Review of Material-Handling Challenges in Energy Production from Biomass and Other Solid Waste Materials

Abstract

1. Introduction

2. Biomass and Other Solid Wastes

2.1. Biomass

2.2. Municipal Solid Waste

2.3. Waste from Food Processing Industries

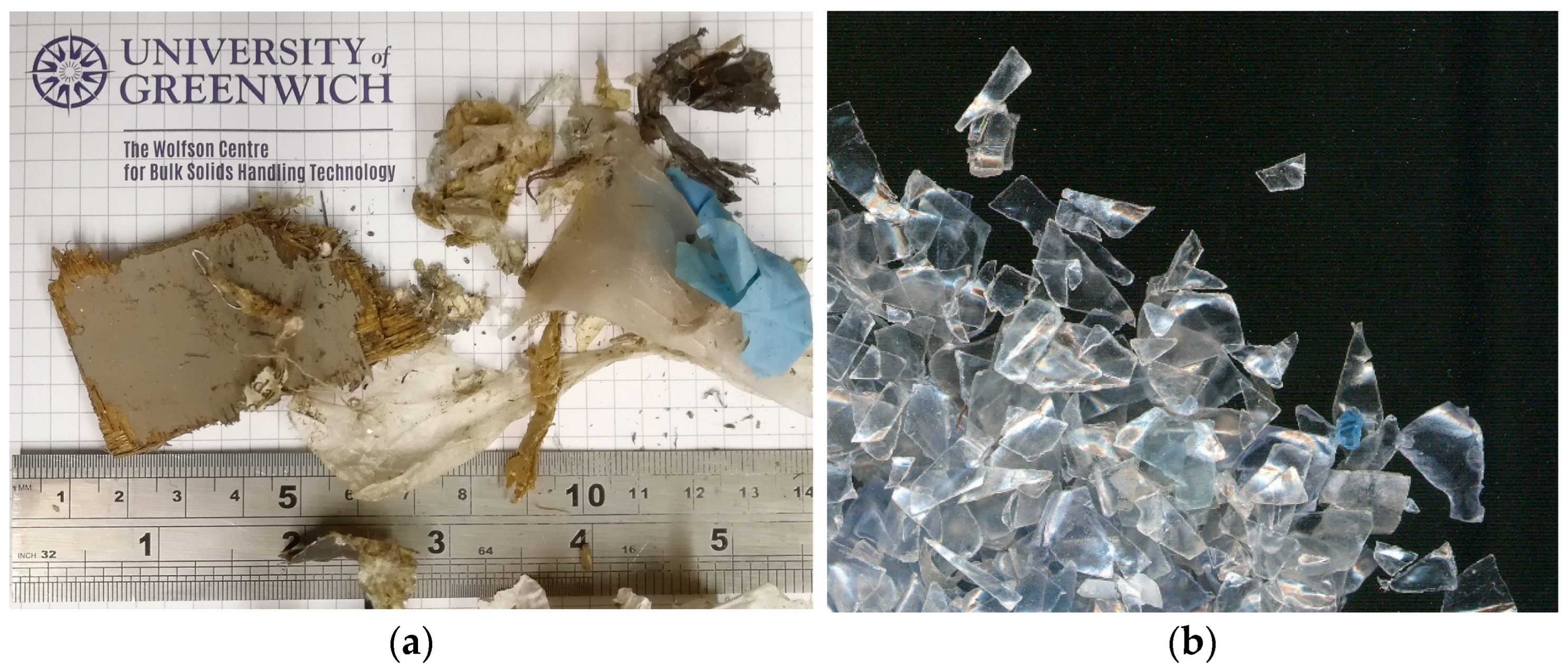

2.4. E-Scrap and Plastic Waste

2.5. Hazardous Wastes

2.6. General Remarks on Solid Wastes for Energy

- 1.

- Solid wastes have an extremely wide range of varieties, including biomass, municipal waste, food waste from the process industry, electronic and electrical waste, and plastic waste, among others.

- 2.

- Solid waste can be non-hazardous, but most of the time, it is hazardous in various forms. Due to the quantity of solid waste, even for non-hazardous waste, landfills will no longer be a favourable solution.

- 3.

- Incineration is an alternative solution. Therefore, using solid wastes for energy production, such as heat and electricity, is widely favoured. Burning the biogenic fraction (such as paper and food waste) can be favourable because it creates renewable, low-carbon energy, but burning the non-biogenic fraction (mostly plastics) releases fossil carbon, so it should be avoided where possible.

- 4.

- In many solid waste treatment processes, costs and environmental impacts are the primary barriers to effectively and efficiently utilising waste for energy (for example, low or even negative calorific values in wastes with high water content).

- 5.

- Material-handling challenges with solid waste are commonly overlooked when developing energy from waste projects, but problems in handling have often led to significant financial losses and even complete project failure when the processes are implemented.

- 6.

- Solid wastes commonly exhibit special material characteristics, which pose challenges in both material characterisation and process design and operations.

3. Material Properties and Challenges in Characterisation

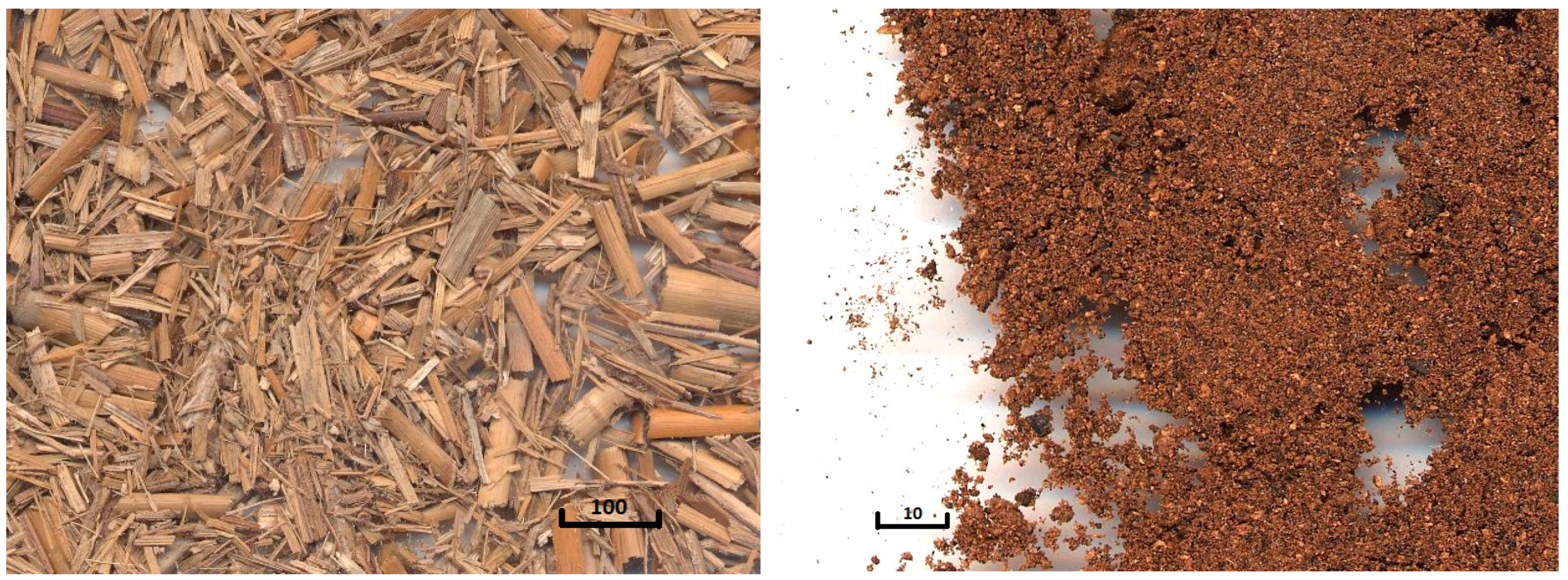

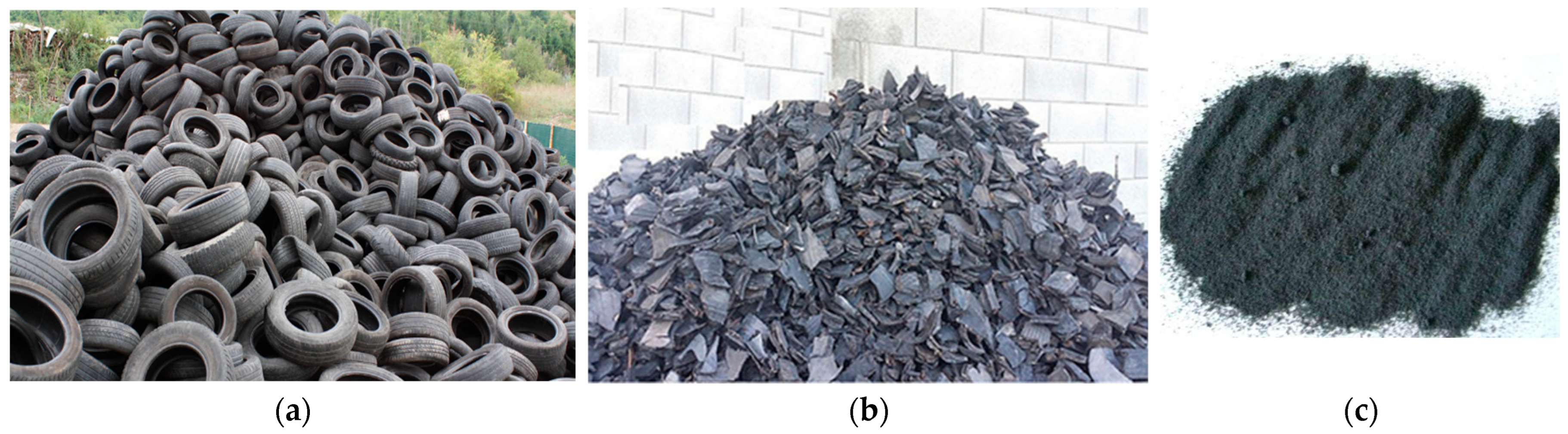

3.1. Particle Size and Shapes

3.2. Solid Density and Bulk Density

3.3. Water Contents

3.4. Flow Behaviours

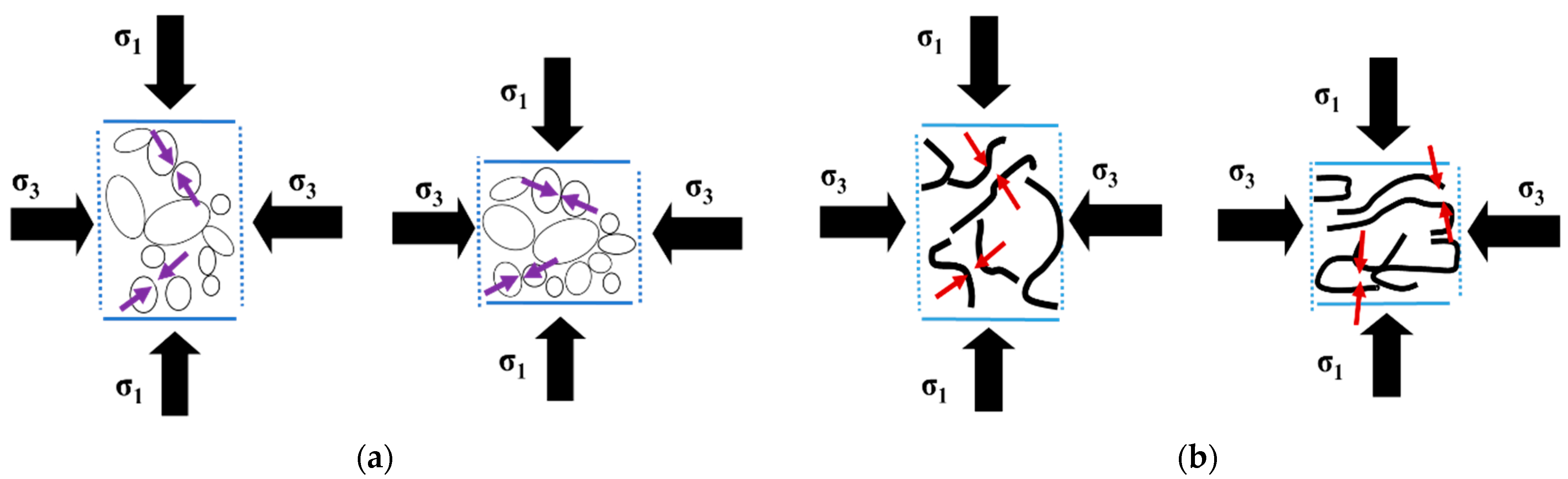

3.5. Compression and Compaction

3.6. Caking and Self-Heating

3.7. Dust Emission of Biowaste Materials

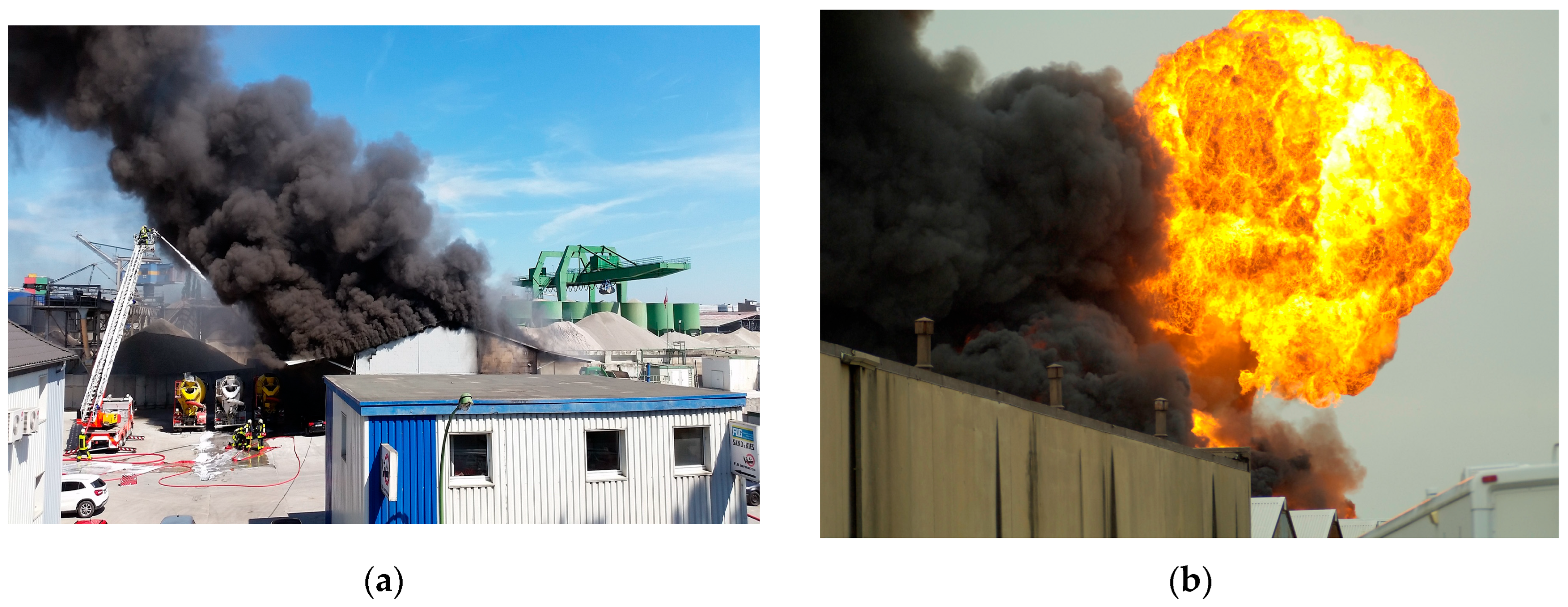

3.8. Fire Ignition and Explosivity

4. Solutions for Material-Handling Challenges

4.1. Common Processes for Energy Production from Biomass and Biowaste

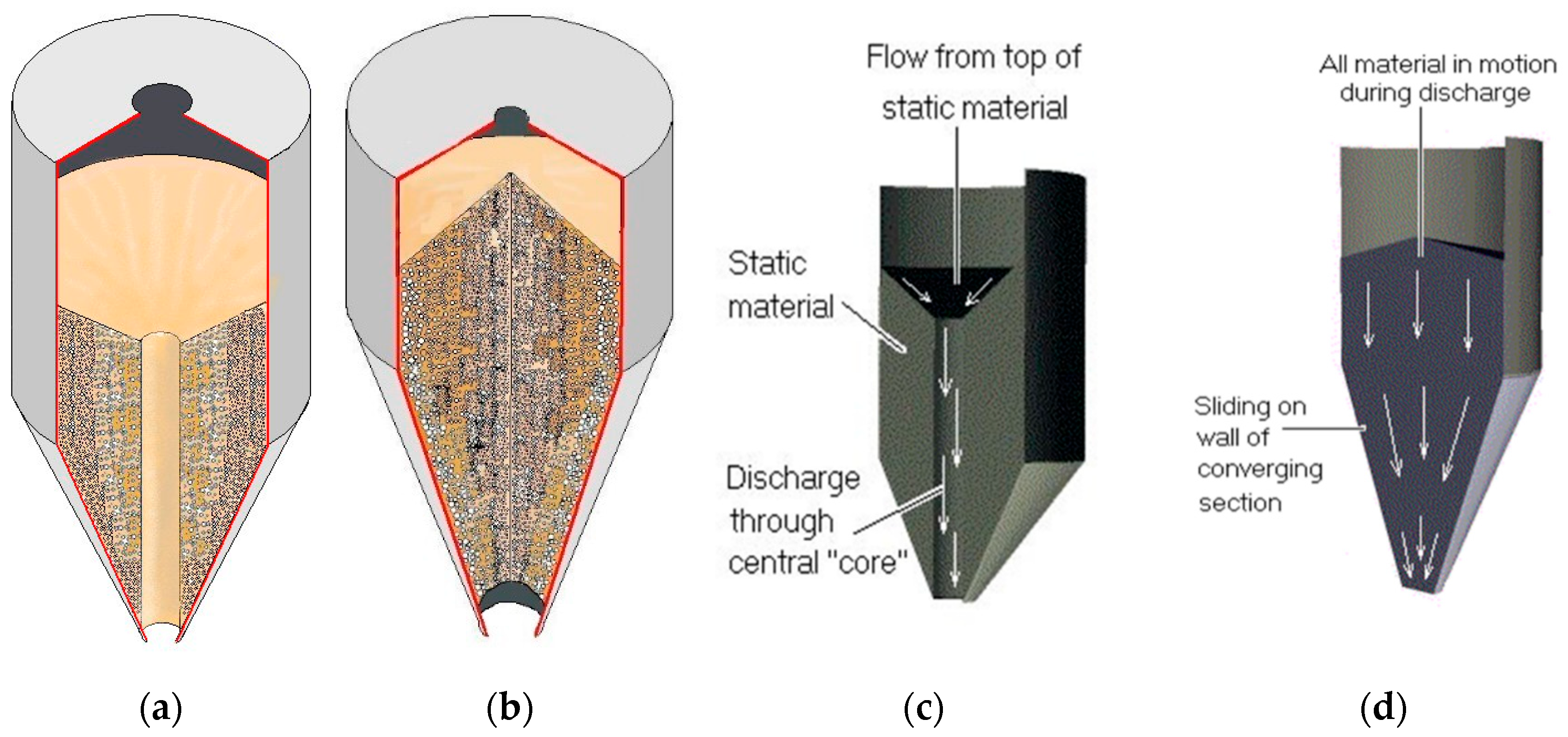

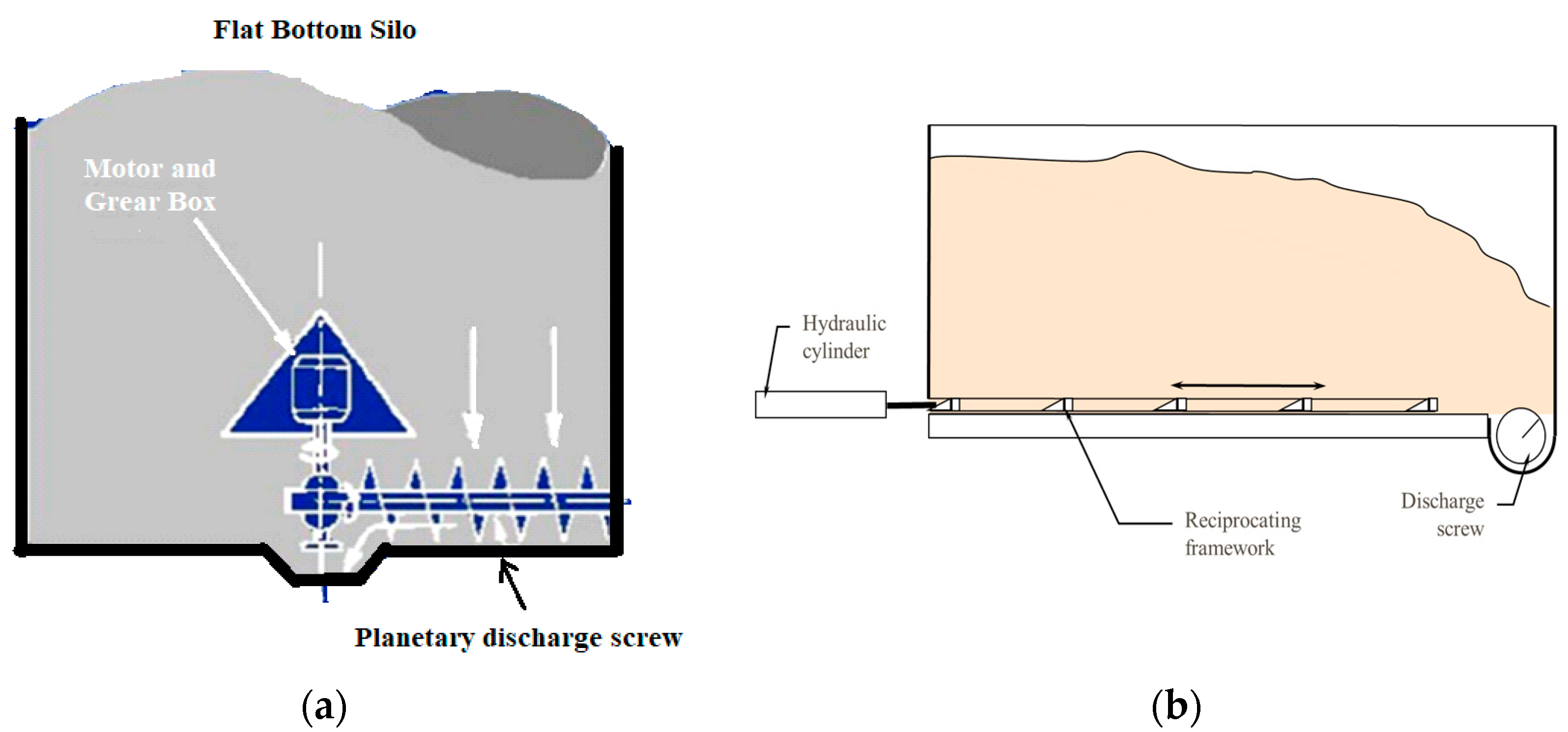

4.2. Challenges of Storage and Flow

4.3. Challenges of Drying Process

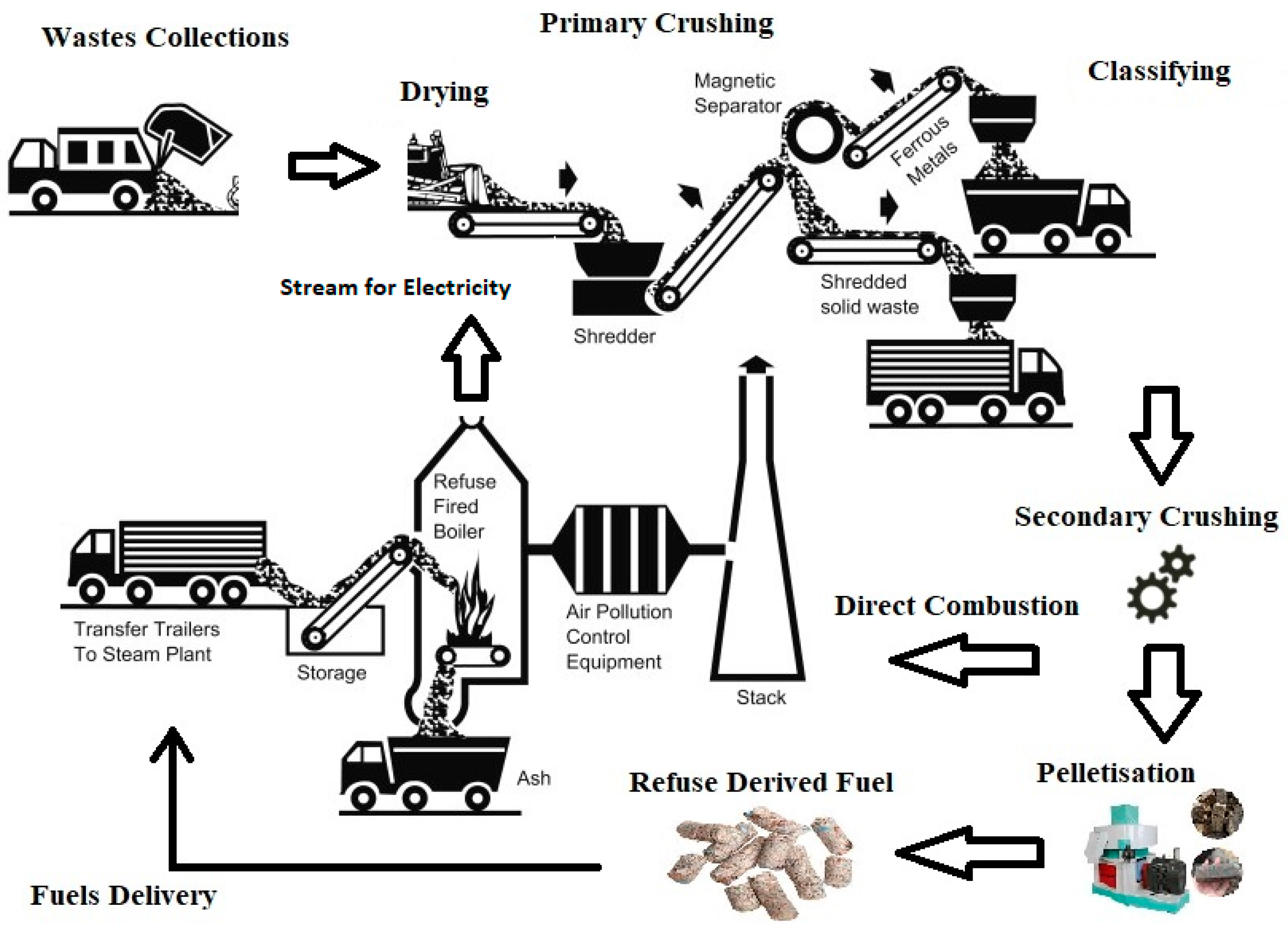

4.4. Challenges of Size Reduction and Classifying

4.5. Challenges of Transport (Mechanical and Pneumatic)

4.6. Handling Hazards, Including Fire, Explosion, and Dust Emissions

4.7. Challenges of Biomass Material Handling and Special Characterisations for Design

5. Conclusions and Remarks

5.1. Conclusions

5.2. Best Practices

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- International Solid Waste Association. Global Waste Management Outlook 2024: Beyond an Age of Waste—Turning Rubbish into a Resource; United Nations Environment Programme: Nairobi, Kenya, 2024; Available online: https://wedocs.unep.org/20.500.11822/44939 (accessed on 25 June 2025).

- Khan, A.H.; López-Maldonado, E.A.; Khan, N.A.; Villarreal-Gómez, L.J.; Munshi, F.M.; Alsabhan, A.H.; Perveen, K. Current solid waste management strategies and energy recovery in developing countries-State of art review. Chemosphere 2022, 291, 133088. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, E.; Mishra, R.; Lo, S.L.; Kumar, S. Global trends in municipal solid waste treatment technologies through the lens of sustainable energy development opportunity. Energy 2023, 275, 127471. [Google Scholar] [CrossRef]

- Khalid, I.; Ullah, S.; Umar, I.S.; Nurdiyanto, H. The problem of solid waste: Origins, composition, disposal, recycling, and reusing. Int. J. Adv. Sci. Comput. Appl. 2022, 1, 27–40. [Google Scholar] [CrossRef]

- Pratap, V.; Bombaywala, S.; Mandpe, A.; Khan, S.U. Solid Waste Treatment: Technological Advancements and Challenges. In Soft Computing Techniques in Solid Waste and Wastewater Management; Elsevier: Amsterdam, The Netherlands, 2021; pp. 215–231. [Google Scholar]

- Khan, M.S.; Mubeen, I.; Caimeng, Y.; Zhu, G.; Khalid, A.; Yan, M. Waste to energy incineration technology: Recent development under climate change scenarios. Waste Manag. Res. 2022, 40, 1708–1729. [Google Scholar] [CrossRef]

- Iodice, S.; Garbarino, E.; Cerreta, M.; Tonini, D. Sustainability assessment of Construction and Demolition Waste management applied to an Italian case. Waste Manag. 2021, 128, 83–98. [Google Scholar] [CrossRef] [PubMed]

- Vukovic, N.; Makogon, E. Waste-to-energy generation: Complex efficiency analysis of modern technologies. Sustainability 2022, 14, 13814. [Google Scholar] [CrossRef]

- Sikder, S.; Toha, M.; Mostafizur Rahman, M. An Overview on Municipal Solid Waste Characteristics and Its Impacts on Environment and Human Health. In Technical Landfills and Waste Management: Volume 1: Landfill Impacts, Characterization and Valorisation; Springer: Cham, Switzerland, 2024; pp. 135–155. [Google Scholar]

- Rathi, B.S.; Kumar, P.S.; Rangasamy, G. A sustainable approach on thermal and catalytic conversion of waste plastics into fuels. Fuel 2023, 339, 126977. [Google Scholar] [CrossRef]

- Shovon, S.M.; Akash, F.A.; Rahman, W.; Rahman, M.A.; Chakraborty, P.; Hossain, H.Z.; Monir, M.U. Strategies of managing solid waste and energy recovery for a developing country—A review. Heliyon 2024, 10, e24736. [Google Scholar] [CrossRef]

- Hameed, Z.; Aslam, M.; Khan, Z.; Maqsood, K.; Atabani, A.E.; Ghauri, M.; Khurram, M.S.; Rehan, M.; Nizami, A.S. Gasification of municipal solid waste blends with biomass for energy production and resources recovery: Current status, hybrid technologies and innovative prospects. Renew. Sustain. Energy Rev. 2021, 136, 110375. [Google Scholar] [CrossRef]

- Hasan, M.M.; Rasul, M.G.; Khan, M.M.K.; Ashwath, N.; Jahirul, M.I. Energy recovery from municipal solid waste using pyrolysis technology: A review on current status and developments. Renew. Sustain. Energy Rev. 2021, 145, 111073. [Google Scholar] [CrossRef]

- Li, J.; An, D.; Shi, Y.; Bai, R.; Du, S. A review of the physical and chemical characteristics and energy-recovery potential of municipal solid waste in China. Energies 2024, 17, 491. [Google Scholar] [CrossRef]

- Shah, A.V.; Srivastava, V.K.; Mohanty, S.S.; Varjani, S. Municipal solid waste as a sustainable resource for energy production: State-of-the-art review. J. Environ. Chem. Eng. 2021, 9, 105717. [Google Scholar] [CrossRef]

- Drożdż, W.; Bilan, Y.; Rabe, M.; Streimikiene, D.; Pilecki, B. Optimizing biomass energy production at the municipal level to move to low-carbon energy. Sustain. Cities Soc. 2022, 76, 103417. [Google Scholar] [CrossRef]

- Peng, X.; Jiang, Y.; Chen, Z.; Osman, A.I.; Farghali, M.; Rooney, D.W.; Yap, P.S. Recycling municipal, agricultural and industrial waste into energy, fertilizers, food and construction materials, and economic feasibility: A review. Environ. Chem. Lett. 2023, 21, 765–801. [Google Scholar] [CrossRef]

- Sajid, M.; Raheem, A.; Ullah, N.; Asim, M.; Rehman, M.S.U.; Ali, N. Gasification of municipal solid waste: Progress, challenges, and prospects. Renew. Sustain. Energy Rev. 2022, 168, 112815. [Google Scholar] [CrossRef]

- Bhatt, K.P.; Patel, S.; Upadhyay, D.S.; Patel, R.N. A critical review on solid waste treatment using plasma pyrolysis technology. Chem. Eng. Process. Process Intensif. 2022, 177, 108989. [Google Scholar] [CrossRef]

- Salem, K.S.; Clayson, K.; Salas, M.; Haque, N.; Rao, R.; Agate, S.; Singh, A.; Levis, J.W.; Mittal, A.; Yarbrough, J.M.; et al. A critical review of existing and emerging technologies and systems to optimize solid waste management for feedstocks and energy conversion. Matter 2023, 6, 3348–3377. [Google Scholar] [CrossRef]

- Radhakrishnan, K.; Kumar, P.S.; Rangasamy, G.; Perumal, L.P.; Sanaulla, S.; Nilavendhan, S.; Manivasagan, V.; Saranya, K. A critical review on pyrolysis method as sustainable conversion of waste plastics into fuels. Fuel 2023, 337, 126890. [Google Scholar] [CrossRef]

- Hasan, M.M.; Rasul, M.G.; Jahirul, M.I.; Khan, M.M.K. Fast pyrolysis of municipal green waste in an auger reactor: Effects of residence time and particle size on the yield and characteristics of produced oil. Energies 2024, 17, 2914. [Google Scholar] [CrossRef]

- Okolie, J.A.; Epelle, E.I.; Tabat, M.E.; Orivri, U.; Amenaghawon, A.N.; Okoye, P.U.; Gunes, B. Waste biomass valorization for the production of biofuels and value-added products: A comprehensive review of thermochemical, biological and integrated processes. Process Saf. Environ. Prot. 2022, 159, 323–344. [Google Scholar] [CrossRef]

- Clauser, N.M.; González, G.; Mendieta, C.M.; Kruyeniski, J.; Area, M.C.; Vallejos, M.E. Biomass waste as sustainable raw material for energy and fuels. Sustainability 2021, 13, 794. [Google Scholar] [CrossRef]

- Zhang, S.; Xia, Z.; Li, C.; Wang, X.; Lu, X.; Zhang, W.; Ma, H.; Zhou, X.; Zhang, W.; Zhu, T.; et al. Chromosome-scale genome assembly provides insights into speciation of allotetraploid and massive biomass accumulation of elephant grass (Pennisetum purpureum Schum.). Mol. Ecol. Resour. 2022, 22, 2363–2378. [Google Scholar] [CrossRef] [PubMed]

- Dodangeh, F.; Nabipour, H.; Rohani, S.; Xu, C. Applications, challenges and prospects of superabsorbent polymers based on cellulose derived from lignocellulosic biomass. Bioresour. Technol. 2024, 408, 131204. [Google Scholar] [CrossRef] [PubMed]

- Askaripour, M.; Saeidi, A.; Mercier-Langevin, P.; Rouleau, A. A review of relationship between texture characteristic and mechanical properties of rock. Geotechnics 2022, 2, 262–296. [Google Scholar] [CrossRef]

- Zhou, M.; Tian, X. Development of different pretreatments and related technologies for efficient biomass conversion of lignocellulose. Int. J. Biol. Macromol. 2022, 202, 256–268. [Google Scholar] [CrossRef] [PubMed]

- Park, S.; Kim, S.J.; Kim, H.E.; Kim, S.Y.; Oh, K.C.; Cho, L.; Jeon, Y.K.; Kim, D. Potential of torrefied coffee grounds to be used as fuel in thermal power plants. J. Biosyst. Eng. 2024, 49, 112–119. [Google Scholar] [CrossRef]

- Saleem, M. Possibility of utilizing agriculture biomass as a renewable and sustainable future energy source. Heliyon 2022, 8, e08905. [Google Scholar] [CrossRef]

- Mathanker, A.; Das, S.; Pudasainee, D.; Khan, M.; Kumar, A.; Gupta, R. A review of hydrothermal liquefaction of biomass for biofuels production with a special focus on the effect of process parameters, co-solvents, and extraction solvents. Energies 2021, 14, 4916. [Google Scholar] [CrossRef]

- Jasinskas, A.; Kleiza, V.; Streikus, D.; Domeika, R.; Vaiciukevičius, E.; Gramauskas, G.; Valentin, M.T. Assessment of quality indicators of pressed biofuel produced from coarse herbaceous plants and determination of the influence of moisture on the properties of pellets. Sustainability 2022, 14, 1068. [Google Scholar] [CrossRef]

- Cheng, Z.; Leal, J.H.; Hartford, C.E.; Carson, J.W.; Donohoe, B.S.; Craig, D.A.; Xia, Y.; Daniel, R.C.; Ajayi, O.O.; Semelsberger, T.A. Flow behavior characterization of biomass Feedstocks. Powder Technol. 2021, 387, 156–180. [Google Scholar] [CrossRef]

- Kalak, T. Potential use of industrial biomass waste as a sustainable energy source in the future. Energies 2023, 16, 1783. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, Z.; Zhang, J.; Liu, Y.; Chen, L.; Yang, M.; Osman, A.I.; Farghali, M.; Liu, E.; Hassan, D.; et al. Municipal solid waste management challenges in developing regions: A comprehensive review and future perspectives for Asia and Africa. Sci. Total Environ. 2024, 930, 172794. [Google Scholar] [CrossRef]

- Nanda, S.; Berruti, F. Municipal solid waste management and landfilling technologies: A review. Environ. Chem. Lett. 2021, 19, 1433–1456. [Google Scholar] [CrossRef]

- Roy, H.; Alam, S.R.; Bin-Masud, R.; Prantika, T.R.; Pervez, M.N.; Islam, M.S.; Naddeo, V. A review on characteristics, techniques, and waste-to-energy aspects of municipal solid waste management: Bangladesh perspective. Sustainability 2022, 14, 10265. [Google Scholar] [CrossRef]

- Djandja, O.S.; Yin, L.X.; Wang, Z.C.; Duan, P.G. From wastewater treatment to resources recovery through hydrothermal treatments of municipal sewage sludge: A critical review. Process Saf. Environ. Prot. 2021, 151, 101–127. [Google Scholar] [CrossRef]

- Chen, L.; Liao, Y.; Ma, X. Economic analysis on sewage sludge drying and its co-combustion in municipal solid waste power plant. Waste Manag. 2021, 121, 11–22. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Liu, C.; Chen, Y.; Zheng, G.; Chen, Y. Source separation, transportation, pretreatment, and valorization of municipal solid waste: A critical review. Environ. Dev. Sustain. 2022, 24, 11471–11513. [Google Scholar] [CrossRef] [PubMed]

- Rao, B.; Wang, G.; Xu, P. Recent advances in sludge dewatering and drying technology. Dry. Technol. 2022, 40, 3049–3063. [Google Scholar] [CrossRef]

- Bhatia, L.; Jha, H.; Sarkar, T.; Sarangi, P.K. Food waste utilization for reducing carbon footprints towards sustainable and cleaner environment: A review. Int. J. Environ. Res. Public Health 2023, 20, 2318. [Google Scholar] [CrossRef]

- Kavitha, S.; Kannah, R.Y.; Kumar, G.; Gunasekaran, M.; Banu, J.R. Introduction: Sources and Characterization of Food Waste and Food Industry Wastes. In Food Waste to Valuable Resources; Academic Press: Oxford, UK, 2020; pp. 1–13. [Google Scholar]

- Dey, S.; Santra, M.; Choudhury, M.; Ghosh, A.R.; Samanta, P. Food waste generation and its industrial utilization: An overview. Environ. Sci. Pollut. Res. 2024, 32, 7493–7512. [Google Scholar] [CrossRef]

- Saba, B.; Bharathidasan, A.K.; Ezeji, T.C.; Cornish, K. Characterization and potential valorization of industrial food processing wastes. Sci. Total Environ. 2023, 868, 161550. [Google Scholar] [CrossRef]

- Babu, S.; Rathore, S.S.; Singh, R.; Kumar, S.; Singh, V.K.; Yadav, S.K.; Yadav, V.; Raj, R.; Yadav, D.; Shekhawat, K.; et al. Exploring agricultural waste biomass for energy, food and feed production and pollution mitigation: A review. Bioresour. Technol. 2022, 360, 127566. [Google Scholar] [CrossRef]

- Kowalski, S.; Gumul, D. The Use of Waste Products from the Food Industry to Obtain High Value-Added Products. Foods 2024, 13, 847. [Google Scholar] [CrossRef]

- Elnakib, S. Food waste recovery: Processing technologies, industrial techniques, and applications. J. Nutr. Educ. Behav. 2022, 54, 373–374. [Google Scholar] [CrossRef]

- Sharma, P.; Gaur, V.K.; Sirohi, R.; Varjani, S.; Kim, S.H.; Wong, J.W. Sustainable processing of food waste for production of bio-based products for circular bioeconomy. Bioresour. Technol. 2021, 325, 124684. [Google Scholar] [CrossRef]

- Pietraccini, M.; Danzi, E.; Marmo, L.; Addo, A.; Amyotte, P. Effect of particle size distribution, drying and milling technique on explosibility behavior of olive pomace waste. J. Loss Prev. Process Ind. 2021, 71, 104423. [Google Scholar] [CrossRef]

- Chauhan, A.; Rajput, V.; Stanikzai, K.; Kumar, S. Understanding the Global Status of Electronic Wastes. In Electronic Waste; CRC Press: Boca Raton, FL, USA, 2025; pp. 31–39. [Google Scholar]

- Dias, P.R.; Cenci, M.P.; Bernardes, A.M.; Huda, N. What drives WEEE recycling? A comparative study concerning legislation, collection and recycling. Waste Manag. Res. 2022, 40, 1527–1538. [Google Scholar] [CrossRef]

- Rene, E.R.; Sethurajan, M.; Ponnusamy, V.K.; Kumar, G.; Dung, T.N.B.; Brindhadevi, K.; Pugazhendhi, A. Electronic waste generation, recycling and resource recovery: Technological perspectives and trends. J. Hazard. Mater. 2021, 416, 125664. [Google Scholar] [CrossRef] [PubMed]

- Dutta, D.; Rautela, R.; Gujjala, L.K.S.; Kundu, D.; Sharma, P.; Tembhare, M.; Kumar, S. A review on recovery processes of metals from E-waste: A green perspective. Sci. Total Environ. 2023, 859, 160391. [Google Scholar] [CrossRef] [PubMed]

- Van Yken, J.; Boxall, N.J.; Cheng, K.Y.; Nikoloski, A.N.; Moheimani, N.R.; Kaksonen, A.H. E-waste recycling and resource recovery: A review on technologies, barriers and enablers with a focus on oceania. Metals 2021, 11, 1313. [Google Scholar] [CrossRef]

- Faraji, F.; Golmohammadzadeh, R.; Pickles, C.A. Potential and current practices of recycling waste printed circuit boards: A review of the recent progress in pyrometallurgy. J. Environ. Manag. 2022, 316, 115242. [Google Scholar] [CrossRef]

- Lahtela, V.; Hamod, H.; Kärki, T. Assessment of critical factors in waste electrical and electronic equipment (WEEE) plastics on the recyclability: A case study in Finland. Sci. Total Environ. 2022, 830, 155627. [Google Scholar] [CrossRef]

- Liu, K.; Tan, Q.; Yu, J.; Wang, M. A global perspective on e-waste recycling. Circ. Econ. 2023, 2, 100028. [Google Scholar] [CrossRef]

- Kaya, M. Recovery of metals and nonmetals from electronic waste by physical and chemical recycling processes. Waste Manag. 2016, 57, 64–90. [Google Scholar] [CrossRef]

- Nithya, R.; Sivasankari, C.; Thirunavukkarasu, A. Electronic waste generation, regulation and metal recovery: A review. Environ. Chem. Lett. 2021, 19, 1347–1368. [Google Scholar] [CrossRef]

- Tiwari, R.; Azad, N.; Dutta, D.; Yadav, B.R.; Kumar, S. A critical review and future perspective of plastic waste recycling. Sci. Total Environ. 2023, 881, 163433. [Google Scholar] [CrossRef]

- Gola, D.; Tyagi, P.K.; Arya, A.; Chauhan, N.; Agarwal, M.; Singh, S.K.; Gola, S. The impact of microplastics on marine environment: A review. Environ. Nanotechnol. Monit. Manag. 2021, 16, 100552. [Google Scholar] [CrossRef]

- Chen, Y.; Awasthi, A.K.; Wei, F.; Tan, Q.; Li, J. Single-use plastics: Production, usage, disposal, and adverse impacts. Sci. Total Environ. 2021, 752, 141772. [Google Scholar] [CrossRef] [PubMed]

- Kwon, G.; Cho, D.W.; Park, J.; Bhatnagar, A.; Song, H. A review of plastic pollution and their treatment technology: A circular economy platform by thermochemical pathway. Chem. Eng. J. 2023, 464, 142771. [Google Scholar] [CrossRef]

- Kulas, D.G.; Zolghadr, A.; Chaudhari, U.S.; Shonnard, D.R. Economic and environmental analysis of plastics pyrolysis after secondary sortation of mixed plastic waste. J. Clean. Prod. 2023, 384, 135542. [Google Scholar] [CrossRef]

- Saha, B.; Vedachalam, S.; Dalai, A.K.; Saxena, S.; Dally, B.; Roberts, W.L. Review on production of liquid fuel from plastic wastes through thermal and catalytic degradation. J. Energy Inst. 2024, 114, 101661. [Google Scholar] [CrossRef]

- Jahirul, M.I.; Rasul, M.G.; Schaller, D.; Khan, M.M.K.; Hasan, M.M.; Hazrat, M.A. Transport fuel from waste plastics pyrolysis—A review on technologies, challenges and opportunities. Energy Convers. Manag. 2022, 258, 115451. [Google Scholar] [CrossRef]

- Kibria, M.G.; Masuk, N.I.; Safayet, R.; Nguyen, H.Q.; Mourshed, M. Plastic waste: Challenges and opportunities to mitigate pollution and effective management. Int. J. Environ. Res. 2023, 17, 20. [Google Scholar] [CrossRef]

- Praveenkumar, T.R.; Sekar, M.; Pasupuleti, R.R.; Gavurová, B.; Kumar, G.A.; Kumar, M.V. Current technologies for plastic waste treatment for energy recovery, its effects on poly aromatic hydrocarbons emission and recycling strategies. Fuel 2024, 357, 129379. [Google Scholar] [CrossRef]

- Xiang, M.; Li, Y.; Yang, J.; Lei, K.; Li, Y.; Li, F.; Zheng, D.; Fang, X.; Cao, Y. Heavy metal contamination risk assessment and correlation analysis of heavy metal contents in soil and crops. Environ. Pollut. 2021, 278, 116911. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.H.; Su, J.F.; Shih, Y.; Wang, J.; Wang, P.Y.; Huang, C.P. Hazardous wastes treatment technologies. Water Environ. Res. 2020, 92, 1833–1860. [Google Scholar] [CrossRef]

- Siddiqua, A.; Hahladakis, J.N.; Al-Attiya, W.A.K. An overview of the environmental pollution and health effects associated with waste landfilling and open dumping. Environ. Sci. Pollut. Res. 2022, 29, 58514–58536. [Google Scholar] [CrossRef] [PubMed]

- Sanito, R.C.; Bernuy-Zumaeta, M.; You, S.J.; Wang, Y.F. A review on vitrification technologies of hazardous waste. J. Environ. Manag. 2022, 316, 115243. [Google Scholar] [CrossRef]

- Ishaq, H.; Dincer, I. A new approach in treating industrial hazardous wastes for energy generation and thermochemical hydrogen production. J. Clean. Prod. 2021, 290, 125303. [Google Scholar] [CrossRef]

- Ramadan, B.S.; Rachman, I.; Ikhlas, N.; Kurniawan, S.B.; Miftahadi, M.F.; Matsumoto, T. A comprehensive review of domestic-open waste burning: Recent trends, methodology comparison, and factors assessment. J. Mater. Cycles Waste Manag. 2022, 24, 1633–1647. [Google Scholar] [CrossRef]

- Gatrell, A.C.; Lovett, A.A. Burning Questions: Incineration of Wastes and Implications for Human Health. In Waste Location; Routledge: London, UK, 2021; pp. 143–157. [Google Scholar]

- Fu, Z.; Lin, S.; Tian, H.; Hao, Y.; Wu, B.; Liu, S.; Luo, L.; Bai, X.; Guo, Z.; Lv, Y. A comprehensive emission inventory of hazardous air pollutants from municipal solid waste incineration in China. Sci. Total Environ. 2022, 826, 154212. [Google Scholar] [CrossRef]

- Jofre-Monseny, J.; Sorribas-Navarro, P. Landfill tax and recycling. Fisc. Stud. 2024, 45, 483–500. [Google Scholar] [CrossRef]

- Schulze, D. Powders and Bulk Solids; Springer International Publishing: Cham, Switzerland, 2021. [Google Scholar]

- Ghanbarzadeh Lak, M.; Ghaffariraad, M.; Jahangirzadeh Soureh, H. Characteristics and Impacts of Municipal Solid Waste (MSW). In Technical Landfills and Waste Management: Volume 1: Landfill Impacts, Characterization and Valorisation; Springer Nature: Cham, Switzerland, 2024; pp. 31–92. [Google Scholar]

- Ulusoy, U. A review of particle shape effects on material properties for various engineering applications: From macro to nanoscale. Minerals 2023, 13, 91. [Google Scholar] [CrossRef]

- Niaz, S.; Forbes, B.; Raimi-Abraham, B.T. Exploiting endocytosis for non-spherical nanoparticle cellular uptake. Nanomanufacturing 2022, 2, 1–16. [Google Scholar] [CrossRef]

- Atelge, M.R.; Atabani, A.E.; Banu, J.R.; Krisa, D.; Kaya, M.; Eskicioglu, C.; Kumar, G.; Lee, C.; Yildiz, Y.Ş.; Unalan, S. A critical review of pretreatment technologies to enhance anaerobic digestion and energy recovery. Fuel 2020, 270, 117494. [Google Scholar] [CrossRef]

- Mor, S.; Ravindra, K. Municipal solid waste landfills in lower-and middle-income countries: Environmental impacts, challenges and sustainable management practices. Process Saf. Environ. Prot. 2023, 174, 510–530. [Google Scholar] [CrossRef]

- Image for Internet Website. Available online: https://pixabay.com/photos/tires-used-tires-pfu-waste-1846674/ (accessed on 25 June 2025).

- Barletta, D.; Berry, R.J.; Larsson, S.H.; Lestander, T.A.; Poletto, M.; Ramírez-Gómez, Á. Assessment on bulk solids best practice techniques for flow characterization and storage/handling equipment design for biomass materials of different classes. Fuel Process. Technol. 2015, 138, 540–554. [Google Scholar] [CrossRef]

- Robinson, D.A.; Friedman, S.P.; Thomas, A.; Hirmas, D.; Sullivan, P.L.; Nemes, A. Soil bulk density and porosity connecting macro-and micro-scales through geometry. Earth-Sci. Rev. 2025, 268, 105173. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Q.; Zhang, T.; Wang, H.; Chen, T. A novel bulk density-based recognition method for kitchen and dry waste: A case study in Beijing, China. Waste Manag. 2020, 114, 89–95. [Google Scholar] [CrossRef] [PubMed]

- McGlinchey, D. Characterisation of Bulk Solids; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Chandrappa, R.; Das, D.B. Solid Waste Management: Principles and Practice; Springer Nature: Berlin/Heidelberg, Germany, 2024. [Google Scholar]

- Tabyang, W.; Suksiripattanapong, C.; Phetchuay, C.; Laksanakit, C.; Chusilp, N. Evaluation of municipal solid waste incineration fly ash based geopolymer for stabilised recycled concrete aggregate as road material. Road Mater. Pavement Des. 2022, 23, 2178–2189. [Google Scholar] [CrossRef]

- Widyarani Wulan, D.R.; Hamidah, U.; Komarulzaman, A.; Rosmalina, R.T.; Sintawardani, N. Domestic wastewater in Indonesia: Generation, characteristics and treatment. Environ. Sci. Pollut. Res. 2022, 29, 32397–32414. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, Y.; Luo, D.; Chong, Z.; Li, E.; Kong, X. A review of municipal solid waste in China: Characteristics, compositions, influential factors and treatment technologies. Environ. Dev. Sustain. 2021, 23, 6603–6622. [Google Scholar] [CrossRef]

- Sharma, A.; Kuthiala, T.; Thakur, K.; Thatai, K.S.; Singh, G.; Kumar, P.; Arya, S.K. Kitchen waste: Sustainable bioconversion to value-added product and economic challenges. Biomass Convers. Biorefinery 2025, 15, 1749–1770. [Google Scholar] [CrossRef]

- Sun, W.; Tribuzi, G.; Bornhorst, G.M. Particle size and water content impact breakdown and starch digestibility of chickpea snacks during in vitro gastrointestinal digestion. Food Res. Int. 2023, 173, 113201. [Google Scholar] [CrossRef]

- Maj, I. Significance and challenges of poultry litter and cattle manure as sustainable fuels: A review. Energies 2022, 15, 8981. [Google Scholar] [CrossRef]

- Geethambika, S.B.; Harthikote Veerendrasimha, V.S.; Prakash, A.K.; Pasagadi, A.S.; Franklin, M.E.E.; Ambrose, R.P.K.; Pushpadass, H.A. Effect of moisture content on physical and flow properties of milk-millet powders. J. Food Process Eng. 2023, 46, e14198. [Google Scholar] [CrossRef]

- Ganesan, V.; Rosentrater, K.A.; Muthukumarappan, K. Flowability and handling characteristics of bulk solids and powders–a review with implications for DDGS. Biosyst. Eng. 2008, 101, 425–435. [Google Scholar] [CrossRef]

- Kulkarni, P.A.; Berry, R.J.; Bradley, M.S.A. Review of the flowability measuring techniques for powder metallurgy industry. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2010, 224, 159–168. [Google Scholar] [CrossRef]

- Mehos, G. Maximum solids discharge rates from hoppers. Chem. Eng. Res. Des. 2023, 191, 564–567. [Google Scholar] [CrossRef]

- Juarez-Enriquez, E.; Olivas, G.I.; Zamudio-Flores, P.B.; Perez-Vega, S.; Salmeron, I.; Ortega-Rivas, E.; Sepulveda, D.R. A review on the influence of water on food powder flowability. J. Food Process Eng. 2022, 45, e14031. [Google Scholar] [CrossRef]

- Schwedes, J.; Schulze, D. Measurement of flow properties of bulk solids. Powder Technol. 1990, 61, 59–68. [Google Scholar] [CrossRef]

- Ku, Q.; Zhao, J.; Mollon, G.; Zhao, S. Compaction of highly deformable cohesive granular powders. Powder Technol. 2023, 421, 118455. [Google Scholar] [CrossRef]

- Lou, Y.; Zhang, Z.; Li, T.; Zhang, Y.; Chen, W. Compressibility characteristics of municipal solid waste considering multiple factors. Environ. Sci. Pollut. Res. 2024, 31, 44401–44414. [Google Scholar] [CrossRef]

- Rodionova, M.V.; Bozieva, A.M.; Zharmukhamedov, S.K.; Leong, Y.K.; Lan, J.C.W.; Veziroglu, A.; Veziroglu, T.N.; Tomo, T.; Chang, J.S.; Allakhverdiev, S.I. A comprehensive review on lignocellulosic biomass biorefinery for sustainable biofuel production. Int. J. Hydrogen Energy 2022, 47, 1481–1498. [Google Scholar] [CrossRef]

- Ren, Y.; Zhang, Z.; Huang, M. A review on settlement models of municipal solid waste landfills. Waste Manag. 2022, 149, 79–95. [Google Scholar] [CrossRef]

- Ogden, C.A.; Ileleji, K.E. Physical characteristics of ground switchgrass related to bulk solids flow. Powder Technol. 2021, 385, 386–395. [Google Scholar] [CrossRef]

- Borowski, G. An Overview of Particle Agglomeration Techniques to Waste Utilization. J. Ecol. Eng. 2021, 22, 263–271. [Google Scholar] [CrossRef] [PubMed]

- Bradley, M.S. Biomass Fuel Transport and Handling. In Fuel Flexible Energy Generation; Woodhead Publishing: London, UK, 2016; pp. 99–120. [Google Scholar]

- Miller, F.C. Composting of Municipal Solid Waste and Its Components. In Microbiology of Solid Waste; CRC Press: Boca Raton, FL, USA, 2020; pp. 115–154. [Google Scholar]

- Sheng, C.; Yao, C. Review on self-heating of biomass materials: Understanding and description. Energy Fuels 2022, 36, 731–761. [Google Scholar] [CrossRef]

- Parvar, Z.; Amiri, H.; Nasiri, A.; Hashemi, M.; Medipour, M.; Pourafshar, M. Integrated windrow-based co-composting of domestic wastewater treatment plant sludge and solid waste for highquality compost fertilizer production. Environ. Health Eng. Manag. J. 2025, 12, 1–12. [Google Scholar]

- Gao, L.; Tan, B.; Fan, L.; Wang, H.; Li, X.; Lu, W.; Jiang, Y. Comparison and analysis of spontaneous combustion control between coal storage silos and biomass silos. Energy 2024, 286, 129623. [Google Scholar] [CrossRef]

- Navar, R.; Semelsberger, T.A.; Davis, B.L. Impacts of caking on corn stover–An assessment of moisture content and consolidating pressure. Powder Technol. 2024, 438, 119661. [Google Scholar] [CrossRef]

- Yang, W.; Pudasainee, D.; Gupta, R.; Li, W.; Wang, B.; Sun, L. Particulate matter emission during municipal solid waste combustion: Submicron particulates formation mechanism. Fuel 2022, 310, 122271. [Google Scholar] [CrossRef]

- Ahmadi Foroushani, M.; Opp, C.; Groll, M. Investigation of Aeolian dust deposition rates in different climate zones of Southwestern Iran. Atmosphere 2021, 12, 229. [Google Scholar] [CrossRef]

- Huang, Y.; Adebiyi, A.A.; Formenti, P.; Kok, J.F. Linking the different diameter types of aspherical desert dust indicates that models underestimate coarse dust emission. Geophys. Res. Lett. 2021, 48, e2020GL092054. [Google Scholar] [CrossRef]

- Li, C.Z.; Zhao, Y.; Xu, X. Investigation of dust exposure and control practices in the construction industry: Implications for cleaner production. J. Clean. Prod. 2019, 227, 810–824. [Google Scholar] [CrossRef]

- Varde, A.S.; Pandey, A.; Du, X. Prediction tool on fine particle pollutants and air quality for environmental engineering. SN Comput. Sci. 2022, 3, 184. [Google Scholar] [CrossRef]

- Richerson, H.B. Hypersensitivity Pneumonitis. In Organic Dusts Exposure, Effects, and Prevention; CRC Press: Boca Raton, FL, USA, 2024; pp. 139–160. [Google Scholar]

- Athaillah, T.; Husin, H.; Aulia, M.R. Briquettes from a Mixture of Cow Menure, Rice Husks and Wood Dust as Alternative Fuel. J. Ecol. Eng. 2024, 25, 290–299. [Google Scholar] [CrossRef]

- Perelli, S.; D’Angelo, D.; Pellegrini, L. Analysis of dust fires and explosions in the food processing industry. Chem. Eng. Trans. 2023, 104, 169–174. [Google Scholar]

- Aminzadegan, S.; Shahriari, M.; Mehranfar, F.; Abramović, B. Factors affecting the emission of pollutants in different types of transportation: A literature review. Energy Rep. 2022, 8, 2508–2529. [Google Scholar] [CrossRef]

- Alshetty, D.; Shiva Nagendra, S.M. Urban characteristics and its influence on resuspension of road dust, air quality and exposure. Air Qual. Atmos. Health 2022, 15, 273–287. [Google Scholar] [CrossRef]

- Hjemsted, K.; Schneider, T. Documentation of a dustiness drum test. Ann. Occup. Hyg. 1996, 40, 627–643. [Google Scholar] [CrossRef]

- Wangchai, S.; Hastie, D.B.; Wypych, P.W. The investigation of particle flow mechanisms of bulk materials in dustiness testers. Part. Sci. Technol. 2016, 34, 241–254. [Google Scholar] [CrossRef]

- Ribalta, C.; Jensen, A.C.; Shandilya, N.; Delpivo, C.; Jensen, K.A.; Fonseca, A.S. Use of the dustiness index in combination with the handling energy factor for exposure modelling of nanomaterials. NanoImpact 2024, 33, 100493. [Google Scholar] [CrossRef] [PubMed]

- Dazon, C.; Bau, S.; Payet, R.; Fierro, V.; Witschger, O. Towards a surface metric to measure the dustiness of nanomaterial powders. Environ. Sci. Process. Impacts 2023, 25, 670–679. [Google Scholar] [CrossRef]

- Rybak, W.; Moroń, W.; Ferens, W. Dust ignition characteristics of different coal ranks, biomass and solid waste. Fuel 2019, 237, 606–618. [Google Scholar] [CrossRef]

- Eckhoff, R.K.; Li, G. Industrial dust explosions. A brief review. Appl. Sci. 2021, 11, 1669. [Google Scholar] [CrossRef]

- Yang, Y.; Luo, Z.; Chen, S.; Liu, L.; Zhou, S.; Shu, C.M. Dynamic behaviours and inerting suppression characteristics of dust explosion of anti-yellowing agent. Process Saf. Environ. Prot. 2025, 199, 107212. [Google Scholar] [CrossRef]

- Jakhar, R.; Samek, L.; Styszko, K. A comprehensive study of the impact of waste fires on the environment and health. Sustainability 2023, 15, 14241. [Google Scholar] [CrossRef]

- Kumar, M.; Barbhai, M.D. Sustainable fire safety solutions: Bioactive natural polysaccharides and secondary metabolites as innovative fire retardants for textiles. Emerg. Manag. Sci. Technol. 2023, 3, 17. [Google Scholar] [CrossRef]

- Moroń, W.; Ferens, W. Analysis of fire and explosion hazards caused by industrial dusts with a high content of volatile matter. Fuel 2024, 355, 129363. [Google Scholar] [CrossRef]

- Singh, G.; Yadav, P.K.S. Hazardous Waste Characteristics and Standard Management Approaches. In Hazardous Waste Management; Elsevier: Amsterdam, The Netherlands, 2022; pp. 145–164. [Google Scholar]

- Foster, W.; Azimov, U.; Gauthier-Maradei, P.; Molano, L.C.; Combrinck, M.; Munoz, J.; Esteves, J.J.; Patino, L. Waste-to-energy conversion technologies in the UK: Processes and barriers—A review. Renew. Sustain. Energy Rev. 2021, 135, 110226. [Google Scholar] [CrossRef]

- Owonikoko, A. Predicting Storage Vessel Geometry Requirements for Discharge of Extreme Shape Materials. Ph.D. Thesis, University of Greenwich, London, UK, 2012. [Google Scholar]

- Feise, H.J. Handling of Solids–Transport and Storage. In Chemical Engineering and Chemical Process Technology—Volume II: Unit Operations–Fluids and Solids; Eolss Publishers: Cardiff, UK, 2010; p. 265. [Google Scholar]

- Villacorta, E.; Haraldseid, I.; Mikalsen, R.F.; Hagen, B.C.; Erland, S.; Kleppe, G.; Krause, U.; Frette, V. Onset of smoldering fires in storage silos: Susceptibility to design, scenario, and material parameters. Fuel 2021, 284, 118964. [Google Scholar] [CrossRef]

- Acar, C.; Dincer, I.; Mujumdar, A. A comprehensive review of recent advances in renewable-based drying technologies for a sustainable future. Dry. Technol. 2022, 40, 1029–1050. [Google Scholar] [CrossRef]

- Payomthip, P.; Towprayoon, S.; Chiemchaisri, C.; Patumsawad, S.; Wangyao, K. Optimization of aeration for accelerating municipal solid waste biodrying. Int. J. Renew. Energy Dev. 2022, 11, 878–888. [Google Scholar] [CrossRef]

- Mujumdar, A.S.; Menon, A.S. Drying of solids: Principles, Classification, and Selection of Dryers. In Handbook of Industrial Drying; CRC Press: Boca Raton, FL, USA, 2020; pp. 1–39. [Google Scholar]

- Echeerı, A.; Maalmı, M. Performance evaluation of a rotary dryer in both co-current and counter-current configurations. J. Therm. Eng. 2021, 7 (Suppl. S14), 1945–1957. [Google Scholar] [CrossRef]

- Wzorek, M. Solar drying of granulated waste blends for dry biofuel production. Environ. Sci. Pollut. Res. 2021, 28, 34290–34299. [Google Scholar] [CrossRef]

- Zhou, X.; Zhou, P.; Zhao, X.; Song, Z.; Wang, W.; Sun, J.; Mao, Y. Applicability of municipal solid waste incineration (MSWI) system integrated with pre-drying or torrefaction for flue gas waste heat recovery. Energy 2021, 224, 120157. [Google Scholar] [CrossRef]

- Li, Y.; Li, X.; Wang, P.; Su, Y.; Xie, B. Size-dependent effects of polystyrene microplastics on anaerobic digestion performance of food waste: Focusing on oxidative stress, microbial community, key metabolic functions. J. Hazard. Mater. 2022, 438, 129493. [Google Scholar] [CrossRef]

- Khodier, K.; Viczek, S.A.; Curtis, A.; Aldrian, A.; O’Leary, P.; Lehner, M.; Sarc, R. Sampling and analysis of coarsely shredded mixed commercial waste. Part I: Procedure, particle size and sorting analysis. Int. J. Environ. Sci. Technol. 2020, 17, 959–972. [Google Scholar] [CrossRef]

- Khodier, K.; Feyerer, C.; Möllnitz, S.; Curtis, A.; Sarc, R. Efficient derivation of significant results from mechanical processing experiments with mixed solid waste: Coarse shredding of commercial waste. Waste Manag. 2021, 121, 164–174. [Google Scholar] [CrossRef] [PubMed]

- Lubongo, C.; Alexandridis, P. Assessment of performance and challenges in use of commercial automated sorting technology for plastic waste. Recycling 2022, 7, 11. [Google Scholar] [CrossRef]

- Moorthi, S.; Megaraj, M. Design and development of single screw conveying machine for pyrolysis of waste plastics using nano zeolite particles in fixed bed reactor. Mater. Today Proc. 2021, 47, 880–884. [Google Scholar] [CrossRef]

- Farré, J.A.; Mateu, C.; Teixidó, M.; Cabeza, L.F. Pneumatic urban waste collection systems: A review. Appl. Sci. 2023, 13, 877. [Google Scholar] [CrossRef]

- McBride, W.; Ilic, D. Design of self-compensating soft loading hood. Part. Part. Syst. Charact. 2007, 24, 370–374. [Google Scholar] [CrossRef]

- Jespen, T. ATEX—Explosive Atmospheres; Springer Series in Reliability Engineering: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- IEC System for Certification to Standards Relating to Equipment for use in Explosive Atmospheres, The International Electrotechnical Commission (IEC), Geneva, Switzerland. Available online: www.iecex.com/certified-equipment-scheme/standards/ (accessed on 25 June 2025).

- Bello, A.S.; Al-Ghouti, M.A.; Abu-Dieyeh, M.H. Sustainable and long-term management of municipal solid waste: A review. Bioresour. Technol. Rep. 2022, 18, 101067. [Google Scholar] [CrossRef]

- Ibrahim, M.A. Risk of spontaneous and anthropogenic fires in waste management chain and hazards of secondary fires. Resour. Conserv. Recycl. 2020, 159, 104852. [Google Scholar] [CrossRef]

- Inferno: Dust Explosion at Imperial Sugar, USCBS. Available online: www.youtube.com/watch?v=Jg7mLSG-Yws (accessed on 25 June 2025).

| Material Class | Particle Shape | Three Dimensions | Flow | Examples |

|---|---|---|---|---|

| “Class 1” | Rounded/angular | Equals | Free flowing | Wood pellets and dry powders (not too fine) |

| “Class 2” | Rounded/angular | Equals | Highly cohesive | Milled nuts, wet powders, and fine powders |

| “Class 3” | Flaky/stringy | 1 or 2 are much bigger than others | Non-flowing | Chopped straw, sawdust, wood shavings, chicken litter, and shredded paper, etc. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, T.; Garg, V.; Bradley, M.S.A. Review of Material-Handling Challenges in Energy Production from Biomass and Other Solid Waste Materials. Energies 2025, 18, 4194. https://doi.org/10.3390/en18154194

Deng T, Garg V, Bradley MSA. Review of Material-Handling Challenges in Energy Production from Biomass and Other Solid Waste Materials. Energies. 2025; 18(15):4194. https://doi.org/10.3390/en18154194

Chicago/Turabian StyleDeng, Tong, Vivek Garg, and Michael S. A. Bradley. 2025. "Review of Material-Handling Challenges in Energy Production from Biomass and Other Solid Waste Materials" Energies 18, no. 15: 4194. https://doi.org/10.3390/en18154194

APA StyleDeng, T., Garg, V., & Bradley, M. S. A. (2025). Review of Material-Handling Challenges in Energy Production from Biomass and Other Solid Waste Materials. Energies, 18(15), 4194. https://doi.org/10.3390/en18154194