Abstract

Advanced gas turbine cooling technologies are required to bridge the gap between turbine inlet temperatures and component thermal limits. Transpiration cooling has emerged as a promising method, leveraging porous structures to enhance cooling effectiveness. Recent advancements in additive manufacturing (AM) enable precise fabrication of complex transpiration cooling architectures, such as triply periodic minimal surface (TPMS) and biomimetic designs. This review analyzes AM-enabled transpiration cooling for gas turbines, elucidating key parameters, heat transfer mechanisms, and flow characteristics of AM-fabricated designs through experimental and numerical studies. Previous research has concluded that well-designed transpiration cooling achieves cooling effectiveness up to five times higher than the traditional film cooling methods, minimizes jet lift-off, improves temperature uniformity, and reduces coolant requirements. Optimized coolant controls, graded porosity designs, complex topologies, and hybrid cooling architectures further enhance the flow uniformity and cooling effectiveness in AM transpiration cooling. However, challenges remain, including 4–77% porosity shrinkage in perforated transpiration cooling for 0.5–0.06 mm holes, 15% permeability loss from defects, and 10% strength reduction in AM models. Emerging solutions include experimental validations using advanced diagnostics, high-fidelity multiphysics simulations, AI-driven and topology optimizations, and novel AM techniques, which aim at revolutionizing transpiration cooling for next-generation gas turbines operating under extreme conditions.

1. Introduction

1.1. Importance of Advanced Cooling Technology for Gas Turbines

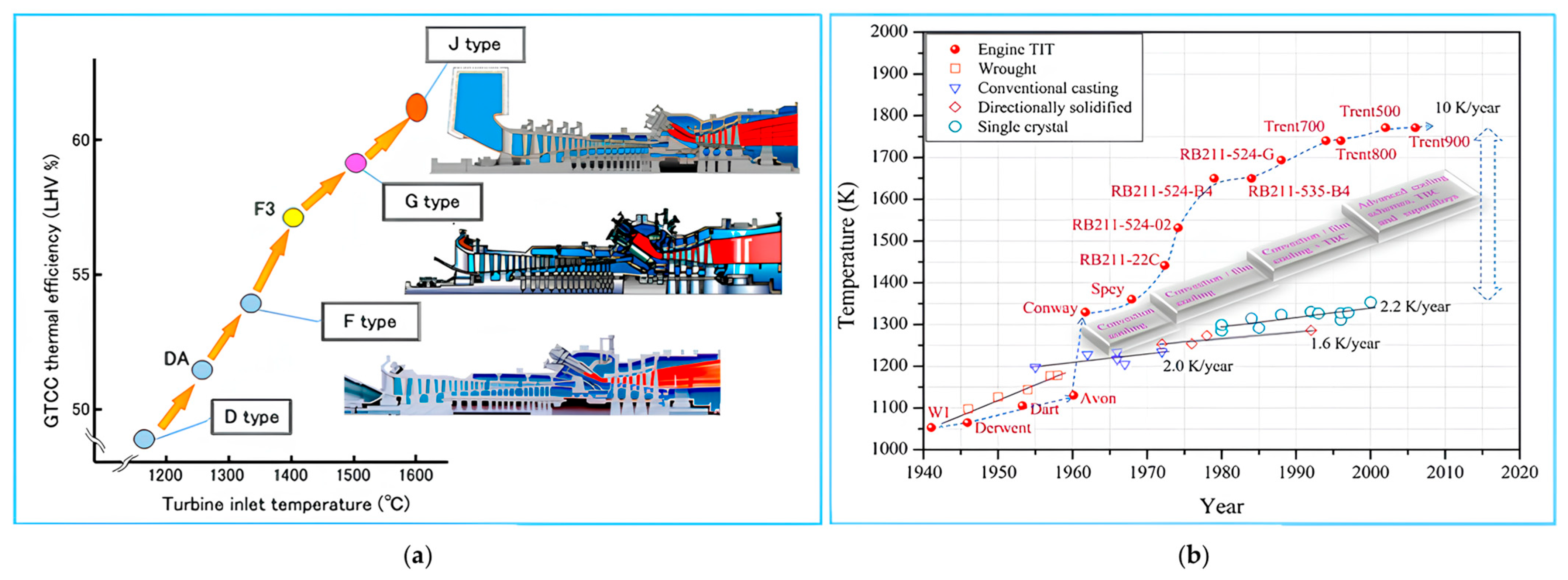

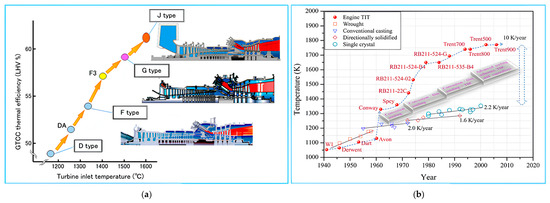

Gas turbines are widely used in aviation and power generation due to their high power density, efficiency, and performance. The global market of gas turbines is projected to grow further due to technological advancements and the shift toward distributed power generation. Performance improvements are motivated by the purpose of decreasing fuel consumption, saving subsequent expenses, and reducing carbon dioxide (CO2) emissions. According to the Brayton cycle, increasing turbine inlet temperature (TIT) is the most effective way to enhance performance [1], as shown in Figure 1a [2]. Modern combined-cycle plants with 1700 °C-class turbines achieve around 65% efficiency [3], while aero-engines will operate at TITs exceeding 1800 °C. Heavy-duty turbines, such as Mitsubishi’s M701J, have reached 1600 °C, with future designs targeting 1700 °C [4].

Figure 1.

Development in gas turbine: (a) TIT effects on gas turbine power and effectiveness and (b) Evolution of temperature capabilities of materials and thermal barrier coatings (These figures are reproduced from [2,5] under a Creative Commons Attribution (CC BY) license).

Despite these advancements, material limitations remain a critical challenge. Modern superalloys and thermal barrier coatings (TBCs) allow turbine blades to withstand temperatures around 1300 °C [6,7], as depicted in Figure 1b [5]; however, combustor temperatures are projected to exceed 1800 °C to obtain higher efficiency and power output. Furthermore, the maximum temperature for superalloys increases at a rate of only 8 °C per year, whereas the TITs are growing by up to 20 °C annually. To bridge this gap, advanced cooling technologies must be implemented to protect turbine components from thermal failure under these extreme operating conditions.

1.2. Evolution from Traditional to Transpiration Cooling

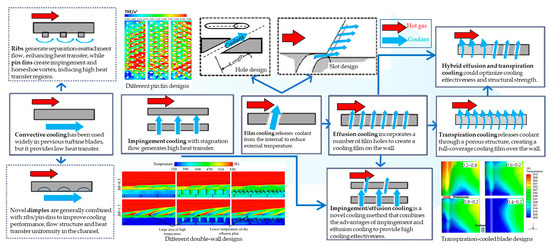

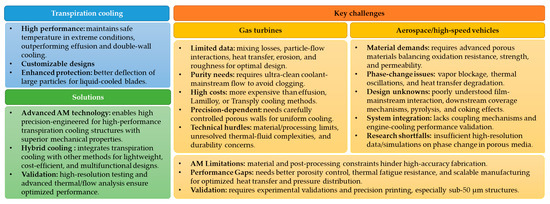

The evolution of gas turbine cooling has progressed from simple convection cooling to advanced transpiration cooling, with each stage improving cooling effectiveness, as shown in Figure 2. Early convection cooling was enhanced through various methods, including rib turbulators [8], pin fins [9], and protrusions/dimples [10]. Impingement cooling subsequently emerged as a high-performance alternative due to its superior heat transfer enhancement (Nu/Nu0) [11,12]. However, internal cooling schemes, even combined ones, such as pin fin-dimple or rib-dimple, leave blade surfaces exposed to hot gas and cannot meet thermal protection requirements. This limitation led to the development of external cooling, i.e., film cooling, which forms a protective layer over the surface to improve cooling effectiveness. Many researchers have developed various techniques to enhance its efficiency [13]. As hole density increases, film cooling transitions to effusion cooling, which provides a full-coverage film layer to hot surfaces.

Impingement/effusion cooling, also known as double-wall cooling, has been used to improve gas turbine thermal protection since the 1980s [14,15]. This scheme combines the advantages of jet impingement and film cooling through a perforated wall with supporting structures. Studies have shown that double-wall cooling achieves higher cooling effectiveness than other conventional cooling methods, with pedestals improving heat transfer uniformity [16,17,18,19]. However, careful design is required to avoid performance degradation. The double-wall cooling system has also faced durability challenges from thermal stresses between layers. Skamniotis et al. [20,21,22] revealed that reducing hole ellipticity and optimizing pedestal spacing can mitigate stresses. Courtis et al. [23] showed that optimized hole spacing, particularly in the spanwise direction, can achieve film effectiveness up to 0.9, whereas increased porosity (φ) reduces mechanical strength, necessitating careful thermomechanical design trade-offs for practical implementation.

Figure 2.

Overview of advanced cooling methods for gas turbine blades. Different pin fin designs, reproduced with permission from [24]. Copyright 2021 Elsevier, Different double-wall designs, reproduced with permission from [18]. Copyright 2021 Elsevier, Transpiration-cooled blade designs, reproduced with permission from [25]. Copyright 2023 Elsevier.

Figure 2.

Overview of advanced cooling methods for gas turbine blades. Different pin fin designs, reproduced with permission from [24]. Copyright 2021 Elsevier, Different double-wall designs, reproduced with permission from [18]. Copyright 2021 Elsevier, Transpiration-cooled blade designs, reproduced with permission from [25]. Copyright 2023 Elsevier.

To balance film coverage uniformity with mechanical strength, transpiration cooling systems can be integrated with film holes [26,27]. However, conventional porous-media-based transpiration materials, such as metal foams, sintered particles, and woven meshes, lack the structural integrity required for turbine blade applications. While porous transpiration cooling has demonstrated high efficiency in rocket engines [28] and has since been adapted for gas turbines [29,30], scramjets [31], and high-speed vehicles [32], ongoing research focuses on novel materials [33], alternative coolants [34], and heat transfer enhancement techniques [35]. Additive manufacturing (AM) offers a promising solution by enabling precise and high-performance cooling designs [2]. Despite its potential, the flow and heat transfer analysis of AM-fabricated transpiration cooling remains underexplored in the existing literature [5,36,37,38,39,40,41,42,43,44,45,46].

1.3. Framework and Objectives

Given the urgent demand for high-performance cooling in gas turbines and the rapid advancements in AM technology, there is a critical need for a comprehensive framework that integrates both domains. This article presents a review of recent research on flow and heat transfer analysis in additively manufactured transpiration cooling systems for gas turbines, which is structured into six key sections. First, the significance and evolution of gas turbine cooling are introduced. The Section 2 summarizes the literature review of transpiration cooling, including research progress and its classification. The development of AM techniques tailored for transpiration cooling applications is then presented in the Section 3. The Section 4 analyzes flow and heat transfer characteristics in AM transpiration cooling, drawing insights from recent experimental and numerical studies, as well as optimization efforts. The Section 5 addresses challenges and future directions. Finally, the paper concludes by summarizing the main findings and their implications.

2. Literature Review of Transpiration Cooling

2.1. Research Progress and Challenges of Transpiration Cooling

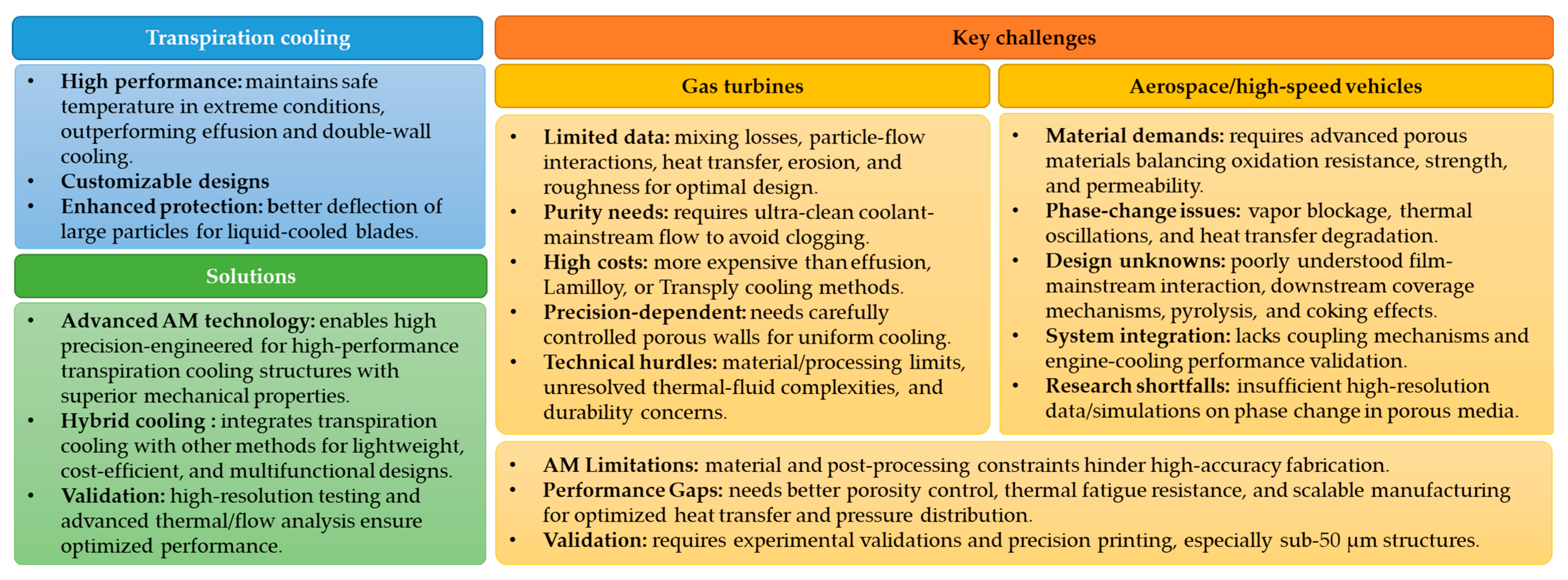

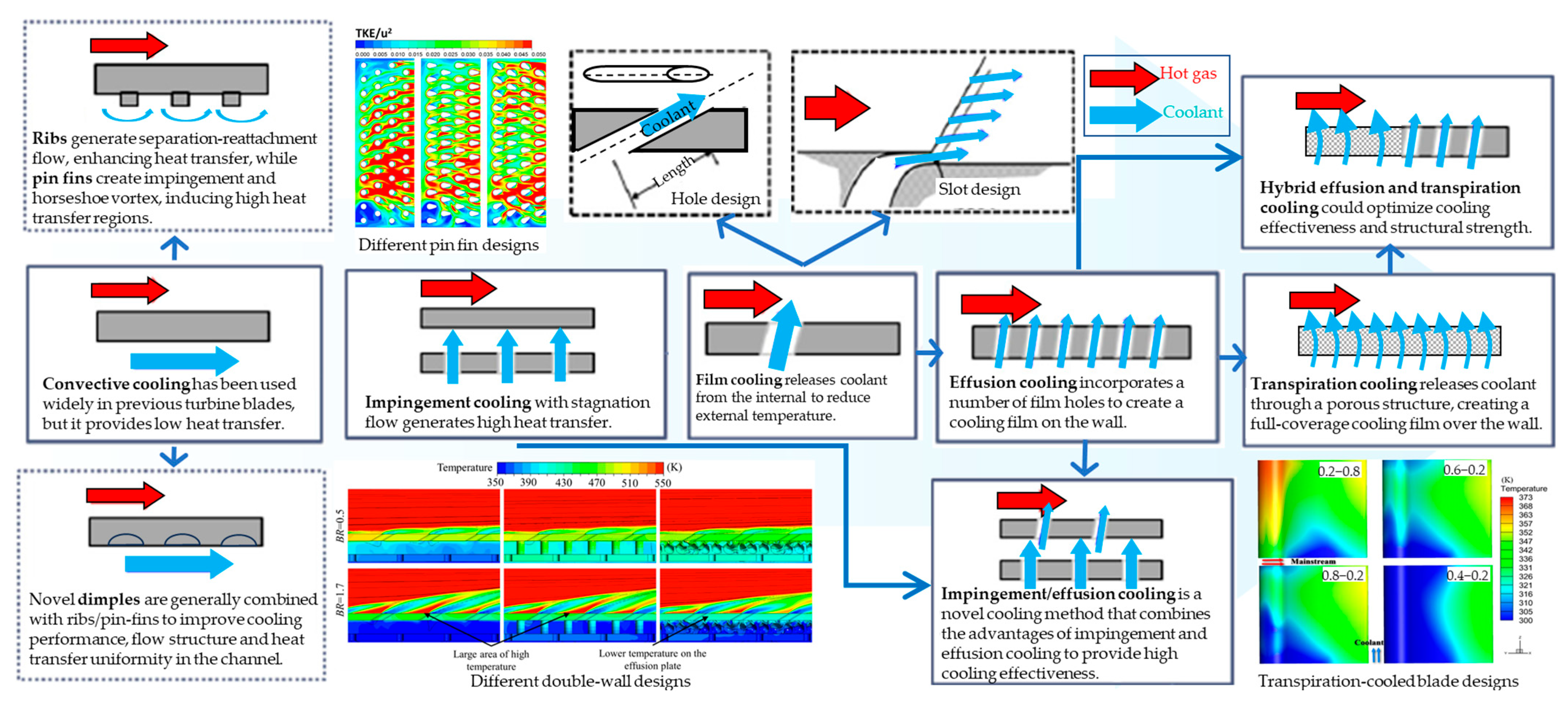

The prior review articles on transpiration cooling have been widely established, mainly for aerospace and high-speed vehicles. Figure 3 summarizes the benefits, existing key challenges, and solutions, highlighting its implementation feasibility for gas turbines and high-speed vehicles. Most reviews [5,36,37,38,39,40,41,42,43,44,45,46] affirmed that transpiration cooling held significant promise for these applications due to high cooling performance, customizable design, and enhanced surface protection. Advances in AM technology enabled the fabrication of precision micro and transpiration cooling structures, addressing critical challenges such as particle-induced clogging, mechanical integrity, and manufacturing limitations. Additionally, research on hybrid cooling methods has been advancing, aiming to enhance thermomechanical performance under extreme conditions.

Figure 3.

Summary of prior review articles on transpiration cooling techniques.

While existing reviews have thoroughly documented conventional transpiration cooling approaches, they identified critical knowledge gaps, especially in AM technology for transpiration cooling structures, experimental/numerical studies on AM-fabricated transpiration cooling systems, and detailed flow/heat transfer analysis for gas turbines. This review, therefore, addresses these gaps by evaluating recent advances in AM techniques, experimental and computational results, and optimized transpiration cooling studies, providing a comprehensive framework for implementing AM transpiration cooling in next-generation gas turbines.

2.2. Classification of Transpiration Cooling

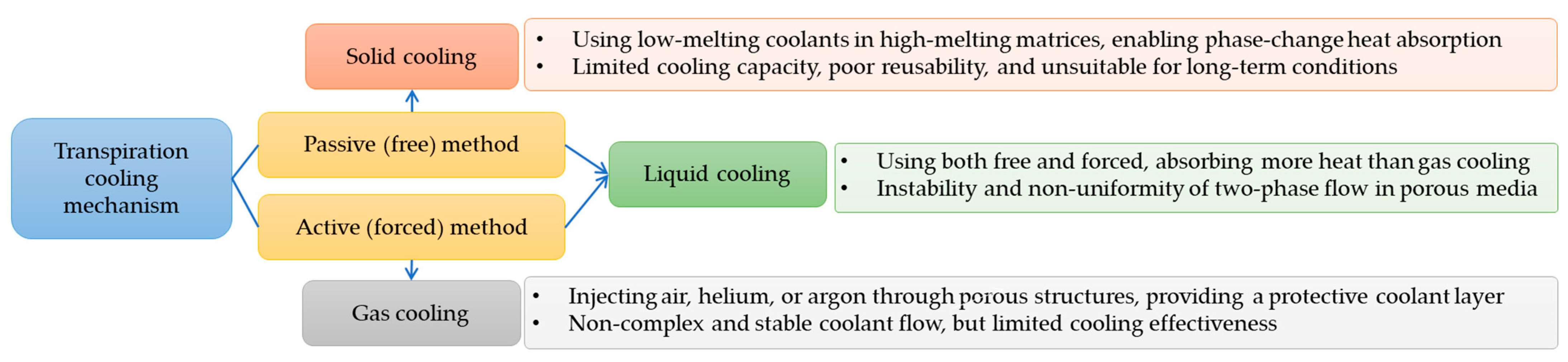

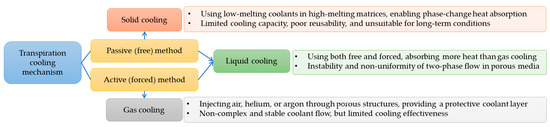

In previous studies, transpiration cooling is also called sweat [47], effusion [48], or full-coverage film cooling [49]. Therefore, it is essential to understand the classification of transpiration cooling, as this framework defines the cooling capacity, material requirement, and manufacturing effect that guide design and performance evaluation. Transpiration cooling employs three primary mechanisms, classified based on working conditions, as summarized in Figure 4 [44]: solid cooling using phase-changing metals for passive heat absorption [50], gas cooling via forced flow through porous structures [49,51], and liquid cooling combining passive and active methods with phase-change enhancement [52,53,54]. The passive approach relies on material vaporization, while forced methods create protective coolant boundary layers through porous media.

Figure 4.

Classification of transpiration cooling based on working conditions.

Hypersonic vehicles and rocket engines operating above 2000 °C can achieve remarkable cooling capacities approaching 1000 MW/m2 through liquid transpiration with phase-change enhancement [55]. Meanwhile, aero-engine turbines are limited to 50–100 MW/m2 when using compressor bleed air through effusion or transpiration cooling, which are also constrained by the temperature limits of superalloys and ceramic matrix composites (CMCs) below 1500 °C. Moreover, liquid transpiration cooling systems, especially in gas turbines, could cause high thermal stress and pore clogging during rapid phase changes.

The current gas-phase (also known as single-phase) transpiration cooling is the most suitable for current gas turbines. The gas-phase transpiration cooling materials can be further categorized into porous media and laminated materials [38]. The porous-media transpiration materials include a metal-based type fabricated through powder sintering or advanced AM techniques and a ceramic-based type, which offers superior high-temperature performance [56]. However, sintered porous materials suffer from limited high-temperature oxidation resistance and structural strength. Meanwhile, ceramic-based transpiration faces brittleness and incompatibility with other metal structures in current technology, even though the ceramic material demonstrates excellent thermal stability and reduced coolant requirements [57].

On the other hand, laminated materials, traditionally constrained by manufacturing complexity and thermal limitations [58], have benefited from recent advances in AM technology [59,60,61,62]. Innovative approaches such as gradient laser sintering of 316 L stainless steel have enabled precise pore structure control, significantly improving anti-blockage performance and cooling efficiency [63]. Metal material with gradient φ has successfully been fabricated through the utilization of the selective laser melting (SLM) technique, in which a gradient-changing scan speed is incorporated in each SLM layer [64]. The smoothly graded pore structures are fabricated using this AM technology, resulting in optimized coolant distribution, which minimizes pore clogging and enhances cooling performance. As a result, metal-based type transpiration cooling is more viable for gas turbines when implemented in precisely engineered and non-stochastic architectures fabricated through advanced AM techniques. The following sections explore the role of AM in transpiration cooling and current flow/heat transfer analysis to address gaps identified in prior studies [5,36,37,38,39,40,41,42,43,44,45,46].

3. Additive Manufacturing for Transpiration Cooling

3.1. Traditional Manufacturing for Transpiration Cooling

Manufacturing developments of transpiration cooling for high-speed vehicles have been well documented in previous work [38,44,45], concluding that metal-based transpiration materials have been traditionally fabricated by powder sintering, fiber sintering, and melt casting, including bronze, stainless steel, titanium, and alloys. Powder-sintered porous metals, such as copper-based cooling systems by NASA [65], have been used in rocket engines. Recent advancements, such as metal powder injection molding (MIM), enabled precise control over pore geometry, allowing complex structures, such as inclined porous struts, for hybrid film/transpiration cooling [26]. Additionally, conventional laminated cooling fabrication involved etching or laser-cutting micro-cooling channels into thin metal sheets, followed by layer stacking and welding [66]. However, this method was time-consuming, limited to specific metals, and incapable of achieving precise complex micro-channel geometries, restricting its overall effectiveness. Therefore, the AM technique is essential to overcome the limitations of the traditional methods for efficiently fabricating advanced transpiration cooling structures for gas turbines.

3.2. Additive Manufacturing Techniques for Transpiration Cooling

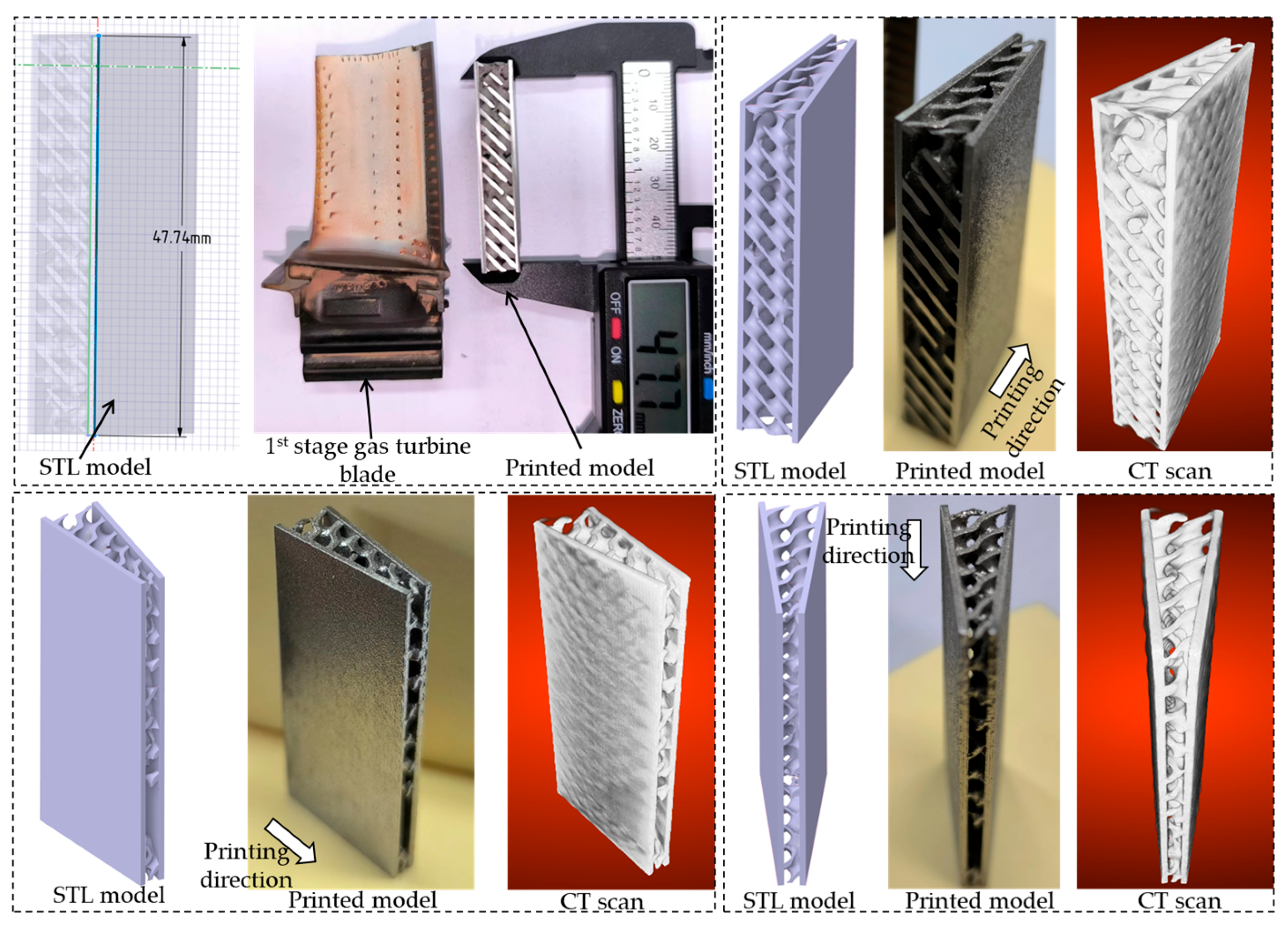

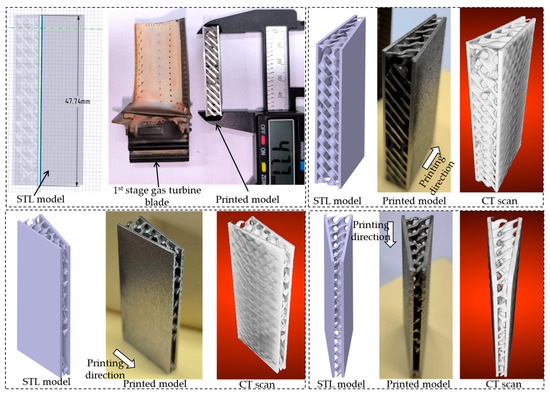

Compared to conventional fabrication methods, the AM technology has offered higher precision by combining computer-aided design (CAD) with minimized material consumption and increased production efficiency. The AM allows full control over pore shape and size, making it ideal for complex designs, such as gas turbine blades with advanced cooling channels. Figure 5 shows the topology-optimized trailing edge (TE) on the scale of a gas turbine blade [67]. This study has concluded that the SLM method provided accurate printing with no micro-voids, staircase effects, or partially melted particles, and post-processing ensured a smooth external surface. Another notable example is Siemens’s application of direct metal laser sintering (DMLS), developed by Electro Optical Systems (EOS), Germany, to fabricate turbine blades with optimized internal cooling structures, demonstrating the capability of the AM technology for high-performance complex cooling channels in gas turbines [68].

Figure 5.

Complex gas turbine cooling structures fabricated using the SLM method. Reproduced with permission from [67]. Copyright 2024 Elsevier.

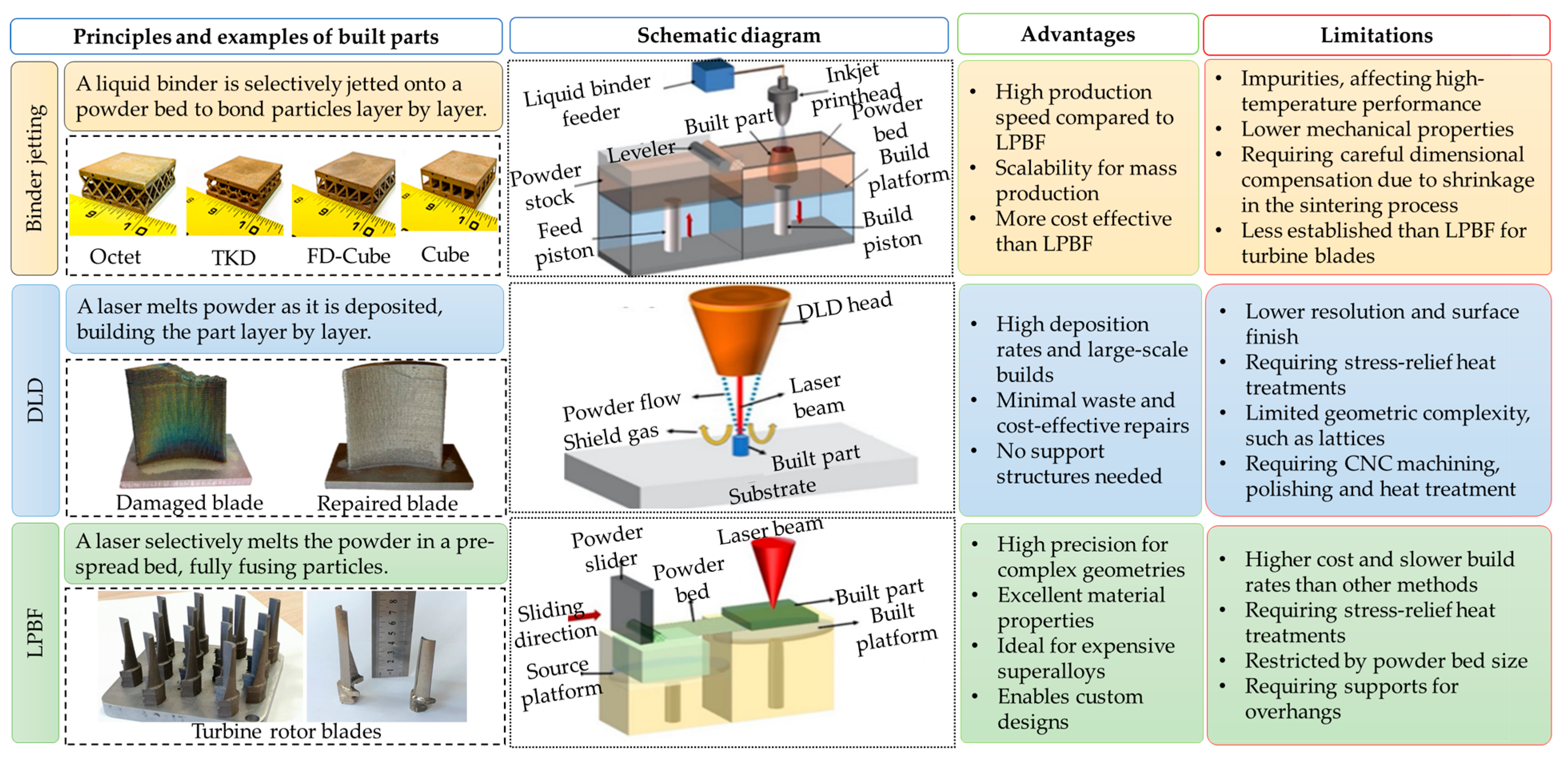

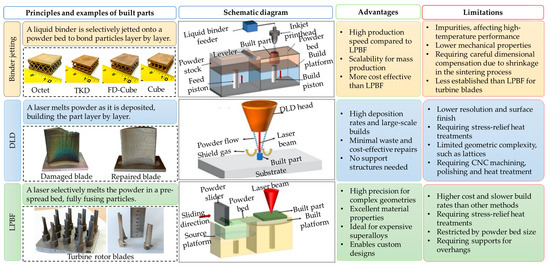

Three metal AM methods have emerged as key technologies for gas turbine applications, including powder bed binder jetting [69], direct laser deposition (DLD) [70], and laser powder bed fusion (LPBF) [71] for both full melt (laser melting) and partial melt (laser sintering). Each method offers distinct advantages and limitations, leading to different use cases in gas turbine component fabrication. Figure 6 summarizes the working principles, advantages, and drawbacks of these AM techniques in the context of gas turbine manufacturing [72].

Figure 6.

A summary of AM techniques for gas turbines. Lattice structures, reproduced with permission from [69]. Copyright 2022 Elsevier. Damaged and repaired blades, reproduced with permission from [70]. Copyright 2014 Elsevier. Turbine rotor blades, reproduced with permission from [71]. Copyright 2020 Elsevier. The schematic diagrams are reproduced from [72] under a Creative Commons Attribution (CC BY) license.

Most of the transpiration-cooling designs for gas turbine research have been successfully fabricated using the LPBF method, enabling detailed flow/heat transfer and structural analysis. Key studies are shown in Table 1. These studies demonstrated that the LPBF method allowed the fabrication of highly complex transpiration-cooling designs with robust mechanical properties and superior cooling performance. This represents a transformative advancement for next-generation gas turbine cooling technologies.

Table 1.

Examples of metal AM-fabricated transpiration-cooling designs for gas turbine research.

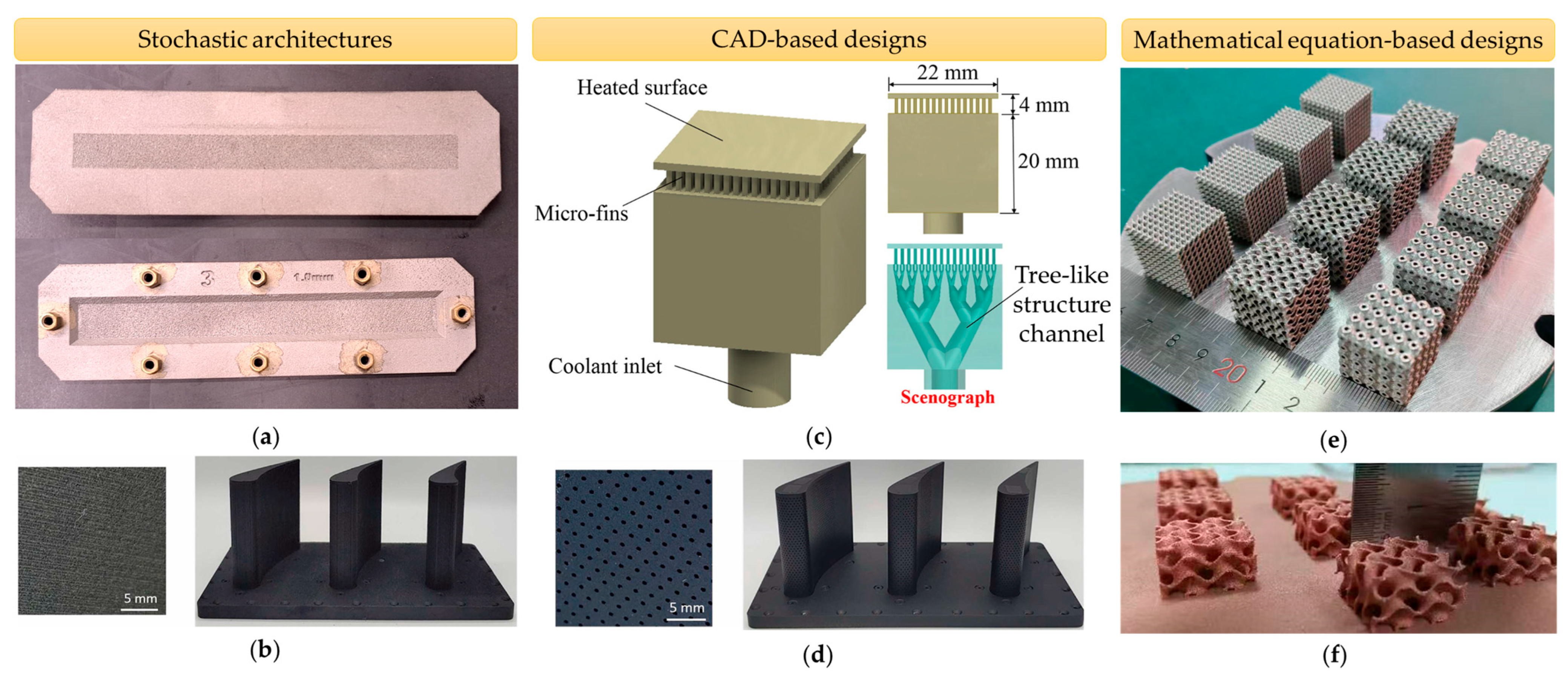

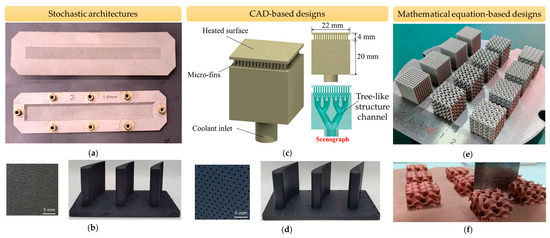

3.3. Additive Manufacturing-Fabricated Advanced Transpiration Cooling Structures

Advancements in AM technology have enabled the fabrication of complex and high-performance transpiration cooling structures for gas turbines, offering superior thermal management compared to conventional cooling techniques [2,46]. These structures can be categorized according to porosity control into stochastic [73,74,75] and deterministic structures [77,78,80,81,82,83], as shown in Figure 7. The random-pore distributions usually caused uncontrolled flow paths, limited cooling uniformity, and low mechanical strength. The non-stochastic designs also provided customizable geometry and permeability, enhanced heat transfer, predictable fluid and heat transfer characteristics, and higher mechanical strength, making them ideal for high-performance transpiration cooling in gas turbines. Notably, the mathematical equation-based designs, such as TPMS, exhibited better thermal conductivity, heat and mass transfer, and mechanical strength than the CAD-based designs [84]. In conclusion, the AM-fabricated non-stochastic structures, particularly TPMS-based designs, have demonstrated strong potential for advancing transpiration cooling in gas turbines, motivating the detailed flow and heat transfer analysis in the next section.

Figure 7.

Advanced transpiration cooling structures in recent studies: (a) AM porous Hastelloy-X specimens (Reproduced with permission from [74]. Copyright 2024 Elsevier), (b) AM-fabricated transpiration-cooled cascade blade (Reproduced with permission from [30]. Copyright 2022 Elsevier), (c) Tree-like structure designs (Reproduced with permission from [83]. Copyright 2019 Elsevier), (d) AM-fabricated effusion-cooled cascade blade (Reproduced with permission from [30]. Copyright 2022 Elsevier), (e) Different TPMSs, and (f) Gyroid structures.

4. Flow and Heat Transfer Analysis

4.1. Heat Transfer Mechanism

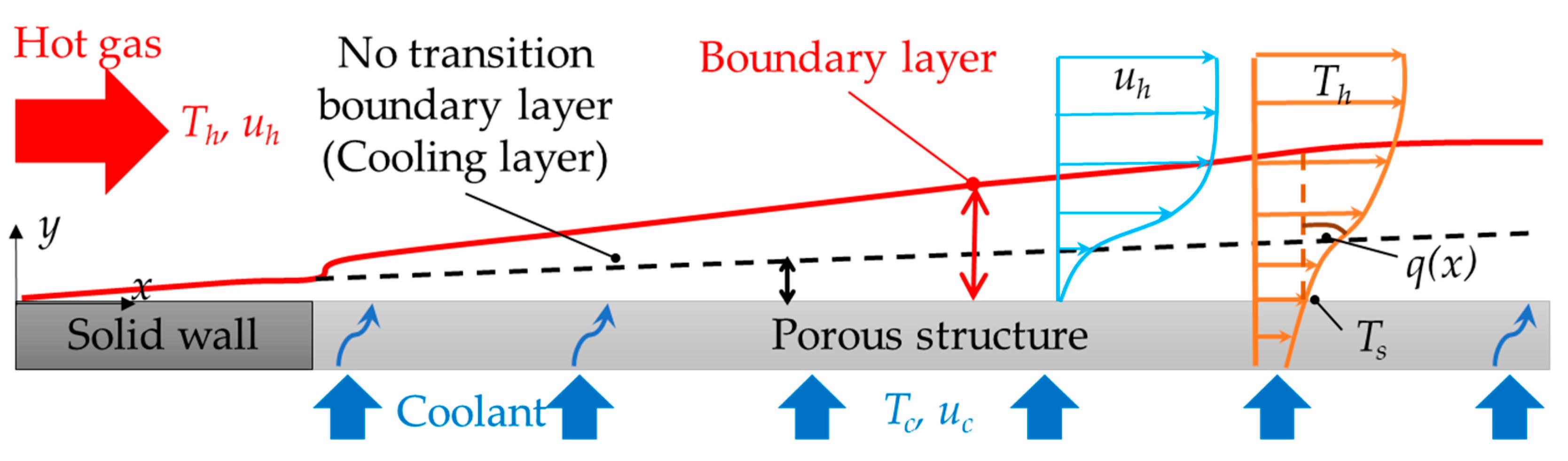

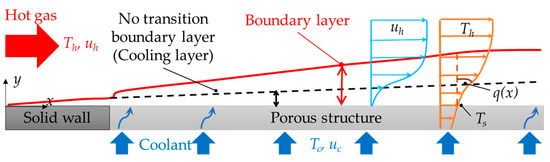

The general gas-phase transpiration cooling mechanism includes forced convection within the structural matrix and a continuously developing cooling film on the hot gas side of the porous surface that protects the hot gas from attaching to the surface [85], as schematically demonstrated in Figure 8. In gas turbine applications, transpiration cooling also employs this dual-mode heat transfer mechanism to achieve enhanced thermal protection. The internal cooling process involves forced convection through the porous structures or micro holes, where coolant extracts thermal energy from the blade or combustor walls. Then, the coolant forms a film-cooling layer that interacts with the mainstream flow through convective heat transfer within the turbulent boundary layer, mass transfer-driven dilution of combustion products, and aerodynamic displacement of the stagnation line [37,86]. This combined mechanism enhances cooling effectiveness compared to discrete film cooling, primarily by eliminating jet lift-off effects.

Figure 8.

Schematic diagram of heat transfer mechanism of gas-phase transpiration cooling.

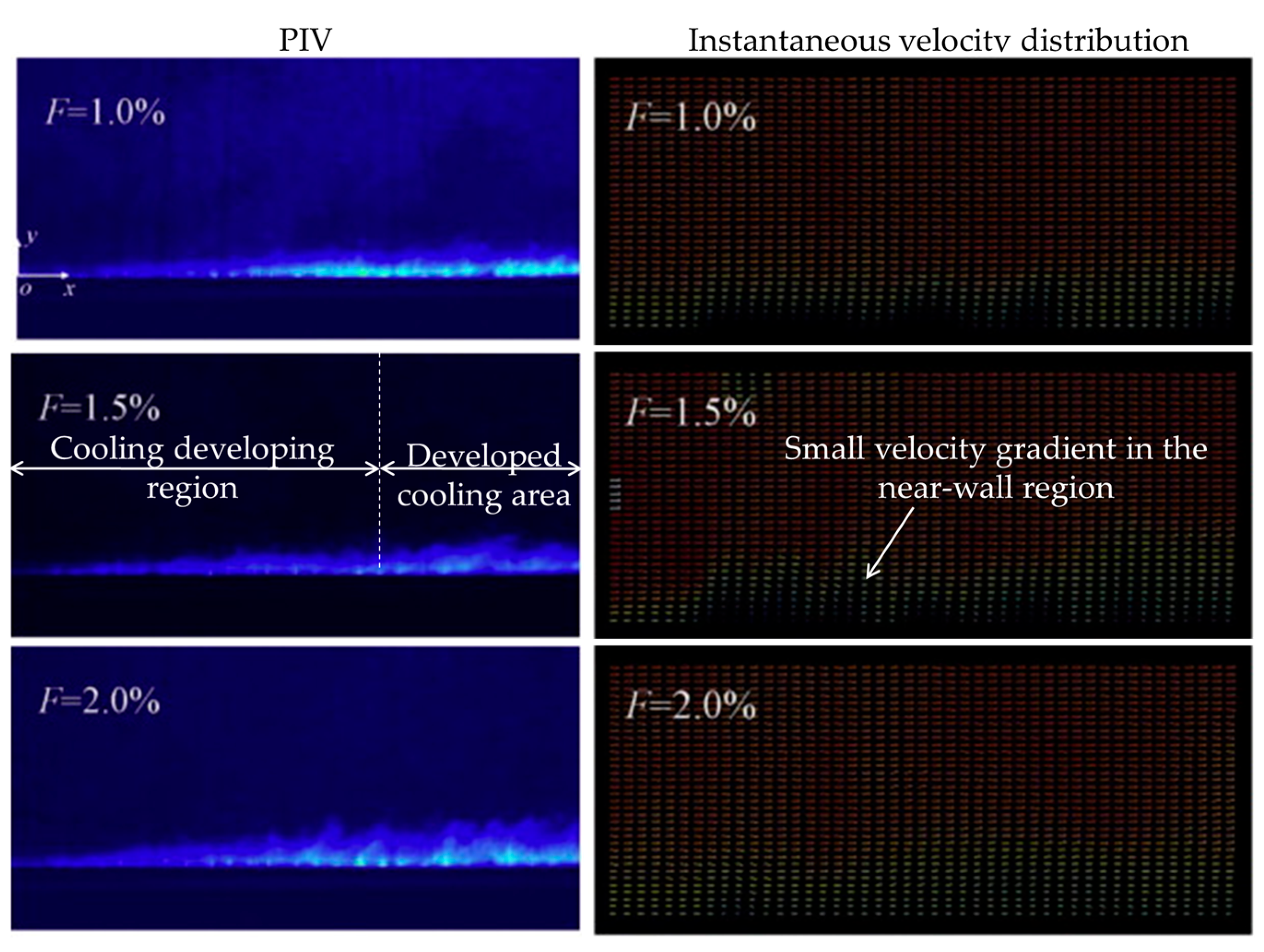

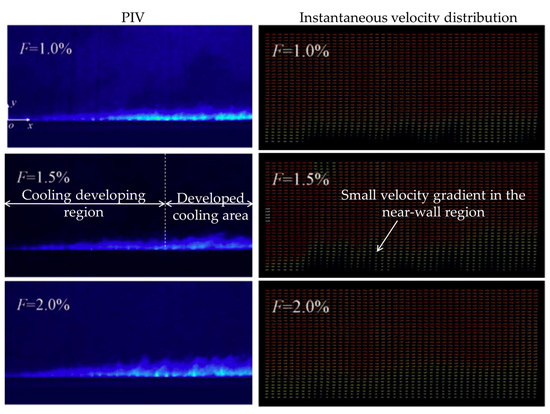

The particle image velocimetry (PIV) image and instantaneous velocity distribution [49] in Figure 9 show that the boundary layer remains thin in the initial cooling development region of a relatively small-diameter perforated plate. As coolant air accumulates downstream, progressive boundary layer growth is observed through the transition zone until reaching the developed cooling region. Within the developed cooling area along the wall, the boundary layer thickness stabilizes, maintaining near-constant values across the entire stabilized zone. Additionally, the boundary layer growth rate strongly depends on the cooling supplied rate, increasing linearly with coolant mass flux. Overall, this relationship closely resembles that in the sintered porous-based transpiration cooling structure [49]. Therefore, the diagram in Figure 8 could also be used to explain the flow and heat transfer phenomena of non-stochastic architectures fabricated through AM technology.

Figure 9.

PIV and instantaneous velocity distributions in the near wall region of a perforated transpiration cooling plate. Reproduced with permission from [49]. Copyright 2015 Elsevier.

4.2. Related Parameters

Many pore-scale studies of transpiration cooling couple the high Reynolds number flow of the mainstream (Reh) and the low Reynolds number flow of the coolant inside the porous matrix (Rec) [82,87,88], defined as follows:

where uh is the mainstream flow velocity (m/s). ρc and ρh are the densities of coolant and mainstream (kg/m3). dh, Ah, Ch are the hydraulic diameter (m), cross-sectional area (m2), and the circumference of the hot flow channel (m). μ signifies the dynamic viscosity of fluid (kg/(m·s)). uD is the Darcy velocity (m/s). dc is the hydraulic diameter of the coolant supply channel, and Sv is the specific surface area (1/m).

In transpiration cooling experiments, the mass flow ratio of coolant to mainstream (MFR), injection ratio (F), and blowing ratio (BR) are the key parameters for determining the coolant flow rate. The MFR is used in system-level cooling efficiency, such as nose cone and turbine blade cooling, to evaluate coolant supply requirements for a given cooling strategy. The MFR is calculated as follows:

where and are the mass flow rate of the coolant and mainstream (kg/s).

The coolant injection ratio (F) is used when focusing on coolant distribution per unit area, defined as follows:

where uc is the equivalent average cross-section coolant velocity (m/s). Aeff is the coolant-covered area on the hot-side surface (m2).

In film or effusion cooling, the blowing ratio (BR) is the primary parameter for evaluating the coolant flow rate, focusing on momentum interaction at the injection point. Unlike the F, the BR is based on the coolant velocity defined per hole/pore rather than the total mass flow rate. The blowing ratio (BR) is expressed as

where vc is the average velocity of coolant flow in the film hole (m/s).

The vc can be derived from the coolant flow rate and the equivalent pore diameter (dpore) of the porous structure in transpiration cooling studies. Due to the significant momentum loss caused by friction within the porous medium, most studies avoid comparing micro-cooling performance using the BR. Instead, cooling effectiveness in various transpiration cooling studies is evaluated based on the injection ratio (F) or the volumetric flow rate () of the coolant.

The convective heat transfer coefficient (h) and Nusselt number (Nu) are also important parameters to make data comparable for different transpiration cooling designs. The h (W/m2K) and Nu on the hot-side surface of transpiration cooling structures are defined as follows:

where Qtot is the total heat transfer (W). Aw is the wetted area (m2). Th is the mainstream and coolant temperatures (K). Ts is the surface temperature (K). Lc is the characteristic length of the transpiration cooling designs (m). kf is the thermal conductivity of fluid (W/m·K).

Generally, for external cooling, the heat transfer analysis quantifies cooling performance through local cooling effectiveness, calculated as

where Tc is the coolant temperature (K).

Film cooling effectiveness (ηa) is typically used in adiabatic wall studies to evaluate localized cooling performance at specific coolant injection points. In contrast, overall cooling effectiveness (ηo) is applied in conjugate heat transfer analyses, assessing the total temperature reduction in the component by accounting for external film cooling and internal cooling mechanisms, that is, the coolant flow through holes or pores.

The Biot number (Bi) is also used to analyze the thermal behavior of porous structures and the efficiency of heat transfer between the solid matrix and the coolant in transpiration cooling [89]. It can be expressed as

where t is the thickness of transpiration cooling structures (m). ks is the thermal conductivity of the solid domain (W/(m·K). In the case of porous-media structure, keff, which is effective thermal conductivity (W/(m·K), is used instead of ks.

The flow resistance of different transpiration cooling designs is usually evaluated using the total pressure loss coefficient (ζPt) [82,90], defined as

where pt,in and pt,out are the total pressure of the coolant inlet and outlet (Pa), respectively.

The skin-friction coefficient (CF) of the transpiration cooling is employed to reveal the shear stress () on the solid surface due to the viscous effects and show the attachment of the coolant film [91]. The CF is expressed as follows:

Another parameter used to quantify the efficiency of the flow contraction through transpiration cooling structures and viscous loss due to the tortuosity of the transpiration topology is the discharge coefficient (CD). The CD is defined as the ratio of the actual mass flow rate to the theoretical mass flow rate [75,79], which can be simplified as follows:

where Apore is the total cross-sectional area of transpiration cooling topology (m2).

Due to material shrinkage, printing resolution, and post-processing, the AM structures often exhibit dimensional variations from their original designs. To assess these manufacturing tolerances, both the designed porosity (φdes) and actual porosity (φact) of test specimens are quantified using

where Vdes represents the designed volume of a geometry from a CAD model (m3). Vsol is the volume of a solid domain with identical dimensions (m3). Mdes signifies the measured weight of a test specimen, while Msol is the measured weight of the solid plate (kg).

Additionally, to analyze the influence of transpiration cooling design on heat transfer, the internal surface area ratio (Rint) and outlet area ratio (Rout) are usually presented [76,92], which can be calculated as

where Aint and Aout are the internal surfaces of the solid–fluid interface inside the specimens and the outlet area of the coolant at the outer surface (m2), respectively. These area values are typically derived from CAD models.

4.3. Experimental Research

4.3.1. Experimental Setup and Measurement Method

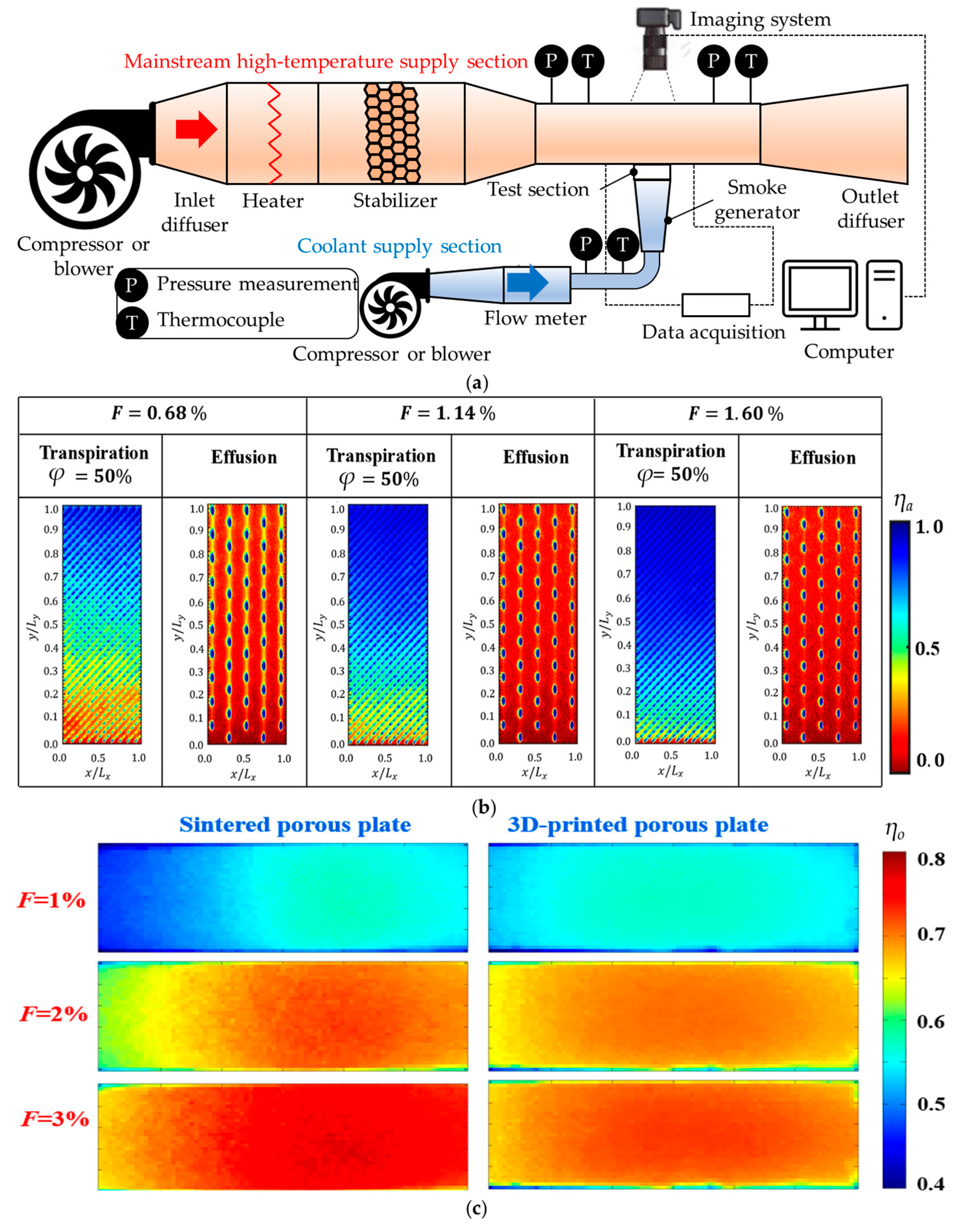

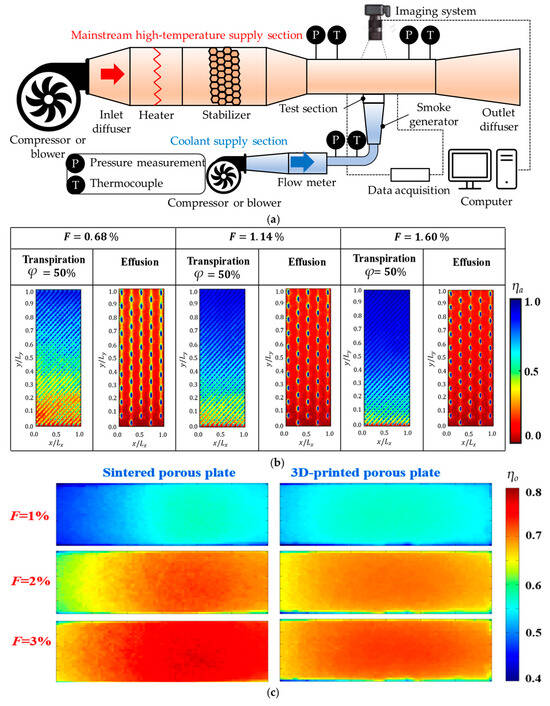

Experiments on AM-based transpiration cooling structures are essential to address various aspects, such as the effect of geometrical designs and the influence of studied conditions, which analytical models often inadequately represent [93,94]. The experimental studies validate theoretical assumptions, reveal the interactions of porosity (φ) or topology on thermo-fluidic behavior, and quantify flow distribution in complex AM geometries. The general experimental setup for analyzing the flow and heat transfer of transpiration cooling is schematically depicted in Figure 10a.

Figure 10.

General experimental setup for investigation on flow and heat transfer of transpiration cooling: (a) Schematic diagram; (b) Illustration of ηa contours (Reproduced with permission from [92]. Copyright 2024 Elsevier) and (c) ηo distributions (Reproduced with permission from [51]. Copyright 2018 Elsevier).

The airflow generated by the blower or compressor passes through the inlet diffuser and enters the heater uniformly, where it is heated to the target temperature. The heated air then flows through flow stabilizers, such as honeycombs or mesh screens, to ensure a uniform mainstream flow within the test section. Maintaining consistent temperature and velocity of the mainstream inside the test section is critical. Additionally, the turbulent intensity of the airflow must be measured. For the coolant system, the coolant is supplied by the blower or compressor, and its flow rate can be adjusted using a flowmeter to vary the MRF, BR, or F. In flow visualization studies, techniques such as smoke-laser sheet imaging [30,73,95] or PIV [49] may be employed.

Pressure-sensitive paint (PSP) and infrared thermography (IR) methods have been widely used to acquire the cooling effectiveness of the transpiration cooling wall, as demonstrated in examples in Figure 10b,c. Meanwhile, the use of transient liquid crystal thermography (TLC) was quite limited. The PSP method measures surface pressure distributions indirectly by detecting oxygen quenching of luminescent molecules, which can then be correlated to temperature in certain applications. It provides high spatial resolution and is particularly useful for aerodynamic studies, but it requires optical access and careful calibration to separate pressure and thermal effects. In contrast, IR thermography directly captures surface temperature distributions by detecting thermal radiation emitted by the material. IR is non-invasive, works in real-time, and is well-suited for thermal analysis, but its accuracy can be affected by surface emissivity variations and environmental reflections. While PSP excels in detailed pressure mapping with temperature derivations, IR is more straightforward for pure thermal visualization, making them complementary tools depending on the experimental focus.

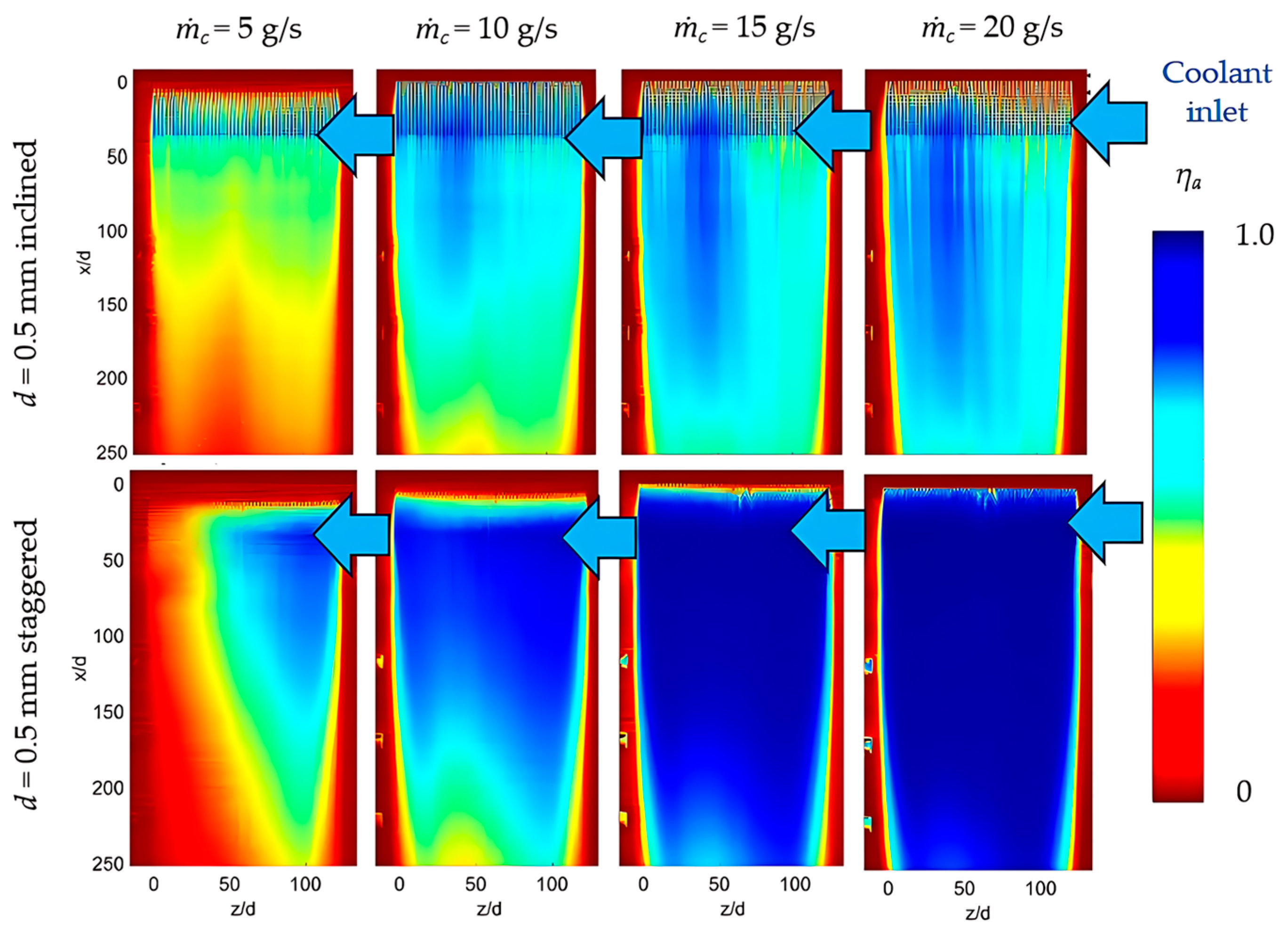

Recent experimental studies on flow and heat transfer of AM transpiration cooling, suited for gas turbine applications, have been conducted, as shown in Table 2. Different measurement techniques used to acquire η, heat transfer coefficient (h), velocity (u), and discharge coefficient (CD) under various conditions are summarized. This study evaluated transpiration cooling performance across various designs, with area-averaged effectiveness (ηo and ηa) ranging from 0.05 to 0.95. Optimal configurations included sintered models with an area-averaged ηo of 0.74, staggered arrangements on an SS turbine blade with an area-averaged ηa of 0.95, and bio-inspired structures with an area-averaged ηo of 0.35–0.57. Graded porosity reduced peak temperatures by 20%, while inserting a lattice decreased area-averaged ηo by 12%. The results demonstrate that cooling efficiency was highly dependent on geometry and φ distribution.

Table 2.

Overview of experimental studies on flow and heat transfer of AM transpiration cooling.

4.3.2. Experimental Studies on AM-Fabricated Random-Pore Porous Structures

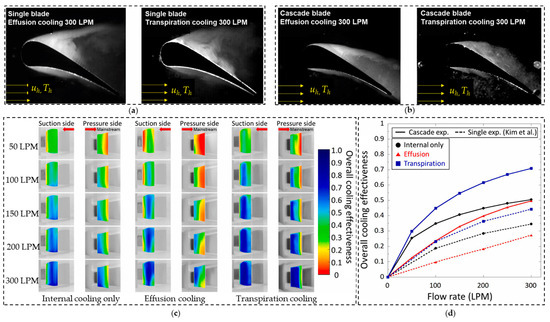

The Korea Advanced Institute of Science and Technology pioneered innovative experimental research on state-of-the-art transpiration-cooled C3X turbine blades, showing remarkable ingenuity in advancing thermal protection for cutting-edge gas turbine cooling. Kim et al. [73] compared internal, effusion, and 3D printed-porous transpiration cooling. The test section featured CaF2 windows with 95% transmittance at 3–5 μm to minimize thermal interference, enabling accurate IR thermometry. The studied models included a 0.5 mm effusion-hole model fabricated by electric discharge machining and a 40 μm porous-based transpiration cooling model structure, additively manufactured within φ = 53%. The results showed that transpiration cooling demonstrated superior performance, achieving 34% and 25% higher ηo than effusion and internal cooling. The cooling effectiveness of the transpiration cooling model was more uniform, especially on the pressure side (PS).

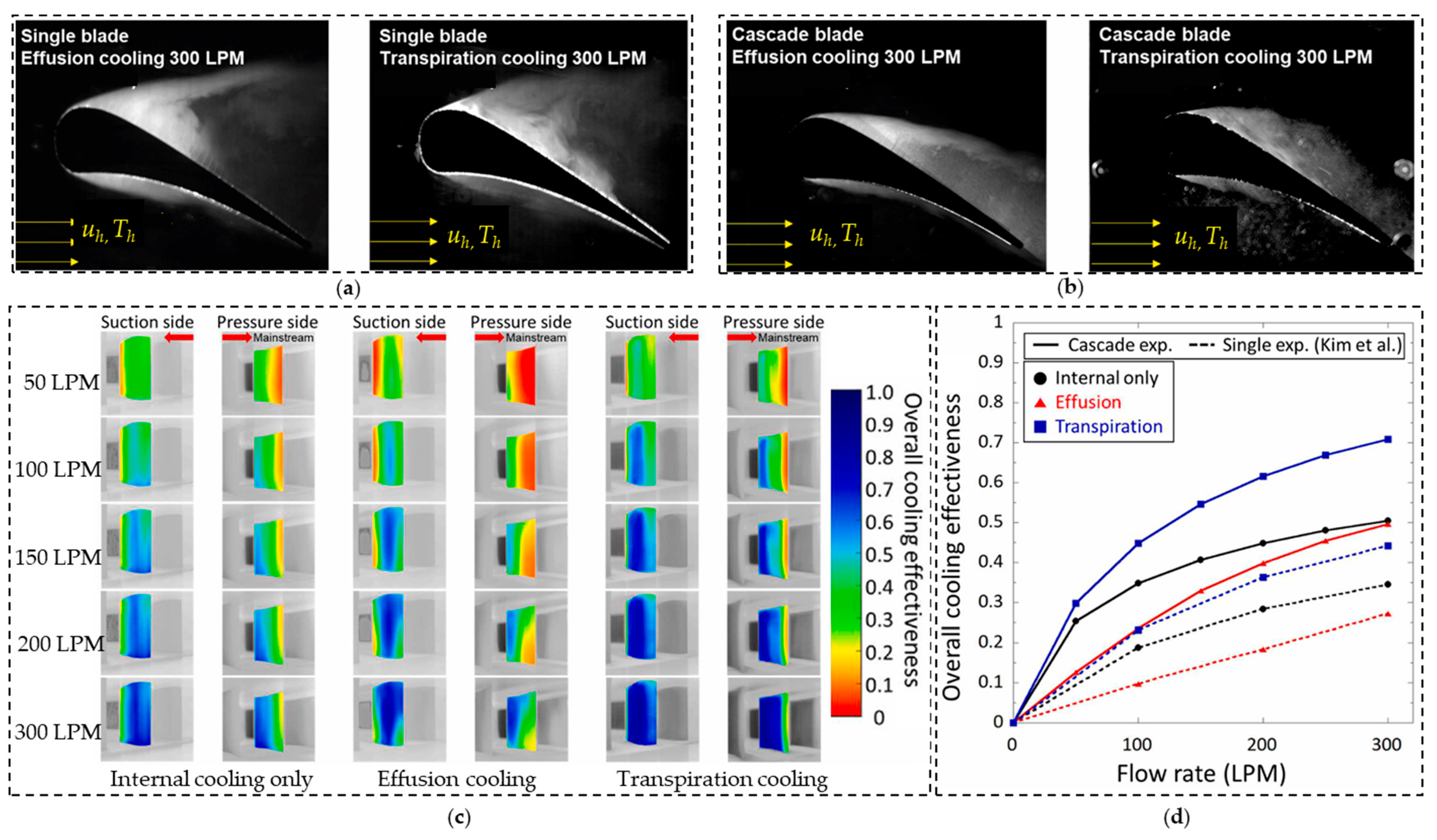

Kim et al. [95] also used smoke-laser visualization with two diode-pumped solid-state lasers and olive oil seeding to visualize coolant flow release from the blade; then, the flow characteristics were captured by a high-speed CCD camera. It was revealed that transpiration cooling provided uniform coverage and low-momentum discharge, which prevented recirculation flow, while effusion cooling showed a large layer thickness, as shown in Figure 11a. Despite comparable coolant-to-mainstream pressure ratios, transpiration cooling required less coolant for better performance. A subsequent study [30] was conducted on a C3X cascade-turbine blade compared with different cooling methods, namely internal cooling only, effusion cooling, and transpiration cooling. They observed that in cascade blades, adjacent blades redirected and accelerated the flow along the blade chord, as shown in Figure 11b. It was obvious that the transpiration cooling showed more uniform and higher cooling effectiveness, as seen in Figure 11c. Moreover, compared to a single blade, the coolant outflow formed a thinner boundary layer in effusion and transpiration cooling. This shifted the suction-side vortex rearward, reducing mainstream/coolant mixing and stabilizing the coolant within the boundary layer. Due to these flow interactions, the cascade arrangement enhanced cooling effectiveness, as shown in Figure 11d.

Figure 11.

Transpiration-air cooled turbine blade: (a) visualization of coolant flow at uh = 20 m/s and coolant volume flow rate of 300 LPM for the single blade; (b) for the cascade blade; (c) ηo distributions on the cascade blade with different cooling; and (d) comparisons of area-averaged cooling effectiveness between cascade and single-turbine blades from Kim et al. [73]. Reproduced with permission from [30]. Copyright 2022 Elsevier.

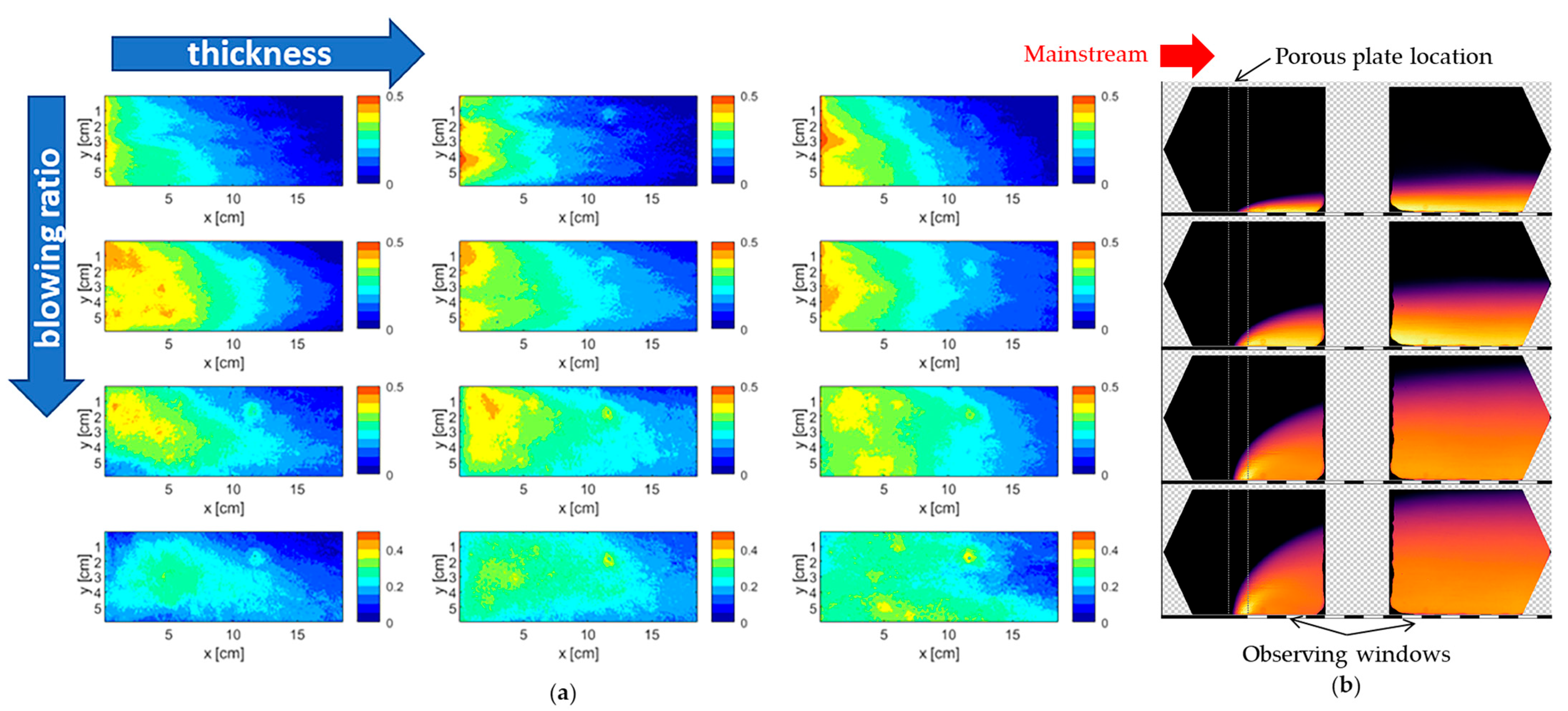

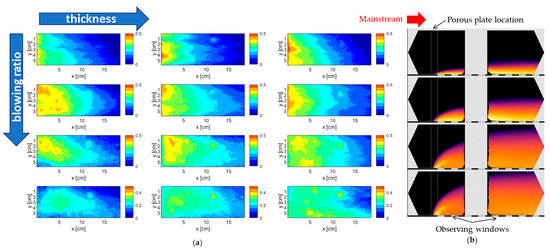

Researchers from Siemens Energy AB, Finspong, Sweden [74], evaluated the distributions of h and ηa of a porous Hastelloy-X transpiration-cooled plate against conventional cylindrical film holes using TLC and IR-based flow visualization with water and CO2. Their results demonstrated that transpiration cooling enhanced lateral-averaged h and ηa compared to the cylindrical holes, owing to superior spanwise coolant coverage and reduced lift-off effects, except at a low BR = 0.46. The thickness (t) of the AM porous plate had a minor influence on the local and area-averaged ηa but provided more uniformity, as shown in Figure 12a. They reported that the highest area-averaged ηa was obtained at a BR = 0.8, and it sharply declined at the highest BR = 2.0 because the excessive coolant supply caused significant jet lift-off and impaired near-wall reattachment, as demonstrated in Figure 12b. To mitigate this, the research team proposed optimizing the build direction of the AM model to achieve a more favorable coolant ejection angle, thereby preserving cooling performance while minimizing flow disturbance from high discharging coolant.

Figure 12.

A porous Hastelloy-X transpiration-cooled plate: (a) contours of ηa at BR = 0.5, 0.8, 1.5, and 2.0 and t = 0.5, 1.0, and 2.0 mm and (b) IR images of concentration of ejected air at BR = 0.5, 0.8, 1.5, and 2.0. Reproduced with permission from [74]. Copyright 2024 Elsevier.

Fantozzi et al. [75] studied the influence of the structural parameters, including laser power, laser speed, and hatch distance of 3D-printed porous materials, on fluid flow, focusing on pore radius distribution and CD. They demonstrated that the CD increased with the pressure ratio and hatch distance but decreased nonlinearly with the thickness-to-diameter ratio. The specimens printed with a laser rotate 90° between layers, providing lower CD values than the model fabricated by a 67° rotation due to the variation in the φ. These studies demonstrated that transpiration cooling outperformed conventional methods in thermal protection, uniformity, and efficiency, with the AM method enabling optimized porous structures for enhanced gas turbine blade performance.

4.3.3. Experimental Investigations on AM-Fabricated Non-Stochastic Structures

Recent advancements in transpiration cooling for gas turbine blades have shown the superior performance of AM-fabricated deterministic structures, such as TPMS and biomimetic designs, over traditional random-pore media. Cheng et al. [64] used deionized water as a coolant for the IWP(A) TPMS-based transpiration cooling with uniform (φ = 35%) and graded porosity (φ = 25~45%) to enhance cooling performance. The experiments using IR thermography were conducted to observe the phase change region on the transpiration-cooled plate. Even though phase-change transpiration cooling offers high heat absorption, its complexity and instability, caused by unpredictable two-phase flow dynamics and excessive coolant use, make it impractical for gas turbine applications [103]. In contrast, single-phase transpiration cooling provides more reliable and controllable cooling performance, making it the preferred choice for gas turbines where stability and uniformity are critical.

Experiments on AM transpiration-cooled turbine blades have revealed improved film uniformity and cooling effectiveness. Ealy [79] used multiple static pressures for flow testing of the 0.5 mm perforated transpiration-cooled leading edge (LE) and revealed nearly identical discharge behavior across both internal and external cavities. This flow improved the film uniformity compared to discrete holes, even though the design yielded lower CD due to area calculation discrepancies. In a subsequent study, Caldero et al. [96] studied the ηo using the PSP method. They found that the effectiveness and pressure loss of the porous cavities in the LE increased at higher BR. The discharged coolant was uniform downstream of the porous region, and mixing became more evident with the higher BR.

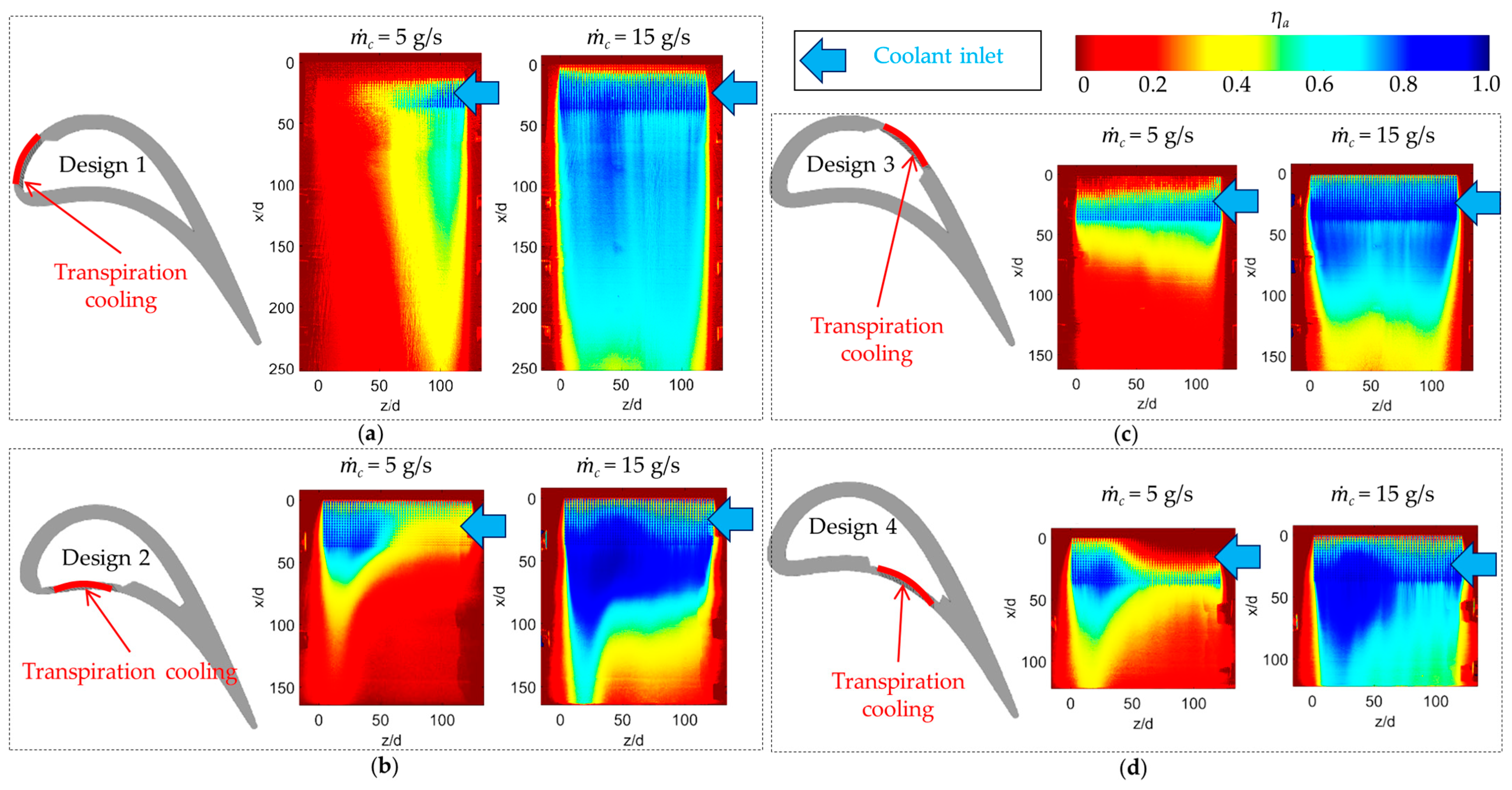

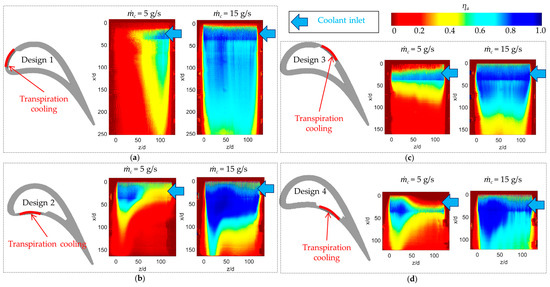

Similarly, research by Wambersie et al. [97] showed high ηa across a 0.5 mm perforated transpiration-cooled turbine blade at a low BR < 0.5. They fabricated the blade using the Stereolithography (SLA) method and employed the PSP measurement that was used in their previous double-wall cooling research [104]. They found high performance on the suction-side (SS) turbine blade due to curvature and flow acceleration, enabling uniform cooling, as shown in Figure 13a,c. While the pressure side (PS) showed the lowest area-averaged ηa, large areas maintained high film effectiveness, as illustrated in Figure 13b,d. This key achievement could help justify reallocating the coolant supply. Moreover, compared to a turbine blade with impingement/effusion cooling, the transpiration cooling at the SS and PS blades provided higher area-averaged ηa and a more uniform distribution.

Figure 13.

Distribution of ηa on transpiration-cooled blade: (a) SS cooling (Design 1); (b) PS cooling (Design 2); (c) SS cooling (Design 3); and (d) PS cooling (Design 4). This figure is reproduced from [97] under a Creative Commons Attribution (CC BY) license.

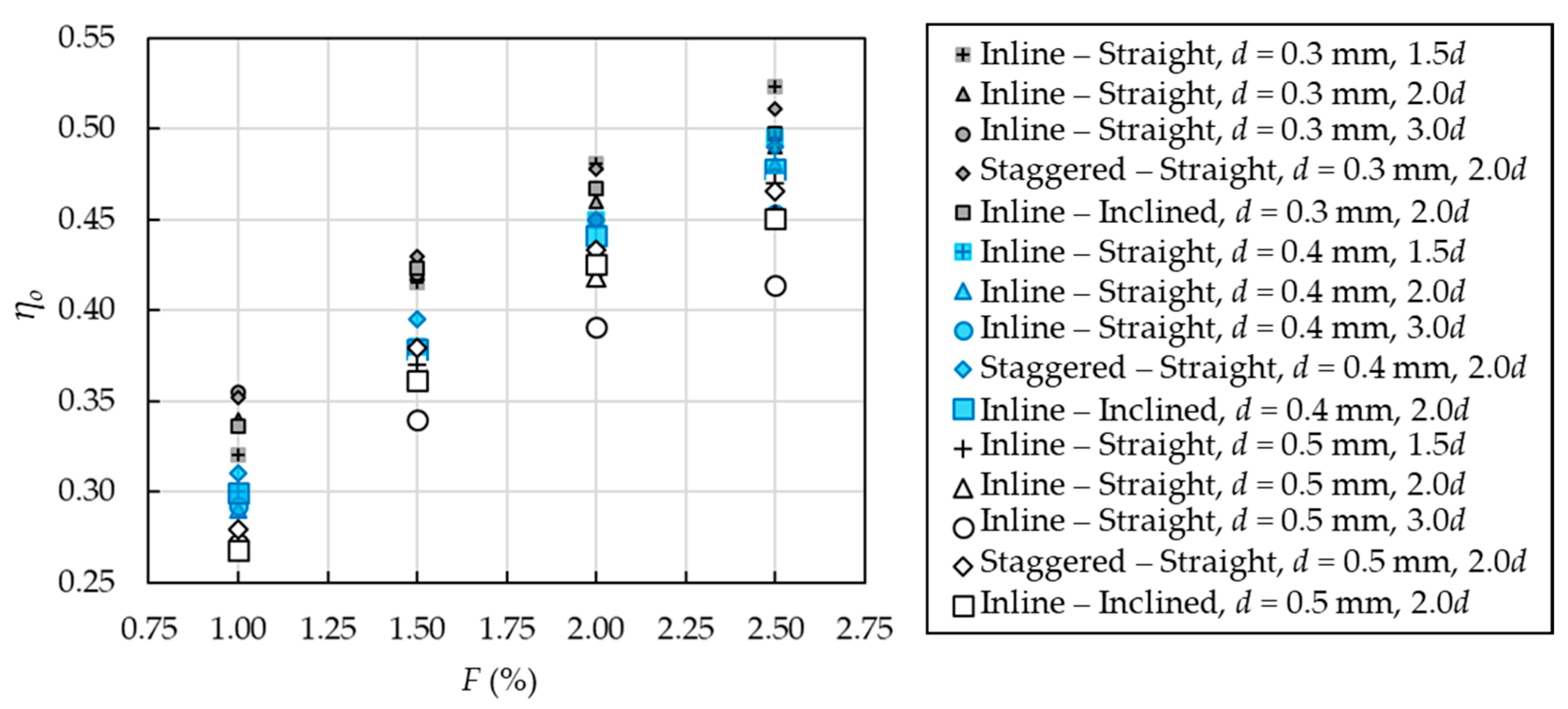

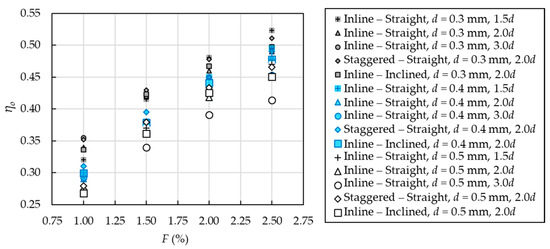

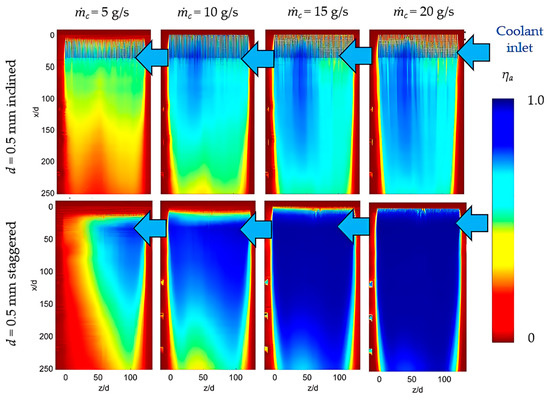

The perforated transpiration-cooled plates have been intensively studied by the research team from the National Energy Technology Laboratory, with the cooperation of the University of Pittsburgh and West Virginia University. Min et al. [77] studied various hole designs, including inline straight holes with a pitch of 1.5 d, 2 d, and 3 d, staggered straight holes with a pitch of 2 d, and 20° inclined holes with a pitch of 2 d. The hole diameter (d) also varied from 0.3 to 0.5 mm. In conclusion, as shown in Figure 14, the smaller holes (d = 0.3 mm) and spacing (pitch of 1.5 d) showed the highest and most uniform ηo but caused low mechanical strength. Chyu et al. [78] reported that integrating lattices with transpiration cooling causes a slightly lower area-averaged ηo due to partial obstruction of cooling holes by the footprint. However, the lattices mitigated ηo losses from pore blockages and offered a better alternative to pin fins for structural support due to their high surface-to-footprint ratio, addressing the inherent weakness of transpiration-only designs.

Figure 14.

Area-averaged ηo comparisons at different F. Data collected from [77].

Heat transfer analysis on innovative hole designs of transpiration-cooled plates has been attempted by many research institutes. Huang et al. [51] compared the effects of partition walls on 0.3 mm perforated transpiration-cooled plates using IR thermography. They found that at a low F = 1%, the printed models with/without partition walls provided a similar area-averaged ηo value, which was higher than the sintered porous model (dpore = 90 μm, φ = 32%, pore size = 33.8 μm). However, the sintered porous model was sensitive to the increase in coolant supply, generating a higher area-averaged ηo than the printed models when F > 2% due to increasing detached coolant on the surface of the printed model. In line with the earlier configuration, Min et al. [76] used IR thermography to investigate five topology designs for AM transpiration-cooled plates, including two perforated plates with varying hole pitches, a sphere-packing design, a wire matrix resembling woven mesh, and a biomimetic blood vessel structure. All studied F demonstrated a superior area-averaged ηo of all transpiration designs over shaped-hole film cooling by 10–40%. They found that the topology of the 3D-printed transpiration-cooled plate significantly influenced the ηo.

Experiments on non-metal transpiration cooling structures have been performed to assess the adiabatic film cooling effectiveness (ηa). Min et al. [99] developed a physical vapor deposition (PVD) micro-lithography technique to fabricate a surface heater for testing transpiration cooling. The IR thermography revealed that smaller coolant hole spacing and diameters improved ηa > 0.46, outperforming conventional film cooling. Aly et al. [98], employing the PSP method to study the influence of the blockage ratio on the ηa, revealed that increasing the blockage ratio reduced the area-averaged ηa, particularly at lower BR, due to a smaller coolant supply. Higher BR and blockage ratio caused non-uniform ηa distributions within the row. Moreover, larger blockage ratios reduced lateral effectiveness, while higher BR compensated for insufficient coolant supply. In short, although the innovative partition wall designs reduced thermal efficiency, potential improvements included shaped holes, extended surfaces, vortex generators, and AM rough surfaces.

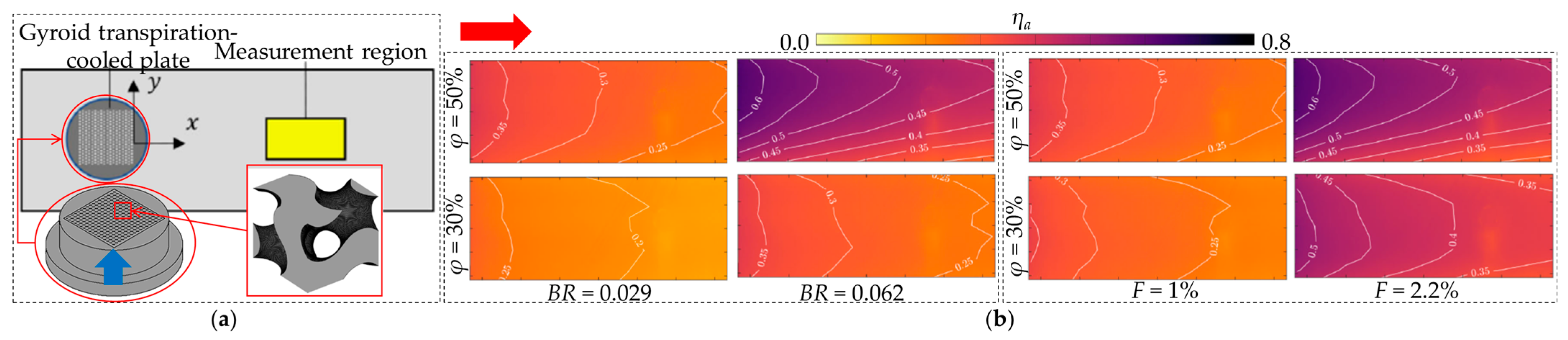

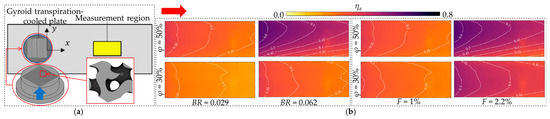

A more complex structure has been fabricated to address non-uniformity, increase cooling effectiveness, and further strengthen the structure. Fier and Bogard [100] fabricated a wire-mesh transpiration-cooled plate using a Prusa i3 3D printer based on fused deposition modeling (FDM). The proposed design demonstrated superior performance to traditional 7-7-7-shaped film-cooling holes, achieving up to 30% higher ηa at equal coolant flow rates. Brimacombe et al. [101] claimed to be the first use of the Gyroid TPMS-based transpiration cooling, 3D-printed via the SLA method at a 25 μm resolution with a 2 mm unit cell size. The IR thermography was used to measure the temperature distribution far downstream from the Gyroid-cooled plate, as shown in Figure 15a. The results showed that increasing BR and F increased the ηa, but the ηa was more sensitive to φ at a constant BR than at a fixed F, as seen in Figure 15b. The area-averaged ηa was higher than that of effusion cooling [105] but less than that of the AM wire-mesh transpiration-cooled plate with φ = 33% [100], which could be attributed to the distance of the measurement area.

Figure 15.

Gyroid TPMS-based transpiration-cooled plate: (a) Downstream heat transfer measurement and (b) the distribution of ηa at different BR, F, and φ. This figure is reproduced from [101] under a Creative Commons Attribution (CC BY) license.

The research team from the Aerospace Research Center, National Research Council of Canada has intensively conducted the heat transfer analysis of the TPMS-based transpiration cooling. Broumand et al. [92] found that the Diamond TPMS-based transpiration-cooled plate with φ = 50% outperformed conventional effusion cooling by up to five times in the area-averaged ηa using the PSP method, where the calibration and uncertainty were well-described in the report. They also revealed that the TPMS designs provided superior film coverage, reduced coolant usage, and mitigated film lift-off at high BR [106]. Using the same measurement method, Son et al. [81] found that the orientation and tortuosity of Diamond, Koch, and Gyroid TPMS topologies altered the distribution of ηa on the plate. Later, Son et al. [102] studied the variations in the unit cell size (L) of the Diamond model while maintaining φ. They found that reducing the L improved ηa. However, excessively small sizes could risk pore blockage from 3D printing or contamination, requiring optimal sizing in practical use.

4.4. Numerical Simulations

Computational modeling of transpiration cooling requires balancing accuracy and efficiency, especially when simulating phase-change effects or resolving complex porous structures. The porous-media two-phase flow model simplifies the simulation of phase-change transpiration cooling, where liquid coolant boils inside the porous structure, forming a gas–liquid mixture [107]. The phase transition absorbs significant latent heat, enhancing cooling efficiency. However, the inherent instability of boiling and non-uniform two-phase flow makes this method more complex than single-phase transpiration cooling [64]. Alternatively, Zhang et al. [80] employed the Lattice Boltzmann Method (LBM) to simulate flow through printed TPMS structures, comparing CAD and computed tomography (CT) scan geometries. They demonstrated the efficiency of the LBM in handling the complex TPMS boundaries through simple voxelized meshes, avoiding the costly unstructured meshes in conventional Navier–Stokes (NS) solvers. However, the LBM struggles with high Reynolds flows, which is the inertial regime in transpiration cooling, whereas the NS solvers with Reynolds-averaged Navier–Stokes (RANS) or large eddy simulation (LES) are more mature. Additionally, the LBM faced scalability limitations for graded or optimized complex topologies, such as the TPMS structure, requiring fine voxel resolutions. Modern NS solvers, in contrast, leverage advanced turbulence modeling to capture multiscale phenomena computationally efficiently for large-scale academic/industrial flow/heat transfer and optimization analyses.

In general, the governing equations for single-phase transpiration cooling can also be divided based on structures: deterministic and stochastic architectures. Table 3 compares the governing equations based on steady-state and non-radiation assumptions. In Table 3, ρ is the density of the fluid (kg/m3). u is the velocity vector (m/s). Sm is a mass source term representing fluid injection from the wall during the cooling of porous transpiration (N/m3). p is the pressure field, signifying the static pressure in the domain (N/m2). F implies an external force, such as gravity (N/m3). cp is the heat capacity of the fluid (J/(kg·K)). Tflu and Tsol are the temperatures of the fluid and solid (K). ST is the term for the energy source added/removed with the coolant (W/m3). K and CF are the permeability (m2) and inertial resistance coefficient (1/m), where the empirical formula provided by Ergun and Orning [108] was mostly used.

Table 3.

Governing equations of single-phase transpiration cooling in recent numerical studies.

For both modes, recent numerical investigations have employed advanced computational fluid dynamics (CFD) tools to analyze various transpiration cooling configurations, utilizing different turbulence models and mesh strategies, as shown in Table 4. Major studies used STAR-CCM+ and ANSYS FLUENT with hexahedral meshes ranging from 2.3 million to 53.4 million cells, depending on the complexity of the model. The k-ω turbulence model showed the advantage of simulating the viscous sub-layer and boundary layer formation and obtained better predictability in heat transfer analysis compared to SST k-ω turbulence models in several studies [109].

Table 4.

Overview of numerical analysis on flow and cooling effectiveness for AM-fabricated transpiration cooling.

However, the SST k-ω model was mostly employed to examine transpiration cooling for gas turbines due to its unique ability to accurately resolve near-wall flow physics, adverse pressure gradients, and mixing phenomena. The SST k-ω model also provided the optimal balance between accuracy and computational cost. Calderon et al. [96] found SST k-ω overpredicted the area-averaged ηa by around 25% within the BR < 0.15. Wang et al. [110] reported the maximum deviation in area-averaged ηo between the simulation and experimental results was 6.9%. Similarly, Yang et al. [116] and Zhou et al. [82] revealed that the maximum relative error of area-averaged ηo was less than 6%. Sun [89] observed that the SST k-ω model was more consistent with the experimental data in the literature compared to the k-ω model, and the deviation was 3%. In short, the use of turbulence models with carefully constructed meshes depended on the validation across the experimental data to balance accuracy in transpiration cooling analysis.

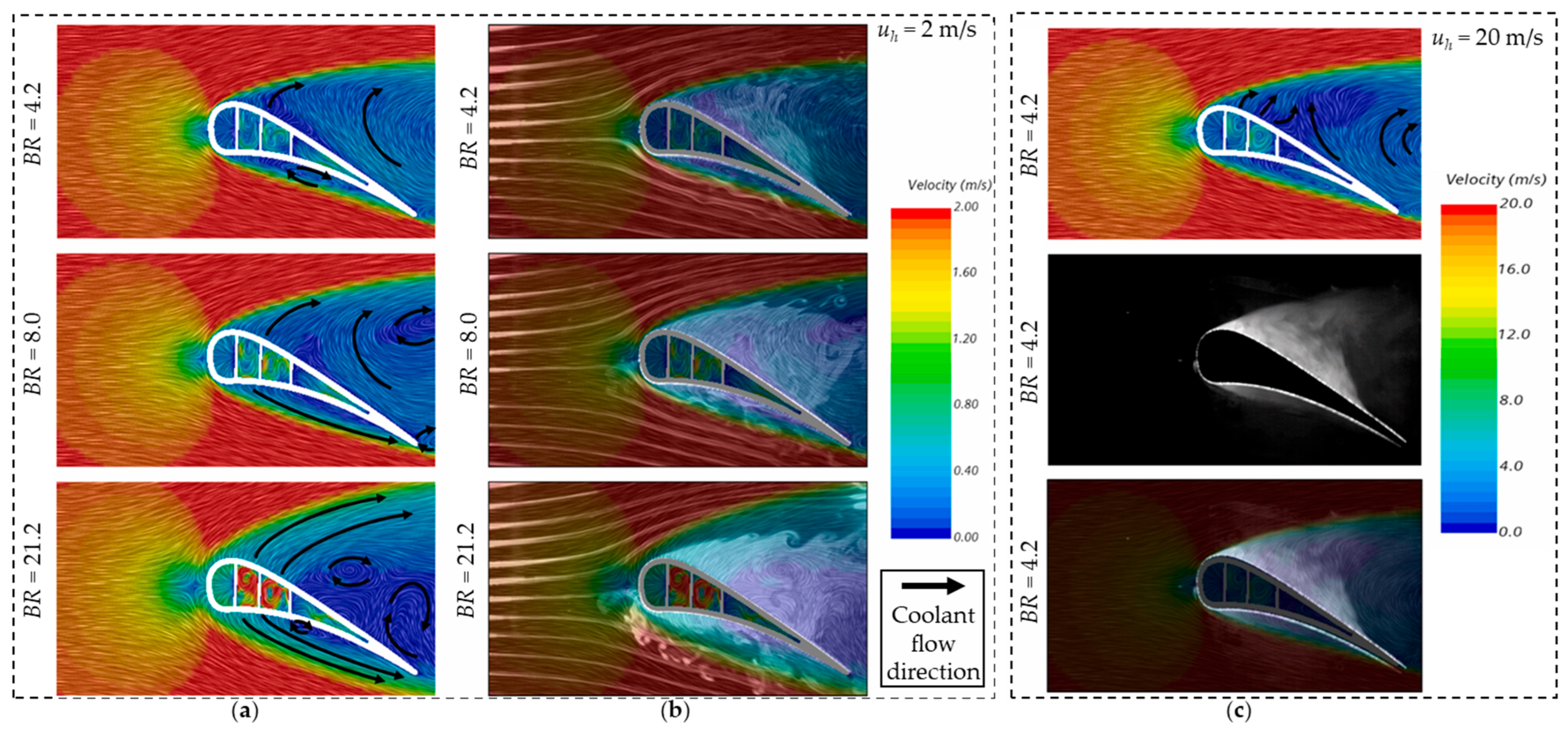

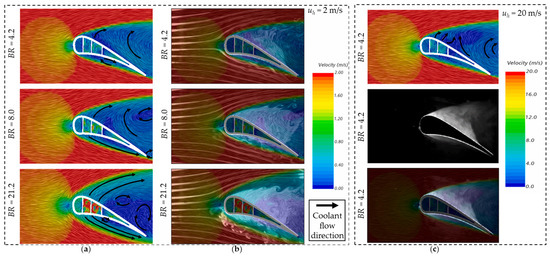

Many previous studies modeled transpiration cooling using the porous-media model due to lower computational costs while maintaining accuracy [118]. Kim et al. [95] revealed a series of flow results of a C3X single-turbine blade at different studied conditions. They found that transpiration cooling formed a stable boundary layer, even with increasing coolant flow, as shown in Figure 16. At high BR, the suction-side rotating flow remained near the TE. Furthermore, transpiration cooling maintained a thick, stable coolant layer on the PS, whereas effusion cooling promoted coolant-mainstream mixing due to wake recirculation. Moreover, increasing the uh from 2 to 20 m/s while fixing the BR = 4.2 showed the same trend, as compared in Figure 16a,c. In addition, a comparative analysis of transpiration cooling simulations with experimental visualization results demonstrated excellent agreement, particularly at a low BR. This validation was further supported by Figure 16c, where simulation data closely matched the observed boundary layer development in overlapping visualizations. Under the tested conditions, the transpiration cooling maintained a thinner thermal boundary layer compared to effusion cooling [73].

Figure 16.

Flow characteristics of a C3X single-turbine transpiration-cooled blade: (a) Numerical results at uh = 2 m/s; (b) Comparison between visualization and numerical results at uh = 2 m/s; (c) Numerical results, visualized coolant flow images and comparison between visualization and numerical results at uh = 20 m/s. Reproduced with permission from [95]. Copyright 2022 Elsevier.

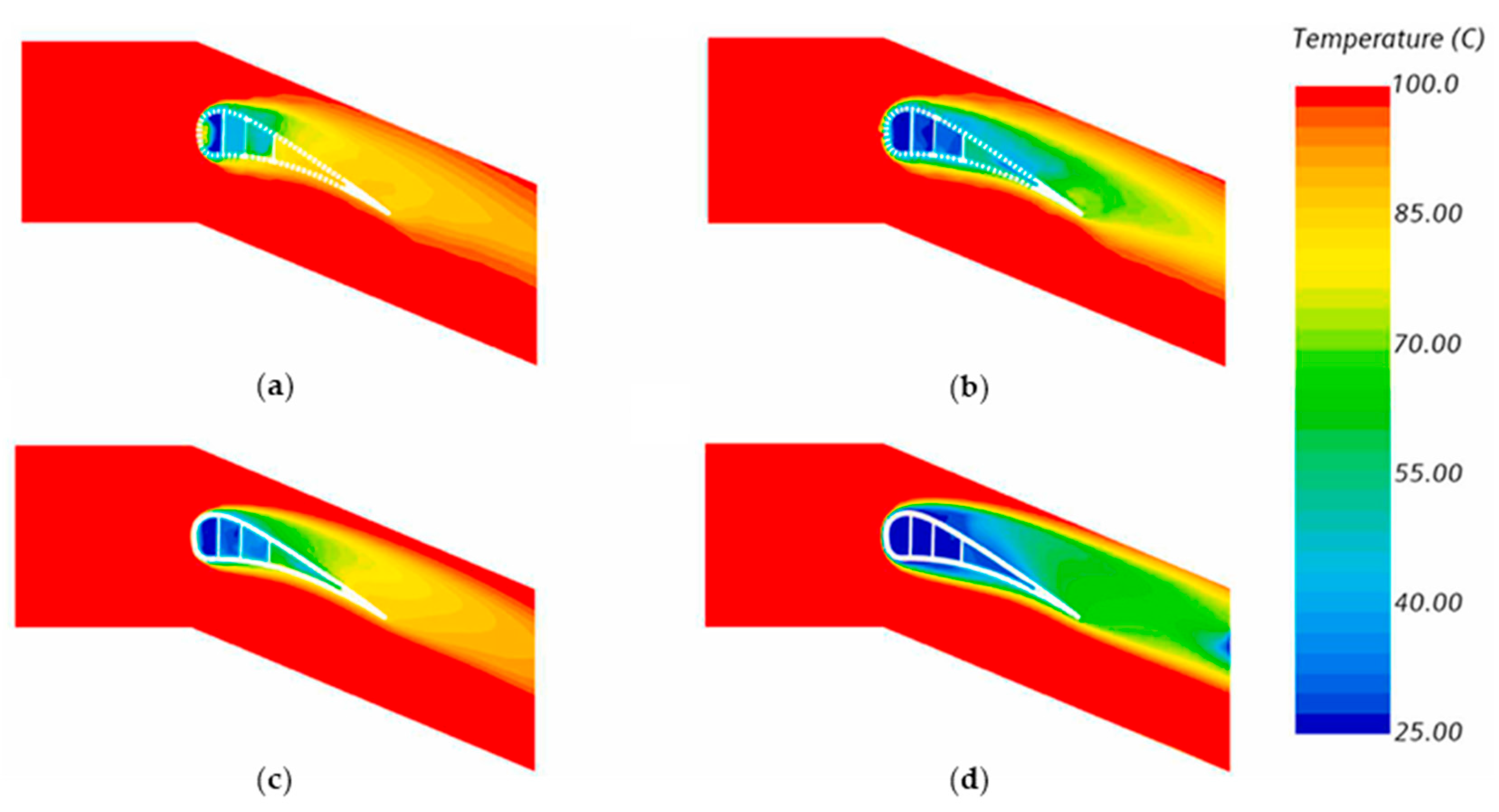

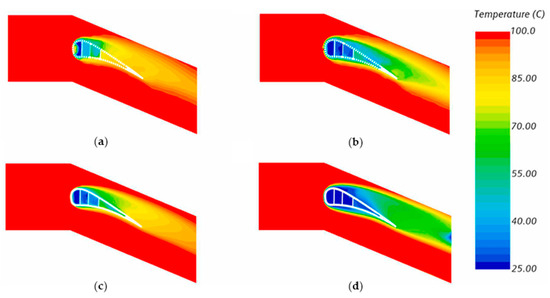

Kim et al. [30] also simulated the effusion and transpiration-cooled blades. The visualization results showed that for effusion and transpiration cooling, the coolant outflow formed a thinner boundary layer compared to the single blade. This thinner layer shifted the suction-side vortex rearward, reducing mainstream/coolant mixing and stabilizing the coolant within the boundary layer. Consequently, the cascade arrangement enhanced cooling performance over a single blade due to inter-blade flow interactions. Moreover, the temperature field analysis in Figure 17 revealed that the high flow resistance of the porous-media transpiration-cooled structure significantly reduced mainstream inflow compared to effusion cooling, enabling a more stable formation of cooler internal air and thermal boundary layers. Consequently, transpiration cooling outperformed effusion cooling for both single and cascade blades.

Figure 17.

Temperature field of a C3X cascade-turbine transpiration-cooled blade at uh = 20 m/s: (a) Effusion cooling with a volume flow rate of 100 LPM; (b) 300 LPM; (c) Transpiration cooling with a volume flow rate of 100 LPM; and (d) 300 LPM. Reproduced with permission from [30]. Copyright 2022 Elsevier.

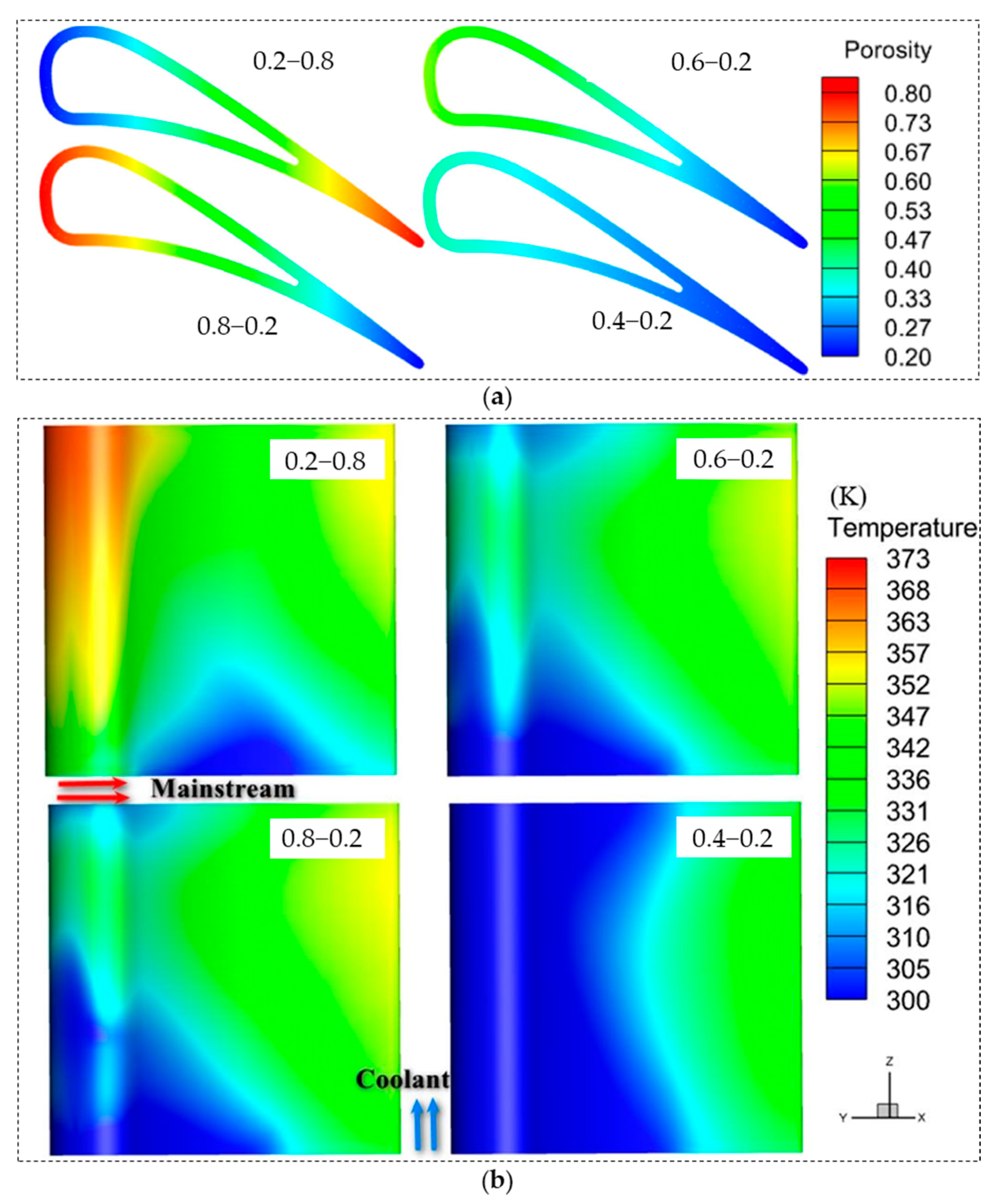

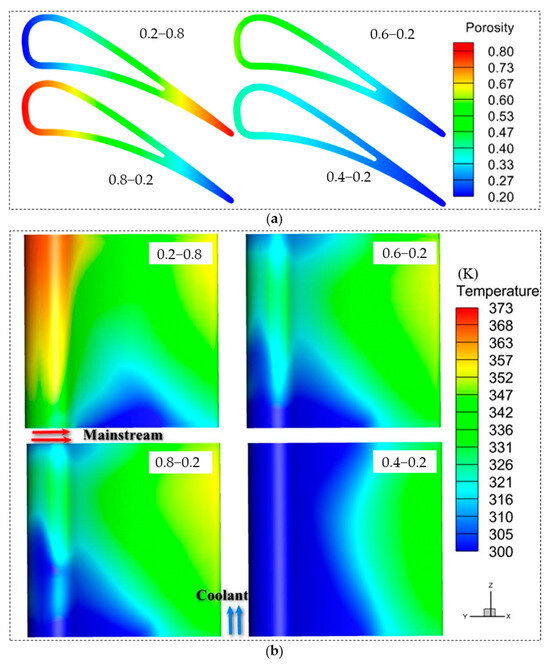

In a related study, Ma et al. [25] focused on the effects of coolant mass flow ratio and the non-uniform φ of C3X cascade-turbine blades, validated with the experimental results of Kim et al. [30]. They concluded that increasing the coolant mass flow rate enhanced the area-averaged ηo of the blade; however, the PS caused lower values compared to the SS due to mainstream flow intrusion, particularly at a high φ = 80%. Along the coolant flow path, as pressure losses approached 100%, coolant flow stagnated, which inadequately cooled the TE. Notably, adopting a gradient φ distribution improved blade surface temperature uniformity and increased area-averaged ηo by 13.97% over conventional uniform φ designs.

Numerical studies have demonstrated the effectiveness of simplified computational methods for analyzing custom-designed transpiration cooling systems. Calderon et al. [96] adopted periodic boundary conditions to reduce the computational domain of a complex transpiration-cooled leading edge. The numerical model provided similar trends of area-averaged ηo and pressure loss to the experiments. Similarly, Fier et al. [100] demonstrated that a 2D RANS simulation effectively captured the essential physics of the wire-mesh transpiration-cooled plate, highlighting the relative simplicity of modeling this technique.

The geometric design of the transpiration cooling shows strong influences on cooling performance. Wang et al. [110] evaluated transpiration-cooled plates with different outlet angles and patterns, revealing that while outlet angles strongly affected temperature uniformity, they only slightly affected cooling efficiency. Complementary work by Zhou et al. [82] revealed that coolant flow resistance in the TPMS-based transpiration cooling was primarily governed by pore throat geometry, though higher resistance did not require greater injection pressure due to mainstream–coolant interactions. The study also identified that counter-rotating vortex pairs (CRVPs) in the coolant film can elevate surface skin friction, but this effect can be mitigated by complex outflow angles.

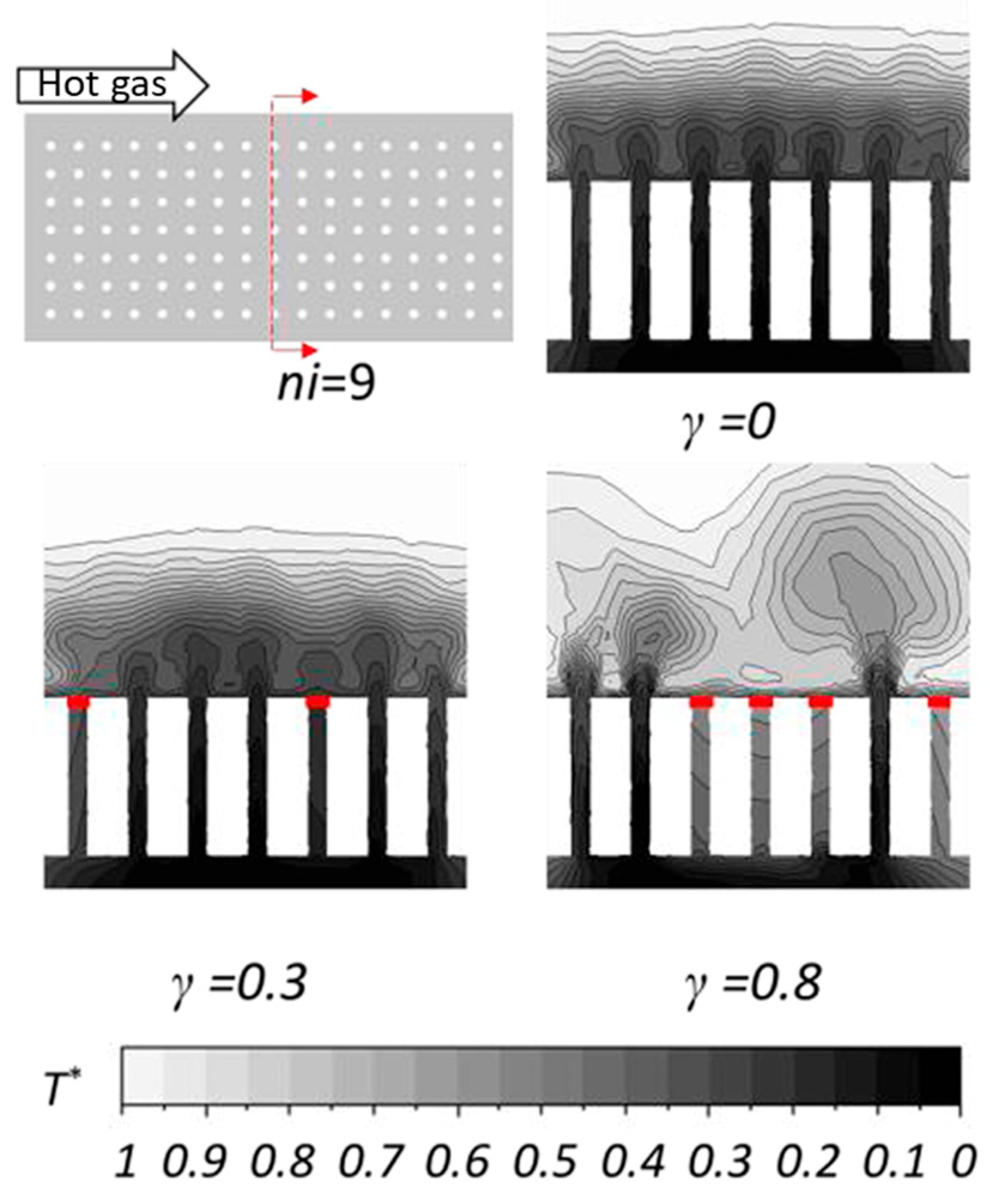

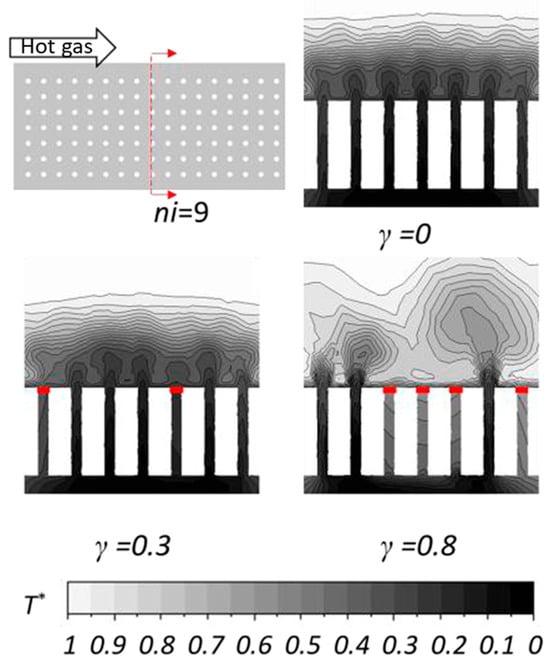

Several investigations have highlighted jet lift-off challenges in transpiration cooling. Huang et al. [51] simulated the 0.25 mm perforated transpiration-cooled plates with different partitional wall designs and found major jet lift-off in the case with the largest partition walls. This phenomenon was further explored by Yang et al. [111,112], who modeled random pore blockage effects on 200 cases of transpiration cooling and confirmed that a high plugging probability (γ) caused a significant jet lift-off, decreasing cooling effectiveness, as shown in Figure 18.

Figure 18.

Simulation results showing jet lift-off of perforated transpiration-cooled plates with different pore blockage conditions. Reproduced with permission from [112]. Copyright 2018 Elsevier.

Nearly aero-engine conditions, where the Th is above 1000 K, have also been simulated to study the impact of the φ and pressure gradient on cooling performance. Huang and He [115] used conjugate heat transfer to analyze the effect of non-uniform φ on perforated transpiration-cooled plates, where the hole diameter was varied to obtain a non-uniformity of 0–50%. Studies concluded that inhomogeneous φ had a significant influence on the cooling effects of the surface film and internal holes. Yang et al. [116] investigated transpiration cooling (d = 0.2 mm) with different φ configurations under varying mainstream pressure gradients. It was found that transpiration cooling outperforms film cooling by up to 100% in effectiveness, but non-uniform coolant distribution reduces efficiency. Li et al. [117] compared the cooling performance between 3D-printable swirl-chamber transpiration and the 30°–90° inclined film holes in a Can-type combustion chamber, considering chemical reactions. They concluded that hybrid cooling was highly effective for combustor liners, recommending smaller inclination angles and compound angles opposing the swirling flow for optimal performance. These studies demonstrated that advanced cooling designs significantly enhanced thermal performance under near-engine conditions, though coolant uniformity remained a key challenge for optimization.

4.5. Effect of Studied Conditions

Most studies agree that increasing coolant supply (MFR, BR or F) generally enhances cooling effectiveness, as shown in Figure 9, Figure 10, Figure 11, Figure 12, Figure 13, Figure 14, Figure 15, Figure 16 and Figure 17. In addition, the arrangement of the perforated holes also altered the cooling effectiveness, as seen in Figure 19. However, excessive coolant flow can degrade performance. Min et al. [99] observed reduced ηa at BR > 0.25 due to hot gas entrainment, while Sun et al. [89] found that increasing the F from 0.2% to 1% reduced the cooling rate from 0.72 to 0.09. They solved these issues by a double coolant supply chamber, which could simultaneously improve ηo and reduce coolant consumption in perforated plate designs.

Figure 19.

Influence of coolant supply and hole arrangement of transpiration cooling structures on cooling effectiveness. This figure is reproduced from [97] under a Creative Commons Attribution (CC BY) license.

Thermal resistance plays a critical role in altering the cooling effectiveness. Huang et al. [51] found that the 3D-printed transpiration-cooled plate, which was fully melted particles, enabled efficient heat conduction from the upstream to the downstream region. Therefore, it exhibited a more uniform ηo distribution and provided a slightly higher area-averaged ηo, particularly at a low F, than the sintered porous plate. This was because the sintered model had a much lower effective thermal conductivity than its bulk material [119], leading to poorer downstream cooling performance. Sun et al. [89] showed that higher Biot numbers degraded temperature uniformity due to increased thermal resistance, particularly at low thermal conductivity.

Meanwhile, Huang and He [115] showed that higher thermal conductivity in solids significantly mitigated inhomogeneous φ effects, as compared to the variation in plate thickness and hole spacing. Also, the inhomogeneous φ strongly affected ηo when a low-conductivity TBC was applied. The thin TBC layer introduced substantial thermal resistance, and lower conductivity worsened inhomogeneous φ effects. Yang et al. [116] further highlighted that under varying mainstream pressure gradients, the small spacing case and streamwise-decreasing φ model provided high cooling effectiveness and improved uniformity. Also, higher pressure gradients increased ηo and uniformity.

In short, these studies showed the need for careful design balancing coolant flow, thermal conductivity, and pore geometry in the AM-fabricated transpiration cooling systems to achieve maximum performance while mitigating jet lift-off and thermal resistance.

4.6. Effect of Structural Designs

4.6.1. Influence of Porosity

Many studies have demonstrated that porosity (φ) is critical in the performance of AM-fabricated transpiration cooling systems. Fantozzi et al. [75] observed that higher-porosity AM porous media exhibited lower discharge coefficients (CDs), highlighting the trade-off between φ and flow efficiency. In an early study, Huang et al. [49] investigated perforated transpiration cooling with hole diameters of 0.5 mm and 1 mm, fabricated by the electric spark method, finding that smaller holes (d = 0.5 mm) with φ = 19.6% achieved an area-averaged ηo comparable to sintered porous media with φ = 36%. However, larger holes (d = 1 mm) reduced the area-averaged ηo due to the enhanced mixing and boundary layer momentum at F > 2%. Huang et al. [51] later revealed that as the area of the reinforcing partition walls of AM transpiration-cooled plates increased (decreasing φ), the area-averaged ηo was slightly decreased within F = 2–3%.

The relationship between φ and η has been extensively studied. Broumand et al. [92] found that the Diamond TPMS transpiration-cooled plate with φ = 50% provided the highest ηa up to 0.75 at F = 1.6%, without any jet lift-off effects. Also, even a φ = 30% provided ηa = 0.36 at F = 0.68%, higher than conventional effusion cooling by 1.8 times. Smaller hole diameters (d = 0.3 mm) were shown to enhance uniformity, with staggered hole patterns providing better performance than inclined configurations [77,89]. Wambersie et al. [97] also showed that decreasing the hole spacing on a turbine blade SS (increasing φ from 20% to 30%) significantly improved film coverage, demonstrating interactions between adjacent films and mainstream flow. However, Yang et al. [116] noted that while increasing φ generally improves area-averaged ηa, reaching up to 0.83, it can lead to non-uniform coolant distribution.

Graded and non-uniform φ distributions have emerged as promising strategies for optimizing cooling performance. Cheng et al. [64] demonstrated that IWP(A)-TPMS structures with graded φ improved coolant distribution and reduced hot-spot temperatures under non-uniform heat flux. Similarly, Ma et al. [25] proposed a φ gradient from the LE to TE of turbine blades to balance coolant seepage and prevent mainstream intrusion, as shown in Figure 20. Their findings revealed that excessive φ = 80% led to uneven pressure distribution and coolant leakage, emphasizing the importance of controlled φ variation.

Figure 20.

Non-φ distributions of the transpiration-cooled blade: (a) the distribution according to the dimensionless distance from the LE and (b) temperature contours on the blade surface. Reproduced with permission from [25]. Copyright 2023 Elsevier.

Inhomogeneous φ and manufacturing tolerances also significantly impact cooling efficiency. Huang and He [115] showed that inhomogeneous φ, which occurred during the AM process, significantly affected the surface film and internal hole cooling, causing local efficiency variations up to 41.5% and 34.5%, respectively, at a 20% non-uniformity setting. However, area-averaged and local ηo changes were minor due to heat conduction. At a non-uniformity of 50%, local impacts increased, but area-averaged ηa differences remained small. The effect of inhomogeneous φ on effusion cooling became negligible when the precision of the AM hole was maintained within a 20% variation. Overall, optimization of the φ is crucial for AM transpiration cooling systems. Graded φ designs with precise manufacturing could be a key candidate for achieving optimal coolant coverage and thermal performance in gas turbines.

4.6.2. Influence of Topology

Experimental and numerical studies have revealed that topological design critically influences the cooling effectiveness and uniformity of AM-fabricated transpiration cooling. Biomimetic approaches show particular promise, with Min et al. [76] demonstrating that blood vessel-inspired structures outperformed conventional round holes despite lower internal surface area ratios (Rint). This design achieved superior cooling through enhanced internal flow interaction and more uniform outlet distribution. Similarly, Sun et al. [113] reported that with the same Aeff, a tree-like channel achieved higher cooling efficiency than round-hole designs at equal coolant flow rates. However, Poupinha et al. [74] revealed that the unfavorable 90° ejection angle of a porous transpiration-cooled plate caused low ηa, requiring optimization of the AM build direction.

Lattice-based cooling structures exhibit significant performance variations based on their geometric configuration. Chyu et al. [78] observed that the different lattices in a transpiration-cooled plate altered the cooling performance, particularly at a BR > 0.25. It was observed that the ηo follows this trend: face-centered cubic > octahedral cubic ≈ body-centered cubic > Kagome. Related studies on this topic indicated that the TPMS lattices presented unique advantages for transpiration-cooling applications [46]. Zhou et al. [82] found that the IWP(B) TPMS-based transpiration cooling demonstrated an optimal balance between injection pressure and cooling performance. The Primitive(B) provided superior temperature uniformity due to reduced coolant transport along the mainstream, while the IWP(A) was the preferred choice when minimizing skin friction was critical, as it effectively suppressed CRVP formation across studied flow rates. Son et al. [81] observed that surface trough orientation and internal flow path tortuosity significantly affected the ηa. They found that the Koch model with higher tortuosity minimized orientation sensitivity, achieving uniform coolant distribution, which was only 3–5% sensitivity across flow rates, while low-tortuosity Diamond exhibited strong orientation dependence up to 15–24%. Meanwhile, the Gyroid, with moderate tortuosity, showed intermediate sensitivity of 12–17%. The Koch robustness to flow direction makes it ideal for complex surfaces with directional flows.

Findings from a similar investigation revealed that the shape of cooling holes substantially influenced thermal protection characteristics. Wang et al. [110] reported that transpiration-cooled plates (d = 0.2 mm, φ = 18.8%) with synclastic outlet angles improved cooling performance over reverse angles, while elliptical holes demonstrated an interesting trade-off between cooling efficiency and temperature uniformity based on their alignment with the mainstream flow. These findings emphasized the importance of hole geometry design for optimized transpiration cooling structures.

4.7. Optimization Studies

Recent advances in AM technologies have enabled innovative optimization approaches for transpiration cooling in gas turbines. The recent optimization studies can be categorized based on their methodologies and findings as follows:

4.7.1. Topology Optimization with Lattices

Yeranee et al. [18] showed that the topology-optimized cooling design incorporating TPMS lattices enhanced double-wall channel performance. The optimized design achieved a 9.5–12.5% enhancement in impingement heat transfer and 4.2–4.6% higher overall cooling effectiveness compared to pin fin configurations while simultaneously reducing pressure losses. They also demonstrated that TPMS-based topology optimization can address thermal challenges in advanced turbine cooling applications. This method could be used to avoid the footprint blockages on transpiration holes found in previous studies [78].

4.7.2. Machine Learning and Convolution-Based Modeling

Yang et al. [112] pioneered the use of convolution modeling to predict transpiration cooling and its associated plugging disadvantages, offering a quantitative understanding of random plugging effects and supporting optimization efforts, particularly in AM transpiration cooling, which held significant potential for mitigating plugging issues. Later, a novel convolution-based modeling approach for predicting ηo distributions was developed by treating the transpiration-cooled plates as void/solid logic functions [120]. Using conjugate CFD data from simple perforated transpiration-cooled plates for training, the high-resolution convolution model successfully reconstructed ηo for both training cases, achieving 4.04% error within 100 training steps and more complex validation geometries. They claimed that the method significantly reduced parameter space dimensionality while preserving physical interactions between coolant holes through an efficient initialization process using decoupled weight functions. In a more recent study, Yang et al. [121] developed a machine learning model using convolutional neural networks to predict the ηa in the perforated transpiration-cooled plates by integrating image conversion, convolution, and nonlinear activation processes. Training and validation used CFD data from regular and random film cooling hole arrays. Results showed that the model achieved few errors, less than 10% for training and 13% for validation. The convolution kernel revealed coolant superposition as a key factor in effusion cooling.

4.7.3. Surrogate Modeling and Evolutionary Algorithms

Several studies combined CFD with surrogate modeling and evolutionary algorithms for optimization. Wang et al. [122] used RANS simulations with the Brinkman–Forchheimer–Darcy model and a Kriging-genetic algorithm (GA) optimization framework for optimizing a transpiration-cooled C3X cascade-turbine blade with multiple porous zones of varying φ. The research revealed that the highest φ should be at the LE and PS for optimal cooling. A subsequent study [123] employed a multi-objective optimization of a transpiration-cooled C3X cascade-turbine blade using CFD modeling and a surrogate-based approach combining an artificial neural network (ANN) and a non-dominated sorting genetic algorithm-II (NSGA-II). The optimization framework treated φ distribution across different vane zones as design variables to balance cooling performance and aerodynamic efficiency. The results showed that the LE coolant discharge significantly enhanced cooling but increased porous-media pressure losses while maintaining consistent mainstream pressure losses, approximately 18% for all cases. They concluded that the optimal design required careful coolant allocation to the leading edge and adjacent SS and PS. Similarly, Lv et al. [27] showed that a porous-media plate beneath film holes improved cooling effectiveness by 30% compared to conventional double-wall cooling, with a further 8.5–8.7% improvement from the GA optimization.

4.7.4. Gradient Porosity and Response Surface Methods

Chen et al. [124] and Liu et al. [90] explored gradient φ designs using a response surface methodology and multi-objective genetic algorithms (MOGAs). Chen et al. [124] demonstrated that gradient φ plates improved temperature uniformity by 20.58–23.78% while reducing injection pressure by 84.5–86.2%. Liu et al. [90] developed an ANN-MOGA framework that increased cooling efficiency by 11.35% and reduced pressure loss by 36.23% compared to uniform φ designs. These studies emphasize the benefits of tailored φ distributions in achieving high-performance cooling.

5. Challenges and Future Directions

5.1. Additive Manufacturing Challenges and Innovations

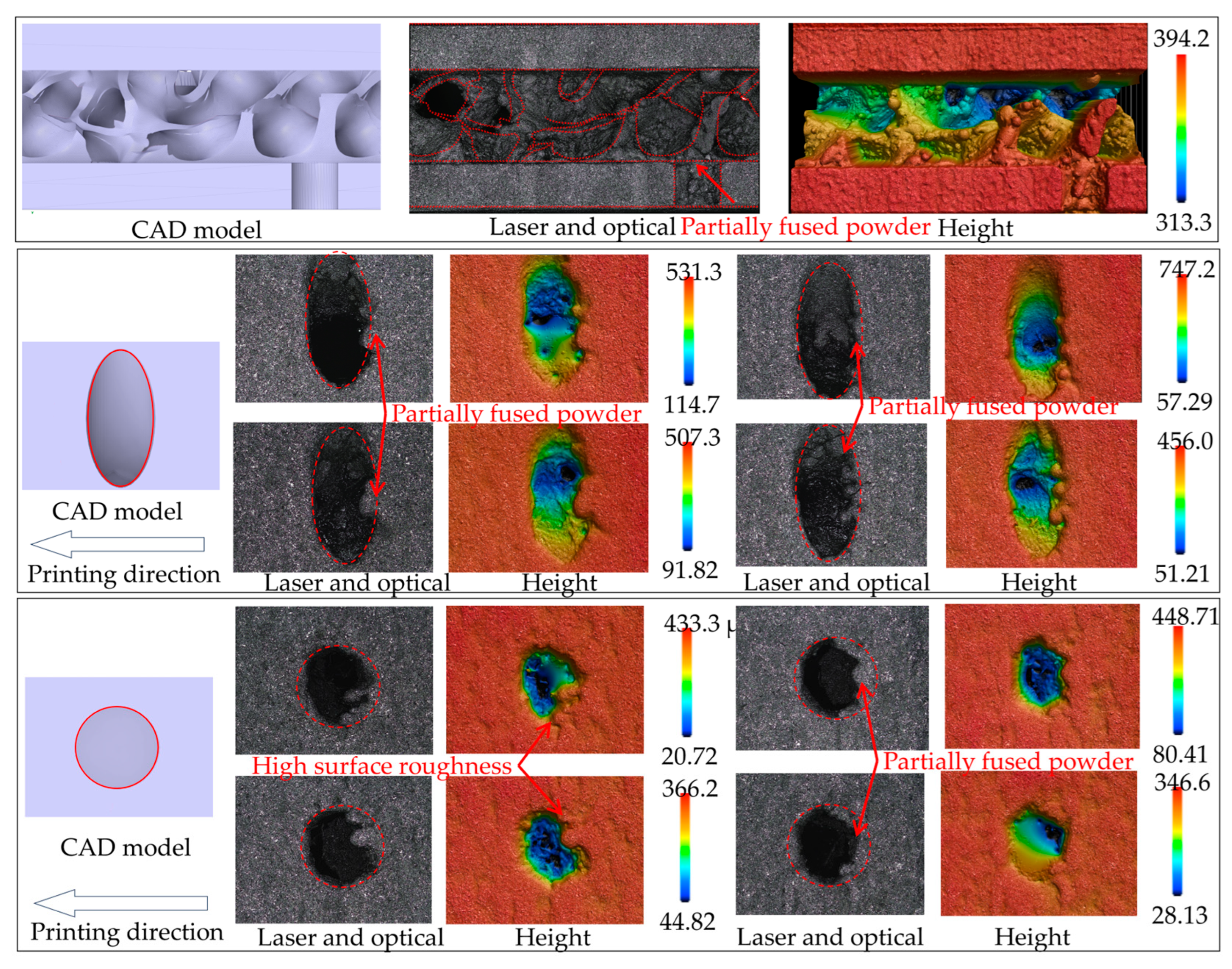

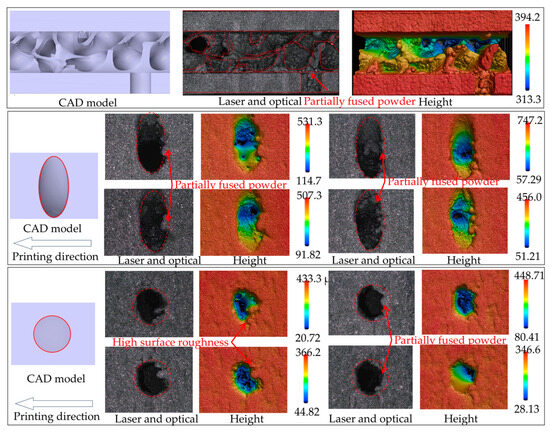

The challenges of AM-fabricated film cooling have been well described by Dutta et al. [2]. They concluded that the AM film cooling surfaces reduced film effectiveness by disrupting jets but enhanced in-hole convection. Yeranee et al. [18] observed that the as-printed model exhibited partially fused powder particles adhering to the pedestal structures, effusion holes, and impingement cooling channels, as shown in Figure 21, attributed to non-optimized AM parameters and printing orientation. Post-processing, such as surface machining or chemical polishing, improved the external surface finish of the effusion and impingement plates, resulting in a relatively smooth exterior. However, high-resolution CT scans revealed the presence of internal micro-voids, particularly within the pedestal near the effusion plate, suggesting potential challenges in achieving fully dense structures with uncontrolled AM settings.

Figure 21.

Deviations, defects, and surface roughness of AM-fabricated gas turbine cooling structures (unit: μm). Reproduced with permission from [18]. Copyright 2024 Elsevier.

The fabrication of transpiration cooling systems through AM technology also presents several persistent challenges that impact system performance. Dimensional accuracy issues remain prevalent, with multiple studies documenting deviations in hole sizes and φ in the AM-fabricated components. Table 5 overviews the deviations in different AM transpiration cooling designs. It can be highlighted that the etching and laser drilling obtained better accuracy than the AM methods, where most of the AM methods caused hole size and φ reduction from the designs. The SLM-produced perforations were consistently undersized compared to the design specifications, showing reductions ranging from 4% for 0.24 mm holes to 77% for 0.06 mm holes [66]. Similar findings were reported by Min et al. [76,77]. They noted that the DLMS caused φ shrinkage of about 40% for 0.3 mm holes and outlet area reduction by 27–39% for 0.5 mm holes in round-hole designs.

Table 5.

Overview of deviations in different AM transpiration cooling geometries.

In addition, Huang et al. [51] reported a designed 0.3 mm hole printing at 0.25 mm due to laser beam limitations and heat diffusion, while Broumand et al. [92] noted that Diamond TPMS structures consistently achieved lower φ than designed, particularly in low-φ cases. Zhang et al. [80] found that while the LPBF-fabricated TPMS structures met φ targets, surface defects reduced permeability by around 15% compared to CAD models. Ealy et al. [79] confirmed these trends through X-ray CT analysis, showing that while 95% of surfaces met 320 µm, tolerances in the SLM Inconel 718 blades feature accuracy degraded significantly beyond 60° from the build direction. These dimensional inaccuracies directly affect pressure losses and flow distribution within the cooling structures.

Process parameter optimization presents another significant challenge, as demonstrated by Fantozzi et al. [75]. They found that increasing laser power while reducing scan speed improved geometric regularity but decreased φ, consequently increasing flow resistance. Son et al. [102] further identified critical limitations in the SLA-printed Diamond TPMS plates, where φ below 10% resulted in unprintable regions with stochastic pore clogging. Surface characteristics also significantly impact performance, with SEM analyses [51,125] confirming that as-printed channels were typically 15% smaller than designed. Huang et al. [51] noted that while adhered metal particles increased surface roughness, they enhanced heat transfer by acting as micro-fins. Min et al. [77] quantified printing accuracy through backlit imaging, finding that smaller pores (d = 0.3 mm) had >10% plugging versus 0% for 0.5 mm holes.

Future advancements in this area are focusing on several promising directions. Recent developments in AM-assisted casting of complex lattices [126,127] have shown the potential to match LPBF mechanical properties at reduced costs while achieving smoother surfaces. Emerging SLA, digital light processing, or liquid crystal display techniques [128,129,130] are enabling the fabrication of complex ceramic cores for transpiration channels, though challenges remain in achieving high green density post-sintering. Particularly noteworthy is the work of Min et al. [131], who developed an AM-processed oxide dispersion-strengthened coating via DMLS that demonstrated exceptional 1200 °C oxidation resistance over 2000 h while maintaining interfacial integrity. These advanced solutions could effectively mitigate the limitations of AM-fabricated transpiration cooling.

5.2. Pore Blockage and Mitigation Strategies

Pore blockage continues to be a critical reliability concern for transpiration cooling systems, with clogged holes potentially causing dangerous local temperature spikes and system failure [15]. Traditional sintered porous media are particularly susceptible to unpredictable dust-induced clogging, though AM techniques offer improved microscale control. Yang et al. [111] demonstrated the impact of increased pore blockage ratios in 0.4 mm perforated plates on cooling effectiveness, particularly in upstream regions.

Recent research has identified several promising approaches to mitigate these issues. Sun et al. [113] showed that at low F, the influence of pore blockage was minor in the tree-like channels, demonstrating their clogging resistance, while the maximum loss of the area-averaged ηo by 16.3% was found at F = 2%. Yang et al. [114] found that the proposed oriented porous structures improved cooling performance, reduced coolant consumption at equivalent cooling performance by 10–270%, and decreased the temperature gradient, eventually minimizing thermal stress and improving the reliability of the porous transpiration cooling. Sun et al. [89] introduced double coolant supply channels and found that the nonuniform coolant distribution increased area-averaged ηo by 3.27% while improving temperature uniformity.

Future work in this area will explore hybrid cooling configurations that combine the benefits of different approaches. Ding et al. [132] demonstrated that binary porous matrices could maintain 44.5% longer effective film lengths while using 20% less coolant compared to single porous matrices. Natsui et al. [133] showed synergistic effects when coupling discrete film cooling holes with transpiration cooling, effectively mitigating detrimental vortex structures. These hybrid approaches, originally developed for aerospace applications [26,134], can be adapted for gas turbine implementations with promising results.

5.3. Mechanical Integrity and Enhanced Design Approaches

The balance between mechanical strength and cooling performance remains a key challenge for AM-fabricated transpiration cooling structures. Min et al. [77] found that while 3d-pitch straight holes had the highest stress net area, staggered holes unexpectedly exhibited lower ultimate tensile strength (UTS) due to intersecting stress concentrations [135]. Huang et al. [51] provided a comparative analysis showing AM porous samples reaching 0.95 GPa UTS with 60% blockage, representing a 440% improvement over traditional sintered materials, but the samples were still 10% weaker than solid SLM specimens.