Abstract

The aim of the publication was to analyze investments in biogas plants with a cogeneration unit for an average size dairy farm. The basis for the calculation was the use of cow manure as the only substrate in methane fermentation. The economic balance also includes ecological and service aspects. The study also shows how much energy and quality potential is lost due to improper manure management and what impact a single farm with dairy cows has on the emission of carbon dioxide equivalent. It has been estimated that as a result of improper storage of manure, even 2/3 of its fertilizing, energy and economic value can be lost, while causing damage to the environment. It has been estimated that for a single farm with 100 cows, without government mechanisms subsidizing investments in RES, the payback period exceeds 15 years, and the Return of Capital Employed is slightly more than 6%.

1. Introduction

Proper biogas extraction from agricultural waste is particularly important due to the reduction of emissions of nitrous oxide (N2O) and methane (CH4)—harmful greenhouse gases (GHGs)—and ammonia (NH3) (creating nuisance odorous emissions). These gases are usually referred to as a conversion factor (carbon dioxide equivalent CO2eq), as a unified metric measure used to compare the emissions from various greenhouse gases on the basis of their global warming potential (GWP) [1,2].

Methane is a gas which contributes 25–28 times more (on a 100-year time scale) and 86 times more (on a 20-year time scale) to global warming than carbon dioxide (CO2) [3,4,5,6]. Nitrous oxide (N2O) is a compound for which the negative impact on climate change is even 265–298 times greater than CO2 [3,4,5,7].

Among the sources of GHG emissions associated with animal husbandry, as much as about 20% come from the dairy sector [8,9,10]. Only 15–30% of this range is related to processes other than the production of milk and other dairy products [11,12,13]. These data indicate that a significantly large potential for reducing emissions of these gases is located within the farm [14,15]. Changing the current management of dairy production can therefore bring equally high effects.

The most common GHGs that stream from farm dairy production are methane and nitrous oxide emissions from enteric fermentation, manure storage and handling, as well as agricultural crops and pasture managements [13,16,17]. In the case of potentially generated N2O, a distinction should be made between direct emissions from the farm and emissions from ammonia and nitrates leaving the farm, which may eventually be converted to N2O in other ecosystems. Although they are often treated as independent sources, there are interactions that affect the overall emissions [13,16].

In the case of dairy production, it is feed that shapes all further greenhouse gas emissions, but in this case the potential and actual impacts are quite complex and the results are difficult to assess [18]. Even a part of undigested feed can cause gas formation in another stage of production (e.g., during storage or disposal [18,19]).

Much more clear-cut results can be obtained by tracking CH4, N2O and NH3 emissions related to manure management. According to publications [17,20,21], the amount of generated GHG is affected by the period and method of manure storage. The production of this natural fertilizing material is continuous, while its use in crops is periodic [22]. The phenomenon of improper storage causes ecological and economic damage—it contributes to the reduction in the quality of manure, as a result of the loss of valuable nutrients. The consequence of this is a decrease in the value of manure as a natural fertilizing product, and thus also its price [23,24].

This publication uses periodic studies of dairy manure from a family farm in south-western Poland. In this country, as in most Eastern European countries, over 61% of manure is used for fertilization purposes [25].

The two most popular storage techniques are stacking in heaps and keeping manure in this form until application to the fields [26,27] and, much less frequently, composting in heaps. In the latter case, the manure is periodically turned and/or otherwise aerated [28,29]. According to the technique, composting introduces oxygen (O2) into the manure heaps, which usually contributes to the emission of gases produced under aerobic conditions, such as ammonia and carbon dioxide [26,30,31]. This is different in static heaps (no activities are performed on them), from which mostly gases characteristic of anaerobic conditions (i.e., methane) are produced [28,29].

The formation of methane is closely related to the agricultural practice of manure heaps. This type of natural fertilizer has a solid form, which means that it is formed into piles during storage, which is not compressed and rarely covered. A poorly compacted heap enables the effective activity of aerobic microorganisms, which quickly decompose the organic parts of the manure, at the same time causing a rapid increase in the heap temperature to the level of 40–60 °C (within several dozen hours) [27,32]. Due to such an intensive process, oxygen supplies in the heap run out and conditions are created that introduce the mechanisms of anaerobic decomposition. From this moment, an intensive process of methane formation begins, which is, after all, a valuable fuel in chemical form (renewable energy source) that is produced in typical biogas plants [33].

In the case of nitrous oxide generated during composted manure, low [30,34,35] and high values [36,37,38] were observed, and their value is very dependent on the content of carbon and nitrogen, as well as their mutual ratio and aerobic conditions, etc.

If, on the other hand, manure is only stored, i.e., not compacted and not covered, quite intensive transformations of nitrogen compounds in manure occur. In particular, these processes concern organic forms (derived from proteins) or less intensively from inorganic forms, i.e., ammonia and ammonium (e.g., NH3 and NH4+), from which nitrites and then nitrates are formed with the participation of oxygen. After the processes of denitrification (anaerobic conditions), nitrates are converted into nitrous oxide N2O and molecular nitrogen N2 [39,40].

The analyses contained in this article concern the comparison between the use of fresh cow manure stored under cover and stored uncovered for energy (biogas) purposes. The process that was used in this study is methane fermentation in mesophilic conditions (more information about methane fermentation and the use of biogas as a fuel in [41,42,43,44,45,46,47,48,49]).

The innovative concept is to indicate how storage significantly affects the value of methane and nitrous oxide emissions (environmental pollutants), and thus the energy value of manure as a substrate for biogas plants (economic and energy). This is not taken into account in dairy cow breeding, as demonstrated by the outcome tested in several international research projects [50,51,52,53].

2. Materials and Methods

The current materials and methods section includes several steps:

- 1.

- Description of the reason and methodology and localization of the research;

- 2.

- The economic and energy scenarios;

- 3.

- Methodology for calculating methane and nitrous oxide emissions from manure;

- 4.

- Methodology for calculating fees for the emission of carbon dioxide equivalent;

- 5.

- Biogas yield testing methodology based on “batch culture” technology;

- 6.

- Methodology for calculating energy production as well as thermal and electric power of a biogas plant equipped with a cogeneration unit.

2.1. Reason and Methodology of the Research

This article presents data from our own research and analyses on the economic and energy potential of methane and nitrous oxide emissions. The research material consisted of samples of cow manure collected from a dairy farm. The breeding farm is located in a village in south-western Poland (region of Lower Silesia). Three different scenarios for storing manure before using it as a substrate in a biogas plant were analyzed. Comparisons of economic and energy balances for each scenario and the ecological potential associated with avoided methane and nitrous oxide emissions are presented. The calculations also include a typical solution, i.e., the use of manure directly as a natural fertilizer in crops. The estimated amount of energy produced and the capacity of the installation were compared with the possible reduction of the emissions of the aforementioned greenhouse gases converted into CO2 equivalent.

The samples were taken from a family dairy cow farm utilizing field cultivation for fodder purposes. More than 30% of the farm was under cultivation for fodder crops. Straw was also obtained from these fields as a deep bedding for the cattle. The natural consequence is therefore the production of cow manure and its traditional use as natural fertilizer (typical manure management in Central and Eastern Europe).

Unfortunately, the manure is very rarely stored properly, usually while waiting to be taken to the field. This neglect is directly related to ecological and economic (energy) losses:

- a.

- Lower fertilizer value—part of the organic matter has already been lost, as well as macronutrients;

- b.

- Lower price for manure as a substrate for biogas plants—the lost part of organic matter means lower methane efficiency;

- c.

- Increased emissions of methane and nitrous oxide (as well as ammonia).

The analyses contained in this study show how much potential is lost as a result of such prosaic negligence as the lack of cover (crumpling) of the heap with manure. This is particularly important in the current difficult situation in Europe in terms of energy (manure could be used as a substrate for biogas plants) or fertilizer (direct, as a natural fertilizer, or indirect as a fertilizing product from digestate).

The cow feeding system in the analyzed farm consists of feeding with fodder from the so-called feed tables in the cowshed or under the shelter (the herd is periodically brought into the barn). Such a method of feeding feed itself contributes to increased (compared to grazing) emissions of greenhouse gases and nitrogen [54,55] (although recently there have been promising scientific reports on modern additives mitigating emissions from ruminants [56,57]).

The fodder not eaten by the animals, as well as the excreta, are collected manually, then transported to a heap, and from there to the field (usually by a tractor with a trailer) and it waits in this condition for the date of manure application. Since this usually takes place (in the region of Central and Eastern Europe) only two or three times a year, it results in a long waiting period for land development from autumn to spring, and the pile is exposed for several weeks in the summer to high air temperatures (between periods of fertilization). Thus, the impacts on the environment (long-term and intensive emissions) and, indirectly, on the energy and fertilization value are significant.

2.2. Analyzed Scenarios of Manure Management

The estimates presented in this paper concern the comparison of the energy, economic and fertilization balance with the direct use of manure as a natural fertilizer and manure stored in various ways before it is used as a substrate for a biogas plant, and then fertilized with digestate. The economic analyses did not take into account the costs of transport or the costs of land occupied by heaps of stored manure or occupied by the infrastructure of a biogas plant with a cogeneration system (for the production of electricity and heat), etc. One of the reasons for the above-mentioned restrictions is the assumption that the removal of manure from the manure plate to the fields is much less frequent than when loading one’s own biogas plant, but individually much longer (incomparably greater distance to arable fields). In turn, the digestate obtained after methane fermentation, although of lower weight than the original one (part of the matter converted into biogas and returned to the process to liquefy the substrate), also requires export. In the case of the costs of land occupied by heaps of stored manure or occupied by biogas plant infrastructure, no impact on costs was given, because the area occupied by such a small biogas plant (and possible digestate) is comparable to the area occupied by fresh manure usually lying on several fields, as shown by research carried out as part of project [53]. The costs of collecting and treating liquid leachates generated during the manure storage period were also not taken into account, as they were not disclosed on the farm in question.

Therefore, the comparison includes the traditional variant (Scenario N) and three variants (B-LS, B-C, B-F) with the energy use of cow manure:

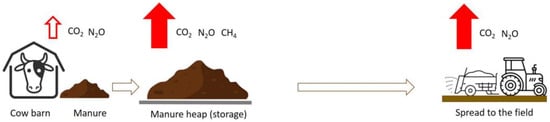

- Scenario N (Natural): periodic storage of manure on a heap (on the farm or in the field) for use as natural fertilizer at the right moment (hypothetically high greenhouse gas emissions)—diagram in Figure 1.

Figure 1. Diagram of Scenario N.

Figure 1. Diagram of Scenario N.

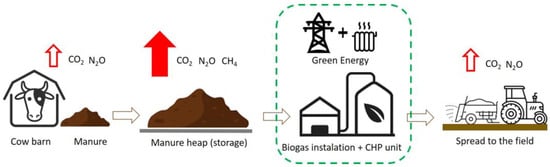

- Scenario B-LS (biogas—long-time): periodic storage of manure on a farm heap and transport from time to time to biogas plants, albeit only after the methane fermentation process, as digestate; it is brought to and managed on the field (hypothetically high greenhouse gas emissions)—diagram in Figure 2.

Figure 2.

Diagram of Scenario B-LS.

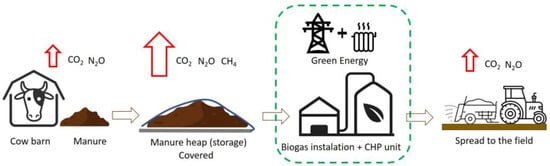

- Scenario B-C (biogas—covered): periodic storage of manure on a farm heap under cover and transport from time to time to biogas plants, however, only after the process of methane fermentation, as digestate; it is brought and managed on the field (hypothetically moderate greenhouse gas emissions)—diagram in Figure 3.

Figure 3.

Diagram of Scenario B-C.

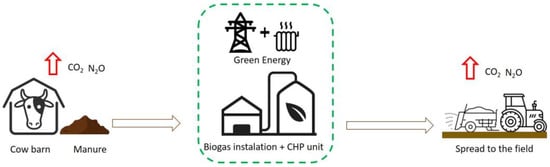

- Scenario B-F (biogas—fresh): manure without storage—it is fed to the biogas plant on an ongoing basis, only after the process of methane fermentation, as digestate exported and managed on the field (hypothetically low greenhouse gas emissions)—diagram in Figure 4.

Figure 4.

Diagram of Scenario B-F.

2.3. Methodology for Calculating of Methane and Nitrous Oxide Emissions

Methane emissions from manure in each scenario were calculated according to the same European Tier 2 procedure [58] by plugging into the formulas generally accepted or national indicators and direct measurements:

where the following abbreviations are used:

EF = VS·B·CF·MCF·MS·D,

- EF—emission factor, kg CH4/animal/year;

- VS—volatile excreted solids (on average daily), kg/animal/day;

- B—possible production of CH4 from animal manure (max. annual), m3 CH4/kg VS (volatile substances);

- CF—conversion factor, change of units from kg to m3;

- MCF—methane conversion factor to the manure management system, %;

- MS—a fraction of livestock category manure, -;

- D—analyzed period in days, days.

The above-mentioned indicators were adopted in accordance with the European procedure contained in the international IPCC reports of 2006 and 2019 [58,59] with delegation to the National Inventory Report of 2022 [60]. The individual values for the indicators, depending on the storage method, are presented in Table 1. Emission calculations are presented for solid cow manure per head.

Table 1.

Indicators adopted for the CH4 emissions calculation.

In the presented Formula (1), the MS coefficient was taken as 1 (100%), because only dairy cows are considered (excluding other categories of livestock). Most indicators are the same for all scenarios, only the MCF values differ—this is due to the adoption of different manure emission factors for them, due to the different storage method. In Scenario N and Scenario B-LS, manure is stored in the traditional way—first for a certain period of time in the barn (deep litter) and then uncovered in a heap on the farm or in the field. Even assuming the conditions for a cold climate in accordance with the IPCC guidelines (value assumed for a cold climate 2006 and 2019 [58,59], it is still assumed that emissions from manure will be high and amount to 17%, while after quick removal from the barn and covering it is only 3%, and with immediate removal and transport to the biogas plant it is close to zero.

Calculations of direct emission of nitrous oxide are given in accordance with Formula (2) (according to IPCC 2006 [58]):

where the following abbreviations are used:

N2OD (mm) = NEX·MS·EF3·CFN,

- N2OD (mm)—direct emissions from manure management, kg N2O/animal/year;

- NEX—N excretion per head of livestock (on average annually), kg N2/animal/year;

- MS—a fraction of livestock category manure, -;

- EF3—emission factor for direct N2O, kg N2O/kg N;

- CFN—conversion factor of (N2O−N) (mm) emissions to N2O (mm) emissions, -.

Individual values of indicators enabling estimation for direct N2O emissions from manure are presented in Table 2.

Table 2.

Indicators adopted for the direct N2O emissions calculation.

For all scenarios, in accordance with the procedure, Nex index equal to 114.6 kg N/head was assumed. For the EF3 indicator, values are given according to the IPCC 2006 corresponding to (as kg N2O−N/kg N): deep bedding equal to 0.01; under cover (compared to solid storage) equal to 0.005; and for anaerobic digester equal to 0 [58].

In turn, the calculations of indirect nitrous oxide emissions—the indirect N2O emissions from volatilization of N in the forms of NH3 and NOx (N2OG (mm)) are given in accordance with Formula (3) (according to IPCC 2006 [58]):

where the following abbreviations are used:

N2OG (mm) = Nvolatilization-MMS·EF4·CFN,

- N2OG (mm)—indirect N2O emissions due to volatilization of N, kg N2O/year;

- Nvolatilization-MMS—amount of manure nitrogen that is lost due to volatilization of NH3 and NOx, kg N/year;

- EF4—emission factor for N2O emissions from atmospheric deposition of nitrogen on soils and water surfaces, kg N2O-N/kg N;

- CFN—conversion factor of (N2O−N) (mm) emissions to N2O (mm) emissions, -.

To provide all indicators to Equation (3), it is necessary to first calculate Nvolatilization-MMS according to simplified Equation (4) (according to IPCC 2006 [58]):

where the following abbreviations are used:

Nvolatilization-MMS = NEX·FracGasMS,

- NEX—N excretion per head of livestock (on average annually), kg N2/animal/year;

- FracGasMS—percent of managed manure nitrogen that volatilises as NH3 and NOx in the manure management system, %.

Individual values of indicators enabling estimation for indirect N2O emissions from volatilization of nitrogen from manure are presented in Table 3.

Table 3.

Indicators adopted for the indirect N2O emissions from volatilization.

The default value of the indicator FracGasMS is 40%, while the values range from 10% to 40% (the lower the volatilization potential, the lower the value) in the IPCC reports (Chapter 10) [58,59]. It should be noted that according to the procedure, the value of the FracGasMS indicator was estimated according to national and regional estimates and experience depending on the cow manure management and storage system—for storage under cover, the indicator is equal to 20%, and in the case of ongoing removal, it is equal to 10% [50,51,52,53,58,59,60,61,62]. The default value of the indicator EF4 is 0.01, while the values range from 0.002 to 0.05 (this factor represents the potential for N2O emissions from atmospheric nitrogen deposition on soils and water surfaces) in the IPCC reports (Chapter 11) [58,59]. It should be noted that according to the procedure, the value of the EF4 indicator was estimated according to regional estimates and experience; for storage under cover, the indicator is equal to 0.01, and in the case of ongoing removal, it is equal to 0.002% [50,51,52,53,58,59,60,61,62].

In addition, an indirect source of N2O is also provided as nitrogen that leaches into soil and/or runs off during solid storage of manure at outdoor areas (N2OL(mm)). The values for these nitrogen streams are given in accordance with simplified Formula (5) (according to IPCC 2006 [58]):

where the following abbreviations are used:

N2OL (mm) = Nleaching-MMS·EF5·CFN,

- N2OL (mm)—indirect N2O emissions due to leaching and runoff, kg N2O/year;

- Nleaching-MMS—amount of manure nitrogen that is lost due to volatilization of NH3 and NOx, kg N/year;

- EF5—emission factor for N2O emissions from nitrogen leaching and runoff, kg N2O-N/kg N leached and runoff, kg N2O-N/kg N;

- CFN—conversion factor of (N2O−N) (mm) emissions to N2O (mm) emissions, -.

To provide all indicators to Equation (5), it is necessary to first calculate Nleaching-MMS according to simplified Equation (6) (according to IPCC 2006 [58]):

where the following abbreviations are used:

Nleaching-MMS = NEX·FracleachingMS,

- NEX—N excretion per head of livestock (on average annually), kg N2/animal/year;

- FracleachingMS—percent of managed manure nitrogen losses due to runoff and leaching during storage of manure; %.

Individual values of indicators enabling estimation for indirect N2O emissions from leaching into soil and/or runoff during solid storage of manure at outdoor areas are presented in Table 4.

Table 4.

Indicators adopted for the indirect N2O emissions from leaching.

The default value of the indicator FracleachingMS is 30%, while the values range from 0% to 80% (higher values apply only to regions where the water holding capacity of the soil has been exceeded as a result of rainfall and/or irrigation) in the IPCC reports (Chapter 11) [58,59]. It should be noted that according to the procedure, the value of the FracGasMS indicator was estimated according to national and regional estimates and experience depending on the cow manure management and storage system—for storage under cover, the indicator is equal to 10%, and in the case of ongoing removal, it is equal to 1% [50,51,52,53,58,59,60,61,62]. The default value of the indicator EF5 is 0.0075, while the values range from 0.0005 to 0.025 (this factor represents the potential for N2O emissions incorporates three components, which are the emission factors for groundwater and surface drainage, rivers and estuaries) in the IPCC reports (Chapter 11) [58,59]. It should be noted that according to the procedure, the value of the EF5 indicator was estimated according to regional estimates and experience; for storage under cover, the indicator is equal to 0.0075, and in the case of ongoing removal, it is equal to 0.0005% [50,51,52,53,58,59,60,61,62].

2.4. Methodology for Calculating Fees for the Emission of Carbon Dioxide Equivalent

In 2022, the volume of allowances in the European Union Emissions Trading System (EU ETS) auctioned or sold about 373 million metric tons of CO₂eq. This year, the largest amount of carbon allowances auctioned or sold took place in Germany—84.2 MtCO₂eq. This amount was closely followed by Poland, which auctioned or sold a total of almost 63 MtCO₂eq of allowances. One allowance—or carbon credit—gives the holder the right to emit one metric tonne of carbon dioxide or its equivalent [63].

Currently, carbon allowances in the EU have increased by EUR 2.90 or 3.30% since early 2023, according to a contract for difference (CFD) trade that tracks the benchmark market for the commodity. The value of this allowances is EUR 90.90 (as of 1 August 2023) per 1 for 1 Mg CO2eq [64].

In many countries, including Poland, support systems for new RES Installations have been introduced in the last few years. One is the offer of guaranteed prices for the purchase of produced electricity—feed-in tariff (FIT) for small biogas plants (with a capacity of less than 0.5 MW). As of the time of research, this price is at the level of EUR 197.27 per 1 MWh (taking into account a maximum of 95% of the reference price) [65]. The price of electricity from the second quarter of 2023 is currently EUR 176.98/MWh (average EUR exchange rate is PLN 4.43/EUR (as of 1 August 2023) [66]. The FIT is therefore approx. 11.1% higher than the market average electricity prices; however, investors in biogas plants may also receive subsidies for the construction of biogas plants—even up to 65% of total price, as well as a bonus of over EUR 35 per 1 MWh if the heat produced by combined heat and power unit (CHP) should be fully used [67]. The cost of purchasing 1 GJ of heat on the regional market currently does not exceed EUR 36 per GJ (depending on the type of fuel used, on average, approx. 28.76) [68].

According to literature reports, it was assumed that the global warming potential (GWP) will be expressed as carbon dioxide equivalent for methane and nitrous oxide equal to 25 and 298, respectively [3,4,60].

2.5. Biogas Yield Testing Methodology

All samples subjected to physico-chemical analysis and in terms of biogas efficiency were sent to the Ecotechnologies laboratory, one of the largest of such laboratories in Poland [69]. This institution has an internationally recognized quality certificate for methane fermentation research received from the organizations VDLUFA (Verband Deutscher Landwirtschaftlicher Unter-suchungs- und Forschungsanstalten) [70] and KTBL (Kuratorium für Technik und Bauwesen in der Landwirtschaft) [71]. Therefore, the methods of biogas yield analysis are based on procedures in accordance with the following standards: VDI 4630 [72] and DIN 38414/S8 [73].

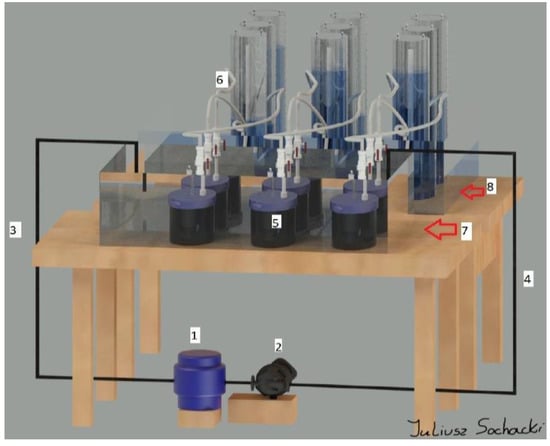

The composition and volume of the produced biogas were determined in the tests on the basis of periodic tests, using the so-called batch culture. This process is carried out in glass reactors with a capacity of 2 dm3 each, located in special heated sections (Figure 5).

Figure 5.

Scheme of the stand for testing the efficiency of biogas, the so-called “batch culture” (3-chamber reactor): 1—water heater with temperature control, 2—water pump, 3 and 4—insulated water pipes, 5—fermentation reactor, 6—pipes transporting biogas, 7 —water bath, 8—system of graduated pipes to measure the volume of gas produced.

Measurement procedures and devices have already been described in previous works [74,75,76].

2.6. Methodology for Calculating Energy Production

In order to develop an energy and economic balance, it is necessary to define the technological and strategic assumptions of the considered installation. In this work, it was assumed that a typically agricultural biogas plant (with mesophilic conditions for the methane fermentation process) will have a biogas storage and a cogeneration installation (CHP), i.e., it will use biogas to obtain heat and electricity from it for commercial purposes.

In the considered scenarios, financial and energy estimates will be based on the energy and fertilization potential of cow manure. In direct terms, the material will be used as a natural fertilizer without any treatment, and indirectly, initially as a substrate (or co-substrate) in a biogas plant.

The generated electricity (Ee, MWh) in a biogas plant with a CHP unit was calculated according to the following formula:

where the following abbreviations are used:

Ee = VCH4·WCH4·ηe,

- VCH4—methane produced in the fermentation process (m3);

- WCH4—calorific value of methane contained in 1 m3;

- ηe—electric efficiency of the cogeneration unit.

The generated heat (Eh, MWh) generated in the cogeneration installation was ascertained in accordance with the following formula:

where the following abbreviations are used:

Eh = VCH4·WCH4·ηh,

- VCH4—methane produced in the fermentation process (m3);

- WCH4—calorific value of methane contained in 1 m3;

- ηh—heat efficiency of the cogeneration unit.

The electric power of a biogas installation (Pe, MW) generated in the cogeneration installation was ascertained in accordance with the following formula:

where the following abbreviations are used:

Pe = Ee/t,

- Ee—electric energy produced yearly;

- t—operating time (h) of the cogeneration unit (yearly).

For thermal power (Pt), a similar equation was used:

where the following abbreviations are used:

Ph = Eh/t,

- Eh—heat produced yearly;

- t—operating time (h) of the cogeneration unit (yearly).

The amount of heat produced is usually given in GJ, therefore for the purpose of conversion it was assumed that 1 MWh equals 3.6 GJ.

The basic coefficients for energy calculations are given in Table 5.

Table 5.

Coefficients for energy calculations.

The above-mentioned Table 5 shows the average coefficients of electrical and thermal efficiency of cogeneration units. The values of these coefficients are not constant over time because they depend on, e.g., the type of fuel, technology and operation of the installation. For greater comparability, values of 0.3 and 0.55 are given for them in Table 3 (which is achievable in most cases) [77,78,79,80,81,82,83]. Also, the number of operating hours per year of this type of CHP unit may be variable, depending indirectly on the quality of the substrate, the method of operation of the biogas plant (including the number and duration of the service) and finally the quality of the installation and proper selection in a given technological line. In order for the estimates to be reflected in average conditions, the total working time per year for a CHP unit was assumed equal to 8200 h [74,75,84,85,86,87].

3. Results

In the following parts of the results section, the final calculations are given in relation to the considered scenarios. In this work, part of the input data, the same or similar as in other studies in this field, were deliberately used, so that it was possible to compare them appropriately.

3.1. Emission Calculations

For the purposes of the analysis of different scenarios, yearly calculations made according to Formulas (1) and (2) are presented in Table 6 wherein the comparative number of dairy cows was assumed as 100.

Table 6.

Emission calculations for different scenarios.

Approximately 100 dairy cows can produce more than 2 Gg of farmyard manure per year (approx. 55 kg of manure from deep litter per cow and day), which must be managed. It can be estimated that such a mass of manure will contribute to the emission of carbon dioxide equivalents (from CH4 and N2O) at the level of almost 300 Mg for the N and B-LS scenarios, less than 60 Mg for the B-C scenario and about 1 Mg for the B-F scenario (variant with a biogas plant). It should be noted that the total emission from nitrous oxide affects the final CO2eq index by as much as 43% to even 77% more than from methane. This is due to much larger and faster losses and 10 times greater impact of N2O on global warming than CH4 from manure.

3.2. Energy and Economic Calculations

The input data were the results obtained from nine series of samples taken for biogas tests. Table 7 shows the average values of individual parameters and the differences in biogas efficiency obtained for variants with uncovered manure (B-LS) and covered manure (B-C) in relation to fresh manure, transferred to the biogas plant on an ongoing basis (B-F). Biogas and methane productions are given in m3 per Mg in terms of fresh weight (FM) of manure (at the same moisture content as at the time of collection).

Table 7.

Methane production from 1 Mg of cow farmyard manure.

Based on the research, it can be concluded that manure waiting on the farm without cover loses almost 75%, and covered manure almost 30% of the volume of methane produced in relation to the material used on an ongoing basis. This is over 20 m3 less methane in the first case, and almost 10 m3 less methane in the second. This is a very big difference considering that it concerns only 1 Mg of farmyard manure.

If we consider the annual cycle of manure use in the biogas plant as generated from only 100 cows, it would mean a methane production lower by 44,630 m3 and 18,057 m3 for uncovered and covered manure, respectively (Table 8).

Table 8.

Methane production from 100 dairy cows manure per year.

Input data, both energy and economic, are presented in Table 9. Note, the values given in the following tables have mostly been rounded (for clarity); in actual calculations, they are not integers and come from the conversion of the Polish currency PLN into EUR.

Table 9.

Input parameters.

On the basis of the annual production of methane, the size of the biogas plant with the cogeneration unit (CHP), and thus the annual production of electricity and heat, can be determined using Formulas (7)–(10). The estimated electric power of the entire installation is (in sequence with the scenarios) 5, 14 or 24 kW with annual electricity production of approx. 124, 274 or 359 MWh (Table 10). It was assumed that the energy used for own needs—i.e., the operation of a biogas installation with a CHP unit—will be 6% electric and 12% thermal.

Table 10.

Energy performance of a biogas plant with a CHP unit.

Data on costs and revenues were taken from market analysis and correlated with previous and local popular science publications [74,75,88,89,90,91]. Reference interest rates were taken from the actual official data of the National Bank of Poland [92]. The presented indicative values and final amounts are listed in Table 11.

Table 11.

Economic indicative values for different scenarios.

The balance shows that the biogas plant with the smallest CHP unit will be the cheapest to build and operate (which is obvious); however, it will generate losses of almost EUR 17000 using fresh manure (Table 12). This translates into a payback period (PBP) of negative value to 15.9 years. In the case of return of capital employed (ROCE), this will be, respectively, negative value and 6.3%.

Table 12.

Economic balance for different scenarios.

The presented financial results differ significantly from each other if we compare the economic indicators of PBP and ROCE, assuming no possibility to use heat from cogeneration units, as well as the possibility of selling digestate (both are situations that can be found on the market, they depend on the location of the installation and the possibility of connecting to district heating system) [74]. In such scenarios, the differences would be much greater and presenting them using such indicators, i.e., PBP and ROCE, makes no sense (Table 13).

Table 13.

Economic balance for different scenarios (excluding revenues from heat and digestate).

The future investor should also take into account that in the coming years there may be a situation in which every product in the European Union will have to include the carbon footprint in their costs. Such an approach, forced by the climate and energy crisis (indirectly also the fertilizer crisis), will compel emitters (e.g., producers of dairy products) to pay fees for emission permits. In such a situation, dairy cow breeders will also be covered, and this may mean significant costs, and thus financial losses. Table 14 shows the profits of taking into account the sale of heat and digestate, but these are reduced by the purchase of CO2 equivalent emission allowances.

Table 14.

Economic balance for different scenarios after introducing fees for carbon emissions allowances.

In the event that emissions-related costs become necessary, a solution where manure is stored uncovered for a long time will generate significant losses for the farm. For the scenario using fresh manure for energy purposes, the change will be negligible (only around EUR 100 per year).

4. Discussion

The use of manure as a substrate for a biogas plant instead of applying it (without processing) to the soil seems to be a beneficial solution, in economic, ecological and social terms. From the investment point of view, however, it is important to consider what effect the size of the herd and the method of manure management have on the legitimacy of building a biogas unit with a cogenerator.

Therefore, a breeding farm with 100 dairy cows, from which manure is collected on a deep litter, i.e., with a large share of straw, was adopted for the analysis of individual scenarios. This type of solution is very popular in Poland and most Eastern European countries and some others in the UE [93,94,95]. Indeed, mostly the farms with a number of cows not exceeding 120 heads do not invest in solutions other than breeding on deep litter and agricultural use of manure [60].

In this study, indirect testing methods were used, but samples were used directly from the place of production/storage. This was in order to be able to capture, at least in part, the characteristics of the formation of a natural crust on the surface of the stored manure, the impact of atmospheric conditions and method of storage along with waiting for soil introduction.

The procedure for estimating methane and nitrous oxide emissions was adopted from the IPCC report methodology recognized in Europe [58,59], which is supported by regional data [60] (according to the IPCC procedure).

As it has been shown in many research works on manure management in relation to methane and nitrous oxide emissions such as CCCFarming, DairyMix, MilKey and MELS [50,51,52,53], in order to reduce the environmental impact as much as possible, the material should be transported to the biogas unit as soon as possible (preferably with a CHP unit). The analyses contained in this study indicate that the storage of manure contributes to the significant depletion of manure and thus environmental pollution. Leaving manure uncovered for a long time (according to this study) may cause potential damage (calculations based on IPCC reports) of methane losses (from one cow a year) at the level of 4.87 Mg; and if the manure was compacted and covered, there would be losses only of 0.86 Mg (Table 6). In turn, laboratory tests show that this may cause (Table 7) a decrease in methane yield from manure typically stored by 2/3 in relation to manure removed on an ongoing basis (Scenario B-F), and in the case of comparing compacted and covered manure, this difference is slightly less than 1/3 of the manure collected on an ongoing basis (Scenario B-F).

How divergent the data on emissions are is evidenced by many research reports. For example, according to one of the scientific sources, one can expect from a breeding farm (per one cow) from 2.5 to 5.8 Mg CO2eq [40,96,97,98,99]. This value corresponds with the one obtained in this work—with the traditional method of storage, approx. 3 Mg CO2eq was calculated. However, this result does not include significant emissions from enteric fermentation of a cow, which may account for another dozen percent [13,100], and no indirect emissions, including from transport, etc., were added. Some indicators published elsewhere, e.g., 15 m3 CH4/Mg [101], would mean that the results quoted (and shown in the study) are significantly overestimated. Unfortunately, the description of the samples and the research methodology are rarely exhaustively described. Failure to specify the type, fraction or storage time often makes it impossible to properly compare the obtained values. In more advanced laboratory measurements, it is possible to convert emissions from the elemental composition. In this study, the emission expressed in CO2eq per 100 cows was assumed. Calculating that a cow produces 55 kg of manure (FM) a day, it would amount to approx. 2007.5 Mg per year (from this 100 cows). Therefore, in individual scenarios, annual emissions from 1 Mg of manure should be expected at the following levels: without cover and compaction (Scenario N and B-LS) 147.5 kg CO2eq; after covering and compacting 29.6 kg CO2eq (Scenario B-C); and 0.5 kg CO2eq when collected on an ongoing basis (Scenario B-F). Other researchers [102] reported a range of emissions from 1 Mg of manure from 16 kg CO2eq to 84 kg CO2eq during manure storage. These values are higher than those provided in this study (except for scenario B-C), but they used a slightly different procedure for estimating emissions and other conversion factors for CH4 and N2O, and the mass of manure produced per day (from 75 cow—1.8 Mg of manure).

In these studies, the N2O emission had a slightly greater impact on the final CO2eq value than CH4. This is also confirmed by other studies, indicating that when the heap is not covered, N2O emissions especially are much higher and this is related to the increase in temperature of the manure [102,103].

It seems that methane fermentation combined with energy recovery in a CHP unit is the most advantageous solution in terms of sustainable development assumptions [7,104,105]. The weakness, however, as shown in this study and as can be found in the literature sources, is the biogas efficiency of manure [106,107]. The reason for such a low methane yield is that there is only a small amount of easily degradable substances in the manure, as most of the energy substances were used at the stage of digestion in the cow. Moreover, although the organic content is relatively high, the availability is low (difficult to decompose during anaerobic fermentation processes [108,109]). Some researchers estimate that up to half of the solid matter in manure is undigested elements, containing mainly cellulose, lignin and hemicellulose [106,110].

For the above reason, it is advisable to use the entire waste potential of the farm, i.e., to treat a mixture of manure with agricultural waste as a substrate. For a significant part of farms, various types of straw are such an additional energy stream [111,112,113,114,115]. Although this material does not have the highest possible ratio of methane produced to a mass unit, its use does not constitute a conflict in the food sense [116,117]. Therefore, there are clear indications from an energy and ecological point of view for the use of manure in anaerobic digestion processes.

However, in the financial aspect, the use of micro biogas plants for farms with dairy cows does not seem to be an effective solution. The purchase costs do not seem to be excessive, especially since preferential credit terms for this type of solution can be obtained. Unfortunately, despite many popular science reports from the regional market about the financial benefits of building a micro biogas plant with cogeneration units [89,90,91] (such as return on investment of 6–10 years, and, in some cases, even 3–5 years), the results of the current study indicate that the true figure is not so obvious. Only solutions in which the investor/farmer properly manages the manure (i.e., covers it and at the same time transports it to a biogas plant as soon as possible) will generate a relatively safe return on investment of less than 16 years. This is regardless of the introduction of charges for CO2 equivalent emissions, but assuming the possibility of selling heat and digestate. Such a long payback period is mainly caused by fixed costs of operation and maintenance—these costs do not decrease directly proportionally to the power, and the micro biogas plant is also disadvantaged by the reduction in electrical efficiency in relation to the (increasing) thermal CHP unit [77,78].

A well-thought-out investment in a biogas plant with a CHP unit [75], as the experience of recent years has shown (COVID-19 and the war in Ukraine), for farms with their own independent source of energy and safe fertilizer can protect the farm from crises in any form: ecological and energy-economic.

Another very important factor may contribute to the improvement of the economic balance. This is the offer of subsidies for investments in RES in less-urbanized areas. In Poland, for example (for installations above 10 kW), these can be a loan up to 100% of eligible investment costs (up to EUR 5,643,341) and/or a subsidy up to 45% of eligible costs with the possibility of increasing it for micro-, small- and medium-sized enterprises (up to EUR 4,514,673) [67,118]. Actions of this nature significantly affect the level of payback of the installation—in the case of the B-F scenario presented in this paper, the payback period would be less than 6.5 years, which is one of the best in the RES industry. Indeed, one could also expect a payback period lower than 4 years, and a return of capital employed ca. 16, which usually means a relatively good financial balance [119].

Another solution that brings measurable profits is the construction of a local biogas plant with a capacity of 250–500 kW and use of other waste streams [76,120,121,122,123]. In the analyzed case, it would be an installation intended for a dozen local farmers (up to 10 km from the installation) and waste streams other than manure. In such a case one could also expect a payback period lower than 4 years with a fairly good return of capital employed, estimated to be above 20 [74,75]. Of course, this would involve higher emissions related to the transport of manure and collection of digestate, but the electrical efficiency of the cogeneration unit would increase to the advantage and ratio of fixed costs to capital expenditures.

If this is not possible, the positive aspect of the micro biogas plant is the compact design, time and ease of installation, as well as the possibility of connecting the micro biogas plant to the power infrastructure. This type of installation can be connected to low (or medium) voltage networks, which are connected to rural transformer stations. It is assumed that a micro biogas plant (properly equipped) can be connected without major problems to provide up to 40 kW of installed electric power. Another future-proof solution is the production of electricity from biogas to a separate grid (microgrid) as an alternative protection against rural grid failures and power outages [124].

Currently, solutions are also being researched that would reduce the failure rate and at the same time increase the profitability of biogas installations in animal farms, including small ones of less than 200 cows. They concern both the stage before manure is created, among others: feed additives [125,126,127,128]; change in composition, or the ratio of roughage to concentrate [129,130]; and to increase the digestibility of organic matter, by mechanical, chemical or biological fragmentation or spreading of particles before introducing it as a substrate to the biogas plant [131,132]. While the results of some studies are quite promising, often their implementation would require stricter dietary supervision or additional devices and procedures. Compacting and covering manure is free of these limitations, because it is a typical field work on cow farms—because on many of them it is necessary to prepare various types of silage in a similar way.

5. Conclusions

When considering economic considerations in a biogas plant, the keys are, above all, the method of storing manure (preferably the shortest and covered), its use for energy purposes (in a micro or small biogas plant with CHP < 500 kW) and the possibility of selling electricity (usually without any problems) and heat (strongly depending on installation location). In the most favorable variant, one can expect a payback period of less than 6.5 years, and a return of capital employed in about 16.

In the event that emissions-related costs become necessary, a solution where manure is stored uncovered for a long time will generate significant losses for the farm. The calculations would look even less favorable for the investor if the carbon footprint (CO2 emission rights eq) was also included in the combustion of conventional fuels in means of transport. What is more, in the absence of the possibility to use the heat produced in the CHP unit in the heating system, it would lead to the rapid insolvency of the livestock farm. That is why it is so important when investing in biogas installations (also equipped with cogeneration units) to take into account not only the current economic indicators, but also the indicators generated by the ecological policy in Europe. Hence, it seems reasonable to consider joint investments in installations with higher capacity and faster rates of return—so-called “small centralization”—using one biogas plant in the commune, to which local residents bring manure, receive digestate in the settlement and use the profits from the biogas plant, or locally lower prices for heat and electricity.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Acknowledgments

The author acknowledge the financial support through the partners of the Joint Call of the Cofund ERA-Nets SusCrop (Grant N° 771134), FACCE ERA-GAS (Grant N° 696356), ICT-AGRI-FOOD (Grant N° 862665) and SusAn (Grant N° 696231), and was carried out as part of research at the Poznan University of Life Sciences.

Conflicts of Interest

The author declares no conflict of interest.

References

- Glossary: Carbon Dioxide Equivalent. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Glossary:Carbon_dioxide_equivalent (accessed on 15 July 2023).

- AR6 Synthesis Report: Climate Change 2023. Available online: https://www.ipcc.ch/report/ar6/syr/ (accessed on 5 August 2023).

- Measuring Emissions: Detailed Guide 2020. Available online: https://environment.govt.nz/publications/measuring-emissions-detailed-guide-2020/ (accessed on 23 October 2022).

- Wang, C.; Amon, B.; Schulz, K.; Mehdi, B. Factors That Influence Nitrous Oxide Emissions from Agricultural Soils as Well as Their Representation in Simulation Models: A Review. Agronomy 2021, 11, 770. [Google Scholar] [CrossRef]

- Poland. 2021 National Inventory Report (NIR)|UNFCCC. Available online: https://unfccc.int/documents/274762 (accessed on 23 October 2022).

- Nadan, M.K.; Baroutian, S. Prospective of Pretreatment and Anaerobic Digestion of Dairy Cow Manure in Fiji. J. Chem. Technol. Biotechnol. 2023, 98, 1584–1597. [Google Scholar] [CrossRef]

- Grossi, G.; Goglio, P.; Vitali, A.; Williams, A.G. Livestock and Climate Change: Impact of Livestock on Climate and Mitigation Strategies. Anim. Front. 2019, 9, 69–76. [Google Scholar] [CrossRef]

- Gerber, P.J.; Food and Agriculture Organization of the United Nations (Eds.) Tackling Climate Change through Livestock: A Global Assessment of Emissions and Mitigation Opportunities; Food and Agriculture Organization of the United Nations: Rome, Italy, 2013; ISBN 978-92-5-107920-1. [Google Scholar]

- Twine, R. Emissions from Animal Agriculture—16.5% Is the New Minimum Figure. Sustainability 2021, 13, 6276. [Google Scholar] [CrossRef]

- By-Nc-Sa, C. The Future of Food and Agriculture–Alternative Pathways to 2050; European Commission: Ispra, Italy, 2018. [Google Scholar]

- Little, S.M.; Benchaar, C.; Janzen, H.H.; Kröbel, R.; McGeough, E.J.; Beauchemin, K.A. Demonstrating the Effect of Forage Source on the Carbon Footprint of a Canadian Dairy Farm Using Whole-Systems Analysis and the Holos Model: Alfalfa Silage vs. Corn Silage. Climate 2017, 5, 87. [Google Scholar] [CrossRef]

- Thoma, G.; Popp, J.; Shonnard, D.; Nutter, D.; Matlock, M.; Ulrich, R.; Kellogg, W.; Kim, D.S.; Neiderman, Z.; Kemper, N.; et al. Regional Analysis of Greenhouse Gas Emissions from USA Dairy Farms: A Cradle to Farm-Gate Assessment of the American Dairy Industry circa 2008. Int. Dairy J. 2013, 31, S29–S40. [Google Scholar] [CrossRef]

- Rotz, C.A. Modeling Greenhouse Gas Emissions from Dairy Farms. J. Dairy Sci. 2018, 101, 6675–6690. [Google Scholar] [CrossRef] [PubMed]

- Mazur, K.; Roman, K.; Wardal, W.J.; Borek, K.; Barwicki, J.; Kierończyk, M. Emission of Harmful Gases from Animal Production in Poland. Environ. Monit Assess. 2021, 193, 341. [Google Scholar] [CrossRef] [PubMed]

- #6 Study Bioenergy.Pdf. BIOEAST. Available online: https://bioeast.eu/wp-content/uploads/2021/10/BIOeast-Report-2021_FINAL_compressed-1.pdf (accessed on 3 July 2023).

- Naranjo, A.; Johnson, A.; Rossow, H.; Kebreab, E. Greenhouse Gas, Water, and Land Footprint per Unit of Production of the California Dairy Industry over 50 Years. J. Dairy Sci. 2020, 103, 3760–3773. [Google Scholar] [CrossRef]

- Peterson, C.B.; Mitloehner, F.M. Sustainability of the Dairy Industry: Emissions and Mitigation Opportunities. Front. Anim. Sci. 2021, 2, 760310. [Google Scholar] [CrossRef]

- Møller, H.B.; Moset, V.; Brask, M.; Weisbjerg, M.R.; Lund, P. Feces Composition and Manure Derived Methane Yield from Dairy Cows: Influence of Diet with Focus on Fat Supplement and Roughage Type. Atmos. Environ. 2014, 94, 36–43. [Google Scholar] [CrossRef]

- Hristov, A.N.; Oh, J.; Giallongo, F.; Frederick, T.W.; Harper, M.T.; Weeks, H.L.; Branco, A.F.; Moate, P.J.; Deighton, M.H.; Williams, S.R.O.; et al. An Inhibitor Persistently Decreased Enteric Methane Emission from Dairy Cows with No Negative Effect on Milk Production. Proc. Natl. Acad. Sci. USA 2015, 112, 10663–10668. [Google Scholar] [CrossRef] [PubMed]

- Sommer, S.G.; Feilberg, A. Gaseous Emissions of Ammonia and Malodorous Gases. In Animal Manure Recycling; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2013; pp. 131–151. ISBN 978-1-118-67667-7. [Google Scholar]

- Amon, B.; Kryvoruchko, V.; Amon, T.; Zechmeister-Boltenstern, S. Methane, Nitrous Oxide and Ammonia Emissions during Storage and after Application of Dairy Cattle Slurry and Influence of Slurry Treatment. Agric. Ecosyst. Environ. 2006, 112, 153–162. [Google Scholar] [CrossRef]

- Dairy Manure as a Fertilizer Source|NC State Extension Publications. Available online: https://content.ces.ncsu.edu/dairy-manure-as-a-fertilizer-source (accessed on 16 July 2023).

- Shan, N.; Li, H.; Li, J.; Ng, E.L.; Ma, Y.; Wang, L.; Chen, Q. A Major Pathway for Carbon and Nitrogen Losses—Gas Emissions during Storage of Solid Pig Manure in China. J. Integr. Agric. 2019, 18, 190–200. [Google Scholar] [CrossRef]

- Johannesson, G.H.; Lauzon, J.; Crolla, A.; Gilroyed, B.; Vanderzaag, A.; Gordon, R. Impact of Manure Storage Conditions and Time on Decomposition of and Losses from Liquid Dairy Manure Stored in a Temperate Climate. Can. J. Soil Sci. 2018, 98, 148–160. [Google Scholar] [CrossRef]

- Petersen, S.O.; Blanchard, M.; Chadwick, D.; Del Prado, A.; Edouard, N.; Mosquera, J.; Sommer, S.G. Manure Management for Greenhouse Gas Mitigation. Animal 2013, 7, 266–282. [Google Scholar] [CrossRef] [PubMed]

- Lopez-Real, J.; Baptista, M. A Preliminary Comparative Study of Three Manure Composting Systems and Their Influence on Process Parameters and Methane Emissions. Compos. Sci. Util. 1996, 4, 71–82. [Google Scholar] [CrossRef]

- Owens, J.L.; Thomas, B.W.; Stoeckli, J.L.; Beauchemin, K.A.; McAllister, T.A.; Larney, F.J.; Hao, X. Greenhouse Gas and Ammonia Emissions from Stored Manure from Beef Cattle Supplemented 3-Nitrooxypropanol and Monensin to Reduce Enteric Methane Emissions. Sci. Rep. 2020, 10, 19310. [Google Scholar] [CrossRef]

- The Composting Handbook, 1st ed. Available online: https://shop.elsevier.com/books/the-composting-handbook/rynk/978-0-323-85602-7#full-description (accessed on 21 July 2023).

- Rynk, R.; van de Kamp, M.; Willson, G.B.; Singley, M.E.; Richard, T.L.; Kolega, J.J.; Gouin, F.R.; Laliberty, L.; Kay, D.; Murphy, D.; et al. On-Farm Composting Handbook (NRAES 54); Northeast Regional Agricultural Engineering Service (NRAES): Ithaca, NY, USA, 1992. [Google Scholar]

- Mahimairaja, S.; Bolan, N.S.; Hedley, M.J.; Macgregor, A.N. Losses and Transformation of Nitrogen during Composting of Poultry Manure with Different Amendments: An Incubation Experiment. Bioresour. Technol. 1994, 47, 265–273. [Google Scholar] [CrossRef]

- Yang, X.; Liu, E.; Zhu, X.; Wang, H.; Liu, H.; Liu, X.; Dong, W. Impact of Composting Methods on Nitrogen Retention and Losses during Dairy Manure Composting. Int. J. Environ. Res. Public Health 2019, 16, 3324. [Google Scholar] [CrossRef] [PubMed]

- Sneath, R.W.; Beline, F.; Hilhorst, M.A.; Peu, P. Monitoring GHG from Manure Stores on Organic and Conventional Dairy Farms. Agric. Ecosyst. Environ. 2006, 112, 122–128. [Google Scholar] [CrossRef]

- Hollas, C.E.; Bolsan, A.C.; Chini, A.; Venturin, B.; Bonassa, G.; Cândido, D.; Antes, F.G.; Steinmetz, R.L.R.; Prado, N.V.; Kunz, A. Effects of Swine Manure Storage Time on Solid-Liquid Separation and Biogas Production: A Life-Cycle Assessment Approach. Renew. Sustain. Energy Rev. 2021, 150, 111472. [Google Scholar] [CrossRef]

- Veeken, A.; de Wilde, V.; Szanto, G.; Hamelers, B. Passively Aerated Composting of Straw-Rich Organic Pig Manure. In Microbiology of Composting; Insam, H., Riddech, N., Klammer, S., Eds.; Springer: Berlin/Heidelberg, Germany, 2002; pp. 607–621. [Google Scholar]

- Szanto, G.L.; Hamelers, H.V.M.; Rulkens, W.H.; Veeken, A.H.M. NH3, N2O and CH4 Emissions during Passively Aerated Composting of Straw-Rich Pig Manure. Bioresour. Technol. 2007, 98, 2659–2670. [Google Scholar] [CrossRef]

- Hao, X.; Larney, F.J. Greenhouse Gas Emissions during Co-Composting of Cattle Feedlot Manure with Construction and Demolition (C&D) Waste. Front. Environ. Sci. Eng. 2017, 11, 15. [Google Scholar] [CrossRef]

- Ahn, H.K.; Mulbry, W.; White, J.W.; Kondrad, S.L. Pile Mixing Increases Greenhouse Gas Emissions during Composting of Dairy Manure. Bioresour. Technol. 2011, 102, 2904–2909. [Google Scholar] [CrossRef]

- Maeda, K.; Hanajima, D.; Morioka, R.; Toyoda, S.; Yoshida, N.; Osada, T. Mitigation of Greenhouse Gas Emission from the Cattle Manure Composting Process by Use of a Bulking Agent. Soil Sci. Plant Nutr. 2013, 59, 96–106. [Google Scholar] [CrossRef]

- Saggar, S. Estimation of Nitrous Oxide Emission from Ecosystems and Its Mitigation Technologies. Agric. Ecosyst. Environ. 2010, 136, 189–191. [Google Scholar] [CrossRef]

- Rivera, J.E.; Chará, J. CH4 and N2O Emissions from Cattle Excreta: A Review of Main Drivers and Mitigation Strategies in Grazing Systems. Front. Sustain. Food Syst. 2021, 5, 657936. [Google Scholar] [CrossRef]

- Sobczak, A.; Chomać-Pierzecka, E.; Kokiel, A.; Różycka, M.; Stasiak, J.; Soboń, D. Economic Conditions of Using Biodegradable Waste for Biogas Production, Using the Example of Poland and Germany. Energies 2022, 15, 5239. [Google Scholar] [CrossRef]

- Das, A.; Das, S.; Das, N.; Pandey, P.; Ingti, B.; Panchenko, V.; Pandey, P. Advancements and Innovations in Harnessing Microbial Processes for Enhanced Biogas Production from Waste Materials. Agriculture 2023, 13, 1689. Available online: https://www.mdpi.com/2077-0472/13/9/1689 (accessed on 9 September 2023). [CrossRef]

- Energetic Potential of Dairy Cow Breeding in Poland. Available online: https://www.springerprofessional.de/en/energetic-potential-of-dairy-cow-breeding-in-poland/23482658 (accessed on 9 September 2023).

- Maj, I. Significance and Challenges of Poultry Litter and Cattle Manure as Sustainable Fuels: A Review. Energies 2022, 15, 8981. [Google Scholar] [CrossRef]

- Kwietniewska, E.; Tys, J. Process Characteristics, Inhibition Factors and Methane Yields of Anaerobic Digestion Process, with Particular Focus on Microalgal Biomass Fermentation. Renew. Sustain. Energy Rev. 2014, 34, 491–500. [Google Scholar] [CrossRef]

- Czekała, W.; Gawrych, K.; Smurzyńska, A.; Mazurkiewicz, J.; Pawlisiak, A.; Chełkowski, D.; Brzoski, M. The Possibility of Functioning Micro-Scale Biogas Plant in Selected Farm. J. Water Land Dev. 2017, 35, 19–25. [Google Scholar] [CrossRef][Green Version]

- Pilarska, A.A.; Pilarski, K.; Wolna-Maruwka, A.; Boniecki, P.; Zaborowicz, M. Use of Confectionery Waste in Biogas Production by the Anaerobic Digestion Process. Molecules 2019, 24, 37. [Google Scholar] [CrossRef]

- Sołowski, G.; Konkol, I.; Cenian, A. Production of Hydrogen and Methane from Lignocellulose Waste by Fermentation. A Review of Chemical Pretreatment for Enhancing the Efficiency of the Digestion Process. J. Clean. Prod. 2020, 267, 121721. [Google Scholar] [CrossRef]

- Kurbanova, M.G.; Egushova, E.A.; Pozdnjakova, O.G. The Influence of Various Factors on the Methane Fermentation Process. IOP Conf. Ser. Mater. Sci. Eng. 2015, 91, 012076. [Google Scholar] [CrossRef]

- The Project. MilKey. Available online: https://www.milkey-project.eu/the-project/ (accessed on 3 July 2023).

- Home-MELS. Available online: https://www.mels-project.eu/ (accessed on 2 December 2022).

- Climate Care Cattle Farming Systems|The Project. Available online: https://cccfarming.eu/ (accessed on 22 July 2023).

- DairyMix. Available online: https://www.eragas.eu/en/eragas/research-projects/dairymix.htm (accessed on 22 July 2023).

- Meier, E.A.; Thorburn, P.J.; Bell, L.W.; Harrison, M.T.; Biggs, J.S. Greenhouse Gas Emissions from Cropping and Grazed Pastures Are Similar: A Simulation Analysis in Australia. Front. Sustain. Food Syst. 2020, 3, 121. [Google Scholar] [CrossRef]

- Schils, R.L.M.; Verhagen, A.; Aarts, H.F.M.; Šebek, L.B.J. A Farm Level Approach to Define Successful Mitigation Strategies for GHG Emissions from Ruminant Livestock Systems. Nutr. Cycl. Agroecosyst. 2005, 71, 163–175. [Google Scholar] [CrossRef]

- Arndt, C.; Hristov, A.N.; Price, W.J.; McClelland, S.C.; Pelaez, A.M.; Cueva, S.F.; Oh, J.; Dijkstra, J.; Bannink, A.; Bayat, A.R.; et al. Full Adoption of the Most Effective Strategies to Mitigate Methane Emissions by Ruminants Can Help Meet the 1.5 °C Target by 2030 but Not 2050. Proc. Natl. Acad. Sci. USA 2022, 119, e2111294119. [Google Scholar] [CrossRef]

- Ouatahar, L.; Bannink, A.; Lanigan, G.; Amon, B. Modelling the Effect of Feeding Management on Greenhouse Gas and Nitrogen Emissions in Cattle Farming Systems. Sci. Total Environ. 2021, 776, 145932. [Google Scholar] [CrossRef]

- 2006 IPCC Guidelines for National Greenhouse Gas Inventories—IPCC. Available online: https://www.ipcc.ch/report/2006-ipcc-guidelines-for-national-greenhouse-gas-inventories/ (accessed on 30 October 2022).

- 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories—IPCC. Available online: https://www.ipcc.ch/site/assets/uploads/2019/12/19R_V0_01_Overview.pdf (accessed on 3 July 2023).

- Poland. 2022 National Inventory Report (NIR)|UNFCCC. Available online: https://unfccc.int/documents/461818 (accessed on 30 July 2023).

- Podlasek, A.; Koda, E.; Vaverková, M.D. The Variability of Nitrogen Forms in Soils Due to Traditional and Precision Agriculture: Case Studies in Poland. Int. J. Environ. Res. Public Health 2021, 18, 465. [Google Scholar] [CrossRef]

- Sefeedpari, P.; Pudełko, R.; Jędrejek, A.; Kozak, M.; Borzęcka, M. To What Extent Is Manure Produced, Distributed, and Potentially Available for Bioenergy? A Step toward Stimulating Circular Bio-Economy in Poland. Energies 2020, 13, 6266. [Google Scholar] [CrossRef]

- EU ETS Allowances Auctioned by Country 2022. Available online: https://www.statista.com/statistics/1329545/eu-ets-allowances-auctioned-or-sold-by-country/ (accessed on 1 August 2023).

- EU Carbon Permits-2023 Data-2005–2022 Historical-2024 Forecast-Price-Quote. Available online: https://tradingeconomics.com/commodity/carbon (accessed on 1 August 2023).

- Dofinansowania Na Budowę Biogazowni/Biometanowni Pod Klucz. Biogas System. Available online: https://biogas-system.com/dofinansowania-na-budowe-biogazowni-biometanowni-pod-klucz/ (accessed on 3 July 2023).

- Energetyki, U.R. Rynek Energii: Średnia Cena Energii Elektrycznej z Rozliczeń Wytwórców w Ramach Grup Kapitałowych w II Kwartale 2023 r. Available online: https://www.ure.gov.pl/pl/urzad/informacje-ogolne/aktualnosci/11215,Rynek-energii-srednia-cena-energii-elektrycznej-z-rozliczen-wytworcow-w-ramach-g.html (accessed on 1 August 2023).

- Bhambhani, A. Poland Launches Energy For The Countryside Program. TaiyangNews, 2023. [Google Scholar]

- Office, E.R. The Role of the President of URE in the Process of Approving Prices and Fee Rates in the Heat Market. Available online: https://www.ure.gov.pl/en/communication/news/329,The-role-of-the-President-of-URE-in-the-process-of-approving-prices-and-fee-rate.html (accessed on 8 September 2023).

- Pracownia Ekotechnologii. Available online: https://ekolab.up.poznan.pl/en (accessed on 1 August 2023).

- Demonstration Des Quantitativen Nachweises von Salmonellen–VDLUFA. Available online: https://www.vdlufa.de/schulungen-2/schulungen-2013/demonstration-des-quantitativen-nachweises-von-salmonellen/ (accessed on 30 October 2022).

- KTBL: Ktbl.De. Available online: https://www.ktbl.de/ (accessed on 30 October 2022).

- VDI 4630; Fermentation of Organic Materials-Characterization of the Substrate, Sampling, Collection of Material Data Fermentation Tests. BPC Instruments: Lund, Sweden, 2016.

- DIN 38414-8. Available online: https://www.en-standard.eu/din-38414-8-german-standard-methods-for-the-examination-of-water-waste-water-and-sludge-sludge-and-sediments-group-s-determination-of-the-amenability-to-anaerobic-digestion-s-8/ (accessed on 1 August 2023).

- Mazurkiewicz, J. Energy and Economic Balance between Manure Stored and Used as a Substrate for Biogas Production. Energies 2022, 15, 413. [Google Scholar] [CrossRef]

- Mazurkiewicz, J. Analysis of the Energy and Material Use of Manure as a Fertilizer or Substrate for Biogas Production during the Energy Crisis. Energies 2022, 15, 8867. [Google Scholar] [CrossRef]

- Mazurkiewicz, J. The Biogas Potential of Oxytree Leaves. Energies 2022, 15, 8872. [Google Scholar] [CrossRef]

- Ciuła, J.; Kowalski, S.; Generowicz, A.; Barbusiński, K.; Matuszak, Z.; Gaska, K. Analysis of Energy Generation Efficiency and Reliability of a Cogeneration Unit Powered by Biogas. Energies 2023, 16, 2180. [Google Scholar] [CrossRef]

- Slavica, P.; Ivica, M.; Dragica, R.; Milios, J.; Slobodan, J.; Vladislav, N. Testing the Energy Efficiency of CHP Engines and Cost-Effectiveness of Biogas Plant Operation. IET Renew. Power Gener. 2023, 17, 555–562. [Google Scholar] [CrossRef]

- Electricity and Heat Production from Biogas CHP: Discover Technologies. Available online: https://www.biogasworld.com/news/biogas-chp-discover-technologies/ (accessed on 20 August 2023).

- Pourmovahed, A.; Opperman, T.; Lemke, B. Performance and Efficiency of a Biogas CHP System Utilizing a Stirling Engine. REPQJ 2011, 1315, 202–207. [Google Scholar] [CrossRef]

- Hakawati, R.; Smyth, B.M.; McCullough, G.; De Rosa, F.; Rooney, D. What Is the Most Energy Efficient Route for Biogas Utilization: Heat, Electricity or Transport? Appl. Energy 2017, 206, 1076–1087. [Google Scholar] [CrossRef]

- CHP-Biogas El.Power 12kW + HeatPower 25kW Cogeneration Combined Heat and Power (CHP) Combined Heat and Power (CHP) [SP12B]-€33,440.00: Profil.Fi, Pumps, Ventilation, Pipes, Valves, Boilers, under Floor Heating, Hybrid Solar Heating, Heat Pumps, Pumps, Generators. Available online: https://profil.fi/generators-and-chp-biogas-gensets/el-power-75kw-heatpower-14-kw-ng-generator (accessed on 20 August 2023).

- Mazlan, M.; Najafi, G.; Hoseini, S.S.; Mamat, R.; Alenzi, R.A.; Mofijur, M.; Yusaf, T. Thermal Efficiency Analysis of a Nanofluid-Based Micro Combined Heat and Power System Using CNG and Biogas. Energy 2021, 231, 120870. [Google Scholar] [CrossRef]

- Ghafoori, M.S.; Loubar, K.; Marin-Gallego, M.; Tazerout, M. Techno-Economic and Sensitivity Analysis of Biomethane Production via Landfill Biogas Upgrading and Power-to-Gas Technology. Energy 2022, 239, 122086. [Google Scholar] [CrossRef]

- Hofmann, F. Biogas Market in Germany and Its Main Drivers. Available online: https://www.thai-german-cooperation.info/userfiles/file/Biogas%20Association%20Roundtable%20Talk/5_FvB_Biogas%20market%20in%20Germany%20and%20its%20main%20drivers_2_0.pdf (accessed on 3 July 2023).

- Antolino, P.C.; Flotats, X. Technical–Economic Study on Implementing a Biogas Plant Operating with Greenhouse Vegetable Waste Generated in the Region of Almeria. Bachelor’s Thesis, Universitat Politècnica de Catalunya, Barcelona, Spain, 2018. Available online: https://www.semanticscholar.org/paper/Technical-economic-study-on-implementing-a-biogas-Antolino/93df198dd30ba339a8a9328d12bcaaf8083bde77 (accessed on 3 July 2023).

- Meyer-Aurich, A.; Schattauer, A.; Hellebrand, H.J.; Klauss, H.; Plöchl, M.; Berg, W. Impact of Uncertainties on Greenhouse Gas Mitigation Potential of Biogas Production from Agricultural Resources. Renew. Energy 2012, 37, 277–284. [Google Scholar] [CrossRef]

- Pochwatka, P.; Kowalczyk-Juśko, A.; Sołowiej, P.; Wawrzyniak, A.; Dach, J. Biogas Plant Exploitation in a Middle-Sized Dairy Farm in Poland: Energetic and Economic Aspects. Energies 2020, 13, 6058. [Google Scholar] [CrossRef]

- Mikrobiogazownia Rolnicza-Dla Kogo i za Ile? Available online: http://wiescirolnicze.pl/technika/mikrobiogazownia-rolnicza-dla-kogo-i-za-ile/ (accessed on 5 August 2023).

- Małe Biogazownie–Jakie są Koszty i co Dają Rolnikom? Available online: https://www.tygodnik-rolniczy.pl/rolnictwo/pieniadze/male-biogazownie-jakie-sa-koszty-i-co-daja-rolnikom-2383690 (accessed on 5 August 2023).

- Beba, J. Mała Czy Duża Biogazownia Rolnicza? Available online: https://www.topagrar.pl/articles/eventy/mala-czy-duza-biogazownia-rolnicza/ (accessed on 5 August 2023).

- Podstawowe Stopy Procentowe NBP. Available online: https://nbp.pl/polityka-pieniezna/decyzje-rpp/podstawowe-stopy-procentowe-nbp/ (accessed on 5 August 2023).

- What Is the Average Size of a Dairy, Beef or Poultry Farm in Europe?|European Livestock Voice. Available online: https://meatthefacts.eu/home/more-than-meats-the-eye/farming-rural-life/what-is-the-average-size-of-a-dairy-beef-or-poultry-farm-in-europe/ (accessed on 5 August 2023).

- EFSA Panel on Animal Health and Animal Welfare (AHAW); Nielsen, S.S.; Alvarez, J.; Bicout, D.J.; Calistri, P.; Canali, E.; Drewe, J.A.; Garin-Bastuji, B.; Gonzales Rojas, J.L.; Gortázar Schmidt, C.; et al. Welfare of Dairy Cows. EFSA J. 2023, 21, e07993. [Google Scholar] [CrossRef] [PubMed]

- Dairy Farming: Current Practices|INRAE. Available online: https://www.inrae.fr/en/reports/dairy-cows-grazing-future/dairy-farming-current-practices (accessed on 5 August 2023).

- Tongwane, M.I.; Moeletsi, M.E. Provincial Cattle Carbon Emissions from Enteric Fermentation and Manure Management in South Africa. Environ. Res. 2021, 195, 110833. [Google Scholar] [CrossRef] [PubMed]

- Dillon, J.A.; Stackhouse-Lawson, K.R.; Thoma, G.J.; Gunter, S.A.; Rotz, C.A.; Kebreab, E.; Riley, D.G.; Tedeschi, L.O.; Villalba, J.; Mitloehner, F.; et al. Current State of Enteric Methane and the Carbon Footprint of Beef and Dairy Cattle in the United States. Anim. Front. 2021, 11, 57–68. [Google Scholar] [CrossRef] [PubMed]

- Warnecke, S.; Paulsen, H.M.; Schulz, F.; Rahmann, G. Greenhouse Gas Emissions from Enteric Fermentation and Manure on Organic and Conventional Dairy Farms—An Analysis Based on Farm Network Data. Org. Agric. 2014, 4, 285–293. [Google Scholar] [CrossRef]

- Chianese, D.S.; Rotz, C.A.; Richard, T.L. Whole-Farm Greenhouse Gas Emissions: A Review with Application to a Pennsylvania Dairy Farm. Appl. Eng. Agric. 2009, 25, 431–442. [Google Scholar] [CrossRef]

- US EPA. Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2016. Available online: https://www.epa.gov/ghgemissions/inventory-us-greenhouse-gas-emissions-and-sinks-1990-2016 (accessed on 2 November 2022).

- ICAR 2020. Section 20—Recording Dairy Cattle Methane Emission for Genetic Evaluation. Available online: https://www.icar.org/Guidelines/20-Recording-Dairy-Cattle-Methane-Emission-for-Genetic-Evaluation.pdf (accessed on 14 October 2021).

- Aguirre-Villegas, H.A.; Larson, R.A. Evaluating Greenhouse Gas Emissions from Dairy Manure Management Practices Using Survey Data and Lifecycle Tools. J. Clean. Prod. 2017, 143, 169–179. [Google Scholar] [CrossRef]

- Chadwick, D.R. Emissions of Ammonia, Nitrous Oxide and Methane from Cattle Manure Heaps: Effect of Compaction and Covering. Atmos. Environ. 2005, 39, 787–799. [Google Scholar] [CrossRef]

- Villarroel-Schneider, J.; Höglund-Isaksson, L.; Mainali, B.; Martí-Herrero, J.; Cardozo, E.; Malmquist, A.; Martin, A. Energy Self-Sufficiency and Greenhouse Gas Emission Reductions in Latin American Dairy Farms through Massive Implementation of Biogas-Based Solutions. Energy Convers. Manag. 2022, 261, 115670. [Google Scholar] [CrossRef]

- Kowalczyk-Juśko, A.; Pochwatka, P.; Mazurkiewicz, J.; Pulka, J.; Kępowicz, B.; Janczak, D.; Dach, J. Reduction of Greenhouse Gas Emissions by Replacing Fertilizers with Digestate. J. Ecol. Eng. 2023, 24, 312–319. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, J.; Achinas, S.; Zhang, Z.; Krooneman, J.; Euverink, G.J.W. The Biomethanation of Cow Manure in a Continuous Anaerobic Digester Can Be Boosted via a Bioaugmentation Culture Containing Bathyarchaeota. Sci. Total Environ. 2020, 745, 141042. [Google Scholar] [CrossRef]

- Wang, J.; Westerholm, M.; Qiao, W.; Mahdy, A.; Wandera, S.M.; Yin, D.; Bi, S.; Fan, R.; Dong, R. Enhancing Anaerobic Digestion of Dairy and Swine Wastewater by Adding Trace Elements: Evaluation in Batch and Continuous Experiments. Water Sci. Technol. 2019, 80, 1662–1672. [Google Scholar] [CrossRef] [PubMed]

- Kafle, G.K.; Chen, L. Comparison on Batch Anaerobic Digestion of Five Different Livestock Manures and Prediction of Biochemical Methane Potential (BMP) Using Different Statistical Models. Waste Manag. 2016, 48, 492–502. [Google Scholar] [CrossRef]

- Tsapekos, P.; Kougias, P.G.; Vasileiou, S.A.; Treu, L.; Campanaro, S.; Lyberatos, G.; Angelidaki, I. Bioaugmentation with Hydrolytic Microbes to Improve the Anaerobic Biodegradability of Lignocellulosic Agricultural Residues. Bioresour. Technol. 2017, 234, 350–359. [Google Scholar] [CrossRef]

- Harrison, T.R.; Gupta, V.K.; Alam, P.; Perriman, A.W.; Scarpa, F.; Thakur, V.K. From Trash to Treasure: Sourcing High-Value, Sustainable Cellulosic Materials from Living Bioreactor Waste Streams. Int. J. Biol. Macromol. 2023, 233, 123511. [Google Scholar] [CrossRef]

- Mazurkiewicz, J.; Marczuk, A.; Pochwatka, P.; Kujawa, S. Maize Straw as a Valuable Energetic Material for Biogas Plant Feeding. Materials 2019, 12, 3848. [Google Scholar] [CrossRef]

- Koryś, K.A.; Latawiec, A.E.; Grotkiewicz, K.; Kuboń, M. The Review of Biomass Potential for Agricultural Biogas Production in Poland. Sustainability 2019, 11, 6515. [Google Scholar] [CrossRef]

- Kupryaniuk, K.; Oniszczuk, T.; Combrzyński, M.; Czekała, W.; Matwijczuk, A. The Influence of Corn Straw Extrusion Pretreatment Parameters on Methane Fermentation Performance. Materials 2020, 13, 3003. [Google Scholar] [CrossRef]

- Croce, S.; Wei, Q.; D’Imporzano, G.; Dong, R.; Adani, F. Anaerobic Digestion of Straw and Corn Stover: The Effect of Biological Process Optimization and Pre-Treatment on Total Bio-Methane Yield and Energy Performance. Biotechnol. Adv. 2016, 34, 1289–1304. [Google Scholar] [CrossRef]

- Sieborg, M.U.; Jønson, B.D.; Larsen, S.U.; Vazifehkhoran, A.H.; Triolo, J.M. Co-Ensiling of Wheat Straw as an Alternative Pre-Treatment to Chemical, Hydrothermal and Mechanical Methods for Methane Production. Energies 2020, 13, 4047. [Google Scholar] [CrossRef]

- Dach, J.; Mazurkiewicz, J.; Janczak, D.; Pulka, J.; Pochwatka, P.; Kowalczyk-Juśko, A. Cow Manure Anaerobic Digestion or Composting–Energetic and Economic Analysis, Singapore, 7–9 March 2020. Available online: https://ieeexplore.ieee.org/document/9077550 (accessed on 2 November 2022).

- Frankowski, J.; Zaborowicz, M.; Dach, J.; Czekała, W.; Przybył, J. Biological Waste Management in the Case of a Pandemic Emergency and Other Natural Disasters. Determination of Bioenergy Production from Floricultural Waste and Modeling of Methane Production Using Deep Neural Modeling Methods. Energies 2020, 13, 3014. [Google Scholar] [CrossRef]

- GUS Energy 2023. Available online: https://stat.gov.pl/en/topics/environment-energy/energy/energy-2023,1,11.html (accessed on 7 September 2023).

- Return on Capital Employed (ROCE): Ratio, Interpretation, and Example. Available online: https://www.investopedia.com/terms/r/roce.asp (accessed on 5 August 2023).

- Czekała, W.; Jasiński, T.; Dach, J. Profitability of the Agricultural Biogas Plants Operation in Poland, Depending on the Substrate Use Model. Energy Rep. 2023, 9, 196–203. [Google Scholar] [CrossRef]

- Janczak, D.; Mazurkiewicz, J.; Czekała, W.; Myszura, M.; Kozłowski, K.; Jeżowska, A. A Possibility of Functioning Biogas Plant at a Poultry Farm. J. Ecol. Eng. 2019, 20, 225–231. [Google Scholar] [CrossRef]

- Frankowski, J.; Czekała, W. Agricultural Plant Residues as Potential Co-Substrates for Biogas Production. Energies 2023, 16, 4396. [Google Scholar] [CrossRef]

- Czekała, W.; Nowak, M.; Bojarski, W. Characteristics of Substrates Used for Biogas Production in Terms of Water Content. Fermentation 2023, 9, 449. [Google Scholar] [CrossRef]

- Mikrobiogazownia Sprawdzi się w Gospodarstwie Hodowlanym-Przedsiębiorczość. Available online: https://www.farmer.pl/biznes/przedsiebiorczosc/mikrobiogazownia-sprawdzi-sie-w-gospodarstwie-hodowlanym,94886.html (accessed on 5 August 2023).

- Bułkowska, K.; Mikucka, W.; Pokój, T. Enhancement of Biogas Production from Cattle Manure Using Glycerine Phase as a Co-Substrate in Anaerobic Digestion. Fuel 2022, 317, 123456. [Google Scholar] [CrossRef]

- Romaniuk, W.; Rogovskii, I.; Polishchuk, V.; Titova, L.; Borek, K.; Wardal, W.J.; Shvorov, S.; Dvornyk, Y.; Sivak, I.; Drahniev, S.; et al. Study of Methane Fermentation of Cattle Manure in the Mesophilic Regime with the Addition of Crude Glycerine. Energies 2022, 15, 3439. [Google Scholar] [CrossRef]

- Benchaar, C.; Hassanat, F.; Martineau, R.; Gervais, R. Linseed Oil Supplementation to Dairy Cows Fed Diets Based on Red Clover Silage or Corn Silage: Effects on Methane Production, Rumen Fermentation, Nutrient Digestibility, N Balance, and Milk Production. J. Dairy Sci. 2015, 98, 7993–8008. [Google Scholar] [CrossRef] [PubMed]

- Hassanat, F.; Benchaar, C. Corn Silage-Based Diet Supplemented with Increasing Amounts of Linseed Oil: Effects on Methane Production, Rumen Fermentation, Nutrient Digestibility, Nitrogen Utilization, and Milk Production of Dairy Cows. J. Dairy Sci. 2021, 104, 5375–5390. [Google Scholar] [CrossRef]