A Review on Key Technologies and Developments of Hydrogen Fuel Cell Multi-Rotor Drones

Abstract

1. Introduction

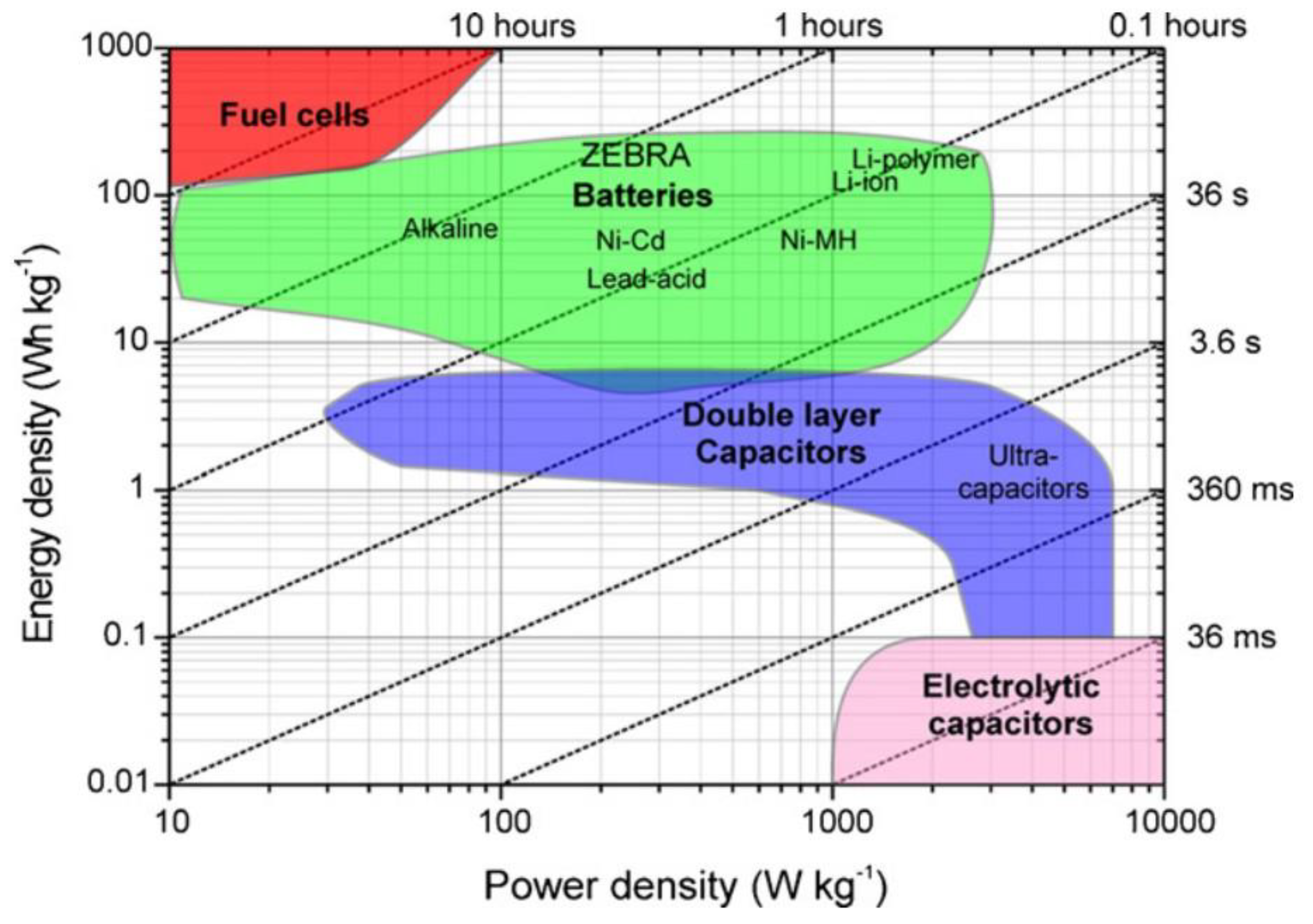

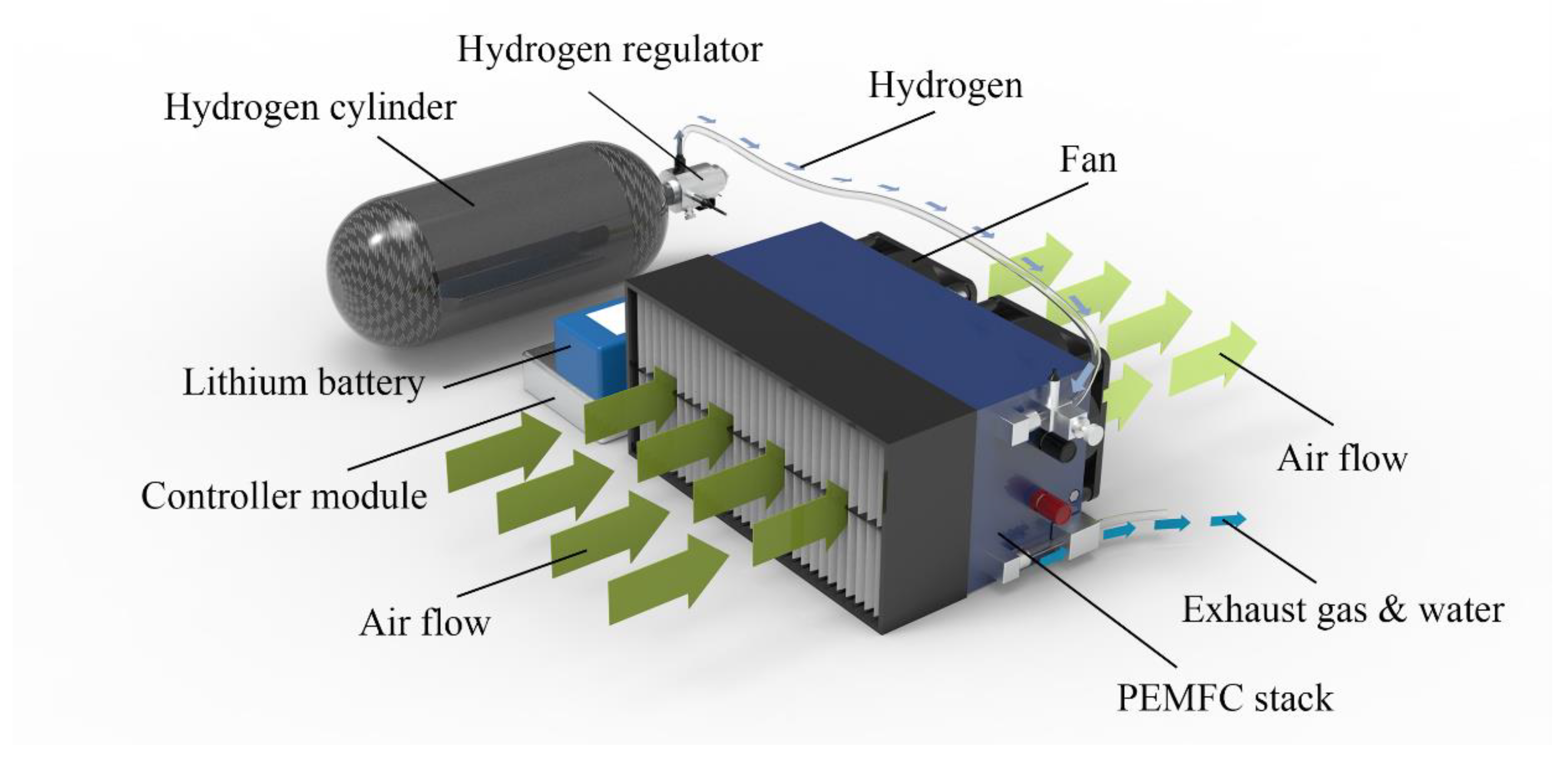

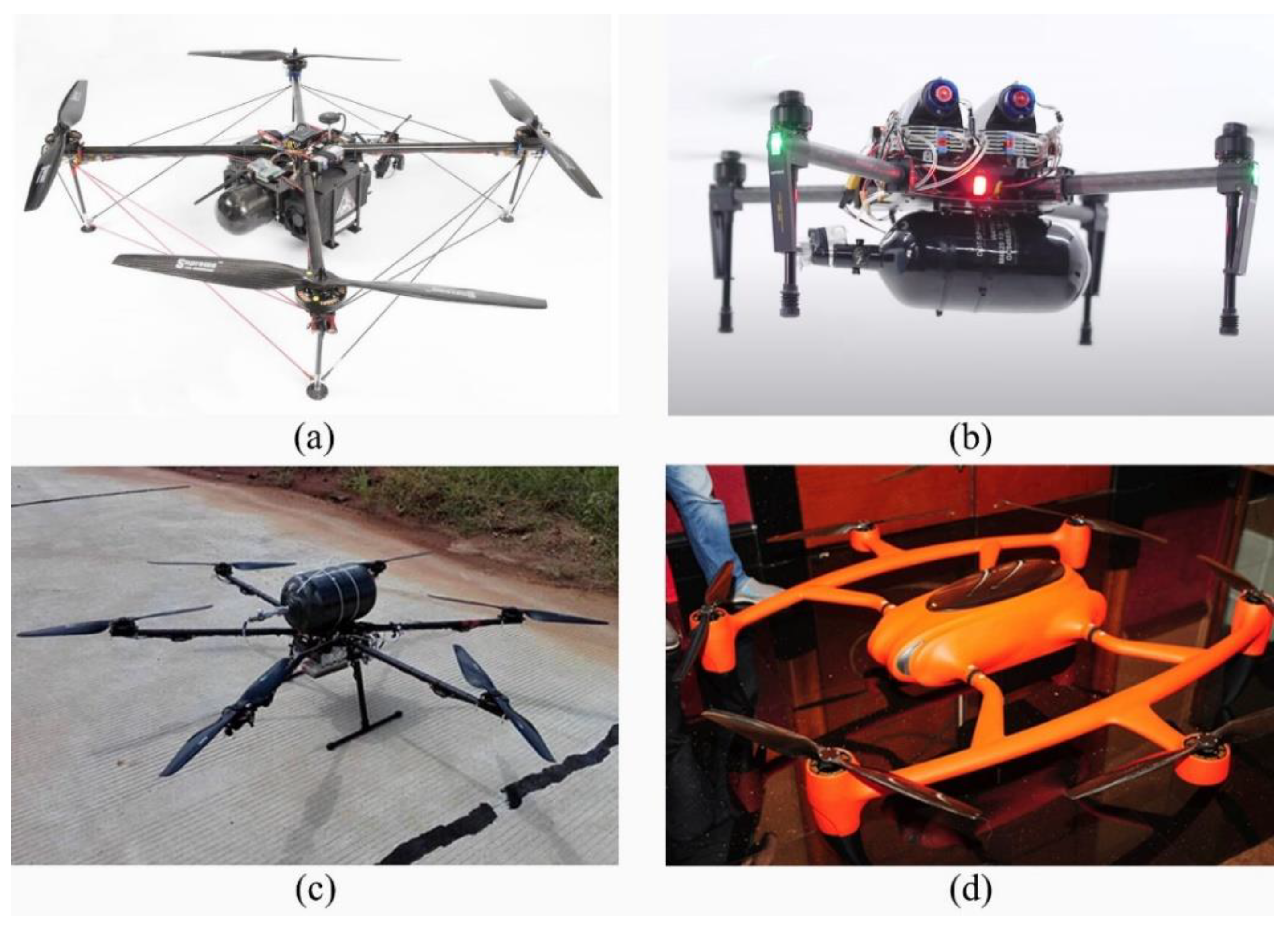

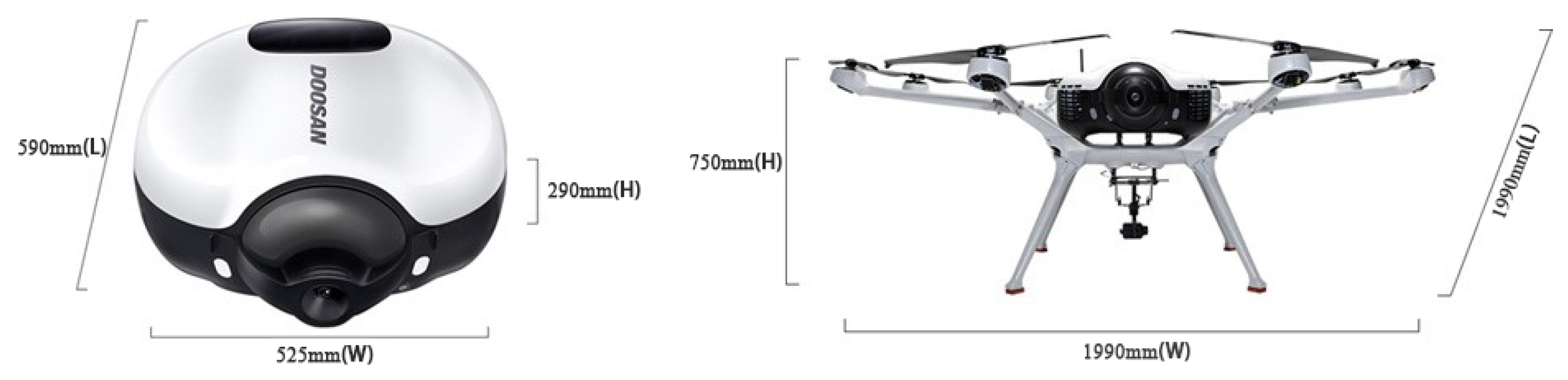

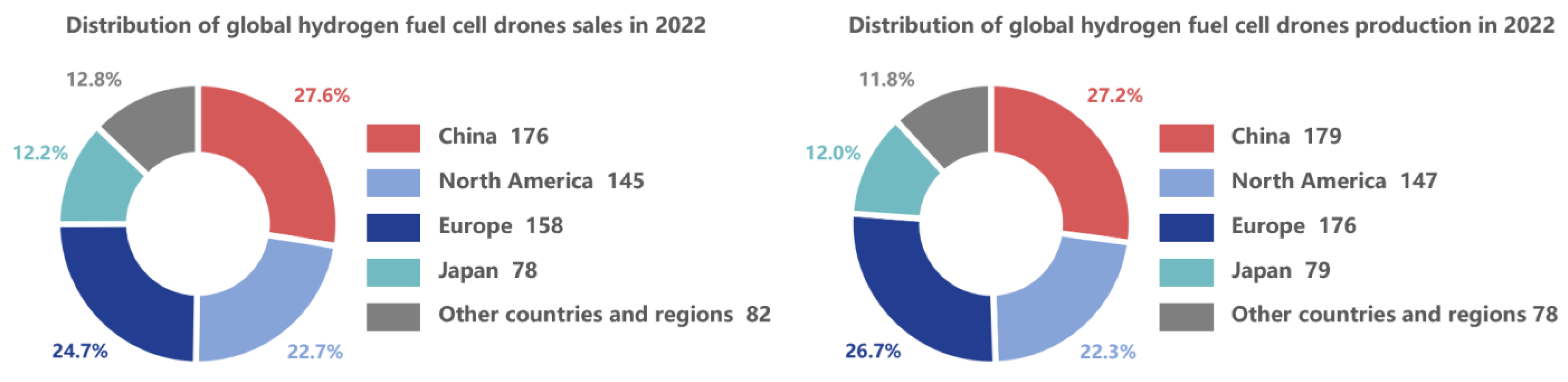

2. Development and Application of Hydrogen Fuel Cell Multi-Rotor Drones

3. Research Status of Key Technologies

3.1. Lightweight Design

3.1.1. Bipolar Plates

3.1.2. High-Pressure Gas Cylinders and Hydrogen Regulators

3.2. Hydrogen Storage Methods

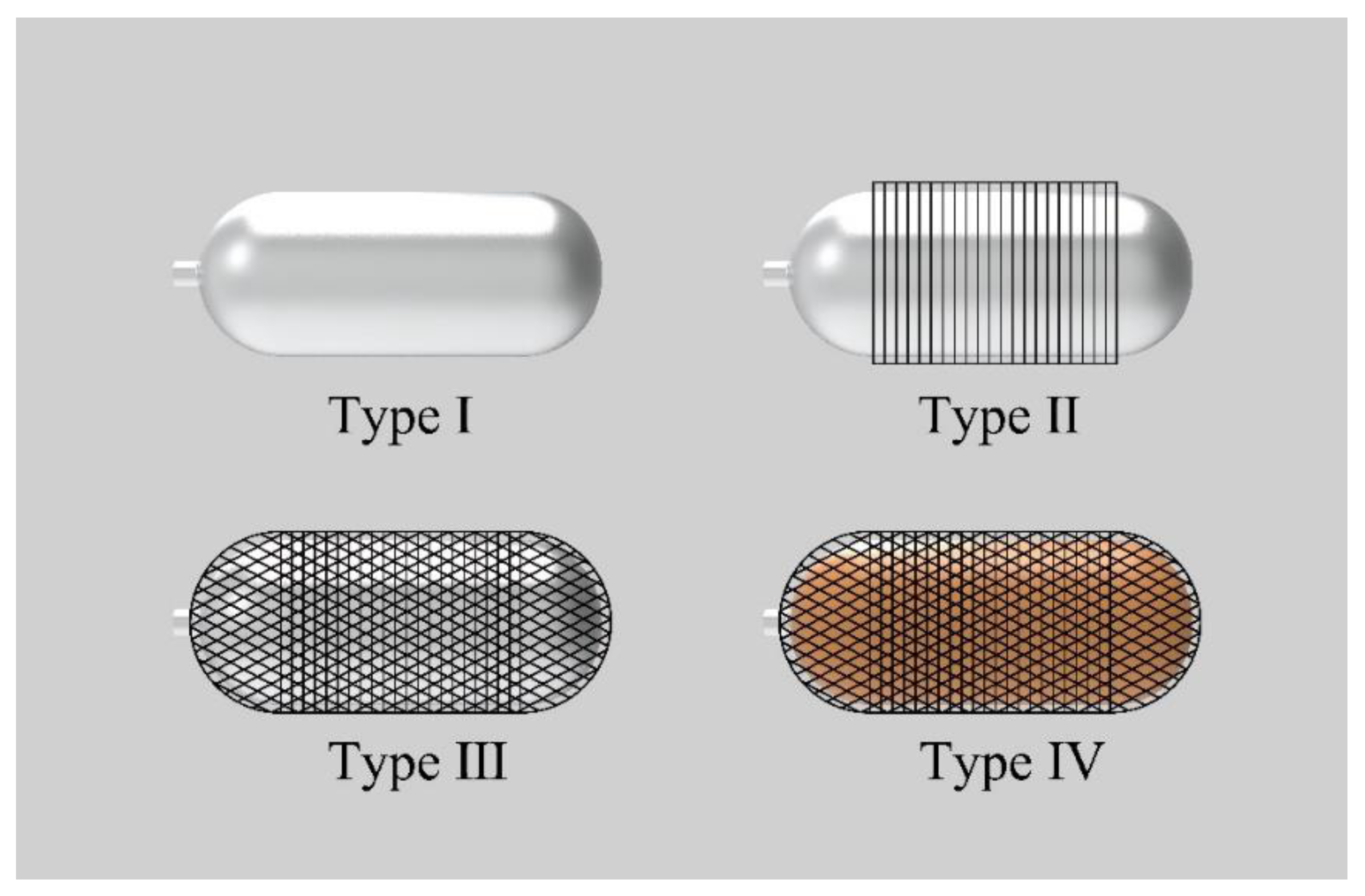

3.2.1. Compressed Gaseous Hydrogen Storage Methods

3.2.2. Liquid Hydrogen Storage Methods

3.2.3. Solid-State Hydrogen Storage Methods

3.2.4. Thermodynamic Properties of Different Hydrogen Storage Methods

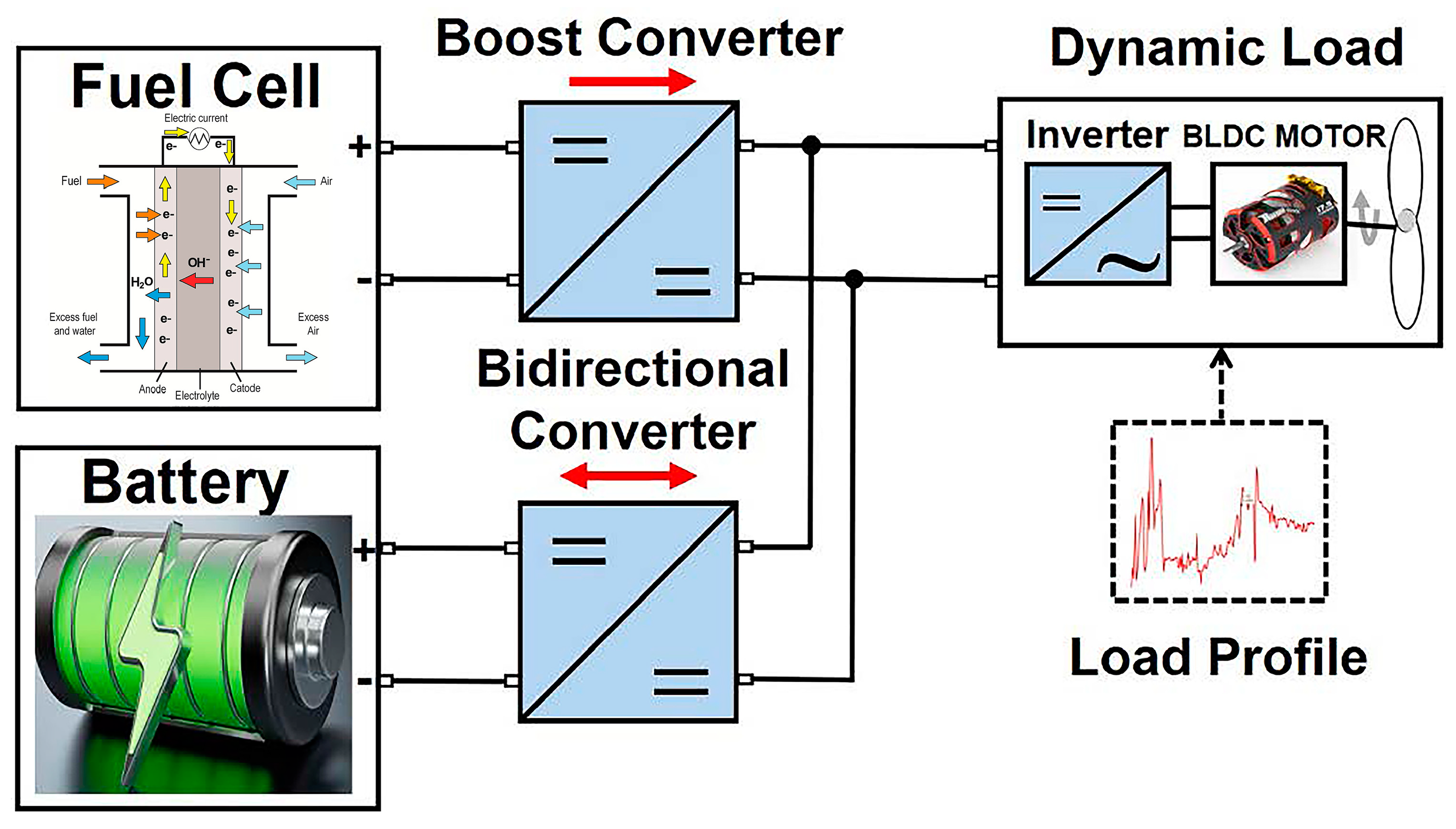

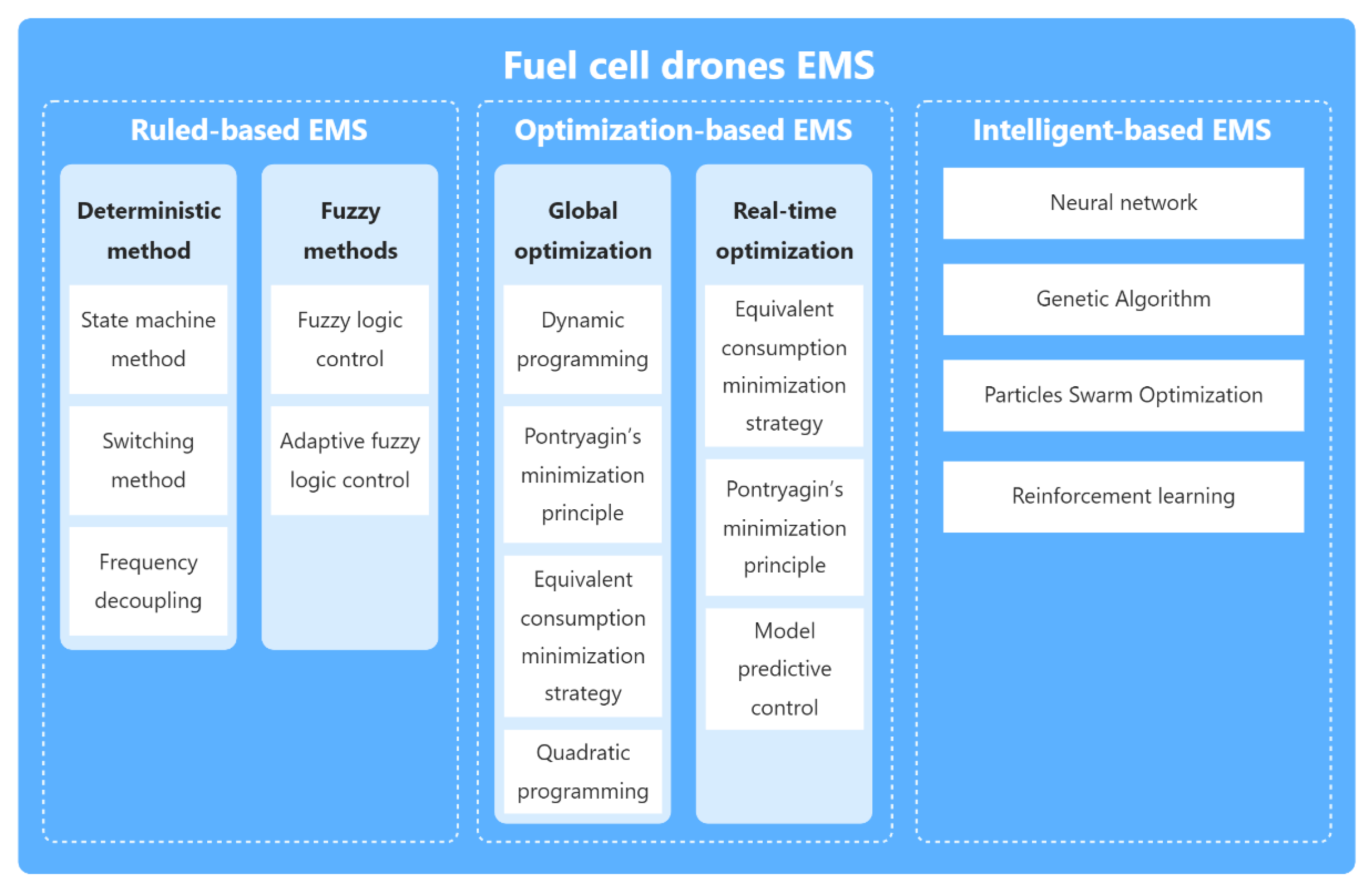

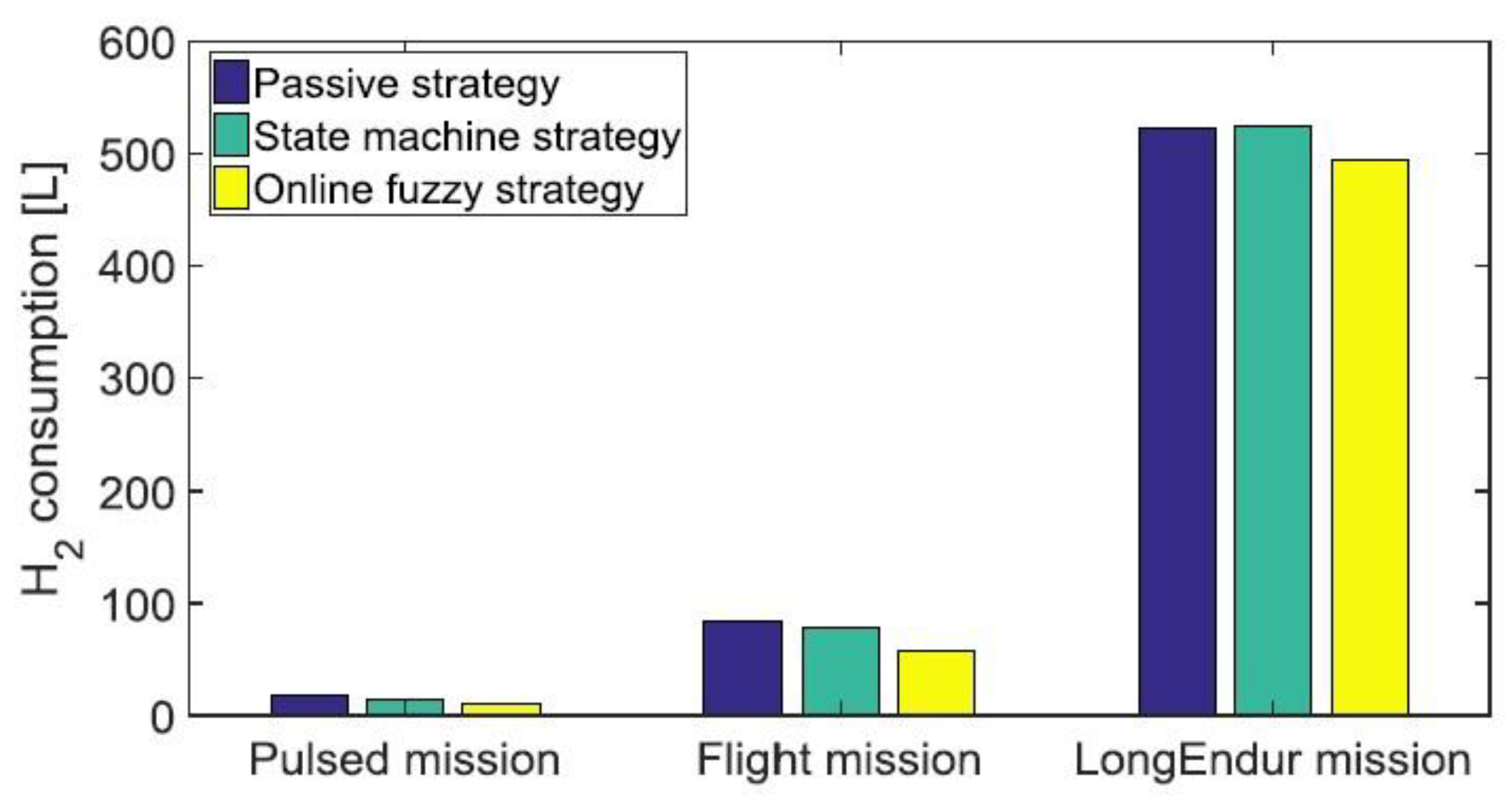

3.3. Energy Management Strategy

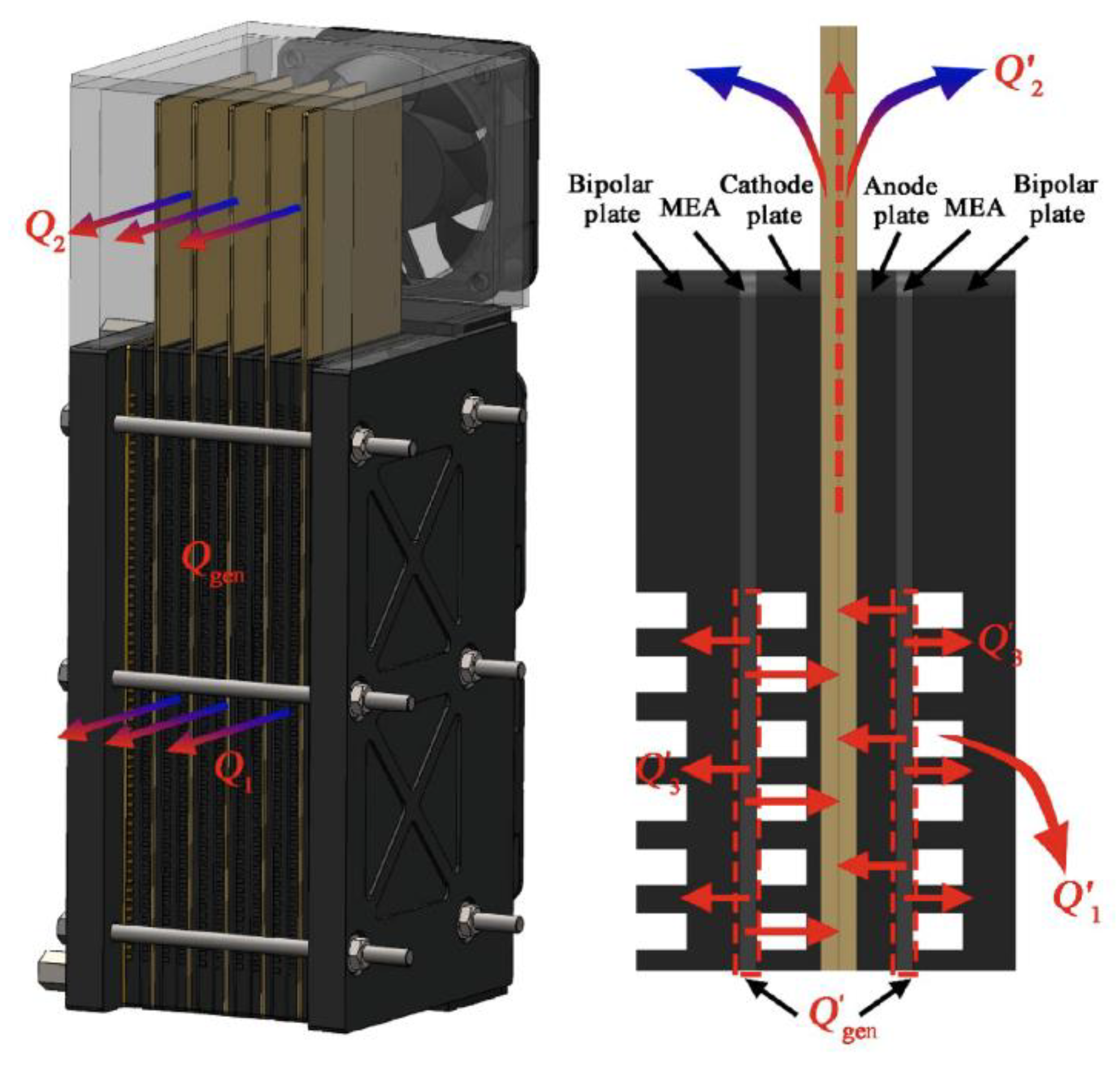

3.4. Thermal Management

3.5. The Influence of Gas Humidity on PEMFC Performance

3.6. Degradation of PEMFC System

3.7. Cold Start of PEMFC System

- (1)

- External heating with air preheating

- (2)

- Electrochemical reaction self-heating by increasing startup current

- (3)

- Optimization control strategy [198]

4. Summary and Future Scope

- Optimization of hydrogen storage methods.

- 2.

- Cathode gas filtration system.

- 3.

- Auxiliary equipment.

Author Contributions

Funding

Conflicts of Interest

References

- Lee, C.; Kim, S.; Chu, B. A Survey: Flight Mechanism and Mechanical Structure of the UAV. Int. J. Precis. Eng. Manuf. 2021, 22, 719–743. [Google Scholar] [CrossRef]

- Hassanalian, M.; Abdelkefi, A. Classifications, applications, and design challenges of drones: A review. Prog. Aerosp. Sci. 2017, 91, 99–131. [Google Scholar] [CrossRef]

- Arat, H.T.; Sürer, M.G. Experimental investigation of fuel cell usage on an air Vehicle’s hybrid propulsion system. Int. J. Hydrogen Energy 2020, 45, 26370–26378. [Google Scholar] [CrossRef]

- Floreano, D.; Wood, R.J. Science, technology and the future of small autonomous drones. Nature 2015, 521, 460–466. [Google Scholar] [CrossRef]

- Mademlis, I.; Mygdalis, V.; Nikolaidis, N.; Montagnuolo, M.; Negro, F.; Messina, A.; Pitas, I. High-Level Multiple-UAV Cinematography Tools for Covering Outdoor Events. IEEE Trans. Broadcast. 2019, 65, 627–635. [Google Scholar] [CrossRef]

- Ahmed, F.; Mohanta, J.C.; Keshari, A.; Yadav, P.S. Recent Advances in Unmanned Aerial Vehicles: A Review. Arab. J. Sci. Eng. 2022, 47, 7963–7984. [Google Scholar] [CrossRef]

- Luo, H.; Zhang, P.; Wang, J.J.; Wang, G.Q.; Meng, F.H. Traffic Patrolling Routing Problem with Drones in an Urban Road System. Sensors 2019, 19, 5164. [Google Scholar] [CrossRef]

- Humpe, A. Bridge Inspection with an Off-the-Shelf 360 degrees Camera Drone. Drones 2020, 4, 67. [Google Scholar] [CrossRef]

- Velusamy, P.; Rajendran, S.; Mahendran, R.K.; Naseer, S.; Shafiq, M.; Choi, J.-G. Unmanned Aerial Vehicles (UAV) in Precision Agriculture: Applications and Challenges. Energies 2021, 15, 217. [Google Scholar] [CrossRef]

- Phang, S.K.; Chiang, T.H.A.; Happonen, A.; Chang, M.M.L. From Satellite to UAV-Based Remote Sensing: A Review on Precision Agriculture. IEEE Access 2023, 11, 127057–127076. [Google Scholar] [CrossRef]

- Chen, C.J.; Huang, Y.Y.; Li, Y.S.; Chen, Y.C.; Chang, C.Y.; Huang, Y.M. Identification of Fruit Tree Pests With Deep Learning on Embedded Drone to Achieve Accurate Pesticide Spraying. IEEE Access 2021, 9, 21986–21997. [Google Scholar] [CrossRef]

- Iost, F.H.; Heldens, W.B.; Kong, Z.D.; de Lange, E.S. Drones: Innovative Technology for Use in Precision Pest Management. J. Econ. Entomol. 2020, 113, 1–25. [Google Scholar] [CrossRef] [PubMed]

- Rejeb, A.; Abdollahi, A.; Rejeb, K.; Treiblmaier, H. Drones in agriculture: A review and bibliometric analysis. Comput. Electron. Agric. 2022, 198, 107017. [Google Scholar] [CrossRef]

- Hu, P.; Zhang, R.; Yang, J.; Chen, L. Development Status and Key Technologies of Plant Protection UAVs in China: A Review. Drones 2022, 6, 354. [Google Scholar] [CrossRef]

- Liu, Z.; Li, J. Application of Unmanned Aerial Vehicles in Precision Agriculture. Agriculture 2023, 13, 1375. [Google Scholar] [CrossRef]

- Yan, Y.H.; Lv, Z.Y.; Yuan, J.B.; Chai, J.G. ANALYSIS OF POWER SOURCE OF MULTIROTOR UAVs. Int. J. Robot. Autom. 2019, 34, 563–571. [Google Scholar] [CrossRef]

- Gong, A.; Verstraete, D. Fuel cell propulsion in small fixed-wing unmanned aerial vehicles: Current status and research needs. Int. J. Hydrogen Energy 2017, 42, 21311–21333. [Google Scholar] [CrossRef]

- Kesselman, S. The First 1,000 Commercial UAS Exemptions. 2014, pp. 1–22. Available online: https://higherlogicdownload.s3.amazonaws.com/AUVSI/b657da80-1a58-4f8f-9971-7877b707e5c8/UploadedFiles/ZAvlBnqWSeSYXPsnKkoc_Section333Report_online022516.pdf (accessed on 16 June 2024).

- Apeland, J.; Pavlou, D.G.; Hemmingsen, T. Sensitivity Study of Design Parameters for a Fuel Cell Powered Multirotor Drone. J. Intell. Robot. Syst. 2021, 102, 6. [Google Scholar] [CrossRef]

- Depcik, C.; Cassady, T.; Collicott, B.; Burugupally, S.P.; Li, X.; Alam, S.S.; Arandia, J.R.; Hobeck, J. Comparison of lithium ion Batteries, hydrogen fueled combustion Engines, and a hydrogen fuel cell in powering a small Unmanned Aerial Vehicle. Energy Convers. Manag. 2020, 207, 112514. [Google Scholar] [CrossRef]

- Pan, Z.F.; An, L.; Wen, C.Y. Recent advances in fuel cells based propulsion systems for unmanned aerial vehicles. Appl. Energy 2019, 240, 473–485. [Google Scholar] [CrossRef]

- Belmonte, N.; Staulo, S.; Fiorot, S.; Luetto, C.; Rizzi, P.; Baricco, M. Fuel cell powered octocopter for inspection of mobile cranes: Design, cost analysis and environmental impacts. Appl. Energy 2018, 215, 556–565. [Google Scholar] [CrossRef]

- Cai, Q.; Brett, D.J.L.; Browning, D.; Brandon, N.P. A sizing-design methodology for hybrid fuel cell power systems and its application to an unmanned underwater vehicle. J. Power Sources 2010, 195, 6559–6569. [Google Scholar] [CrossRef]

- Savvaris, A.; Xie, Y.; Malandrakis, K.; Lopez, M.; Tsourdos, A. Development of a fuel cell hybrid-powered unmanned aerial vehicle. In Proceedings of the 24th Mediterranean Conference on Control and Automation (MED), Athens, Greece, 24 June 2016. [Google Scholar]

- Samimi, F.; Rahimpour, M.R. Direct Methanol Fuel Cell. In Methanol; Elsevier: Amsterdam, The Netherlands, 2018; pp. 381–397. [Google Scholar]

- Guangul, F.M.; Chala, G.T. A Comparative Study between the Seven Types of Fuel Cells. Appl. Sci. Eng. Prog. 2020, 13, 185–194. [Google Scholar] [CrossRef]

- Sazali, N.; Wan Salleh, W.N.; Jamaludin, A.S.; Mhd Razali, M.N. New Perspectives on Fuel Cell Technology: A Brief Review. Membranes 2020, 10, 99. [Google Scholar] [CrossRef]

- Sharaf, O.Z.; Orhan, M.F. An overview of fuel cell technology: Fundamentals and applications. Renew. Sustain. Energy Rev. 2014, 32, 810–853. [Google Scholar] [CrossRef]

- Tang, A.; Crisci, L.; Bonville, L.; Jankovic, J. An overview of bipolar plates in proton exchange membrane fuel cells. J. Renew. Sustain. Energy 2021, 13, 022701. [Google Scholar] [CrossRef]

- Liu, C.Y.; Sung, C.C. A review of the performance and analysis of proton exchange membrane fuel cell membrane electrode assemblies. J. Power Sources 2012, 220, 348–353. [Google Scholar] [CrossRef]

- Zhang, G.; Kandlikar, S.G. A critical review of cooling techniques in proton exchange membrane fuel cell stacks. Int. J. Hydrogen Energy 2012, 37, 2412–2429. [Google Scholar] [CrossRef]

- Ramezanizadeh, M.; Nazari, M.A.; Ahmadi, M.H.; Chen, L.E. A review on the approaches applied for cooling fuel cells. Int. J. Heat Mass Transf. 2019, 139, 517–525. [Google Scholar] [CrossRef]

- Graf, C.; Friedrich, K.A.; Vath, A.; Nicoloso, N. Dynamic load and temperature behavior of a PEFC-hybrid-system. J. Fuel Cell Sci. Technol. 2006, 3, 403–409. [Google Scholar] [CrossRef]

- Fluckiger, R.; Tiefenauer, A.; Ruge, M.; Aebi, C.; Wokaun, A.; Buchi, F.N. Thermal analysis and optimization of a portable, edge-air-cooled PEFC stack. J. Power Sources 2007, 172, 324–333. [Google Scholar] [CrossRef]

- Zakhvatkin, L.; Schechter, A.; Buri, E.; Avrahami, I. Edge Cooling of a Fuel Cell during Aerial Missions by Ambient Air. Micromachines 2021, 12, 1432. [Google Scholar] [CrossRef]

- Kurnia, J.C.; Chaedir, B.A.; Sasmito, A.P.; Shamim, T. Progress on open cathode proton exchange membrane fuel cell: Performance, designs, challenges and future directions. Appl. Energy 2021, 283, 116359. [Google Scholar] [CrossRef]

- Nguyen, H.Q.; Shabani, B. Proton exchange membrane fuel cells heat recovery opportunities for combined heating/cooling and power applications. Energy Convers. Manag. 2020, 204, 112328. [Google Scholar] [CrossRef]

- EnergyOr shows off world’s first fuel cell multirotor UAV. Fuel Cells Bull. 2015, 2015, 5–6. [CrossRef]

- EnergyOr fuel cell multirotor drone in 2 h flight with camera. Fuel Cells Bull. 2016, 2016, 3–4. [CrossRef]

- Horizon launches Hycopter fuel cell multirotor UAV. Fuel Cells Bull. 2015, 2015, 4. [CrossRef]

- Liu, L.; Cao, X.; Zhang, X.; He, Y. Review of development of light and small scale solar/hydrogen powered unmanned aerial vehicles. Acta Aeronaut. Astronaut. Sin. 2019, 41, 623474. [Google Scholar]

- Dutczak, J. Compressed hydrogen storage in contemporary fuel cell propulsion systems of small drones. IOP Conf. Ser. Mater. Sci. Eng. 2018, 421, 042013. [Google Scholar] [CrossRef]

- Chinese UAV maker MMC flies hydrogen fuel cell drone for 4 h. Fuel Cells Bull. 2016, 2016, 4–5. [CrossRef]

- Antunes, J. Fly Farther and Longer with FlightWave’s Hydrogen-Powered Jupiter-H2 Drone. Available online: https://www.commercialuavnews.com/infrastructure/fly-farther-longer-flightwaves-hydrogen-powered-jupiter-h2-drone (accessed on 25 April 2023).

- Intelligent Energy fuel cells for new ISS UAV. Fuel Cells Bull. 2020, 2020, 6. [CrossRef]

- Loughborough. Intelligent Energy’s 2.4 kW Fuel Cell Power Module Integrated into Latest UAV Product from ISS Aerospace. Available online: https://www.intelligent-energy.com/news/intelligent-energys-2-4kw-fuel-cell-power-module-integrated-into-latest-uav-product-from-iss-aerospace/ (accessed on 17 March 2023).

- HES multirotor drone, designed and built in US, has 3h flight time. Fuel Cells Bull. 2018, 2018, 5. [CrossRef]

- Skycorp hydrogen fuel cell powered drone with advanced AI. Fuel Cells Bull. 2018, 2018, 5. [CrossRef]

- Intelligent Energy powers two multirotor UAVs to new records. Fuel Cells Bull. 2019, 2019, 5–6. [CrossRef]

- Nordic Unmanned in hydrogen drone flight. Fuel Cells Bull. 2021, 2021, 5–6. [CrossRef]

- FuelCellWorks. MetaVista Breaks Guinness World Record of Multi Rotor UAV Flight Time Using Intelligent Energy Fuel Cell Power Module. Available online: https://fuelcellsworks.com/news/metavista-breaks-guinness-world-record-of-multi-rotor-uav-flight-time-using-intelligent-energy-fuel-cell-power-module/ (accessed on 16 March 2023).

- Intelligent Energy links up with UAV maker, unveils new module. Fuel Cells Bull. 2017, 2017, 4. [CrossRef]

- Intelligent Energy unveils 800 W fuel cell for commercial UAVs. Fuel Cells Bull. 2018, 2018, 6. [CrossRef]

- Intelligent Energy launches 2.4 kW fuel cell module for UAVs. Fuel Cells Bull. 2019, 2019, 6. [CrossRef]

- FuelCellsWorks. Unlocking the Potential of Hydrogen for Increased Drone Capabilities: Intelligent Energy Launches New Product to Provide Higher Power Up to1.6 kW for UAVs. Available online: https://fuelcellsworks.com/news/unlocking-the-potential-of-hydrogen-for-increased-drone-capabilities-intelligent-energy-launches-new-product-to-provide-higher-power-up-to-1-6kw-for-uavs/ (accessed on 16 June 2024).

- Intelligent Energy module provides up to 1.6 kW for UAVs. Fuel Cells Bull. 2019, 2019, 5. [CrossRef]

- Intelligent Energy fuel cells power endurance drone for US Army. Fuel Cells Bull. 2020, 2020, 5–6. [CrossRef]

- Doosan sets foot in UAV fuel cell market. Fuel Cells Bull. 2018, 2018, 6. [CrossRef]

- Doosan Mobility Innovation demos fuel cell drone for Africa. Fuel Cells Bull. 2020, 2020, 6. [CrossRef]

- DMI launches modular hydrogen fuel cell power pack for drones. Fuel Cells Bull. 2020, 2020, 6. [CrossRef]

- Chia, A.F.Y.; Min, K.M. Design and Performance Analysis of a Fuel Cell Powered Heavy-Lift Multirotor Drone. In Proceedings of the 2021 the Asia-Pacific International Symposium on Aerospace Technology (APISAT 2021), Jeju, Republic of Korea, 15–17 November 2021; Lecture Notes in Electrical Engineering. Springer: Cham, Switzerland, 2023; Volume 1, pp. 269–282. [Google Scholar]

- DMI fuel cell drone delivers face masks to remote Korean islands. Fuel Cells Bull. 2020, 2020, 5–6. [CrossRef]

- Ballard turnkey fuel cell solutions to power commercial UAVs. Fuel Cells Bull. 2019, 2019, 6. [CrossRef]

- FuelCellWorks. China: World Record Flight Time for Hydrogen Fuel Cell Drone. Available online: https://fuelcellsworks.com/news/china-world-record-flight-time-for-hydrogen-fuel-cell-drone/ (accessed on 24 March 2023).

- GB/T 38954-2020; Hydrogen Fuel Cell Power System for Unmanned Aerial Vehicles. Chinese Standard: Beijing, China, 2020.

- Boukoberine, M.N.; Zia, M.F.; Benbouzid, M.; Zhou, Z.; Donateo, T. Hybrid fuel cell powered drones energy management strategy improvement and hydrogen saving using real flight test data. Energy Convers. Manag. 2021, 236, 113987. [Google Scholar] [CrossRef]

- Coxworth, B. Hydrogen-Powered Hycopter Quadcopter Could Fly for 4 Hours at a Time. Available online: https://newatlas.com/horizon-energy-systems-hycopter-fuel-cell-drone/37585/ (accessed on 28 April 2024).

- Phoenix. Available online: https://www.spectronik.com/drone (accessed on 10 May 2024).

- Ball, M. UAV Fuel Cells Tested in Cold-Weather Conditions. Available online: https://www.unmannedsystemstechnology.com/2019/12/uav-fuel-cells-tested-in-cold-weather-conditions/ (accessed on 28 April 2024).

- A Drone System Optimized around Achieving the Best Fuel Cell Powerpack Performance DS30W. Available online: https://www.doosanmobility.com/en/products/drone-ds30 (accessed on 10 May 2024).

- Apeland, J.; Pavlou, D.; Hemmingsen, T. Suitability Analysis of Implementing a Fuel Cell on a Multirotor Drone. J. Aerosp. Technol. Manag. 2020, 12, e3220. [Google Scholar] [CrossRef]

- HydroCopter 4. Available online: https://www.hydrogencraft.com/en/Uploads/file/20240107/d93aadd7d5eaade8e6b483f5df78585c.pdf (accessed on 10 May 2024).

- A Durable, Versatile Commercial Drone Solution DT30X. Available online: https://www.doosanmobility.com/en/products/drone-dt30 (accessed on 10 May 2024).

- Mohsan, S.A.H.; Othman, N.Q.H.; Li, Y.; Alsharif, M.H.; Khan, M.A. Unmanned aerial vehicles (UAVs): Practical aspects, applications, open challenges, security issues, and future trends. Intell. Serv. Robot. 2023, 16, 109–137. [Google Scholar] [CrossRef] [PubMed]

- Tsuchiya, H. Mass production cost of PEM fuel cell by learning curve. Int. J. Hydrogen Energy 2004, 29, 985–990. [Google Scholar] [CrossRef]

- Porstmann, S.; Wannemacher, T.; Drossel, W.G. A comprehensive comparison of state-of-the-art manufacturing methods for fuel cell bipolar plates including anticipated future industry trends. J. Manuf. Process. 2020, 60, 366–383. [Google Scholar] [CrossRef]

- Kim, K.H.; Lim, J.W.; Kim, M.; Dai, G.L. Development of carbon fabric/graphite hybrid bipolar plate for PEMFC. Compos. Struct. 2013, 98, 103–110. [Google Scholar] [CrossRef]

- Hermann, A.; Chaudhuri, T.; Spagnol, P. Bipolar plates for PEM fuel cells: A review. Int. J. Hydrogen Energy 2005, 30, 1297–1302. [Google Scholar] [CrossRef]

- Marchetti, G.A. Thin Graphite Bipolar Plate with Associated Gaskets and Carbon Cloth Flow-Field for Use in an Ionomer Membrane Fuel Cell. U.S. Patent 6,503,654, 7 January 2003. [Google Scholar]

- Emanuelson, C.R.; Taylor, A.W.; Luoma, L.W. Separator Plate For Electrochemical Cells. Patent CA1164934A, 3 April 1984. [Google Scholar]

- Fan, R.; Peng, Y.; Tian, H.; Zheng, J.; Zhang, C.J.A.P.-C.S. Graphite-Filled Composite Bipolar Plates for Fuel Cells: Material, Structure, and Performance. Acta Phys. Chim. Sin. 2020, 37, 2009095. [Google Scholar] [CrossRef]

- Kuan, H.C.; Ma, C.C.M.; Chen, K.H.; Chen, S.M. Preparation, electrical, mechanical and thermal properties of composite bipolar plate for a fuel cell. J. Power Sources 2004, 134, 7–17. [Google Scholar] [CrossRef]

- Muller, A.; Kauranen, P.; von Ganski, A.; Hell, B. Injection moulding of graphite composite bipolar plates. J. Power Sources 2006, 154, 467–471. [Google Scholar] [CrossRef]

- Jo, J.; Zhang, X.; Ansari, A. Lightweight Pem Fuel Cell Stack for Unmanned Aerial Vehicle. In Proceedings of the ASME Heat Transfer Conference, Online, 7–11 June 2021. [Google Scholar]

- Song, Y.; Zhang, C.; Ling, C.-Y.; Han, M.; Yong, R.-Y.; Sun, D.; Chen, J. Review on current research of materials, fabrication and application for bipolar plate in proton exchange membrane fuel cell. Int. J. Hydrogen Energy 2020, 45, 29832–29847. [Google Scholar] [CrossRef]

- Tawfik, H.; Hung, Y.; Mahajan, D. Metal bipolar plates for PEM fuel cell—A review. J. Power Sources 2007, 163, 755–767. [Google Scholar] [CrossRef]

- Hung, Y.; El-Khatib, K.M.; Tawfik, H. Corrosion-resistant lightweight metallic bipolar plates for PEM fuel cells. J. Appl. Electrochem. 2005, 35, 445–447. [Google Scholar] [CrossRef][Green Version]

- DMI, POSCO SPS aim to cut weight of fuel cell drones. Fuel Cells Bull. 2021, 2021, 6. [CrossRef]

- Wang, H.L.; Sweikart, M.A.; Turner, J.A. Stainless steel as bipolar plate material for polymer electrolyte membrane fuel cells. J. Power Sources 2003, 115, 243–251. [Google Scholar] [CrossRef]

- Lin, C.H.; Tsai, S.Y. An investigation of coated aluminium bipolar plates for PEMFC. Appl. Energy 2012, 100, 87–92. [Google Scholar] [CrossRef]

- Yan, P.F.; Ying, T.; Yang, Y.; Cao, F.Y.; Li, Y.X.; Wang, J.Y.; Zeng, X.Q. Investigation of anodized Ta/Ag coating on magnesium bipolar plate for lightweight proton exchange membrane fuel cells. Corros. Sci. 2022, 197, 110086. [Google Scholar] [CrossRef]

- Xu, Z.; Qiu, D.; Yi, P.; Peng, L.; Lai, X.J. Towards mass applications: A review on the challenges and developments in metallic bipolar plates for PEMFC—ScienceDirect. Prog. Nat. Sci. Mater. Int. 2020, 30, 815–824. [Google Scholar] [CrossRef]

- Dobrovol’skii, Y.A.; Ukshe, A.E.; Levchenko, A.V.; Arkhangel’skii, I.V.; Ionov, S.G.; Avdeev, V.V.; Aldoshin, S.M. Materials for bipolar plates for proton-conducting membrane fuel cells. Russ. J. Gen. Chem. 2007, 77, 752–765. [Google Scholar] [CrossRef]

- Aukland, N.; Boudina, A.; Eddy, D.S.; Mantese, J.V.; Thompson, M.P.; Wang, S.S. Alloys that form conductive and passivating oxides for proton exchange membrane fuel cell bipolar plates. J. Mater. Res. 2004, 19, 1723–1729. [Google Scholar] [CrossRef]

- Gou, Y.; Jiang, G.; Geng, J.T.; Shao, Z.G. Properties of NbC/a-C:H films on titanium bipolar plates for proton exchange membrane fuel cells. Fuel Cells 2022, 23, 51–59. [Google Scholar] [CrossRef]

- Li, T.; Zhang, H.Y.; Wang, Y.; Wu, C.L.; Yan, Y.G.; Chen, Y.G. TiCr transition layer promoting the growth of high-stability TiCrN coating for titanium bipolar plate. Surf. Coat. Technol. 2022, 451, 129026. [Google Scholar] [CrossRef]

- Wang, Z.D.; Zhang, B.; Gao, K.X.; Liu, R.X. Adjustable TiN coatings deposited with HiPIMS on titanium bipolar plates for PEMFC. Int. J. Hydrogen Energy 2022, 47, 39215–39224. [Google Scholar] [CrossRef]

- Yin, Q.; Zhang, K.; Fu, X.Z.; Wang, X.Z.; Luo, J.L. Rapid coating preparation strategy for chromium nitride coated titanium bipolar plates of proton exchange membrane fuel cells. Int. J. Hydrogen Energy 2022, 47, 31435–31445. [Google Scholar] [CrossRef]

- Zhang, H.B.; Hou, M.; Lin, G.Q.; Han, Z.Y.; Fu, Y.; Sun, S.C.; Shao, Z.G.; Yi, B.L. Performance of Ti-Ag-deposited titanium bipolar plates in simulated unitized regenerative fuel cell (URFC) environment. Int. J. Hydrogen Energy 2011, 36, 5695–5701. [Google Scholar] [CrossRef]

- Wu, S.; Yang, W.; Yan, H.; Zuo, X.; Cao, Z.; Li, H.; Shi, M.; Chen, H. A review of modified metal bipolar plates for proton exchange membrane fuel cells. Int. J. Hydrogen Energy 2021, 46, 8672–8701. [Google Scholar] [CrossRef]

- Gao, P.; Xie, Z.; Ouyng, C.; Wu, X.; Lei, T.; Liu, C.; Huang, Q. Carbon composite coatings on Ti for corrosion protection as bipolar plates of proton exchange membrane fuel cells. Micro Nano Lett. 2018, 13, 931–935. [Google Scholar] [CrossRef]

- Zhang, F.; Zhao, P.C.; Niu, M.; Maddy, J. The survey of key technologies in hydrogen energy storage. Int. J. Hydrogen Energy 2016, 41, 14535–14552. [Google Scholar] [CrossRef]

- Li, M.X.; Bai, Y.F.; Zhang, C.Z.; Song, Y.X.; Jiang, S.F.; Grouset, D.; Zhang, M.J. Review on the research of hydrogen storage system fast refueling in fuel cell vehicle. Int. J. Hydrogen Energy 2019, 44, 10677–10693. [Google Scholar] [CrossRef]

- Barthélémy, H. Hydrogen storage—Industrial prospectives. Int. J. Hydrogen Energy 2012, 37, 17364–17372. [Google Scholar] [CrossRef]

- Zheng, J.; Liu, X.; Xu, P.; Liu, P.; Zhao, Y.; Yang, J. Development of high pressure gaseous hydrogen storage technologies. Int. J. Hydrogen Energy 2012, 37, 1048–1057. [Google Scholar] [CrossRef]

- Rohit, G.; Santosh, M.S.; Kumar, M.N.; Raghavendra, K. Numerical investigation on structural stability and explicit performance of high-pressure hydrogen storage cylinders. Int. J. Hydrogen Energy 2023, 48, 5565–5575. [Google Scholar] [CrossRef]

- Cho, S.M.; Kim, C.; Kim, K.S.; Kim, D.K. Lightweight hydrogen storage cylinder for fuel cell propulsion systems to be applied in drones. Int. J. Press. Vessel. Pip. 2021, 194, 104428. [Google Scholar] [CrossRef]

- Cho, S.M.; Kim, K.S.; Kim, W.; Choi, S.J. Application of PET as a non-metallic liner for the 6.8 L type-4 cylinder based on the hydrogen cycling test. Int. J. Hydrogen Energy 2022, 47, 6965–6973. [Google Scholar] [CrossRef]

- Roh, H.S.; Hua, T.Q.; Ahluwalia, R.K. Optimization of carbon fiber usage in Type 4 hydrogen storage tanks for fuel cell automobiles. Int. J. Hydrogen Energy 2013, 38, 12795–12802. [Google Scholar] [CrossRef]

- Alcántar, V.; Aceves, S.M.; Ledesma, E.; Ledesma, S.; Aguilera, E. Optimization of Type 4 composite pressure vessels using genetic algorithms and simulated annealing. Int. J. Hydrogen Energy 2017, 42, 15770–15781. [Google Scholar] [CrossRef]

- Lee, Y.; Park, E.T.; Jeong, J.; Shi, H.; Kim, J.; Kang, B.S.; Song, W. Weight optimization of hydrogen storage vessels for quadcopter UAV using genetic algorithm. Int. J. Hydrogen Energy 2020, 45, 33939–33947. [Google Scholar] [CrossRef]

- Guo, L.; Su, J.; Wang, Z.; Shi, J.; Guan, X.; Cao, W.; Ou, Z. Hydrogen safety: An obstacle that must be overcome on the road towards future hydrogen economy. Int. J. Hydrogen Energy 2024, 51, 1055–1078. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, S.; Cui, B.; Zhang, N. Analysis of Crash Characteristics of Hydrogen Storage Structure of Hydrogen Powered UAV. Aerospace 2022, 9, 687. [Google Scholar] [CrossRef]

- Ma, Q.; He, Y.; You, J.; Chen, J.; Zhang, Z. Probabilistic risk assessment of fire and explosion of onboard high-pressure hydrogen system. Int. J. Hydrogen Energy 2024, 50, 1261–1273. [Google Scholar] [CrossRef]

- Zhang, Z.; Yu, F.; Qu, D. Analysis of millisecond collision of composite high pressure hydrogen storage cylinder. Int. J. Hydrogen Energy 2023, 48, 11578–11591. [Google Scholar] [CrossRef]

- Chen, L.; Xu, K.; Yang, Z.; Yan, Z.; Dong, Z. Optimal Design and Operation of Dual-Ejector PEMFC Hydrogen Supply and Circulation System. Energies 2022, 15, 5427. [Google Scholar] [CrossRef]

- Chen, J.X.; Veenstra, M.; Purewal, J.; Hobein, B.; Papasauva, S. Modeling a hydrogen pressure regulator in a fuel cell system with Joule-Thomson effect. Int. J. Hydrogen Energy 2019, 44, 1272–1287. [Google Scholar] [CrossRef]

- The LW351 Series Operating and Service Manual. Available online: https://www.pressure-tech.com/files/124/LW-351%20Series%20-%20O&S%20Manual.pdf (accessed on 16 June 2024).

- Zhang, Y.H.; Jia, Z.C.; Yuan, Z.M.; Yang, T.; Qi, Y.; Zhao, D.L. Development and Application of Hydrogen Storage. J. Iron Steel Res. Int. 2015, 22, 757–770. [Google Scholar] [CrossRef]

- Chen, Y.Z.; Zhao, S.L.; Ma, H.J.; Wang, H.; Hua, L.; Fu, S. Analysis of Hydrogen Embrittlement on Aluminum Alloys for Vehicle-Mounted Hydrogen Storage Tanks: A Review. Metals 2021, 11, 1303. [Google Scholar] [CrossRef]

- Niste, V.B.; Tanaka, H.; Ratoi, M.; Sugimura, J. WS2 nanoadditized lubricant for applications affected by hydrogen embrittlement. RSC Adv. 2015, 5, 40678–40687. [Google Scholar] [CrossRef]

- Tarhan, C.; Çil, M.A. A study on hydrogen, the clean energy of the future: Hydrogen storage methods. J. Energy Storage 2021, 40, 102676. [Google Scholar] [CrossRef]

- Moradi, R.; Groth, K.M. Hydrogen storage and delivery: Review of the state of the art technologies and risk and reliability analysis. Int. J. Hydrogen Energy 2019, 44, 12254–12269. [Google Scholar] [CrossRef]

- Stroman, R.O.; Schuette, M.W.; Swider-Lyons, K.; Rodgers, J.A.; Edwards, D.J. Liquid hydrogen fuel system design and demonstration in a small long endurance air vehicle. Int. J. Hydrogen Energy 2014, 39, 11279–11290. [Google Scholar] [CrossRef]

- Aziz, M. Liquid Hydrogen: A Review on Liquefaction, Storage, Transportation, and Safety. Energies 2021, 14, 5917. [Google Scholar] [CrossRef]

- Kang, D.; Yun, S.; Kim, B.-k. Review of the Liquid Hydrogen Storage Tank and Insulation System for the High-Power Locomotive. Energies 2022, 15, 4357. [Google Scholar] [CrossRef]

- Yatsenko, E.A.; Goltsman, B.M.; Novikov, Y.V.; Izvarin, A.I.; Platov, I.V.R. Review on modern ways of insulation of reservoirs for liquid hydrogen storage. Int. J. Hydrogen Energy 2022, 47, 41046–41054. [Google Scholar] [CrossRef]

- Osborn, W.; Markmaitree, T.; Shaw, L.L.; Ren, R.M.; Hu, J.Z.; Kwak, J.H.; Yang, Z.G. Solid-State Hydrogen Storage: Storage Capacity, Thermodynamics, and Kinetics. JOM 2009, 61, 45–51. [Google Scholar] [CrossRef]

- Khafidz, N.Z.A.; Yaakob, Z.; Lim, K.L.; Timmiati, S.N. The kinetics of lightweight solid-state hydrogen storage materials: A review. Int. J. Hydrogen Energy 2016, 41, 13131–13151. [Google Scholar] [CrossRef]

- Rimza, T.; Saha, S.; Dhand, C.; Dwivedi, N.; Patel, S.S.; Singh, S.; Kumar, P. Carbon-Based Sorbents for Hydrogen Storage: Challenges and Sustainability at Operating Conditions for Renewable Energy. Chemsuschem 2022, 15, e202200281. [Google Scholar] [CrossRef]

- Manilov, A.I.; Skryshevsky, V.A. Hydrogen in porous silicon—A review. Mater. Sci. Eng. B-Adv. Funct. Solid-State Mater. 2013, 178, 942–955. [Google Scholar] [CrossRef]

- Muduli, R.C.; Kale, P. Silicon nanostructures for solid-state hydrogen storage: A review. Int. J. Hydrogen Energy 2023, 48, 1401–1439. [Google Scholar] [CrossRef]

- Thomas, K.M. Adsorption and desorption of hydrogen on metal–organic framework materials for storage applications: Comparison with other nanoporous materials. Dalton Trans. 2009, 1487–1505. [Google Scholar] [CrossRef]

- Samantaray, S.S.; Putnam, S.T.; Stadie, N.P. Volumetrics of Hydrogen Storage by Physical Adsorption. Inorganics 2021, 9, 45. [Google Scholar] [CrossRef]

- Pedicini, R.; Sacca, A.; Carbone, A.; Passalacqua, E. Hydrogen storage based on polymeric material. Int. J. Hydrogen Energy 2011, 36, 9062–9068. [Google Scholar] [CrossRef]

- First UAV test flight with Cella solid-state hydrogen storage. Fuel Cells Bull. 2016, 3, 4–5.

- Kim, H.; Oh, T.H.; Kwon, S. Simple catalyst bed sizing of a NaBH4 hydrogen generator with fast startup for small unmanned aerial vehicles. Int. J. Hydrogen Energy 2016, 41, 1018–1026. [Google Scholar] [CrossRef]

- Kwon, S.M.; Kim, M.J.; Kang, S.; Kim, T. Development of a high-storage-density hydrogen generator using solid-state NaBH4 as a hydrogen source for unmanned aerial vehicles. Appl. Energy 2019, 251, 113331. [Google Scholar] [CrossRef]

- Salman, M.S.; Rambhujun, N.; Pratthana, C.; Lai, Q.; Aguey-Zinsou, K.F. Solid-state hydrogen storage as a future renewable energy technology. In Nano Tools and Devices for Enhanced Renewable Energy; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- O’Hayre, R.; Cha, S.-W.; Colella, W.G.; Prinz, F.B. Fuel Cell Fundamentals; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Wang, H.; Lin, H.J.; Cai, W.T.; Ouyang, L.Z.; Zhu, M. Tuning kinetics and thermodynamics of hydrogen storage in light metal element based systems—A review of recent progress. J. Alloys Compd. 2016, 658, 280–300. [Google Scholar] [CrossRef]

- Chen, Z.; Ma, Z.; Zheng, J.; Li, X.; Akiba, E.; Li, H.-W. Perspectives and challenges of hydrogen storage in solid-state hydrides. Chin. J. Chem. Eng. 2021, 29, 1–12. [Google Scholar] [CrossRef]

- Lang, C.; Jia, Y.; Yao, X. Recent advances in liquid-phase chemical hydrogen storage. Energy Storage Mater. 2020, 26, 290–312. [Google Scholar] [CrossRef]

- Yanxing, Z.; Maoqiong, G.; Yuan, Z.; Xueqiang, D.; Jun, S. Thermodynamics analysis of hydrogen storage based on compressed gaseous hydrogen, liquid hydrogen and cryo-compressed hydrogen. Int. J. Hydrogen Energy 2019, 44, 16833–16840. [Google Scholar] [CrossRef]

- Rivard, E.; Trudeau, M.; Zaghib, K. Hydrogen Storage for Mobility: A Review. Materials 2019, 12, 1973. [Google Scholar] [CrossRef] [PubMed]

- Ozbek, E.; Yalin, G.; Ekici, S.; Karakoc, T.H. Evaluation of design methodology, limitations, and iterations of a hydrogen fuelled hybrid fuel cell mini UAV. Energy 2020, 213, 118757. [Google Scholar] [CrossRef]

- Erdinc, O.; Uzunoglu, M. Recent trends in PEM fuel cell-powered hybrid systems: Investigation of application areas, design architectures and energy management approaches. Renew. Sustain. Energy Rev. 2010, 14, 2874–2884. [Google Scholar] [CrossRef]

- Vural, B.; Dusmez, S.; Uzunoglu, M.; Ugur, E.; Akin, B. Fuel Consumption Comparison of Different Battery/Ultracapacitor Hybridization Topologies for Fuel-Cell Vehicles on a Test Bench. IEEE J. Emerg. Sel. Top. Power Electron. 2014, 2, 552–561. [Google Scholar] [CrossRef]

- Ustolin, F.; Taccani, R. Fuel cells for airborne usage: Energy storage comparison. Int. J. Hydrogen Energy 2018, 43, 11853–11861. [Google Scholar] [CrossRef]

- Ahmadi, S.; Bathaee, S.M.T.; Hosseinpour, A.H. Improving fuel economy and performance of a fuel-cell hybrid electric vehicle (fuel-cell, battery, and ultra-capacitor) using optimized energy management strategy. Energy Convers. Manag. 2018, 160, 74–84. [Google Scholar] [CrossRef]

- Karunarathne, L.; Economou, J.T.; Knowles, K. Power and energy management system for fuel cell unmanned aerial vehicle. Proc. Inst. Mech. Eng. Part G-J. Aerosp. Eng. 2012, 226, 437–454. [Google Scholar] [CrossRef]

- Gang, B.G.; Kwon, S. Design of an energy management technique for high endurance unmanned aerial vehicles powered by fuel and solar cell systems. Int. J. Hydrogen Energy 2018, 43, 9787–9796. [Google Scholar] [CrossRef]

- Xu, L.; Huangfu, Y.; Ma, R.; Xie, R.; Song, Z.; Zhao, D.; Yang, Y.; Wang, Y.; Xu, L. A Comprehensive Review on Fuel Cell UAV Key Technologies: Propulsion System, Management Strategy, and Design Procedure. IEEE Trans. Transp. Electrif. 2022, 8, 4118–4139. [Google Scholar] [CrossRef]

- Apeland, J.; Pavlou, D.; Hemmingsen, T. State-of-Technology and Barriers for Adoption of Fuel Cell Powered Multirotor Drones. In Proceedings of the International Conference on Unmanned Aircraft Systems (ICUAS), Athens, Greece, 1–4 September 2020; pp. 1359–1367. [Google Scholar]

- Zhang, X.; Liu, L.; Dai, Y.; Lu, T. Experimental investigation on the online fuzzy energy management of hybrid fuel cell/battery power system for UAVs. Int. J. Hydrogen Energy 2018, 43, 10094–10103. [Google Scholar] [CrossRef]

- Lei, T.; Min, Z.; Fu, H.; Zhang, X.; Li, W.; Zhang, X. Dynamic balanced energy management strategies for fuel-cell hybrid power system of unmanned air vehicle. Acta Aeronaut. Astronaut. Sin. 2020, 41, 15. [Google Scholar]

- Boukoberine, M.N.; Donateo, T.; Benbouzid, M. Optimized Energy Management Strategy for Hybrid Fuel Cell Powered Drones in Persistent Missions using Real Flight Test Data. IEEE Trans. Energy Convers. 2022, 37, 2080–2091. [Google Scholar] [CrossRef]

- Liu, H.; Yao, Y.; Wang, J.; Qin, Y.; Li, T.J. A control architecture to coordinate energy management with trajectory tracking control for fuel cell/battery hybrid unmanned aerial vehicles. Int. J. Hydrogen Energy 2022, 47, 15236–15253. [Google Scholar] [CrossRef]

- Yao, Y.; Wang, J.; Zhou, Z.; Li, H.; Liu, H.; Li, T. Grey Markov prediction-based hierarchical model predictive control energy management for fuel cell/battery hybrid unmanned aerial vehicles. Energy 2023, 262, 125405. [Google Scholar] [CrossRef]

- Yan, Y.; Wang, B.; Wang, C.; Zhao, D.; Xiao, C. Adaptive maximum power point tracking based on Kalman filter for hydrogen fuel cell in hybrid unmanned aerial vehicle applications. Int. J. Hydrogen Energy 2023, 48, 25939–25957. [Google Scholar] [CrossRef]

- Zeng, D.; Guo, X.; Guo, K.; Dong, Z.; Yu, X. Design and Management of a Hydrogen Fuel Cell Powered Quadrotor. In Proceedings of the 2023 International Conference on Unmanned Aircraft Systems (ICUAS), Warsaw, Poland, 6–9 June 2023; pp. 644–651. [Google Scholar]

- Chen, Q.; Zhang, G.; Zhang, X.; Sun, C.; Jiao, K.; Wang, Y. Thermal management of polymer electrolyte membrane fuel cells: A review of cooling methods, material properties, and durability. Appl. Energy 2021, 286, 116496. [Google Scholar] [CrossRef]

- Afshari, E.; Asghari, S.; Jahantigh, N.; Shamsizadeh, P. Recent advancements and prospects of thermal management strategies in polymer electrolyte membrane (PEM) fuel cells. In Handbook of Thermal Management Systems; Elsevier: Amsterdam, The Netherlands, 2023; pp. 417–440. [Google Scholar]

- Shahsavari, S.; Desouza, A.; Bahrami, M.; Kjeang, E. Thermal analysis of air-cooled PEM fuel cells. Int. J. Hydrogen Energy 2012, 37, 18261–18271. [Google Scholar] [CrossRef]

- Meng, H.; Yu, X.; Luo, X.; Tu, Z. Modelling and operation characteristics of air-cooled PEMFC with metallic bipolar plate used in unmanned aerial vehicle. Energy 2024, 300, 131559. [Google Scholar] [CrossRef]

- Chang, Z.; Fan, Y.; Jiang, W.; Zhang, J.; Zhang, J. Simulation Research on Thermal Management of Hydrogen Fuel Cell for UAV. In 6GN for Future Wireless Networks; Lecture Notes of the Institute for Computer Sciences, Social Informatics and Telecommunications Engineering; Springer: Cham, Switzerland, 2024; pp. 390–408. [Google Scholar]

- Zhao, J.; Huang, Z.; Jian, B.; Bai, X.; Jian, Q. Thermal performance enhancement of air-cooled proton exchange membrane fuel cells by vapor chambers. Energy Convers. Manag. 2020, 213, 112830. [Google Scholar] [CrossRef]

- Huang, Z.; Jian, Q. Cooling efficiency optimization on air-cooling PEMFC stack with thin vapor chambers. Appl. Therm. Eng. 2022, 217, 119238. [Google Scholar] [CrossRef]

- Huang, Z.; Jian, Q.; Zhao, J. Thermal management of open-cathode proton exchange membrane fuel cell stack with thin vapor chambers. J. Power Sources 2021, 485, 229314. [Google Scholar] [CrossRef]

- Bai, X.; Jian, Q. Experimental study of a passive thermal management system using vapor chamber for proton exchange membrane fuel cell stack. Renew. Energy 2023, 216, 119095. [Google Scholar] [CrossRef]

- Li, Q.; Liu, Z.; Sun, Y.; Yang, S.; Deng, C. A Review on Temperature Control of Proton Exchange Membrane Fuel Cells. Processes 2021, 9, 235. [Google Scholar] [CrossRef]

- Yin, C.; Hua, S.; Nie, W.; Yang, H.; Tang, H. Comparative study on air-cooled fuel cell stacks with metal and graphite bipolar plate designs for unmanned aerial vehicles. eTransportation 2024, 21, 100344. [Google Scholar] [CrossRef]

- He, L.; Yang, Y.; Zhang, Y.; Li, P.; Xin, Y. A review of thermal management of proton exchange membrane fuel cell systems. J. Renew. Sustain. Energy 2023, 15, 012703. [Google Scholar] [CrossRef]

- Yuan, W.-W.; Ou, K.; Kim, Y.-B. Thermal management for an air coolant system of a proton exchange membrane fuel cell using heat distribution optimization. Appl. Therm. Eng. 2020, 167, 114715. [Google Scholar] [CrossRef]

- Wang, Y.-X.; Chen, Q.; Zhang, J.; He, H. Real-time power optimization for an air-coolant proton exchange membrane fuel cell based on active temperature control. Energy 2021, 220, 119497. [Google Scholar] [CrossRef]

- Yu, X.; Zhang, C.; Li, M.; Wang, G.; Tu, Z.; Yu, T.; Dong, H.; Zhao, F. Thermal management of an open-cathode PEMFC based on constraint generalized predictive control and optimized strategy. Renew. Energy 2024, 220, 119608. [Google Scholar] [CrossRef]

- Yin, C.; Gao, Y.; Li, K.; Wu, D.; Song, Y.; Tang, H. Design and numerical analysis of air-cooled proton exchange membrane fuel cell stack for performance optimization. Energy Convers. Manag. 2021, 245, 114604. [Google Scholar] [CrossRef]

- Sveshnikova, A.; Abrosimov, K.; Khayrullina, A.; Ustinov, A. Effect of ambient air conditions on PEM fuel cell performance. J. Renew. Sustain. Energy 2017, 9, 044301. [Google Scholar] [CrossRef]

- Huang, B.T.; Chatillon, Y.; Bonnet, C.; Lapicque, F.; Leclerc, S.; Hinaje, M.; Raël, S. Experimental Investigation of Air Relative Humidity (RH) Cycling Tests on MEA/Cell Aging in PEMFC Part I: Study of High RH Cycling Test With air RH at 62%/100%. Fuel Cells 2012, 12, 335–346. [Google Scholar] [CrossRef]

- Chen, Z.; Ingham, D.; Ismail, M.; Ma, L.; Hughes, K.J.; Pourkashanian, M. Effects of hydrogen relative humidity on the performance of an air-breathing PEM fuel cell. Int. J. Numer. Methods Heat Fluid Flow 2019, 30, 2077–2097. [Google Scholar] [CrossRef]

- Ozen, D.N.; Timurkutluk, B.; Altinisik, K. Effects of operation temperature and reactant gas humidity levels on performance of PEM fuel cells. Renew. Sustain. Energy Rev. 2016, 59, 1298–1306. [Google Scholar] [CrossRef]

- Kim, S.; Hong, I. Effects of humidity and temperature on a proton exchange membrane fuel cell (PEMFC) stack. J. Ind. Eng. Chem. 2008, 14, 357–364. [Google Scholar] [CrossRef]

- Wang, B.; Lin, R.; Liu, D.; Xu, J.; Feng, B. Investigation of the effect of humidity at both electrode on the performance of PEMFC using orthogonal test method. Int. J. Hydrogen Energy 2019, 44, 13737–13743. [Google Scholar] [CrossRef]

- Ou, K.; Yuan, W.-W.; Choi, M.; Yang, S.; Kim, Y.-B. Performance increase for an open-cathode PEM fuel cell with humidity and temperature control. Int. J. Hydrogen Energy 2017, 42, 29852–29862. [Google Scholar] [CrossRef]

- Nefedkin, S.I.; Klimova, M.A.; Glasov, V.S.; Pavlov, V.I.; Tolmachev, Y.V. Effect of the corrugated bipolar plate design on the self-humidification of a high power density PEMFC stack for UAVs. Fuel Cells 2021, 21, 234–253. [Google Scholar] [CrossRef]

- Chu, T.; Wang, Q.; Xie, M.; Wang, B.; Yang, D.; Li, B.; Ming, P.; Zhang, C. Investigation of the reversible performance degradation mechanism of the PEMFC stack during long-term durability test. Energy 2022, 258, 124747. [Google Scholar] [CrossRef]

- Li, B.; Wan, K.; Xie, M.; Chu, T.; Wang, X.; Li, X.; Yang, D.; Ming, P.; Zhang, C. Durability degradation mechanism and consistency analysis for proton exchange membrane fuel cell stack. Appl. Energy 2022, 314, 119020. [Google Scholar] [CrossRef]

- Fan, L.; Zhao, J.; Luo, X.; Tu, Z. Comparison of the performance and degradation mechanism of PEMFC with Pt/C and Pt black catalyst. Int. J. Hydrogen Energy 2022, 47, 5418–5428. [Google Scholar] [CrossRef]

- Wei, X.; Wang, R.-Z.; Zhao, W.; Chen, G.; Chai, M.-R.; Zhang, L.; Zhang, J. Recent research progress in PEM fuel cell electrocatalyst degradation and mitigation strategies. EnergyChem 2021, 3, 100061. [Google Scholar] [CrossRef]

- Patil, V.; Reshmi, P.V.; Prajna, S.; Yashaswi; Yashaswini; Haleshappa, D.; Jayarama, A.; Pinto, R. Degradation mechanisms in PEM fuel cells: A brief review. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Okonkwo, P.C.; Ben Belgacem, I.; Emori, W.; Uzoma, P.C. Nafion degradation mechanisms in proton exchange membrane fuel cell (PEMFC) system: A review. Int. J. Hydrogen Energy 2021, 46, 27956–27973. [Google Scholar] [CrossRef]

- Luo, L.; Huang, B.; Cheng, Z.; Jian, Q. Rapid degradation characteristics of an air-cooled PEMFC stack. Int. J. Energy Res. 2020, 44, 4784–4799. [Google Scholar] [CrossRef]

- Vichard, L.; Harel, F.; Ravey, A.; Venet, P.; Hissel, D. Degradation prediction of PEM fuel cell based on artificial intelligence. Int. J. Hydrogen Energy 2020, 45, 14953–14963. [Google Scholar] [CrossRef]

- Zhan, Z.; Yuan, C.; Hu, Z.; Wang, H.; Sui, P.C.; Djilali, N.; Pan, M. Experimental study on different preheating methods for the cold-start of PEMFC stacks. Energy 2018, 162, 1029–1040. [Google Scholar] [CrossRef]

- Wan, Z.; Chang, H.; Shu, S.; Wang, Y.; Tang, H. A Review on Cold Start of Proton Exchange Membrane Fuel Cells. Energies 2014, 7, 3179–3203. [Google Scholar] [CrossRef]

- Wei, L.; Dafalla, A.M.; Jiang, F. Effects of reactants/coolant non-uniform inflow on the cold start performance of PEMFC stack. Int. J. Hydrogen Energy 2020, 45, 13469–13482. [Google Scholar] [CrossRef]

- Lei, L.; He, P.; He, P.; Tao, W.-Q. Numerical Research on the Cold Start-up Strategy of a PEMFC Stack from −30 °C. J. Therm. Sci. 2022, 32, 898–910. [Google Scholar] [CrossRef]

- Pan, W.; Li, P.; Gan, Q.; Chen, X.; Wang, F.; Dai, G. Thermal stability analysis of cold start processes in PEM fuel cells. Appl. Energy 2020, 261, 114430. [Google Scholar] [CrossRef]

| DMFC | PEMFC | SOFC | |

|---|---|---|---|

| Operating temperature/°C | <120 | <120 | 800–1000 |

| Released power | <5 kW | 5–250 kW | 100–250 kW |

| Type of electrolyte | Nafion membrane | Nafion membrane | Yttria stabilized zirconia |

| Anode reaction | CH3OH + H2O → CO2 + 6H+ + 6e− | H2 → 2H+ + 2e− | H2 + O2− → H2O + 2e− |

| Cathode reaction | 3/2O2 + 6H+ + 6e− → 3H2O | 1/2O2 + 2H+ + 2e− → H2O | 1/2O2 + 2e− → O2− |

| Advantages | Easy fuel storage, simple structure without thermal management | High power density, fast startup | Diversified fuel, non-noble metal for catalyst |

| Disadvantages | Low power density | Low energy density of storing hydrogen at high pressure or in metal hydride | Slow startup and complex auxiliary equipments due to high operating temperature |

| Name | Manufacturer | Year | FC System Power | Number of Rotors | H2 Storage Method | Flight Time | Weight of the Drone | Refs. |

|---|---|---|---|---|---|---|---|---|

| H2Quad-400 | EnergyOr (Montreal, QC, Canada) | 2015 | 400 W | 4 | Compressed gaseous | 133 min | 9.5 kg | [38] |

| —— | Intelligent Energy (Loughborough, UK) | 2015 | 650 W | 4 | Compressed gaseous | 85 min | 4.3 kg (with a 2 L cylinder) | [66] |

| Hycopter | HES (Singapore) | 2015 | —— | 4 | Compressed gaseous | 180 min | 5 kg | [40,67] |

| Ranger | Zhongyu (Wuhan, China) | 2015 | 1200 W | 6 | Compressed gaseous | 210 min | 12.7 kg | [41] |

| HYDrone-1800 | MMC (Shenzhen, China) | 2016 | 1800 W | 6 | Compressed gaseous | 270 min | 20 kg | [42,43] |

| Jupiter-H2 | FlightWave (Santa Monica, CA, USA) | 2016 | 650 W | 8 | Compressed gaseous | ≥120 min | —— | [44] |

| Sensus4 | ISS Aerospace (Berkshire, UK) | 2018 | 800 W | 4 | Compressed gaseous | 90 min@1.5 kg, 30 min@6 kg | —— | [45] |

| e-Drone Zero | Skycorp (Tartu, Estonia ) | 2018 | 800 W | 4 | Compressed gaseous | 120 min | —— | [48] |

| Sensus6 | ISS Aerospace (Berkshire, UK) | 2019 | 2400 W | 6 | Compressed gaseous | 120 min@8 kg, 25 min@20 kg | —— | [46] |

| Phoenix | Spectronik (Singapore) | 2019 | 2000 W | 6 | Compressed gaseous | 90 min | 19.0 kg (with a 9 L cylinder) | [68] |

| BFD H2-6 | Ballard (Burnaby, BC, Canada) | 2019 | 1200 W | 6 | Compressed gaseous | 90 min | —— | [69] |

| —— | Meta Vista (Seoul, South Korea) | 2019 | 800 W | 4 | Liquid | ≥720 min | —— | [51] |

| DS30 | DMI (Gyeonggi-do, South Korea) | 2019 | 2700 W | 8 | Compressed gaseous | 120 min | 21.9 kg (with a 10.8 L cylinder) | [70] |

| BG-200 | Nordic Unmanned (Sandnes, Norway) | 2020 | 2000 W | 8 | Compressed gaseous | 99 min | 20.7 kg (with a 7.2 L cylinder) | [50,71] |

| —— | Xinyan Chuangneng (Beijing, China) | 2020 | 2000 W | 6 | Compressed gaseous | 331 min | (with a 19 L cylinder) | [64] |

| Hydrocopter-04 | Hydrogen Craft (Huzhou, China) | 2020 | 3400 W | 6 | Compressed gaseous | 180 min, 150 min@lkg, 96 min@5 kg | 20 kg (with a 12 L cylinder) | [72] |

| DT30X | DMI (Gyeonggi-do, South Korea) | 2023 | 2700 W | 6 | Compressed gaseous | 150 min | 21 kg (with 10.8 L Type 4 cylinder) | [73] |

| Cylinder Types | Materials | Hydrogen Storage Pressure (MPa) | Mass Percent (%) | Volumetric Hydrogen Storage Density (g/L) | Service Life (a) |

|---|---|---|---|---|---|

| Type I | All metal | 17.5–20 | ≈1 | 14.28–17.28 | 15 |

| Type II | Metal liner with hoop wrapping | 26.3–30 | ≈1.5 | 14.28–17.28 | 15 |

| Type III | Metal liner with full composite wrapping | 30–70 | 2.4–4.1 | 35–40 | 15–20 |

| Type IV | Plastic liner with full composite wrapping | >70 | 2.5–5.7 | 38–40 | 15–20 |

| Storage System | Mass Storage Efficiency (%kg H2/kg storage) | Volumetric Storage Density (kg H2/L storage) | Gravimetric Storage Energy Density (kWh/kg) | Volumetric Storage Energy Density (kWh/L) |

|---|---|---|---|---|

| Compressed H2, 300 bars | 3.1 | 0.014 | 1.2 | 0.55 |

| Compressed H2, 700 bars | 4.8 | 0.033 | 1.9 | 1.30 |

| Cryogenic Liquid H2 | 14.2 | 0.043 | 5.57 | 1.68 |

| Cryo-compression tank (LLNL) | 7.38 | 0.045 | 2.46 | 1.51 |

| Metal hydride (conservative) | 0.65 | 0.028 | 0.26 | 1.12 |

| Strategies | Suitable Missions | Mission Risk |

|---|---|---|

| Rule-based EMS | Suitable for scenarios characterized by relatively stable mission requirements and infrequent load fluctuations, such as fixed-route cruising and stationary monitoring. | The mission risk is relatively low. These strategies are easy to implement and require less computational power, but they may not be able to cope with sudden high power demands or extreme load fluctuations. |

| Optimization-based EMS | Suitable for scenarios that require efficient energy utilization and complex missions, such as long-duration multi-stage missions, reconnaissance, and surveillance in complex urban environments. | The mission risk is moderately high. These strategies can optimize energy allocation and improve overall efficiency, but they have a higher computational complexity, requiring certain system performance and real-time requirements, as well as being sensitive to initial conditions and parameter settings. |

| Intelligent-based EMS | Suitable for highly dynamic and uncertain missions, such as independent exploration and search and rescue in complex terrain environments. | The missions carry high risks. These strategies possess strong adaptability and learning capabilities, enabling them to cope with complex environmental changes and mission requirements. However, they require a large amount of training data and computational resources, and may suffer from overfitting and poor generalization abilities. |

| Degradation Types | Degradation Mechanisms | Mitigation Measures |

|---|---|---|

| Proton exchange membrane degradation |

|

|

| Catalyst layer degradation |

|

|

| Gas diffusion layer (GDL) dagradation |

|

|

| Overall system design |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, Z.; Liu, S.; Zhu, W.; Ren, D.; Xu, Q.; Feng, Y. A Review on Key Technologies and Developments of Hydrogen Fuel Cell Multi-Rotor Drones. Energies 2024, 17, 4193. https://doi.org/10.3390/en17164193

Shen Z, Liu S, Zhu W, Ren D, Xu Q, Feng Y. A Review on Key Technologies and Developments of Hydrogen Fuel Cell Multi-Rotor Drones. Energies. 2024; 17(16):4193. https://doi.org/10.3390/en17164193

Chicago/Turabian StyleShen, Zenan, Shaoquan Liu, Wei Zhu, Daoyuan Ren, Qiang Xu, and Yu Feng. 2024. "A Review on Key Technologies and Developments of Hydrogen Fuel Cell Multi-Rotor Drones" Energies 17, no. 16: 4193. https://doi.org/10.3390/en17164193

APA StyleShen, Z., Liu, S., Zhu, W., Ren, D., Xu, Q., & Feng, Y. (2024). A Review on Key Technologies and Developments of Hydrogen Fuel Cell Multi-Rotor Drones. Energies, 17(16), 4193. https://doi.org/10.3390/en17164193