Heat Transfer Enhancement in Turbine Blade Internal Cooling Channels with Hybrid Pin-Fins and Micro V-Ribs Turbulators

Abstract

1. Introduction

2. Research Objects and Methodology

2.1. Research Objects

2.2. Research Methodology

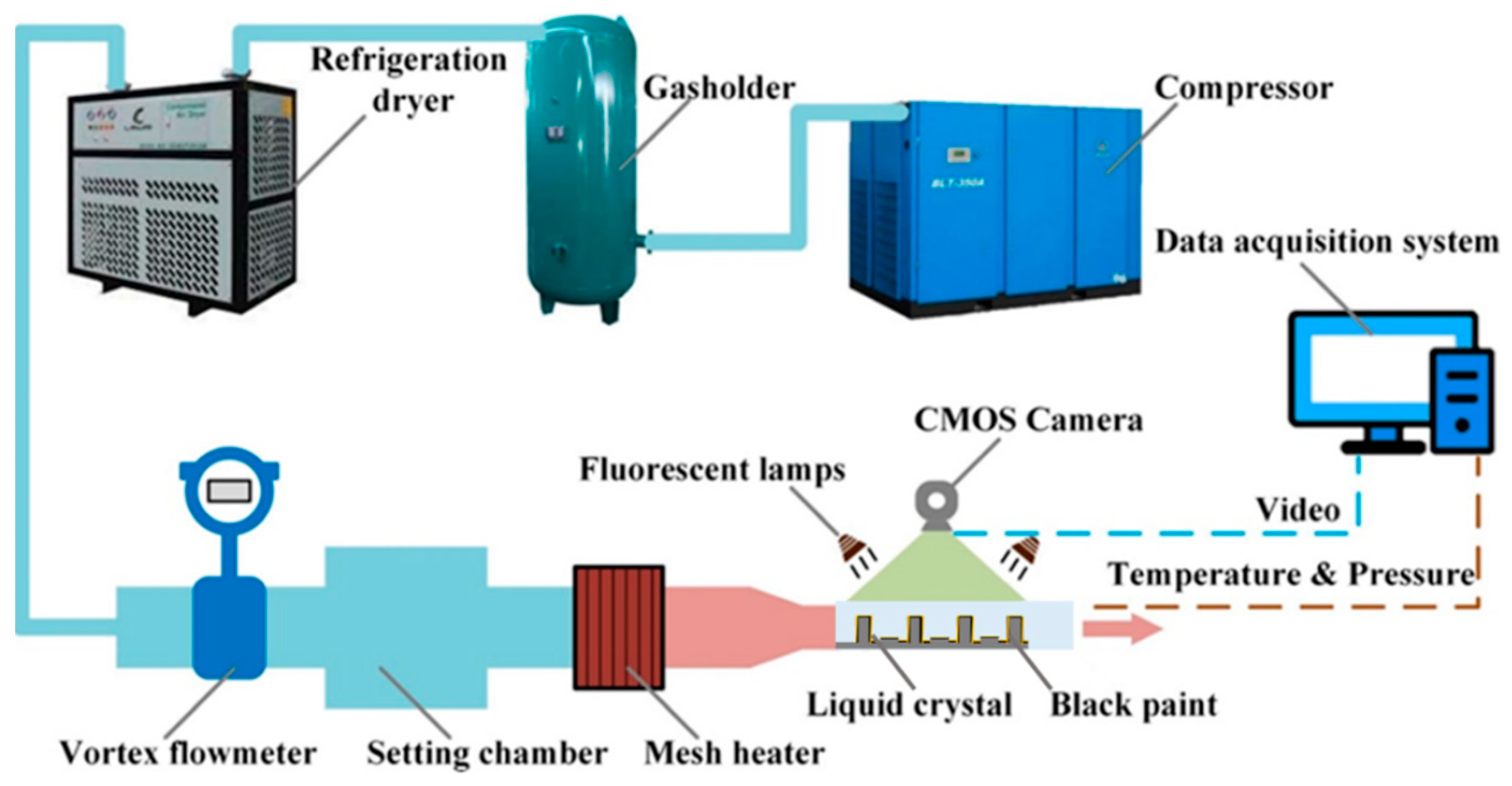

2.2.1. Experiment Method

- 1.

- Transient Liquid Crystal Thermography

- 2.

- Uncertainty Analysis

2.2.2. Numerical Method

- 1.

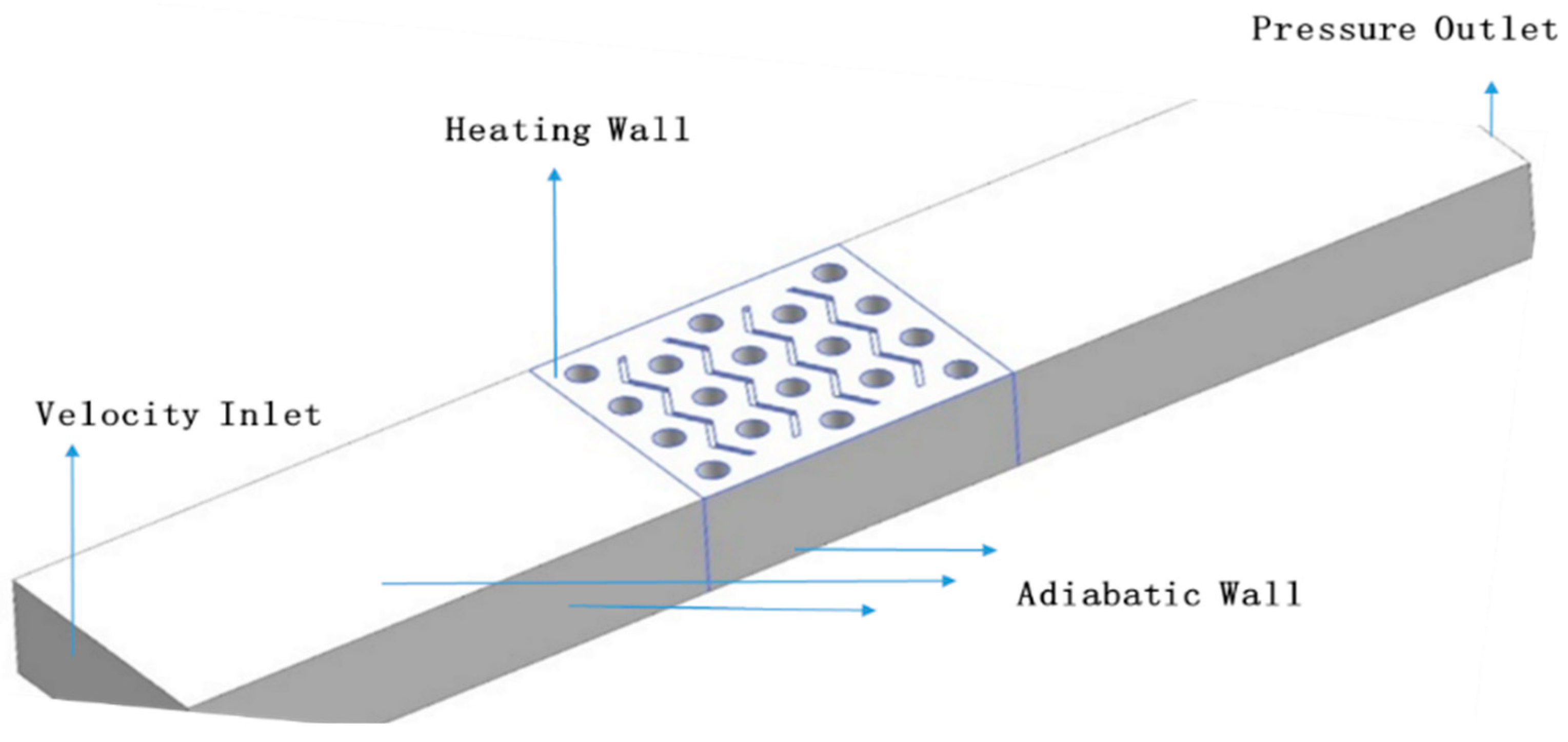

- Numerical Model and Boundary Conditions

- 2.

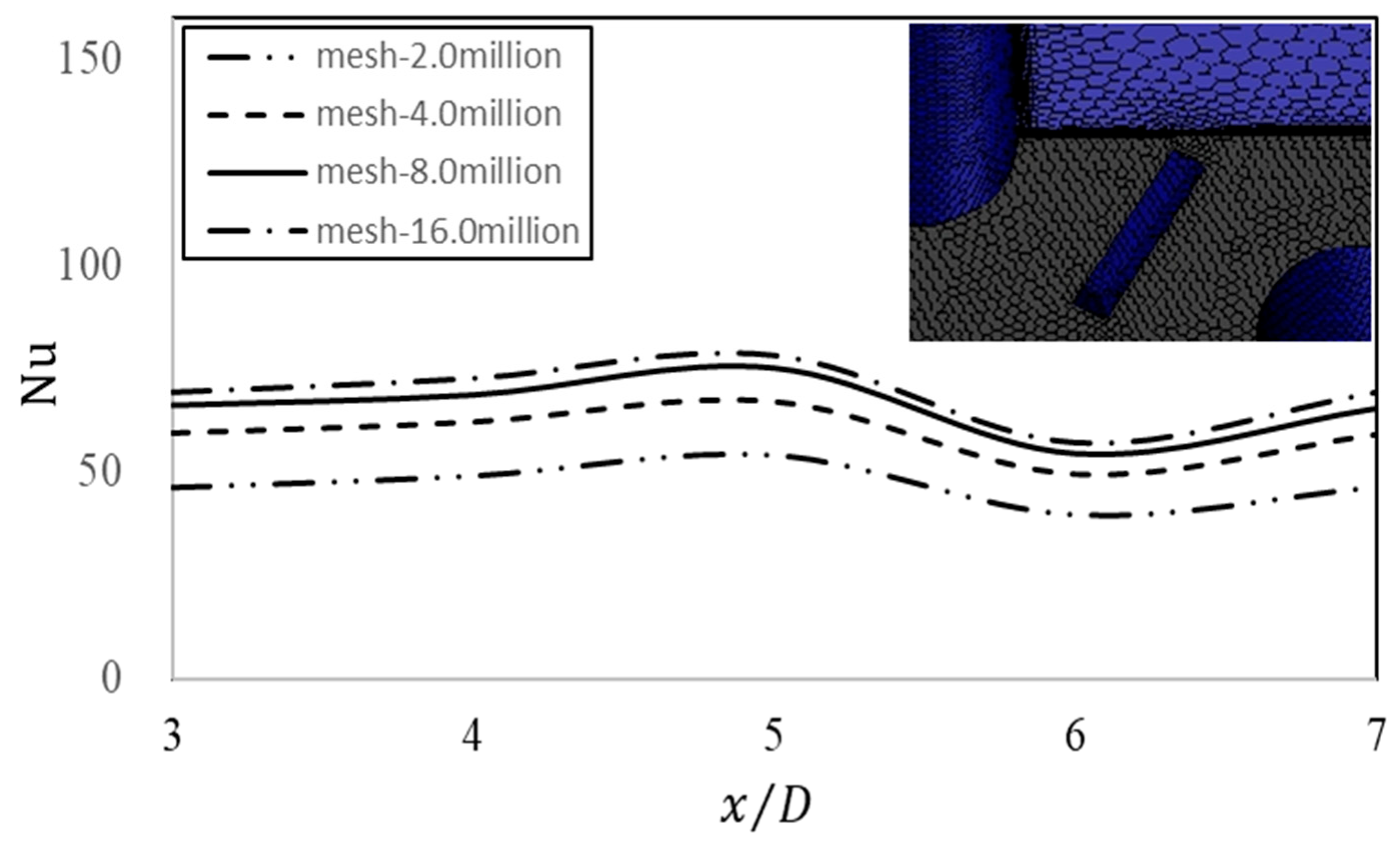

- Grid Independence Verification

- 3.

- Turbulence Model Validation

- 4.

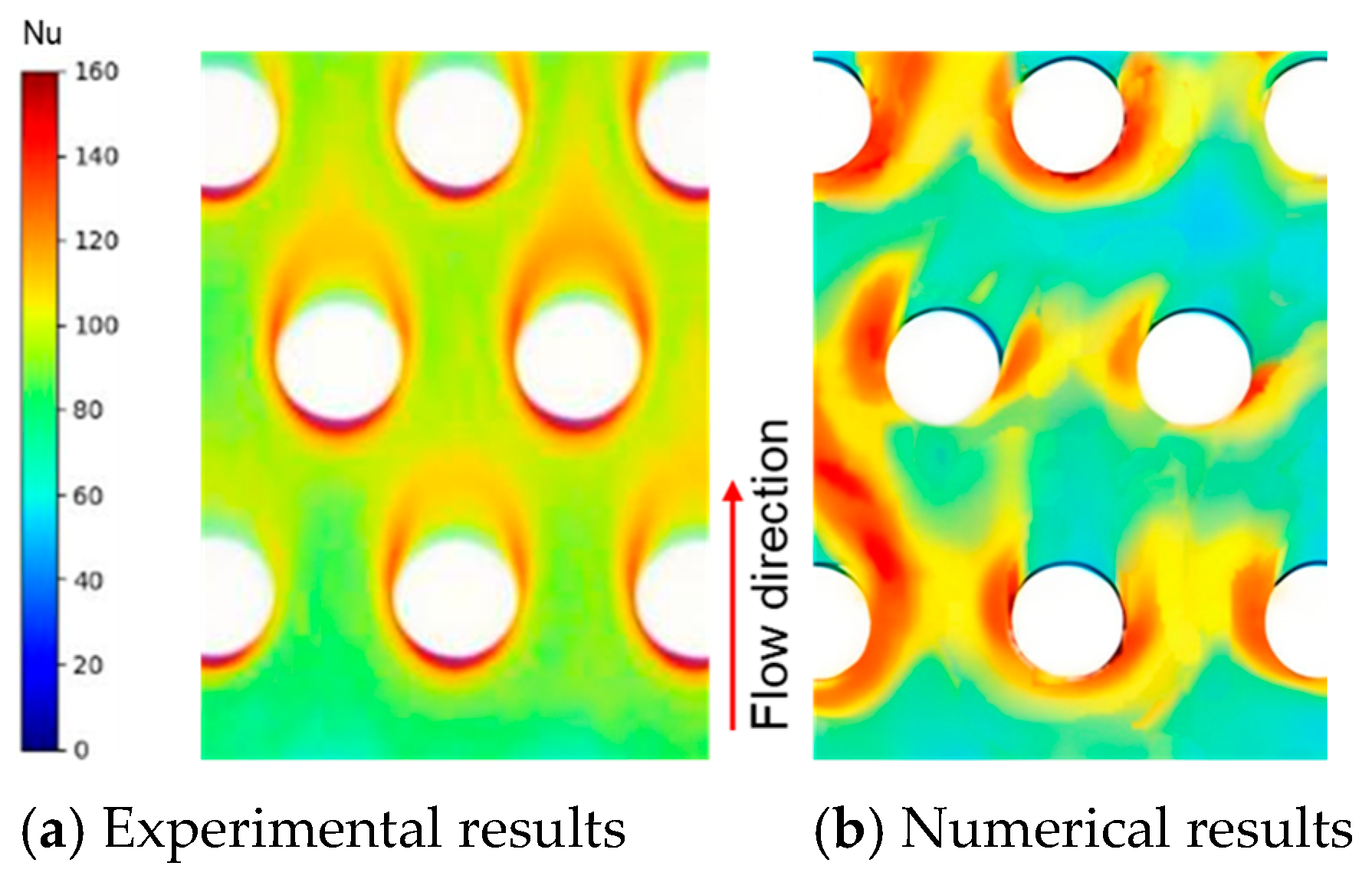

- Numerical Results Validation

3. Results and Discussion

3.1. Average Heat Transfer Characteristics

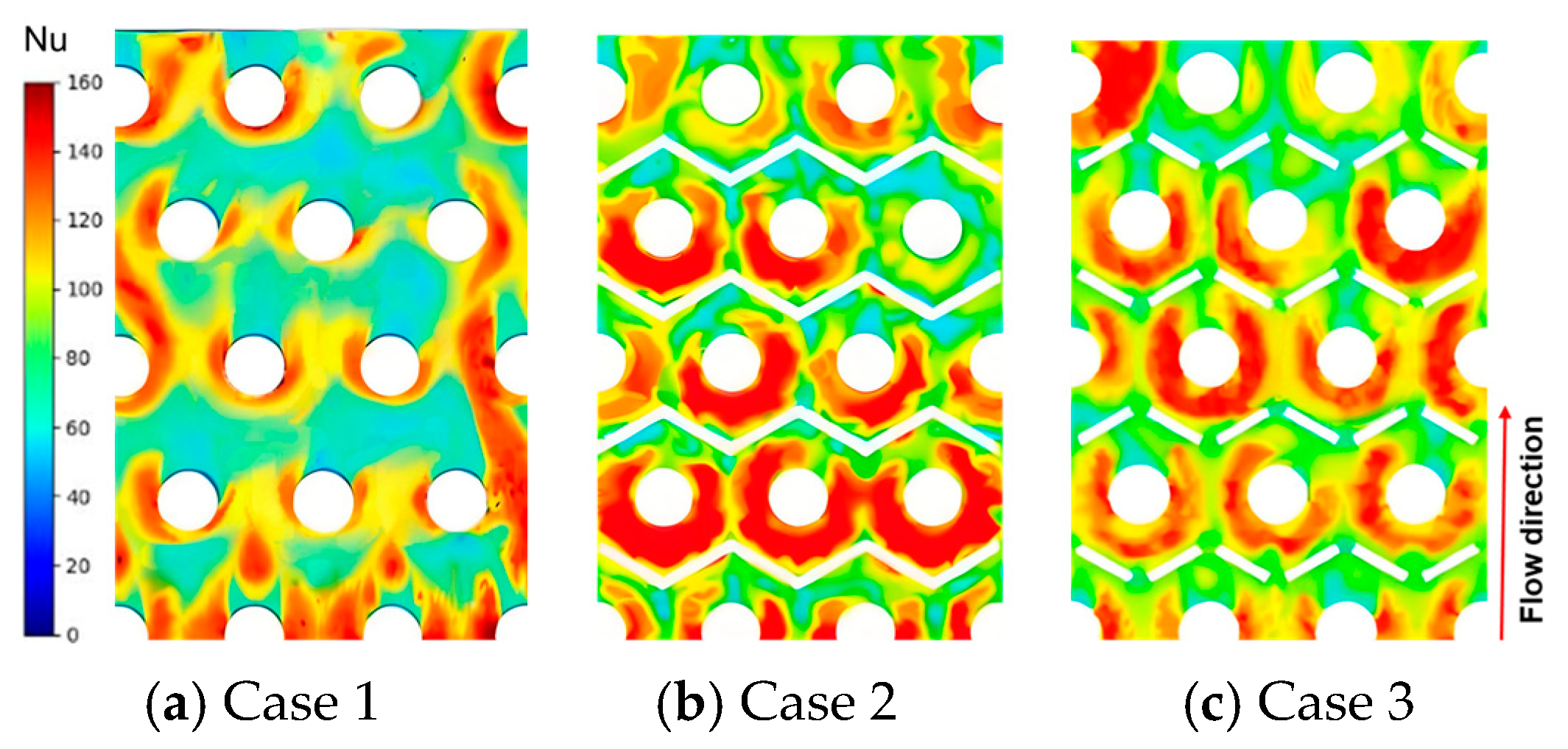

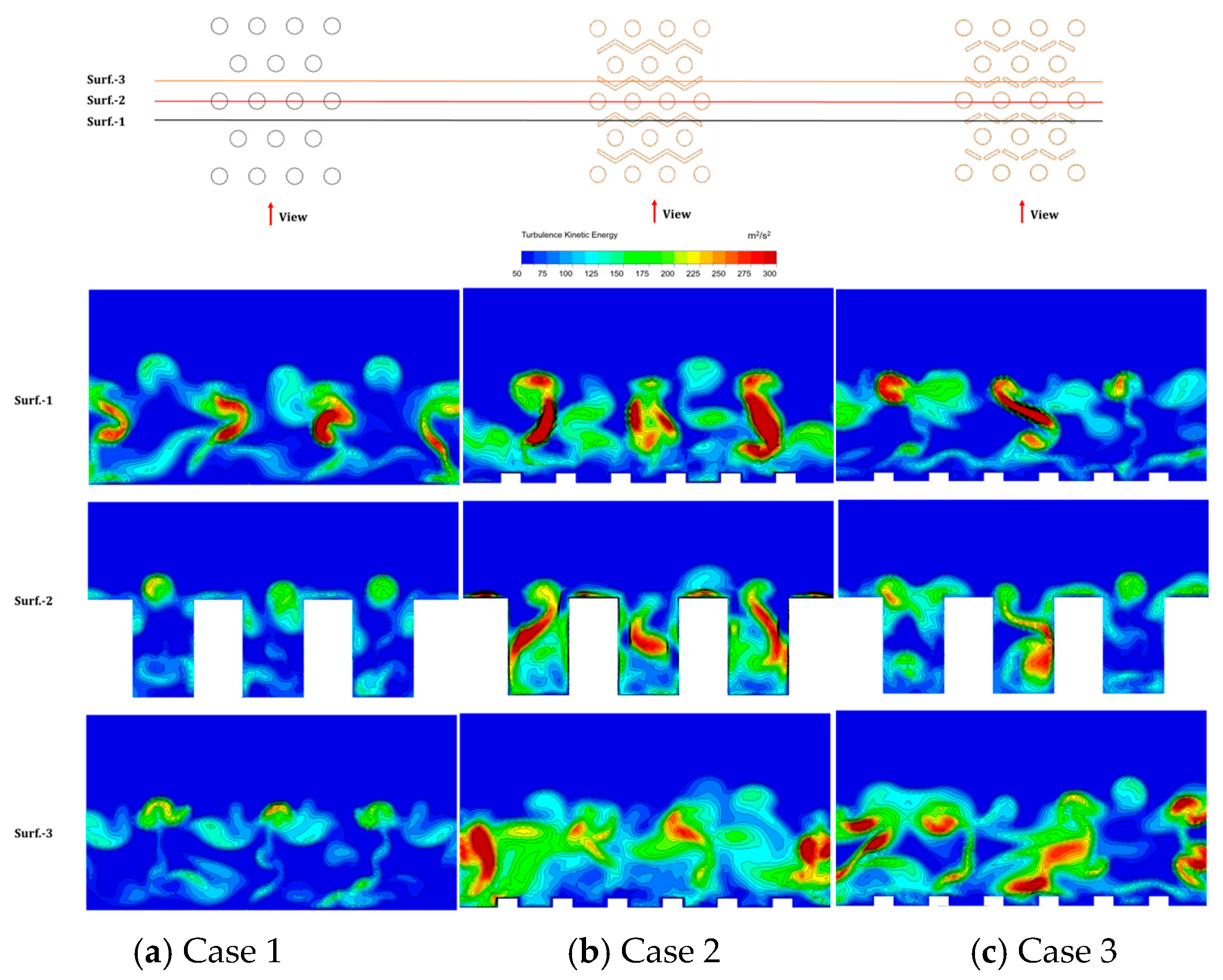

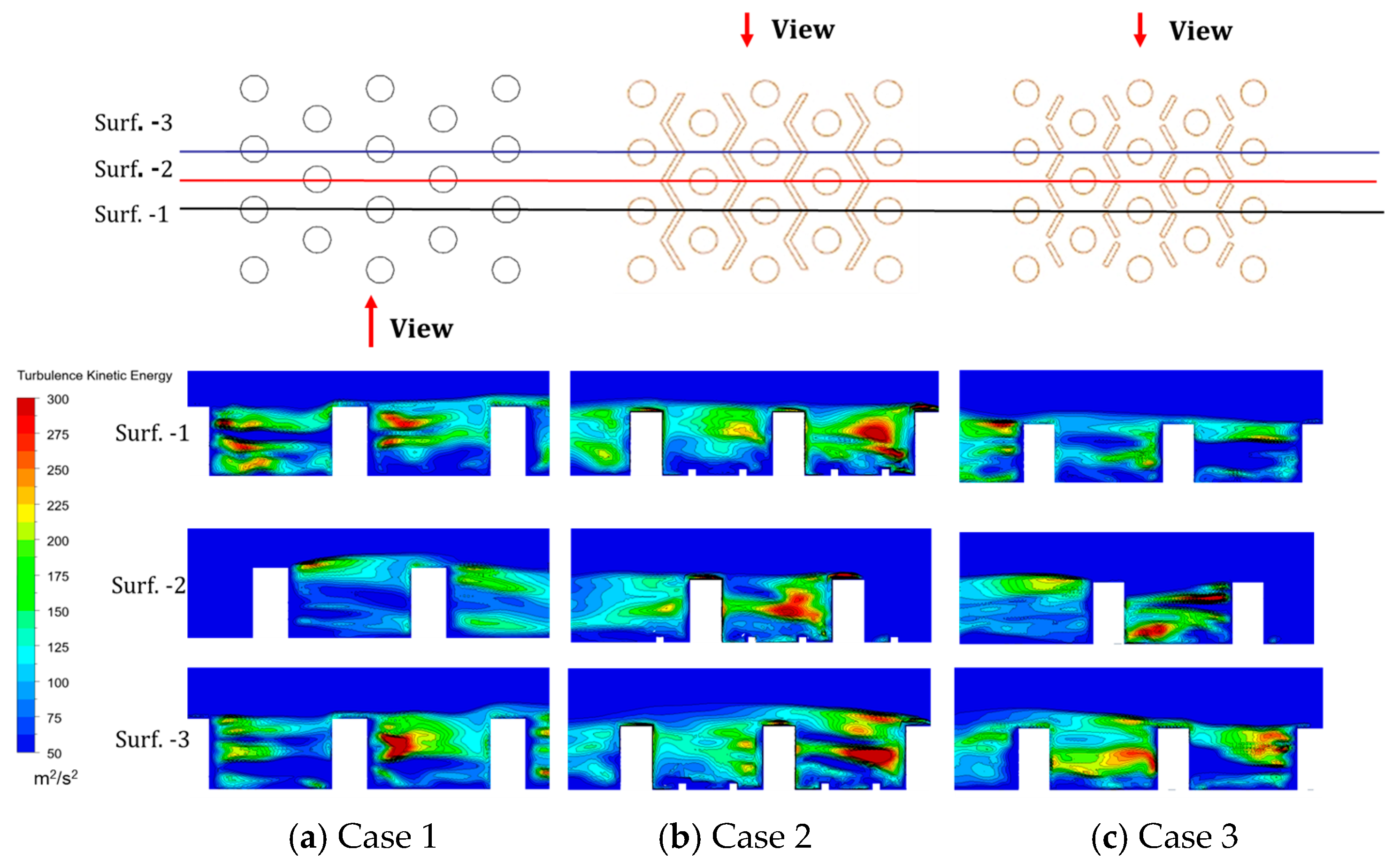

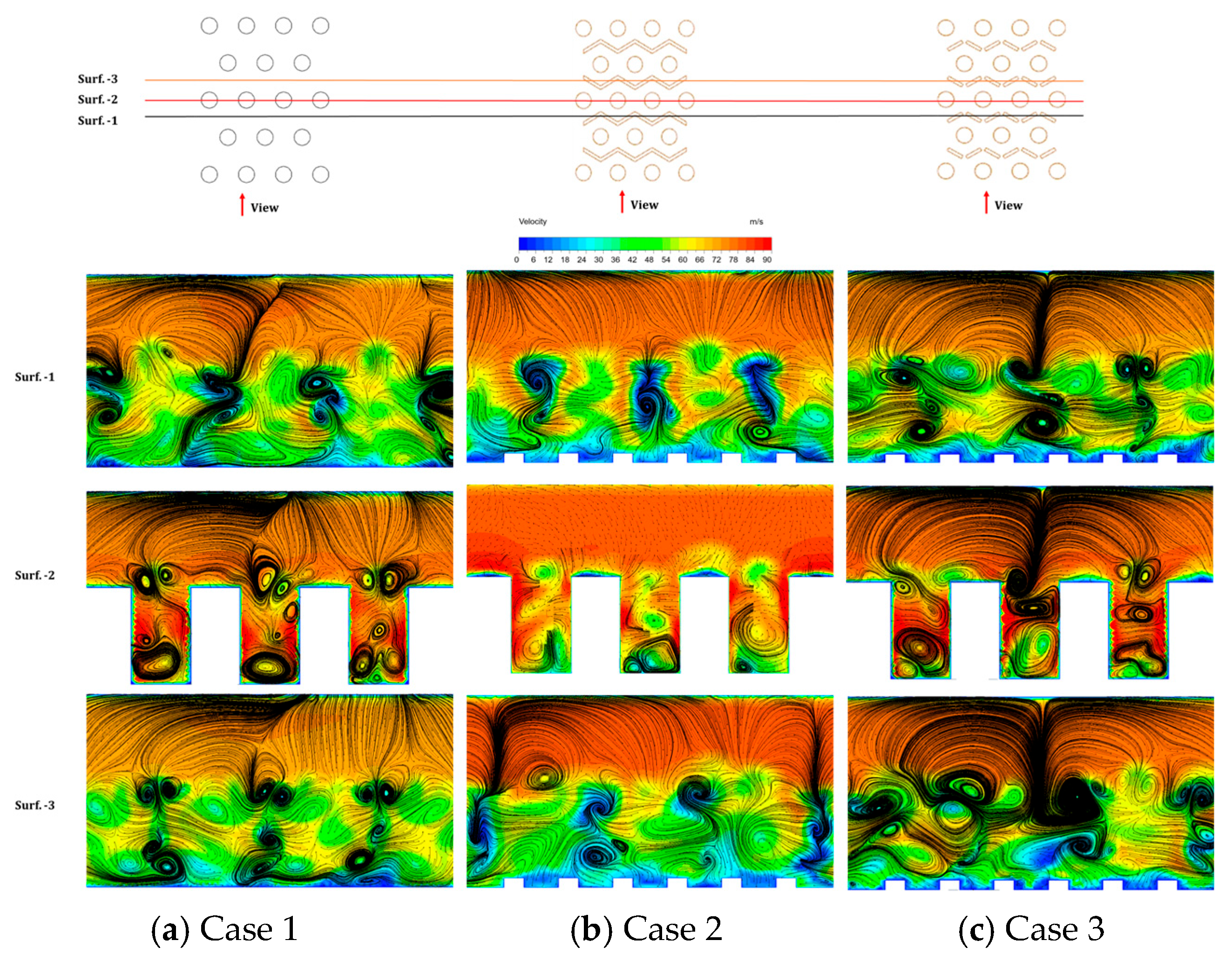

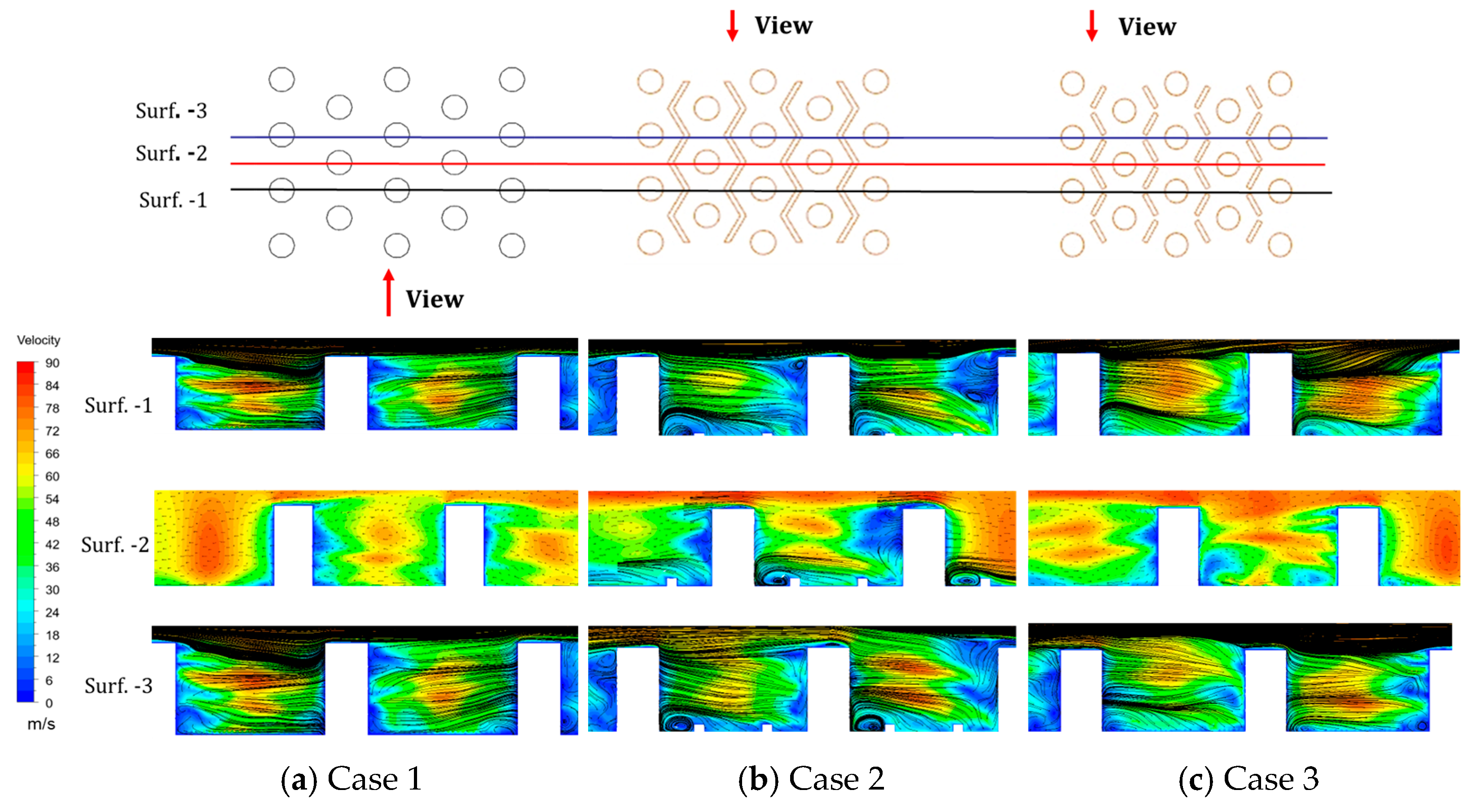

3.2. Local Flow Mechanisms

4. Conclusions

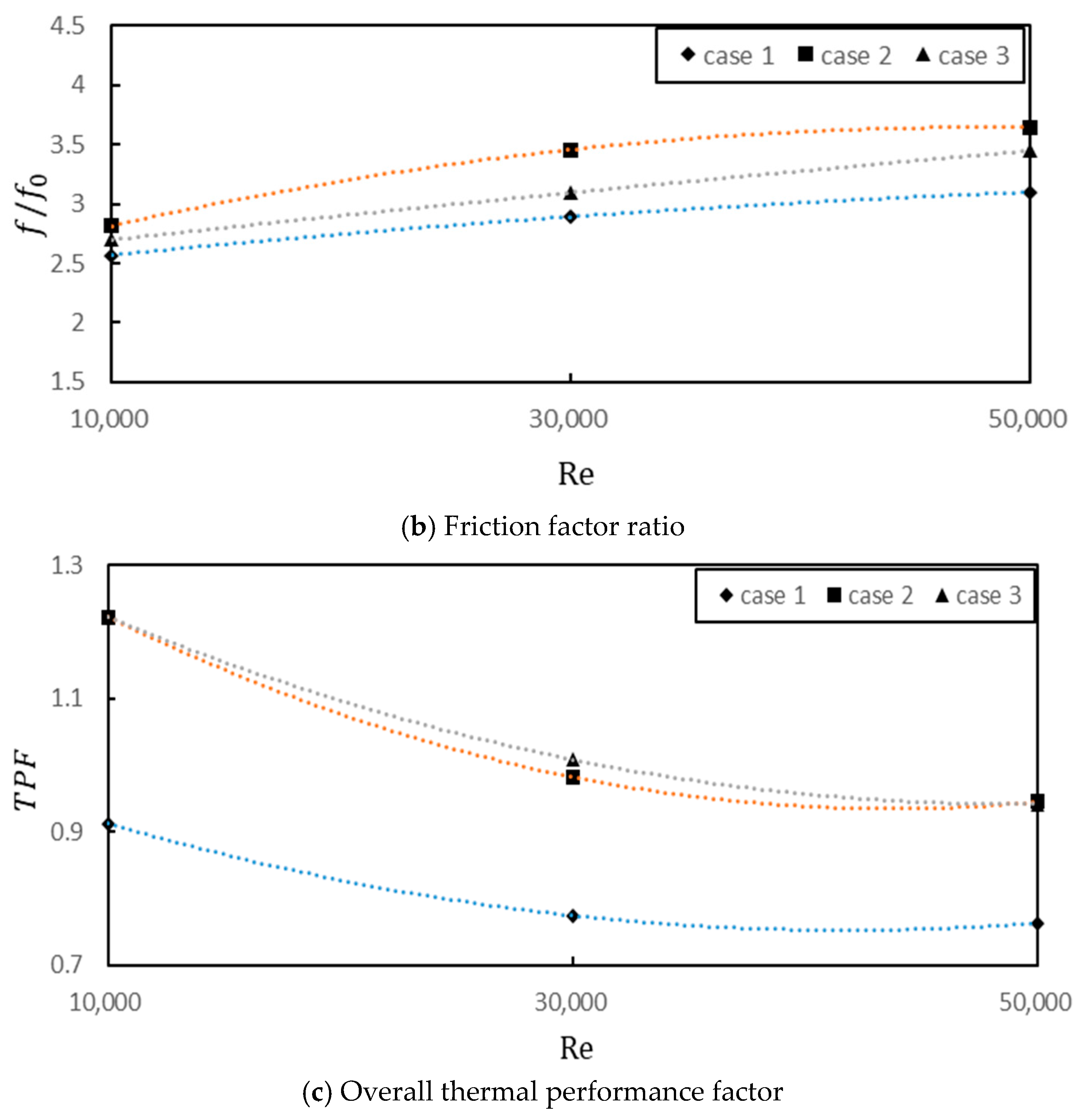

- (1)

- Through comparisons with experimental data and results from classic empirical correlations, the SST k-ω model has been validated as suitable for investigating the heat transfer characteristics for combining pin-fins with micro V-ribs.

- (2)

- A low heat transfer zone was identified behind pin-fin trailing edges, where direct V-rib placement improved thermal distribution. The continuous V-rib configuration achieved maximum heat transfer enhancement (27.6% higher than baseline). This is primarily attributed to the turbulence enhancement effect induced by the integrated micro V-rib configuration.

- (3)

- Flow resistance increased with Re for all cases, with the broken V-rib design showing the lowest absolute pressure loss (though still 7.2% higher than baseline). This leads to non-uniform cold-hot fluid mixing effects along different flow orientations, consequently affecting heat transfer performance.

- (4)

- The thermal enhancement mechanism stems from vortex generation downstream of pin-fins; flow separation at trailing edges creates shear-induced vortices that promote transverse momentum exchange and asymmetric flow redistribution, significantly improving wall heat transfer.

- (5)

- In future work, CFD will be employed to investigate the heat transfer performance of the composite micro V-rib configuration under rotating conditions, while the experimental apparatus will be upgraded simultaneously. This will involve installing a sector rig (incorporating 4 turbine blades) at the combustor exit to enable full-temperature, full-pressure heat transfer evaluation.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, W.; Yan, Y.; Zhou, Y.; Cui, J. Review of Advanced Effusive Cooling for Gas Turbine Blades. Energies 2022, 15, 8568. [Google Scholar] [CrossRef]

- Bunker, R.S. Gas Turbine Heat Transfer: Ten Remaining Hot Gas Path Challenges. J. Turbomach. 2006, 129, 193–201. [Google Scholar] [CrossRef]

- Xu, L.; Sun, Z.; Ruan, Q.; Xi, L.; Gao, J.; Li, Y. Development Trend of Cooling Technology for Turbine Blades at Super-High Temperature of above 2000 K. Energies 2023, 16, 668. [Google Scholar] [CrossRef]

- Han, J.-C.; Dutta, S.; Ekkad, S. Gas Turbine Heat Transfer and Cooling Technology; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Ligrani, P. Heat Transfer Augmentation Technologies for Internal Cooling of Turbine Components of Gas Turbine Engines. Int. J. Rotating Mach. 2013, 2013, 275653. [Google Scholar] [CrossRef]

- Osipov, S.; Rogalev, A.; Rogalev, N.; Shevchenko, I.; Vegera, A. Asymmetric Method of Heat Transfer Intensification in Radial Channels of Gas Turbine Blades. Inventions 2022, 7, 117. [Google Scholar] [CrossRef]

- Casarsa, L.; Arts, T. Experimental Investigation of the Aerothermal Performance of a High Blockage Rib-Roughened Cooling Channel. J. Turbomach. 2005, 127, 580–588. [Google Scholar] [CrossRef]

- Han, J.C.; Zhang, Y.M.; Lee, C.P. Augmented Heat Transfer in Square Channels with Parallel, Crossed, and V-Shaped Angled Ribs. J. Heat Transf. 1991, 113, 590–596. [Google Scholar] [CrossRef]

- Tanda, G. Heat transfer in rectangular channels with transverse and V-shaped broken ribs. Int. J. Heat Mass Transf. 2004, 47, 229–243. [Google Scholar] [CrossRef]

- Khalatov, A.A.; Dashevskyy, Y.Y.; Pysmennyi, D.M. Heat Transfer and Friction Factor in the Rib Roughened Blade Leading Edge Cooling Passage, Volume 5: Heat Transfer, Parts A and B, Vancouver, British Columbia, Canada, 2011; ASMEDC: Vancouver, BC, Canada, 2011; pp. 1193–1203. [Google Scholar]

- Wang, L.; Sundén, B. Experimental investigation of local heat transfer in a square duct with various-shaped ribs. Heat Mass Transf. 2006, 43, 759–766. [Google Scholar] [CrossRef]

- Montelpare, S.; Ricci, R. An experimental method for evaluating the heat transfer coefficient of liquid-cooled short pin fins using infrared thermography. Exp. Therm. Fluid Sci. 2004, 28, 815–824. [Google Scholar] [CrossRef]

- Zhu, H.; Xu, D. Heat Transfer and Pressure Drop of Short Pin-Fin Array with Different Diameter and Shape. J. Aerosp. Power 2002, 17, 246–249. [Google Scholar]

- Liu, L.; Zhu, X.; Liu, H.; Du, Z. Effect of Longitudinal Vortex Generator on Impingement Cooling over Leading Edge of a Gas Turbine Blade. J. Chin. Soc. Power Eng. 2018, 38, 719–724+762. [Google Scholar]

- Bai, W.; Liang, D.; Chen, W.; Chyu, M. Rib influence on heat transfer and pressure drop in pin-fin array. J. Aerosp. Power 2019, 34, 2509–2515. [Google Scholar]

- Chang, S.W.; Cheng, T.H. Thermal performance of channel flow with detached and attached pin-fins of hybrid shapes under inlet flow pulsation. Int. J. Heat Mass Transf. 2021, 164, 120554. [Google Scholar] [CrossRef]

- Afzal, A.; Chung, H.; Muralidhar, K.; Hee Cho, H. Neural-Network-Assisted Optimization of Rectangular Channels with Intersecting Ribs for Enhanced Thermal Performance. Heat Transf. Eng. 2019, 41, 1609–1625. [Google Scholar] [CrossRef]

- Darvish Damavandi, M.; Safikhani, H.; Yahyaabadi, M. Multi-objective optimization of asymmetric v-shaped ribs in a cooling channel using CFD, artificial neural networks and genetic algorithms. J. Braz. Soc. Mech. Sci. Eng. 2016, 39, 2319–2329. [Google Scholar] [CrossRef]

- Kumar, K.; Prajapati, D.R.; Samir, S. Heat transfer and friction factor correlations development for solar air heater duct artificially roughened with ‘S’ shape ribs. Exp. Therm. Fluid Sci. 2017, 82, 249–261. [Google Scholar] [CrossRef]

- Ma, Y.; Yan, H.; Hooman, K.; Xie, G. Enhanced heat transfer in a pyramidal lattice sandwich panel by introducing pin- fifins/protrusions/dimples. Int. J. Therm. Sci. 2020, 156, 106468. [Google Scholar] [CrossRef]

- Gutiérrez de Arcos, D.; Waidmann, C.; Poser, R.; von Wolfersdorf, J.; Göhring, M. Rotationally Induced Local Heat Transfer Features in a Two-Pass Cooling Channel: Experimental–Numerical Investigation. Int. J. Turbomach. Propuls. Power 2024, 9, 34. [Google Scholar] [CrossRef]

- Xu, C.; Zhang, P.; Rao, Y. Experiments and numerical analysis of turbulent heat transfer enhancement over oval-dimple arrays. J. Propuls. Technol. 2024, 45, 149–157. [Google Scholar]

- Ekkad, S.V.; Han, J.-C. A transient liquid crystal thermography technique for gas turbine heat transfer measurements. Meas. Sci. Technol. 2000, 11, 957–968. [Google Scholar] [CrossRef]

- Moffat, R.J. Describing the uncertainties in experimental results. Exp. Therm. Fluid Sci. 1988, 1, 3–17. [Google Scholar] [CrossRef]

- Ismail, B.C.; Urmila, G.H.I.A.; Patrick, J.R.; Christopher, J.F.; Hugh, C.; Raad, P.E. Procedure for Estimation and Reporting of Uncertainty Due to Discretization in CFD Applications. J. Fluids Eng. 2008, 130, 078001. [Google Scholar]

- ASME V&V 20-2009; Standard for Verification and Validation in Computational Fluid Dynamics and Heat Transfer. American Society of Mechanical Engineers: New York, NY, USA, 2009.

- Metzger, D.E.; Shepard, W.B.; Haley, S.W. Row Resolved Heat Transfer Variations in Pin-Fin Arrays Including Effects of Non-Uniform Arrays and Flow Convergence, Volume 4: Heat Transfer; Electric Power, Dusseldorf, West Germany, 1986; American Society of Mechanical Engineers: Dusseldorf, Germany, 1986. [Google Scholar]

- Kim, B.-C.; Chang, K. Assessment of hybrid RANS/LES models in heat and fluid flows around staggered pin-fin arrays. Energies 2020, 13, 3752. [Google Scholar] [CrossRef]

- Paniagua, L.; Lehmkuhl, O.; Oliet, C.; Pérez-Segarra, C.D. Large eddy simulations (LES) on the flow and heat transfer in a wall-bounded pin matrix. Numer. Heat Transf. Part B 2014, 65, 103–128. [Google Scholar] [CrossRef]

- Bauer, J.; Tyacke, J. Comparison of low Reynolds number turbulence and conjugate heat transfer modelling for pin-fin roughness elements. Appl. Math. Model. 2022, 103, 696–713. [Google Scholar] [CrossRef]

- Luan, Y.; Rao, Y.; Weigand, B. Experimental and numerical study of heat transfer and pressure loss in a multi-convergent swirl tube with tangential jets. Int. J. Heat Mass Transf. 2022, 190, 122797. [Google Scholar] [CrossRef]

| Structure | Geometric Parameter | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pin-Fins | V-Ribs | ||||||||

| D/mm | H/mm | Lx/mm | Ly/mm | h/mm | w/mm | lx/mm | ly/mm | α/° | |

| Case 1 | 8 | 16 | 18 | 18 | --- | --- | --- | --- | --- |

| Case 2 | 8 | 16 | 18 | 18 | 1.6 | 1.6 | 36 | --- | --- |

| Case 3 | 8 | 16 | 18 | 18 | 1.6 | 1.6 | 36 | 1.27 | 60 |

| Experiment Result | Turbulence Model | ||||

|---|---|---|---|---|---|

| SST k-ω | Standard k-ω | RNG k-ε | Low k-ε | ||

| Re | 10,000 | ||||

| Nu | 52.53 | 53.81 | 56.52 | 49.96 | 51.67 |

| Structure | Re | ([27]) | (Num.) | Deviation/% |

|---|---|---|---|---|

| Case 1 | 10,000 | 58.97 | 56.63 | 3.96 |

| 30,000 | 125.84 | 116.52 | 7.40 | |

| 50,000 | 179.02 | 170.61 | 4.69 |

| Structure | Re | Nu (Exp.) | Nu (Num.) | Deviation/% | (Exp.) | (Num.) | Deviation/% |

|---|---|---|---|---|---|---|---|

| Case 2 | 10,000 | 52.53 | 53.81 | 2.44 | 0.09 | 0.09 | 1.03 |

| 30,000 | 108.59 | 111.52 | 2.70 | 0.08 | 0.08 | 3.13 | |

| 50,000 | 161.40 | 164.33 | 1.82 | 0.08 | 0.08 | 3.74 |

| Re | ||||||||

|---|---|---|---|---|---|---|---|---|

| Case 2 | Case 3 | Case 2 | Case 3 | Deviation/% | Case 2 | Case 3 | Deviation/% | |

| 10,000 | 70.23 | 62.46 | 2.25 | 2.00 | 12.44 | 1.60 | 1.44 | 10.84 |

| 30,000 | 143.41 | 128.37 | 1.91 | 1.71 | 11.72 | 1.26 | 1.17 | 7.67 |

| 50,000 | 202.81 | 186.23 | 1.80 | 1.65 | 8.90 | 1.16 | 1.09 | 6.90 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, L.; Zuo, Q.; Rao, Y. Heat Transfer Enhancement in Turbine Blade Internal Cooling Channels with Hybrid Pin-Fins and Micro V-Ribs Turbulators. Energies 2025, 18, 3296. https://doi.org/10.3390/en18133296

Hu L, Zuo Q, Rao Y. Heat Transfer Enhancement in Turbine Blade Internal Cooling Channels with Hybrid Pin-Fins and Micro V-Ribs Turbulators. Energies. 2025; 18(13):3296. https://doi.org/10.3390/en18133296

Chicago/Turabian StyleHu, Longbing, Qiuru Zuo, and Yu Rao. 2025. "Heat Transfer Enhancement in Turbine Blade Internal Cooling Channels with Hybrid Pin-Fins and Micro V-Ribs Turbulators" Energies 18, no. 13: 3296. https://doi.org/10.3390/en18133296

APA StyleHu, L., Zuo, Q., & Rao, Y. (2025). Heat Transfer Enhancement in Turbine Blade Internal Cooling Channels with Hybrid Pin-Fins and Micro V-Ribs Turbulators. Energies, 18(13), 3296. https://doi.org/10.3390/en18133296