A Review of Machine Learning Methods in Turbine Cooling Optimization

Abstract

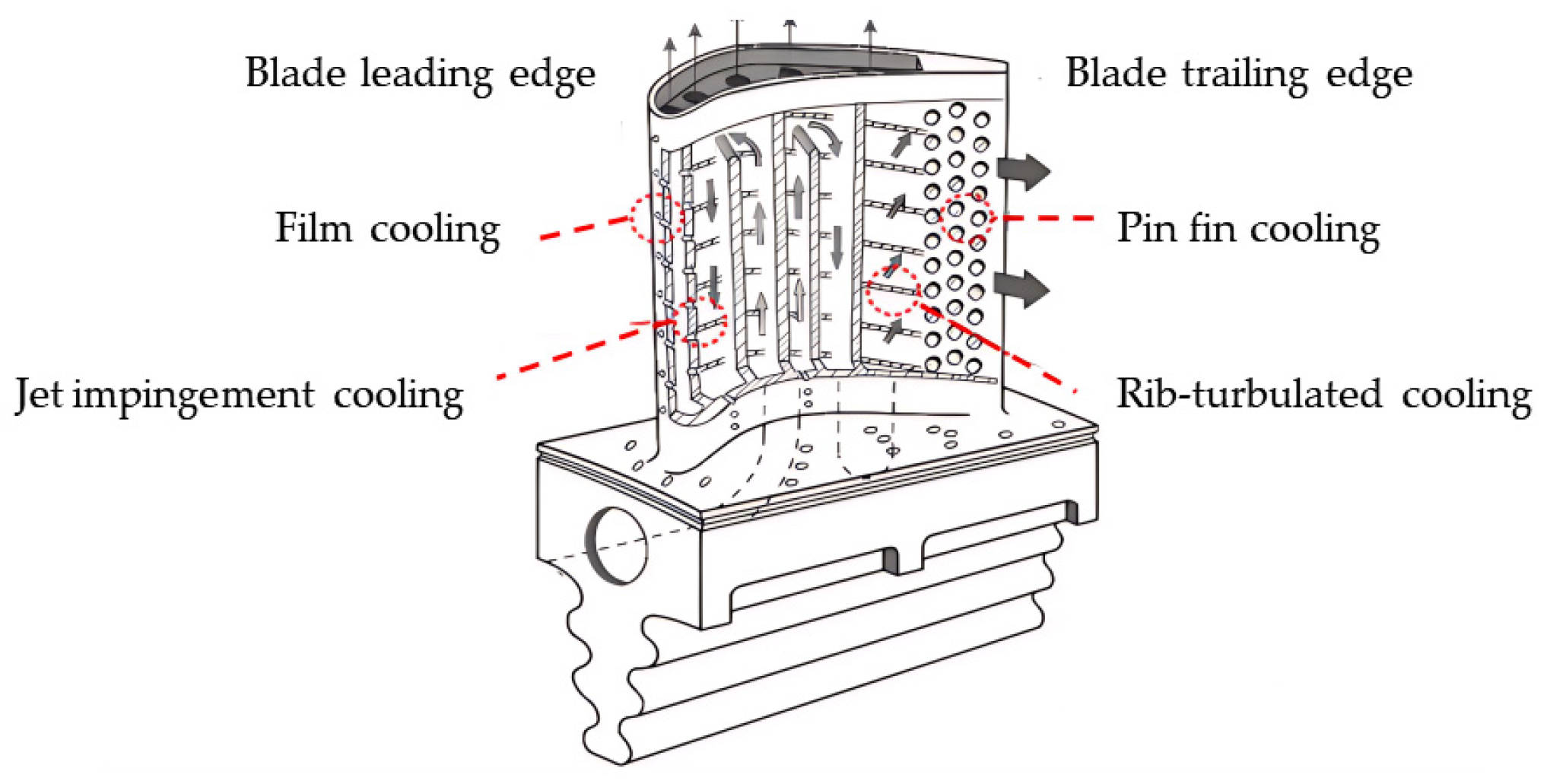

1. Introduction

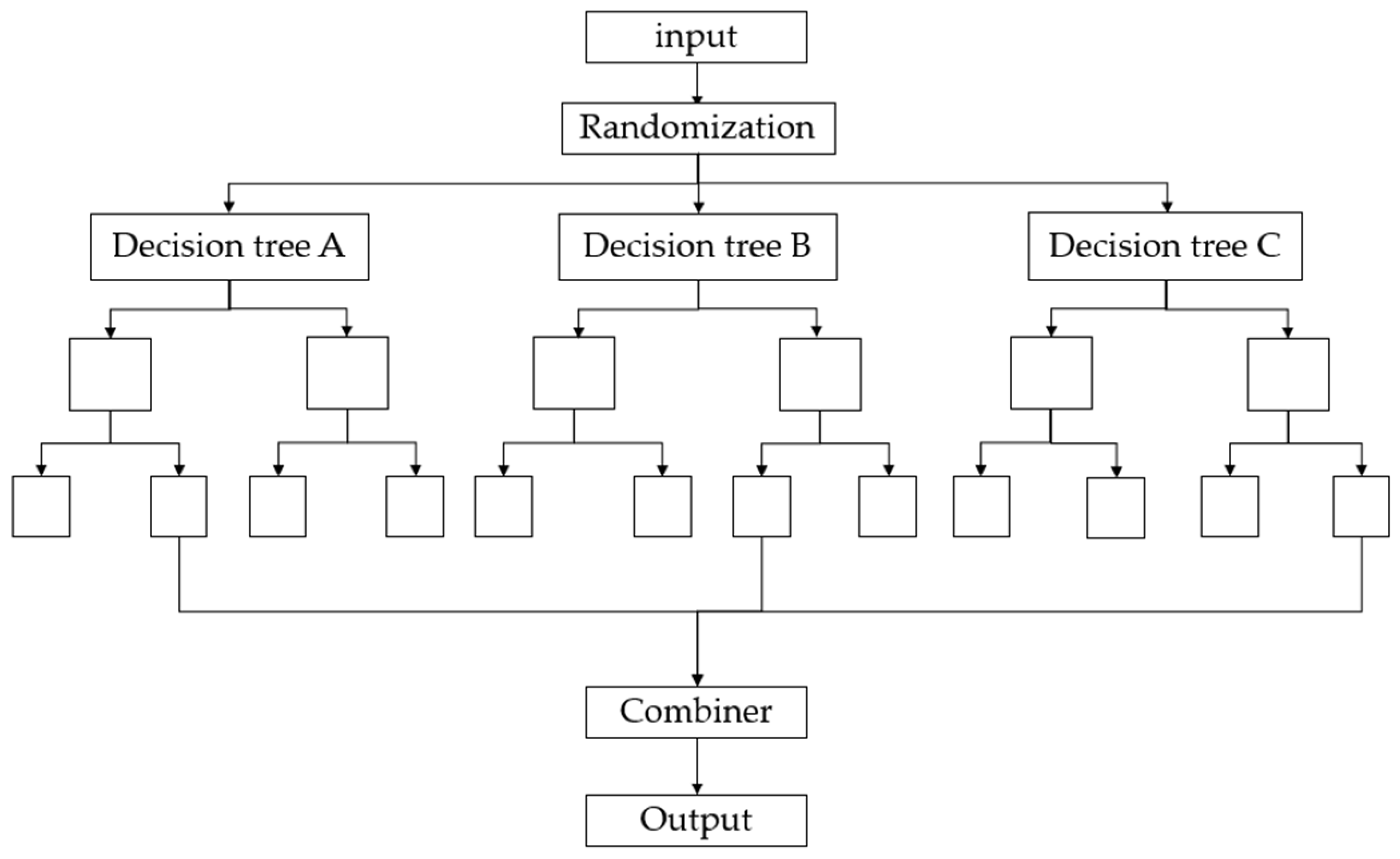

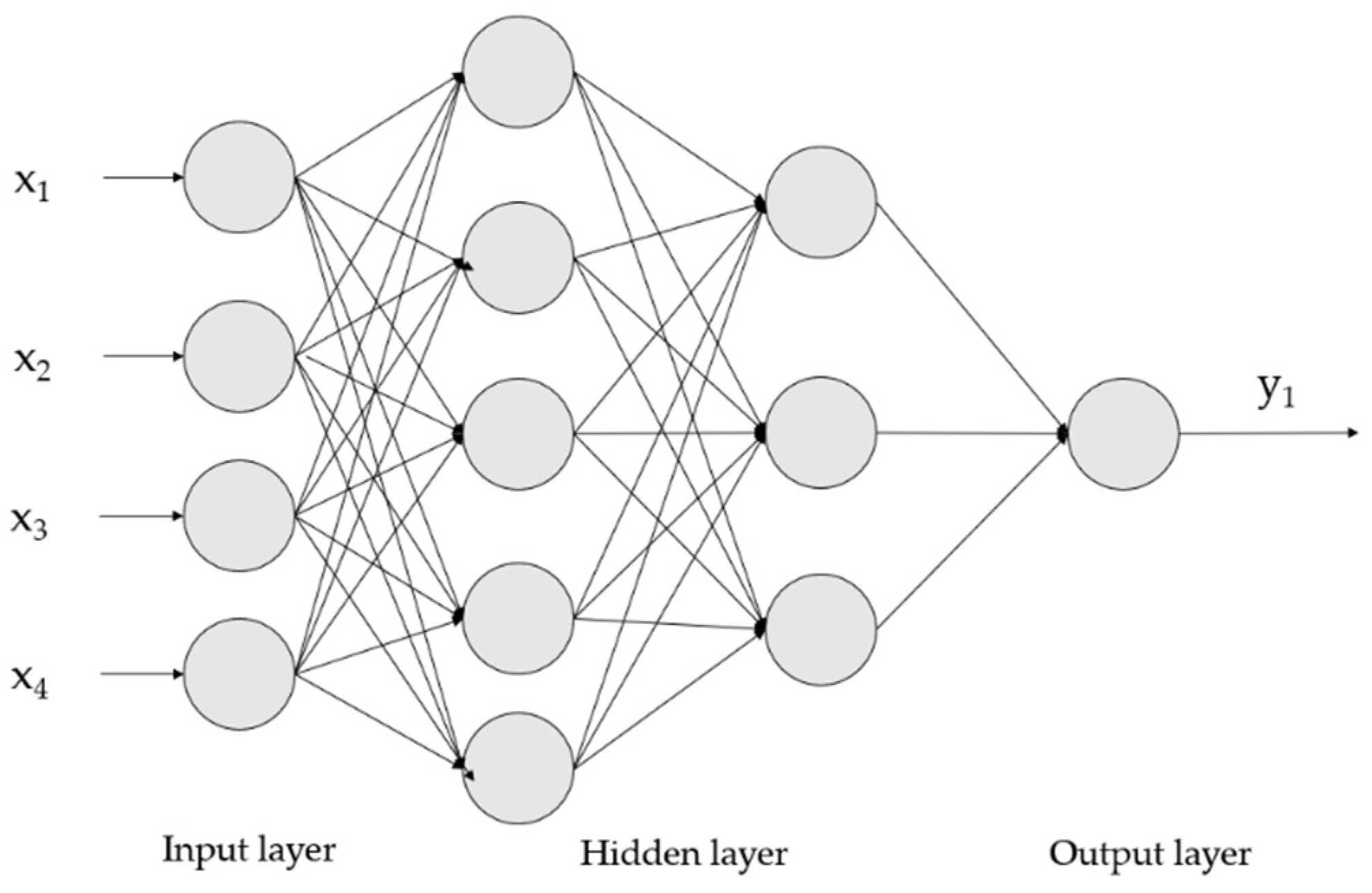

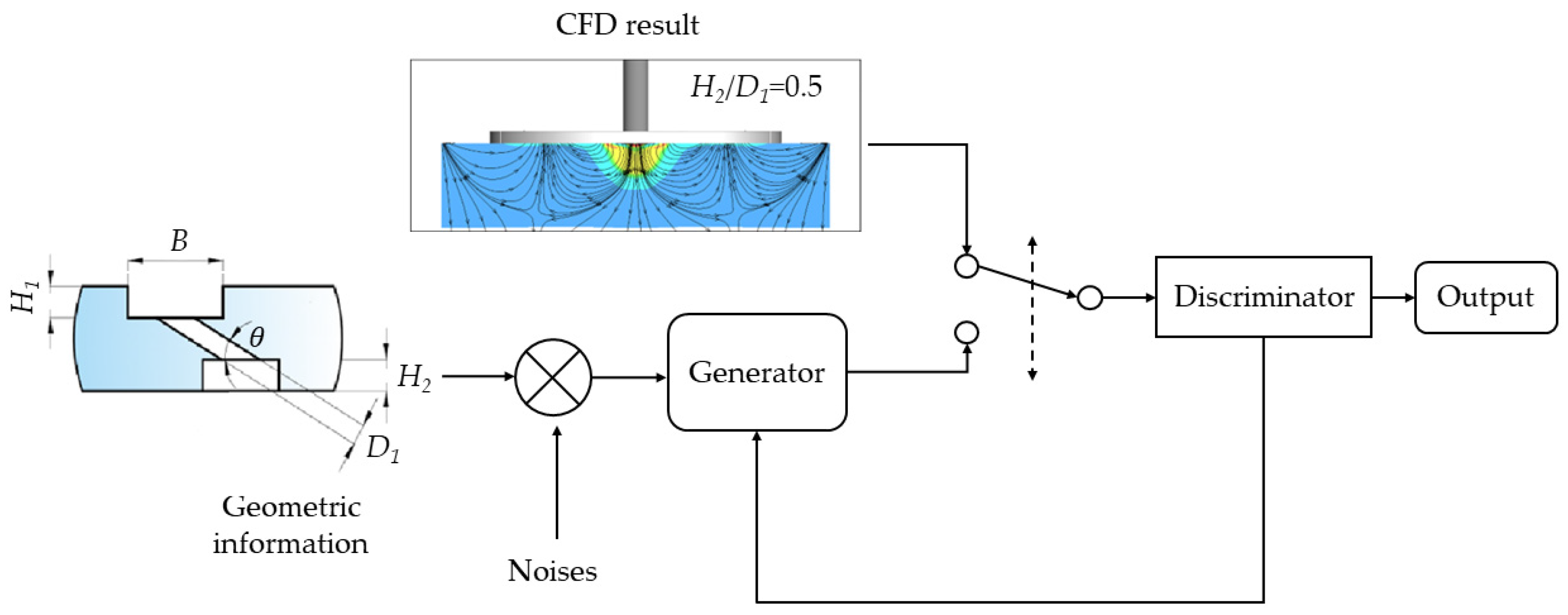

2. Machine Learning Algorithms

2.1. A Review of Machine Learning Algorithms

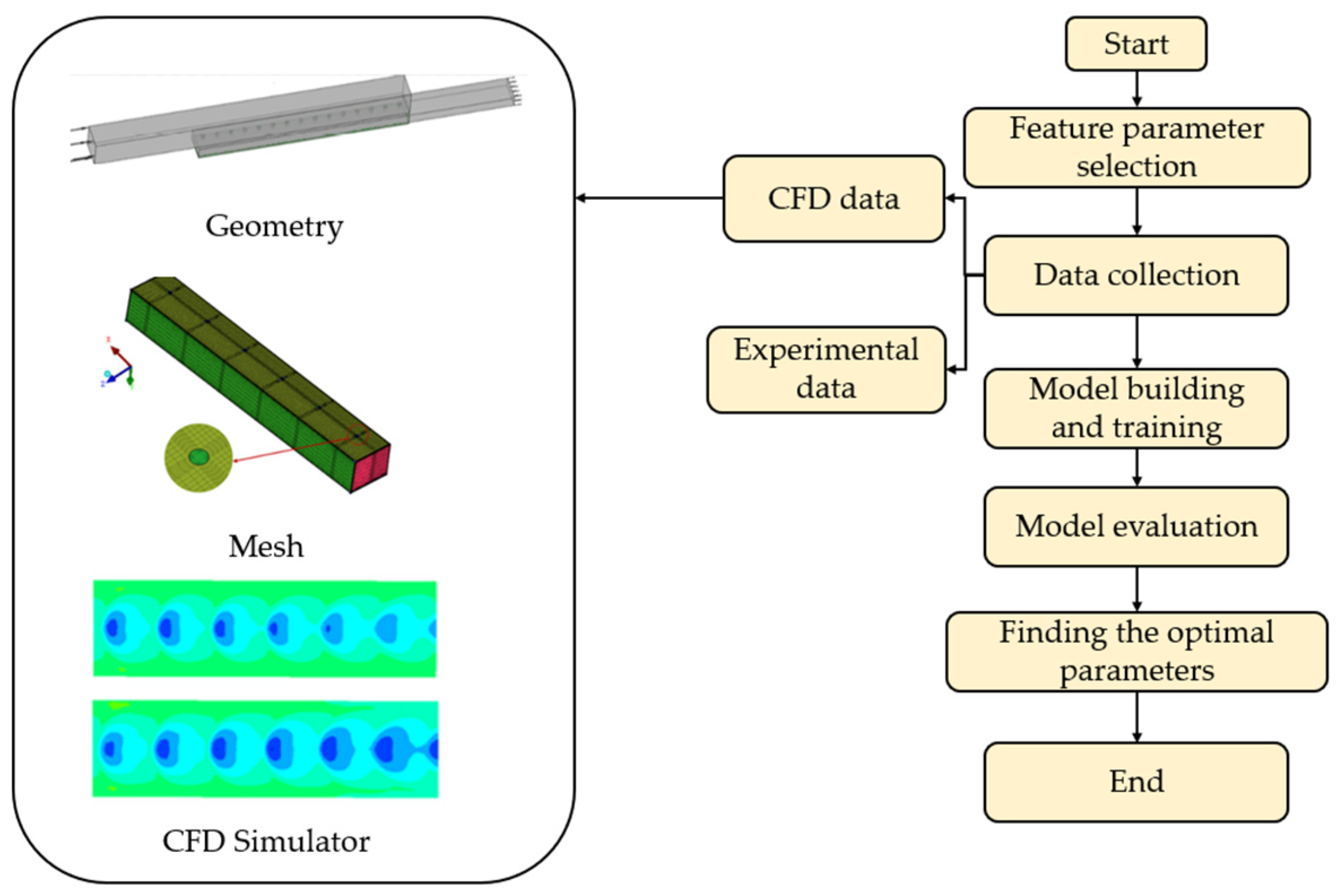

2.2. Optimized Model Building Process Based on ML

3. Machine Learning in Internal Cooling

3.1. Pin Fin Cooling Optimization

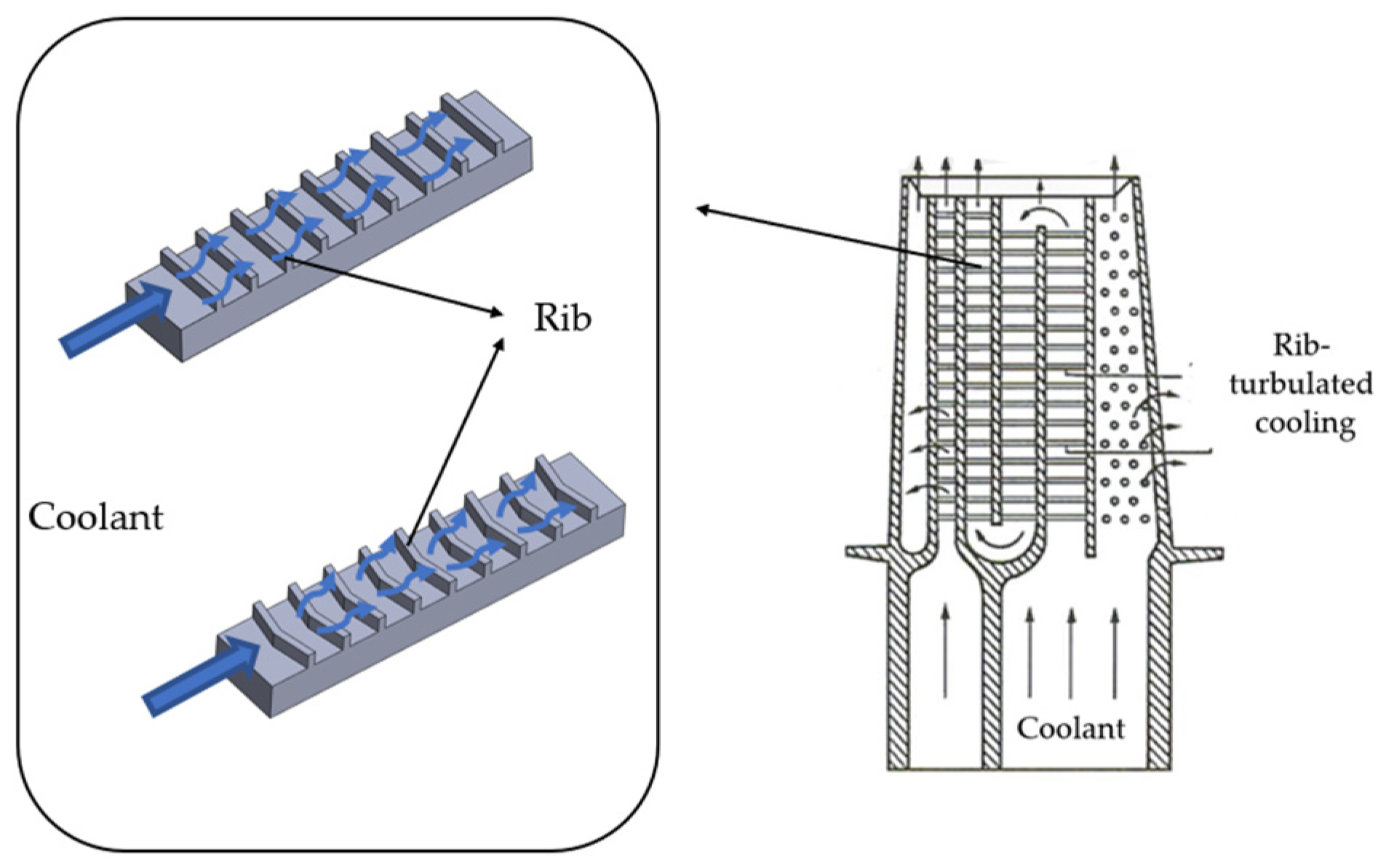

3.2. Rib-Turbulated Cooling Optimization

3.3. Jet Impingement Optimization

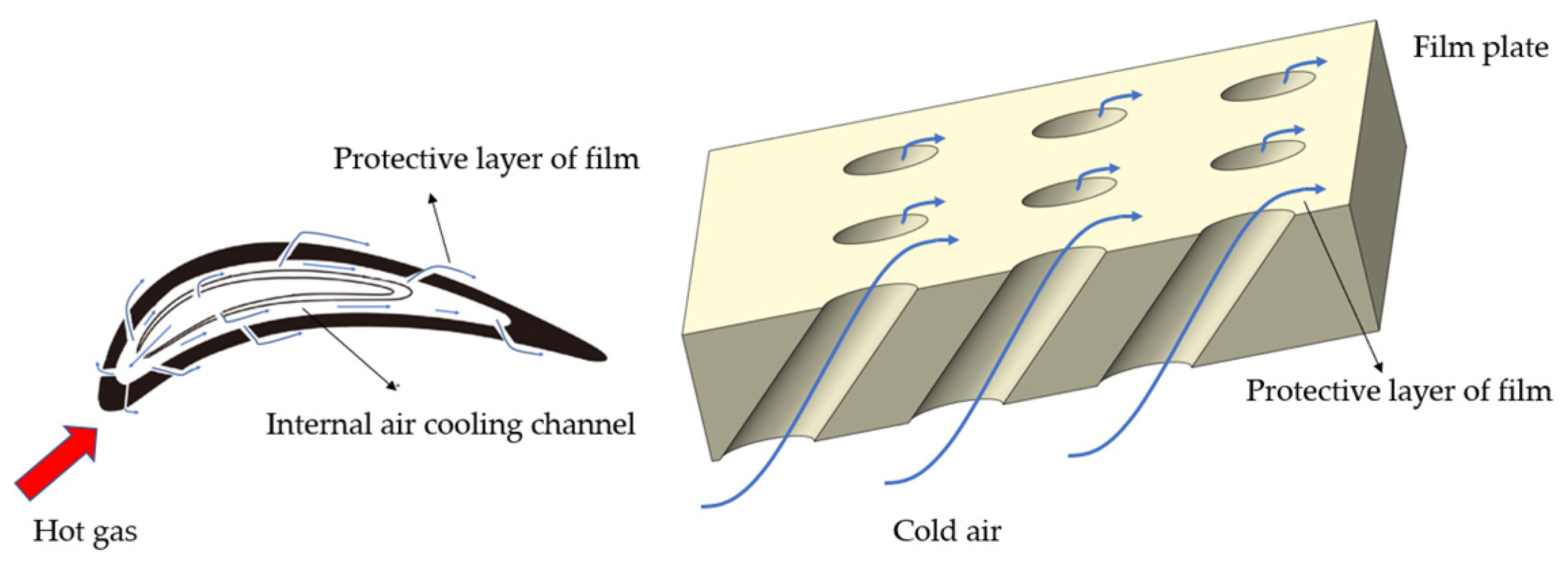

4. Machine Learning in External Cooling

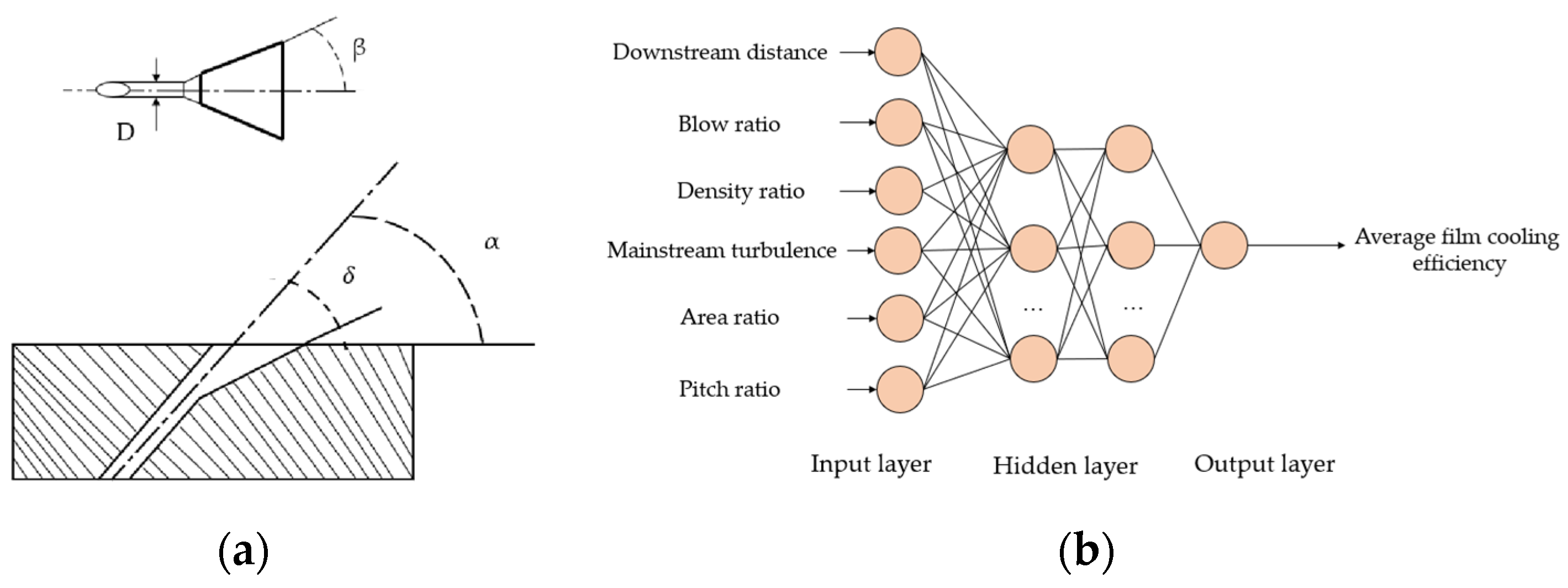

4.1. Film Cooling Performance Prediction

4.2. Flat Film Cooling Optimization

4.3. Turbine Blade Film Cooling Optimization

5. Machine Learning in Composite Cooling

5.1. Prediction of Total Blade Cooling Efficiency

5.2. Composite Cooling Optimization

6. Conclusions and Future Perspectives

- In blade cooling optimization studies, agent models like RSA, KRG, RBF, RBNN, ANN, and deep learning algorithms are commonly employed, according to a recent study. However, a significant amount of high-fidelity data is typically required to build the model so as to guarantee the reliability of single-fidelity models, and the data collection procedure is incredibly time-consuming;

- A variety of internal cooling technologies have been optimized for different aspects, including pin fin turbulated cooling, rib-turbulated cooling, impingement jet cooling, and channel cooling. Based on the CHT analysis of the flow and temperature fields, single-fidelity or multi-fidelity models are employed to optimize the cooling structure. However, the current research primarily concentrates on the optimization of static blade states, with fewer studies addressing the optimization of internal blade cooling under rotating conditions;

- Compared with flat film cooling, the optimization of film cooling on turbine blades needs to take into account the shape of film holes and the arrangement of holes. At present, most studies mainly focus on film cooling efficiency and aerodynamic loss as the optimization objectives. On the basis of CFD calculation, combined with a single-fidelity model and optimization algorithm, the cooling performance is optimized. However, there are few studies on conjugate heat transfer analysis, multi-fidelity model, and structural optimization under rotation;

- The majority of current research on transpiration cooling optimization is focused on enhancing blade cooling performance. Nevertheless, the transpiration cooling structure is challenging to manufacture and possesses low strength, and thus, structural strength optimization is less of a priority.

- The combination of high-fidelity data with low-fidelity data to train multi-fidelity agent models can reduce the calculation cost while maintaining the prediction accuracy. Consequently, in the process of optimizing the cooling structure of blades, a multi-fidelity agent model can be employed to predict the target parameters;

- The rotation of the blade will alter the flow field and heat transfer efficacy. In order to ensure the optimization process is more suitable for the actual circumstances, it is vital to consider the influence of rotation when optimizing blade cooling technology. Furthermore, the influence of the CHT on the optimization process is worthy of consideration;

- The application of novel technologies and materials enhances the heat transmission capability of the blade. However, the structural strength and thermal stress act as constraints that impede the deployment of these novel technologies and materials. Consequently, intelligent algorithms must be interdisciplinary and employ multi-objective analysis throughout the optimization process of the cooling structure of the blade;

- In the context of composite structure optimization design, the three primary factors are variable selection, objective function, and constraints. It can be observed that the topology-optimized structure exhibits superior temperature uniformity and a smaller pressure drop. Therefore, the application of topological optimization technology in the design of leaf composite cooling structures and thermal boundary conditions as conditions to obtain optimized structures is very promising.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| ML | Machine learning |

| RBF | Radial basis function |

| NN | Neural network |

| RBFNN | Radial basis function neural network |

| GP | Gaussian process |

| KRG | Kriging |

| ANN | Artificial neural network |

| RSA | Response surface analysis |

| GA | Genetic algorithm |

| CNN | Convolutional neural network |

| CGAN | Conditional generation adversarial network |

| RNN | Recurrent neural network |

| CHT | Conjugate heat transfer |

| LHS | Latin hypercube sampling |

| SQP | Sequential quadratic programming |

| GMDH-ANN | Group method of data handling—artificial neural network |

References

- Xu, L.; Sun, Z.; Ruan, Q.; Xi, L.; Gao, J.; Li, Y. Development Trend of Cooling Technology for Turbine Blades at Super-High Temperature of above 2000 K. Energies 2023, 16, 668. [Google Scholar] [CrossRef]

- Kong, X.; Zhang, Z.; Zhu, J.; Xu, J.; Zhang, Y. Research Progress on Cooling Structure of Aeroengine Air-Cooled Turbine Blade. J. Propuls. Technol. 2022, 43, 1–23. (In Chinese) [Google Scholar]

- Liu, H.; Li, G.; Zhang, S.; Li, A.; Zhang, Y.; Lu, X. Application Progress of Machine Learning in Turbomachinery. J. Eng. Thermophys. 2023, 44, 938–951. (In Chinese) [Google Scholar]

- Wang, Q.; Yang, L.; Rao, Y. A Review of Deep Learning Methods in Turbine Cooling. J. Eng. Thermophys. 2022, 43, 656–662. (In Chinese) [Google Scholar]

- Zhang, G.; Zhu, R.; Xie, G.; Li, S.; Sundén, B. Optimization of cooling structures in gas turbines: A review. Chin. J. Aeronaut. 2022, 35, 18–46. [Google Scholar] [CrossRef]

- Zhou, Z. Machine Learning; Tsinghua University Press: Beijing, China, 2016. (In Chinese) [Google Scholar]

- Ding, S.; Qi, B.; Tan, H. An Overview on Theory and Algorithm of Support Vector Machines. J. Univ. Electron. Sci. Technol. China 2011, 40, 9. (In Chinese) [Google Scholar]

- Zhang, L.; Chen, Y.; Li, T.; Mu, X. Research on Decision Tree Classification Algorithms. Comput. Eng. 2011, 37, 66–67+70. (In Chinese) [Google Scholar]

- Quinlan, J.R. Induction of decision trees. Mach. Learn. 1986, 1, 81–106. [Google Scholar] [CrossRef]

- Salzberg, S.L. C4.5: Programs for Machine Learning by J. Ross Quinlan. Morgan Kaufmann Publishers, Inc., 1993. Mach. Learn. 1994, 16, 235–240. [Google Scholar] [CrossRef]

- Fang, K.; Wu, J.; Zhu, J.; Xie, B. Review of Random Forest Methods. Stat. Inf. Forum 2011, 26, 32–38. (In Chinese) [Google Scholar]

- Domingos, P.; Pazzani, M. On the Optimality of the Simple Bayesian Classifier under Zero-One Loss. Mach. Learn. 1997, 29, 103–130. [Google Scholar] [CrossRef]

- Kohonen, T. An introduction to neural computing. Neural Netw. 1988, 1, 3–16. [Google Scholar] [CrossRef]

- Lecun, Y.; Bottou, L.; Bengio, Y.; Haffner, P. Gradient-based learning applied to document recognition. Proc. IEEE 1998, 86, 2278–2324. [Google Scholar] [CrossRef]

- Goodfellow, I.; Pouget-Abadie, J.; Mirza, M.; Xu, B.; Warde-Farley, D.; Ozair, S.; Courville, A.; Bengio, Y. Generative adversarial networks. Commun. ACM 2020, 63, 139–144. [Google Scholar] [CrossRef]

- Mulligan, R.F. A fractal analysis of foreign exchange markets. Int. Adv. Econ. Res. 2000, 6, 33–49. [Google Scholar]

- Bogard, D.G.; Thole, K.A. Gas Turbine Film Cooling. J. Propuls. Power 2006, 22, 249–270. [Google Scholar] [CrossRef]

- Metzger, D.E.; Fan, Z.X.; Shepard, W.B. Pressure Loss and Heat Transfer Through Multiple Rows of Short Pin Fins. In International Heat Transfer Conference Digital Library; Begel House Inc.: Danbury, CT, USA, 1982. [Google Scholar]

- Metzger, D.E.; Berry, R.A.; Bronson, J.P. Developing Heat Transfer in Rectangular Ducts with Staggered Arrays of Short Pin Fins. J. Heat Transf. 1982, 104, 700–706. [Google Scholar] [CrossRef]

- VanFossen, G.J. Heat-Transfer Coefficients for Staggered Arrays of Short Pin Fins. J. Eng. Power 1982, 104, 268–274. [Google Scholar] [CrossRef]

- Simoneau, R.J.; VanFossen, G.J., Jr. Effect of Location in an Array on Heat Transfer to a Short Cylinder in Crossflow. J. Heat Transf. 1984, 106, 42–48. [Google Scholar] [CrossRef]

- Chyu, M.K.; Natarajan, V. Heat transfer on the base surface of threedimensional protruding elements. Int. J. Heat Mass Transf. 1996, 39, 2925–2935. [Google Scholar] [CrossRef]

- Chyu, M.K.; Yen, C.H.; Siw, S. Comparison of Heat Transfer From Staggered Pin Fin Arrays With Circular, Cubic and Diamond Shaped Elements. In Proceedings of the ASME Turbo Expo 2007: Power for Land, Sea, and Air, Montreal, QC, Canada, 14–17 May 2007; pp. 991–999. [Google Scholar]

- Dogruoz, M.B.; Urdaneta, M.; Ortega, A. Experiments and modeling of the hydraulic resistance and heat transfer of in-line square pin fin heat sinks with top by-pass flow. Int. J. Heat Mass Transf. 2005, 48, 5058–5071. [Google Scholar] [CrossRef]

- Chyu, M.K.; Siw, S.C.; Moon, H.K. Effects of Height-to-Diameter Ratio of Pin Element on Heat Transfer From Staggered Pin-Fin Arrays. In Proceedings of the ASME Turbo Expo 2009: Power for Land, Sea, and Air, Orlando, FL, USA, 8–12 June 2009; pp. 705–713. [Google Scholar]

- Kwon, B.; Ejaz, F.; Hwang, L.K. Machine learning for heat transfer correlations. Int. Commun. Heat Mass Transf. 2020, 116, 104694. [Google Scholar] [CrossRef]

- Johnson, J.J.; King, P.I.; Clark, J.P.; Ooten, M.K. Genetic Algorithm Optimization of a High-Pressure Turbine Vane Pressure Side Film Cooling Array. J. Turbomach. 2014, 136, 011011. [Google Scholar] [CrossRef]

- Ghosh, S.; Mondal, S.; Kapat, J.S.; Ray, A. Shape Optimization of Pin Fin Arrays Using Gaussian Process Surrogate Models Under Design Constraints. In Proceedings of the ASME Turbo Expo 2020: Turbomachinery Technical Conference and Exposition, Virtual, Online, 21–25 September 2020. [Google Scholar]

- Ghosh, S.; Mondal, S.; Kapat, J.S.; Fernandez, E.; Ray, A. Parametric Shape Optimization of Pin Fin Arrays Using Surrogate Model Based Bayesian Methods. J. Thermophys. Heat Transf. 2020, 35, 245–255. [Google Scholar] [CrossRef]

- Ghosh, S.; Mondal, S.; Kapat, J.S.; Ray, A. Parametric shape optimization of pin fin arrays using a multi-fidelity surrogate model based Bayesian method. Appl. Therm. Eng. 2024, 247, 122876. [Google Scholar] [CrossRef]

- Liao, G.; Sun, Z.; Zhang, F. Optimization analysis of internal pin-fins steam cooling channel of gas turbine blade based on genetic algorithm. J. Eng. Therm. Energy Power 2022, 37, 48–56. (In Chinese) [Google Scholar]

- Kim, H.-M.; Moon, M.-A.; Kim, K.-Y. Multi-objective optimization of a cooling channel with staggered elliptic dimples. Energy 2011, 36, 3419–3428. [Google Scholar] [CrossRef]

- Yeranee, K.; Rao, Y.; Yang, L.; Li, H. Enhanced thermal performance of a pin-fin cooling channel for gas turbine blade by density-based topology optimization. Int. J. Therm. Sci. 2022, 181, 107783. [Google Scholar] [CrossRef]

- Hu, K.; Wang, X.; Zhong, S.; Lu, C.; Yu, B.; Yang, L.; Rao, Y. Optimization of turbine blade trailing edge cooling using self-organized geometries and multi-objective approaches. Energy 2024, 289, 130013. [Google Scholar] [CrossRef]

- Moon, M.A.; Kim, K.Y. Optimization of Rotating Cooling Channel with Pin Fins Downstream of Turning Region. J. Thermophys. Heat Transf. 2012, 26, 85–97. [Google Scholar] [CrossRef]

- Emerson, W.H. Heat Transfer in a duct in regions of separated flow. In Proceedings of the International Heat Transfer Conference, Chicago, IL, USA, 7–12 August 1967; Volume 3. [Google Scholar]

- Webb, R.L.; Eckert, E.R.G.; Goldstein, R.J. Heat transfer and friction in tubes with repeated-rib roughness. Int. J. Heat Mass Transf. 1971, 14, 601–617. [Google Scholar] [CrossRef]

- Han, J.C.; Glicksman, L.R.; Rohsenow, W.M. An investigation of heat transfer and friction for rib-roughened surfaces. Int. J. Heat Mass Transf. 1978, 21, 1143–1156. [Google Scholar] [CrossRef]

- Han, J.C. Heat Transfer and Friction in Channels With Two Opposite Rib-Roughened Walls. J. Heat Transf. 1984, 106, 774–781. [Google Scholar] [CrossRef]

- Wang, Z.; Yin, Y.; Wang, Y.; Sun, T.; Luan, Y. Similarity characteristics of geometric scaling matrix cooling channels in turbine blade. Appl. Therm. Eng. 2022, 212, 118601. [Google Scholar] [CrossRef]

- Moon, M.-A.; Kim, K.-Y. Analysis and optimization of fan-shaped pin–fin in a rectangular cooling channel. Int. J. Heat Mass Transf. 2014, 72, 148–162. [Google Scholar] [CrossRef]

- Darvish Damavandi, M.; Safikhani, H.; Yahyaabadi, M. Multi-objective optimization of asymmetric v-shaped ribs in a cooling channel using CFD, artificial neural networks and genetic algorithms. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 2319–2329. [Google Scholar] [CrossRef]

- Xu, L.; Ruan, Q.C.; Shen, Q.Y.; Xi, L.; Gao, J.M.; Li, Y.L. Optimization design of lattice structures in internal cooling channel with variable aspect ratio of gas turbine blade. Energies 2021, 14, 3954. [Google Scholar] [CrossRef]

- Xu, L.; Chen, Q.; Xi, L.; Gao, J.; Li, Y. Multi-objective optimization design of micro-class truss lattice structure for filling internal cooling channel. J. Xi’an Jiaotong Univ. 2020, 54, 1–11. (In Chinese) [Google Scholar]

- Xi, L.; Xu, L.; Gao, J.; Zhao, Z.; Li, Y. Optimization of cooling performance of X-type truss array channel based on response surface methodology. J. Aerosp. Power 2024, 39, 24–32. (In Chinese) [Google Scholar]

- Xi, L.; Xu, L.; Gao, J.; Zhao, Z.; Li, Y. Cooling performance analysis and structural parameter optimization of X-type truss array channel based on neural networks and genetic algorithm. Int. J. Heat Mass Transf. 2022, 186, 122452. [Google Scholar] [CrossRef]

- Kiyici, F.; Yilmazturk, S.; Arican, E.; Costa, E.; Porziani, S. U-turn Optimization of a Ribbed Turbine Blade Cooling Channel Using a Meshless Optimization Technique. In Proceedings of the 55th AIAA Aerospace Sciences Meeting, Grapevine, TX, USA, 9–13 January 2017. [Google Scholar]

- Samad, A.; Lee, K.-D.; Kim, K.-Y. Multi-objective optimization of a dimpled channel for heat transfer augmentation. Heat Mass Transf. 2008, 45, 207–217. [Google Scholar] [CrossRef]

- Samad, A.; Lee, K.-D.; Kim, K.-Y. Shape Optimization of a Dimpled Channel to Enhance Heat Transfer Using a Weighted-Average Surrogate Model. Heat Transf. Eng. 2010, 31, 1114–1124. [Google Scholar] [CrossRef]

- Xi, L.; Gao, J.; Xu, L.; Zhao, Z.; Li, Y. Study on heat transfer performance of steam-cooled ribbed channel using neural networks and genetic algorithms. Int. J. Heat Mass Transf. 2018, 127, 1110–1123. [Google Scholar] [CrossRef]

- Xi, L.; Gao, J.; Xu, L.; Zhao, Z.; Li, Y. Prediction and optimization on flow and heat transfer performance of thick-wall ribbed channel in turbine blade. J. Xi’an Jiaotong Univ. 2021, 55, 25–34. (In Chinese) [Google Scholar]

- Kim, C.; Son, C. Rapid design approach for U-bend of a turbine serpentine cooling passage. Aerosp. Sci. Technol. 2019, 92, 417–428. [Google Scholar] [CrossRef]

- Ghosh, S.; Fernandez, E.; Kapat, J. Fluid-Thermal Topology Optimization of Gas Turbine Blade Internal Cooling Ducts. J. Mech. Des. 2022, 144, 051703. [Google Scholar] [CrossRef]

- Moon, M.A.; Kim, K.Y. Exergetic analysis for optimization of a rotating equilateral triangular cooling channel with staggered square ribs. Int. J. Fluid Mach. Syst. 2016, 9, 229–236. [Google Scholar] [CrossRef]

- Moon, M.-A.; Park, M.-J.; Kim, K.-Y. Shape optimization of staggered ribs in a rotating equilateral triangular cooling channel. Heat Mass Transf. 2014, 50, 533–544. [Google Scholar] [CrossRef]

- Bradbury, L. The structure of a self-preserving turbulent plane jet. J. Fluid Mech. 1965, 23, 31–64. [Google Scholar] [CrossRef]

- Sparrow, E.M.; Wong, T.C. Impingement transfer coefficients due to initially laminar slot jets. Int. J. Heat Mass Transf. 1975, 18, 597–605. [Google Scholar] [CrossRef]

- Koopman, R.N.; Sparrow, E.M. Local and average transfer coefficients due to an impinging row of jets. Int. J. Heat Mass Transf. 1976, 19, 673–683. [Google Scholar] [CrossRef]

- Han, J.C.; Dutta, S.; Ekkad, S.V. Gas Turbine Heat Transfer and Cooling Technology, 2nd ed.; CRC Press: New York, NY, USA, 2000. [Google Scholar]

- Jahromi, H.B.; Kowsary, F. A comprehensive parametric study and multi-objective optimization of turbulent jet array impingement for uniform cooling of gas turbine blades with minimized compression power. Int. J. Therm. Sci. 2024, 201, 109035. [Google Scholar] [CrossRef]

- Chi, Z.; Liu, H.; Zang, S. Geometrical optimization of nonuniform impingement cooling structure with variable-diameter jet holes. Int. J. Heat Mass Transf. 2017, 108, 549–560. [Google Scholar] [CrossRef]

- Chen, J.; Yao, R.; Wang, J.; Wang, X. Multi-objective optimization on internal cooling strategies for gas turbine blade leading edges. Int. Commun. Heat Mass Transf. 2023, 145, 106818. [Google Scholar] [CrossRef]

- Jacobs, J.; Tripp, J.; Underwood, D.; Lengsfeld, C. Optimization of Micro-Textured Surfaces for Turbine Vane Impingement Cooling. In Proceedings of the ASME Turbo Expo 2013: Turbine Technical Conference and Exposition, San Antonio, TX, USA, 3–7 June 2013. [Google Scholar]

- Xu, L.; Yang, Z.; Xi, L.; Duan, D.; Yang, X.; Gao, J.; Li, Y. Multi-objective performance optimization of target surface of bionic blue whale-skin impinged by array jet. Int. Commun. Heat Mass Transf. 2023, 141, 106611. [Google Scholar] [CrossRef]

- Goldstein, R.J. Film Cooling. In Advances in Heat Transfer; Irvine, T.F., Hartnett, J.P., Eds.; Elsevier: Amsterdam, The Netherlands, 1971; Volume 7, pp. 321–379. [Google Scholar]

- Eckert, E.R.G.; Eriksen, V.L.; Goldstein, R.J.; Ramsey, J.W. Film cooling following injection through inclined circular tubes. Isr. J. Technol. 1974, 8, 145–154. [Google Scholar]

- Fric, T.F.; Roshko, A. Vortical structure in the wake of a transverse jet. J. Fluid Mech. 1994, 279, 1–47. [Google Scholar] [CrossRef]

- Ni, M.; Zhu, H.; Qiu, Y.; Xu, D.; Liu, S. Review of aero-turbine blade cooling technologies. Gas Turbine Technol. 2005, 18, 10. (In Chinese) [Google Scholar]

- Brown, A.; Saluja, C.L. Film cooling from a single hole and a row of holes of variable pitch to diameter ratio. Int. J. Heat Mass Transf. 1979, 22, 525–534. [Google Scholar] [CrossRef]

- Jin, Y.; Li, S.; Jung, O. Prediction of flow properties on turbine vane airfoil surface from 3D geometry with convolutional neural network. In Proceedings of the ASME Turbo Expo 2019: Turbomachinery Technical Conference and Exposition, Phoenix, AZ, USA, 17–21 June 2019. [Google Scholar]

- Wang, Y.; Wang, W.; Tao, G.; Zhang, X.; Luo, S.; Cui, J. Two-dimensional film-cooling effectiveness prediction based on deconvolution neural network. Int. Commun. Heat Mass Transf. A Rapid Commun. J. 2021, 129, 105621. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, S.; Wang, C.; Tan, X. Recent advances in film cooling enhancement: A review. Chin. J. Aeronaut. 2020, 33, 1119–1136. (In Chinese) [Google Scholar] [CrossRef]

- Naghashnejad, M.; Amanifard, N.; Deylami, H.M. A predictive model based on a 3-D computational approach for film cooling effectiveness over a flat plate using GMDH-type neural networks. Heat Mass Transf. 2014, 50, 139–149. [Google Scholar] [CrossRef]

- Qin, Y.; Li, X.; Ren, J. Prediction of the adiabatic film cooling effectiveness influenced by multi parameters based on BP neural network. J. Eng. Thermophys. 2011, 32, 1127–1130. (In Chinese) [Google Scholar]

- Milani, P.M.; Ling, J.; Eaton, J.K. Generalization of machine-learned turbulent heat flux models applied to film cooling flows. J. Turbomach. 2019, 142, 011007. [Google Scholar] [CrossRef]

- Dolati, S.; Amanifard, N.; Deylami, H.M. Numerical study and GMDH-type neural networks modeling of plasma actuator effects on the film cooling over a flat plate. Appl. Therm. Eng. 2017, 123, 734–745. [Google Scholar] [CrossRef]

- Luo, L.; Xing, H.; Wang, S. Prediction of adiabatic film cooling efficiency distribution of single hole based on machine learning. J. Propuls. Technol. 2022, 43, 218–228. (In Chinese) [Google Scholar]

- Zhu, J.; Li, D.; Tao, Z.; Qiu, L.; Cheng, Z. Predicting method of film cooling effectiveness distribution based on constrained neural network. J. Aerosp. Power 2023, 38, 1537–1545. (In Chinese) [Google Scholar]

- Li, Z.; Wen, F.; Tang, X.; Su, L.; Wang, S. Prediction of single-row hole film cooling performance based on deep learning. Acta Aeronaut. Astronaut. Sin. 2021, 42, 313–324. (In Chinese) [Google Scholar]

- Dávalos, J.O.; García, J.C.; Urquiza, G.; Huicochea, A.; Santiago, O.D. Prediction of Film Cooling Effectiveness on a Gas Turbine Blade Leading Edge Using ANN and CFD. Int. J. Turbo Jet-Engines 2018, 35, 101–111. [Google Scholar] [CrossRef]

- Yang, L.; Wang, Q.; Huang, K.; Rao, Y. Establishment of a long-short-term-memory model to predict film cooling effectiveness under superposition conditions. Int. J. Heat Mass Transf. 2020, 160, 120231. [Google Scholar] [CrossRef]

- Yang, L.; Rao, Y. Predicting the adiabatic effectiveness of effusion cooling by the convolution modeling method. In Proceedings of the ASME Turbo Expo 2019: Turbomachinery Technical Conference and Exposition, Phoenix, AZ, USA, 17–21 June 2019. [Google Scholar]

- Yang, L.; Min, Z.; Yue, T.; Rao, Y.; Chyu, M.K. High resolution cooling effectiveness reconstruction of transpiration cooling using convolution modeling method. Int. J. Heat Mass Transf. 2019, 133, 1134–1144. [Google Scholar] [CrossRef]

- Yang, L.; Dai, W.; Rao, Y.; Chyu, M.K. A machine learning approach to quantify the film cooling superposition effect for effusion cooling structures. Int. J. Therm. Sci. 2021, 162, 106774. [Google Scholar] [CrossRef]

- Dai, W.; Yang, L.; Rao, Y. Modeling method of film cooling of turbine endwall based on generative adversarial networks. J. Eng. Thermophys. 2020, 41, 2420–2424. (In Chinese) [Google Scholar]

- Wang, C.H.; Sun, X.K.; Zhang, J.Z. Uncertainty analysis of trench film cooling on flat plate. Appl. Therm. Eng. 2019, 156, 562–575. [Google Scholar] [CrossRef]

- Lee, K.D.; Kim, K.Y. Optimization of a Cylindrical Film Cooling Hole using Surrogate Modeling. Numer. Heat Transf. Part A Appl. 2009, 55, 362–380. [Google Scholar] [CrossRef]

- Kim, J.H.; Kim, K.Y. Surrogate-based optimization of a cratered cylindrical hole to enhance film-cooling effectiveness. J. Therm. Sci. Tech. JPN 2016, 11, JTST0025. [Google Scholar] [CrossRef]

- Kim, J.H.; Kim, K.Y. Shape optimization of a bended film-cooling hole to enhance cooling effectiveness. J. Therm. Sci. Tech. Jpn. 2019, 14, JTST0011. [Google Scholar] [CrossRef]

- Lee, K.D.; Kim, K.Y. Shape optimization of a fan-shaped hole to enhance film-cooling effectiveness. Int. J. Heat Mass Transf. 2010, 53, 2996–3005. [Google Scholar] [CrossRef]

- Lee, K.D.; Kim, K.Y. Optimization of a Fan-Shaped Hole for Film Cooling Using a Surrogate Model. In Proceedings of the ASME Turbo Expo 2009: Power for Land, Sea, and Air, Orlando, FL, USA, 8–12 June 2009; Volume 3, pp. 505–514. [Google Scholar]

- Choi, J.U.; Kim, G.M.; Lee, H.C.; Kwak, J.S. Optimization of the Coanda bump to improve the film cooling effectiveness of an inclined slot. Int. J. Therm. Sci. 2019, 139, 376–386. [Google Scholar] [CrossRef]

- Lee, K.D.; Kim, S.M.; Kim, K.Y. Numerical Analysis of Film-Cooling Performance and Optimization for a Novel Shaped Film-Cooling Hole. In Proceedings of the ASME Turbo Expo 2012: Turbine Technical Conference and Exposition, Copenhagen, Denmark, 11–15 June 2012; pp. 1345–1355. [Google Scholar]

- Zhang, H.; Li, Y.F.; Chen, Z.Y.; Su, X.R.; Yuan, X. Multifidelity Based Optimization of Shaped Film Cooling Hole and Experimental Validation. In Proceedings of the ASME Turbo Expo: Turbomachinery Technical Conference and Exposition, Phoenix, AZ, USA, 17–21 June 2019. [Google Scholar]

- Zhang, H.; Li, Y.F.; Chen, Z.Y.; Su, X.R.; Yuan, X. Multi-fidelity model based optimization of shaped film cooling hole and experimental validation. Int. J. Heat Mass Transf. 2019, 132, 118–129. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, J.-Z.; Wang, C.-H. Multi-objective optimization of round-to-slot film cooling holes on a flat surface. Aerosp. Sci. Technol. 2020, 100, 105737. [Google Scholar] [CrossRef]

- Wang, Y.N.; Wang, Z.R.; Qian, S.Y.; Wang, W.; Zheng, Y.; Cui, J.H. Uncertainty quantification of the superposition film cooling with trench using supervised machine learning. Int. J. Heat Mass Transf. 2022, 198, 123353. [Google Scholar] [CrossRef]

- Vinogradov, K.A.; Kretinin, G.V.; Otryahina, K.V.; Didenko, R.A.; Karelin, D.V.; Shmotin, Y.N. Robust Optimization of the Hpt Blade Cooling and Aerodynamic Efficiency. In Proceedings of the ASME Turbo Expo: Turbine Technical Conference and Exposition, Seoul, Republic of Korea, 13–17 June 2016. [Google Scholar]

- Smith, R.; Dutta, S. Conjugate Thermal Optimization with Unsupervised Machine Learning. J. Heat. Transf. 2021, 143, 052901. [Google Scholar] [CrossRef]

- Dutta, S.; Smith, R. Nonlinear Optimization of Turbine Conjugate Heat Transfer with Iterative Machine Learning and Training Sample Replacement. Energies 2020, 13, 4587. [Google Scholar] [CrossRef]

- García, J.C.; Dávalos, J.O.; Urquiza, G.; Galván, S.; Ochoa, A.; Rodríguez, J.A.; Ponce, C. Film cooling optimization on leading edge gas turbine blade using differential evolution. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2019, 233, 1656–1666. [Google Scholar] [CrossRef]

- Mostofizadeh, A.R.; Adami, M.; Shahdad, M.H. Multi-objective optimization of 3D film cooling configuration with thermal barrier coating in a high pressure vane based on CFD-ANN-GA loop. J. Braz. Soc. Mech. Sci. 2018, 40, 211. [Google Scholar] [CrossRef]

- El Ayoubi, C.; Ghaly, W.; Hassan, I. Aerothermal shape optimization for a double row of discrete film cooling holes on the suction surface of a turbine vane. Eng. Optim. 2015, 47, 1384–1404. [Google Scholar] [CrossRef]

- El Ayoubi, C.; Hassan, O.; Ghaly, W.; Hassan, I. Aero-Thermal Optimization and Experimental Verification for the Discrete Film Cooling of a Turbine Airfoil. In Proceedings of the ASME Turbo Expo: Turbine Technical Conference and Exposition, San Antonio, TX, USA, 3–7 June 2013. [Google Scholar]

- El Ayoubi, C.; Ghaly, W.; Hassan, I. Optimization of Film Cooling Holes on the Suction Surface of a High Pressure Turbine Blade. In Proceedings of the ASME Turbo Expo 2012: Turbine Technical Conference and Exposition, Copenhagen, Denmark, 11–15 June 2012; pp. 1683–1693. [Google Scholar]

- Huang, Y.; Zhang, J.; Wang, C. Shape-optimization of round-to-slot holes for improving film cooling effectiveness on a flat surface. Heat Mass Transf. 2018, 54, 1741–1754. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, J.; Wang, C. Optimization of fan-shaped holes on turbine blade suction surface to improve film cooling performance. J. Cent. South Univ. Sci. Technol. 2018, 49, 2868–2876. (In Chinese) [Google Scholar]

- Johnson, J.; King, P.; Clark, J.; Ooten, M. Design optimization methods for improving HPT vane pressure side cooling properties using genetic algorithms and efficient CFD. In Proceedings of the 50th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Nashville, TN, USA, 9–12 January 2012. [Google Scholar]

- Johnson, J.J.; King, P.I.; Clark, J.P.; Ooten, M.K. Genetic algorithm optimization of an HPT vane pressure side film cooling array. In Proceedings of the ASME Turbo Expo: Turbine Technical Conference & Exposition, Copenhagen, Denmark, 11–15 June 2012. [Google Scholar]

- Lee, S.; Yee, K.; Rhee, D.-H. Optimum arrangement of film cooling holes considering the manufacturing tolerance. J. Propuls. Power 2017, 33, 793–803. [Google Scholar] [CrossRef]

- Lee, S.; Rhee, D.-H.; Yee, K. Optimal arrangement of the film cooling holes considering the manufacturing tolerance for high pressure turbine nozzle. In Proceedings of the Turbo Expo: Power for Land, Sea, and Air, Seoul, Republic of Korea, 13–17 June 2016; p. V02CT45A029. [Google Scholar]

- Kim, Y.; Lee, S.; Yee, K. Variable-fidelity optimization of film-cooling hole arrangements considering conjugate heat transfer. J. Propuls. Power 2018, 34, 1140–1151. [Google Scholar] [CrossRef]

- Jiang, Y.; Lin, H.; Yue, G.; Zheng, Q.; Xu, X. Aero-thermal optimization on multi-rows film cooling of a realistic marine high pressure turbine vane. Appl. Therm. Eng. 2017, 111, 537–549. [Google Scholar] [CrossRef]

- Jiang, Y.; Wan, X.; Magagnato, F.; Yue, G.; Zheng, Q. Multi-step optimizations of leading edge and downstream film cooling configurations on a high pressure turbine vane. Appl. Therm. Eng. 2018, 134, 203–213. [Google Scholar] [CrossRef]

- Muller, S.D.; Walther, J.H.; Koumoutsakos, P.D. Evolution strategies for film cooling optimization. AIAA J. 2001, 39, 537–539. [Google Scholar] [CrossRef][Green Version]

- Moeini, A.; Zargarabadi, M.R. Genetic algorithm optimization of film cooling effectiveness over a rotating blade. Int. J. Therm. Sci. 2018, 125, 248–255. [Google Scholar] [CrossRef]

- Zhao, Z.; Gao, J.; Xu, L.; Li, Y. Experimental study on the cooling performance of a certain type of high-temperature turbine blade. J. Xi’an Jiaotong Univ. 2024, 58, 54–67. (In Chinese) [Google Scholar]

- Li, H.; Li, L.; Tang, Z.; Tan, Z.; Zhang, Z.; Bao, Y. Local physical gradient-based coupling information interpolate method and application on double-wall turbine blade multidisciplinary analysis. Aerosp. Sci. Technol. 2024, 148, 109066. [Google Scholar] [CrossRef]

- Wang, Q.; Yang, L.; Huang, K. Fast prediction and sensitivity analysis of gas turbine cooling performance using supervised learning approaches. Energy 2022, 246, 123373. [Google Scholar] [CrossRef]

- Li, J.; Wang, Y.; Qiu, Z.; Zhang, D.; Xie, Y. Fast performance prediction and field reconstruction of gas turbine using supervised graph learning approaches. Aerosp. Sci. Technol. 2023, 140, 108425. [Google Scholar] [CrossRef]

- Yang, L.; Chen, W.; Chyu, M.K. A convolution modeling method for pore plugging impact on transpiration cooling configurations perforated by straight holes. Int. J. Heat Mass Transf. 2018, 126, 1057–1066. [Google Scholar] [CrossRef]

- Wang, W.; Tao, G.; Ke, D.; Luo, J.; Cui, J. Transpiration cooling of high pressure turbine vane with optimized porosity distribution. Appl. Therm. Eng. 2023, 223, 119831. [Google Scholar] [CrossRef]

- Wang, W.; Tao, G.; Ke, D.; Ruan, Z.; Liu, J.; Luo, J.; Cui, J. Multi-objective optimization of transpiration cooling for high pressure turbine vane. Appl. Therm. Eng. 2024, 246, 122926. [Google Scholar] [CrossRef]

- Kim, K.M.; Moon, H.; Park, J.S.; Cho, H.H. Optimal design of impinging jets in an impingement/effusion cooling system. Energy 2014, 66, 839–848. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, J.; Wang, C. Multi-Objective Optimization of a Double-Wall Cooling Structure for Overall Cooling Effectiveness and Relative Pressure Drop. Chin. Intern. Combust. Engine Eng. 2023, 44, 101–108. (In Chinese) [Google Scholar]

- Wang, C.; Zhang, J.; Wang, C.; Tan, X. Multi-optimization of a specific laminated cooling structure for overall cooling effectiveness and pressure drop. Numer. Heat Transf. Part A Appl. 2020, 79, 195–221. [Google Scholar] [CrossRef]

- Li, W.; Tan, X.; Xiao, X.; Shan, Y.; Zhang, J. Multiobjective Optimization of Double-Wall Cooling Structure of Integrated Strut Flame Stabilizer and Sensitivity Analysis of Parameters. J. Aerosp. Eng. 2023, 36, 04023040. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, L.; Jin, S.; Ye, W.; Li, Y.; Gao, J. A Review of Machine Learning Methods in Turbine Cooling Optimization. Energies 2024, 17, 3177. https://doi.org/10.3390/en17133177

Xu L, Jin S, Ye W, Li Y, Gao J. A Review of Machine Learning Methods in Turbine Cooling Optimization. Energies. 2024; 17(13):3177. https://doi.org/10.3390/en17133177

Chicago/Turabian StyleXu, Liang, Shenglong Jin, Weiqi Ye, Yunlong Li, and Jianmin Gao. 2024. "A Review of Machine Learning Methods in Turbine Cooling Optimization" Energies 17, no. 13: 3177. https://doi.org/10.3390/en17133177

APA StyleXu, L., Jin, S., Ye, W., Li, Y., & Gao, J. (2024). A Review of Machine Learning Methods in Turbine Cooling Optimization. Energies, 17(13), 3177. https://doi.org/10.3390/en17133177