The Influence of the Changes in Natural Gas Supplies to Poland on the Amount of Hydrogen Produced in the SMR Reactor

Abstract

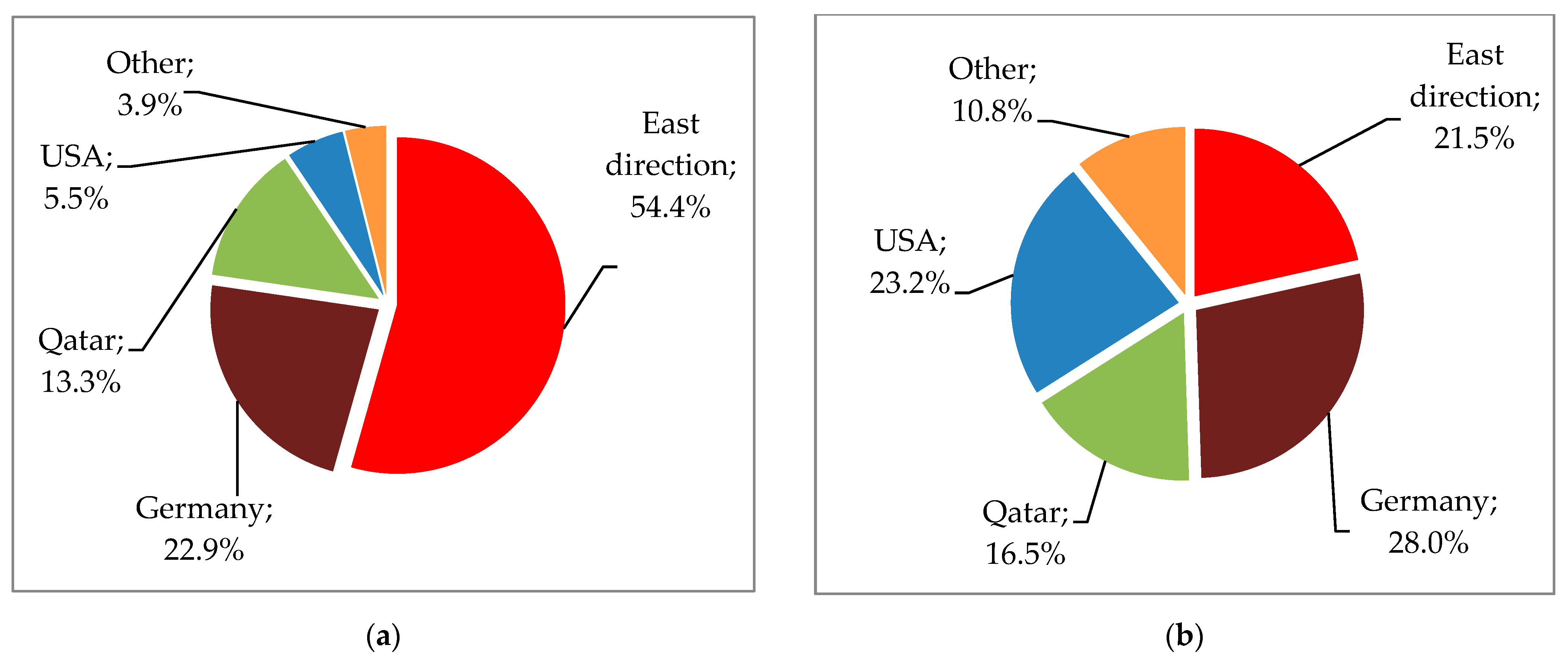

1. Introduction

2. Materials and Methods

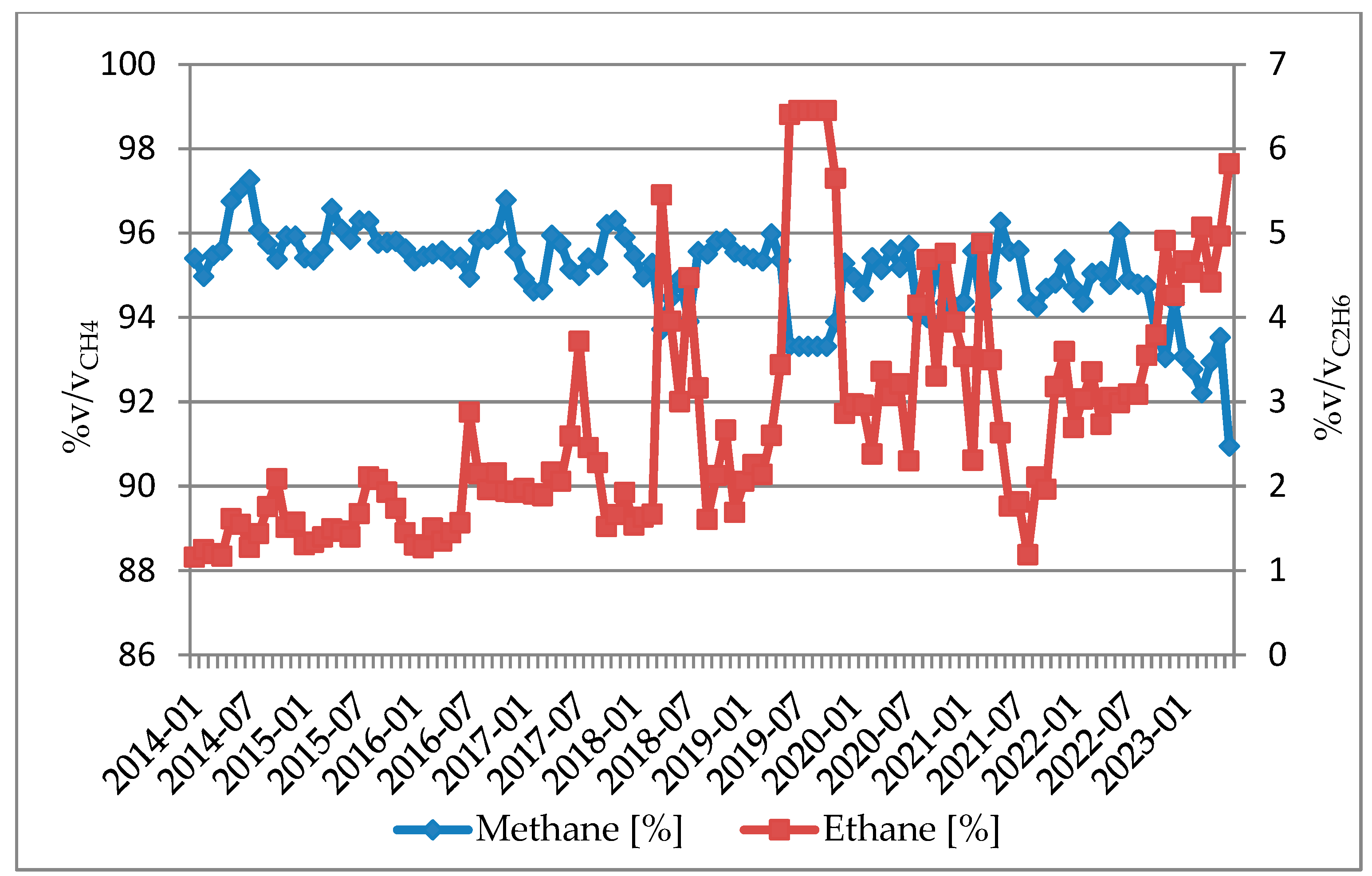

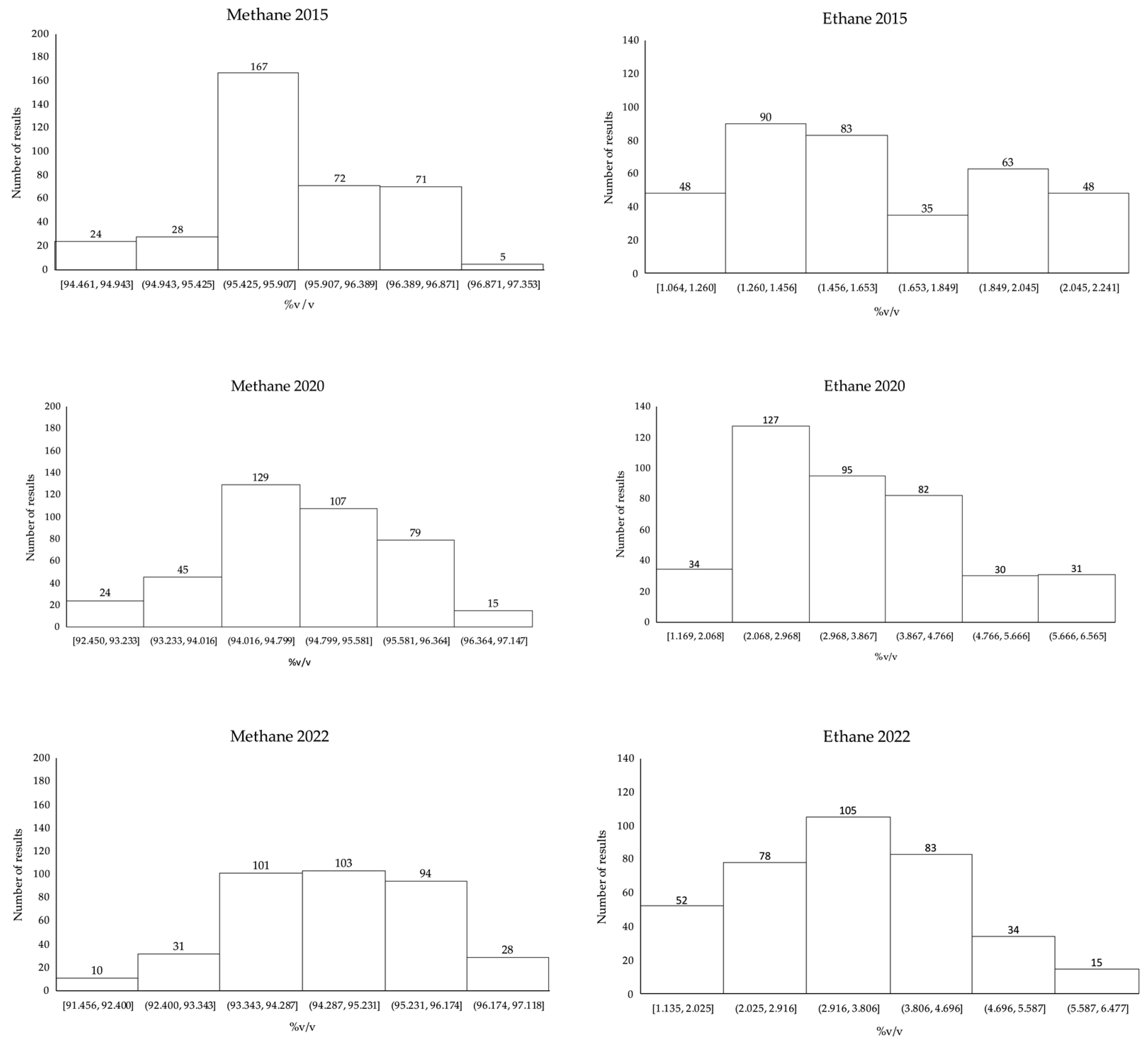

2.1. Materials

2.2. Methods

2.2.1. Simulation Method

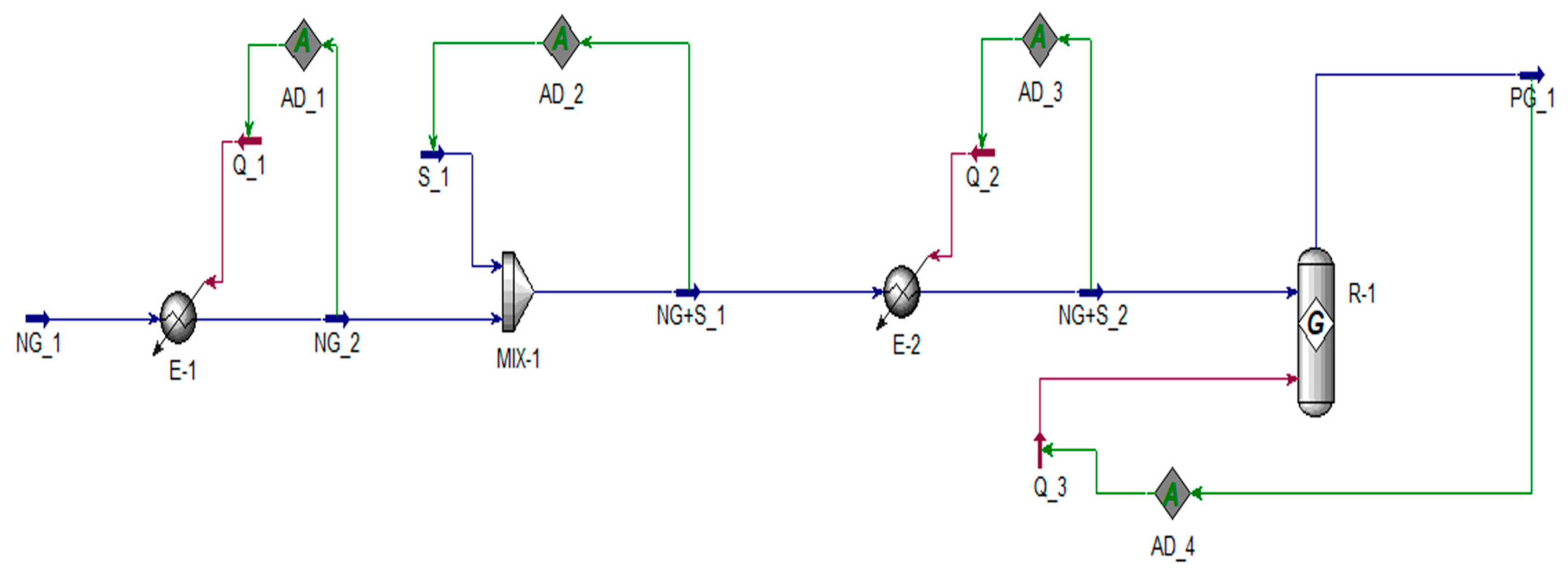

2.2.2. Process Description

2.2.3. Assumptions

- -

- The process does not result in heat loss to the ambient through the walls of the piping, exchangers, mixer, and reactor shell.

- -

- The key elements influencing the steam reforming process in the tube reactor are the chemical composition of the feedstock, the heat balance, the temperature and pressure of the process, the properties and mass of the catalyst used, and the reactor design (including, inter alia, the material and thickness of the catalytic tubes, the operating characteristics of the burners, etc.). These elements directly influence the reactions taking place, the mass and heat transport through the porous catalyst grains, the mass and heat transfer processes between the catalyst grains and the fluid core, the heat transfer between the flue gases and the process gas flowing through the catalytic tubes, and the heat transfer of the flue gases from the burners to the combustion chamber, taking into account the furnace parameters and the catalysts used. These elements influence the overall kinetics and thermodynamics of the process, which has a direct impact on the degree of feedstock reactivity and the energy intensity of the process. Currently, the most accurate SMR reactor models are based on empirical models. Their development requires knowledge of detailed reaction kinetics and thermodynamics parameters, detailed information on the reformer design, catalyst-specific constants (e.g., catalyst density, grain density, grain porosity, pore curvature factor, average pore radius), and bed (specific surface area, bulk density, porosity). Some of the parameters can be found in the literature, while others need to be determined empirically or obtained directly from manufacturers. To simplify the model to a degree acceptable to the subject of the work, it was assumed that the processes taking place in the catalytic tube space could be described by a Gibbs reactor.

- -

- Pressure losses of gas flowing through the pipelines and apparatus are not taken into account (except for pressure drops in the exchanger E-2 = 0.02 MPa and R-1 = 0.07 MPa).

- -

- The heat supplied to the exchangers E-1, E-2, and reactor R-1 (Q_1, Q_2, and Q_3, respectively) depends on the desired temperatures maintained by the corresponding logic element. For the NG_2 stream via AD_1 with an expectation value of 370 °C, a tolerance of 0.1 °C and an iteration step of 1000 kJ/h. For the NG + S_2 stream, the desired temperature was maintained via AD_3 with an expectation value of 570 °C, a tolerance of 0.1 °C and an iteration step of 2000 kJ/h. The temperature of the PG_1 stream was maintained by AD_4 with a tolerance of 0.1 °C and an iteration step of 10,000 kJ/h. The model did not include the combustion of fuel gases for the heat input to the reaction space of the catalytic tubes.

- -

- The steam supplied to MX-1 remains at a constant temperature and pressure, while the amount directed to the mixer varies. Stream S_1 is derived from the expected value taken in AD-2. The desired number of moles in S_1 was calculated based on the number of moles of C in NG_2, while keeping S/C constant at 3.3 kmol H2O/kmol C (to the nearest 0.01). It is assumed that the steam is supplied from an external source.

2.2.4. Limitations

3. Results

4. Conclusions

- The methane concentration in the analyzed natural gas stream ranged from 91.46% to 97.35% v/v, while ethane and propane concentrations varied between 1.20% and 6.44% v/v, and between 0.11% and 1.34% v/v, respectively.

- The number of moles of carbon (C) in the natural gas varied from 294.1 kmol C/h in Simulation No. 1 to 326.1 kmol C/h in Simulation No. 3.

- The water steam fed into the process ranged from 970.6 to 1076.0 kmol H2O/h, and it depended on the quality of the natural gas. More steam was introduced as the number of C moles in the natural gas stream increased. The simulations were run so that the ratio of steam atoms to carbon atoms in the feedstock (S/C = 3.3).

- Changes in the water steam–natural gas mixture led to variations in the quality and quantity of the process gas PG_1 exiting the reactor. Key components in PG_1, including hydrogen, methane, carbon (IV) oxide, and carbon (II) oxide, showed slight fluctuations.

- The amount of process gas produced ranged from 1697 to 1852 kmol/h, with Simulation No. 3 yielding the maximum and Simulation No. 1 the minimum,

- To minimize the impact of temperature changes on the results, a constant temperature assumption was applied. The inlet temperature to the reactor was set at 570 °C, and the outlet temperature at 830 °C.

- Notably, as the concentration of ethane and propane in natural gas increased, the amount of hydrogen generated in the reactor increased. This observation implies that variations in the analyzed natural gas quality could theoretically affect hydrogen production by up to 8%. The simulations recorded a change in the amount of hydrogen produced contained in the process gas in the range of 732.6–797.7 kmol/h. As the ethane concentration in the process gas increased, the heat demand of the reactions occurring in the reformer also increased. The molar heat of the gas stream also changed, affecting the thermal balance of the process.

- The simulations highlighted the potential challenge of overloading the plant when using natural gas with a high ethane content. This overload could disrupt the heat balance and other critical processes. Thus, maintaining nominal hydrogen production might require limiting the amount of natural gas fed into the process.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- 2023 Statistical Review of World Energy. Available online: https://www.bp.com/en/global/corporate/energy-economics/statistical-review-of-world-energy.html (accessed on 30 June 2023).

- EIA. Europe Was the Main Destination for U.S. LNG Exports in 2022. Available online: https://www.eia.gov/todayinenergy/detail.php?id=55920 (accessed on 30 June 2023).

- Łoskot-Strachota, A. The EU Gas Market: Revolutionary Changes and the Spectre of Another Winter. OSW COMMENTARY 2023-05-25. Available online: https://www.osw.waw.pl/en/publikacje/osw-commentary/2023-05-25/eu-gas-market-revolutionary-changes-and-spectre-another-winter (accessed on 30 June 2023).

- International Energy Agency, Gas Market Report, Q1 2023, including Gas Market Highlights 2022. February 2023. Available online: https://iea.blob.core.windows.net/assets/c6ca64dc-240d-4a7c-b327-e1799201b98f/GasMarketReportQ12023.pdf (accessed on 30 June 2023).

- International Energy Agency. Natural Gas Supply-Demand Balance of the European Union in 2023. Available online: https://iea.blob.core.windows.net/assets/227fc286-a3a7-41ef-9843-1352a1b0c979/Naturalgassupply-demandbalanceoftheEuropeanUnionin2023.pdf (accessed on 29 June 2023).

- European Commission, REPowerEU: Joint European Action for More Affordable, Secure and Sustainable Energy. European Commission, 2022. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_22_1511 (accessed on 30 June 2023).

- Lambert, L.A.; Tayah, J.; Lee-Schmid, C.; Abdalla, M.; Abdallah, I.; Ali, A.H.M.; Esmail, S.; Ahmed, W. The EU’s natural gas Cold War and diversification challenges. Energy Strategy Rev. 2022, 43, 100934. [Google Scholar] [CrossRef]

- Haines, R.J. The geopolitics of Russian’s networked energy infrastructure. Orbis 2015, 59, 557–599. [Google Scholar] [CrossRef]

- Ruszel, M. The significance of the Baltic Sea Region for natural gas supplies to the V4 countries. Energy Policy 2020, 146, 1–9. [Google Scholar] [CrossRef]

- Szurlej, A. The state policy for natural gas sector. Arch. Min. Sci. 2013, 58, 925–940. [Google Scholar]

- Pikus, P.; Korda-Burza, A.; Szurlej, A. Transformation of the domestic natural gas market—Structural and regulatory aspects (Transformacja krajowego rynku gazu ziemnego—Aspekty strukturalne i regulacyjne). Rynek Energii 2020, 5, 3–10. (In Polish) [Google Scholar]

- The Institute for Energy Economics and Financial Analysis (IEEFA), Global LNG Outlook 2023–2027. February 2023. Available online: https://ieefa.org/resources/global-lng-outlook-2023-27 (accessed on 12 July 2023).

- ACER. Key Developments in EU Gaswholesale Markets 2023 Market Monitoring Report. Available online: https://www.acer.europa.eu/sites/default/files/documents/Publications/ACER_MMR_Key_Developments_Gas_2023.pdf (accessed on 29 June 2023).

- LNG Terminal Expansion Program. Available online: https://www.gaz-system.pl/pl/terminal-lng/program-rozbudowy-terminalu-lng.html (accessed on 12 July 2023).

- Energy Policy of Poland until 2040. Warsaw. 2021. Available online: https://www.gov.pl/web/climate (accessed on 30 June 2023).

- Ministry of Climate and Environment. Available online: https://www.gov.pl/web/climate (accessed on 30 June 2023).

- Energy Regulatory Office. Available online: https://www.ure.gov.pl/en (accessed on 10 July 2023).

- Cieślik, T.; Narloch, P.; Szurlej, A.; Kogut, K. Indirect Impact of the COVID-19 Pandemic on Natural Gas Consumption by Commercial Consumers in a Selected City in Poland. Energies 2022, 15, 1393. [Google Scholar] [CrossRef]

- Pellegrino, S.; Lanzini, A.; Leone, P. Greening the gas network—The need for modelling the distributed injection of alternative fuels. Renew. Sustain. Energy Rev. 2017, 70, 266–286. [Google Scholar] [CrossRef]

- Rosłonek, G. Liquefied Natural Gas—LNG. Part I—General issues and basics of the settlement process (Skroplony gaz ziemny—LNG. Część I—Zagadnienia ogólne i podstawy procesu rozliczeniowego). Naft. -Gaz 2016, 2, 87–94. (In Polish) [Google Scholar] [CrossRef]

- Szoplik, J.; Stelmasińska, P. Analysis of gas network storage capacity for alternative fuels in Poland. Energy 2019, 172, 343–353. [Google Scholar] [CrossRef]

- Mozgovoy, A.; Burmeister, F.; Albus, R. Contribution of LNG use for the low calorific natural gas network’s safe and sustainable operation. Energy Procedia 2015, 64, 83–90. [Google Scholar] [CrossRef][Green Version]

- GAZ-SYSTEM. Katalog Punktów Systemu Przesyłowego. Available online: https://swi.gaz-system.pl/swi/public/#!/ksp/points?lang=pl (accessed on 30 June 2023).

- Kuczyński, S.; Kogut, K. Selected aspects of hydrogen transmission safety: Monitoring and hydrogen explosion limits and its admixture with natural gas (Wybrane aspekty bezpieczeństwa przesyłu wodoru: Monitoring oraz granice wybuchowości wodoru i jego mieszaniny z gazem ziemnym). Wiadomości Naft. I Gazow. 2023, 4, 142–149. (In Polish) [Google Scholar]

- Kuczyński, S.; Łaciak, M.; Szurlej, A.; Włodek, T. Impact of liquefied natural gas composition changes on methane number as a fuel quality requirement. Energies 2020, 13, 5060. [Google Scholar] [CrossRef]

- Kuczyński, S.; Łaciak, M.; Olijnyk, A.; Szurlej, A.; Włodek, T. Thermodynamic and Technical Issues of Hydrogen and Methane-Hydrogen Mixtures Pipeline Transmission. Energies 2019, 12, 569. [Google Scholar] [CrossRef]

- Czekała, W.; Jasiński, T.; Dach, J. Profitability of the agricultural biogas plants operation in Poland, depending on the substrate use model. Energy Rep. 2023, 9, 196–203. [Google Scholar] [CrossRef]

- Grządzielski, W. Sieci gazowe wsparciem dla rozwoju OZE. Rynek Energii 2023, 3, 18–22. [Google Scholar]

- International Energy Agency. Global Hydrogen Review 2023. Available online: https://www.iea.org/reports/global-hydrogen-review-2023 (accessed on 20 September 2023).

- Biały, R.; Szurlej, A.; Sikora, A.P.; Potempa, M. The challenges facing the European chemical industry in the context of the EU’s Hydrogen Strategy (Wyzwania stojące przed europejskim przemysłem chemicznym w kontekście unijnej strategii wodorowej). Przemysł Chem. 2020, 8, 1101–1105. (In Polish) [Google Scholar]

- Komorowska, A.; Benalcazar, P.; Kamiński, J. Evaluating the competitiveness and uncertainty of offshore wind-to-hydrogen production: A case study of Poland. Int. J. Hydrogen Energy 2023, 48, 14577–14590. [Google Scholar] [CrossRef]

- Blacharski, T.; Kogut, K.; Szurlej, A. The perspectives for the use of hydrogen for electricity storage considering the foreign experience. In Proceedings of the E3S Web of Conferences, ENERGY AND FUELS 2016, Cracow, Poland, 21–23 September 2016. [Google Scholar]

- Włodek, T.; Polański, K.; Panek, W. Effect of hydrogen on natural gas pipeline transmission system in aspect of possibilities of hydrogen energy storage in northern Poland (Wpływ obecności wodoru na system przesyłowy gazu ziemnego w północnej Polsce w aspekcie możliwości magazynowania energii w postaci wodoru). Przemysł Chem. 2019, 98, 817–820. (In Polish) [Google Scholar]

- Jędral, W. Energy storage and hydrogen power as an outcome of the energy transition (Magazynowanie energii i energetyka wodorowa jako wynik tranformacji energetycznej). Rynek Energii 2022, 4, 8–15. (In Polish) [Google Scholar]

- Tuz, L.; Kąc, S.; Sierakowski, D. Technology of electron beam welding of 10CrMo9-10 steel with the specific quality requirements. Manuf. Lett. 2023, 35, 53–57. [Google Scholar] [CrossRef]

- Tuz, L. Evaluation of microstructure and selected mechanical properties of laser beam welded S690QL high-strength steel. Adv. Mater. Sci. 2018, 18, 34–42. [Google Scholar] [CrossRef]

- Tuz, L. Determination of the causes of low service life of the air fan impeller made of high-strength steel. Eng. Fail. Anal. 2021, 127, 105502. [Google Scholar] [CrossRef]

- El Hajj Chehade, A.M.; Daher, E.A.; Assaf, J.C.; Riachi, B.; Hamd, W. Simulation and optimization of hydrogen production by steam reforming of natural gas for refining and petrochemical demands in Lebanon. Int. J. Hydrogen Energy 2020, 45, 33235–33247. [Google Scholar] [CrossRef]

- Holt, J.E.; Kreusser, J.; Herritsch, A.; Watson, M. Numerical modelling of a steam methane reformer. ANZIAM J. 2018, 59, 112–127. [Google Scholar] [CrossRef]

- Hou, K.; Hughes, R. The kinetics of methane steam reforming over a Ni/a-Al2O catalyst. Chem. Eng. J. 2001, 82, 311–328. [Google Scholar] [CrossRef]

- Xu, J.; Froment, G.F. Methane steam reforming, methanation and water-gas shift: I. Intrinsic kinetics. AICheE J. 1989, 35, 88–96. [Google Scholar] [CrossRef]

- Zyryanova, M.M.; Snytnikov, P.V.; Shigarov, A.B.; Belyaev, V.D.; Kirillov, V.A.; Sobyanin, V.A. Low temperature catalytic steam reforming of propane-methane mixture into methane-rich gas: Experiment and microkinetic modeling. Fuel 2014, 135, 76–82. [Google Scholar] [CrossRef]

- Øyen, S.B.; Jakobsen, H.A.; Haug-Warberg, T.; Solvik, J. Differential Gibbs and Helmholtz reactor models for ideal and non-ideal gases: Applications to the SMR and methanol processes. Chem. Eng. Sci. 2021, 234, 116257. [Google Scholar] [CrossRef]

- Solvik, J.; Haug-Warberg, T.; Jakobsen, H.A. Implementation of chemical reaction equilibrium by Gibbs and Helmholtz energies in tubular reactor models: Application to the steam-methane reforming process. Chem. Eng. Sci. 2016, 140, 261–278. [Google Scholar] [CrossRef]

- Bahadori, A.; Kashiwao, T. Modeling and analysis of hydrogen production in steam methane reforming (SMR) process. Petroleum Sci. Technol. 2019, 37, 1425–1435. [Google Scholar] [CrossRef]

- Izquierdo, U.; Barrio, V.L.; Cambra, J.F.; Requies, J.; Guemez, M.B.; Arias, P.L.; Kolb, G.; Zapf, R.; Gutierrex, A.M.; Arraibi, J.R. Hydrogen production from methane and natural gas steam reforming in conventional and microreactor reaction systems. Int. J. Hydrogen Energy 2012, 8, 7026–7033. [Google Scholar] [CrossRef]

- Shokrollahi Yancheshmeh, M.S.; Seifzadeh Haghighi, S.; Gholipour, M.R.; Dehghani, O.; Rahimpour, M.R.; Raeissi, S. Modeling of ethane pyrolysis process: A study on effects of steam and carbon dioxide on ethylene and hydrogen productions. Chem. Eng. J. 2013, 215–216, 550–560. [Google Scholar] [CrossRef]

| Terminal | Country | Average Utilization 2018–2021 | Average Utilization 2022 |

|---|---|---|---|

| Zeebrugge LNG Terminal | BE | 29 | 61 |

| Barcelona LNG Terminal | ES | 23 | 23 |

| Bilbao LNG Terminal | ES | 60 | 76 |

| Sagunto LNG Terminal | ES | 16 | 46 |

| Dunkerque LNG Terminal | FR | 25 | 75 |

| Fos Cavaou LNG Terminal | FR | 48 | 92 |

| Revythoussa LNG Terminal | GR | 27 | 39 |

| Panigaglia LNG Terminal | IT | 42 | 54 |

| FSRU Independence | LT | 37 | 72 |

| Rotterdam Gate Terminal | NL | 41 | 92 |

| Świnoujście LNG Terminal | PL | 61 | 80 |

| Sines LNG Terminal | PT | 77 | 82 |

| 2020 | 2021 | 2022 | |

|---|---|---|---|

| Gas sales to end users | 201,133.2 | 206,626.7 | 171,795.0 |

| Industry | 132,731.7 | 126,137.1 | 96,963.7 |

| Trade and services | 14,570.0 | 15,639.3 | 11,913.4 |

| Households | 49,878.7 | 59,265.2 | 56,200.9 |

| Total | 203,145.9 | 208,626.0 | 173,763.2 |

| # Year | CH4 [%v/v] | C2H6 [%v/v] | C3H8 [%v/v] | N2 * [%v/v] | i-C4H10 [%v/v] | i-C5H12 [%v/v] | n-C4H10 [%v/v] | n-C5H12 [%v/v] | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 2015 | 94.46 | 1.20 | 0.24 | 3.99 | 0.04 | 0.01 | 0.06 | 0.01 |

| 2 | 97.35 | 1.47 | 0.25 | 0.84 | 0.04 | 0.01 | 0.04 | 0.00 | |

| 3 | 2020 | 92.45 | 5.26 | 1.34 | 0.53 | 0.11 | 0.02 | 0.29 | 0.00 |

| 4 | 97.15 | 1.64 | 0.16 | 0.94 | 0.03 | 0.01 | 0.09 | 0.00 | |

| 5 | 2022 | 91.46 | 6.44 | 0.70 | 1.23 | 0.06 | 0.01 | 0.10 | 0.01 |

| 6 | 97.12 | 2.57 | 0.11 | 0.18 | 0.01 | 0.01 | 0.01 | 0.00 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Biały, R.; Żywczak, A.; Szurlej, A. The Influence of the Changes in Natural Gas Supplies to Poland on the Amount of Hydrogen Produced in the SMR Reactor. Energies 2024, 17, 1221. https://doi.org/10.3390/en17051221

Biały R, Żywczak A, Szurlej A. The Influence of the Changes in Natural Gas Supplies to Poland on the Amount of Hydrogen Produced in the SMR Reactor. Energies. 2024; 17(5):1221. https://doi.org/10.3390/en17051221

Chicago/Turabian StyleBiały, Rafał, Antoni Żywczak, and Adam Szurlej. 2024. "The Influence of the Changes in Natural Gas Supplies to Poland on the Amount of Hydrogen Produced in the SMR Reactor" Energies 17, no. 5: 1221. https://doi.org/10.3390/en17051221

APA StyleBiały, R., Żywczak, A., & Szurlej, A. (2024). The Influence of the Changes in Natural Gas Supplies to Poland on the Amount of Hydrogen Produced in the SMR Reactor. Energies, 17(5), 1221. https://doi.org/10.3390/en17051221