1. Introduction

The global pursuit of net-zero emissions underscores the urgent need for scalable and sustainable energy carriers. Hydrogen (H

2) has emerged as a cornerstone of decarbonization strategies due to its versatility and potential to reduce carbon emissions across energy-intensive sectors. However, its widespread adoption is hindered by critical challenges related to production scalability, infrastructure development, and technological integration. Addressing these barriers is essential to help accelerate the energy transition. Two main aspects related to hydrogen-based technology implementation will be discussed in the next sections: the green ammonia (NH

3) market [

1] and hydrogen transportation technologies. These aspects are essential for making the hydrogen transition viable.

The rise of green ammonia as a key hydrogen carrier reflects its potential to overcome hydrogen storage and transportation challenges. With its high hydrogen density and existing global trade networks, green ammonia offers a viable solution for enabling long-distance hydrogen transport and supporting renewable energy deployment. The market for green ammonia is projected to grow rapidly, driven by investments in production facilities, international partnerships, and emerging regulatory frameworks aimed at reducing the carbon footprint of industrial processes.

Efficient hydrogen transportation is also pivotal for realizing a global hydrogen economy [

2]. Current technologies face trade-offs between energy efficiency, safety, and infrastructure costs. Options such as compressed gas, liquefied hydrogen, liquid organic hydrogen carriers (LOHCs), and ammonia each offer distinct advantages and challenges [

3]. Developing these technologies while helping to ensure regulatory compliance, reduce energy losses, and reduce safety risks is crucial to scaling up hydrogen’s role in the global energy transition.

1.1. Green Ammonia Market

The global effort to develop clean and sustainable energy solutions, in line with the 2050 Paris Agreement goals, has highlighted hydrogen’s key role in reducing carbon emissions and addressing climate change. Green hydrogen, based on renewable energy sources, is becoming an essential sustainable energy carrier in various energy and industrial sectors. However, while hydrogen-based technologies hold great promise for creating highly decarbonized energy systems, they also pose significant challenges. Major difficulties lie in the efficient storage, transportation, and distribution of hydrogen over long distances. These challenges stem from hydrogen being the lightest element in the periodic table, which leads to its low energy density and high volatility, making these processes more complex.

Among the various methods for transporting green hydrogen and considering the numerous commercial and technical challenges, green ammonia emerges as the most promising alternative favored by many project developers [

4]. Green ammonia offers a high hydrogen density by weight, making it an efficient and compact carrier for hydrogen transport and storage, thereby enabling greater energy density per unit volume.

Another significant advantage of green ammonia is the existence of a well-established global infrastructure for its production, transportation, and storage (

Figure 1). The existing ammonia industry provides a network of pipelines, storage tanks, and distribution systems that can be harnessed to transport and distribute green hydrogen derived from ammonia, reducing the need for costly and time-consuming infrastructure development.

As a transformative technology, green ammonia can facilitate the production, transportation, and use of renewable energy resources, as well as foster international cooperation in the renewable energy sector to help accelerate the growth of the green hydrogen market. The global green ammonia market, valued at USD 0.3 billion in 2023, is projected to reach USD 17.9 billion by 2030, growing at a compound annual growth rate of 72.9% [

5].

Numerous global projects aimed at establishing green ammonia production facilities are expected to commence operations by the middle of this decade. However, a major challenge for project developers is meeting the regulatory standards for lifetime emissions of hydrogen imports. These standards are emerging in key markets with high hydrogen demand. Most planned green ammonia production sites are designed as off-grid initiatives, featuring dedicated wind or solar farms [

6]. This approach is due to either the lack of access to a power grid to handle substantial power requirements or the absence of internationally standardized certification systems for procuring green energy from the grid.

While hydrogen production via electrolysis can be operated flexibly according to the local supply of volatile renewable electricity, the Haber–Bosch process for ammonia production typically requires almost constant operation and a corresponding base load power supply [

7].

To meet regulatory emissions requirements, net-zero backup solutions are necessary on-site. Due to existing synergies, such as the availability of high storage capacities for hydrogen in green ammonia facilities [

8], hydrogen-fed energy converters, such as reciprocating internal combustion engines and fuel cells, represent a highly valuable techno-economic alternative among existing technologies for backup power. In addition to avoiding storage costs, hydrogen-fed internal combustion engines are characterized by low power-specific capital costs, high operating flexibility, fast response times, low hydrogen purity requirements, and easy scalability compared to competing technologies.

This study provides a comparative evaluation of hydrogen engines with alternative storage and backup power solutions using economic key performance indicators (KPIs) specifically for off-grid use in existing and future green ammonia production facilities. By offering a detailed analysis of the environmental and techno-economic feasibility of these solutions, this paper highlights the significant potential of hydrogen engines to play a critical role in enabling the widespread adoption of green ammonia production facilities.

Figure 1.

Major transportation routes for green ammonia; illustration based on IRENA [

9].

Figure 1.

Major transportation routes for green ammonia; illustration based on IRENA [

9].

1.2. H2 Transportation and Related Technologies

Transporting green hydrogen over long distances poses several significant challenges. One primary concern is energy efficiency, as hydrogen’s low density by volume demands considerable energy for its transportation. Addressing the substantial energy losses inherent in this process is crucial, underscoring the importance of reducing inefficiencies to make hydrogen transport viable [

10]. Safety is another critical issue. Hydrogen’s high volatility and flammability present inherent risks during transportation [

11]. Establishing secure containment and handling protocols is essential to mitigate these potential hazards and help ensure the safe transport of hydrogen.

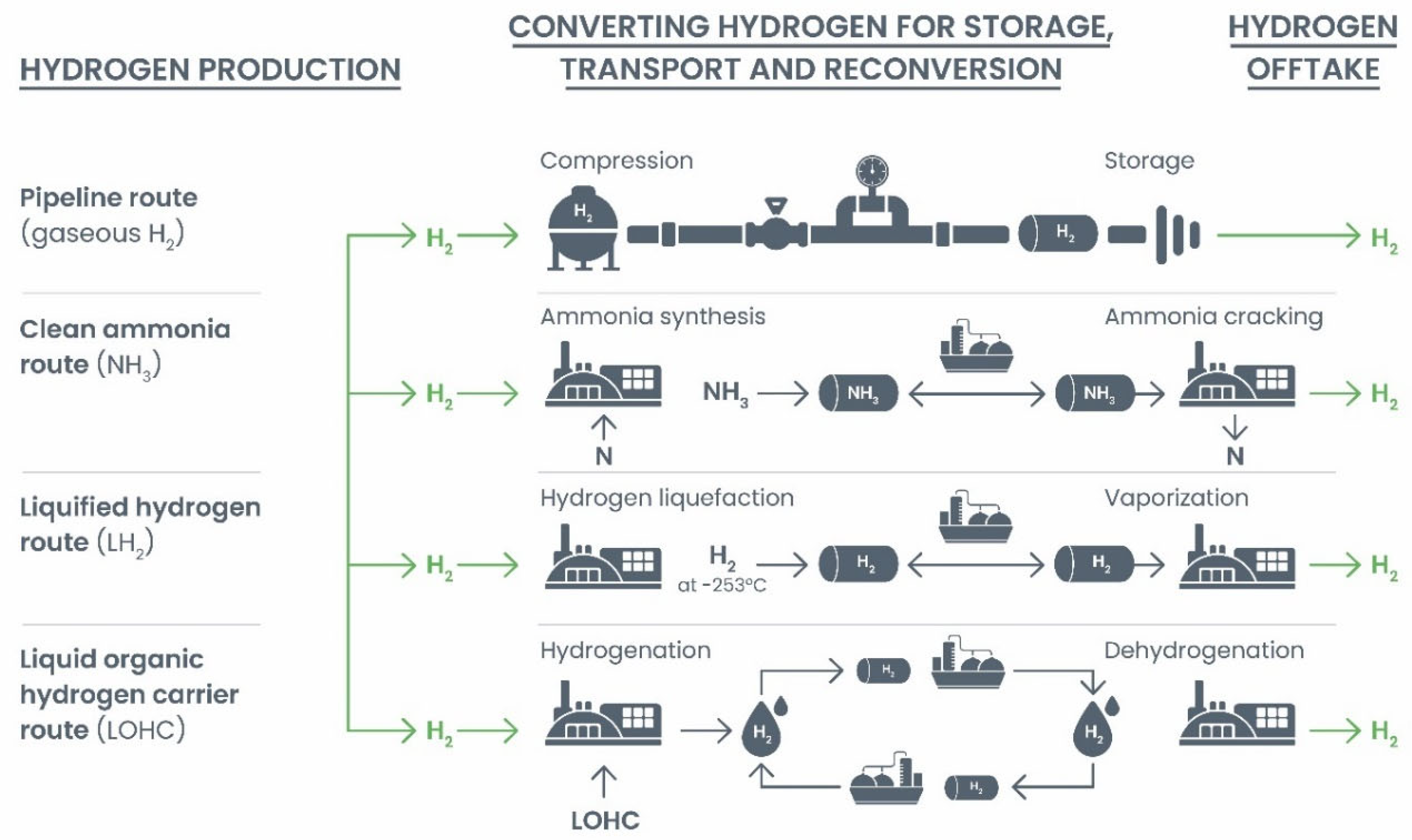

The development of necessary infrastructure, such as pipelines or high-pressure storage and transportation systems, requires substantial investments. Building this infrastructure is not only costly but also essential for establishing a reliable and efficient hydrogen transport network. Various alternatives exist for transporting hydrogen over different distances, each with varying levels of technological maturity. These alternatives must be carefully considered and developed to address the unique challenges associated with hydrogen transportation and to support the growing demand for green hydrogen as a clean energy carrier. Hydrogen [

12] can be transported using various methods, each suited to different distances and applications (

Figure 2):

Compressed gas tubes (tube trailers): This method is used to transport hydrogen in gaseous form over short distances, typically supplying industrial users or hydrogen refueling stations.

Hydrogen pipelines: This method is one of the most efficient and cost-effective for long-distance hydrogen transport. Made from materials that can safely contain hydrogen, pipelines use strategically placed compressor stations along their routes to maintain pressure and control flow, enhancing efficiency.

Liquefied hydrogen (LH2): This method involves cooling hydrogen to extremely low temperatures (−253 °C or −423 °F) to convert it into a dense liquid that occupies less space. Specialized cryogenic containers and tankers are used for LH2 transportation. Although the liquefaction process is energy-intensive, it offers a viable option for long-distance transport due to the reduced volume of liquid hydrogen.

Liquid organic hydrogen carriers (LOHCs): LOHCs are organic compounds that absorb and release hydrogen through chemical reactions, allowing hydrogen to be stored and transported under ambient temperature and pressure conditions without significant losses. When needed, the hydrogen-rich LOHC is heated to the dehydrogenation temperature and exposed to a dehydrogenation catalyst to release hydrogen. However, handling LOHCs involves potential environmental exposure and fire risks, as they are flammable hydrocarbons.

Ammonia: Traditionally used in various industries, ammonia is gaining attention as a promising hydrogen carrier due to its well-established international trade networks [

13]. Although both ammonia and hydrogen are gaseous at standard conditions, ammonia is more efficient in delivering hydrogen over long distances after liquefaction. A liter of liquid ammonia contains a greater mass of hydrogen than a liter of liquid hydrogen because ammonia has a higher packing density of approximately 686 kg/m

3 compared to 71.1 kg/m

3 for liquid hydrogen. Although its hydrogen content by weight is only 17.65% compared to 100% for liquid hydrogen, ammonia’s volumetric hydrogen content (107.7 kgH

2/m

3) significantly exceeds that of liquid hydrogen (70.8 kgH

2/m

3) and LOHC (47.1 kgH

2/m

3), making it a more efficient carrier.

Ammonia also has a higher boiling point (−33.34 °C) than hydrogen, which requires less energy for liquefaction and storage, resulting in lower thermodynamic losses. While ammonia requires an additional liquefaction step compared to LOHC and methanol, which are liquids at standard conditions, the established infrastructure for ammonia transportation, combined with its lower flammability compared to other hydrogen carriers and carbon-based fuels, makes it a comparatively safe option.

Figure 2.

Hydrogen transportation routes (Roland Berger) [

14].

Figure 2.

Hydrogen transportation routes (Roland Berger) [

14].

Despite its advantages, ammonia’s high toxicity poses significant safety risks. However, as the world’s second most frequently produced chemical, its long-established global transportation infrastructure has developed extensive safety standards to mitigate these risks.

2. Technical Background

For hydrogen and ammonia to become a sustainable and alternative viable solution to satisfy end-user demands and needs, dispatchability of electricity, heat, and cold energy must be accounted for when integrating renewable energy resources in the transition to cleaner energy [

15,

16]. Energy storage technologies must be adopted to compensate for the intermittency—in the short- and long-term—of solar and wind power, generated for instance from photovoltaic (PV) fields and wind turbine farms. Accordingly, this section contains a comprehensive qualitative comparison of the benefits of different solutions and also details how these solutions can be integrated together.

2.1. Energy Storage Solutions

Energy storage systems play a vital role in stabilizing renewable energy supplies in the global energy transition. Among these, battery energy storage systems (BESSs) are extensively used to store excess energy generated during the day and release it during periods of low or no generation, such as evenings and nights. However, while BESSs remain essential for short-term renewable energy integration, they alone cannot meet the demands of a fully renewable energy system [

17]. Hydrogen and green ammonia provide complementary solutions, addressing long-term storage needs and enabling renewable energy transport across regions. Their integration represents a critical step toward a sustainable, resilient, and decarbonized energy future [

18,

19]. Continued research, innovation, and supportive policies are essential to unlocking their full potential and achieving a global renewable-based energy system.

2.1.1. BESSs

Lithium-ion and lead-acid batteries are the most adopted BESS technologies. Modern lithium-ion batteries, in particular, achieve high round-trip efficiencies of up to 95%. When factoring in components, such as inverters and transformers, the system efficiency remains competitive at around 90%. A notable benefit of BESSs is their rapid response time, allowing them to absorb, store, or release energy within milliseconds, which greatly enhances power grid flexibility. These systems are primarily designed for short-term energy balancing, as evidenced by their positioning in efficiency-capacity graphs. They effectively handle day/night energy fluctuations from PV systems, storing surplus energy from daylight for evening use with less loss.

However, BESSs are not well-suited for addressing long-term energy storage needs, such as those arising from seasonal variations in renewable energy availability. For multi-day or seasonal storage applications, hydrogen-based systems emerge as a viable alternative. Although their round-trip efficiency is generally lower than BESSs, hydrogen systems excel in storing energy over long durations and large scales, making them essential for managing extended renewable energy fluctuations. To give a clearer picture of the potential of alternative energy storage solutions,

Figure 3 shows the storage capacity and discharge duration of various storage technologies. The discharge duration represents how long a storage system can supply energy, calculated from the ratio of available energy to discharge capacity.

2.1.2. Hydrogen and Ammonia Energy Carriers as a Long-Term and Flexible Energy Storage Solution

Green hydrogen, produced by electrolyzing water using renewable energy, has garnered attention as a key technology for long-term energy storage. Beyond storage, hydrogen can power fuel cells, turbines, and synthetic fuel production, offering the flexibility to bridge gaps between energy production and consumption over extended periods [

20]. However, hydrogen storage poses challenges due to its low energy density. The hydrogen must be either compressed to high pressures or liquefied at extremely low temperatures (−253 °C), both of which consume significant energy. Consequently, round-trip efficiency—converting electricity to hydrogen and back—ranges from 40% to 45%. Despite these limitations, hydrogen can be stored in large underground caverns or pressurized vessels, making it a promising option for seasonal storage. Hydrogen also enables sector coupling by serving as a decarbonized input for industries like steel production, chemicals, and fuels [

21]. This capability reduces costs through shared infrastructure and economies of scale, enhancing hydrogen’s role in energy systems with sustainability considerations.

Green ammonia is another promising medium for long-term and seasonal energy storage. Synthesized from green hydrogen and nitrogen using the Haber–Bosch process, this method offers several advantages:

Liquid ammonia has a comparable or higher energy density than compressed hydrogen and is easier to store and transport. Unlike hydrogen, which requires cryogenic storage, ammonia can be liquefied at −33 °C under atmospheric pressure, lowering refrigeration costs.

- 2.

Established infrastructure

Existing industrial-scale ammonia production and distribution networks, primarily for fertilizers, can be repurposed for energy applications with minimal capital investment.

Recent studies are demonstrating the near future possibility of using ammonia directly in internal combustion engines and gas turbines; it can be co-fired with other fuels or converted back—in situ—to hydrogen for direct use in internal combustion engines [

22] and eventually fuel cells. Advances in low-emission ammonia combustion technologies further enhance its role in the energy transition. While its round-trip efficiency of 30–40% theoretically could limit its suitability for high-efficiency applications, green ammonia’s cost-effectiveness and long-term storage potential make it invaluable for large-scale renewable energy integration, as this study demonstrates.

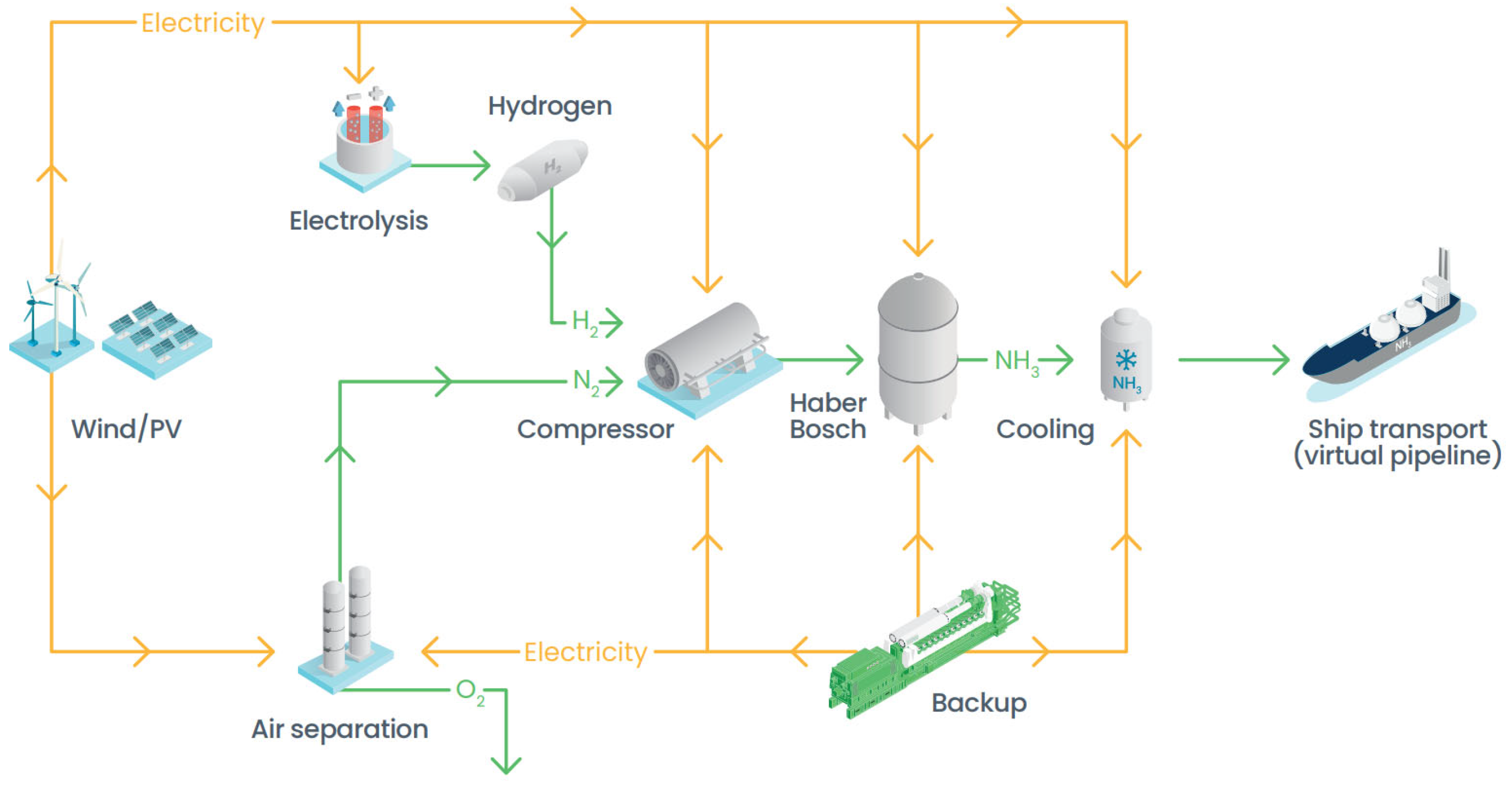

2.2. Green Ammonia Production

The green ammonia process achieves a significant advancement over conventional ammonia production methods [

23] primarily by substituting the catalytic steam reforming of natural gas with the electrolytic production of hydrogen powered by renewable electricity. This shift reduces reliance on fossil fuels and offers a pathway toward a more sustainable and less carbon-intensive chemical industry. Moreover, from an energy-systems perspective, the ability to couple ammonia production directly with variable renewable energy (VRE) resources—such as wind and solar—introduces new pathways for large-scale energy storage and grid balancing. The following sections outline the key steps and considerations in establishing a modern green ammonia production facility, as shown in

Figure 4.

2.2.1. Air Separation and Nitrogen Extraction

A foundational step in green ammonia synthesis is the extraction of nitrogen, traditionally achieved using an air separation unit (ASU). The ASU cools and compresses ambient air to separate nitrogen from other atmospheric components, yielding a high-purity nitrogen stream suitable for subsequent reactions. Air separation is energy-intensive [

23], especially at large scales; improving its efficiency is crucial for the overall sustainability of the process. Advanced integration of ASU with other plant operations—for instance, using the heat generated by compression stages for other thermal needs—can improve the plant’s total energy efficiency. Beyond this conventional approach, innovative efforts are exploring the possibility of extracting nitrogen from organic waste streams or other sustainable sources [

8]. Although these routes remain under active research, they carry the potential for reduced capital expenditure (CAPEX) and a smaller overall carbon footprint if integrated successfully with waste-to-energy systems.

2.2.2. Electrolysis and Green Hydrogen Production

The production of green ammonia marks a transformative shift from conventional ammonia manufacturing, which predominantly relies on natural gas reforming. Green ammonia plants instead use electricity generated entirely from renewable energy sources, such as wind, solar, or hydropower, to drive water electrolysis. This process enables the production of hydrogen with significantly less carbon emissions using specialized devices called electrolyzers, which split water into hydrogen and oxygen. Several electrolyzer technologies are available for this purpose, each with distinct characteristics and potential benefits.

Electrolyzer technologies and efficiencies: The key electrolyzer technologies include alkaline electrolyzers, proton-exchange membrane (PEM) electrolyzers, and solid oxide electrolyzers (SOECs). Alkaline and PEM electrolyzers are the most commercially mature options, achieving electrical-to-hydrogen conversion efficiencies of approximately 60–70%. SOECs, on the other hand, operate at high temperatures and have the potential to reach even higher efficiencies—up to 80% or more—though they remain in the early stages of commercialization. The choice of technology depends on factors such as efficiency requirements, operational conditions, and system integration needs.

Thermodynamic and operational challenges: The water-splitting process requires significant energy input (~237 kJ/mol under standard conditions), which must be supplied by intermittent renewable energy sources. This intermittency poses operational challenges for electrolyzers, such as fluctuating load factors that can impact efficiency and system reliability. To address these challenges, innovative strategies are being developed, including dynamic load-following operations and hybrid energy storage solutions. These approaches aim to ensure cost competitiveness while enabling seamless integration with variable renewable electricity supplies.

Advancements in research and development: Significant research efforts are focused on improving the design and performance of electrolyzer cells to enhance efficiency, reduce capital costs, and extend operational lifetimes. Additionally, the development of advanced control systems is critical for managing power input fluctuations caused by renewable energy variability. These innovations are essential for reducing energy losses, maintaining stable production rates, and ensuring the economic viability of green ammonia facilities under real-world operating conditions.

By addressing these technological and operational aspects in a harmonized manner, green ammonia production can become a scalable and sustainable alternative to conventional methods, contributing significantly to global decarbonization efforts.

2.2.3. Ammonia Haber–Bosch Reaction and Purification

Once hydrogen and nitrogen are obtained, they are combined in a high-pressure, high-temperature reactor employing the Haber–Bosch process. This reactor constitutes the core of ammonia production, where reactions take place at pressures in the range of 150–200 bar and temperatures often above 400 °C [

24]. Such extreme operating conditions require specialized, corrosion-resistant materials for reactor vessels, piping, and seals.

Selecting the optimal catalyst can improve the process. Iron-based catalysts remain the industrial standard, commonly promoted with elements like potassium or aluminum oxides. Novel catalyst research includes ruthenium-based and other transition-metal systems that potentially could operate at lower temperatures and pressures, thereby reducing the energy input required per unit of ammonia produced. The most common challenge in ammonia production is maintaining the longest possible catalyst lifetime. Accordingly, deactivation mechanisms (e.g., sintering, poisoning by impurities) must be mitigated through rigorous process control and periodic regeneration strategies.

The Haber–Bosch process is constrained by operational efficiency and, consequently, the latest scientific research focuses on improving the process. Typically, only 10–20% of the reactants convert to ammonia in a single pass, necessitating high recycle flows. When coupling the process with renewable energy source (RES) availability, the ability to modulate reactor throughput based on hydrogen availability becomes crucial to downsize the storage equipment and thus reduce costs. Process designs that accommodate partial-load or start-stop scenarios without significant energy or catalyst penalties are key areas of development. Furthermore, heat recovery from the exothermic reaction can be used to preheat reactant gases or generate steam, enhancing overall plant efficiency.

After the synthesis process, the product mixture contains ammonia along with unreacted nitrogen and hydrogen. Separation units (often employing condensation and refrigeration technologies) selectively isolate the ammonia from the other gases. However, condensing ammonia at elevated pressures requires energy-intensive refrigeration cycles. Thermally integrated designs that capture waste heat or cold from other parts of the plant can reduce the net energy demand of the refrigeration process. The recovered ammonia is subjected to further purification steps to meet the desired specifications, whether for use in fertilizers, industrial chemicals, or as a prospective carbon-free fuel source. Trace impurities (e.g., residual water, argon, or oxygen) can critically affect catalyst performance if the ammonia is later decomposed or used in fuel cells.

2.2.4. Ammonia Storage and Transportation

Green ammonia is typically stored in specialized tanks or cryogenic vessels designed to maintain it in liquid form, with storage conditions—such as pressure and temperature—determined by economic factors and safety requirements. Ensuring safety in ammonia storage and transportation is critical due to its toxicity and reactivity. Robust safety mechanisms, including pressure relief valves, gas detection systems, and spill containment measures, are essential to mitigate risks. Comprehensive risk assessments, such as Hazard and Operability (HAZOP) studies [

25], play a pivotal role in guiding facility design to reduce the likelihood and impact of accidental releases. From an infrastructure perspective, large-scale storage facilities are crucial for decoupling production from distribution, enabling better alignment of supply and demand, particularly given the intermittency of RES. For transportation, existing pipelines, ships, and rail networks may require retrofitting to safely accommodate ammonia, posing both technical and regulatory challenges that must be addressed to ensure a reliable supply chain.

2.3. Green Ammonia Technical and Economic Considerations

Green ammonia production represents a transformative approach by using renewable electricity for hydrogen generation instead of relying on fossil fuels. By focusing on key aspects such as nitrogen extraction, electrolyzer performance, efficient Haber–Bosch operation, and stringent safety standards for storage and transport, green ammonia has the potential to serve as both a vital agricultural input and a carbon-free energy vector. From an energy-systems perspective, integrating ammonia production with VRE resources can provide large-scale energy storage and grid flexibility, thereby advancing broader decarbonization goals. However, despite its promise, the green ammonia process faces several techno-economic challenges that must be addressed to unlock its full environmental and societal benefits.

One major challenge lies in the cost and availability of renewable energy. The levelized cost of renewable electricity varies significantly by region, directly influencing the overall cost of green ammonia production. Factors such as local electricity prices, capacity factors of renewables, and access to low-cost financing are critical determinants. Hybrid approaches that combine renewable generation with grid power and battery or hydrogen storage could help mitigate energy cost volatility. Another key issue is electrolyzer efficiency and durability. Electrolyzers must maintain high performance over extended lifetimes to justify capital investments, yet frequent load changes due to variable renewable inputs can accelerate degradation. This consideration necessitates robust designs and highlights the importance of life-cycle analyses for electrolyzer components and recycling pathways as scale-up progresses.

Investment and policy support are also crucial to help accelerate green ammonia adoption. Market demand can be stimulated through mechanisms such as government subsidies, carbon pricing, research grants, and clear regulatory frameworks for applications like marine fuel, grid-scale energy storage, or co-firing feedstock in power plants.

Additionally, supply chain and infrastructure development present significant hurdles. Establishing safe storage, transportation, and distribution networks—particularly in regions lacking existing ammonia infrastructure—requires coordinated efforts among industry stakeholders, policymakers, and local communities. Strategic siting of green ammonia plants near renewable energy sources, such as wind or solar farms, could further reduce logistical barriers and transmission losses.

Despite these challenges, continuous advancements in renewable energy technologies, next-generation catalysts, and high-efficiency electrolyzers provide optimism for overcoming these barriers [

26]. Growing investments in green hydrogen initiatives and decarbonization strategies underscore the momentum behind green ammonia as a pivotal energy carrier and industrial feedstock. As these trends converge, green ammonia is poised to play an instrumental role in global efforts to reduce greenhouse gas emissions, enhance energy security, and foster a more sustainable chemical sector.

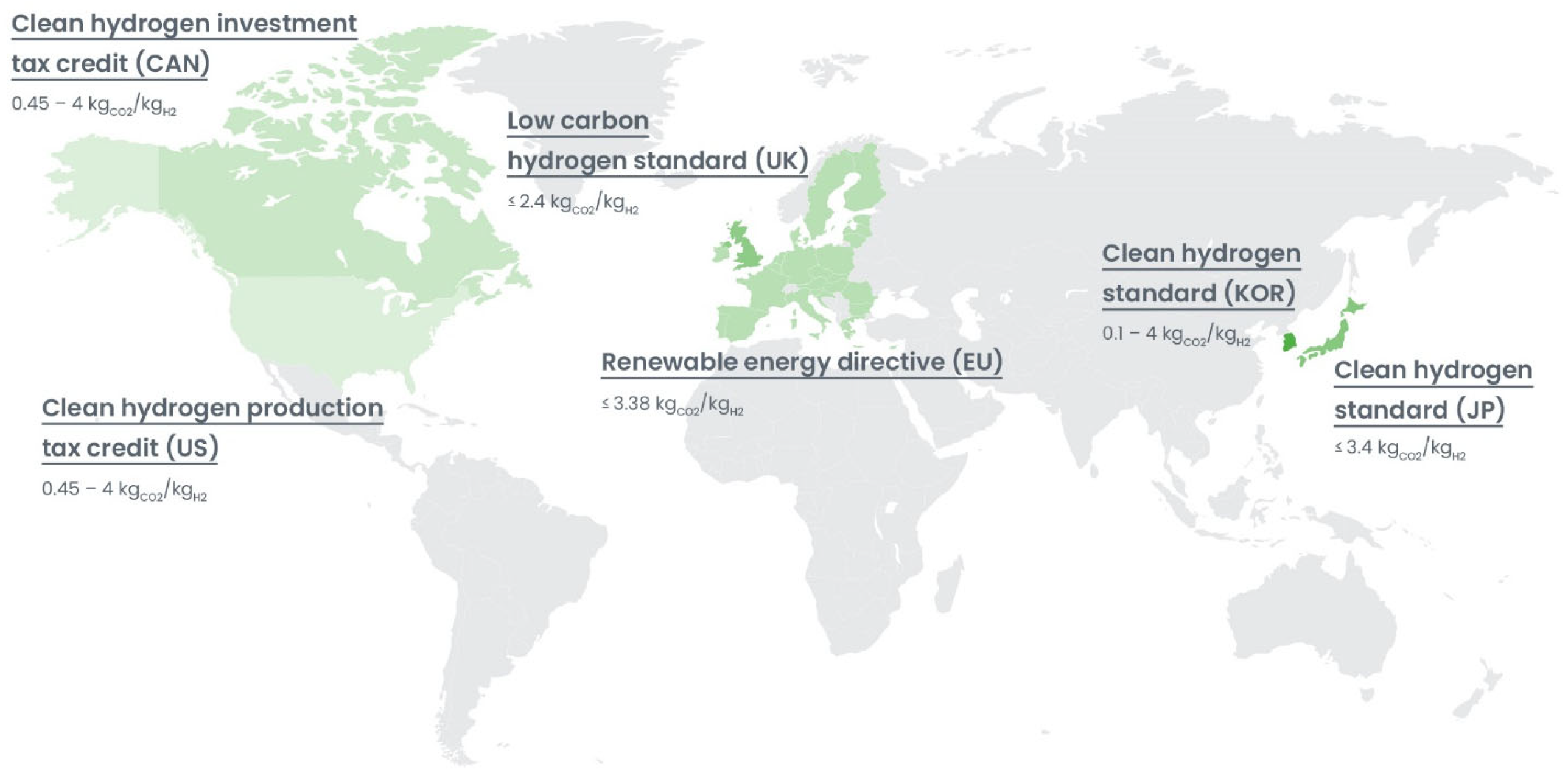

3. Regulatory Requirements on Clean Hydrogen

This section outlines regulatory policies, such as emissions standards, that might act as limits related to green ammonia and green hydrogen solutions [

27,

28,

29]. While country-by-country regulation could change, the proposed approach aims to provide a general procedure for identifying green technologies’ potential use.

3.1. Regional Clean Hydrogen Emission Standards

Legislative bodies in high-demand regions worldwide are developing various standards to address the CO2 impact of clean hydrogen. The goal is to strike a balance between enabling an economically viable increase in hydrogen imports while maintaining the climate protection benefits of hydrogen.

The Renewable Energy Directive of the European Union (EU) 2018/2001 (RED II) mandates that 32% of energy consumed within the EU must be renewable by 2030. RED II primarily mentions renewable fuels of non-biological origin (RFNBOs) in the context of transport fuels, defining them as “liquid or gaseous fuels used in the transport sector other than biofuels or biogas, with energy content derived from renewable sources other than biomass”. This definition generally covers hydrogen produced by electrolysis and hydrogen-derived fuels. As of 1 January 2021, RFNBOs must deliver greenhouse gas (GHG) emissions savings of 70% compared to fossil fuels, equivalent to 3.38 kgCO2/kgH2 in life-cycle emissions. Meeting this requirement allows RFNBOs to count toward member states’ renewable energy targets. In January 2023, the European Commission adopted a delegated act on GHG savings and the calculation of life-cycle emissions.

The Commission’s proposal in July 2021 to revise the Renewable Energy Directive (RED III) broadens the definition of RFNBOs by removing the transport sector restriction, allowing RFNBOs to count as renewable energy regardless of the end-use sector. Additionally, RED III states that RFNBOs produced with grid electricity are considered renewable in proportion to the average share of renewable electricity in the country of production, measured two years prior. However, if there is a direct connection between the renewable electricity generator and the RFNBO producer, and no grid electricity is used, the electricity can be considered 100% renewable, provided the renewable generator began operation concurrently with or after the RFNBO producer.

The Japanese government is actively promoting the establishment of international hydrogen supply chains in collaboration with countries in the Indo-Pacific, Europe, and the Middle East, including partnerships with Australia and the United Arab Emirates. Hydrogen is viewed as an industrial sector capable of achieving decarbonization, a stable energy supply, and economic growth.

Japan’s strategy includes government subsidies for establishing the hydrogen supply chain and infrastructure development, based on carbon intensity rather than the “color”, or production method, of the hydrogen. Clean hydrogen is defined as a threshold of 3.4 kgCO2/kgH2 (well-to-gate) and ammonia with 0.84 kgCO2/kgNH3 (gate-to-gate). To support these policies, the Ministry of Economy, Trade, and Industry established a new division for hydrogen and ammonia policy in July 2023.

Outlined in the British Energy Security Strategy of 2022, the UK aims to deliver up to 10 GW of low-carbon hydrogen production capacity by 2030, with at least half from electrolytic hydrogen, subject to affordability and value for money. To help ensure hydrogen significantly contributes to carbon reduction targets, the Low Carbon Hydrogen Standard Policy defines a Low Carbon Hydrogen Standard with specific requirements. Under the policy, hydrogen providers must do the following:

Achieve a GHG emissions intensity of 20 g CO2e/MJLHV or less.

Calculate GHG emissions up to the point of production.

Provide a risk mitigation plan for fugitive hydrogen emissions.

Meet additional requirements for biogenic inputs, where relevant and appropriate for the feedstock source and classification.

The Clean Hydrogen Production Tax Credit (part of the Inflation Reduction Act in the United States) and the Clean Hydrogen Investment Tax Credit (part of Canada’s climate protection initiative) offer significant incentives for developing net-zero hydrogen supply infrastructure. Following Japan’s technology-neutral funding approach, North America bases funding primarily on the carbon intensity of the produced hydrogen, setting a maximum lifetime CO2 load of 4 kgCO2/kgH2. While specific standards for the decarbonization effect of imported hydrogen are yet to be defined, it is anticipated that they will align with future domestic production limits.

3.2. Challenges for Green Ammonia Hubs

These stringent regulations on lifetime emissions in key destination regions for green hydrogen imports present a major challenge for project developers (

Figure 5,

Table 1). In many cases, the focus on developing green ammonia hubs in the Global South leads to a high dependency on locally produced RES. This dependency arises because the local electricity grid cannot support large-scale projects (in the gigawatt range), and the necessary certification for regulatory compliance often is unattainable in these regions.

As a result, high-capacity local backup systems are essential. However, using conventional backup technologies, such as diesel engines, compromises the lifetime emissions of the hydrogen produced. Even a 25% reliance on diesel backups can result in emissions exceeding 3 kgCO

2/kgH

2 (

Figure 6). The emission limits discussed in

Section 3.1 leave no margin for additional emissions along the supply chain, including those from ship transportation.

Therefore, the implementation of net-zero backup systems is essential for project developers to ensure the economic feasibility of green ammonia hubs. Given the existing hydrogen production and storage capacities in these hubs, hydrogen-based energy solutions are particularly suitable as backup technology.

4. Materials and Methods

This section compares the green ammonia process to traditional methodologies with an emphasis on the approach presented in this paper. After considering the processes involved in ammonia production, as well as the challenges related to the implementation of viable solutions in the full green hydrogen/ammonia value chain [

30], the proposed approach integrates internal combustion engines capable of operating on 100% hydrogen and compares them with existing fuel cell-based solutions. Due to the technical limitations related to the ammonia and hydrogen green value chain [

31], gas engine limitations and competitive advantages are summarized using commercially available data [

32].

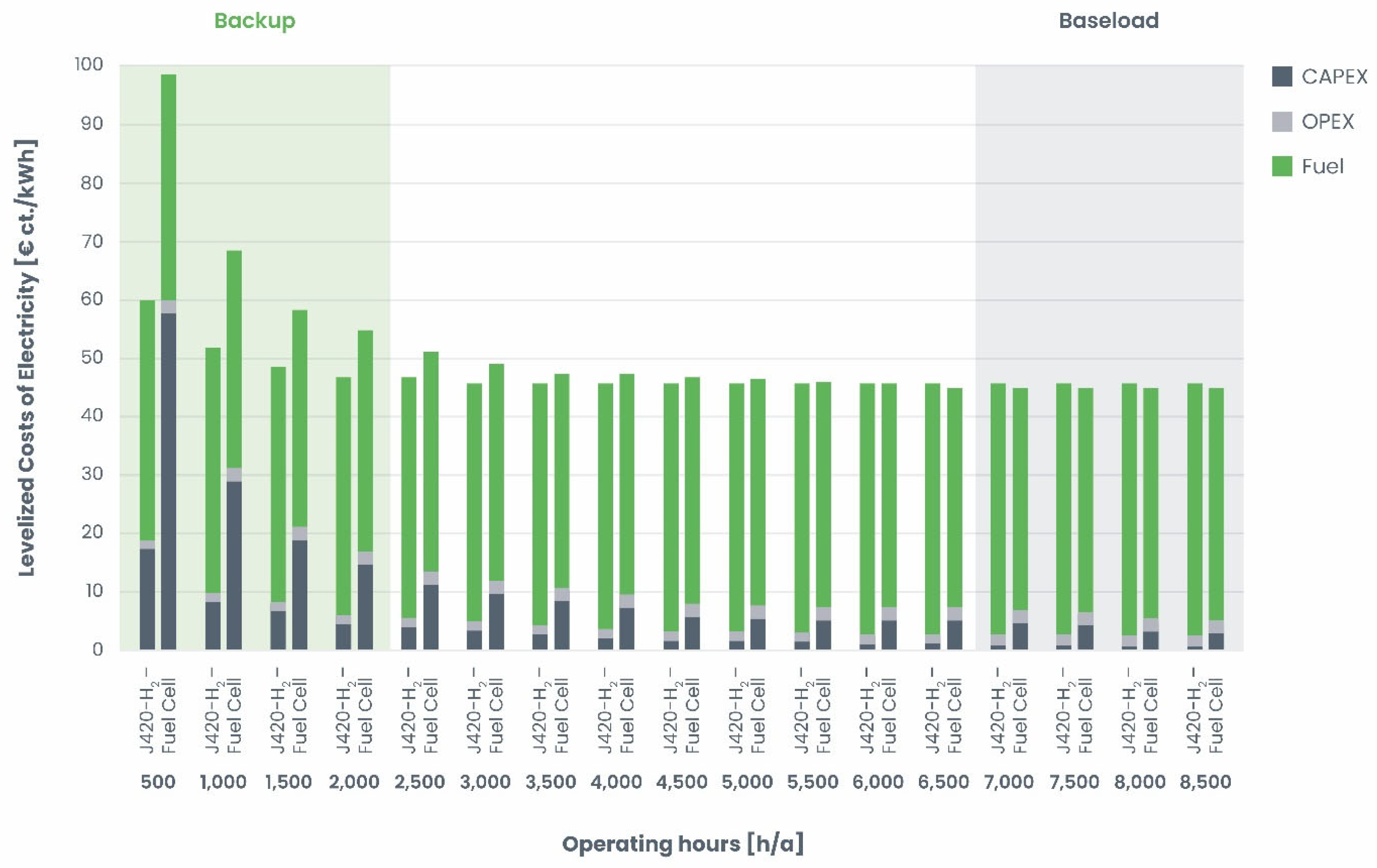

4.1. 100% Hydrogen-Ready Internal Combustion Engines

Decentralized hydrogen power generation typically relies on either fuel cells or hydrogen engines, each offering distinct advantages and facing specific challenges. Hydrogen engines are relatively simple, closely resembling conventional internal combustion engines and thus requiring fewer infrastructure modifications [

22,

33]. They also involve lower CAPEX, as fuel cells often rely on rare earth elements and energy-intensive electrochemical materials that significantly increase production costs. In addition, hydrogen engines generate waste heat at higher temperatures than most fuel cells, enhancing their potential for integrated heat use (e.g., trigeneration systems) and delivering high power output suitable for heavy-duty applications with rapid acceleration needs. Their flexibility in operating on various fuels, including those derived from renewable resources or fossil sources, eases the transition toward cleaner energy. Moreover, their ability to handle sharp load ramps without rapid degradation, physical grid stabilization through rotating mass, and tolerance for hydrogen with higher impurity levels further underscores their economic and operational advantages.

Despite these benefits, hydrogen engines exhibit lower electrical energy efficiency than fuel cells and produce emissions from nitrogen oxides (NO

x), albeit at levels substantially reduced compared to conventional fossil fuels. From an economic perspective, the lower efficiency is offset by reduced upfront costs, particularly in settings where full-load hours are limited, making capital expenditure a more critical factor than overall efficiency. Consequently, hydrogen engines can achieve a favorable levelized cost of electricity (LCOE) in scenarios where reduced operating hours render efficiency less pivotal (

Figure 7). This trade-off highlights the importance of application-specific analyses when selecting the most suitable technology for decentralized hydrogen-based power generation. Therefore, hydrogen engines show significantly higher economic efficiency in low-capacity factor applications such as backup operations. Note that gas turbines operating on 100% hydrogen are excluded from this study due to the current lack of commercially available and technologically mature solutions.

4.2. Economic and Technical Aspects of the Technology

Within this study, hydrogen-based storage and backup systems are compared with battery–electric solutions. The hydrogen engine and the fuel cell, recognized as established decentralized energy solutions, are evaluated as re-electrification technologies for hydrogen storage. For battery–electric storage, Li-Ion batteries are considered an established technology. Additionally, redox flow batteries are considered an alternative battery–electric solution for large-scale projects.

Table 2 provides a comparative evaluation of four backup energy solutions—H

2-Engine, H

2-FC (Fuel Cell), Redox Flow, and Li-Ion batteries—highlighting their efficiency, cost, and lifespan [

34,

35,

36,

37].

Li-Ion batteries exhibit the highest round-trip efficiency (90%) and the lowest re-electrification costs (35 EUR/kW), making them highly efficient, but they are also the most expensive in terms of storage costs (45 EUR/kWh) and limited by the shortest storage lifespan (13 years). In contrast, hydrogen-based solutions (H2-Engine and H2-FC) offer significantly lower round-trip efficiencies (25% and 28%, respectively) but feature the lowest storage costs (1.2 EUR/kWh) and longer storage lifetimes (30 years). Redox Flow batteries strike a balance with moderate efficiency (72%) and comparatively lower re-electrification costs (35 EUR/kW), although their storage costs (36 EUR/kWh) and shorter storage lifespan (25 years) reflect a mid-range option. Hydrogen engines also outperform fuel cells in terms of re-electrification lifespan (25 years vs. 10 years), suggesting they may be a more durable hydrogen-based alternative. Overall, the findings indicate that application-specific priorities—such as cost sensitivity, efficiency requirements, or longevity—will dictate the most suitable technology for backup energy systems.

This study presents a power dispatching balance calculation for the proposed green ammonia hub systems, focusing on component design and cost estimation. We assume constant energy consumption for the Haber–Bosch process and its associated peripherals (air separation, desalination, compression, and ammonia cooling) based on the latest references. This energy consumption is viewed as a demand to be met under the power flow dispatch.

In this study, the Haber–Bosch process is powered primarily by green electrons from renewable energy systems (solar PVs and wind turbines). The electrolyzer operates according to the remaining availability of green electricity. Surplus electricity is stored in hydrogen tanks, similar to BESSs. The stored hydrogen is used for ammonia production and backup power generation during undersupply periods. For both the hydrogen storage system and the BESS, the calculation model determines the required storage capacity based on the dynamic balancing calculations, with the secondary condition that the storage capacity does not fall below a minimum storage load of 5% over the entire year.

The facility operates in an islanded (off-grid) mode, ensuring self-sufficiency without grid backup. This study focuses on providing a robust sensitivity analysis, so enhancement of the demand side through an Energy Management System (EMS) is not considered. Consequently, multi-energy storage options are not presented to clearly show the effect of each storage technology on the levelized cost of storage (LCOS).

5. Case Studies

For a comparative evaluation of the existing net-zero backup solutions, cost-efficiency calculations were performed for the following five distinct case studies (

Figure 8).

Case Study Canada: Located on the Burin Peninsula in Newfoundland, the green ammonia production in this case study is based exclusively on offshore wind power. Local meteorological conditions result in capacity factors for wind power of 0.6. A relatively high RES-to-electrolysis capacity ratio also enables high full load hours for electrolysis operation.

Case Study Chile: On the west coast of the Antofagasta Region, with the well-known high Patagonian offshore-wind potential, the second case study is characterized by comparatively low production capacities. Compared to the Canadian case study, the ratio of installed RES capacity and electrolyzer capacity is significantly lower, resulting in longer periods of undersupply for the electrolyzer and Haber–Bosch process.

Case Study Namibia: The Namibian case study, located within the Tsau-Khaeb National Park, uses a combination of offshore wind and PV for its power supply, with the wind power plants representing the dominant power source. The installed capacity and production volume of the Namibian case study are equivalent to the Canadian case.

Case Study Oman: An increased share of PV on the total installed RES capacity is set for the Oman case study in the Salalah Free Zone. The ratio between electrolysis capacity and the annual green ammonia production volume is more than twice as high compared to in the Canadian and Namibian cases.

Case Study Australia: Located on the Gove peninsula in the Northern Territory of Australia, this final case study represents the option of a significant share of PV power supply for hydrogen and green ammonia production. A comparatively low RES-to-electrolyzer capacity ratio is also characteristic of this case.

These case studies were selected to cover a diverse range of announced green ammonia projects, considering factors such as location, production capacity, and renewable energy supply. The focus included regions where the establishment of green ammonia hubs had already been announced, driven by the high potential for renewable energy integration.

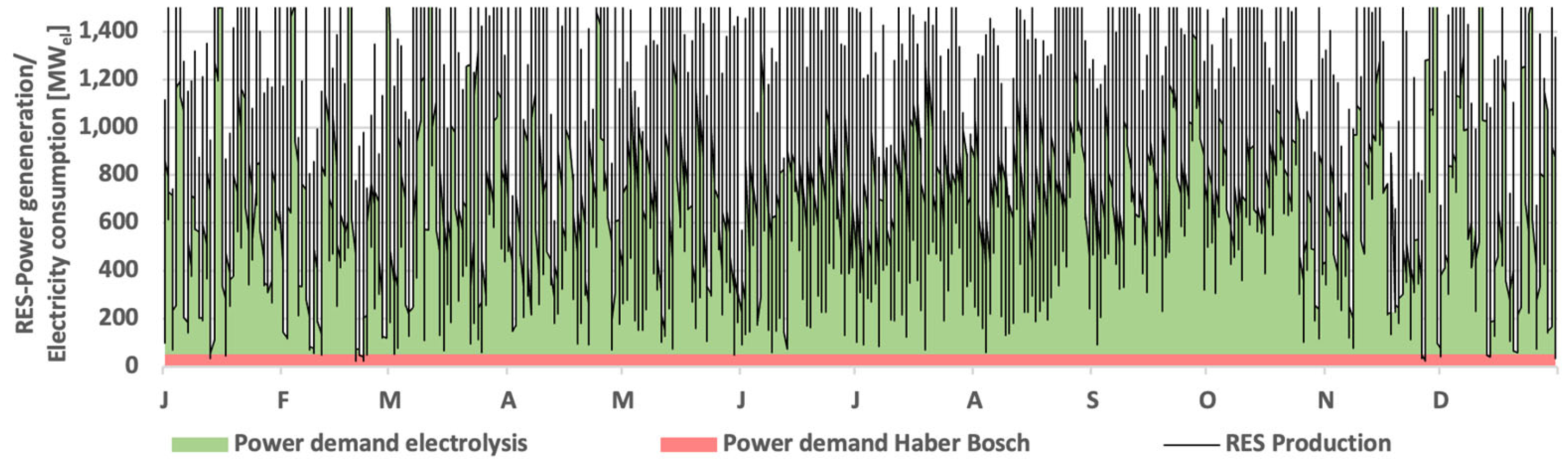

Calculations are based on hourly load profiles for offshore wind and PV electricity for the exact location of the case studies. The model’s robustness is ensured by using data from NASA’s MERRA Reanalysis and CM-SAF’s SARAH dataset for solar irradiance [

38,

39]. For the Oman case study, the annual electricity generation and consumption for green ammonia production are shown in

Figure 9. Within green ammonia production, flexible electrolysis for hydrogen production accounts for the highest share of the electricity demand.

6. Discussion

Using these case studies and the data shown in

Table 2, a sensitivity analysis was conducted to determine the variability of backup capacity demands.

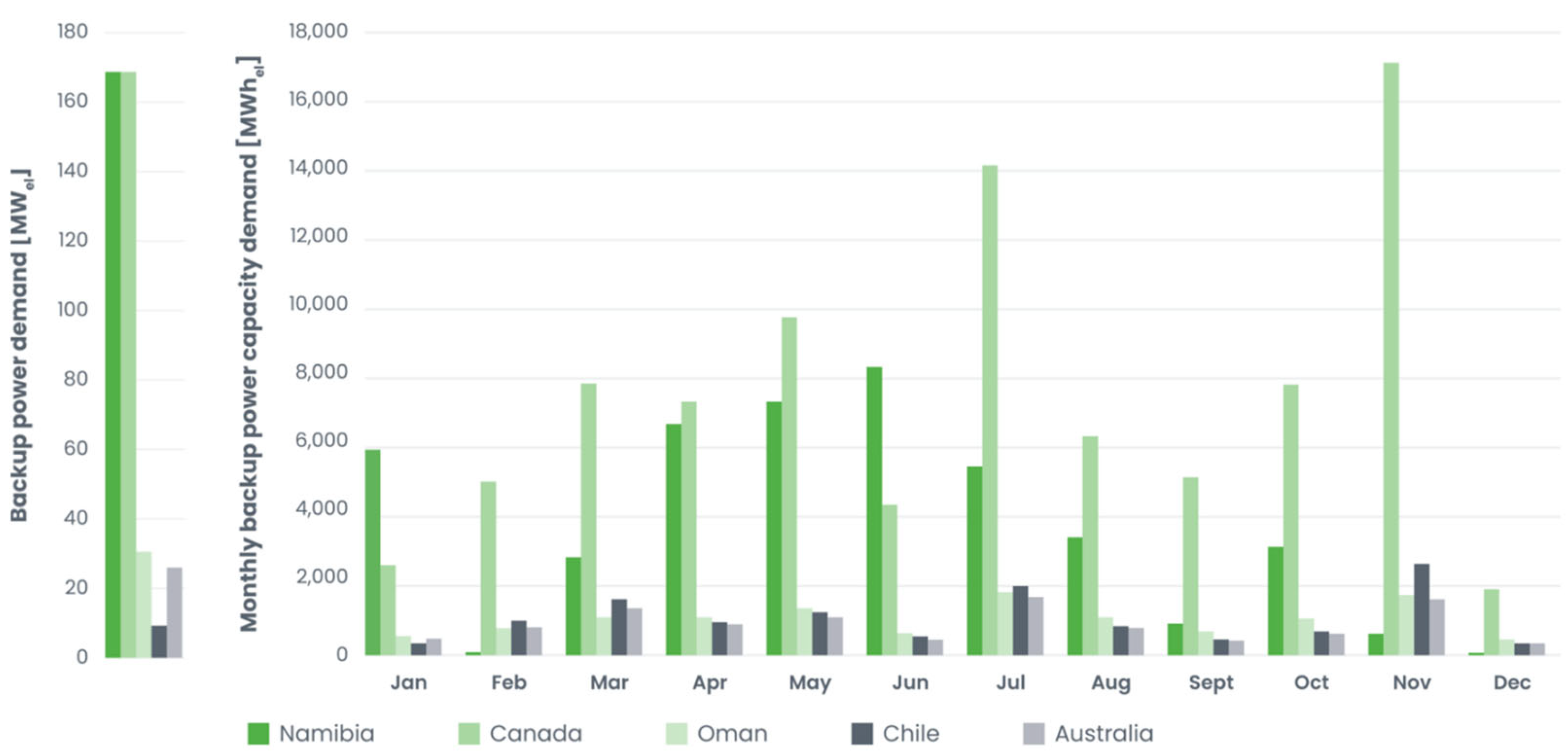

Figure 10 shows the required yearly backup power based on power dispatching balance calculations. The left graph in

Figure 10 shows that, even large projects with a production capacity of 1 million tons of ammonia per year, such as the Namibia and Canada case studies, require backup systems of merely about 170 MW

el, which can be covered by decentralized energy solutions. The left-hand chart shows the maximum instantaneous backup generation requirement

. Namibia and Canada impose the most stringent contingencies, each surpassing

. These peaks are roughly an order of magnitude higher than those of Oman (≈28 MW), Australia (≈24 MW), and Chile (≈13 MW), implying markedly different sizing envelopes for fast-ramping assets such as grid-forming battery inverters or diesel gensets. In engineering terms, the Namibian and Canadian systems must maintain transient capacity factors approaching unity during extreme deficit hours, whereas the remaining sites can satisfy reliability criteria with substantially smaller firm-capacity installations.

The right side of

Figure 10 chart integrates backup dispatch on a monthly basis to yield the cumulative energy demand

Namibia carries the largest aggregate burden through most of the year, stabilising in the 5–8 GWh/month range but surging above 16 GWh/month in November. Canada exhibits a more pronounced seasonal modulation: minima below 2 GWh/month in mid-winter, a plateau around 6–8 GWh/month during spring, a summer crest near 14 GWh/month in July, and an annual maximum exceeding 17 GWh/month in late autumn. Oman’s requirement is concentrated in spring (5–8 GWh/month), while Chile and Australia remain consistently below 2 GWh/month. Juxtaposing

and

underscores that a site dominating peak-power demand does not necessarily impose the greatest energy throughput; consequently, system designers should size firm-capacity devices and energy-storage reservoirs independently, accounting for both the magnitude and the temporal heterogeneity of backup-power demand.

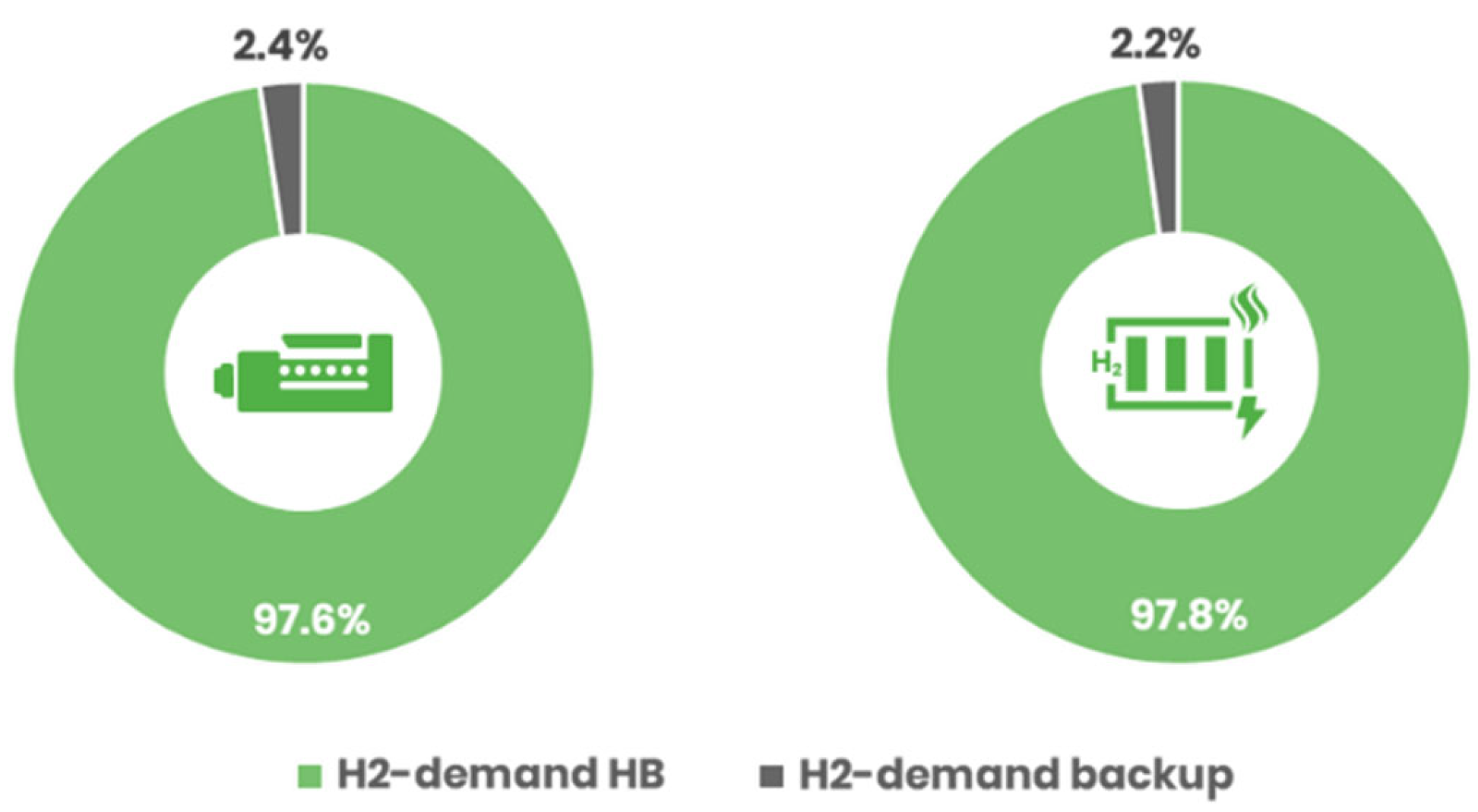

For uninterrupted base load operation of ammonia production, high hydrogen production and storage capacities are required in a self-sufficient system to provide the hydrogen for the Haber–Bosch process. In comparison, the total annual hydrogen demand to operate the hydrogen-based backup power plants is significantly lower. For the Oman case, as an example, less than 3% of the annual hydrogen production is required (

Figure 11).

However, the additional storage capacities required for the Oman case are significantly higher at approximately 10% (

Figure 12). This requirement is mainly due to the seasonally heterogeneous distribution of backup power demand over the year. For the Oman case, a two-week phase of power shortage within the month of February is decisive for the design of the hydrogen storage facility.

For the other case studies that include a less well-balanced composition of wind and solar power, these phases of undersupply result in significantly higher additional hydrogen storage capacities (

Figure 13, right). The same applies to the share of backup power generation in the total annual hydrogen demand (

Figure 13, left). The marginally lower surplus storage requirements of the fuel cell-based backup system compared to the engine are due to the slightly higher efficiency of fuel cell technology.

The calculations show that the case studies with the highest storage capacity requirements, such as the Canadian, Chilean, and Namibian cases (

Figure 13, right), have significantly lower CAPEX and total cost of ownership (TCO) for the use of hydrogen storage and engines compared to batteries (

Figure 14). This disparity is primarily due to the significantly lower capacity-specific investment costs [EUR/kWh] of hydrogen storage systems, which have a greater impact on total costs when storage requirements are high. For the Australian case with a share of PV in the electricity supply, daily fluctuations dominate the backup demand, making battery electric solutions appear more cost-effective. The higher TCO for fuel cell-based systems compared to engines mainly results from the necessary replacement of fuel cell stacks over the system’s life cycle.

In terms of LCOS, hydrogen engine-based backup systems are economically competitive and promising for green ammonia hubs due to significantly reduced capacity-specific storage costs. Compared to fuel cells, hydrogen engines show advantages in power-specific backup costs. These LCOS advantages persist across all scenarios, ranging from 17% for Namibia to 66% for Canada. The abundant RES surplus and significant cost advantage of hydrogen engines offset their relatively low round-trip efficiency. In green ammonia projects dominated by PV power, like the Australian case, battery–electric backup systems effectively balance daily power fluctuations.

7. Conclusions

This paper explores the latest alternative solutions for supplying electricity, heat, and cold energy in an eco-friendly and techno-economically viable manner. It examines the integration of green hydrogen and green ammonia in decarbonized systems, including a 100% hydrogen-fed internal combustion engine like the Jenbacher JMS420, and compares these solutions to alternative stationary backup solutions.

While electrochemical energy storage ensures fast and reliable short-term support to renewable energy resources, it is comprised of hardware components that, once located and designed, cannot be easily interchanged and moved. Instead, alternative energy carriers like green hydrogen and green ammonia can have an invaluable role in the future. While both hydrogen and ammonia can be seen as energy carriers, they can also be used as long-term storage fuels capable of supporting similar backup solutions as well as BESSs. Using hydrogen-powered energy solutions for the on-site decarbonization of energy self-sufficient green ammonia hubs is a promising backup solution, mainly due to the synergies regarding the existing hydrogen production, storage capacities in the green ammonia process, and the low storage costs compared to battery electric systems.

The analysis of the five case studies shows that an energy supply based on local renewable energies requires backup capacities to bridge longer periods of undersupply. The comparative economic evaluation of backup technologies in this study shows that this backup capacity cannot be covered by BESSs. A more balanced backup system, however, consists of a combination of hydrogen- and battery-based backup solutions, whereby the battery-based systems compensate for daily fluctuations while the hydrogen storage systems address seasonal surpluses.

Regarding reconversion to electricity in a hydrogen-based storage system, the gas engine is characterized above all by low line-specific investment and operating costs compared to the fuel cell. In backup applications with low operating hours, these cost advantages compensate for the drawback of its lower overall efficiency.

Another key advantage of combustion engines is their fuel flexibility. Due to the limitation of solutions now commercially available, this study only considers hydrogen as an energy source for reconversion. Current developments in the motorized use of ammonia and small-scale thermal cracking processes will take advantage of this fuel flexibility and enable the use of ammonia-based backup systems with significantly lower storage costs in the medium term.

Future studies will integrate additional economic considerations, such as CO2 credit recognition and CO2 carbon tax avoidance. In these studies, enhanced dispatch challenges and improved master-planning solutions will also be linked to CO2 emissions trends and to regulatory limitations that are increasingly imposed by various countries.

Author Contributions

Conceptualization, A.S., M.S.-J. and A.P.; methodology, S.M. and A.S.; software, A.S. and S.M.; validation, A.S. and S.M.; formal analysis, S.M.; investigation, A.S.; resources, S.M. and A.S.; data curation, A.S.; writing—original draft preparation, S.M. and A.S.; writing—review and editing, S.M., A.P. and A.S.; visualization, A.S.; supervision, A.S., M.S.-J. and A.P.; project administration A.S. and A.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

Author Markus Strömich-Jenewein, Abdessamad Saidi, and Andrea Pivatello was employed by the company INNIO Group. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Zhao, H. Green Ammonia Supply Chain and Associated Market Structure. Fuel 2024, 366, 131216. [Google Scholar] [CrossRef]

- Negro, V.; Noussan, M.; Chiaramonti, D. The Potential Role of Ammonia for Hydrogen Storage and Transport: A Critical Review of Challenges and Opportunities. Energies 2023, 16, 6192. [Google Scholar] [CrossRef]

- Rao, P.C.; Yoon, M. Potential Liquid-Organic Hydrogen Carrier (Lohc) Systems: A Review on Recent Progress. Energies 2020, 13, 6040. [Google Scholar] [CrossRef]

- Bora, N.; Kumar Singh, A.; Pal, P.; Kumar Sahoo, U.; Seth, D.; Rathore, D.; Bhadra, S.; Sevda, S.; Venkatramanan, V.; Prasad, S.; et al. Green Ammonia Production: Process Technologies and Challenges. Fuel 2024, 369, 131808. [Google Scholar] [CrossRef]

- Deloitte. Green Hydrogen: Energizing the Path to Net Zero; Deloitte: London, UK, 2023. [Google Scholar]

- Nastasi, B.; Mazzoni, S. Renewable Hydrogen Energy Communities Layouts towards Off-Grid Operation. Energy Convers. Manag. 2023, 291, 117293. [Google Scholar] [CrossRef]

- Azim, R.M.; Torii, S. Exploring the Potential of Ammonia and Hydrogen as Alternative Fuels for Transportation. Open Eng. 2024, 14, 20240024. [Google Scholar] [CrossRef]

- Berwal, P.; Kumar, S.; Khandelwal, B. A Comprehensive Review on Synthesis, Chemical Kinetics, and Practical Application of Ammonia as Future Fuel for Combustion. J. Energy Inst. 2021, 99, 273–298. [Google Scholar] [CrossRef]

- IRENA. Global Hydrogen Trade to Meet the 1.5 °C Climate Goal; International Renewable Energy Agency: Masdar City, United Arab Emirates, 2022; ISBN 9789292604301. [Google Scholar]

- Chorowski, M.; Lepszy, M.; Machaj, K.; Malecha, Z.; Porwisiak, D.; Porwisiak, P.; Rogala, Z.; Stanclik, M. Challenges of Application of Green Ammonia as Fuel in Onshore Transportation. Energies 2023, 16, 4898. [Google Scholar] [CrossRef]

- Marhavilas, P.K.; Filippidis, M.; Koulinas, G.K.; Koulouriotis, D.E. Safety Considerations by Synergy of Hazop/Dmra with Safety Color Maps—Applications on: A Crude-Oil Processing Industry/a Gas Transportation System. Processes 2021, 9, 1299. [Google Scholar] [CrossRef]

- European Commission. Assessment of Hydrogen Delivery Options Context; European Commission: Brussels, Belgium, 2021. [Google Scholar]

- Aziz, M.; TriWijayanta, A.; Nandiyanto, A.B.D. Ammonia as Effective Hydrogen Storage: A Review on Production, Storage and Utilization. Energies 2020, 13, 3062. [Google Scholar] [CrossRef]

- Roland Berger. Hydrogen Transportation; Roland Berger: Munich, Germany, 2021. [Google Scholar]

- Zhao, C.; Andersen, P.B.; Træholt, C.; Hashemi, S. Grid-Connected Battery Energy Storage System: A Review on Application and Integration. Renew. Sustain. Energy Rev. 2023, 182, 113400. [Google Scholar] [CrossRef]

- Du, H.; Shen, P.; Chai, W.S.; Nie, D.; Shan, C.; Zhou, L. Perspective and Analysis of Ammonia-Based Distributed Energy System (DES) for Achieving Low Carbon Community in China. IScience 2022, 25, 105120. [Google Scholar] [CrossRef]

- Niaz, H.; Zarei, M.; Shams, M.H.; Won, W.; Liu, J.J. Curtailment to Cashflow: Exploring BESS and Hydrogen for Renewable Energy Profitability. J. Energy Storage 2024, 77, 109990. [Google Scholar] [CrossRef]

- Estevez, R.; López-Tenllado, F.J.; Aguado-Deblas, L.; Bautista, F.M.; Romero, A.A.; Luna, D. Current Research on Green Ammonia (NH3) as a Potential Vector Energy for Power Storage and Engine Fuels: A Review. Energies 2023, 16, 5451. [Google Scholar] [CrossRef]

- Viswanathan, V.; Mongird, K.; Franks, R.; Li, X.; Sprenkle, V.; Baxter, R. 2022 Grid Energy Storage Technology Cost and Performance Assessment; US Department of Energy: Washington, DC, USA, 2022.

- Spatolisano, E.; Restelli, F. The Role of Ammonia in Decarbonization: A Techno-Economic Assessment of NH3 as H2 Carrier and NH3 as Energy Vector. Chem. Eng. Trans. 2024, 109, 607–612. [Google Scholar] [CrossRef]

- Khaligh, V.; Ghezelbash, A.; Liu, J.; Won, W.; Koo, J.; Na, J. Multi-Period Hydrogen Supply Chain Planning for Advancing Hydrogen Transition Roadmaps. Renew. Sustain. Energy Rev. 2024, 200, 114536. [Google Scholar] [CrossRef]

- Herbinet, O.; Bartocci, P.; Grinberg Dana, A. On the Use of Ammonia as a Fuel—A Perspective. Fuel Commun. 2022, 11, 100064. [Google Scholar] [CrossRef]

- Amhamed, A.I.; Shuibul Qarnain, S.; Hewlett, S.; Sodiq, A.; Abdellatif, Y.; Isaifan, R.J.; Alrebei, O.F. Ammonia Production Plants—A Review. Fuels 2022, 3, 408–435. [Google Scholar] [CrossRef]

- Smith, C.; Hill, A.K.; Torrente-Murciano, L. Current and Future Role of Haber-Bosch Ammonia in a Carbon-Free Energy Landscape. Energy Environ. Sci. 2020, 13, 331–344. [Google Scholar] [CrossRef]

- Duong, P.A.; Ryu, B.R.; Song, M.K.; Nguyen, H.V.; Nam, D.; Kang, H. Safety Assessment of the Ammonia Bunkering Process in the Maritime Sector: A Review. Energies 2023, 16, 4019. [Google Scholar] [CrossRef]

- Oner, O.; Khalilpour, K. Evaluation of Green Hydrogen Carriers: A Multi-Criteria Decision Analysis Tool. Renew. Sustain. Energy Rev. 2022, 168, 112764. [Google Scholar] [CrossRef]

- UK Government. UK Low Carbon Hydrogen Standard Greenhouse Gas Emissions Methodology and Conditions of Standard Compliance Contents; Department for Energy Security and Net Zero: London, UK, 2023.

- Erbach, G.; Svensson, S. BRIEFING Towards Climate Neutrality; European Parliamentary Research Service: Brussels, Belgium, 2023. [Google Scholar]

- European Commission Report. The Potential of Hydrogen for Decarbonising EU Industry; European Commission: Brussels, Belgium, 2021. [Google Scholar]

- Wu, S.; Salmon, N.; Li, M.M.J.; Bañares-Alcántara, R.; Tsang, S.C.E. Energy Decarbonization via Green H2 or NH3? ACS Energy Lett. 2022, 7, 1021–1033. [Google Scholar] [CrossRef]

- Erdemir, D.; Dincer, I. A Quicker Route to Hydrogen Economy with Ammonia. Int. J. Hydrogen Energy 2024, 82, 1230–1237. [Google Scholar] [CrossRef]

- INNIO Group–Jenbacher. HYDROGEN Investing in a Green Future; INNIO Group: Jenbach, Austria, 2021; Available online: https://www.jenbacher.com/en/energy-solutions/energy-sources/hydrogen (accessed on 10 June 2025).

- Awad, O.I.; Zhou, B.; Harrath, K.; Kadirgama, K. Characteristics of NH3/H2 Blend as Carbon-Free Fuels: A Review. Int. J. Hydrogen Energy 2023, 48, 38077–38100. [Google Scholar] [CrossRef]

- Kampker, A.; Heimes, H.; Kehrer, M.; Hagedorn, S.; Reims, P.; Kaul, O. Fuel cell system production cost modeling and analysis. Energy Rep. 2023, 9 (Suppl. 1), 248–255. [Google Scholar] [CrossRef]

- Orangi, S.; Manjong, N.; Perez Clos, D.; Usai, L.; Burheim, O.S.; Strømman, A.H. Historical and prospective lithium-ion battery cost trajectories from a bottom-up production modeling perspective. J. Energy Storage 2024, 76, 109800. [Google Scholar] [CrossRef]

- Joyo, F.H.; Falasco, A.; Groppi, D.; Sferra, A.S.; Astiaso Garcia, D. Hydrogen and Ammonia Production and Transportation from Offshore Wind Farms: A Techno-Economic Analysis. Energies 2025, 18, 2292. [Google Scholar] [CrossRef]

- Mylonopoulos, F.; Durgaprasad, S.; Coraddu, A.; Polinder, H. Lifetime design, operation, and cost analysis for the energy system of a retrofitted cargo vessel with fuel cells and batteries. Int. J. Hydrogen Energy 2024, 91, 1262–1273. [Google Scholar] [CrossRef]

- Available online: https://re.jrc.ec.europa.eu/pvg_tools/en/ (accessed on 11 June 2025).

- Available online: https://www.renewables.ninja/ (accessed on 11 June 2025).

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).