; Yamamoto, T. Development of Ga-doped ZnO transparent electrodes for liquid crystal display panels. Thin Solid Films 2012, 520, 4131–4138. [Google Scholar] [CrossRef]

- Kim, D.S.; Park, J.H.; Lee, S.J.; Ahn, K.J.; Lee, M.S.; Ham, M.H.; Lee, W.; Myoung, J.M. Effects of oxygen concentration on the properties of Al-doped ZnO transparent conductive films deposited by pulsed DC magnetron sputtering. Mat. Sci. Semicon. Proc. 2013, 16, 997–1001. [Google Scholar] [CrossRef]

- Posadowski, W.; Wiatrowski, A.; Domaradzki, J.; Mazur, M. Selected properties of AlxZnyO thin films prepared by reactive pulsed magnetron sputtering using a two-element Zn/Al target. Beilstein J. Nanotechnol. 2022, 13, 344–354. [Google Scholar] [CrossRef]

- Yang, L.; Xu, T.; Bai, Z.; Qin, S. Improved Open-Circuit Voltage of AZO/CsPbBr3/Carbon Structure Perovskite Solar Cells by an Al-Doped ZnO Electron Transport Layer. J. Phys. Chem. C 2023, 127, 7492–7500. [Google Scholar] [CrossRef]

- Kiliszkiewicz, M.; Domaradzki, J.; Posadowski, W.; Mazur, M.; Wiatrowski, A.; Dawidowski, W.; Mazur, P.; Wojcieszak, D.; Chodasewcz, P.; Bartczak, M. Effect of sputtering power and oxygen partial pressure on structural and opto-electronic properties of Al-doped ZnO transparent conducting oxides. Appl. Surf. Sci. 2024, 670, 160601. [Google Scholar] [CrossRef]

- Pan, Q.; Song, X. Al-doped ZnO films deposited by magnetron sputtering: Effect of sputtering parameters on the electrical and optical properties. Mater. Sci. Pol. 2017, 35, 374–381. [Google Scholar] [CrossRef][Green Version]

- G-Berasategui, E.; Zubizarreta, C.; Bayón, R.; Barriga, J.; Barros, R.; Martins, R.; Fortunato, E. Study of the optical, electrical and corrosion resistance properties of AZO layers deposited by DC pulsed magnetron sputtering. Surf. Coat. Technol. 2015, 271, 141–147. [Google Scholar] [CrossRef]

- Kim, K.H.; Kim, K.H.; Park, K.C.; Ma, D.Y. Structural, electrical and optical properties of aluminum doped zinc oxide films prepared by radio frequency magnetron sputtering. J. Appl. Phys. 1997, 81, 7764–7772. [Google Scholar] [CrossRef]

- Park, K.C.; Ma, D.Y.; Kim, K.H. The physical properties of Al-doped zinc oxide films prepared by RF magnetron sputtering. Thin Solid Films 1997, 305, 201–209. [Google Scholar] [CrossRef]

- Cebulla, R.; Wendt, R.; Ellmer, K. Al-doped zinc oxide films deposited by simultaneous rf and dc excitation of a magnetron plasma: Relationships between plasma parameters and structural and electrical film properties. J. Appl. Phys. 1998, 83, 1087–1095. [Google Scholar] [CrossRef]

- Jayaraj, M.K.; Antony, A.; Ramachandran, M. Transparent conducting zinc oxide thin film prepared by off-axis rf magnetron sputtering. Mater. Sci. 2002, 25, 227–230. [Google Scholar] [CrossRef]

- Agashe, C.; Kluth, O.; Schöpe, G.; Siekmann, H.; Hüpkes, J.; Rech, B. Optimization of the electrical properties of magnetron sputtered aluminum-doped zinc oxide films for opto-electronic applications. Thin Solid Films 2003, 442, 167–172. [Google Scholar] [CrossRef]

- Cai, Y.; Liu, W.; He, Q.; Zhang, Y.; Yu, T.; Sun, Y. Influence of negative ion resputtering on Al-doped ZnO thin films prepared by mid-frequency magnetron sputtering. Appl. Surf. Sci. 2010, 256, 1694–1697. [Google Scholar] [CrossRef]

- Tsukamoto, N.; Watanabe, D.; Saito, M.; Sato, Y.; Oka, N.; Shigesato, Y. In situ analyses on negative ions in the sputtering process to deposit Al-doped ZnO films. J. Vac. Sci. Technol. A 2010, 28, 846–850. [Google Scholar] [CrossRef]

- Nguyen, H.C.; Trinh, T.T.; Le, T.; Tran, C.V.; Tran, T.; Park, H.; Dao, V.A.; Yi, J. The mechanisms of negative oxygen ion formation from Al-doped ZnO target and the improvements in electrical and optical properties of thin films using off-axis dc magnetron sputtering at low temperature. Semicond. Sci. Tech. 2011, 26, 105022. [Google Scholar] [CrossRef]

- Kumar, B.R.; Rao, T.S. Effect of Aluminum concentration on structural and optical properties of DC reactive magnetron sputtered Zinc Aluminum Oxide thin films for transparent electrode applications. J. Phys. Conf. Ser. 2012, 390, 012032. [Google Scholar] [CrossRef]

- Bikowski, A.; Welzel, T.; Ellmer, K. The correlation between the radial distribution of high-energetic ions and the structural as well as electrical properties of magnetron sputtered ZnO:Al films. J. Appl. Phys. 2013, 114, 223716. [Google Scholar] [CrossRef]

- Sarma, B.K.; Rajkumar, P. Al-doped ZnO transparent conducting oxide with appealing electro-optical properties—Realization of indium free transparent conductors from sputtering targets with varying dopant concentrations. Mater. Today Commun. 2020, 23, 100870. [Google Scholar] [CrossRef]

- Malkomes, N.; Vergöhl, M.; Szyszka, B. Properties of aluminum-doped zinc oxide films deposited by high rate mid-frequency reactive magnetron sputtering. J. Vac. Sci. Technol. A 2001, 19, 414–419. [Google Scholar] [CrossRef]

- Gürbüz, O.; Kurt, İ.; Çalışkan, S.; Güner, S. Influence of Al concentration and annealing temperature on structural, optical, and electrical properties of Al co-doped ZnO thin films. Appl. Surf. Sci. 2015, 349, 549–560. [Google Scholar] [CrossRef]

- Gürbüz, O.; Güner, S. Role of annealing temperature on electrical and optical properties of Al-doped ZnO thin films. Ceram. Int. 2015, 41, 3968–3974. [Google Scholar] [CrossRef]

- Martín, A.; Espinós, J.P.; Justo, A.; Holgado, J.P.; Yubero, F.; González-Elipe, A.R. Preparation of transparent and conductive Al-doped ZnO thin films by ECR plasma enhanced CVD. Surf. Coat. Technol. 2002, 151–152, 289–293. [Google Scholar] [CrossRef]

- Dobrzański, L.A.; Szindler, M.; Drygała, A.; Szindler, M.M. Silicon solar cells with Al2O3 antireflection coating. Cent. Eur. J. Phys. 2014, 12, 666–670. [Google Scholar] [CrossRef]

- Cossuet, T.; Appert, E.; Chaix-Pluchery, O.; Roussel, H.; Rapenne, L.; Renou, G.; Sauvage, F.; Consonni, V. Epitaxial TiO2 Shell Grown by Atomic Layer Deposition on ZnO Nanowires Using a Double-Step Process and Its Beneficial Passivation Effect. J. Phys. Chem. C 2020, 124, 13447–13455. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, Z.; Zhang, W.; Jiang, Z.; Chen, W.; Chen, R.; Huang, Y.; Yang, Z.; Zhang, Y.; Han, L.; et al. Barrier Designs in Perovskite Solar Cells for Long-Term Stability. Adv. Energy Mater. 2020, 10, 2001610. [Google Scholar] [CrossRef]

- Ursaki, V.V.; Lehmann, S.; Zalamai, V.V.; Morari, V.; Nielsch, K.; Tiginyanu, I.M.; Monaico, E.V. Core–Shell Structures Prepared by Atomic Layer Deposition on GaAs Nanowires. Crystals 2022, 12, 1145. [Google Scholar] [CrossRef]

- Kim, H.; Lee, H.B.R.; Maeng, W.J. Applications of atomic layer deposition to nanofabrication and emerging nanodevices. Thin Solid Films 2009, 517, 2563–2580. [Google Scholar] [CrossRef]

- Lim, S.J.; Lee, S.K.; Jo, M.; Lee, C.S.; Kwon, S.; Kim, H. In-situ doping during ZnO atomic layer deposition. J. Korean Phys. Soc. 2008, 53, 253–257. [Google Scholar] [CrossRef]

- Lee, D.J.; Kim, H.M.; Kwon, J.Y.; Choi, H.; Kim, S.H.; Kim, K.B. Structural and Electrical Properties of Atomic Layer Deposited Al-Doped ZnO Films. Adv. Funct. Mater. 2011, 21, 448–455. [Google Scholar] [CrossRef]

- Kulesza-Matlak, G.; Drabczyk, K.; Sypień, A.; Pająk, A.; Major, Ł.; Lipiński, M. Interlayer Microstructure Analysis of the Transition Zone in the Silicon/Perovskite Tandem Solar Cell. Energies 2021, 14, 6819. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).