Achieving Techno-Economic Feasibility for Hybrid Renewable Energy Systems through the Production of Energy and Alternative Fuels

Abstract

1. Introduction

The Local Context—The Energy Sector and Hybrid Renewable Energy Systems

- Hybrid renewable energy plants have conventionally focused on electricity as the main product and, in most cases, the only product. For instance, in a review of 100% RE systems it was revealed that 97% of all RE energy research focused on electricity [19]. Ghana’s National Energy Statistics 2022 reveal that biomass contributes 34%, petroleum 50% and electricity 17% to energy consumption. Thus, fuels remain an important source of energy, especially for residential 39%, transport (38%) and industrial consumption (16%) [62].

- Ghana, through the Energy Sector Recovery Programme (ESRP), placed a moratorium on the signing of new power purchasing agreements due to overcapacity in its energy system [52]. This is an indication that electricity may not be the only universally desired product from WTE projects. Such plants may sometimes require the energy to be converted to fuels to create value for the market.

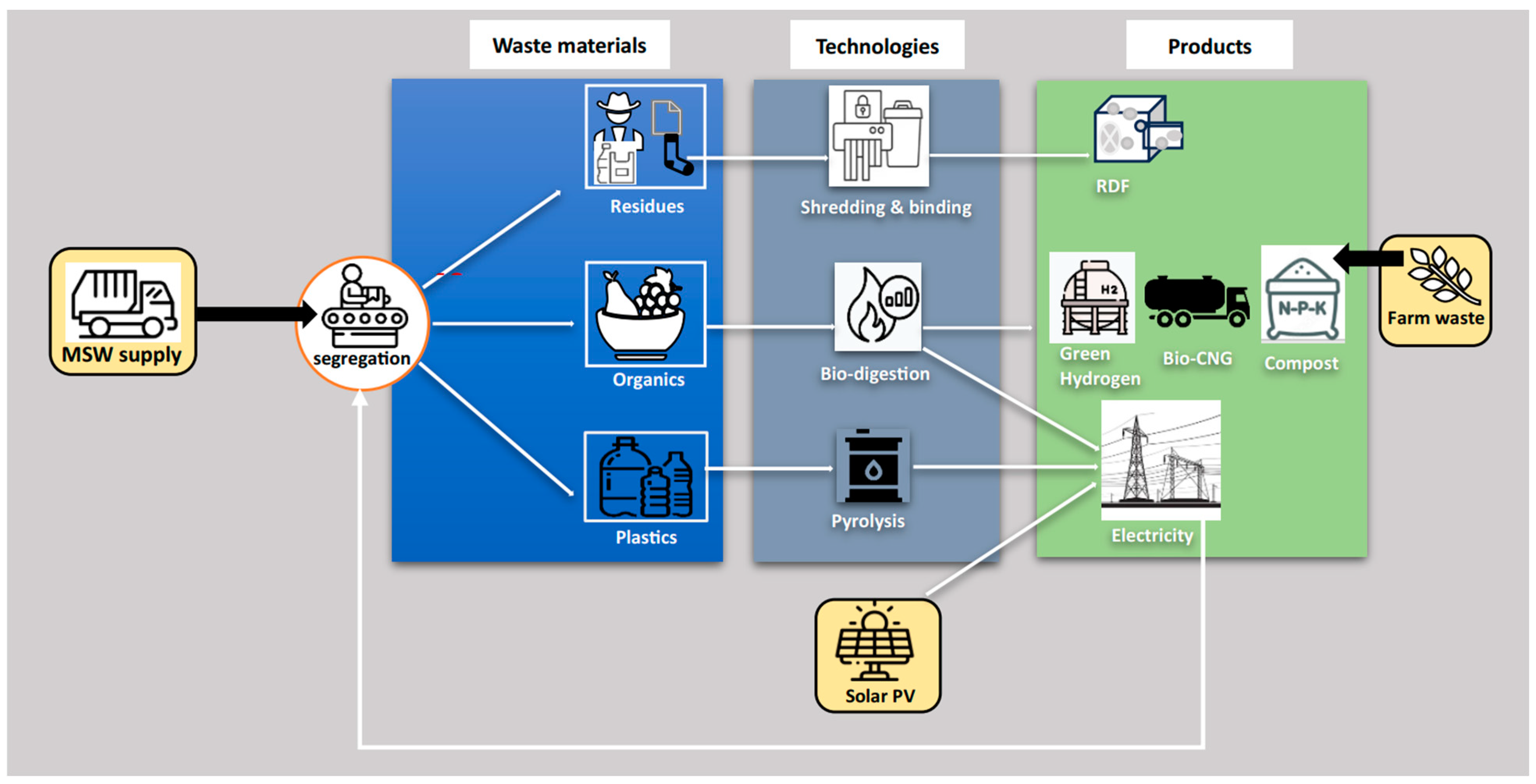

- Waste segregation in Ghana is estimated to be at only 2%. Thus, previous projects, such as Safisana, have invested additional resources into public education and other social research activities to receive highly segregated organic waste for AD systems. However, this does not provide a holistic solution to the remaining fraction of the waste. Also, the Integrated Recycling and Compost Plant (IRECOP), Kumasi Compost and Recycling Plant (KCARP) and Accra Compost and Recycling Plant (ACARP) dispose of residual waste at landfills after organic waste and plastics have been recovered [63]. The case study plant being considered in this study has the capacity to use all waste fractions that are practically available to produce various products.

2. Materials and Methods

2.1. Study Area

2.2. Technical Description of the Pilot Plant

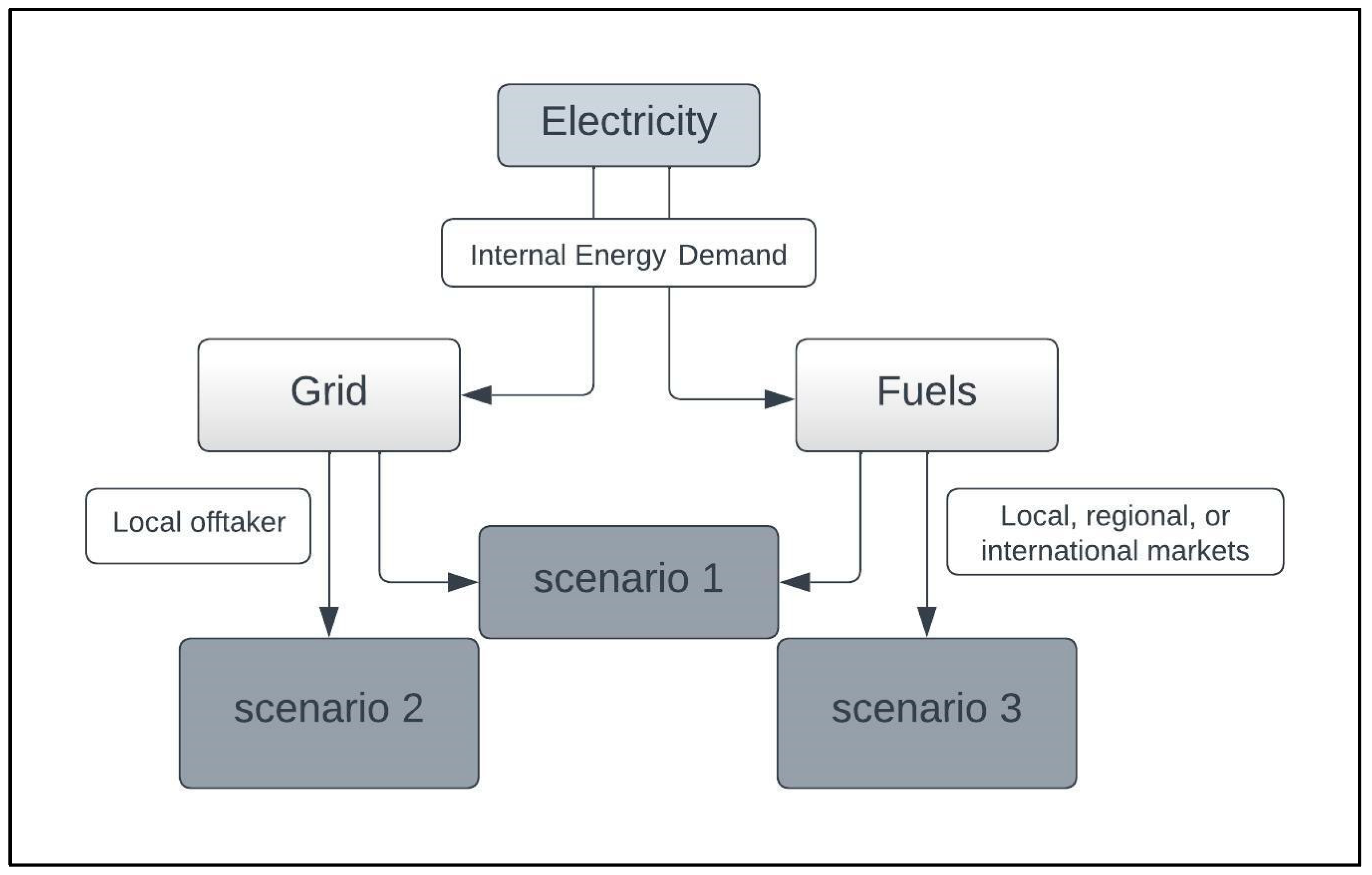

2.3. Description of Scenarios

- Scenario 1 (Electricity and Fuel)—this provides an integrated option for the plant, with both a PPA for electricity exported to the grid and other fuels. This is the base case scenario, because the pilot plant has been constructed to test various options to provide key locally applicable data for academic research activities and technological advancement. In the very uncertain and relatively young market for fuels such as green H2, a secure source of revenue from a PPA provides greater security for an investor while also providing an opportunity for them to invest in cleaner fuels for industrial activities. It also presents a higher investment cost and internal energy demand due to it needing more equipment.

- Scenario 2 (Electricity only)—this considers electricity as the only product from the plant. It is assumed that a long-term power purchasing agreement (20 years) is secured, in which the off-taker takes on all the energy produced for grid supply. In this scenario, all the methane produced from an AD system is converted to electricity and the digestate is given at no cost to local farmers. No additional activities are required, thus generating the smallest investment and operational cost scenario.

- Scenario 2 (Fuels only)—this considers producing four types of fuels for local and international markets: bio-CNG, RDF, green H2 and compost. The pilot plant will be committed to meeting the specifications of the buyers as much as financially feasible. Although this provides greater flexibility in terms of a wider spread of markets, including local and international consumers, the risk is higher with greater competition from other suppliers. However, long-term purchase agreements may be secured with buyers to reduce such risks and provide substantial price competitiveness. This model will require more investment in market research and business case development to reduce the risk. The compost product, for instance, will face significant competition from other local waste processing facilities such as KCARP in Kumasi and IRECOP, Jekora Ventures Limited (JVL) and Safisana in Accra [63].

2.4. Computation of Energy Output

2.4.1. Solar PV System

2.4.2. Anaerobic Digestion (AD) System

2.4.3. Pyrolysis System

2.5. Output of Fuels

2.5.1. Green Hydrogen (H2)

| Description of Reaction | Reaction [39,78,79] | Equation (5) |

|---|---|---|

| Dry reforming of methane within the reformer reactor | (5a) | |

| Water–gas shift reaction | (5b) | |

| Steam reforming of methane | (5c) |

2.5.2. Bio-CNG

2.5.3. Compost

2.5.4. Refuse-Derived Fuel (RDF)

2.6. Financial Analysis

2.6.1. General Assumptions

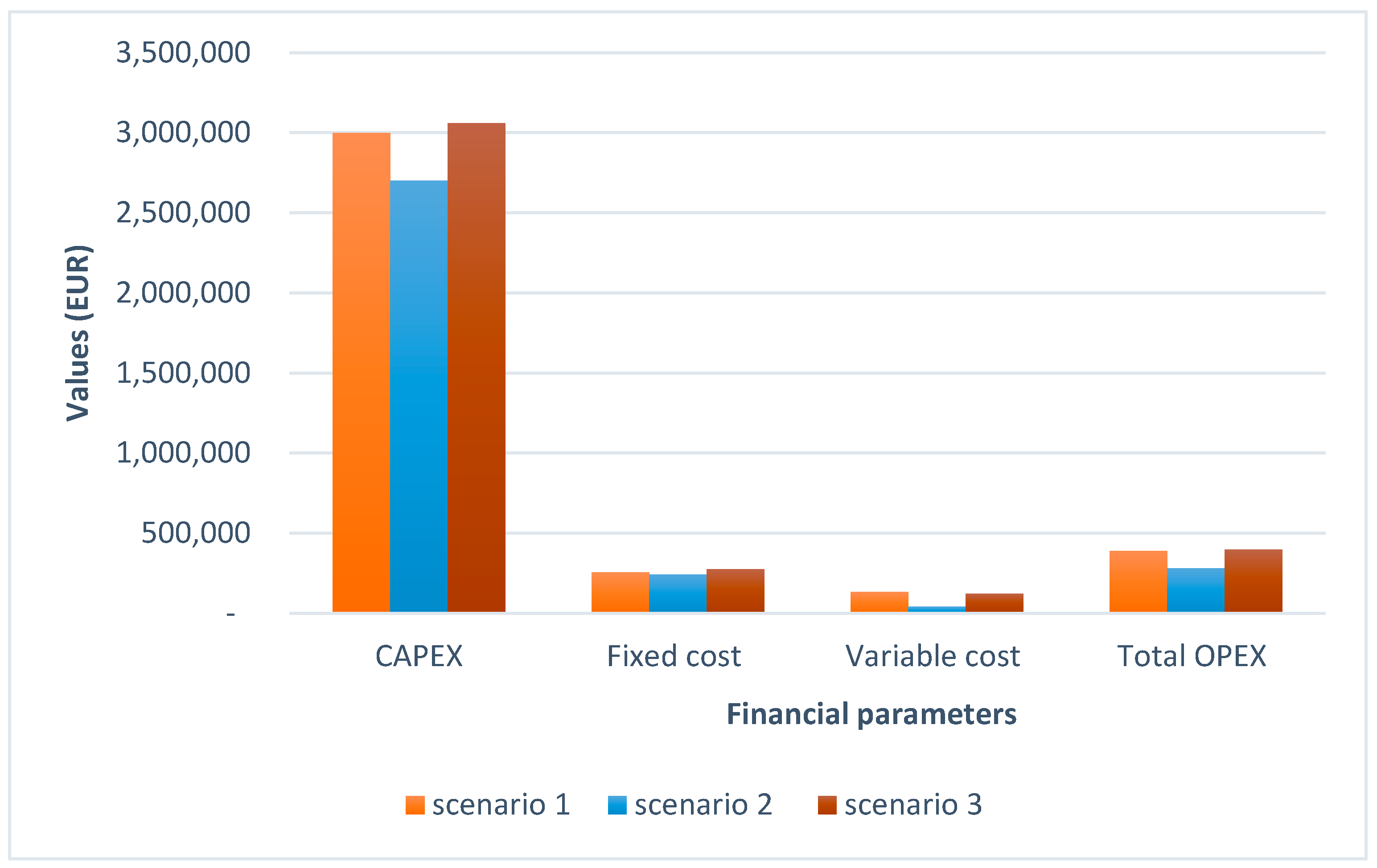

- CAPEX—the capital cost of the all infrastructure and equipment, which is spread over a construction period of 3 years. For the purposes of this study, detailed investments such as land and road construction are considered as support from the government. The CAPEX considered here refers to equipment and installation costs.which represents the sum of the costs of AD, pyrolysis, composting, segregation, laboratories and other infrastructure, such as the bunker and shed. In the context of this study, the laboratory is assumed to be used only for research purposes for the facility and not income generating.

- Capital Financing—this is determined by the following factors: the debt-to-equity ratio, cost of equity and cost of debt. The cost of debt also depends on the maturity and grace period of the loan and the interest rate. For this study, the interest rate used was 3.05 %/annum, the grace period = 0 and the debt-to-equity ratio was 70:30 [86].

- OPEX—the pilot plant is currently undergoing operationalization tests and full-scale operation has not yet begun. Thus, although all the development-related costs are taken from the plant, its operational conditions are not yet verified or optimized. The OPEX is divided into the fixed and variable cost [87]. Human labour is needed to operate the segregation system and composting, while the energy systems remain largely independent, except for periodic and unscheduled maintenance that needs to be carried out. The OPEX was calculated aswhere FC is the fixed cost, which incorporates costs from labour, interest on debt, insurance, equipment replacement costs and scheduled maintenance. VC is the variable cost, which incorporates internal energy consumption, tax, materials, unscheduled maintenance and miscellaneous costs.

- Operation hours per annum (t)—the total operational hours per year is taken as 8040 hrs/yr.

- Lifespan—20 years.

- Annual inflation provides a good reflection of the rate of escalation of the prices of goods and services within the country. Thus, inflation provides a good basis for projecting the annual escalation of the selling prices of the products under study. It is taken as the average of the last 25 years, since the recent economic situation in the country presents a worse-case scenario with poor performance due to the impact of COVID-19. According to inflation data obtained from the World Bank, the average for the period is computed as 16.12% [88].

- Cooperate Income tax (CIT)—according to the Ghana Revenue Authority, the CIT for waste management companies is 1% within the first 7 years and 25% from the 8th year onwards [89].

- Discount rate—10%.

- Revenues—the revenues were obtained through a calculation of the product of the quantity of products and their market price in Euros (EUR). For electricity, the price used is adopted from the tariff at which the ECG buys power from the Independent Power Producers (IPPs), known as the Bulk Generation Charge (BGC). As of May 2023, the tariff was 0.088 EUR/kWh [90].

- Annual escalation rate of revenues—this was calculated based on the historic figures obtained for the escalation of tariffs for BGCs based on PURC tariffs since 2006. The average annual rate of increase was calculated as 25%.

2.6.2. Financial Feasibility Parameters

3. Results

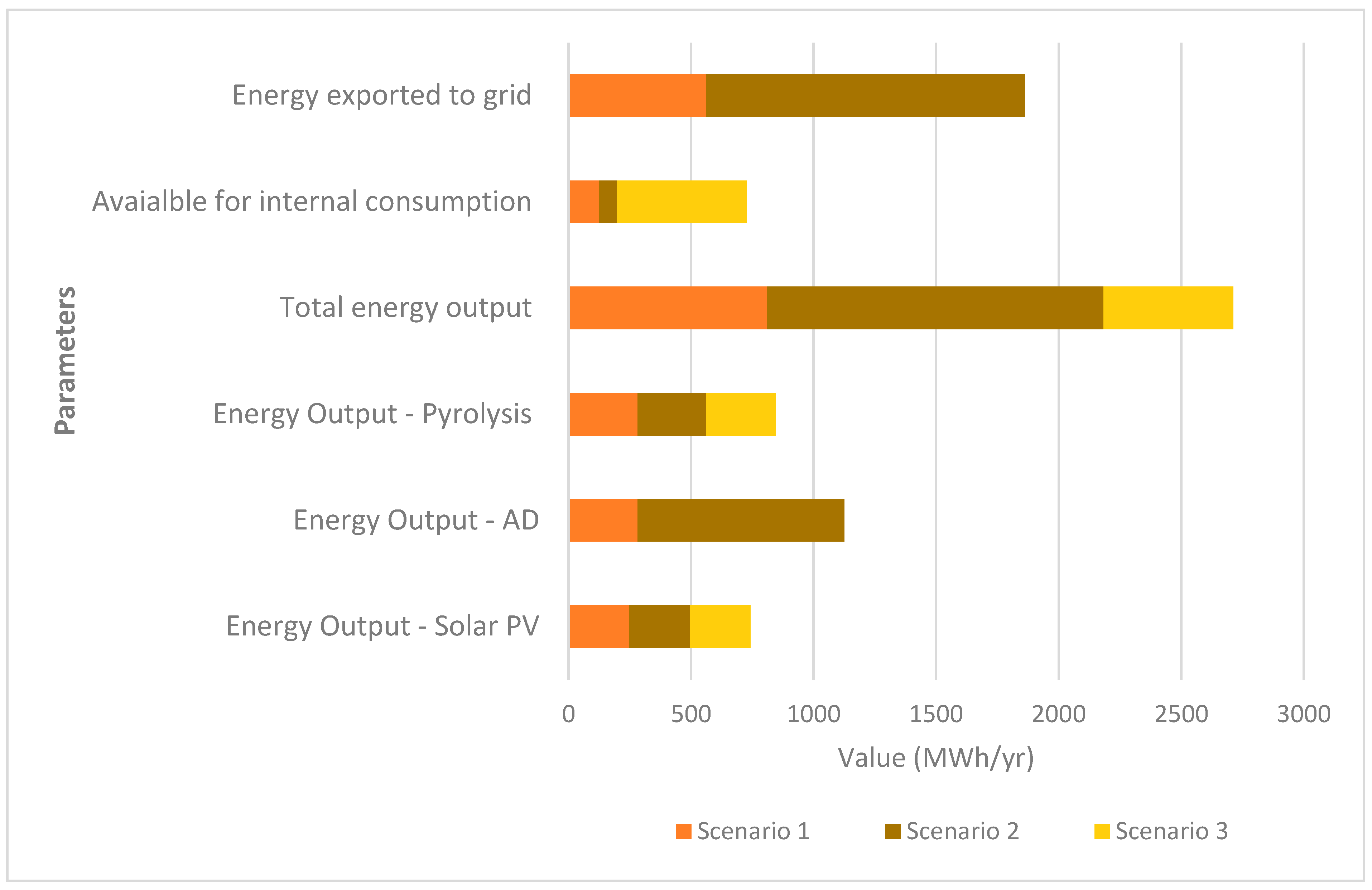

3.1. Technical Results for the Scenarios

3.2. Financial Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- IEA. Africa Energy Outlook 2019—Analysis and Key Findings. A Report by the International Energy Agency; IEA: Paris, France, 2019. [Google Scholar]

- International Renewable Energy Agency. Renewable Power Generation Costs in 2022; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2023. [Google Scholar]

- Ferronato, N.; Torretta, V. Waste Mismanagement in Developing Countries: A Review of Global Issues. Int. J. Environ. Res. Public Health 2019, 16, 1060. [Google Scholar] [CrossRef]

- Hoang, N.H.; Fogarassy, C. Sustainability Evaluation of Municipal Solid Waste Management System for Hanoi (Vietnam)-Why to Choose the “waste-to-Energy” Concept. Sustainability 2020, 12, 1085. [Google Scholar] [CrossRef]

- Anyaoha, K.E.; Zhang, D.L. Transition from Fossil-Fuel to Renewable-Energy-Based Smallholder Bioeconomy: Techno-Economic Analyses of Two Oil Palm Production Systems. Chem. Eng. J. Adv. 2022, 10, 100270. [Google Scholar] [CrossRef]

- Mutz, D.; Hengevoss, D.; Hugi, C.; Gross, T. Waste to Energy Options in Municipal Solid Waste Management: A Guide for Decidion Makers in Developing and Emergin Countries; Hinchliffe, D., Frommann, J., Gunsilius, E., Eds.; Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH: Eschborn, Germany, 2017. [Google Scholar]

- Tozlu, A.; Özahi, E.; Abuşoğlu, A. Waste to Energy Technologies for Municipal Solid Waste Management in Gaziantep. Renew. Sustain. Energy Rev. 2016, 54, 809–815. [Google Scholar] [CrossRef]

- Manwell, J.F. Hybrid Energy Systems. Encycl. Energy 2004, 3, 215–226. [Google Scholar]

- Bajpai, P.; Dash, V. Hybrid Renewable Energy Systems for Power Generation in Stand-Alone Applications: A Review. Renew. Sustain. Energy Rev. 2012, 16, 2926–2939. [Google Scholar] [CrossRef]

- Buragohain, S.; Mohanty, K.; Mahanta, P. Hybridization of Solar Photovoltaic and Biogas System: Experimental, Economic and Environmental Analysis. Sustain. Energy Technol. Assess. 2021, 45, 101050. [Google Scholar] [CrossRef]

- Agyenim, F.B.; Dzamboe, P.D.; Mohammed, M.; Bawakyillenuo, S.; Okrofu, R.; Decker, E.; Agyemang, V.K.; Nyarko, E.H. Powering Communities Using Hybrid Solar–Biogas in Ghana, a Feasibility Study. Environ. Technol. Innov. 2020, 19, 100837. [Google Scholar] [CrossRef]

- Odoi-Yorke, F.; Abaase, S.; Zebilila, M.; Atepor, L. Feasibility Analysis of Solar PV/Biogas Hybrid Energy System for Rural Electrification in Ghana. Cogent Eng. 2022, 9, 2034376. [Google Scholar] [CrossRef]

- Mabalane, P.N.; Oboirien, B.O.; Sadiku, E.R.; Masukume, M. A Techno-Economic Analysis of Anaerobic Digestion and Gasification Hybrid System: Energy Recovery from Municipal Solid Waste in South Africa. Waste Biomass Valorization 2021, 12, 1167–1184. [Google Scholar] [CrossRef]

- Xiong, J.; Ng, T.S.A.; Wang, S. An Optimization Model for Economic Feasibility Analysis and Design of Decentralized Waste-to-Energy Systems. Energy 2016, 101, 239–251. [Google Scholar] [CrossRef]

- El Ibrahimi, M.; Khay, I.; El Maakoul, A.; Bakhouya, M. Techno-Economic and Environmental Assessment of Anaerobic Co-Digestion Plants under Different Energy Scenarios: A Case Study in Morocco. Energy Convers. Manag. 2021, 245, 114553. [Google Scholar] [CrossRef]

- Salman, C.A.; Schwede, S.; Thorin, E.; Yan, J. Predictive Modelling and Simulation of Integrated Pyrolysis and Anaerobic Digestion Process. Energy Procedia 2017, 105, 850–857. [Google Scholar] [CrossRef]

- Petrollese, M.; Cocco, D. Techno-Economic Assessment of Hybrid CSP-Biogas Power Plants. Renew. Energy 2020, 155, 420–431. [Google Scholar] [CrossRef]

- Lagorse, J.; Simões, M.G.; Miraoui, A.; Costerg, P. Energy Cost Analysis of a Solar-Hydrogen Hybrid Energy System for Stand-Alone Applications. Int. J. Hydrogen Energy 2008, 33, 2871–2879. [Google Scholar] [CrossRef]

- Hansen, K.; Breyer, C.; Lund, H. Status and Perspectives on 100% Renewable Energy Systems. Energy 2019, 175, 471–480. [Google Scholar] [CrossRef]

- Winquist, E.; Rikkonen, P.; Pyysiäinen, J.; Varho, V. Is Biogas an Energy or a Sustainability Product?—Business Opportunities in the Finnish Biogas Branch. J. Clean. Prod. 2019, 233, 1344–1354. [Google Scholar] [CrossRef]

- Irmak, S. Biomass as Raw Material for Production of High-Value. In Biomass Volume Estimation and Valorization for Energy; Tumuluru, J.S., Ed.; IntechOpen: Rijeka, Croatia, 2017; pp. 201–225. [Google Scholar]

- Chen, K.C.; Leach, M.; Black, M.J.; Tesfamichael, M.; Kemausuor, F.; Littlewood, P.; Marker, T.; Mwabonje, O.; Mulugetta, Y.; Murphy, R.J.; et al. BioLPG for Clean Cooking in Sub-Saharan Africa: Present and Future Feasibility of Technologies, Feedstocks, Enabling Conditions and Financing. Energies 2021, 14, 3916. [Google Scholar] [CrossRef]

- Namugenyi, I.; Coenen, L.; Scholderer, J. Realising the Transition to Bioenergy: Integrating Entrepreneurial Business Models into the Biogas Socio-Technical System in Uganda. J. Clean. Prod. 2022, 333, 130135. [Google Scholar] [CrossRef]

- Rahmatzafran, A.; Rosslee, D.; Rianawati, E.; Loeksmanto, H.I.; Hilbert, J.; Alemmu, S.; Mohammed, M.; Eremed, B.W.; Salie, Y. Biogas Markets and Frameworks in Argentina, Ethiopia, Ghana, Indonesia, and South Africa; DiBiCoo–Digital Global Biogas Cooperation 2020. pp. 1–222. Available online: https://ec.europa.eu/research/participants/documents/downloadPublic?documentIds=080166e5d1e4e65c&appId=PPGMS (accessed on 24 March 2023).

- Lee, R.D. Evaluating Uganda’s Waste Management System for the Production of Refuse-Derived Fuel (RDF) and Its Potential Implementation in the Country’s Growing Cement Industry. Ph.D. Thesis, Technische Universität Wien, Wien, Austria, 2019. [Google Scholar]

- García, R.; Gil, M.V.; Rubiera, F.; Chen, D.; Pevida, C. Renewable Hydrogen Production from Biogas by Sorption Enhanced Steam Reforming (SESR): A Parametric Study. Energy 2021, 218, 119491. [Google Scholar] [CrossRef]

- Wang, S.; Wen, Y.; Shi, Z.; Nuran Zaini, I.; Göran Jönsson, P.; Yang, W. Novel Carbon-Negative Methane Production via Integrating Anaerobic Digestion and Pyrolysis of Organic Fraction of Municipal Solid Waste. Energy Convers. Manag. 2022, 252, 115042. [Google Scholar] [CrossRef]

- Bustamante, M.A.; Restrepo, A.P.; Alburquerque, J.A.; Pérez-Murcia, M.D.; Paredes, C.; Moral, R.; Bernal, M.P. Recycling of Anaerobic Digestates by Composting: Effect of the Bulking Agent Used. J. Clean. Prod. 2013, 47, 61–69. [Google Scholar] [CrossRef]

- de Beer, J.; Cihlar, J.; Hensing, I.; Zabeti, M. Status and Prospects of Co-Processing of Waste in EU Cement Plants; Ecofys-Navigant Company: Utrecht, The Netherlands, 2017. [Google Scholar]

- WBCSD. Guidelines for the Selection and Use of Fuels and Raw Materials in the Cement Manufacturing Process; World Business Council for Sustainable Development: Geneva, Switzerland, 2005. [Google Scholar]

- Beguedou, E.; Narra, S.; Afrakoma Armoo, E.; Agboka, K.; Damgou, M.K. Alternative Fuels Substitution in Cement Industries for Improved Energy Efficiency and Sustainability. Energies 2023, 16, 3533. [Google Scholar] [CrossRef]

- Reza, B.; Soltani, A.; Ruparathna, R.; Sadiq, R.; Hewage, K. Environmental and Economic Aspects of Production and Utilization of RDF as Alternative Fuel in Cement Plants: A Case Study of Metro Vancouver Waste Management. Resour. Conserv. Recycl. 2013, 81, 105–114. [Google Scholar] [CrossRef]

- Elnaas, A.; Belherazem, A.; Müller, W.; Nassour, A.; Nelles, M. Biodrying for Mechanical Biological Treatment of Mixed Municipal Solid Waste and Potential for RDF Production. In Proceedings of the 6th International Conference on Environmental Technology and Knowledge Transfer, Beijing, China, 19–20 May 2016; p. 155. [Google Scholar]

- Wappler, M.; Unguder, D.; Lu, X.; Ohlmeyer, H.; Teschke, H.; Lueke, W. Building the Green Hydrogen Market—Current State and Outlook on Green Hydrogen Demand and Electrolyzer Manufacturing. Int. J. Hydrogen Energy 2022, 47, 33551–33570. [Google Scholar] [CrossRef]

- Reith, R.H.; Wijffels, R.H.; Barten, H. Bio-Methane & Bio-Hydrogen: Status and Perspectives of Biological Methane and Hydrogen Production; Reith, J.H., Wijffels, R.H., Barten, H., Eds.; Dutch Biological Hydrogen Foundation: Hague, The Netherlands, 2003; ISBN 9090171657. [Google Scholar]

- Dawood, F.; Anda, M.; Shafiullah, G.M. Hydrogen Production for Energy: An Overview. Int. J. Hydrogen Energy 2020, 45, 3847–3869. [Google Scholar] [CrossRef]

- Saur, G.; Milbrandt, A. Renewable Hydrogen Potential from Biogas in the United States; National Renewable Energy laboratory (NREL): Golden, CO, USA, 2014; pp. 1–44. [Google Scholar]

- Kumar, R.; Kumar, A.; Pal, A. Overview of Hydrogen Production from Biogas Reforming: Technological Advancement. Int. J. Hydrogen Energy 2022, 47, 34831–34855. [Google Scholar] [CrossRef]

- Minh, D.P.; Siang, T.J.; Vo, D.V.N.; Phan, T.S.; Ridart, C.; Nzihou, A.; Grouset, D. Hydrogen Production from Biogas Reforming: An Overview of Steam Reforming, Dry Reforming, Dual Reforming, and Tri-Reforming of Methane; Elsevier Ltd.: Amsterdam, The Netherlands, 2018; ISBN 9780128111970. [Google Scholar]

- Wee, A.N.C.H.; Erison, A.E.; Edward Anyek, E.H.; Pakpahan, G.R.; Lim, J.R.; Tiong, A.N.T. Techno-Economic Assessment of Hydrogen Production via Steam Reforming of Palm Oil Mill Effluent. Sustain. Energy Technol. Assess. 2022, 53, 102575. [Google Scholar] [CrossRef]

- Tamilselvan, R.; Selwynraj, A.I. Model Development for Biogas Generation, Purification and Hydrogen Production via Steam Methane Reforming. Int. J. Hydrogen Energy 2024, 50, 211–225. [Google Scholar] [CrossRef]

- Ayodele, T.R.; Alao, M.A.; Ogunjuyigbe, A.S.O.; Munda, J.L. Electricity Generation Prospective of Hydrogen Derived from Biogas Using Food Waste in South-Western Nigeria. Biomass Bioenergy 2019, 127, 105291. [Google Scholar] [CrossRef]

- Seglah, P.A.; Wang, Y.; Wang, H.; Wobuibe Neglo, K.A.; Zhou, K.; Sun, N.; Shao, J.; Xie, J.; Bi, Y.; Gao, C. Utilization of Food Waste for Hydrogen-Based Power Generation: Evidence from Four Cities in Ghana. Heliyon 2023, 9, e14373. [Google Scholar] [CrossRef]

- Guilayn, F.; Jimenez, J.; Martel, J.L.; Rouez, M.; Crest, M.; Patureau, D. First Fertilizing-Value Typology of Digestates: A Decision-Making Tool for Regulation. Waste Manag. 2019, 86, 67–79. [Google Scholar] [CrossRef]

- Valve, H.; Lazarevic, D.; Humalisto, N. When the Circular Economy Diverges: The Co-Evolution of Biogas Business Models and Material Circuits in Finland. Ecol. Econ. 2021, 185, 107025. [Google Scholar] [CrossRef]

- El Maguiri, A.; Zegzouti, Y.; Souabi, S.; Idrissi, L.; El Hadek, M.; Rene, E.R.; Pala, A.I.; Hafidi, M. Landfills: Environmental Impacts, Assessment and Management Complimentary Contributor Copy. In Landfills: Environmental Impacts, Assessment and Management; Norma, C., Ed.; Nova Science Publishers, Inc.: New York, NY, USA, 2017; p. 298. ISBN 9781536125597. [Google Scholar]

- Van Den Berg, K.; Duong, T.C. Solid and Industrial Hazardous Waste Management Assessment—Options and Action Area to Implement the National Strategy; World Bank: Washington, DC, USA, 2018; p. 107. [Google Scholar]

- Gogela, U.; Salie, Y.; Pineo, C.; Basson, L. The Business Case for Biogas from Solid Waste in the Western Cape; GreenCape: Cape Town, South Africa, 2017. [Google Scholar]

- Njoku, P.O.; Edokpayi, J.N.; Odiyo, J.O. Modeling Landfill Gas Potential and Potential Energy Recovery from Thohoyandou Landfill Site, South Africa. J. Air Waste Manag. Assoc. 2020, 70, 820–833. [Google Scholar] [CrossRef]

- Sarquah, K.; Narra, S.; Beck, G.; Awafo, E.A.; Antwi, E. Bibliometric Analysis; Characteristics and Trends of Refuse Derived Fuel Research. Sustainability 2022, 14, 1994. [Google Scholar] [CrossRef]

- Atuahene, S.A.; Sheng, Q.X. Powering Ghana’s Future: Unraveling the Dynamics of Electricity Generation and the Path to Sustainable Energy. Environ. Sci. Eur. 2023, 35, 25. [Google Scholar] [CrossRef]

- Ministry of Energy. Energy Sector Recovery Program; Ministry of Energy: Accra, Ghana, 2019. [Google Scholar]

- Ministry of Energy. 2022 Energy Outlook for Ghana; Ministry of Energy: Accra, Ghana, 2022. [Google Scholar]

- Asante, K.; Gyamfi, S.; Amo-boateng, M. Techno-Economic Analysis of Waste-to-Energy with Solar Hybrid: A Case Study from Kumasi, Ghana. Sol. Compass 2023, 6, 100041. [Google Scholar] [CrossRef]

- Adaramola, M.; Agelin-Chaab, M.; Paul, S. Analysis of Hybrid Energy Systems for Application in Southern Ghana. Energy Convers. Manag. 2014, 88, 284–295. [Google Scholar] [CrossRef]

- Agyekum, E.B.; Nutakor, C. Feasibility Study and Economic Analysis of Stand-Alone Hybrid Energy System for Southern Ghana. Sustain. Energy Technol. Assess. 2020, 39, 100695. [Google Scholar] [CrossRef]

- Addo, E.O.K.; Asumadu, J.; Okyere, P.Y. Optimal Design of Renewable Hybrid Energy System for a Village in Ghana. In Proceedings of the 2014 9th IEEE Conference on Industrial Electronics and Applications, Hangzhou, China, 9–11 June 2014; pp. 1520–1526. [Google Scholar]

- UNEP. Ethiopia’s Waste-to-Energy Plant Is a First in Africa. Available online: https://www.unep.org/news-and-stories/story/ethiopias-waste-energy-plant-first-africa (accessed on 10 March 2023).

- Tena, N. 400 kW Hybrid Waste to Energy Power Plant a First for Ghana. Available online: https://www.esi-africa.com/industry-sectors/generation/400kw-hybrid-waste-to-energy-power-plant-a-first-for-ghana/#:~:text=The%20400-kilowatt%20production%20facility,organic%20manure%20for%20their%20farms (accessed on 10 March 2023).

- Ministry of Finance. Composite Budget for 2022–2025; Program Based Budget Estimates for 2022: Atwima Nwabiagya Municipal Assembly; Ministry of Finance: Accra, Ghana, 2022. [Google Scholar]

- Ofori, G.M.-L. Waste to Energy: An Alternative Energy Source for Ghana. Lund University: Lund, Sweden, 2016. [Google Scholar]

- Energy Commission. National Energy Statistics; Energy Commission: Accra, Ghana, 2023. [Google Scholar]

- Sarquah, K.; Narra, S.; Beck, G.; Bassey, U.; Antwi, E.; Hartmann, M.; Sarfo, N.; Derkyi, A.; Awafo, E.A.; Nelles, M. Characterization of Municipal Solid Waste and Assessment of Its Potential for Refuse-Derived Fuel (RDF) Valorization. Energies 2023, 16, 200. [Google Scholar] [CrossRef]

- Ministry of Finance. Composite Budget for 2019–2022—Programme Based Budget Estimates for 2019: Atwima Nwabiagya Municipal Assembly 2019; Ministry of Finance: Accra, Ghana, 2019. [Google Scholar]

- Miezah, K.; Obiri-Danso, K.; Kádár, Z.; Fei-Baffoe, B.; Mensah, M.Y. Municipal Solid Waste Characterization and Quantification as a Measure towards Effective Waste Management in Ghana. Waste Manag. 2015, 46, 15–27. [Google Scholar] [CrossRef]

- Amoatey, N.K.; Darmey, J.; Tabbicca, K.E. Estimation of the Methane Generation Potential of the Tamale Landfill Site Using LandGEM. Ghana Min. J. 2023, 23, 27–32. [Google Scholar]

- Parliament of Ghana, Committee on Mines and Energy. Power Purchasing Agreement and Energy Conversion Agreement between ECG and Jacobsen Jelco Ghana Limited; Parliament of Ghana: Accra, Ghana, 2014. [Google Scholar]

- Natural Resources Canada. RETScreen International. Clean Energy Project Analysis: RETScreen Engineering and Cases Textbook, 3rd ed.; Natural Resources Canada: Ottawa, ON, Canada, 2005; ISBN 0662391918. [Google Scholar]

- Obeng, M.; Gyamfi, S.; Derkyi, N.S.; Kabo-bah, A.T.; Peprah, F. Technical and Economic Feasibility of a 50 MW Grid-Connected Solar PV at UENR Nsoatre Campus. J. Clean. Prod. 2020, 247, 119159. [Google Scholar] [CrossRef]

- Owolabi, A.B.; Nsafon, B.E.K.; Huh, J.S. Validating the Techno-Economic and Environmental Sustainability of Solar PV Technology in Nigeria Using RETScreen Experts to Assess Its Viability. Sustain. Energy Technol. Assess. 2019, 36, 100542. [Google Scholar] [CrossRef]

- Ramli, M.S.; Wahid, S.S.A.; Hassan, K.K. A Comparison of Renewable Energy Technologies Using Two Simulation Softwares: HOMER and RETScreen. AIP Conf. Proc. 2017, 1875, 030013. [Google Scholar] [CrossRef]

- Behzadi, A.; Arabkoohsar, A.; Peri, V.S. Innovative Hybrid Solar-Waste Designs for Cogeneration of Heat and Power, an Effort for Achieving Maximum Efficiency and Renewable Integration. Appl. Therm. Eng. 2021, 190, 116824. [Google Scholar] [CrossRef]

- Dima, F.A.F.J.; Li, Z.; Mang, H.P.; Zhu, L. Feasibility Analysis of Biogas Production by Using GIS and Multicriteria Decision Aid Methods in the Central African Republic. Sustainability 2022, 14, 13418. [Google Scholar] [CrossRef]

- Couturier, C.; Berger, S.; Herault, I.; Meiffren, I.; Herault, I. Anaerobic Digestion of Urban Sludge Situation, State of the Art; La Digestion Anaerobie des Boues Urbaines Etat des Lieux, Etat de L’art; Solagro: Toulouse, France, 2001. [Google Scholar]

- Bassey, U.; Sarquah, K.; Hartmann, M.; Tom, A.O.; Beck, G.; Antwi, E.; Narra, S.; Nelles, M. Thermal Treatment Options for Single-Use, Multilayered and Composite Waste Plastics in Africa. Energy 2023, 270, 126872. [Google Scholar] [CrossRef]

- Esfilar, R.; Bagheri, M.; Golestani, B. Technoeconomic Feasibility Review of Hybrid Waste to Energy System in the Campus: A Case Study for the University of Victoria. Renew. Sustain. Energy Rev. 2021, 146, 111190. [Google Scholar] [CrossRef]

- Nikolaidis, P.; Poullikkas, A. A Comparative Overview of Hydrogen Production Processes. Renew. Sustain. Energy Rev. 2017, 67, 597–611. [Google Scholar] [CrossRef]

- Alves, H.J.; Bley Junior, C.; Niklevicz, R.R.; Frigo, E.P.; Frigo, M.S.; Coimbra-Araújo, C.H. Overview of Hydrogen Production Technologies from Biogas and the Applications in Fuel Cells. Int. J. Hydrogen Energy 2013, 38, 5215–5225. [Google Scholar] [CrossRef]

- Saebea, D.; Authayanun, S.; Patcharavorachot, Y.; Arpornwichanop, A. Thermodynamic Analysis of Hydrogen Production from the Adsorption-Enhanced Steam Reforming of Biogas. Energy Procedia 2014, 61, 2254–2257. [Google Scholar] [CrossRef]

- Braga, L.B.; Silveira, J.L.; Da Silva, M.E.; Tuna, C.E.; Machin, E.B.; Pedroso, D.T. Hydrogen Production by Biogas Steam Reforming: A Technical, Economic and Ecological Analysis. Renew. Sustain. Energy Rev. 2013, 28, 166–173. [Google Scholar] [CrossRef]

- Chapter 5.3.3—Application of Hydrogen by Use of Chemical Reactions of Hydrogen and Carbon Dioxide. In Science and Engineering of Hydrogen-Based Energy Technologies: Hydrogen Production and Practical Applications in Energy Generation; Miranda, P.E., Ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2018; pp. 279–289. ISBN 9780128142516. [Google Scholar]

- Falcinelli, S.; Capriccioli, A.; Rosi, M.; Martì, C.; Parriani, M.; Laganà, A. Methane Production from H2 + CO2 Reaction: An Open Molecular Science Case for Computational and Experimental Studies. Physchem 2021, 1, 82–94. [Google Scholar] [CrossRef]

- Galgani, P. Compost, Biogas and Biochar in Northern Ghana Climate Impact and Economic Feasibility; Leiden University: Leiden, The Netherlands; Delft University of Technology: Delft, The Netherlands, 2012. [Google Scholar]

- Zeng, Y.; De Guardia, A.; Dabert, P. Improving Composting as a Post-Treatment of Anaerobic Digestate. Bioresour. Technol. 2016, 201, 293–303. [Google Scholar] [CrossRef] [PubMed]

- European Commission. Exchange Rate (InforEuro). Available online: https://commission.europa.eu/funding-tenders/procedures-guidelines-tenders/information-contractors-and-beneficiaries/exchange-rate-inforeuro_en (accessed on 27 January 2024).

- Pueyo, A.; Bawakyillenuo, S.; Osiolo, H. Cost and Returns of Renweable Energy in Sub-Saharan Africa: A Comparison of Kenya and Ghana; Institute of Development Studies: Brighton, UK, 2016. [Google Scholar]

- Afful-Dadzie, A.; Mallett, A.; Afful-Dadzie, E. The Challenge of Energy Transition in the Global South: The Case of Electricity Generation Planning in Ghana. Renew. Sustain. Energy Rev. 2020, 126, 109830. [Google Scholar] [CrossRef]

- The World Bank. Country Data. Available online: https://data.worldbank.org/country/ghana?view=chart (accessed on 4 September 2023).

- Ghana Revenue Authority. Corporate Income Tax (CIT). Available online: https://gra.gov.gh/domestic-tax/tax-types/corporate-income-tax/ (accessed on 4 June 2023).

- Bank of Ghana. Interbank Exchange Rate: May 2023. Available online: https://www.bog.gov.gh/economic-data/exchange-rate/ (accessed on 4 July 2023).

- Jin, S.; Greaves, D. Wave Energy in the UK:Status Review and Future Perspectives. Renew. Sustain. Energy Rev. 2021, 143, 110932. [Google Scholar] [CrossRef]

- Weinand, J.M.; Hoffmann, M.; Göpfert, J.; Terlouw, T.; Schönau, J.; Kuckertz, P.; McKenna, R.; Kotzur, L.; Linßen, J.; Stolten, D. Global LCOEs of Decentralized Off-Grid Renewable Energy Systems. Renew. Sustain. Energy Rev. 2023, 183, 113478. [Google Scholar] [CrossRef]

- Public Utilities Regulatory Commission (PURC). Publication of Electricity, Natural Gas and Water Tariffs; PURC: Accra, Ghana, 2023; p. 9. [Google Scholar]

- Adaramola, M.S.; Quansah, D.A.; Agelin-Chaab, M.; Paul, S.S. Multipurpose Renewable Energy Resources Based Hybrid Energy System for Remote Community in Northern Ghana. Sustain. Energy Technol. Assess. 2017, 22, 161–170. [Google Scholar] [CrossRef]

- Ministry of Energy. Ghana Renewable Energy Master Plan; Ministry of Energy: Accra, Ghana, 2019. [Google Scholar]

- IEA; IRENA; UNSD; World Bank; WHO. Tracking SDG 7: The Energy Progress Report; World Bank: Washington, DC, USA, 2021. [Google Scholar]

- Murphy, J.D.; McKeogh, E.; Kiely, G. Technical/Economic/Environmental Analysis of Biogas Utilisation. Appl. Energy 2004, 77, 407–427. [Google Scholar] [CrossRef]

- Daadi, B.E.; Latacz-Lohmann, U. Composting Municipal Solid Waste for Agriculture in Northern Ghana: Rural Farmers’ Willingness to Pay for Compost Quality and Access Attributes. Q Open 2022, 2, qoac012. [Google Scholar] [CrossRef]

- Hadidi, L.A.; Omer, M.M. A Financial Feasibility Model of Gasification and Anaerobic Digestion Waste-to-Energy (WTE) Plants in Saudi Arabia. Waste Manag. 2017, 59, 90–101. [Google Scholar] [CrossRef] [PubMed]

- Scarlat, N.; Motola, V.; Dallemand, J.F.; Monforti-Ferrario, F.; Mofor, L. Evaluation of Energy Potential of Municipal Solid Waste from African Urban Areas. Renew. Sustain. Energy Rev. 2015, 50, 1269–1286. [Google Scholar] [CrossRef]

| Technology | Scenario 1 | Scenario 2 | Scenario 3 | |||

|---|---|---|---|---|---|---|

| Installed Capacity (kW) | Installed Cost (EUR /kW) | Installed Capacity (kW) | Installed Cost (EUR /kW) | Installed Capacity (kW) | Installed Cost (EUR /kW) | |

| Solar PV | 200 | 1050 | 200 | 1050 | 200 | 1050 |

| AD (CHP) | 100 | 5000 | 300 | 2333 | 0 | 0 |

| Pyrolysis (CHP) | 100 | 5000 | 100 | 5000 | 100 | 5000 |

| Total capacity | 400 | 600 | 300 | |||

| Average Installed cost | 3683 | 2794 | 3025 | |||

| Product Name | Manufacturer | Weight/bag (kg) | Price/bag (GHC) | Price/kg (GHC) | EUR/kg |

|---|---|---|---|---|---|

| Asaase Gyefo | Safisana Ghana Limited | 30 | 40 | 1.33 | 0.11 |

| Fortifier | Jekora Ventures Limited | 50 | 50 | 1 | 0.08 |

| Asaase Nufusuo | Farmers Hope | 50 | 250 | 5 | 0.4 |

| ACARP | ACARP | 50 | 85 | 1.7 | 0.14 |

| Grow Plenty | Green Gro Ghana | 25 | 40 | 1.6 | 0.13 |

| IRECOP | IRECOP | 50 | 65 | 1.2 | 0.1 |

| Super soil | S&M organics | 50 | 250 | 5 | 0.4 |

| Best fertiliser | Best Fertiliser Company Limited | 25 | 35 | 1.4 | 0.11 |

| Green organic fertilisers | GML Green Energy Ghana Limited | 30 | 90 | 3 | 0.24 |

| Average values | 40 | 100 | 2.36 | 0.19 | |

| Parameter | Unit | Scenario 1 | Scenario 2 | Scenario 3 |

|---|---|---|---|---|

| NPV | EUR | 13,696,677.02 | 1,648,472 | 9,876,832.04 |

| IRR | % | 24 | 12 | 21 |

| LCOE | EUR/kWh | 0.53 | 0.34 | 0.68 |

| PBP | Year | 8 | 13 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Armoo, E.A.; Mohammed, M.; Narra, S.; Beguedou, E.; Agyenim, F.B.; Kemausuor, F. Achieving Techno-Economic Feasibility for Hybrid Renewable Energy Systems through the Production of Energy and Alternative Fuels. Energies 2024, 17, 735. https://doi.org/10.3390/en17030735

Armoo EA, Mohammed M, Narra S, Beguedou E, Agyenim FB, Kemausuor F. Achieving Techno-Economic Feasibility for Hybrid Renewable Energy Systems through the Production of Energy and Alternative Fuels. Energies. 2024; 17(3):735. https://doi.org/10.3390/en17030735

Chicago/Turabian StyleArmoo, Ekua Afrakoma, Mutala Mohammed, Satyanarayana Narra, Essossinam Beguedou, Francis Boateng Agyenim, and Francis Kemausuor. 2024. "Achieving Techno-Economic Feasibility for Hybrid Renewable Energy Systems through the Production of Energy and Alternative Fuels" Energies 17, no. 3: 735. https://doi.org/10.3390/en17030735

APA StyleArmoo, E. A., Mohammed, M., Narra, S., Beguedou, E., Agyenim, F. B., & Kemausuor, F. (2024). Achieving Techno-Economic Feasibility for Hybrid Renewable Energy Systems through the Production of Energy and Alternative Fuels. Energies, 17(3), 735. https://doi.org/10.3390/en17030735