Abstract

Industry 4.0 and Industry 5.0 have introduced a lot of innovative technologies in industrial plants, transforming them into complex digital systems. On the other hand, the importance of Energy Management Systems in industrial plants is growing for both sustainability and economic reasons, but the opportunity of Industry 4.0/5.0 technologies in enhancing energy management systems is not fully understood. Thus, this paper analyzes how Industry 4.0/5.0 technologies can be applied to meet the requirements of Energy Management Systems, focusing on each aspect such as design, monitoring, control, and budget planning. It identifies additional opportunities that arise with different levels of technological implementation, suggesting organic implementation steps. The final aim is to provide a comprehensive framework for fostering a strategic and conscious implementation approach of these tools in the Energy Management Systems of industrial plants, giving clear and comprehensive suggestions.

1. Introduction

In today’s world, managing energy efficiently is not just a way to cut costs; it is a crucial strategy for any organization aiming for economic stability and environmental sustainability. It has strategic value as a source of competitive advantage and flexibility in the global market, ensuring a reduction in production costs and compliance with other constraints on quality and delivery times [1,2,3]. Also, considering that industries are major energy consumers and, as a result, significant contributors to greenhouse gas emissions, it is clear that focusing on energy management is essential for sustainable progress [4,5].

On the other hand, the advent of Industry 4.0 and its evolution into Industry 5.0 has brought about a new era of technological progress in the fields of wireless connection, data analytics, and automation [6]. As a result, industrial plants are changing their appearance and becoming increasingly complex digital systems [7]. The technologies and, consequently, the new opportunities of innovation arising from the Industry 4.0/5.0 era are various and quite different. Nevertheless, some disadvantages and drawbacks related to the introduction of Industry 4.0/5.0 technologies are present such as significant investments in terms of hardware, software, and staff training and resistance to change. Digitalization and advanced automation require robust IT infrastructure, data centers, sensors, and connected devices that operate continuously, which can also lead to a significant increase in energy needs. Therefore, when engaging in the assessment and implementation of these new technologies, it is crucial to carefully weigh the opportunities against the costs to keep a balanced approach.

In order to guide this change in a conscious and effective way, it is important to acquire a clear comprehension of the scenario available.

Furthermore, the impact of innovation depends strongly on the specific aspect of the industrial environment examined, and while there is a rising body of scientific literature exploring the connection between Industry 4.0/5.0 technologies and various aspects of energy management and production (e.g., IoT applications in energy, renewables, and smart grids, artificial intelligence for performance monitoring and optimization, etc.), the broader implications of these technologies for energy management systems have yet to be fully explored, identifying in a comprehensive way the opportunities now available and providing suggestions about the steps to guide a successful implementation.

In a recent work, Tesch da Silva et al. identified technologies used to monitor, manage, and predict energy consumption, highlighting the limitations in the implementation of energy efficiency strategies caused by a lack of adequate monitoring systems and resources, both technical and human, for efficiently gaining knowledge from collected data [8].

Hasan and Trianni focused on highlighting the role of Industry 4.0 technologies in boosting the impacts on production resources and operational performances in relation to the selection of energy efficiency measures [9].

Acknowledging the contributions of these studies, our research aims to provide a comprehensive analysis of the potential applications of Industry 4.0 and 5.0 technologies within an energy management system (EMS). We intend to systematically explore the impact of these technologies on EMS, offering a structured overview of the emerging opportunities for all the key aspects of an EMS (e.g., design, monitoring and control, budgetary planning and control, etc.). To the best of our knowledge, this is the first paper that focuses on providing a clear overall framework of the opportunities deriving from these new tools in the specific context of a transformation of the energy management system of an industrial plant towards the paradigms of 4.0 and 5.0.

The paper seeks to answer the following research questions:

- How can Industry 4.0 and 5.0 technologies be integrated into an energy management system (EMS)?

- What steps should be followed to support the successful implementation of the different technologies in EMS?

The paper is structured as follows: Section 2 describes the background of the problem, discussing the various aspects of an energy management system and the key technologies that characterize the paradigms of “Industry 4.0” and “Industry 5.0”. Section 3 provides a description of the methodology adopted for the analysis and the definition of a comprehensive framework for the implementation of 4.0/5.0 technologies in an EMS, while Section 4 shows the proposed framework. Finally, Section 5 concludes the article, presenting the main conclusions and possible developments of the study.

2. Background

2.1. Energy Management Systems (EMS)

The objective of energy management is to provide energy to the organization in the most efficient and effective way possible, both in terms of supply and utilization by the final users [10,11]. To guarantee those objectives, energy management requires a systematic and continuous approach, as described by the International Standard for Energy Management System, the ISO 50001 [10,12].

Energy is a transversal aspect in the management of an industrial production plant, just like quality, safety, and sustainability. According to ISO 50001, an Energy Management System is a “set of interrelated or interacting elements to establish an energy policy and energy objectives, and processes and procedures to achieve those objectives” [12]. The key aspects of an energy management system can be highlighted following the structure of the international standard ISO 50001 [12].

First, starting from an energy policy, through the definition of objectives, the organization shall translate the policy at all relevant functions and levels. Furthermore, the objectives must explain themselves in specific energy targets, which are continuously monitored.

To do so, it is important to define energy performance indicators (EnPIs) and the corresponding energy performance baselines (EnB). These indicators can be of different typologies. The simplest ones, represented by single absolute values of energy consumption or ratios between them and relevant factors, are more commonly used. Moreover, they can be derived from either the Energy Intensity (EI) ratio or the Specific Energy Consumption (SEC) ratio. In addition, to take into account influential drivers, statistical and engineering models can be used to create more complex indicators [13,14].

After their definition, the indicators must be monitored in order to not only rapidly identify possible anomalies in the energy performance but also compare their value with the ones planned in the final energy review at the end of the year.

Another important activity in the energy management system is the definition of the energy budget and the consequent analysis of the variance between the prediction and actual values [15,16]. This kind of analysis is necessary in carrying out budgetary control and enabling top management to identify the reasons behind the occurrence and assign responsibility to different cost/responsibility centers [2].

Data collection and monitoring are fundamental to leading all the activities mentioned above.

Furthermore, as for all management systems, the implementation of suitable and effective communication and documentation management is critical: all methods and criteria used to develop the energy review, energy indicators, evaluations of the action plan, its status, and energy management opportunities (EMOs), and all the general internal and external communication must be retained in the system [12].

Regarding operational activities, according to ISO 50001 (2018), “the organization shall plan, implement and control the processes, related to its Significant Energy Uses to meet requirements and to implement the actions determined”. This means that the organization must set operational criteria for all relevant processes and activities such as the maintenance of significant equipment and systems.

Moreover, design and procurement are also important aspects in the energy management system. Regarding the first, the organization has to consider and evaluate the opportunity of an energy performance improvement when designing new or modified facilities, equipment, systems, and energy-using processes. Regarding the latter, the organization must define evaluation criteria and specifications for the energy performance of the equipment and services and for the purchase of energy [12].

2.2. Industry 4.0/5.0 and Key Technologies

Intelligence is a key element for the future development of manufacturing and is set to affect the business globally, at different levels, with the aim of providing the flexibility necessary to change in response to production rapidly [17].

The concept of “Industry 4.0” was introduced in 2011 by the initiative of the German federal government and refers to the “4th industrial revolution”—the last, still ongoing, transformation in the industry environment after the previous three, characterized, respectively, by the steam machine, the use of electricity in industrial processes, and the utilization of ICT (Information and Communications Technology) and industrial automation [6,18,19].

As a result of the increasing advances in IT and electronics, the paradigm of Industry 4.0 is connected to the concept of advanced or “Smart” manufacturing and is founded on the integration of organizations, equipment, humans, and products and the continuous communication between them in order to establish an efficient, collaborative, and sustainable industrial production [17,20].

To summarize the main aspects of the technological innovation described in the paradigm “Industry 4.0”, nine key technologies have been identified in the scientific literature [19,21]:

- Internet of Things (IoT);

- Big Data and Analytics;

- Simulation;

- Cloud;

- System Integration: Horizontal and Vertical System Integration;

- Augmented Reality;

- Autonomous Robots;

- Additive manufacturing;

- Cyber security.

The Internet of Things (IoT) paradigm is defined as an integrated system of interconnected and intelligent devices that connect objects, people, and places [19].

In this context, a smart object is an object that has self-awareness, the capacity for self-diagnosis, and location awareness; it can interact with other smart objects and the surrounding environment (e.g., actuators) and possesses some capacities of data processing. In the manufacturing industry, the IoT uses wireless devices such as RFID and wireless sensor networks to acquire information from the shop floor (such as the machine status, inventory levels, energy consumption, etc.). [22].

As a consequence, to gain value from all the new data now available, new algorithms, based on machine learning, have been developed to carry out data mining and analytics. Four different types of machine learning algorithms (unsupervised learning, supervised learning, semi-supervised learning, and reinforcement learning) are used in manufacturing to analyze data both offline and online for various purposes (such as trend analysis, process monitoring, fault diagnosis, fault classification, online soft sensing, quality prediction, etc.) [7].

Moreover, simulation is a technique that can be used to predict the behavior of real complex systems in industrial plants. In doing so, simulation can provide the knowledge necessary to support manufacturing decisions, such as designing factory layouts, supply chain interoperations, developing production plans, and evaluating the benefits and risks of strategies [23].

Cloud-based IT platforms are used by organizations to increase their capacity for data sharing across the sites and companies [19]. Moreover, progress in cloud computing can provide access to larger datasets and to clusters of remote processors, allowing the user to achieve a modeling performance that he would not have obtained otherwise [24].

A key concept of “Industry 4.0” is to improve the manufacturing environment to make data available for all the relevant actors. The paradigm stretches in three directions of integration [25]:

- horizontal integration across the entire value creation network;

- vertical integration and networked manufacturing systems;

- end-to-end engineering across the entire product life cycle.

Moreover, augmented reality (AR) is a term used to describe an enhanced version of reality where the view of the physical world (live or not) is augmented with superimposed images, generated by a computer. This technology could be used to improve both the design process and the real operations [24,26]. As for robots, they are becoming increasingly more autonomous, flexible, and cooperative, beginning to interact with one another as well as the environment, and working safely near humans [19,24].

In order to fulfil the need for mass customization, new nontraditional manufacturing methods are being developed. Additive manufacturing is capable of satisfying this request, since it can create objects with advanced attributes (new materials, complex shapes) and enable delocalized production, reducing transport distances and the need for stock [19,27].

Additionally, cyber security is a critical issue in the new industrial scenario generated by this rapid innovation in data storage and IT devices. Various properties, such as confidentiality, integrity, authentication, authorization, non-repudiation, availability, and privacy, must be guaranteed in order to provide security for the IoT systems [28].

Recently, the concept of “Industry 5.0” has been introduced—in particular, after the publishing of the policy paper “Industry 5.0, a transformative vision for Europe—Governing systemic transformations towards a sustainable industry” in 2021 [29]. This document, drawn up by the ESIR (Expert group on the economic and societal impact of research and innovation—a high-level expert group that provides evidence-based policy advice to the European Commission on how to develop transformative research and innovation policy), argues that the industrial model based predominantly on technology and growth orientation (i.e., Industry 4.0) is not sufficient to achieve the European objectives for 2030 and 2050.

Thus, Industry 5.0 builds on Industry 4.0’s foundation of smart technologies and automation but places a greater focus on personalization, sustainability, and the collaboration between humans and machines. It seeks to achieve a balance between technological advancements and the enhancement of human creativity and well-being, with the goal of more resilient, sustainable, and customized production processes. This approach not only aims to increase efficiency and productivity but also to ensure that technological progress benefits society as a whole, addressing ethical, environmental, and social concerns in the industrial sector [30,31].

The EU Commission identified six enabling technologies of Industry 5.0 [32]:

- Individualized human–machine interaction (HMI);

- Bioinspired technologies and smart materials;

- Digital twins and simulation;

- Data transmission, storage, and analysis technologies;

- Artificial Intelligence (AI);

- Technologies for energy efficiency, renewables, storage, and autonomy.

Individualized HMI comprises various technologies for aiding humans in both physical and cognitive tasks such as multilingual speech and gesture recognition, tracking technologies designed to monitor the mental and physical strain and stress levels of employees, robotics, including collaborative robots (“cobots”) that cooperate with humans and provide assistance, augmented, virtual, or mixed reality technologies, and tools for enhancing physical human capabilities—exoskeletons, bioinspired working gear, and safety equipment—or cognitive human capabilities. The concept of Virtual Reality (VR) as “immersing users in an artificially created reality” existed before Augmented Reality was considered. Although there are some exceptions, such as VR caves, VR has historically been centered on applications that involve wearing headsets—head-mounted systems that block out the real world and replace it with a virtual environment for the user [33,34,35]. XR, often standing for “extended reality”, is commonly used as a general term encompassing various related concepts—primarily, Augmented Reality and Virtual Reality [33,35].

Furthermore, bioinspired technologies and smart materials address the integration of properties, such as self-healing or self-repairing capabilities, a lightweight composition, recyclability, or the generation of raw materials from waste, and the incorporation of living materials and embedded sensor technologies and biosensors, as well as materials with intrinsic traceability [32].

Digital Twins (DT) are virtual representations or digital counterparts of a physical entity (object, system, or process). Both physical and digital twins require network devices to ensure uninterrupted connectivity and the constant exchange of data. This exchange can occur through direct physical communication or indirect cloud-based connections. This continuous connection allows the digital twin to receive real-time physical twin data, reflecting the physical twin’s current status and its evolution over its lifecycle. Additionally, it receives dynamic environment data, providing insights into the surrounding conditions. Furthermore, DT continuously transmits predictions and recommendations for system maintenance and performance optimization to its physical twin, domain experts, and other digital twins within the environment [36,37,38,39].

Within the category “data transmission, storage, and analysis technologies”, instead, several technological innovations are identified: from network sensors and edge computing to cybersecurity and traceability. Fog Computing (FC) is a system-level architecture developed to bridge the gap between IoT and cloud computing by distributing resources and services across the spectrum from the Cloud to the IoT [40]. Similarly, Edge Computing (EC) aims to bring computational resources closer to the data source. In this case, EC enables data processing at the network edge, reducing latency, communication costs, and enhancing data security and privacy. Thus, EC is crucial for real-time applications such as remote patient monitoring, autonomous vehicles, and Unmanned Aerial Vehicles [30,41].

It is also important to note that while IoT, right now, uses different wireless technologies such as 2G, 3G, 4G, Bluetooth, and Wi-Fi, these technologies are not fully suited for IoT, which demands low power and lower data rates. This is leading to a shift from various wireless technologies toward the development of 5G and 6G [41]. 6G is the future radio infrastructure that aims to provide added value services with better latency, support for high-quality services, and an extensive IoT infrastructure integrated with AI capabilities [30].

Artificial Intelligence has been defined as “a system’s ability to correctly interpret external data, to learn from such data, and to use those learnings to achieve specific goals and tasks through flexible adaptation” [42]. An interesting subset of AI is generative AI. It is used to create new content (e.g., images, text, etc.) and is developed through training on huge amounts of data in order to create outputs based on user prompts [43]

Finally, given the high energy demands of most of the mentioned technologies, the following measures and properties are considered crucial by the EU Commission in obtaining sustainable progress: renewable energy sources, hydrogen and Power-to-X (PtX) technologies, smart dust and energy autonomous sensors, energy-efficient data transmission, and data analysis methods. PtX technologies refer to a group of processes that convert electrical power into various forms of energy carriers or chemical products. These technologies are usually used to store excess electricity from renewable sources, such as wind or solar energy, and convert it into more versatile and storable energy forms or valuable chemicals [44].

3. Methodology for Framework Design

3.1. Introduction

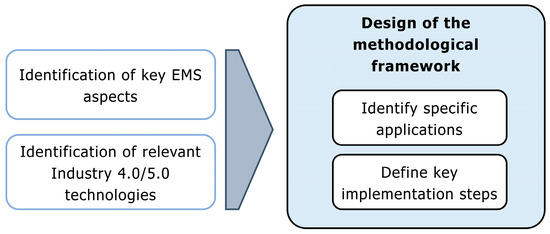

Figure 1 presents the methodology for the design of the framework. First, both key aspects of an energy management system and key Industry 4.0/5.0 technologies have been identified. Then, using the two lists as a starting point, each item of the former list has been evaluated in relation to each item of the latter to identify specific applications.

Figure 1.

Methodological steps for designing the proposed framework.

Then, after the definition of key implementation steps for introducing and developing technological innovations in EMS, a comprehensive and logical framework of the applications of Industry 4.0/5.0 technologies in an energy management system has been developed.

3.2. Identification of Key EMS Aspects

From the overview provided in Section 2.1, the key aspects of an energy management system have been identified as follows:

- Energy Policy (Clause 5.2): Sets the foundation for defining EnPIs and the energy baseline, crucial for establishing energy performance goals.

- Energy Planning (Clause 6.1): Includes identifying legal and other requirements essential for defining and analyzing the energy budget and its variance.

- Energy Objectives, Targets, and Action Plans (Clause 6.2): Setting and meeting energy targets critical for monitoring compliance and performance.

- Energy Review (Clause 6.3): Focuses on identifying significant energy uses and opportunities for improvement, aiding in the analysis of energy management opportunities, and the identification of anomalies in energy performance.

- Energy Performance Indicators (EnPIs) (Clause 6.4): Essential for the definition, monitoring, and control of compliance with energy targets.

- Energy Baseline (Clause 6.5): Establishes a reference for the comparison of performance over time, integral to the definition of EnPIs.

- Competence, Training, and Awareness (Clause 7.2–3): Ensures staff are aware of their role in the energy management system, supporting effective communication and documentation management.

- Communication (Clause 7.4): Developing internal and external communication processes about EnMS.

- Documentation and Records (Clause 7.5): Maintaining documents and records for effective implementation, crucial for communication and documentation management.

- Operational Control (Clause 8.1): Establishing procedures for significant energy uses, including the optimization of process/equipment set points, maintenance, and set-up operations.

- Design (Clause 8.2): Considering energy performance in design, relevant to evaluating alternatives in purchasing and design.

- Procurement of Energy Services, Products, and Equipment (Clause 8.3): Integrating energy performance considerations into procurement practices.

- Monitoring, Measurement, and Analysis (Clause 9.1): Key for data collection, monitoring, the control of compliance with EnPIs, and identifying anomalies in energy performance.

- Evaluation of Legal Compliance (Clause 9.1.2): Regular evaluations ensure adherence to legal requirements, impacting the energy budget and its variance.

- Internal Audit (Clause 9.2): Ensuring the EnMS conforms to planned arrangements and is effectively implemented and maintained.

- Management Review (Clause 9.3): Ensuring the continuing suitability, adequacy, and effectiveness of the EnMS.

- Nonconformity, Corrective and Preventive Actions (Clause 10.1): Addressing nonconformities and taking corrective actions.

- Continuous Improvement (Clause 10.2): The overarching goal encompassing all aspects of the EnMS, including the analysis of energy management opportunities and optimization processes.

3.3. Identification of Relevant Industry 4.0/5.0 Technologies

As for the nature of Industry 4.0 and Industry 5.0 paradigms, there is a clear overlap between the relevant enabling technologies.

To create a more direct framework, technologies have been grouped into six categories, as described in Table 1.

Table 1.

Categories of Industry 4.0 and Industry 5.0 technologies.

3.4. Assosiations’ Analysis

In order to identify how the “Industry 4.0” and “Industry 5.0” technologies identified in Table 1 could be applied to the key aspects of an energy management system (described previously), the authors have searched the scientific literature elements to argue for the existence of the specific intersection and describe the methods and practices found to implement it.

Applications of the specific technology in other fields for similar purposes (e.g., maintenance, optimization, etc.), which are not explicitly found in the literature in reference to energy management systems, have also been included to give a comprehensive outlook of all opportunities of improvement.

Finally, the ensemble of identified practices has been revised including inputs from practitioners and technologies experts using interviews and an exploratory technology review of existing technologies.

3.5. Design

In order to create a comprehensive and logical framework, the design comprises two steps:

- Identify specific applications

- Define the key implementation steps for introducing and developing technological innovations in the EMS

First, to identify specific applications, each item of the list of the Energy Management System’s (EMS) key aspects and the list of relevant “Industry 4.0/5.0” key technologies selected has been intersected. For every intersection, the authors have searched the scientific literature and industry practices elements to argue for the existence of the specific intersection and describe the methods and practices needed to implement it.

The result of this first analysis is then further examined to identify how the different technologies can be implemented on a progressive path. Thus, attention has been focused on defining implementation steps to associate with each intersection.

The implementation steps have been defined as follows:

- Preliminary Introductions

These should be the first actions, as they lay the foundation for further implementations.

- 2.

- Basic Implementations

Once the foundation is established, these steps can be taken to begin seeing tangible improvements.

- 3.

- Optimization and Integration

Once the basic systems are in place and the staff are trained, you can move on to optimization.

- 4.

- Innovations and Scalability

These steps focus on expansion and continuous innovation.

- 5.

- Maintenance and Continuous Improvement

Finally, this step regards the maintenance and continuous improvement of the technologies implemented.

4. Results

4.1. Association EMS Aspect-I 4.0/5.0 Technology

Table 2 reports how all relevant “Industry 4.0/5.0” key technologies can be associated with the key aspects of the Energy Management System (EMS), as identified following the “Associations’ analysis” step in the methodology.

Table 2.

Association of key aspects of ISO 50001 and Industry 4.0/5.0 technologies.

The innovative tools provided by Industry 4.0/5.0 can have multiple benefits for the various aspects of an energy management system.

Internet of Things (IoT), big data and analytics, the cloud, and simulation are key technologies showing the diverse possibilities of applications inside an energy management system. In fact, the definition of energy performance baselines (EnB) and energy performance indicators (EnPIs) can benefit from the presence of an IoT-based intelligent infrastructure that allows for the monitoring and collection of large amounts of complex data that could be used as the input for machine learning or simulation models.

When used to define EnPIs, this kind of model can take into account the influence of operational parameters and ambient conditions, as well as non-linear behavior. These baseline models provide greater reliability and efficiency in controlling compliance with the energy targets and in detecting anomalies in the energy behavior of the system. In fact, they can provide a better estimation of the baseline behavior of the system. The deviation between the energy consumption calculated with the model and the actual energy consumption could be statistically analyzed to evaluate its significance and thus allow for a more sensitive control system [7,22,23,45,46,47,48,49,50,51].

Moreover, simulation and Digital Twins can be implemented to promote several applications such as design, operational control, maintenance, performance monitoring, and prediction [52].

Furthermore, the wireless and real-time data acquisition provided by IoT increases the ability of operators to act in a timely manner in regard to anomalous deviations in the energy consumption [7,22,46,48,49].

Additionally, energy accounting procedures can be supported by data analytics. Complex models can be used to predict future energy consumption and consequently define the energy budget. Moreover, these techniques enable the evaluation of the variance between the predicted energy budget and the actual energy cost, identifying and correctly directing the cause to the right responsibility/cost center [2,16].

At the same time, through the use of different machine learning models, it is possible to evaluate the best purchasing contract according to the specific need of the organization. In fact, due to the heterogeneous nature of the different contract proposals for services and equipment, it is generally quite difficult to distinguish the best alternative. Moreover, different scenarios can also be tested through simulation to identify the best opportunity in terms of design or purchase. (e.g., choice among different hourly tariffs, the dimensioning and selection of equipment, set point optimization, etc.) [23,51,53].

Even maintenance processes might benefit from the use of more complex modeling, such as machine learning in an attempt to improve the maintenance policy and decrease the downtime. Indeed, depending on the complexity of the evolution of the failure, the availability of data and the technique used, it is not only possible to detect failures in assets but also to operate a diagnostic control, identifying the cause of the failure [49,54,55]. Moreover, generative AI can be used to improve training and continually support and improve knowledge transfer, enhancing onboarding and daily tasks through virtual assistance [56].

On the other hand, the execution of activities such as set-up and maintenance interventions could be greatly improved by the utilization of augmented reality or autonomous robots in order to support the operators and improve their safety—for example, providing guidance from a more skilled operator through a remote connection [26,57,58] The use of robots might also optimize the execution of the specific activity, increasing its speed and quality [24]. Additionally, these activities could gain efficiency and effectiveness through the use of mobile devices that can provide the operator with additional data, information, and specifics for performing the task in a better way [59,60]. Additive manufacturing can also be useful for the maintenance process, creating spare parts in order to reduce the downtime of the machines affected [61].

Furthermore, almost every task that requires the use of analytics or the handling of enormous amounts of data could benefit from the use of cloud platforms and cloud computing. Continuous progress in terms of storage capacity and development power is critical to the implementation of a real-time management system [7,19,24]. Similarly, the use of fog and edge computing can foster the better real-time control and optimization of energy usage [8,62,63]. The presence of real-time information sharing also supports the continuous collection of improvement suggestions (kaizen) to drive continuous improvement.

Finally, the system integration has the potential to make the communication management more flexible and controlled, connecting all the relevant actors of the management system in order to foster the achievement of the energy targets [25]. Data and information shared among stakeholders need to be protected by effective cybersecurity practices. To further secure critical information, blockchain can play an important role by providing a transparent, immutable record of energy transactions and communications, fostering trust inside the organization [64,65].

4.2. Proposed Framework of I 4.0/5.0 Technologies in ISO 50001

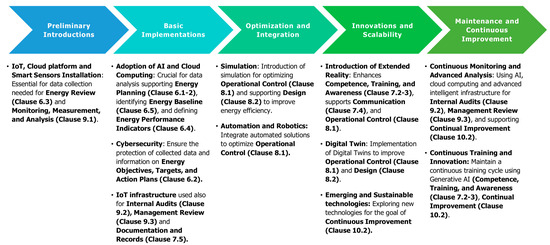

Figure 2 represents the proposed framework. For each implementation step, relevant “Industry 4.0/5.0” technologies are identified to support an organic introduction in the Energy Management System.

Figure 2.

Implementation steps for “Industry 4.0/5.0” key technologies in an Energy Management System.

In the first implementation step “Preliminary Introductions”, the technologies useful to any modern energy management system are to be implemented, such as IoT, cloud platforms, and smart sensors. They enable real-time data collection and analysis. This is critical for understanding the current energy use (Energy Review, Clause 6.3) and for setting the basis for effective monitoring, measurement, and analysis (Clause 9.1).

Then, in the next step “Basic implementations”, AI and cloud computing can be introduced to analyze data collected via IoT and sensors and identify patterns, thus gaining insights that could escape human analysis, supporting energy planning (Clause 6.1 and Clause 6.2), establishing an energy baseline (Clause 6.5), and defining key performance indicators (Clause 6.4). At the same time, it is important to start to pay attention to implementing an effective cybersecurity to protect the integrity and confidentiality of data collected and analyzed, especially for sensitive information about the objectives and action plan data (Clause 6.2).

The “Optimization and Integration” step concerns the introduction of other technologies, such as simulation and robotics. These technologies are used to improve operational control (Clause 8.1) and support design decisions (Clause 8.2), leading to greater energy efficiency and waste reduction, reducing human errors, and increasing efficiency.

In the next step “Innovations and Scalability”, simulation technologies are improved to create Digital Twins for real-time monitoring (Clause 8.1) and scenario analysis (Clause 8.2). Similarly, AR and VR technologies are introduced to improve training (Clause 7.2–3), communication (Clause 7.4), and operational control (Clause 8.1). Emerging technologies begin to be investigated, promoting continuous improvement (Clause 10.12).

Finally, the last implementation step, “Maintenance and Continuous Improvement”, expects the continuous use of AI and cloud computing for data analysis, supporting internal audits, management reviews, and the identification of areas for improvement. Leveraging generative AI for training can ensure that staff remain up to date (Clause 7.2–3), promoting a culture of continuous improvement (Clause 10.2).

5. Conclusions

In this paper, a comprehensive analysis has been presented in order to highlight the new opportunities arising from the “Industry 4.0”and “Industry 5.0” paradigms in reference to the energy management system.

In the Section 4, two main outputs are proposed: a clear analysis of how relevant “Industry 4.0/5.0” technologies can be applied for the key aspects of ISO 50001 and an implementation framework that defines five implementation steps of “Industry 4.0/5.0” technologies in the energy management systems.

The framework provides new insights into the integration process of Industry 4.0/5.0 technologies in the energy management system, highlighting how key technologies can be used to improve the system itself, with specific potential benefits. Defining five implementation steps offers practical applications for businesses and energy managers, clearly suggesting how Industry 4.0/5.0 technologies can be effectively implemented to foster the EMS improvement.

Indeed, the proposed framework aims to be a new tool in supporting the decision-making process of energy managers that want to lead their industrial plant towards the paradigm of 4.0/5.0 but are not yet conscious of what methods and technologies can be applied to their energy management system to achieve that objective.

These advancements, while promising, are not without their challenges and drawbacks. Among them, there are not only the economic investments required for the acquisition of new technology, which are often energy-intensive, but also the necessity of new skills from the workforce, alongside potential resistance to change from within organizations. In the process of assimilating technologies from Industry 4.0 and 5.0 into their operations, organizations must prioritize a balanced methodology, and the proposal of this framework aims to support organizations in doing so.

Future investigations could explore the role of organizational culture in facilitating or hindering technology integration, providing deeper insights. In addition, comparative studies across different industries could help evaluate differences in adoption, highlighting challenges and benefits.

Finally, further developments of this work could focus on the application of the described framework to specific case studies in order to evaluate the impact of the achievable benefits as well as the possible drawbacks that an implementation of the new technologies could provoke.

Author Contributions

Conceptualization, V.I., A.S. and V.C.; methodology, V.I. and A.S.; writing—original draft preparation, A.S.; writing—review and editing, A.S. and V.I.; supervision, V.I. All authors have read and agreed to the published version of the manuscript.

Funding

The authors wish to acknowledge the support of Project ECS 0000024 Rome Technopole—CUP B83C22002820006, NRP Mission 4 Component 2 Investment 1.5, Funded by the European Union—NextGenerationEU.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Sa, A.; Thollander, P.; Cagno, E. Assessing the Driving Factors for Energy Management Program Adoption. Renew. Sustain. Energy Rev. 2017, 74, 538–547. [Google Scholar] [CrossRef]

- Santolamazza, A.; Introna, V.; Cesarotti, V. Energy Budget Control in Manufacturing Systems with On-Site Energy Generation: An Advanced Methodology for Analyzing Specific Cost Variations. In Proceedings of the Summer School Francesco Turco; AIDI—Italian Association of Industrial Operations Professors: Italy, 2017; Volume 2017, pp. 404–410. [Google Scholar]

- Santolamazza, A.; Introna, V.; Cesarotti, V. Towards an Energy Management System Transformation in an Industrial Plant through Industry 4.0 Technologies. In Proceedings of the Summer School Francesco Turco; AIDI—Italian Association of Industrial Operations Professors: Italy, 2019; Volume 2019, pp. 235–244. [Google Scholar]

- Edelenbosch, O.Y.; Kermeli, K.; Crijns-Graus, W.; Worrell, E.; Bibas, R.; Fais, B.; Fujimori, S.; Kyle, P.; Sano, F.; van Vuuren, D.P. Comparing Projections of Industrial Energy Demand and Greenhouse Gas Emissions in Long-Term Energy Models. Energy 2017, 122, 701–710. [Google Scholar] [CrossRef]

- Salvatori, S.; Benedetti, M.; Bonfà, F.; Introna, V.; Ubertini, S. Inter-Sectorial Benchmarking of Compressed Air Generation Energy Performance: Methodology Based on Real Data Gathering in Large and Energy-Intensive Industrial Firms. Appl. Energy 2018, 217, 266–280. [Google Scholar] [CrossRef]

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The Expected Contribution of Industry 4.0 Technologies for Industrial Performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Ge, Z.; Song, Z.; Ding, S.X.; Huang, B. Data Mining and Analytics in the Process Industry: The Role of Machine Learning. IEEE Access 2017, 5, 20590–20616. [Google Scholar] [CrossRef]

- Tesch Da Silva, F.S.; Da Costa, C.A.; Paredes Crovato, C.D.; Da Rosa Righi, R. Looking at Energy through the Lens of Industry 4.0: A Systematic Literature Review of Concerns and Challenges. Comput. Ind. Eng. 2020, 143, 106426. [Google Scholar] [CrossRef]

- Hasan, A.S.M.M.; Trianni, A. Boosting the Adoption of Industrial Energy Efficiency Measures through Industry 4.0 Technologies to Improve Operational Performance. J. Clean. Prod. 2023, 425, 138597. [Google Scholar] [CrossRef]

- Introna, V.; Cesarotti, V.; Benedetti, M.; Biagiotti, S.; Rotunno, R. Energy Management Maturity Model: An Organizational Tool to Foster the Continuous Reduction of Energy Consumption in Companies. J. Clean. Prod. 2014, 83, 108–117. [Google Scholar] [CrossRef]

- Petrecca, G. Energy Conversion and Management; Springer International Publishing: Cham, Switzerland, 2014; ISBN 978-3-319-06559-5. [Google Scholar]

- ISO 50001:2018; Energy Management Systems—Requirements with Guidance for Use. ISO—International Organization for Standardization: Geneva, Switzerland, 2018.

- Benedetti, M.; Cesarotti, V.; Introna, V. From Energy Targets Setting to Energy-Aware Operations Control and Back: An Advanced Methodology for Energy Efficient Manufacturing. J. Clean. Prod. 2018, 167, 1518–1533. [Google Scholar] [CrossRef]

- Bunse, K.; Vodicka, M.; Schönsleben, P.; Brülhart, M.; Ernst, F.O. Integrating Energy Efficiency Performance in Production Management—Gap Analysis between Industrial Needs and Scientific Literature. J. Clean. Prod. 2011, 19, 667–679. [Google Scholar] [CrossRef]

- Capehart, L.; Turner, C.; Kennedy, J. Guide to Energy Management, 4th ed.; Fairmont Press: New York, NY, USA, 2002; ISBN 978-0-8247-4120-4. [Google Scholar]

- Cesarotti, V.; Ciminelli, M.; Di Silvio, B.; Fedele, T.; Introna, V. Energy Budgeting and Control for Industrial Plant through Consumption Analysis and Monitoring. In Proceedings of the IASTED International Conference on Energy and Power Systems, Palma De Mallorca, Spain, 29–31 August 2007; pp. 389–394. [Google Scholar]

- Karkalos, N.E.; Markopoulos, A.P.; Davim, J.P. Computational Methods for Application in Industry 4.0; SpringerBriefs in Applied Sciences and Technology; Springer International Publishing: Cham, Switzerland, 2019; ISBN 978-3-319-92392-5. [Google Scholar]

- Frank, A.G. Industry 4.0 Technologies_ Implementation Patterns in Manufacturing Companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Vaidya, S.; Ambad, P.; Bhosle, S. Industry 4.0—A Glimpse. Procedia Manuf. 2018, 20, 233–238. [Google Scholar] [CrossRef]

- Wang, S. Towards Smart Factory for Industry 4.0: A Self-Organized Multi-Agent System with Big Data Based Feedback and Coordination. Comput. Netw. 2016, 101, 158–168. [Google Scholar] [CrossRef]

- Laudante, E. Industry 4.0, Innovation and Design. A New Approach for Ergonomic Analysis in Manufacturing System. Des. J. 2017, 20, S2724–S2734. [Google Scholar] [CrossRef]

- Shrouf, F.; Miragliotta, G. Energy Management Based on Internet of Things: Practices and Framework for Adoption in Production Management. J. Clean. Prod. 2015, 100, 235–246. [Google Scholar] [CrossRef]

- Goodall, P.; Sharpe, R.; West, A. A Data-Driven Simulation to Support Remanufacturing Operations. Comput. Ind. 2019, 105, 48–60. [Google Scholar] [CrossRef]

- Oztemel, E.; Gursev, S. Literature Review of Industry 4.0 and Related Technologies. J. Intell. Manuf. 2018, 31, 127–182. [Google Scholar] [CrossRef]

- Peres, R.S.; Dionisio Rocha, A.; Leitao, P.; Barata, J. IDARTS—Towards Intelligent Data Analysis and Real-Time Supervision for Industry 4.0. Comput. Ind. 2018, 101, 138–146. [Google Scholar] [CrossRef]

- Gattullo, M.; Scurati, G.W.; Fiorentino, M.; Uva, A.E.; Ferrise, F.; Bordegoni, M. Towards Augmented Reality Manuals for Industry 4.0: A Methodology. Robot. Comput.-Integr. Manuf. 2019, 56, 276–286. [Google Scholar] [CrossRef]

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The Role of Additive Manufacturing in the Era of Industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- Roy, R.; Stark, R.; Tracht, K.; Takata, S.; Mori, M. Continuous Maintenance and the Future—Foundations and Technological Challenges. CIRP Ann. 2016, 65, 667–688. [Google Scholar] [CrossRef]

- European Commission. Directorate General for Research and Innovation. Industry 5.0, a Transformative Vision for Europe: Governing Systemic Transformations towards a Sustainable Industry; Publications Office: Luxembourg, 2021. [Google Scholar]

- Maddikunta, P.K.R.; Pham, Q.-V.; Prabadevi, B.; Deepa, N.; Dev, K.; Gadekallu, T.R.; Ruby, R.; Liyanage, M. Industry 5.0: A Survey on Enabling Technologies and Potential Applications. J. Ind. Inf. Integr. 2022, 26, 100257. [Google Scholar] [CrossRef]

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, Conception and Perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- European Commission. Directorate General for Research and Innovation. Enabling Technologies for Industry 5.0: Results of a Workshop with Europe’s Technology Leaders; Publications Office: Luxembourg, 2020. [Google Scholar]

- Doolani, S.; Wessels, C.; Kanal, V.; Sevastopoulos, C.; Jaiswal, A.; Nambiappan, H.; Makedon, F. A Review of Extended Reality (XR) Technologies for Manufacturing Training. Technologies 2020, 8, 77. [Google Scholar] [CrossRef]

- Kaplan, A.D.; Cruit, J.; Endsley, M.; Beers, S.M.; Sawyer, B.D.; Hancock, P.A. The Effects of Virtual Reality, Augmented Reality, and Mixed Reality as Training Enhancement Methods: A Meta-Analysis. Hum. Factors 2021, 63, 706–726. [Google Scholar] [CrossRef]

- Rauschnabel, P.A.; Felix, R.; Hinsch, C.; Shahab, H.; Alt, F. What Is XR? Towards a Framework for Augmented and Virtual Reality. Comput. Hum. Behav. 2022, 133, 107289. [Google Scholar] [CrossRef]

- Barricelli, B.R.; Casiraghi, E.; Fogli, D. A Survey on Digital Twin: Definitions, Characteristics, Applications, and Design Implications. IEEE Access 2019, 7, 167653–167671. [Google Scholar] [CrossRef]

- Cimino, C.; Negri, E.; Fumagalli, L. Review of Digital Twin Applications in Manufacturing. Comput. Ind. 2019, 113, 103130. [Google Scholar] [CrossRef]

- Leng, J.; Wang, D.; Shen, W.; Li, X.; Liu, Q.; Chen, X. Digital Twins-Based Smart Manufacturing System Design in Industry 4.0: A Review. J. Manuf. Syst. 2021, 60, 119–137. [Google Scholar] [CrossRef]

- Santolamazza, A.; Groth, C.; Introna, V.; Porziani, S.; Scarpitta, F.; Urso, G.; Valentini, P.P.; Costa, E.; Ferrante, E.; Sorrentino, S.; et al. A Digital Shadow Cloud-Based Application to Enhance Quality Control in Manufacturing. IFAC-PapersOnLine 2020, 53, 10579–10584. [Google Scholar] [CrossRef]

- Tange, K.; De Donno, M.; Fafoutis, X.; Dragoni, N. A Systematic Survey of Industrial Internet of Things Security: Requirements and Fog Computing Opportunities. IEEE Commun. Surv. Tutor. 2020, 22, 2489–2520. [Google Scholar] [CrossRef]

- Shafique, K.; Khawaja, B.A.; Sabir, F.; Qazi, S.; Mustaqim, M. Internet of Things (IoT) for Next-Generation Smart Systems: A Review of Current Challenges, Future Trends and Prospects for Emerging 5G-IoT Scenarios. IEEE Access 2020, 8, 23022–23040. [Google Scholar] [CrossRef]

- Kaplan, A.; Haenlein, M. Siri, Siri, in My Hand: Who’s the Fairest in the Land? On the Interpretations, Illustrations, and Implications of Artificial Intelligence. Bus. Horiz. 2019, 62, 15–25. [Google Scholar] [CrossRef]

- Sætra, H.S. Generative AI: Here to Stay, but for Good? Technol. Soc. 2023, 75, 102372. [Google Scholar] [CrossRef]

- Wulf, C.; Zapp, P.; Schreiber, A. Review of Power-to-X Demonstration Projects in Europe. Front. Energy Res. 2020, 8, 191. [Google Scholar] [CrossRef]

- Al-Ali, A.R.; Zualkernan, I.A.; Rashid, M.; Gupta, R.; Alikarar, M. A Smart Home Energy Management System Using IoT and Big Data Analytics Approach. IEEE Trans. Consum. Electron. 2017, 63, 426–434. [Google Scholar] [CrossRef]

- Benedetti, M.; Cesarotti, V.; Introna, V.; Serranti, J. Energy Consumption Control Automation Using Artificial Neural Networks and Adaptive Algorithms: Proposal of a New Methodology and Case Study. Appl. Energy 2016, 165, 60–71. [Google Scholar] [CrossRef]

- Negri, E.; Fumagalli, L.; Macchi, M. A Review of the Roles of Digital Twin in CPS-Based Production Systems. Procedia Manuf. 2017, 11, 939–948. [Google Scholar] [CrossRef]

- Nikula, R.-P.; Ruusunen, M.; Leiviskä, K. Data-Driven Framework for Boiler Performance Monitoring. Appl. Energy 2016, 183, 1374–1388. [Google Scholar] [CrossRef]

- Santolamazza, A.; Cesarotti, V.; Introna, V. Evaluation of Machine Learning Techniques to Enact Energy Consumption Control of Compressed Air Generation in Production Plants. In Proceedings of the Summer School Francesco Turco; AIDI—Italian Association of Industrial Operations Professors: Italy, 2018; Volume 2018, pp. 79–86. [Google Scholar]

- Sunthornnapha, T. Utilization of MLP and Linear Regression Methods to Build a Reliable Energy Baseline for Self-Benchmarking Evaluation. Energy Procedia 2017, 141, 189–193. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent Manufacturing in the Context of Industry 4.0: A Review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Yu, W.; Patros, P.; Young, B.; Klinac, E.; Walmsley, T.G. Energy Digital Twin Technology for Industrial Energy Management: Classification, Challenges and Future. Renew. Sustain. Energy Rev. 2022, 161, 112407. [Google Scholar] [CrossRef]

- Di Silvio, B.; Cesarotti, V.; Introna, V. Evaluation of Electricity Rates through Characterization and Forecasting of Energy Consumption: A Case Study of an Italian Industrial Eligible Customer. Int. J. Energy Sect. Manag. 2007, 1, 390–412. [Google Scholar] [CrossRef]

- Tran, D.A.T.; Chen, Y.; Chau, M.Q.; Ning, B. A Robust Online Fault Detection and Diagnosis Strategy of Centrifugal Chiller Systems for Building Energy Efficiency. Energy Build. 2015, 108, 441–453. [Google Scholar] [CrossRef]

- Xiao, F.; Zheng, C.; Wang, S. A Fault Detection and Diagnosis Strategy with Enhanced Sensitivity for Centrifugal Chillers. Appl. Therm. Eng. 2011, 31, 3963–3970. [Google Scholar] [CrossRef]

- Alavi, M.; Georgia Institute of Technology; Leidner, D.E.; Mousavi, R. A Knowledge Management Perspective of Generative Artificial Intelligence. JAIS 2024, 25, 1–12. [Google Scholar] [CrossRef]

- Koch, P.J.; van Amstel, M.K.; Dębska, P.; Thormann, M.A.; Tetzlaff, A.J.; Bøgh, S.; Chrysostomou, D. A Skill-Based Robot Co-Worker for Industrial Maintenance Tasks. Procedia Manuf. 2017, 11, 83–90. [Google Scholar] [CrossRef]

- Masoni, R.; Ferrise, F.; Bordegoni, M.; Gattullo, M.; Uva, A.E.; Fiorentino, M.; Carrabba, E.; Di Donato, M. Supporting Remote Maintenance in Industry 4.0 through Augmented Reality. Procedia Manuf. 2017, 11, 1296–1302. [Google Scholar] [CrossRef]

- Chen, S.-L.; Chen, Y.-Y.; Hsu, C. A New Approach to Integrate Internet-of-Things and Software-as-a-Service Model for Logistic Systems: A Case Study. Sensors 2014, 14, 6144–6164. [Google Scholar] [CrossRef]

- Hao, Y.; Helo, P. The Role of Wearable Devices in Meeting the Needs of Cloud Manufacturing: A Case Study. Robot. Comput.-Integr. Manuf. 2017, 45, 168–179. [Google Scholar] [CrossRef]

- Khajavi, S.H.; Partanen, J.; Holmström, J. Additive Manufacturing in the Spare Parts Supply Chain. Comput. Ind. 2014, 65, 50–63. [Google Scholar] [CrossRef]

- Al Faruque, M.A.; Vatanparvar, K. Energy Management-as-a-Service Over Fog Computing Platform. IEEE Internet Things J. 2016, 3, 161–169. [Google Scholar] [CrossRef]

- Sampaio, H.V.; Westphall, C.B.; Koch, F.; Do Nascimento Boing, R.; Santa Cruz, R.N. Autonomic Energy Management with Fog Computing. Comput. Electr. Eng. 2021, 93, 107246. [Google Scholar] [CrossRef]

- Miglani, A.; Kumar, N.; Chamola, V.; Zeadally, S. Blockchain for Internet of Energy Management: Review, Solutions, and Challenges. Comput. Commun. 2020, 151, 395–418. [Google Scholar] [CrossRef]

- Curtis, P.D.; Mehravari, N. Evaluating and Improving Cybersecurity Capabilities of the Energy Critical Infrastructure. In Proceedings of the 2015 IEEE International Symposium on Technologies for Homeland Security, HST 2015, Waltham, MA, USA, 14–16 April 2015. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).