Absorption Heat Transformer and Vapor Compression Heat Pump as Alternative Options for Waste Heat Upgrade in the Industry

Abstract

1. Introduction

2. Method

2.1. Approach to the Analysis

- -

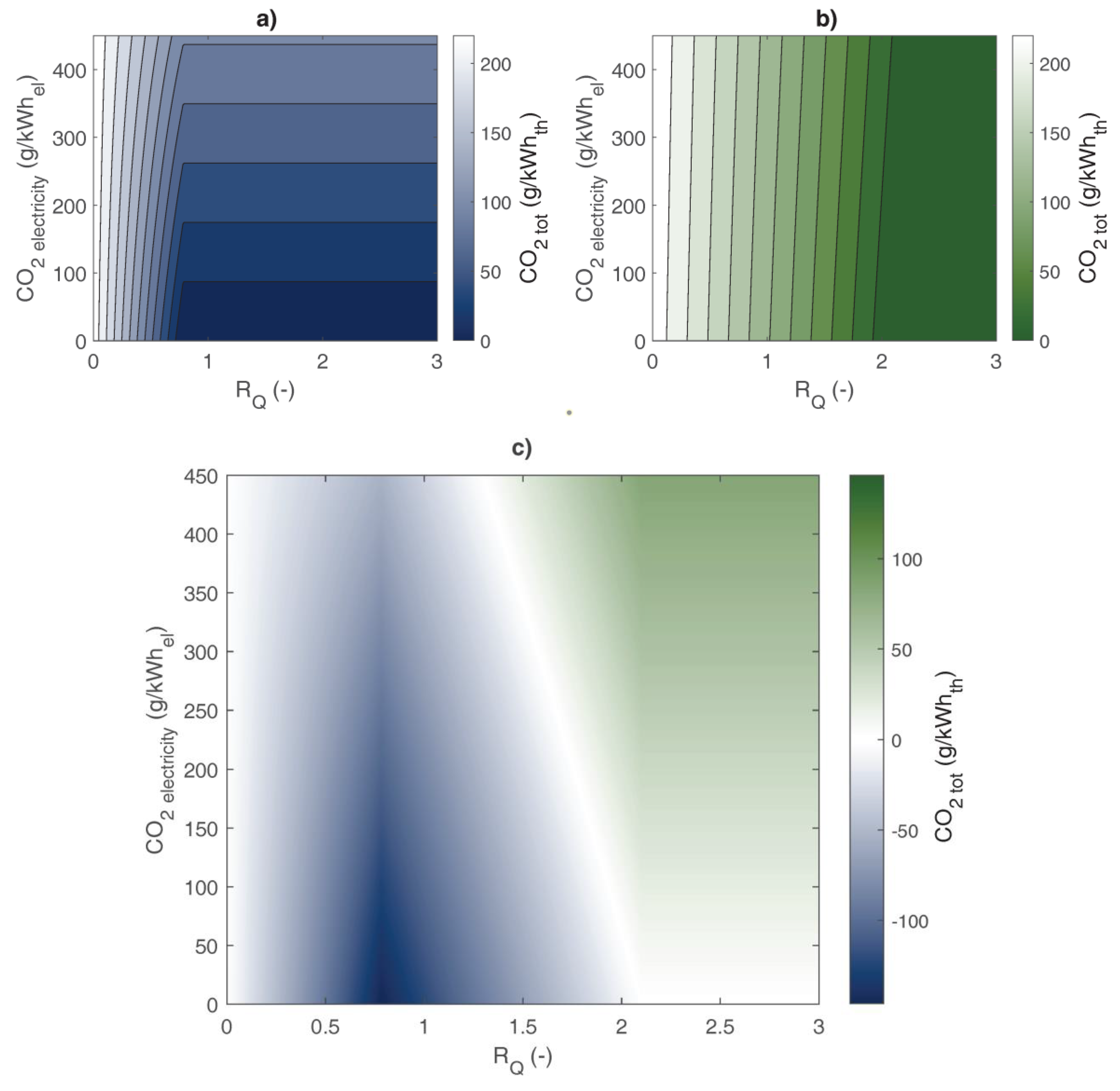

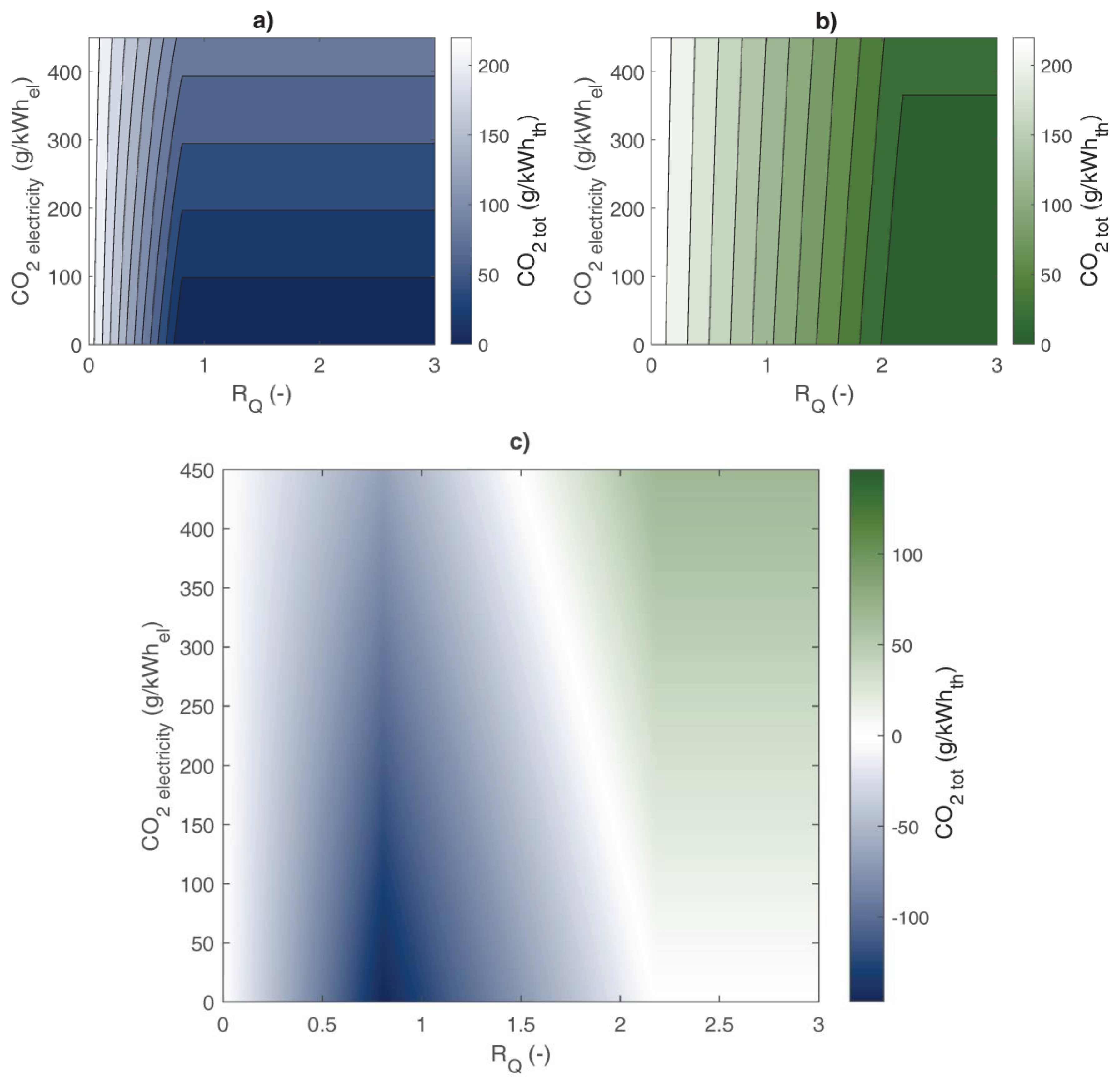

- The ratio between the available waste heat ( and the demand of heat at high temperature (, named RQ. This parameter is varied between 0 and 3, which represents a broad range of applications. Values close to zero refer to those cases where the available waste heat is significantly lower than the need of high temperature heat. In this case, the auxiliary boiler will be required to provide a non-negligible fraction of . Values close to 1 could refer to those industrial process where the process heat delivered at high temperature is almost entirely rejected at low temperature, after been used. Values above 1 are more likely to be found in those cases when a large source of the waste heat, decoupled from the potential user, is available.

- -

- The carbon content of electricity in is used in the environmental analysis for the calculation of the emissions per unit of . This parameter has particular influence on the emissions associated with the electricity consumption of the HTHP compressor, of the AHT internal pumps and of the circulation pumps of the circuit connected with both the technologies. The carbon content of electricity will be varied between 0 (completely decarbonized electricity) to 450 . A larger impact of this parameter is expected on the solution based on HTHP than on the one based on the AHT.

- -

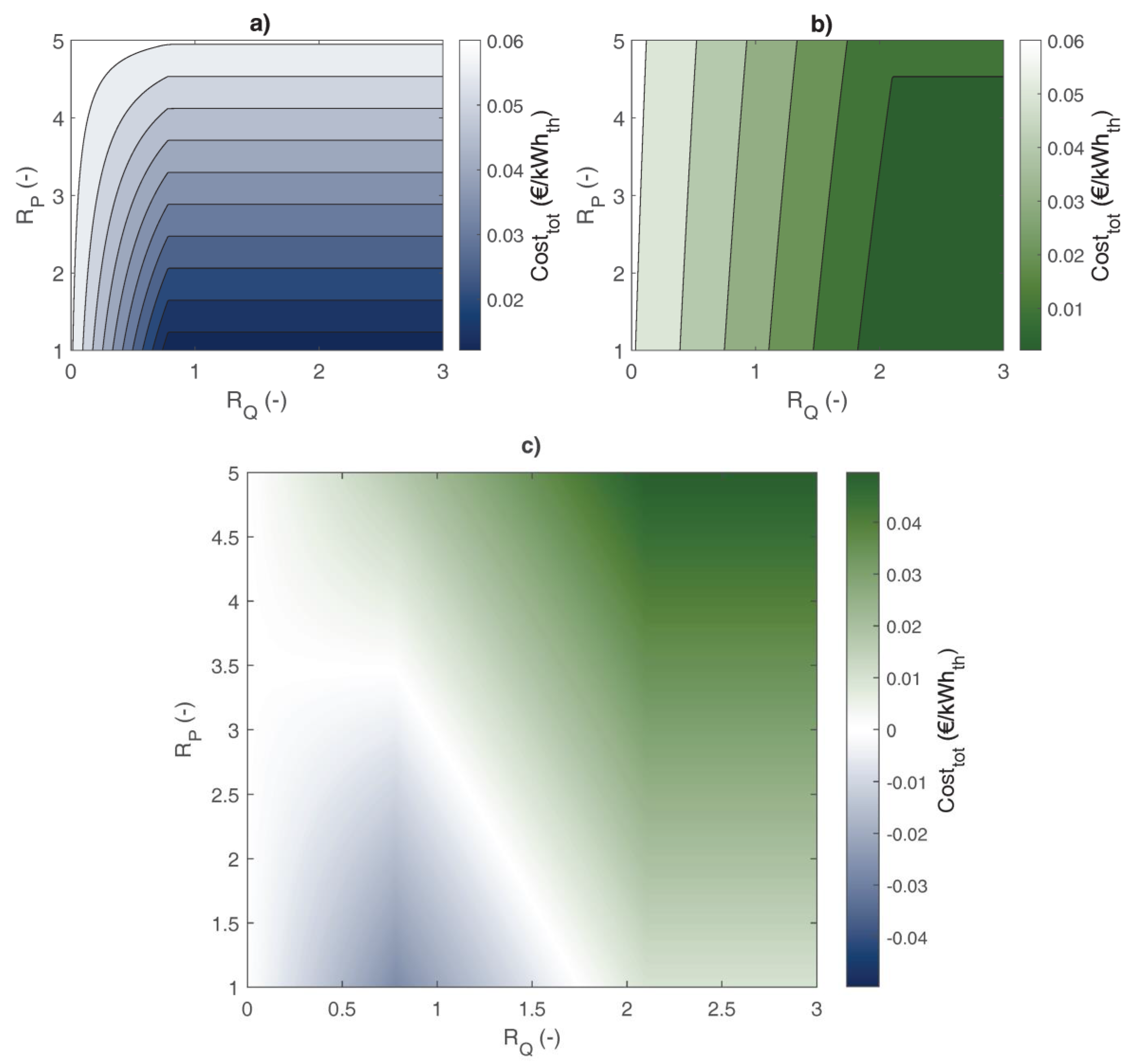

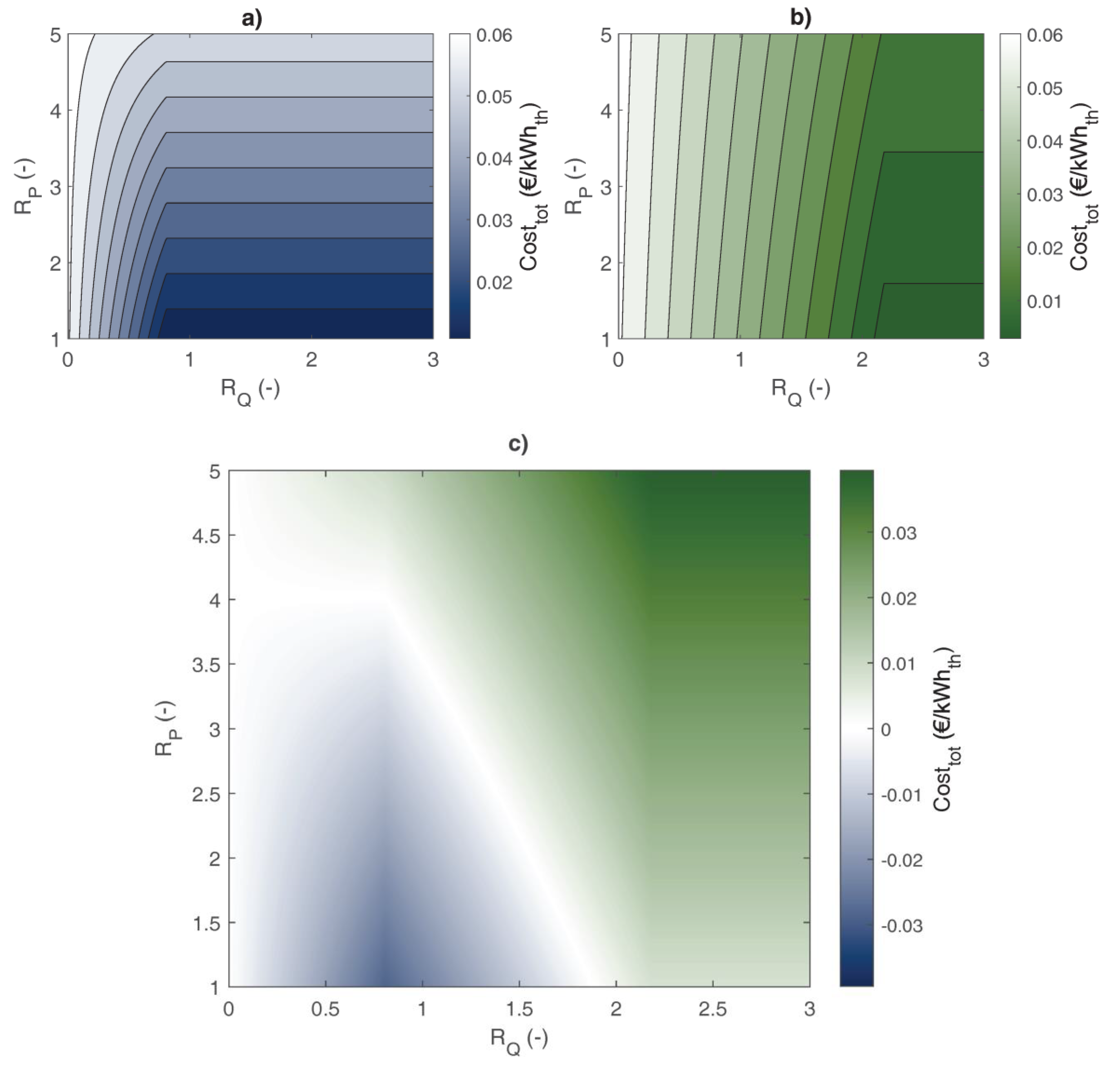

- The ratio between electricity and natural gas cost (RP) is used as a parameter for the economic analysis. The range of considered values spans from 1 to 5, i.e., covering cases with equal cost per kWh of the two energy vectors up to cases where the electricity is much more expensive than the natural gas. To provide cost indication for the heat delivered by the system to the user, a natural gas price of 0.053 EUR/kWh [24] has been considered. This choice influences the absolute value of the cost but does not impact the comparison between the two technological options, since the electricity price is calculated as a function of the natural gas price. Thus, the thresholds and trends presented in Section 4 are applicable independently of the gas price.

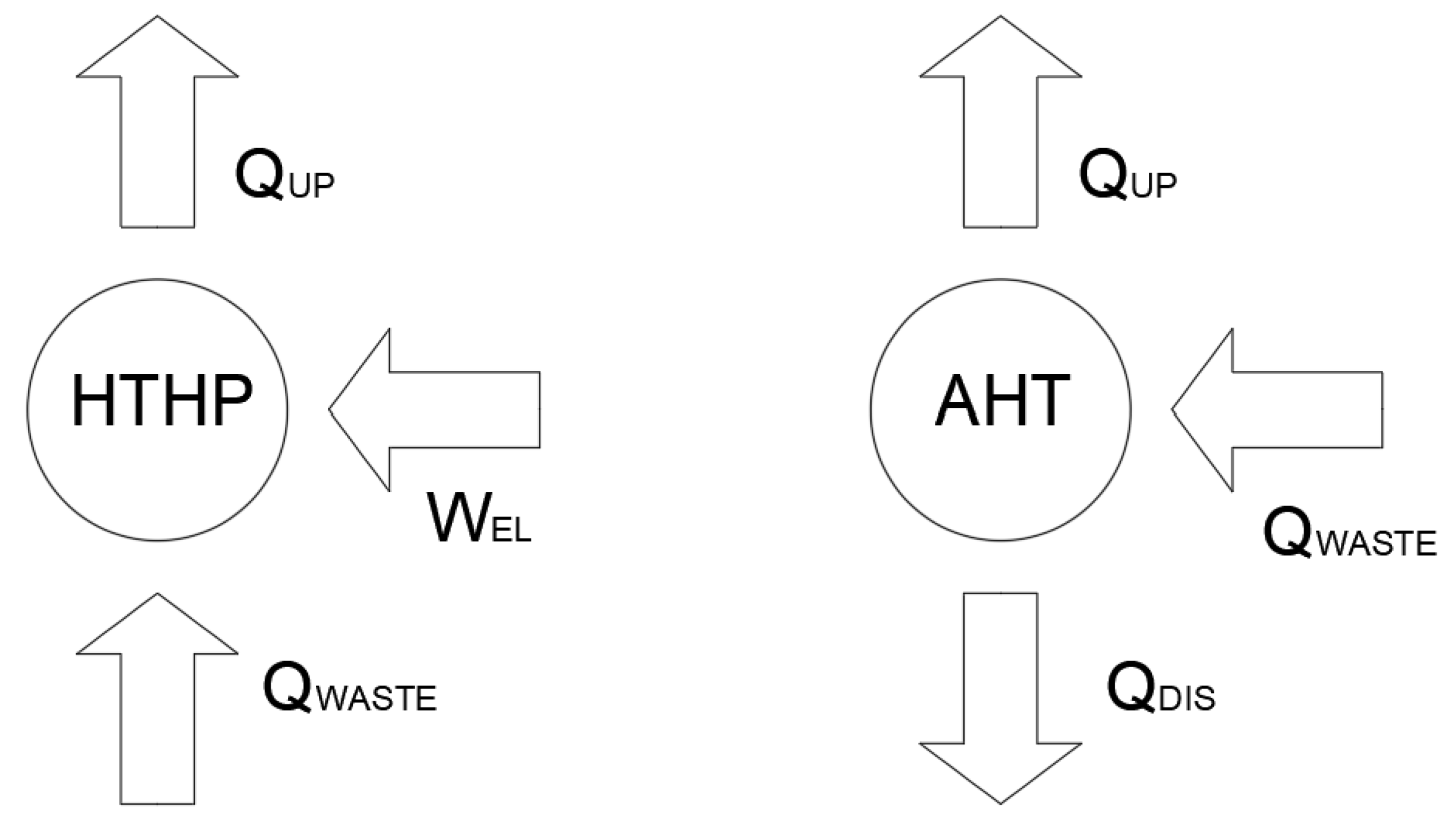

2.2. AHT + Boiler System

2.3. HTHP + Boiler System

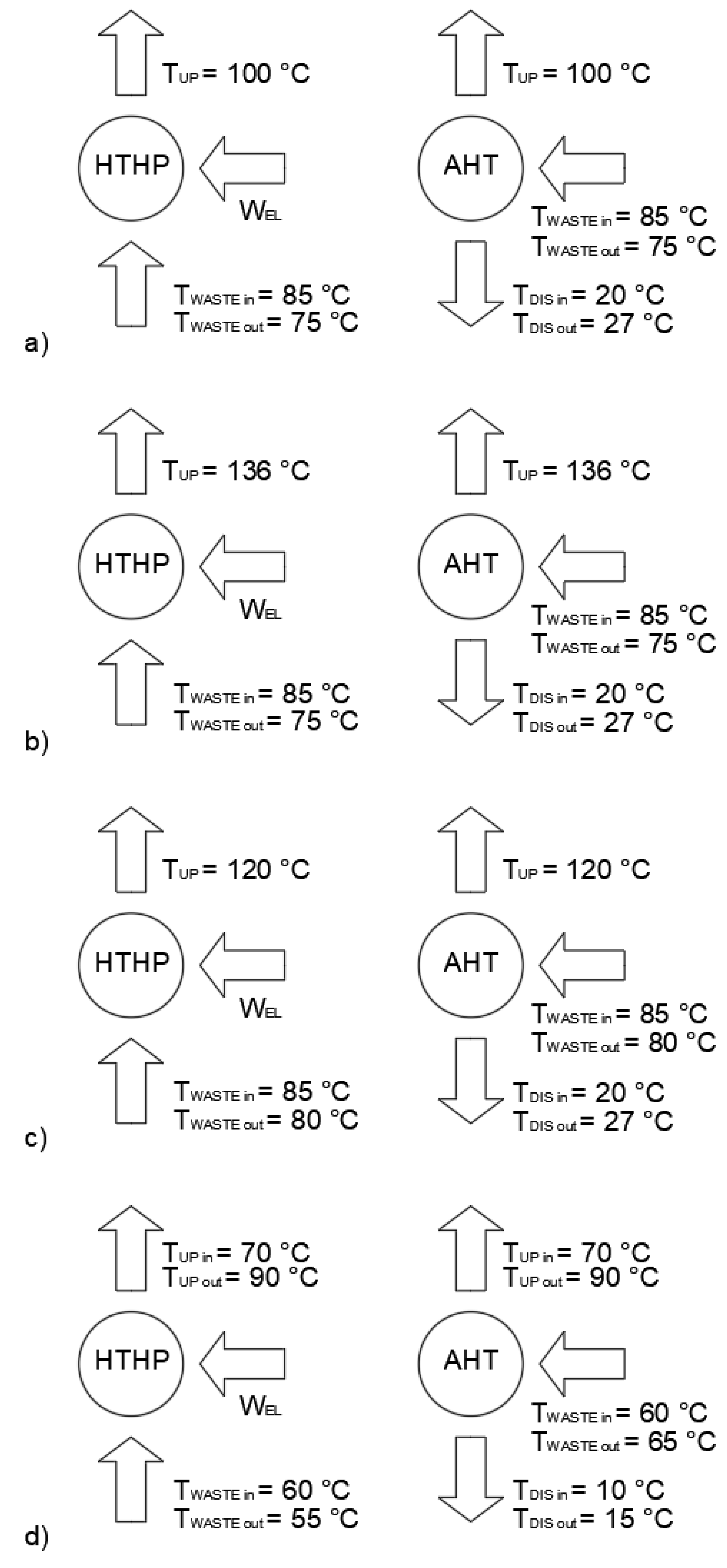

2.4. Case Studies

- Desalination: process driven by heat from a cogeneration plant, with heat rejection through a cooling tower.

- Carbon capture: regeneration of the ammines in a carbon-capture process driven by heat from a cogeneration plant and with heat rejection through a cooling tower.

- Industrial steam: steam generation at 2 bar for an industrial process driven by the condensation loop of a distillation column and with condensation heat rejected through a cooling tower.

- District heating: medium temperature district heating network driven by waste heat from data centers with ground water for the heat rejection.

3. Modelling Approach

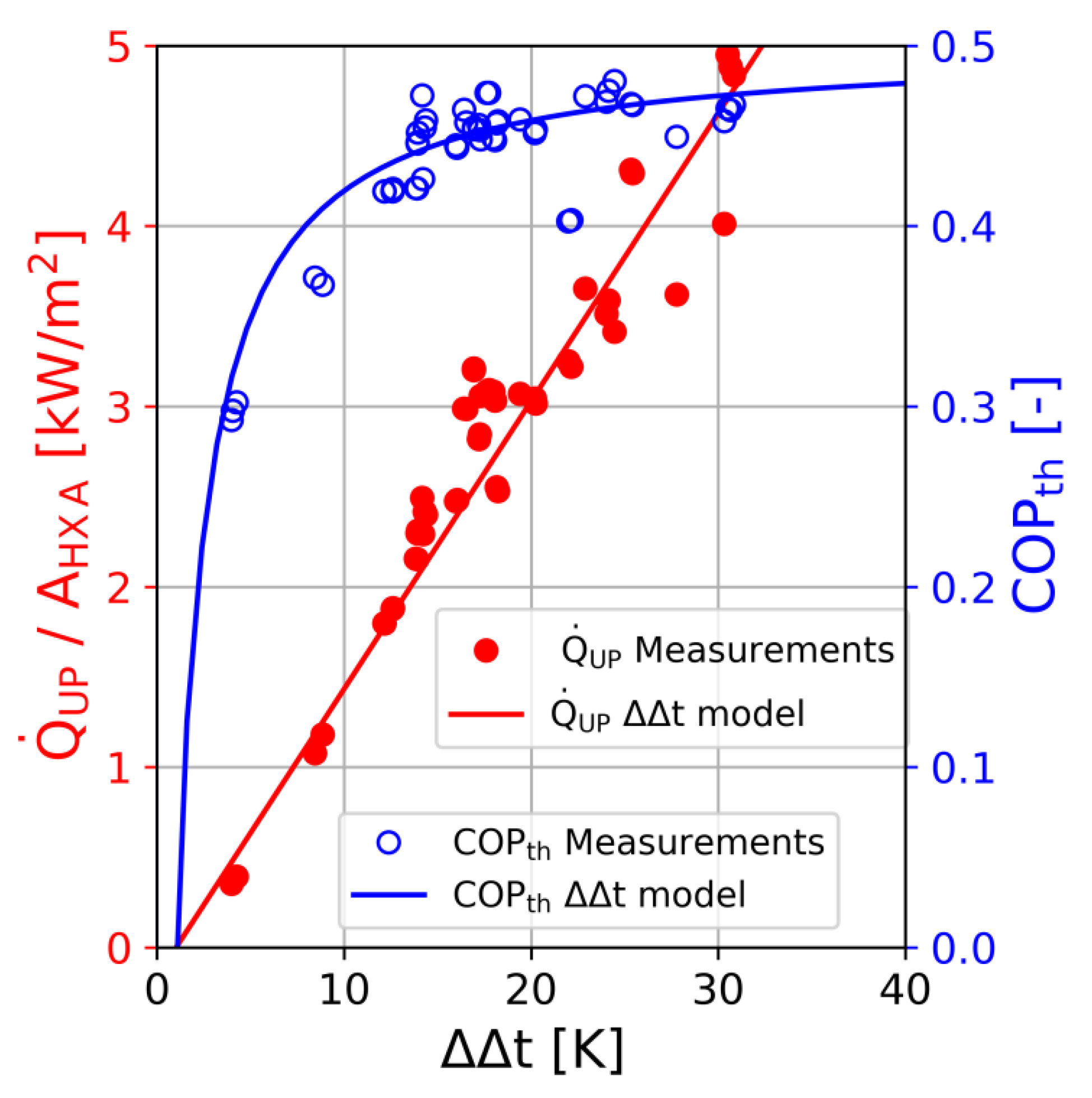

3.1. Heat Transformer

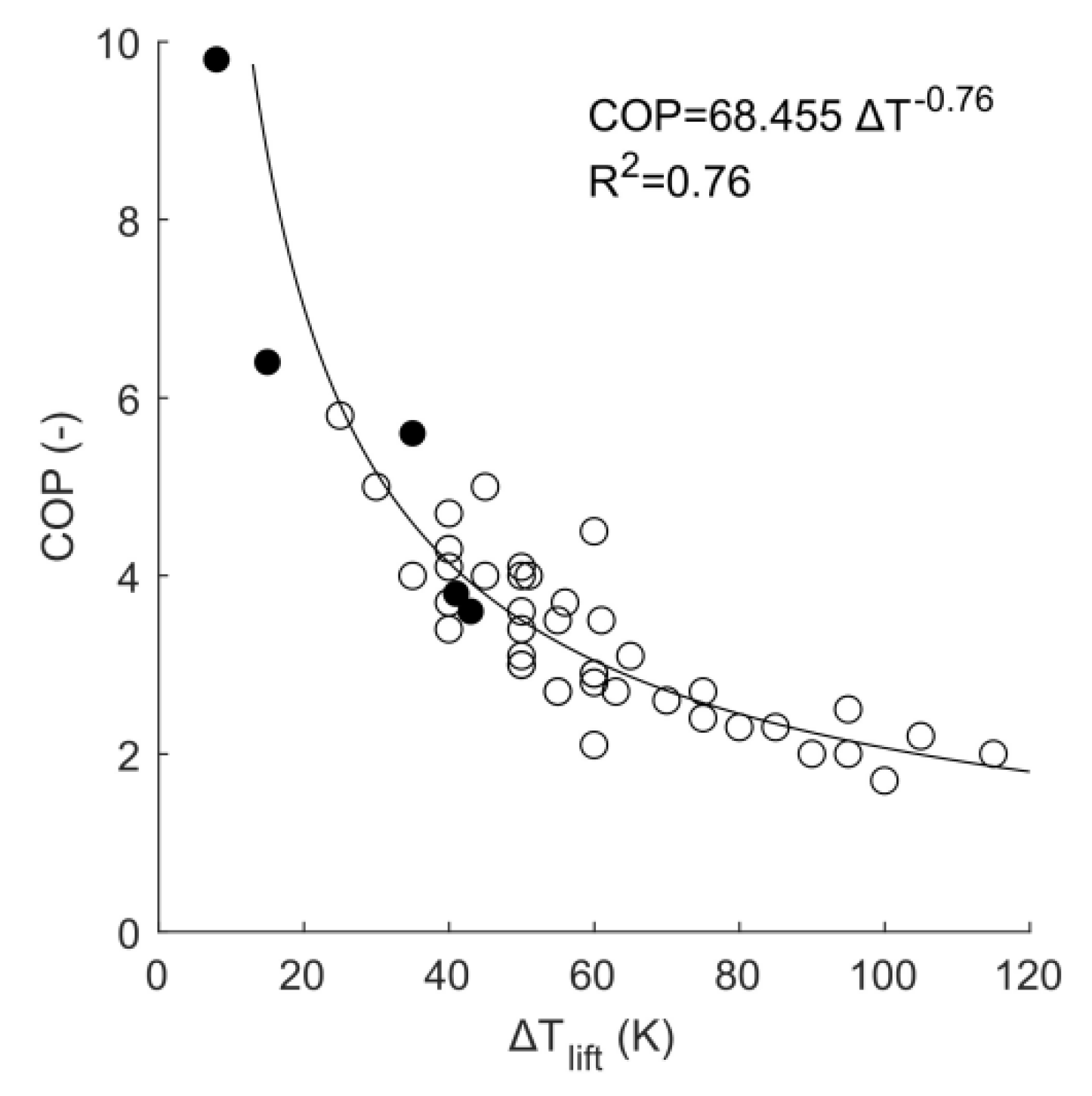

3.2. Heat Pump

3.3. Gas Boiler

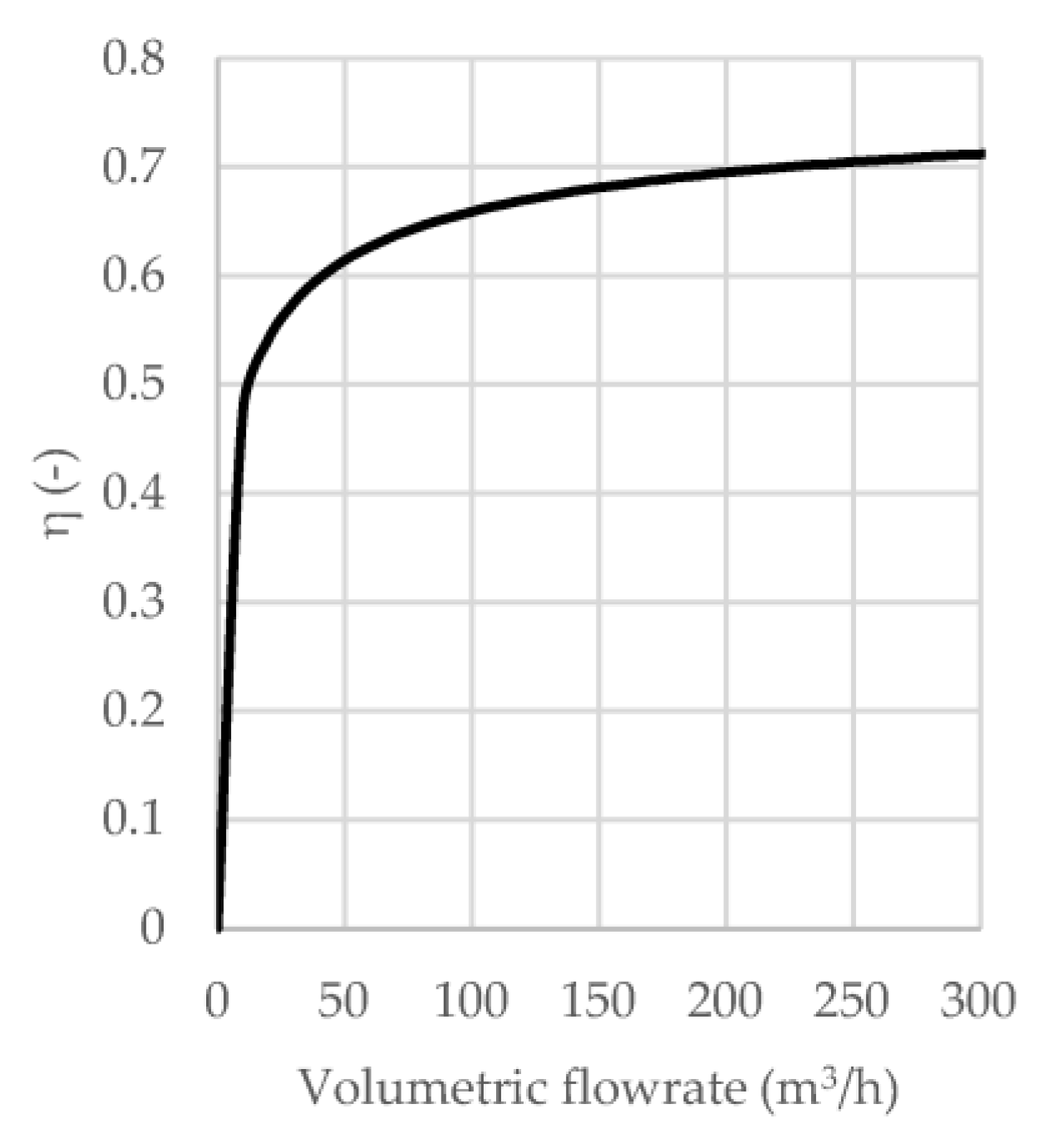

3.4. Auxiliary Hydraulic Loops

4. Results

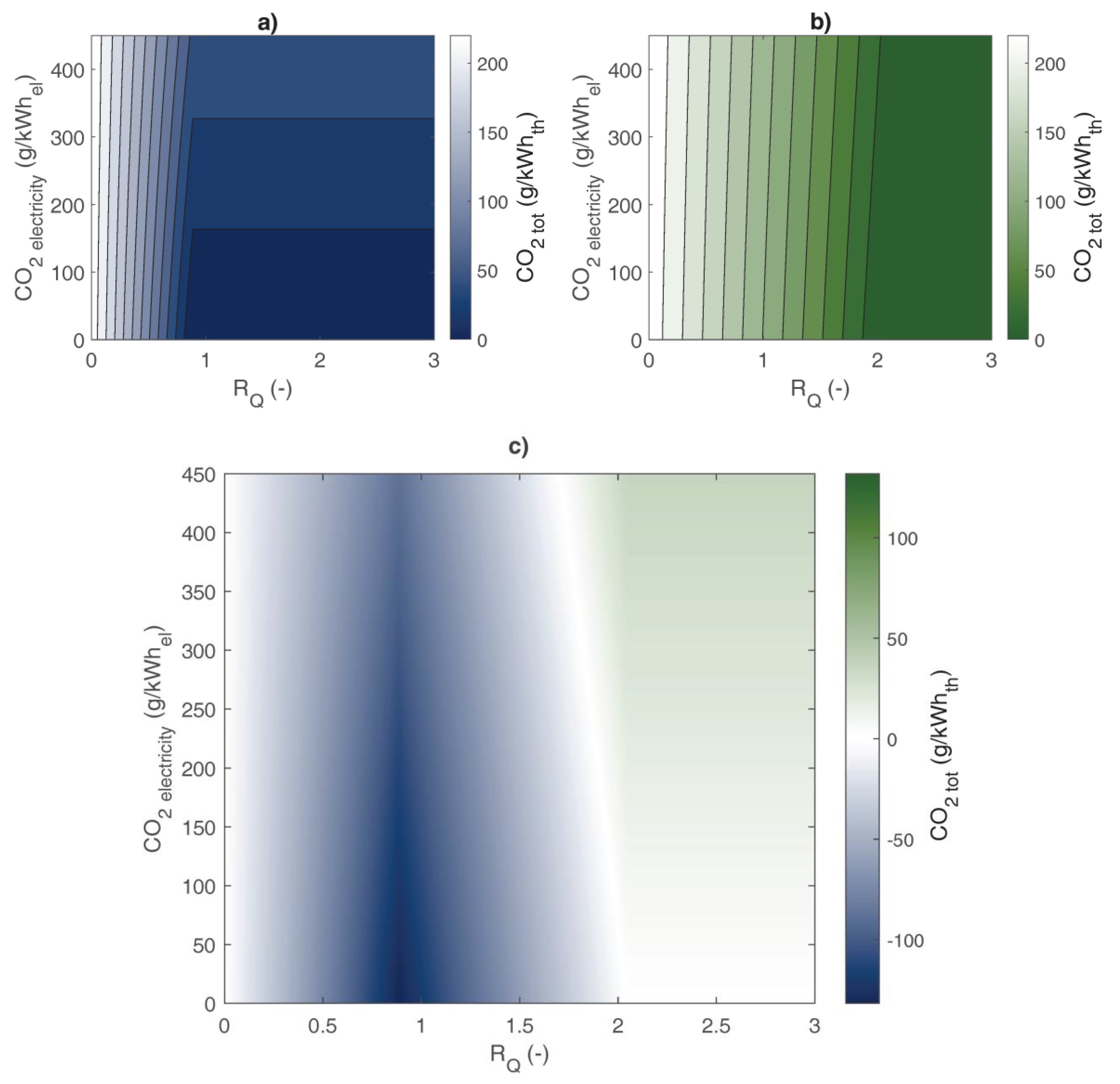

4.1. Case Study 1 (Desalination)

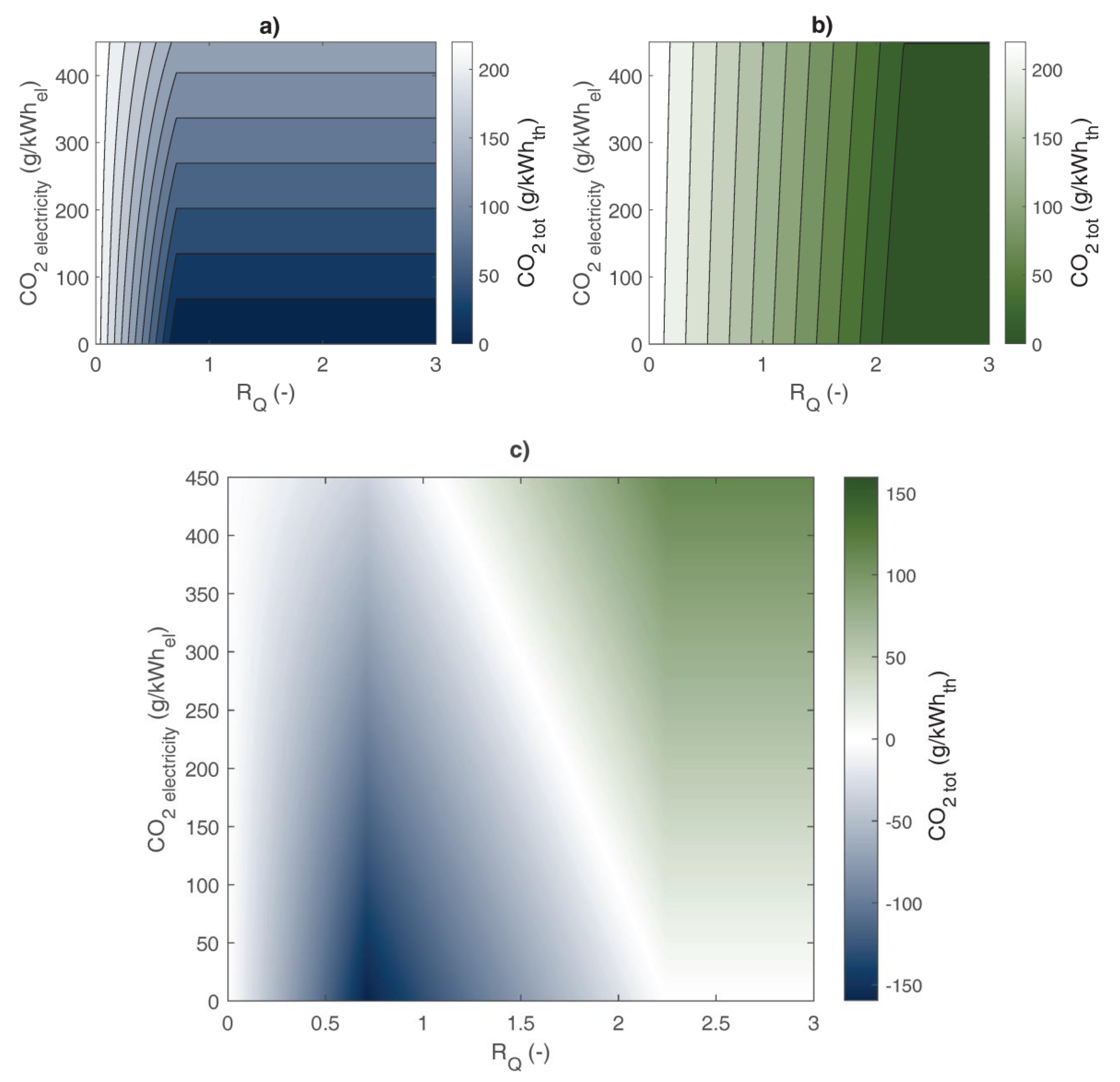

4.2. Case Study 2 (Carbon Capture)

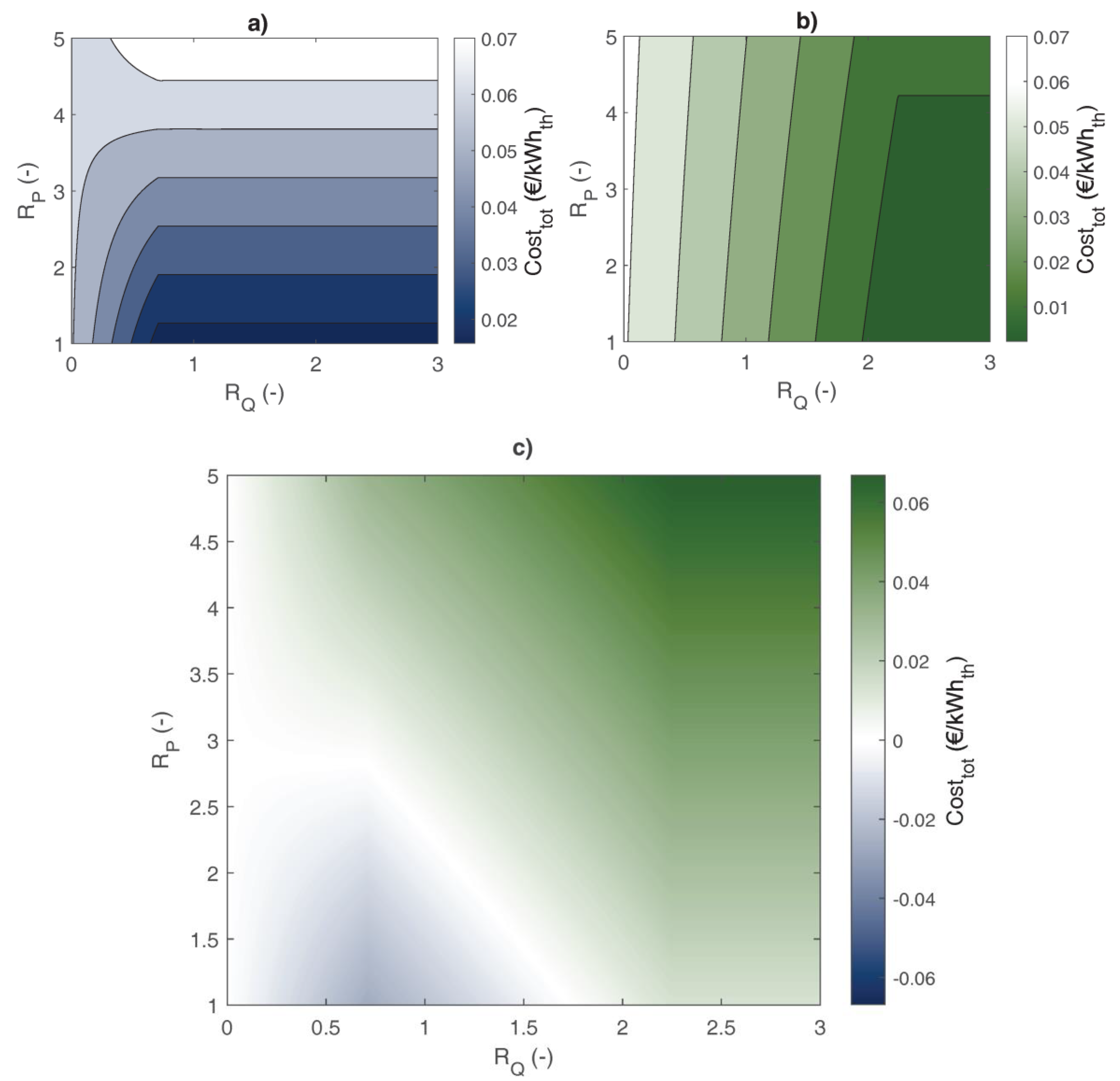

4.3. Case Study 3 (Industrial Steam) and Case Study 4 (District Heating)

5. Conclusions

- -

- The ratio between the heat demand and the available waste heat (RQ), which affects the heat production of the heat upgrade technology and the fraction of heat provided by the gas boiler.

- -

- The carbon intensity of the electricity, whose consumption is higher in the HTHP system than in the AHT system.

- -

- The ratio between electricity and gas prices (RP), which affects the economic convenience of the heat provided by the heat pump compared to that of the backup boiler.

- -

- The analysis and comparison of the case studies presented show that both HTHP and AHT systems can be used for heat recovery. The choice of the most suitable system depends on the specific operating conditions.

- -

- The main parameter influencing the results of the analyses is the COP of the heat pump. Other less influential parameters are the consumption of auxiliaries and the thermal and electrical COP of the heat transformer.

- -

- By increasing the ratio between the available waste heat and the demand for upgraded heat (RQ), the HTHP system is initially the one with the lowest emissions per unit of heat supplied. As the available waste heat increases, a threshold is reached where the CO2 emissions of the two options are equal and above which the AHT system becomes the one with the lowest emissions. The position of the threshold depends on the carbon intensity of the electricity.

- -

- The HTHP system achieves lower CO2 emissions than the AHT system when a limited amount of waste heat is available (RQ < 1), while the AHT system is always preferred when a large amount of waste heat is available compared to the heat demand (RQ > 2). In between, the choice of system should be based on the operating conditions that affect the performance of the heat pump and heat transformer.

- -

- Regarding the cost of the upgraded heat, a similar threshold is found as in the environmental analysis. However, the cost threshold is anticipated with respect to the emission threshold, especially when the ratio between electricity and gas prices (RP) is high. The HTHP system achieves lower operative costs than the AHT system when a limited amount of waste heat is available (RQ < 0.8), and the electricity price is sufficiently low when compared to the gas price (RP < 2.5). On the contrary, the AHT system is better when a large quantity of waste heat is available (RQ > 2) and when RP > 3.5. In between, the determination of the system delivering heat at the lower cost depends on the working conditions impacting on the heat pump and heat transformer performances.

- -

- Outside the ranges of conditions where the advantage of one technology over the other is unambiguous regardless of the type of analysis carried out, there is a range in all the case studies where the preference of one system over the other depends on the type of analysis carried out. Typically, the environmental analysis shows a wider range of favorable conditions for the HTHP system than the cost analysis.

- -

- Focusing on the specific case studies included in this work, for desalination, HTHP is in most cases the option with the lowest cost and emissions, thanks to the high COP that characterizes this application. For carbon capture, the system based on the AHT is often the preferred option, especially considering the cost of the upgraded heat produced. The production of industrial steam and the district heating case are similar and intermediate with respect to the previous ones.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Area, | |

| Auxiliaries, | |

| Coefficient of performance | |

| Greenhouse gas emission, | |

| Specific cost, | |

| Pressure | |

| Heat, | |

| Heat flow rate, | |

| Ratio | |

| Characteristic equation slope parameter for heat exchanger, | |

| Temperature, K | |

| Volume of circulated fluid per unit of heat, | |

| Work, | |

| Work, | |

| Greek letters | |

| Difference | |

| Characteristic temperature difference, | |

| Efficiency | |

| Subscripts | |

| AHT | Absorption heat transformer |

| Gas boiler | |

| Design | |

| Discharged | |

| Electric | |

| Heat pump | |

| Heat transformer | |

| High temperature | |

| High temperature heat pump | |

| Absorber heat exchanger | |

| Hydraulic | |

| Internal | |

| Low temperature | |

| Natural gas | |

| P | Price |

| Q | Heat |

| Rejected | |

| Source | |

| Thermal | |

| Total | |

| Upgraded | |

| Abbreviations | |

| AHT | Absorption heat transformer |

| GWP | Global warming potential |

| HTHP | High temperature heat pump |

References

- Forman, C.; Muritala, I.K.; Pardemann, R.; Meyer, B. Estimating the global waste heat potential. Renew. Sustain. Energy. Rev. 2016, 57, 1568–1579. [Google Scholar] [CrossRef]

- Hintemann, R.; Hinterholzer, S. Energy consumption of data centers worldwide How will the Internet become green? In Proceedings of the ICT4S 2019, Lappeenranta, Finnland, 10–14 June 2009. [Google Scholar]

- Koot, M.; Wijnhoven, F. Usage impact on data center electricity needs: A system dynamic forecasting model. Appl. Energy 2021, 291, 116798. [Google Scholar] [CrossRef]

- Zevenhoven, C.A.P.; Khan, U.; Haikarainen, C.; Saeed, L.; Tveit, T.-M.; Saxén, H. Performance improvement of an industrial Stirling engine heat pump. In Proceedings of the 33rd International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems, Osaka, Japan, 29 June–3 July 2020; Available online: http://www.proceedings.com/55242.html (accessed on 10 November 2024).

- Arpagaus, C.; Bless, F.; Uhlmann, M.; Schiffmann, J.; Bertsch, S.S. High temperature heat pumps: Market overview, state of the art, research status, refrigerants, and application potentials. Energy 2018, 152, 985–1010. [Google Scholar] [CrossRef]

- Averfalk, H.; Ingvarsson, P.; Persson, U.; Gong, M.; Werner, S. Large heat pumps district heating systems. Renew. Sustain. Energy. Rev. 2017, 79, 1275–1284. [Google Scholar] [CrossRef]

- David, A.; Mathiesen, B.V.; Averfalk, H.; Werner, S.; Lund, H. Heat Roadmap Europe: Large-Scale Electric Heat Pumps in District Heating Systems. Energies 2017, 10, 578. [Google Scholar] [CrossRef]

- Piel, E.; Mata, C.; Lucas, P.; Pesce, G. DHC Market Outlook Insights & Trends; Euroheat & Power’s Unit Market Intelligence: 2023. Available online: https://api.euroheat.org/uploads/DHC_Market_Outlook_Insights_Trends_2023_36d6fe8924.pdf (accessed on 10 November 2024).

- Lund, H.; Werner, S.; Wiltshire, R.; Svendsen, S.; Thorsen, J.E.; Hvelplund, F.; Vad Mathiesen, B. 4th Generation District Heating (4GDH): Integrating smart thermal grids into future sustainable energy systems. Energy 2014, 68, 1–11. [Google Scholar] [CrossRef]

- International Energy Agency. The Future of Heat Pumps in China; IEA: Paris, France, 2024; Available online: https://www.iea.org/reports/the-future-of-heat-pumps-in-china (accessed on 5 December 2024).

- Bergamini, R.; Jensen, J.K.; Elmegaard, B. Thermodynamic competitiveness of high temperature vapor compression heat pumps for boiler substitution. Energy 2019, 182, 110–121. [Google Scholar] [CrossRef]

- Jensen, E.H.; Andreasen, A.; Jørsboe, J.K.; Andersen, M.P.; Hostrup, M.; Elmegaard, B.; Riber, C.; Fosbøl, P.L. Electrification of amine-based CO2 capture utilizing heat pumps. Carbon Capture Sci. Technol. 2024, 10, 100154. [Google Scholar] [CrossRef]

- He, W.F.; Han, D.; Ji, C. Investigation on humidification dehumidification desalination system coupled with heat pump. Desalination 2018, 436, 152–160. [Google Scholar] [CrossRef]

- Ayati, E.; Rahimi-Ahar, Z.; Hatamipour, M.S.; Ghalavand, Y. Water productivity enhancement in variable pressure humidification dehumidification (HDH) desalination systems using heat pump. Appl. Therm. Eng. 2019, 160, 114114. [Google Scholar] [CrossRef]

- Cudok, F.; Giannetti, N.; Corrales Ciganda, J.L.; Aoyama, J.; Babu, P.; Coronas, A.; Fujii, T.; Inoue, N.; Saito, K.; Yamaguchi, S.; et al. Absorption heat transformer—State-of-the-art of industrial applications. Renew. Sustain. Energy Rev. 2021, 141, 110757. [Google Scholar] [CrossRef]

- Liu, Z.; Lu, D.; Tao, S.; Chen, R.; Gong, M. Experimental study on using 85 °C low-grade heat to generate. Energy 2024, 299, 131491. [Google Scholar] [CrossRef]

- Ma, X.; Chen, J.; Li, S.; Sha, Q.; Liang, A.; Li, W.; Zhang, J.; Zheng, G.; Feng, Z. Appliacation of absorption heat transformer to recover waste heat from a synthetic rubber plant. Appl. Therm. Eng. 2003, 23, 797–806. [Google Scholar] [CrossRef]

- Fujii, T.; Nishiguchi, A.; Uchida, S. Development Activities of Low Temperature Waste Heat Recovery Appliances Using Absorption Heat Pumps. In Proceedings of the International Symposium on Next-Generation Air Conditioning and Refrigeration Technology, Tokyo, Japan, 17–19 February 2010. [Google Scholar]

- Aoyama, J.; Oikawa, Y.; Ebara, S. Absorption Heat Pump—Type II Heat Transformer. In Proceedings of the 14th IIT Gustav Lorentzen Conference on Natural Refrigerants, Kyoto, Japan, 7–9 December 2020. [Google Scholar]

- Vieren, E.; Demeester, T.; Beyne, W.; Magni, C.; Abedini, H.; Arpagaus, C.; Bertsch, S.; Arteconi, A.; De Paepe, M.; Lecompte, S. The Potential of Vapor Compression Heat Pumps Supplying Process Heat between 100 and 200 °C in the Chemical Industry. Energies 2023, 16, 6473. [Google Scholar] [CrossRef]

- Brückner, S.; Liu, S.; Miró, L.; Radspieler, M.; Cabeza, L.F.; Lävemann, E. Industrial waste heat recovery technologies: An economic analysis of heat transformation technologies. Appl. Energy 2015, 151, 157–167. [Google Scholar] [CrossRef]

- Ciotti, G.; Cottes, M.; Mazzolini, M.; Sappa, A.; Simeoni, P. A decision support system for industrial waste heat recovery: The CE-HEAT Project. In Proceedings of the XXIV Summer School “Francesco Turco”—Industrial Systems Engineering, Brescia, Italy, 11–13 September 2019. [Google Scholar]

- Payà, J.; Cazorla-Marìn, A.; Arpagaus, C.; Corrales Cigarda, J.L.; Hassan, A.H. Low-Pressure Steam Generation with Concentrating Solar Energy and Different Heat Upgrade Technologies: Potential in the European Industry. Sustainability 2024, 16, 1733. [Google Scholar] [CrossRef]

- Eurostat. Gas Prices for Non-Household Consumers—Bi-Annual Data (from 2007 Onwards). Available online: https://ec.europa.eu/eurostat/databrowser/view/nrg_pc_203/default/table?lang=en (accessed on 11 December 2024).

- Puig Arnavat, M.; Lopez-Villada, J.; Bruno, J.C.; Coronas, A. Analysis and parameter identification for characteristic equations of single- and double-effect absorption chillers by means of multivariable regression. Int. J. Refrig. 2010, 33, 70–78. [Google Scholar] [CrossRef]

- Corrales Ciganda, J.L.; Cudok, F. Performance evaluation of an absorption heat transformer for industrial heat waste recovery using the characteristic equation. Appl. Therm. Eng. 2021, 193, 116986. [Google Scholar] [CrossRef]

- Corrales Ciganda, J.L.; Martinez-Urrutia, A. Steady State Measurements and Dynamic Behaviour of an Absorption Heat Transformer Operating in an Industrial Environment. In Proceedings of the 14th IEA Heat Pump Conference, Chicago, IL, USA, 15–18 May 2023. [Google Scholar]

- Famiglietti, J.; Acconito, L.; Arpagaus, C.; Toppi, T. Environmental life cycle assessment of industrial high temperature to residential small-size heat pumps: A critical review. Energy Convers. Manag. X 2025, 26, 100947. [Google Scholar] [CrossRef]

| Case Study | |||

|---|---|---|---|

| Desalination | 85–75 °C | 100 °C | 20–27 °C |

| Carbon capture | 85–75 °C | 136 °C | 20–27 °C |

| Industrial steam | 85–80 °C | 120 °C | 20–27 °C |

| District heating | 60–55 °C | 70–90 °C | 10–15 °C |

| Case Study | |||

|---|---|---|---|

| 1 | 8.74 | 0.49 | 25.90 |

| 2 | 3.45 | 0.45 | 23.35 |

| 3 | 4.59 | 0.48 | 20.20 |

| 4 | 5.16 | 0.46 | 18.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Villa, G.; Corrales Ciganda, J.L.; Abrami, G.; Toppi, T. Absorption Heat Transformer and Vapor Compression Heat Pump as Alternative Options for Waste Heat Upgrade in the Industry. Energies 2025, 18, 3454. https://doi.org/10.3390/en18133454

Villa G, Corrales Ciganda JL, Abrami G, Toppi T. Absorption Heat Transformer and Vapor Compression Heat Pump as Alternative Options for Waste Heat Upgrade in the Industry. Energies. 2025; 18(13):3454. https://doi.org/10.3390/en18133454

Chicago/Turabian StyleVilla, Giorgio, Josè Luis Corrales Ciganda, Gianluca Abrami, and Tommaso Toppi. 2025. "Absorption Heat Transformer and Vapor Compression Heat Pump as Alternative Options for Waste Heat Upgrade in the Industry" Energies 18, no. 13: 3454. https://doi.org/10.3390/en18133454

APA StyleVilla, G., Corrales Ciganda, J. L., Abrami, G., & Toppi, T. (2025). Absorption Heat Transformer and Vapor Compression Heat Pump as Alternative Options for Waste Heat Upgrade in the Industry. Energies, 18(13), 3454. https://doi.org/10.3390/en18133454