Research on the Impact of Supplying the Air-Cooled D21A1 Engine with RME B100 Biodiesel on Its Operating Parameters

Abstract

:1. Introduction

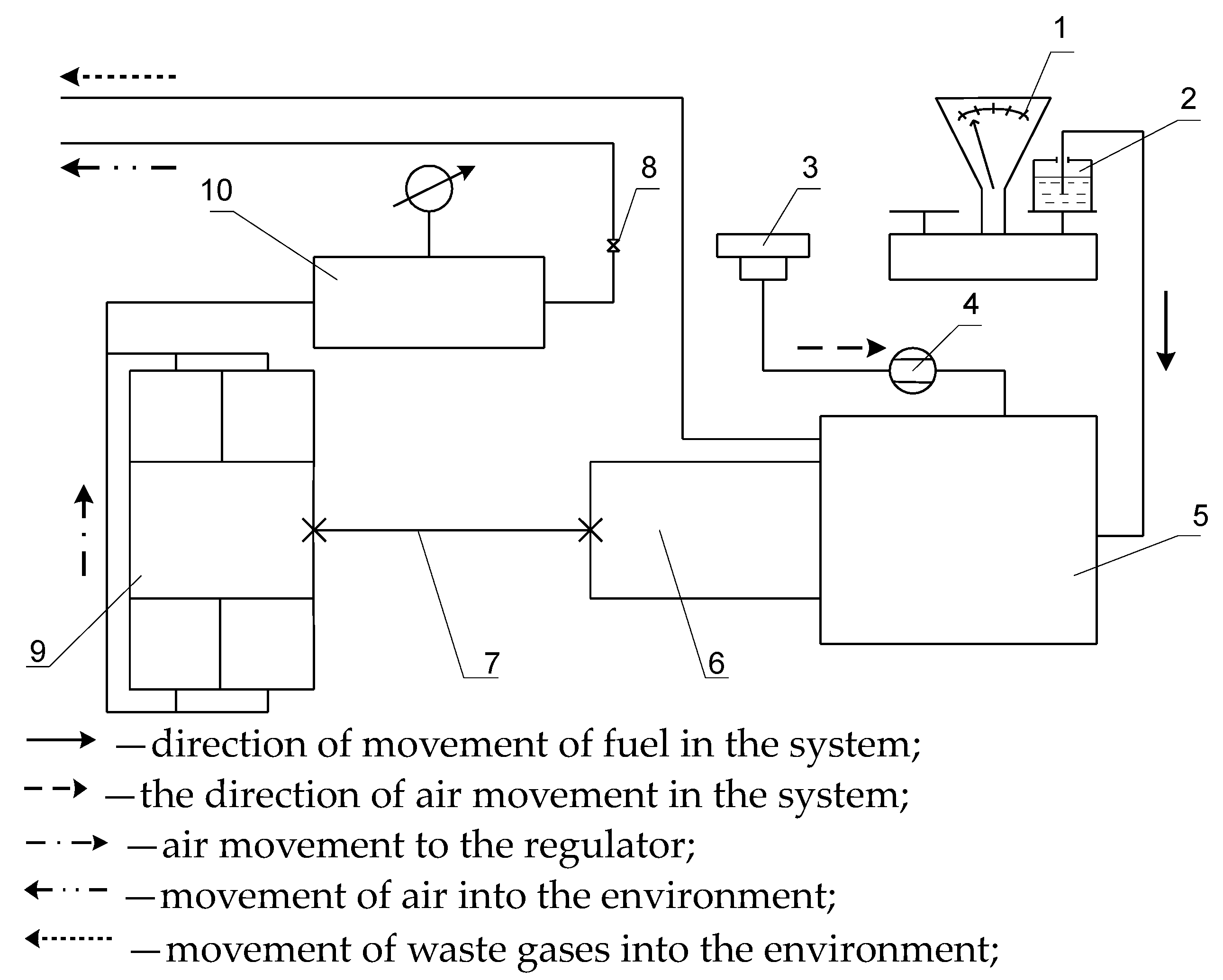

2. Materials and Methods

- The development of an installation for researching the main technical and operational performance indicators of the D21A1 diesel engine on RME B100 biodiesel fuel;

- A study on the technical and operational parameters of the D21A1 diesel engine on RME B100 biodiesel fuel.

- The analysis of the influence of factors related to the use of alternative fuels on the nature of work processes in the internal combustion engine;

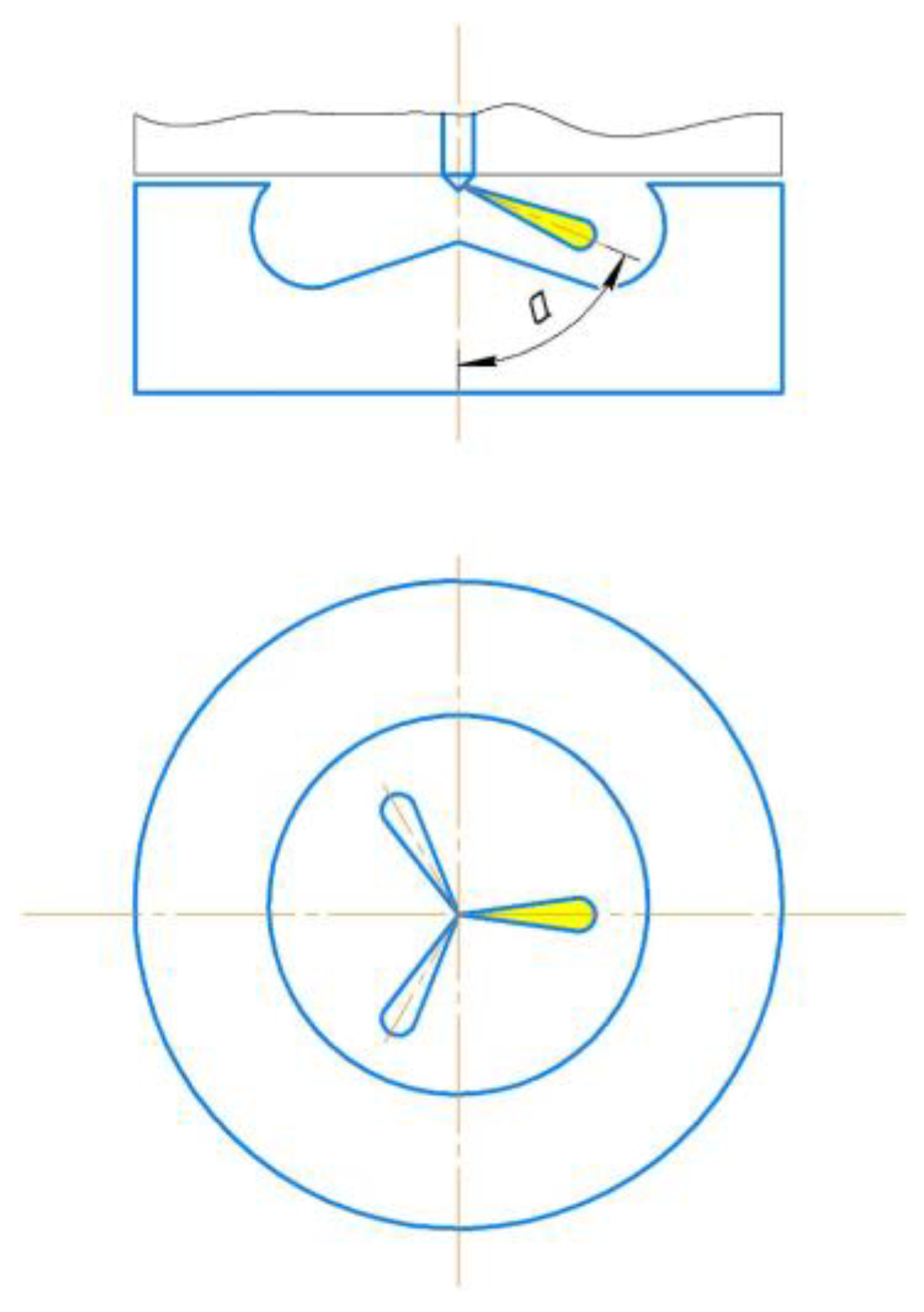

- The systematization and analysis of the proposed ways of organizing the working process and the determination of the most suitable parameters of the combustion chamber for improved mixture formation in internal combustion engines.

- Weight readings of the fuel tank to determine the mass consumption of fuel mixtures during the experiment;

- Readings of the excess pressure manometer in the airflow regulator;

- The air temperature at the compressor outlet, the air temperature at the intercooler between the compressor stages, as well as the ambient temperature using a mercury thermometer;

- The engine crankshaft rotation frequency using the ТСР10-Р tachometer.

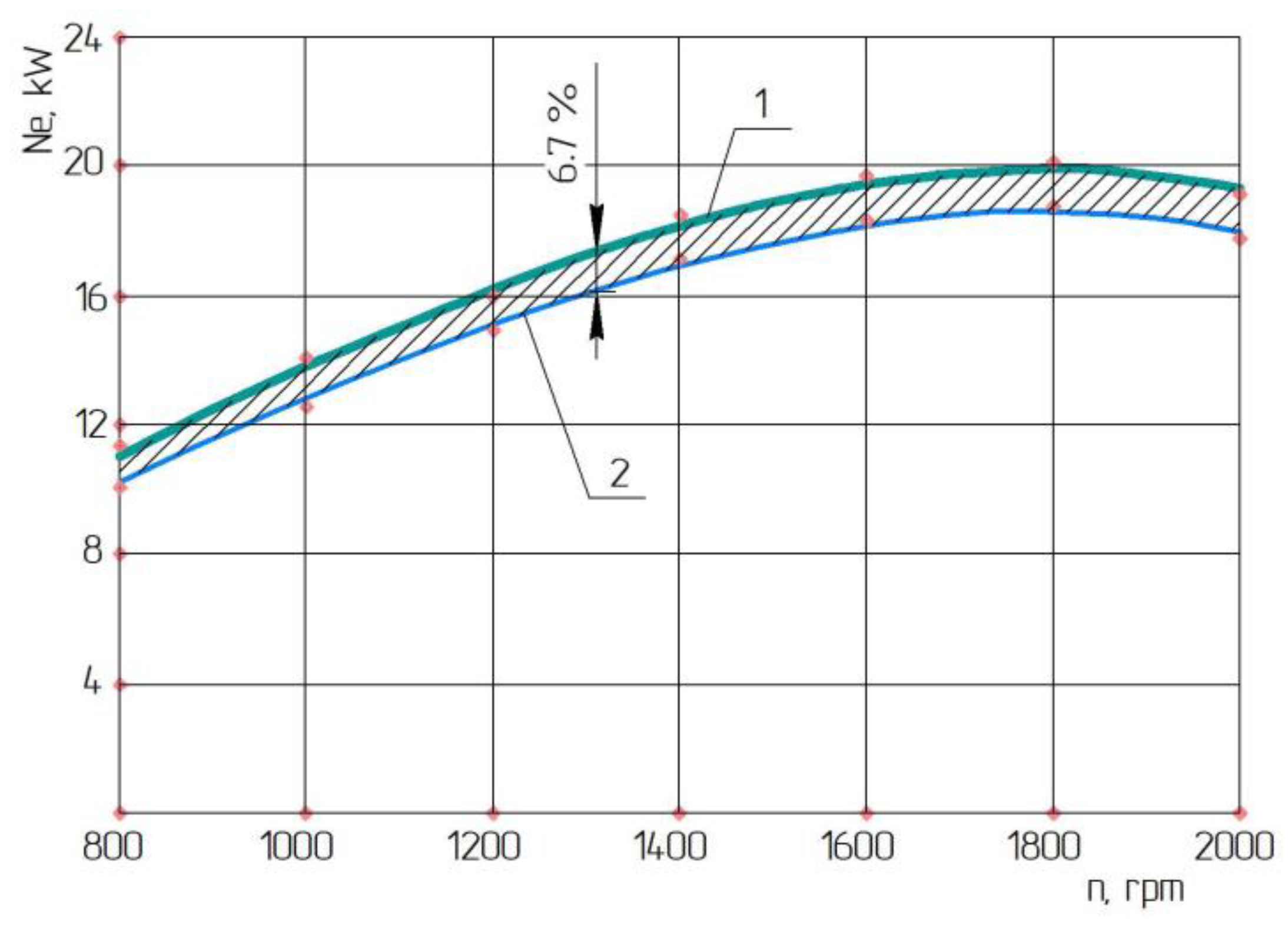

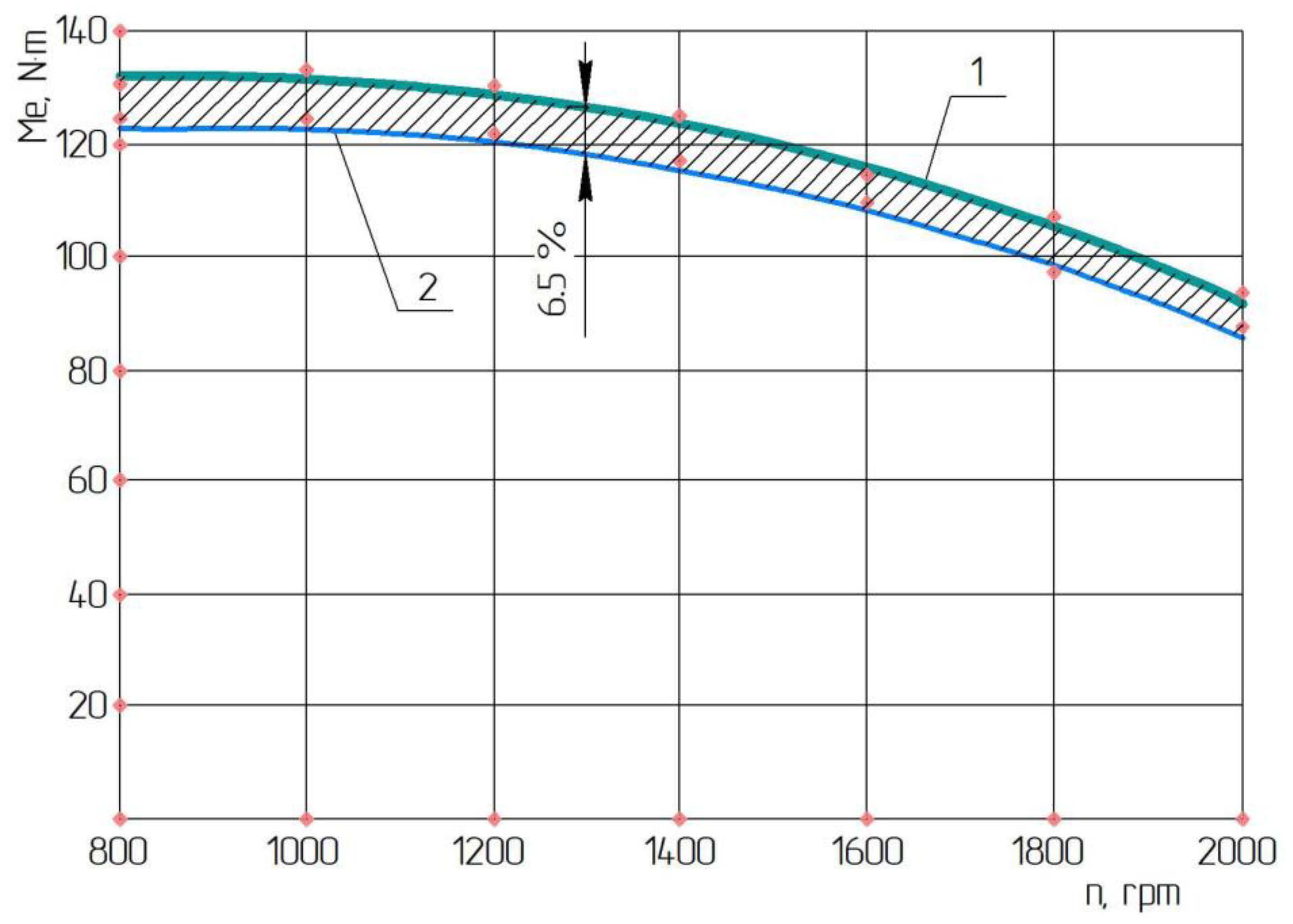

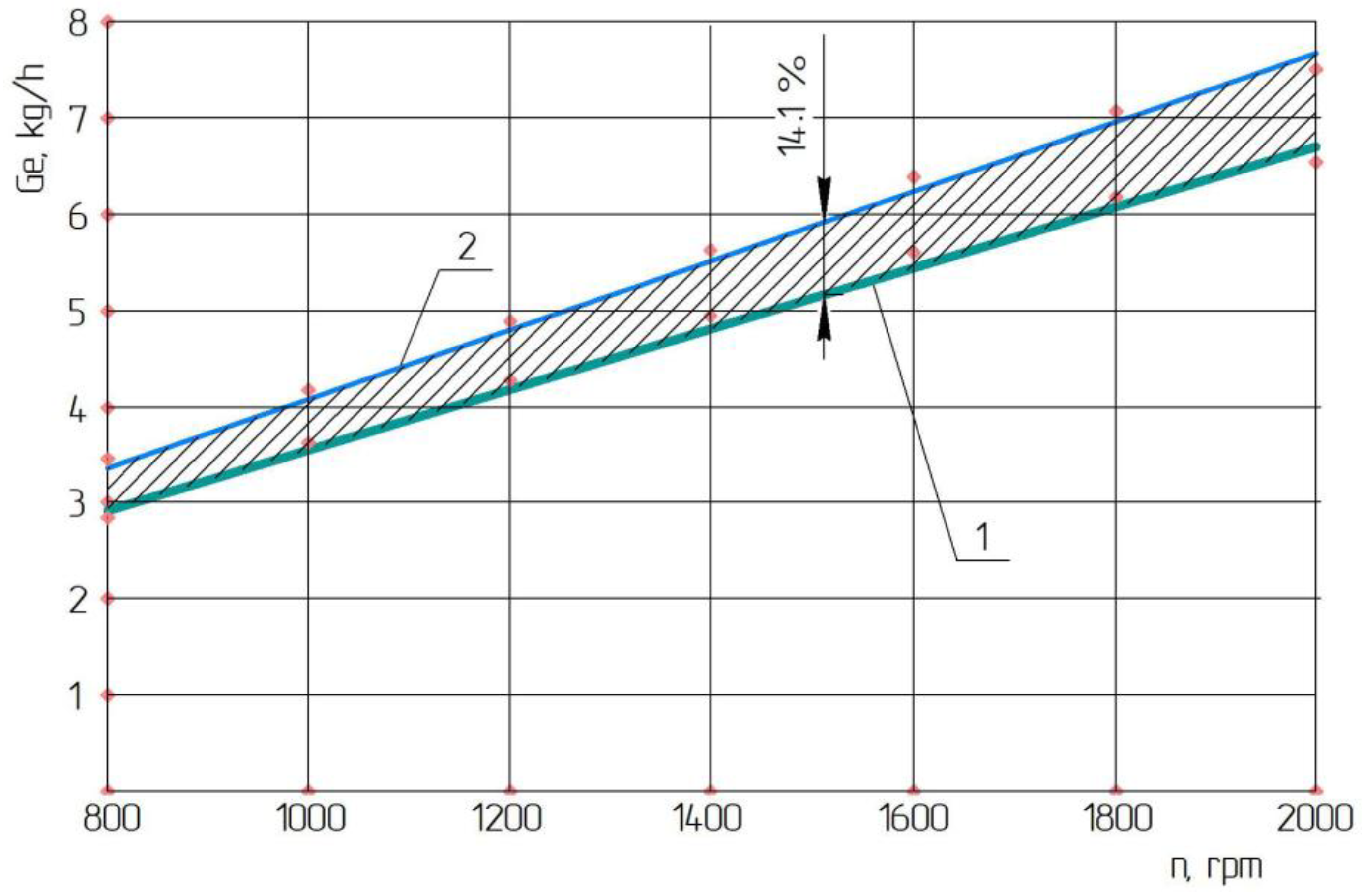

3. Results and Discussion

- Torque;

- Effective power;

- Specific effective fuel consumption;

- Effective pressure.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bembenek, M.; Melnyk, V.; Mosora, Y. Study of Parameters of the Mixture and Heat Generation of the DD15 Diesel Engine of the Sandvik LH514 Loader in the Process of Using Alternative Fuels Based on RME. In Proceedings of the Мaterials and Technologies in Engineering (MTE-2023): Engineering, Materials, Technologies, Transport: Conference Program of the International Conference, Lutsk, Ukraine, 16–18 May 2023. [Google Scholar]

- Lievtierov, A.M.; Savytskyi, V.D. Pokrashchennia ekolohichnykh kharakterystyk dyzelia, shcho pratsiuie na biodyzelnykh palyvnykh kompozytsiiakh. Avtomob. Transp. 2015, 36, 110–117. (In Ukrainian) [Google Scholar]

- Melnyk, V.M.; Voitsekhivska, T.I.; Shtykh, M.M. Doslidzhennia vplyvu kuta rozpylennia na ekspluatatsiini pokaznyky roboty dvyhuna pry vykorystanni biodyzelnoho palyva. Naft. Enerhetyka 2021, 1, 60–66. (In Ukrainian) [Google Scholar] [CrossRef]

- Melnyk, V.M. Efektyvnist vykorystannia alternatyvnoho palyva z vidnovliuvalnykh dzherel na dyzelnykh dvyhunakh. Ekolohichna Bezpeka Ta Zbalansovane Resur. 2018, 1, 91–99. (In Ukrainian) [Google Scholar]

- Oluwabunmi Bitire, S.; Tien-Chien, J. The impact of process parameters on the responses of a diesel engine running on biodiesel-diesel blend: An optimization study. Egypt. J. Pet. 2022, 31, 11–19. [Google Scholar] [CrossRef]

- Adaileh, W.M.; AlQdah, K.S. Performance of Diesel Engine Fuelled by a Biodiesel Extracted from A Waste Cocking Oil. Energy Procedia 2012, 18, 1317–1334. [Google Scholar] [CrossRef]

- Sharma, A.; Tyagi, A.; Singh, Y.; K Singh, N.; K Pandey, N. Effect of process parameters on the diesel engine performance fuelled with Prosopis juliflora biodiesel response surface methodology approach. Process Mech. Eng. 2021, 236, 440–451. [Google Scholar] [CrossRef]

- Buyukkaya, E. Effects of biodiesel on a DI diesel engine performance, emission and combustion characteristics. Fuel 2010, 89, 3099–3105. [Google Scholar] [CrossRef]

- Abed, K.A.; Gad, M.S.; El Morsi, A.K.; Sayed, M.M.; Abu Elyazeed, S. Effect of biodiesel fuels on diesel engine emissions. Egypt. J. Pet. 2019, 28, 183–188. [Google Scholar] [CrossRef]

- Verma, P.; Sharma, M.P. Performance and Emission Characteristics of Biodiesel Fuelled Diesel Engines. Energy 2015, 5, 245–250. [Google Scholar]

- Rizwanul, I.M.; Masjuki, H.H.; Kalam, M.A.; Mofijur, M.; Abedi, M.J. Effect of antioxidant on the performance and emission characteristics of a diesel engine fueled with palm biodiesel blends. Energy Convers. Manag. 2014, 79, 265–272. [Google Scholar] [CrossRef]

- Sharma, R.; Narang, S. Performance and emission analysis of palm and jatropha biofuel blends with diesel on an unmodified CI engine. Int. J. Res. Eng. 2015, 5, 245–250. [Google Scholar]

- Tizvir, A.; Shojaeefard, M.H.; Zahedi, A.; Molaeimanesh, G.R. Performance and emission characteristics of biodiesel fuel from Dunaliella tertiolecta microalgae. Renew. Energy 2022, 182, 552–561. [Google Scholar] [CrossRef]

- Shekofteh, M.; Mesri Gundoshmian, T.; Jahanbakhshi, A.; Heidari-Maleni, A. Performance and emission characteristics of a diesel engine fueled with functionalized multi-wall carbon nanotubes (MWCNTs-OH) and diesel–biodiesel–bioethanol blends. Energy Rep. 2020, 6, 1438–1447. [Google Scholar] [CrossRef]

- Nedayali, A.; Shirneshan, A. Experimental Study of the Effects of Biodiesel on the Performance of a Diesel Power Generator. Energy Environ. 2016, 27, 553–565. [Google Scholar] [CrossRef]

- Iliev, S. A Study of Effect of Biodiesel on the Performance and emissions of a Common-rail Diesel Engine. In Proceedings of the Conference: 2020 12th Electrical Engineering Faculty Conference (BulEF), Varna, Bulgaria, 9–12 September 2020. [Google Scholar] [CrossRef]

- Tuan Nghia, N.; Xuan Khoa, N.; Cho, W.; Lim, O. A Study the Effect of Biodiesel Blends and the Injection Timing on Performance and Emissions of Common Rail Diesel Engines. Energies 2022, 15, 242. [Google Scholar] [CrossRef]

- Lapuerta, M.; Armas, O.; Rodríguez-Fernández, J. Effect of biodiesel fuels on diesel engine emissions. Prog. Energy Combust. Sci. 2008, 34, 198–223. [Google Scholar] [CrossRef]

- Kryshtopa, S.; Kryshtopa, L.; Melnyk, V.; Prunko, I.; Demianchuk, Y. Experimental research on diesel engine working on a mixture of diesel fuel and fusel oils. Transp. Probl. 2017, 12, 53–63. [Google Scholar] [CrossRef]

- Melnyk, V.; Romanyshyn, L.; Mosora, Y. Technology of obtaining mixed alternative fuel based on organic substances for mining technological transport engines. Manag. Syst. Prod. Eng. 2023, 31, 71–77. [Google Scholar] [CrossRef]

- Sivakumar, M.; Shanmugasundaram, N.; Rameshkumar, R.; Syed Thasthagir, M. Effects of pongamia methyl esters and its blends on a diesel engine performance, combustion, and emission characteristics. Environ. Prog. Sustain. Energy 2017, 36, 269–276. [Google Scholar] [CrossRef]

- Qasim, M.; Ansari, T.M.; Hussain, M. Emissions and performance characteristics of a diesel engine operated with fuel blends obtained from a mixture of pretreated waste engine oil and waste vegetable oil methyl esters. Environ. Prog. Sustain. Energy 2018, 37, 2148–2155. [Google Scholar] [CrossRef]

- Behcet, R.; Aydın, H.; İlkılıç, C.; İşcan, B.; Aydın, S. Diesel engine applications for evaluation of performance and emission behavior of biodiesel from different oil stocks. Environ. Prog. Sustain. Energy 2015, 34, 890–896. [Google Scholar] [CrossRef]

- Uyaroğlu, A.; Uyumaz, A.; Çelikten, İ. Comparison of the combustion, performance, and emission characteristics of inedible Crambe abyssinica biodiesel and edible hazelnut, corn, soybean, sunflower, and canola biodiesels. Environ. Prog. Sustain. Energy 2018, 37, 1438–1447. [Google Scholar] [CrossRef]

- Temizer, İ. The combustion analysıs and wear effect of biodiesel fuel used in a diesel engine. Fuel 2020, 270, 117571. [Google Scholar] [CrossRef]

- Agarwal, A.K. Biofuels (alcohols and biodiesel) applications as fuels for internal combustion engines. Prog. Energy Combust. Sci. 2007, 33, 233–271. [Google Scholar] [CrossRef]

- Melnyk, V.M.; Liakh, M.M.; Synoverskyi, M.M. Doslidzhennia parametriv sumisho- i teploutvorennia dyzelia u protsesi vykorystannia alternatyvnykh palyv. Naft. Enerhetyka 2020, 1, 109–123. [Google Scholar] [CrossRef]

- Pandey, S. A critical review: Application of methanol as a fuel for internal combustion engines and effects of blending methanol with diesel (biodiesel) ethanol on performance, emission, and combustion characteristics of engines. Heat Transf. 2022, 51, 3334–3352. [Google Scholar] [CrossRef]

- Hussein Hassan, Q.; Shaker Abdul Ridha, G.; Abdul Hussein Hafedh, K.; Alalwan, H.A. The impact of Methanol-Diesel compound on the performance of a Four-Stroke CI engine. Mater. Proc. 2021, 42, 1993–1999. [Google Scholar] [CrossRef]

- Nour, M.; Attia, A.M.A.; Sameh, A.N. Improvement of CI engine combustion and performance running on ternary blends of higher alcohol. Fuel 2019, 251, 10–22. [Google Scholar] [CrossRef]

- Gao, Z.; Lin, S.; Ji, J.; Li, M. An experimental study on combustion performance and flame spread characteristics over liquid diesel and ethanol-diesel blended fuel. Energy 2019, 170, 349–355. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Rakopoulos, D.C.; Kosmadakis, G.M.; Papagiannakis, R.G. Experimental comparative assessment of butanol or ethanol diesel-fuel extenders impact on combustion features, cyclic irregularity, and regulated emissions balance in heavy-duty diesel engine. Energy 2019, 174, 1145–1157. [Google Scholar] [CrossRef]

- Bayraktar, H. An experimental study on the performance parameters of an experimental CI engine fueled with diesel–methanol–dodecanol blends. Fuel 2008, 87, 158–164. [Google Scholar] [CrossRef]

- Khorsheed Zangana, L.M.; Hameed Yaseen, A.; Hussein Hassan, Q.; Mohammed, M.M.; Fakhir Mohammed, M.; Alalwan, H.A. Investigated kerosene-diesel fuel performance in internal combustion engine. Clean. Eng. Technol. 2023, 12, 100591. [Google Scholar] [CrossRef]

- Singh, D.; Deep, A.; Sandhu, S.S.; Sarma, A.K. Experimental Assessment of Combustion, Performance and Emission Characteristics of a CI Engine Fueled with Biodiesel and Hybrid Fuel Derived from Waste Cooking Oil. Environ. Prog. Sustain. Energy 2019, 38, 13112. [Google Scholar] [CrossRef]

- Singh, D.; Sarma, A.K.; Sandhu, S.S. An experimental investigation of injection timings and injection pressures on a compression ignition engine fueled with hybrid fuel-1 derived from waste cooking oil. Environ. Prog. Sustain. Energy 2021, 40, 13606. [Google Scholar] [CrossRef]

- Math, M.C.; Prem Kumar, S.; Chetty, S.V. Technologies for biodiesel production from used cooking oil—A review. Energy Sustain. Dev. 2010, 14, 339–345. [Google Scholar] [CrossRef]

- Li, H.; Campbell, L.; Hadavi, S.; Gava, J. Fuel Consumption and GHG Reductions by using Used Cooking Oil as a Fuel in a HGV under Real World Driving Conditions. SAE Tech. Pap. 2014, 2727. [Google Scholar] [CrossRef]

- Prabhakar, S.; Annamalai, K.; Joshua Ramesh Lalvani, I. Experimental study of using hybrid vegetable oil blends in diesel engine. J. Sci. Ind. Res. 2012, 71, 612–615. [Google Scholar]

- Ibrahim, M.A.; El-Araby, R.; Abdelkader, E.; El Saied, M.; Abdelsalam, A.M.; Ismail, E.H. Waste cooking oil processing over cobalt aluminate nanoparticles for liquid biofuel hydrocarbons production. Sci 2023, 13, 3876. [Google Scholar] [CrossRef]

- DSTU 7688:2015; Diesel Fuel Euro. Specifications. УкрНДІНП «МАСМА»: Kyiv, Ukraine, 2015; 7р. (In Ukrainian)

- Lebedevas, S.; Vaicekauskas, A.; Suškov, P. Presumptions of effective operation of diesel engines running on rme biodiesel. Research on kinetics of combustion of rme biodiesel. Transport 2007, 22, 126–133. [Google Scholar] [CrossRef]

- Kurczyński, D. Effect of the rme biodiesel on the diesel engine fuel consumption and emission. Mech. Eng. Transp. 2021, 23, 308–316. [Google Scholar] [CrossRef]

- Pereira, F.M.; Velásquez, J.A.; Riechi, J.L.; Teixeira, J.; Ronconi, L.; Riolfi Jr, S.; Karas, É.L.; Abreu, R.A.; Travain, J.C. Impact of pure biodiesel fuel on the service life of engine-lubricant: A case study. Fuel 2020, 261, 116418. [Google Scholar] [CrossRef]

- Panithasan, M.S.; Venkadesan, G. Evaluation of the Influence of 1,4-Dioxane and Exhaust Gas Recirculation on the Performance and Emission Values of a Diesel Engine Fuelled with Low Viscous Biofuel Blend. Energy Sustain. 2021. [Google Scholar] [CrossRef]

- Venkatesan, V.; Nallusamy, N. Pine oil-soapnut oil methyl ester blends: A hybrid biofuel approach to completely eliminate the use of diesel in a twin cylinder off-road tractor diesel engine. Fuel 2020, 262, 116500. [Google Scholar] [CrossRef]

- Panithasan, M.S.; Venkadesan, G. Evaluating the outcomes of a single-cylinder CRDI engine operated by lemon peel oil under the influence of DTBP, rice husk nano additive and water injection. Int. J. Engine Res. 2021, 24, 308–323. [Google Scholar] [CrossRef]

| Parameter Name | Unit of Measurement | Parameter Value |

|---|---|---|

| Cylinder diameter | mm | 105 |

| Piston stroke | mm | 120 |

| Degree of compression | - | 16.5 |

| Minimum rot. speed | rpm | 800 |

| Nominal rot. speed | rpm | 1800 |

| Nozzle | - | closed type with a multi-jet sprayer, pinless |

| The number and diameter of the nozzle holes | mm | 3 × 0.3 |

| Engine displacement volume | cm3 | 2000 |

| Engine power | kW | 21 |

| Torque | Nm | 103 |

| Specific effective fuel consumption | g/(kWh) | 241 |

| Engine mass | kg | 295 |

| Rotation Speed, rpm | λD | λRME | T1, K | T2, K | NKD, kW | NKRME, kW |

|---|---|---|---|---|---|---|

| 800 | 2.50 | 2.35 | 295 | 338 | 11.2 | 10.1 |

| 1000 | 2.80 | 2.72 | 295 | 339 | 13.4 | 12.8 |

| 1200 | 3.20 | 3.04 | 296 | 341 | 16.2 | 15.1 |

| 1400 | 3.47 | 3.26 | 296 | 345 | 18.2 | 16.7 |

| 1600 | 3.64 | 3.46 | 297 | 347 | 19.4 | 18.1 |

| 1800 | 3.70 | 3.50 | 296 | 348 | 19.9 | 18.5 |

| 2000 | 3.63 | 3.47 | 296 | 348 | 19.4 | 18.1 |

| Indicator Name | Unit of Measurement | Value for Diesel Fuel | Value for RME B100 |

|---|---|---|---|

| Chemical composition: С Н О | % | 87 12.6 0.4 | 77 12.1 10.9 |

| Sulfur content | % | 0.0010 | 0.0015 |

| Lower heat of combustion | MJ/kg | 42.50 | 39.45 |

| Cetane number | - | 51.0 | 54.4 |

| Density at temperature 323 К | kg/m3 | 820–845 | 874 |

| Saturated vapor pressure at temperature 481 К | bar | - | 0.001 |

| Molecular weight | kg/kmol | 180–200 | 296 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bembenek, M.; Karwat, B.; Melnyk, V.; Mosora, Y. Research on the Impact of Supplying the Air-Cooled D21A1 Engine with RME B100 Biodiesel on Its Operating Parameters. Energies 2023, 16, 6430. https://doi.org/10.3390/en16186430

Bembenek M, Karwat B, Melnyk V, Mosora Y. Research on the Impact of Supplying the Air-Cooled D21A1 Engine with RME B100 Biodiesel on Its Operating Parameters. Energies. 2023; 16(18):6430. https://doi.org/10.3390/en16186430

Chicago/Turabian StyleBembenek, Michał, Bolesław Karwat, Vasyl Melnyk, and Yurii Mosora. 2023. "Research on the Impact of Supplying the Air-Cooled D21A1 Engine with RME B100 Biodiesel on Its Operating Parameters" Energies 16, no. 18: 6430. https://doi.org/10.3390/en16186430

APA StyleBembenek, M., Karwat, B., Melnyk, V., & Mosora, Y. (2023). Research on the Impact of Supplying the Air-Cooled D21A1 Engine with RME B100 Biodiesel on Its Operating Parameters. Energies, 16(18), 6430. https://doi.org/10.3390/en16186430