Determination of the Effect of the Addition of Second-Generation Biodiesel BBuE to Diesel Fuel on Selected Parameters of “B” Fuels

Abstract

:1. Introduction

2. Genesis and Innovation of Research

3. Materials and Methods

3.1. Biodiesel Production

3.2. Research Scope

4. Results and Discussion

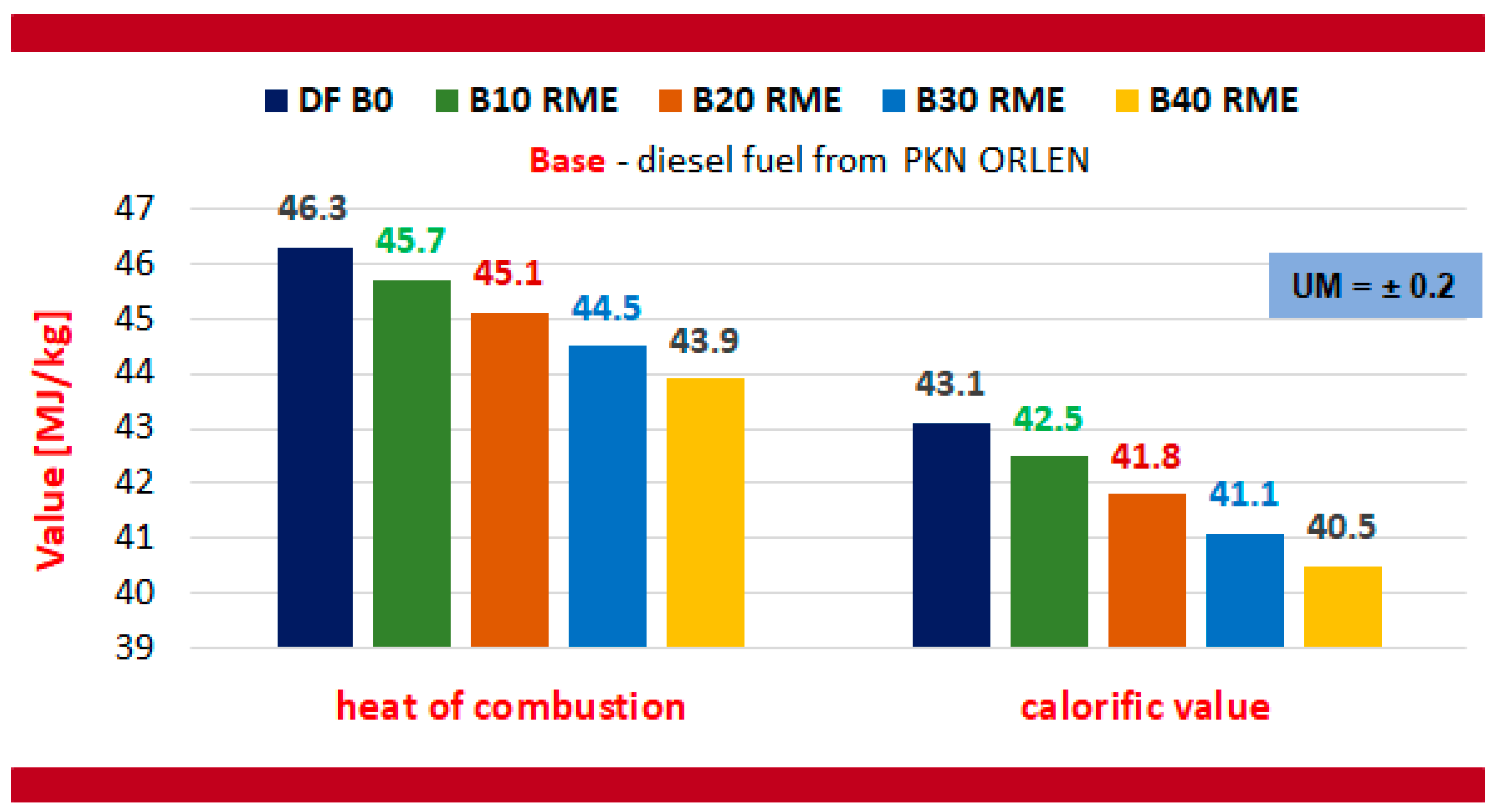

- Q—heat of combustion of fuel MJ/kg;

- Wa—moisture content in biodiesel BBuE is 0.206%, and in biodiesel RME it is 0.221%;

- Ha—hydrogen content in BBuE biodiesels and RME is 12% (w/w), while in diesel, it is 13% (w/w);

- r—heat of vaporization of water contained in the fuel (assumed—2.934 MJ/kg);

- 8.94—is the conversion rate of hydrogen to water.

5. Conclusions

- BBuE biodiesel comprises fatty acids with shorter molecules than those in RME biodiesel. In BBuE, C6:0 to C16:1 fatty acids are approximately 78.3% (w/w), while the same fatty acids in RME are approximately 4.9% (w/w). However, fatty acids from C18:0 to C18:3 in BBuE are approximately 21.6% (w/w); in RME, these acids are 91.0% (w/w).

- BBuE biodiesel has a slightly higher heat of combustion, higher calorific value, and higher cetane count value than RME biodiesel. The data specified above show that the density of RME is higher by approximately 3.1% compared to RME. The resulting BBuE cetane number is 5.6 units higher than DF and 1.3 units higher than RME.

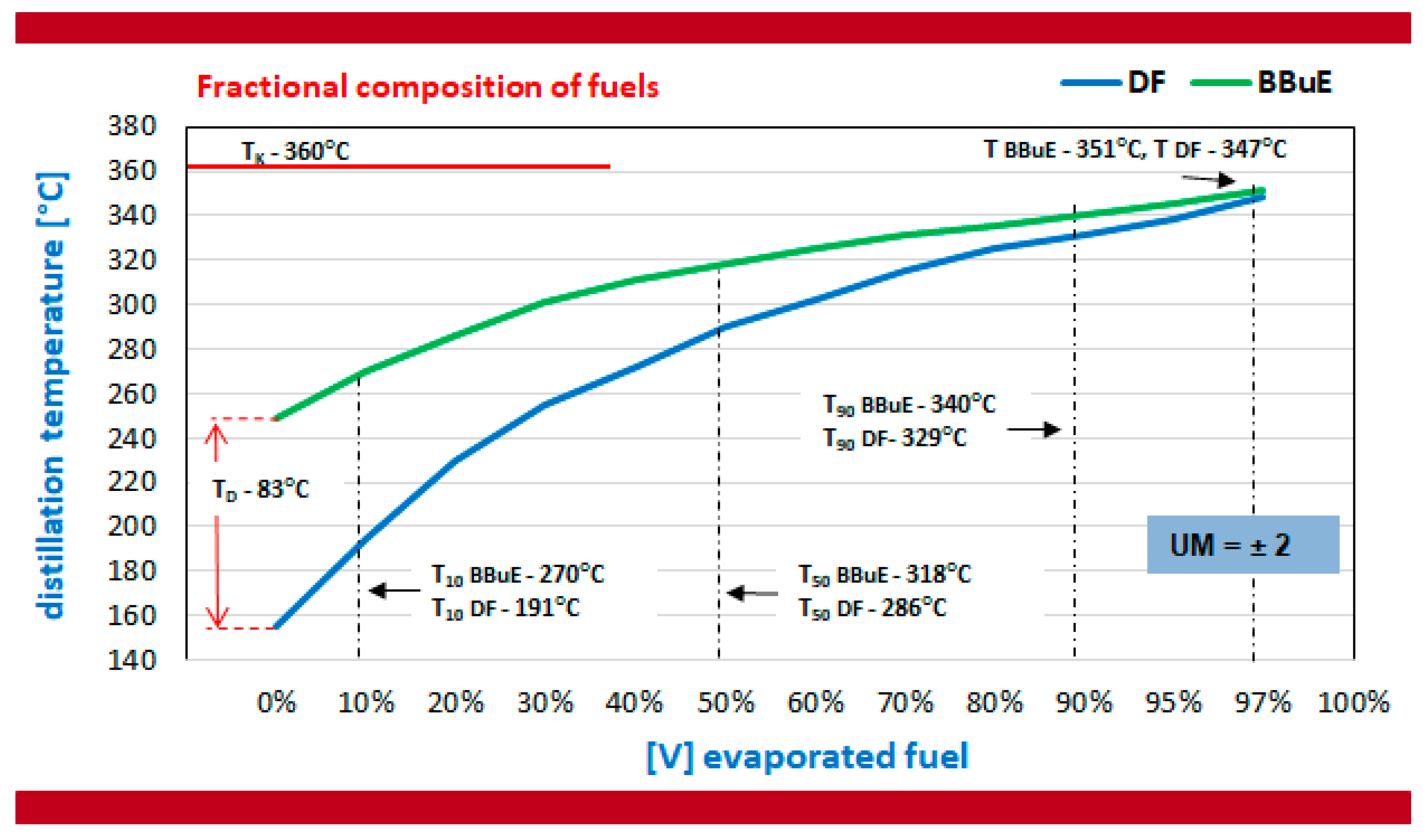

- The parameters of the BBuE biodiesel distillation process have more favourable values from the point of view of their use as a fuel for compression-ignition engines, compared to the parameters of the RME biodiesel distillation process. The onset temperature for the distillation of BBuE biodiesel is 14.7% lower than that for RME.

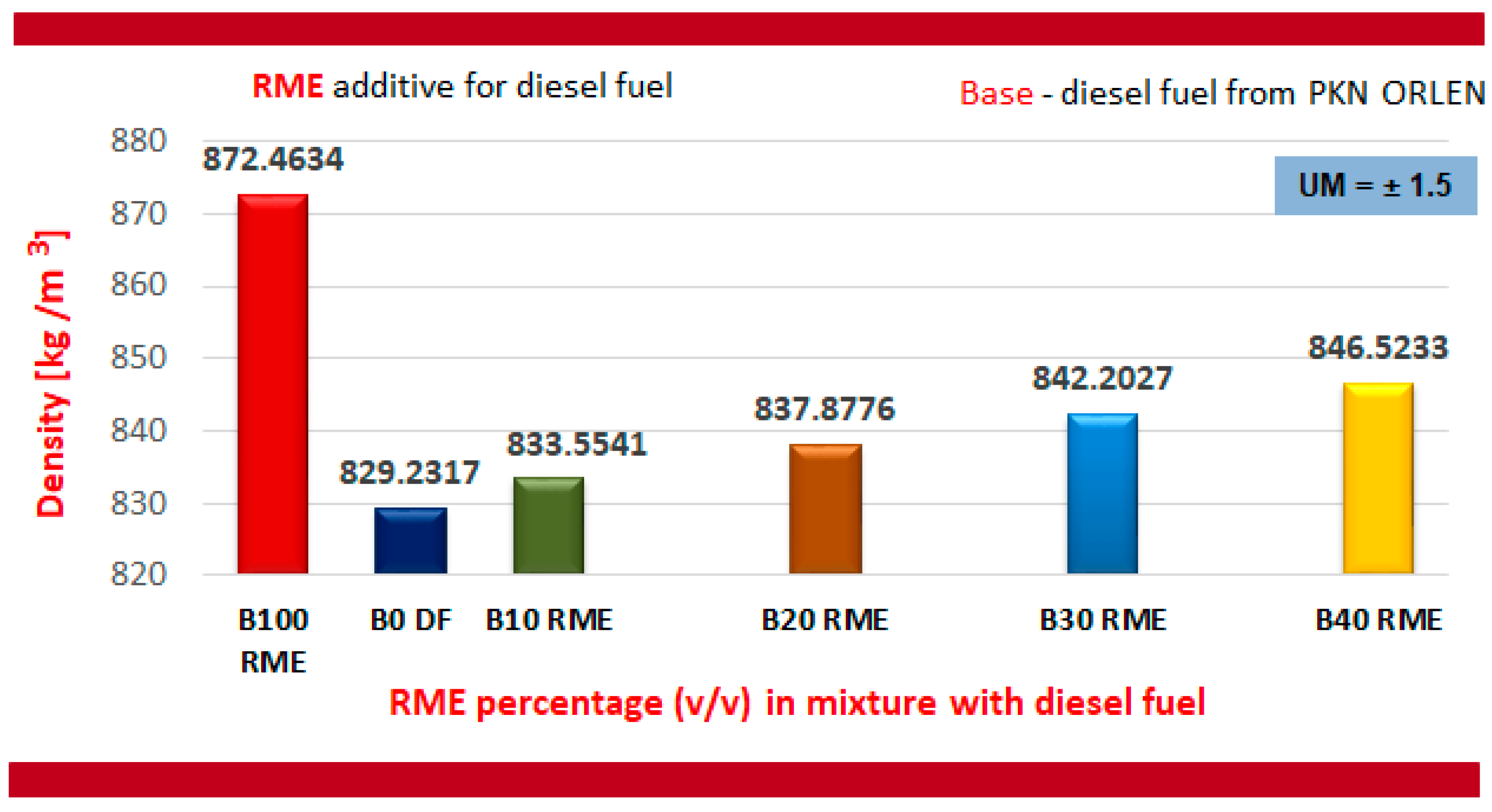

- The density of BBuE and RME biodiesels at 15 °C is higher than that of DF diesel. BBuE biodiesel has a slightly higher density compared to RME. The density of BBuE is 6.6% higher, and RME 5.2% higher, than that of diesel.

- The properties of BBuE biodiesel are more like those of diesel fuel than those of RME biodiesel.

- The dynamic viscosity of BBuE and DF mixtures is lower than that of RME and DF mixtures in the temperature range from −20 °C to +50 °C.

- The combustion heat and calorific values of BBuE and DF mixtures are slightly higher than those of RME and DF mixtures. The resulting calorific value of B40 BBuE fuel is only approximately 1.5% higher than that of B40 RME fuel.

- The addition of BBuE and RME up to 40% (v/v) resulted in a slight increase in density. For B40, BBuE was increased by approximately 2.7%, while for B40, RME was increased by about 2% relative to DF.

- Slightly higher cetane number values were obtained for BBuE and DF mixtures than for RME and DF mixtures.

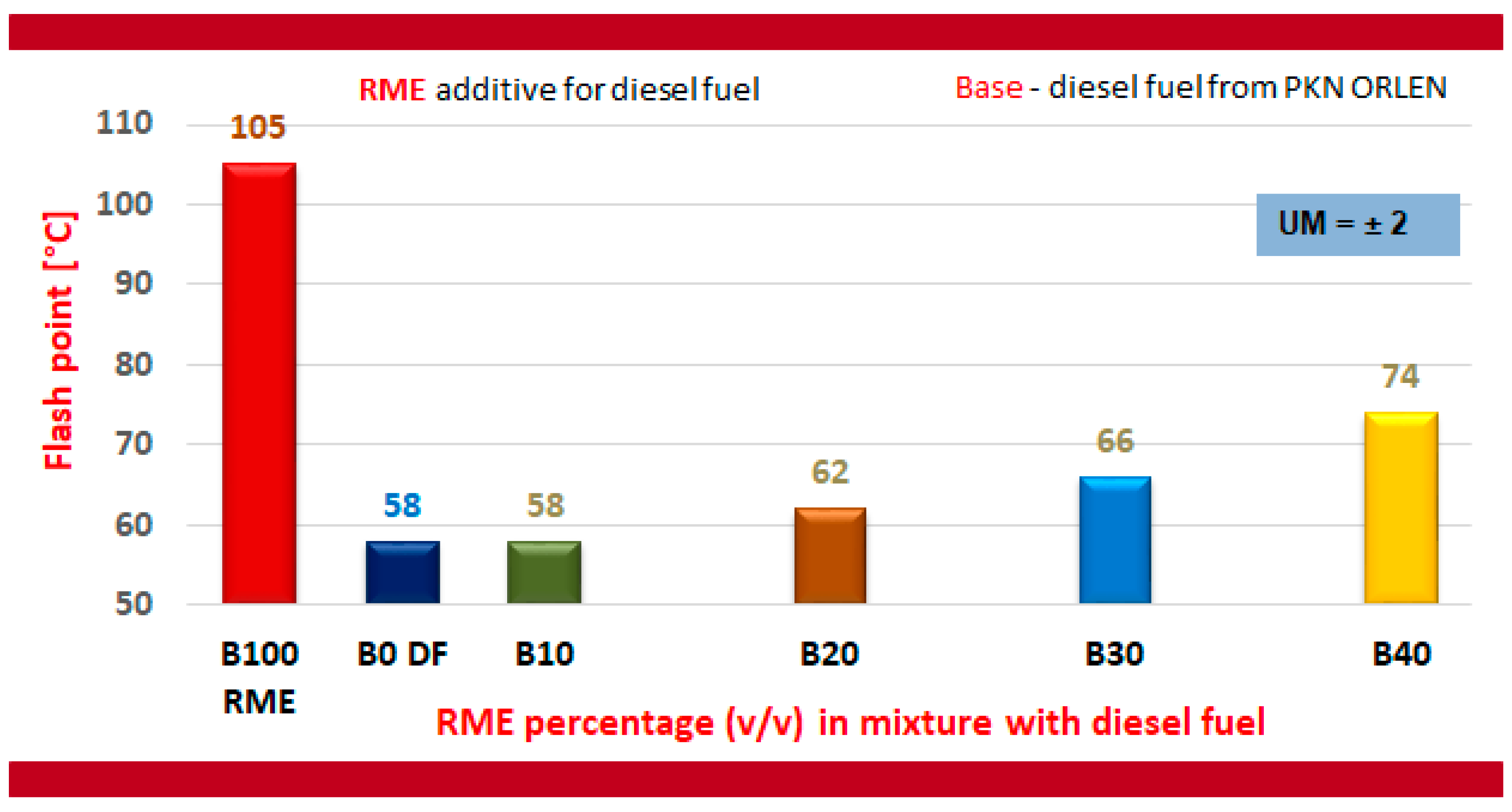

- Mixtures of BBuE and DF achieved slightly lower flash points.

- Fuels obtained from blending BBuE biodiesel with DF have more comparable properties to pure DF diesel than fuels obtained as blends of RME biodiesel with DF.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| B10, B20, B30 andB40 | blends of esters and diesel |

| BBuE | babassu butyl esters |

| B0 DF | olej napędowy bez dodatku FAME |

| B10 BBuE | fuel composed of 10% (v/v) BBuE and 90% (v/v) DF |

| B20 BBuE | fuel composed of 20% (v/v) BBuE and 80% (v/v) DF |

| B30 BBuE | fuel composed of 30% (v/v) BBuE and 70% (v/v) DF |

| B40 BBuE | fuel composed of 40% (v/v) BBuE and 60% (v/v) DF |

| B10 RME | fuel composed of 10% (v/v) RME and 90% (v/v) DF |

| B20 RME | fuel composed of 20% (v/v) RME and 80% (v/v) DF |

| B30 RME | fuel composed of 30% (v/v) RME and 70% (v/v) DF |

| B40 RME | fuel composed of 40% (v/v) RME and 60% (v/v) DF |

| C6:0 | caproic acid |

| C8:0 | caprylicacid |

| C10:0 | capricacid |

| C12:0 | lauric acid |

| C14:0 | Muriatic acid |

| C16:0 | palmitic acid |

| C16:1 | palmitoleic acid |

| C18:0 | stearic acid |

| C18:1 | oleic acid |

| C18:2 | linoleic acid |

| C18:3 | linolenic acid |

| C20:0 | arachidic acid |

| C20:1 | eicosanoidacid |

| C22:0 | behenic acid |

| C22:1 | erucicacid |

| C24:0 | lignoceric acid |

| C24:1 | nervonic acid |

| C4H9OH | n-butyl alcohol |

| DF | diesel fuel |

| FAME | fatty acid methyl ester |

| H2SO4 | sulphuric acid |

| KOH | potassium hydroxide |

| NaOH | sodium hydroxide |

| RME | rapeseed methyl esters |

| T | distillation end temperature, °C |

| TD | distillation temperature difference for the compared fuels for a specific temperature, °C |

| TK | temperature to which the whole volume of fuel should be distilled, °C |

| T0 | distillation start temperature, °C |

| T10 | distillation temperature of 10% by volume of fuel, °C |

| T50 | distillation temperature of 50% by volume of fuel, °C |

| T90 | distillation temperature of 90% of the fuel volume, °C |

| T95 | distillation temperature of 95% of the fuel volume, °C |

| v/v | volumetric share |

| w/w | weight share |

| UM | measurement uncertainty |

References

- Directive 2003/30/EC of the European Parliament and of the Council of 8 May 2003 on the Promotion of the Use of Biofuels or Other Renewable Fuels for Transport; European Parliament: Strasbourg, France, 2003.

- Chen, H.; Ding, M.; Li, Y.; Xu, H.; Li, Y.; Wei, Z. Feedstocks, environmental effects, and development suggestions for biodiesel in China. J. Traffic Transp. Eng. 2020, 7, 791–807. [Google Scholar] [CrossRef]

- Athar, M.; Zaidi, S. A review of the feedstocks, catalysts, and intensification techniques for sustainable biodiesel production. J. Environ. Chem. Eng. 2020, 8, 104523. [Google Scholar] [CrossRef]

- Sing, D.; Sharma, D.; Soni, S.L.; Sharma, S.; Sharma, P.K. A review on feedstocks, production processes, and yield for different generations of biodiesel. Fuel 2020, 262, 116553. [Google Scholar] [CrossRef]

- Kurczyński, D.; Łagowski, P. Performance indices of a common rail-system CI engine powered by diesel oil and biofuel blends. J. Energy Inst. 2019, 92, 1897–1913. [Google Scholar] [CrossRef]

- Singh, D.; Sharma, D.; Soni, S.L.; Sharma, S.; Kumari, D. Chemical compositions, properties, and standards for different generation biodiesels: A review. Fuel 2019, 253, 60–71. [Google Scholar] [CrossRef]

- Saladini, F.; Patrizi, N.; Pulselli, F.M.; Marchettini, N.; Bastianoni, S. Guidelines for energy evaluation of first, second and third generation biofuels. Renew. Sustain. Energy Rev. 2016, 66, 221–227. [Google Scholar] [CrossRef]

- Ilkiliç, C. The effect of sunflower oil methyl ester and diesel fuel blend on the performance of a diesel engine. Energy Sources Part A Recovery Util. Environ. Eff. 2008, 30, 1761–1770. [Google Scholar] [CrossRef]

- Kurczyński, D.; Łagowski, P.; Wcisło, G. Experimental study of fuel consumption and exhaust gas composition of a diesel engine powered by biodiesel from waste of animal origin. Energies 2021, 14, 3472. [Google Scholar] [CrossRef]

- Demirbas, A. Potential resources of non-edible oils for biodiesel. Energy Source Part B 2009, 4, 310–314. [Google Scholar] [CrossRef]

- Deepanraj, B.; Srinivas, M.; Arun, N.; Sankaranarayanan, G.; Salam, A.P. Comparison of jatropha and karanja biofuels on their combustion characteristics. Int. J. Green Energy 2017, 14, 1231–1237. [Google Scholar] [CrossRef]

- Yadav, A.K.; Khan, M.E.; Dubey, A.M.; Pal, A. Performance and emission characteristics of a transportation diesel engine operated with non-edible vegetable oils biodiesel. Case Stud. Therm. Eng. 2016, 8, 236–244. [Google Scholar] [CrossRef]

- Veljkovic, V.B.; Lakicevic, S.H.; Stamenkovic, O.S.; Todorovic, Z.B.; Lazic, M.L. Biodiesel production from tobacco (Nicotiana tabacum L.) seed oil with a high content of free fatty acids. Fuel 2006, 85, 2671–2675. [Google Scholar] [CrossRef]

- Kurczyński, D.; Łagowski, P.; Wcisło, G. Experimental study into the effect of the second-generation BBuE biofuel use on the diesel engine parameters and exhaust composition. Fuel 2021, 284, 118982. [Google Scholar] [CrossRef]

- Abed, K.A.; El Morsi, A.K.; Sayed, M.M.; El Shaib, A.A.; Gad, M.S. Effect of waste cooking-oil biodiesel on performance and exhaust emissions of a diesel engine. Egypt. J. Pet. 2018, 27, 985–989. [Google Scholar] [CrossRef]

- Borah, M.J.; Das, A.; Das, V.; Bhuyan, N.; Deka, D. Transesterification of waste cooking oil for biodiesel production catalyzed by Zn substituted waste eggshell derived CaO nanocatalyst. Fuel 2019, 242, 345–354. [Google Scholar] [CrossRef]

- Fonseca, M.J.; Teleken, J.G.; de Cinque Almeida, V.; da Silva, C. Biodiesel from waste frying oils: Methods of production and purification. Energy Convers. Manag. 2019, 184, 205–218. [Google Scholar] [CrossRef]

- Sahar; Sadaf, S.; Iqbal, J.; Ullah, I.; Bhatti, H.N.; Nouren, S.; Habib-ur-Rehman; Nisar, J.; Iqbal, M. Biodiesel production from waste cooking oil: An efficient technique to convert waste into biodiesel. Sustain. Cities Soc. 2018, 41, 220–226. [Google Scholar] [CrossRef]

- Uddin, M.N.; Techato, K.; Rasul, M.G.; Hassan, N.M.S.; Mofijur, M. Waste coffee oil: A promising source for biodiesel production. Energy Procedia 2019, 160, 677–682. [Google Scholar] [CrossRef]

- Gnanasekaran, S. Prediction of CI engine performance, emission, and combustion characteristics using fish oil as a biodiesel at different injection timing using fuzzy logic. Fuel 2016, 183, 214–229. [Google Scholar]

- Adewale, P.; Dumont, M.-J.; Ngadi, M. Recent trends of biodiesel production from animal fat wastes and associated production techniques. Renew. Sustain. Energy Rev. 2015, 45, 574–588. [Google Scholar] [CrossRef]

- Banković-Ilić, I.B.; Stojković, I.J.; Stamenković, O.S.; Veljkovic, V.B.; Yung-Tse, H. Waste animal fats as feedstocks for biodiesel production. Renew. Sustain. Energy Rev. 2014, 32, 238–254. [Google Scholar] [CrossRef]

- Cunha, A., Jr.; Feddern, V.; De Prá, M.C.; Higarashi, M.M.; de Abreu, P.G.; Coldebella, A. Synthesis and characterization of ethylic biodiesel from animal fat wastes. Fuel 2013, 105, 228–234. [Google Scholar] [CrossRef]

- Thompson, W.; Meyer, S. Second generation biofuels and food crops: Co-products or competitors? Glob. Food Secur. 2013, 2, 89–96. [Google Scholar] [CrossRef]

- Biernat, K. Perspectives for global development of biofuel technologies to 2050. Chemik 2012, 66, 1178–1189. [Google Scholar]

- Faried, M.; Samer, M.; Abdelsalam, E.; Yousef, R.S.; Attia, Y.A.; Ali, A.S. Biodiesel production from microalgae: Processes, technologies, and recent advancements. Renew. Sustain. Energy Rev. 2017, 79, 893–913. [Google Scholar] [CrossRef]

- Chen, J.; Li, J.; Dong, W.; Zhang, X.; Tyagi, R.D.; Drogui, P.; Surampalli, R.Y. The potential of microalgae in biodiesel production. Renew. Sustain. Energy Rev. 2018, 90, 336–346. [Google Scholar] [CrossRef]

- Akubude, V.C.; Nwaigwe, K.N.; Dintwa, E. Production of biodiesel from microalgae via nanocatalyzed transesterification process: A review. Mater. Sci. Energy Technol. 2019, 2, 216–225. [Google Scholar] [CrossRef]

- Rajak, U.; Nashine, P.; Verma, T.N. Assessment of diesel engine performance using spirulina microalgae biodiesel. Energy 2019, 166, 1025–1036. [Google Scholar] [CrossRef]

- Sun, J.; Xiong, X.; Wang, M.; Du, H.; Li, J.; Zhou, D.; Zuo, J. Microalgae biodiesel production in China: A preliminary economic analysis. Renew. Sustain. Energy Rev. 2019, 104, 296–306. [Google Scholar] [CrossRef]

- Dharmaprabhakaran, T.; Karthikeyan, S.; Periyasamy, M.; Mahendran, G. Algal biodiesel- promising source to power CI engines. Mater. Today Proc. 2020, 33, 2870–2873. [Google Scholar] [CrossRef]

- Bajdor, K.; Biernat, K. Biofuels as alternative energy carriers in IC engines; classification and development prospects. Arch. Motoryz. 2011, 1, 5–19. [Google Scholar] [CrossRef]

- Malik, S.; Shahid, M.; Liu, C.-G.; Khan, A.Z.; Nawaz, M.Z.; Zhu, H.; Mehmood, M.M. Developing fourth-generation biofuels secreting microbial cell factories for enhanced productivity and efficient product recovery; a review. Fuel 2021, 298, 120858. [Google Scholar] [CrossRef]

- Kozak, M. Exhaust Emissions from a Diesel Passenger Car Fuelled with a Diesel Fuel-Butanol Blend; SAE Technical Paper 2011-28-0017; SAE: Warrendale, PA, USA, 2011. [Google Scholar] [CrossRef]

- Kozak, M.; Lijewski, P.; Waligórski, M. Exhaust Emissions from a Hybrid City Bus Fuelled by Conventional and Oxygenated Fuel. Energies 2022, 15, 1123. [Google Scholar] [CrossRef]

- Kozak, M.; Merkisz, J. Oxygenated Diesel Fuels and Their Effect on PM Emissions. Appl. Sci. 2022, 12, 7709. [Google Scholar] [CrossRef]

- Teixeira, M.A. Babassu—A new approach for an ancient Brazilian biomass. Biomass Bioenergy 2008, 32, 857–864. [Google Scholar] [CrossRef]

- Teixeira, M.A.; da Graça Carvalho, M. Regulatory mechanism for biomass renewable energy in Brazil, a case study of the Brazilian Babassu oil extraction industry. Energy 2007, 32, 999–1005. [Google Scholar] [CrossRef]

- Girardi, J.C.; Bariccatti, R.A.; de Souza, S.N.M.; Amaral, C.Z.D.; Guedes, C.L.B. Natural compounds as antifreeze additives to improve babassu biodiesel. Fuel 2021, 289, 119746. [Google Scholar] [CrossRef]

- Ferreira, M.E.M.; Neto, A.C.; Costa, P.A.B. Exergy Evaluation of the Production Process of Babassu Biodiesel Synthesized via Methanolic and Ethanolic Route. Int. J. Appl. Sci. Technol. 2014, 4, 204–219. [Google Scholar]

- Sakthivel, R.; Ramesh, K.; Purnachandran, R.; Shameer, P.M. A review on the properties, performance, and emission aspects of the third-generation biodiesels. Renew. Sustain. Energy Rev. 2018, 82, 2970–2992. [Google Scholar] [CrossRef]

- Srivastava, A.; Prasad, R. Triglycerides-based diesel fuels. Renew. Sustain. Energy Rev. 2000, 4, 111–133. [Google Scholar] [CrossRef]

- Demirbas, A. Progress and Recent Trends in Biodiesel Fuels. Energy Convers. Manag. 2009, 50, 14–34. [Google Scholar] [CrossRef]

- Paiva, E.J.M.; da Silva, M.L.C.P.; Barboza, J.C.S.; de Oliveira, P.C.; de Castro, H.F.; Giordani, D.S. Non-edible babassu oil as a new source for energy production–a feasibility transesterification survey assisted by ultrasound. Ultrason. Sonochem. 2013, 20, 833–838. [Google Scholar] [CrossRef] [PubMed]

- Bouaid, A.; Boulifi, N.E.; Martínez, M.; Aracil, J. Biodiesel Production from Babassu Oil: A Statistical Approach. J. Chem. Eng. Process Technol. 2015, 6, 232. [Google Scholar] [CrossRef]

- de Oliveira, V.F.; Parente, E.J.S., Jr.; Manrique-Rueda, E.D.; Cavalcante, C.L., Jr.; Luna, F.M.T. Fatty acid alkyl esters obtained from babassu oil using C1–C8 alcohols and process integration into a typical biodiesel plant. Chem. Eng. Res. Des. 2020, 160, 224–232. [Google Scholar] [CrossRef]

- Kale, P.T.; Ragit, S.S. Optimization of Babassu (Orbignya sp.) biodiesel Production from Babassu Oil by Taguchi Technique and Fuel Characterization. Int. J. Pet. Sci. Technol. 2017, 11, 35–50. [Google Scholar]

- Moreira, K.S.; Moura Júnior, L.S.; Monteiro, R.R.C.; de Oliveira, A.L.B.; Valle, C.P.; Freire, T.M.; Fechine, P.B.A.; de Souza, M.C.M.; Fernandez-Lorente, G.; Guisan, J.M.; et al. Optimization of the Production of Enzymatic Biodiesel from Residual Babassu Oil (Orbignya sp.) via RSM. Catalysts 2020, 10, 414. [Google Scholar] [CrossRef]

- Brandão Júnior, J.; Andrade do Nascimento, J.G.; França Silva, M.P.; Lima Brandão, E.d.A.; de Castro Bizerra, V.; dos Santos, K.M.; Serpa, J.d.F.; Santos, J.C.S.d.; da Fonseca, A.M.; Vasconcelos de Oliveira, D.L.; et al. Performance of Eversa Transform 2.0 Lipase in Ester Production Using Babassu Oil (Orbignya sp.) and Tucuman Oil (Astrocaryum vulgar): A Comparative Study between Liquid and Immobilized Forms in Fe3O4 Nanoparticles. Catalysts 2023, 13, 571. [Google Scholar] [CrossRef]

- Alexandre, J.Y.N.H.; Cavalcante, F.T.T.; Freitas, L.M.; Castro, A.P.; Borges, P.T.; de Sousa Junior, P.G.; Filho, M.N.R.; Lopes, A.A.S.; da Fonseca, A.M.; Lomonaco, D.; et al. A Theoretical and Experimental Study for Enzymatic Biodiesel Production from Babassu Oil (Orbignya sp.) Using Eversa Lipase. Catalysts 2022, 12, 1322. [Google Scholar] [CrossRef]

- Leśniak, A. Determining the Effect of the Fatty Acid Composition of Babassu Oil on the Properties of Second-Generation Biodiesel and the Parameters of a Compression Ignition Engine. Ph.D. Thesis, Poznan University of Technology, Poznań, Poland, 2019. [Google Scholar]

- PN-EN 590:2022-08; Automotive Fuels-Diesel Fuels-Requirements and Test Methods. The Polish Committee for Standardization: Warsaw, Poland, 2022.

- PN-EN 14214+A2:2019-05; Liquid Petroleum Products-Fatty Acid Methyl Esters (FAME) for Use in Automotive Compression-Ignition (Diesel) Engines and Heating Applications-Requirements and Test Methods. The Polish Committee for Standardization: Warsaw, Poland, 2019.

- PN-EN 14103:2020-06; Oil and Fat Processing Products-Fatty acid Methyl Esters (FAME)-Determination of Esters and Linolenic Acid Methyl Ester. The Polish Committee for Standardization: Warsaw, Poland, 2020.

- PN-EN ISO 3675:2004; Petroleum and Liquid Petroleum Products-Laboratory Density Determination-Areometer Method. The Polish Committee for Standardization: Warsaw, Poland, 2004.

- PN-EN 14111:2022-11; Oil and Fat Processing Products-Fatty Acid Methyl Esters (FAME)-Determination of Iodine Number. The Polish Committee for Standardization: Warsaw, Poland, 2022.

- PN-EN 14104:2021-06; Oil and Fat Processing Products-Fatty Acid Methyl Esters (FAME)-Determination of Acid Value. The Polish Committee for Standardization: Warsaw, Poland, 2021.

- PN-EN ISO 3679:2015-04; Determination of Ignition or Non-Ignition and Flash Point-Rapid Equilibrium Method in the Closed Crucible. The Polish Committee for Standardization: Warsaw, Poland, 2015.

- PN-EN ISO 3405:2019-05; Petroleum Preparations and Similar Products of Natural and Synthetic Origin-Determination of Fractional Composition by Distillation under Atmospheric Pressure. The Polish Committee for Standardization: Warsaw, Poland, 2019.

- PN-EN ISO 5165:2021-02; Petroleum Products-Determination of Ignition Properties of Gas Oils-ENGINE Method for Determination of Cetane Number. The Polish Committee for Standardization: Warsaw, Poland, 2021.

- PN-C-04375-1:2013-07; Testing of Solid and Liquid Fuels-Calorimetric Bomb Calorimetry and Calorific Value Determination-Part 1: General, Apparatus, Methods. The Polish Committee for Standardization: Warsaw, Poland, 2013.

- PN-EN ISO 3104:2021-03; Petroleum Products-Transparent and Opaque Liquids-Determination of Kinematic Viscosity and Calculation of Dynamic Viscosity. The Polish Committee for Standardization: Warsaw, Poland, 2021.

- PN-EN ISO 12937:2005; Petroleum Products-Determination of Water-Karl Fischer Coulometric Titration. The Polish Committee for Standardization: Warsaw, Poland, 2005.

- PN-EN ISO 8754:2007; Petroleum and Associated Products-Determination of Sulphur Content-Energy Dispersive X-ray Fluorescence Spectrometry. The Polish Committee for Standardization: Warsaw, Poland, 2007.

- PN-EN 14110:2019-05; Produkty Przetwarzania Olejów i Tłuszczów-Estry Metylowe Kwasów Tłuszczowych-Oznaczanie Zawartości Metanolu. The Polish Committee for Standardization: Warsaw, Poland, 2019.

- PN-EN 14105:2021-05; Produkty Przetwarzania Olejów i Tłuszczów-Estry Metylowe Kwasów Tłuszczowych (FAME)-Oznaczanie Zawartości Wolnego i Ogólnego Glicerolu Oraz Mono-, di- i Triacylogliceroli. The Polish Committee for Standardization: Warsaw, Poland, 2021.

- Tamilselvan, P.; Nallusamy, N.; Rajkumar, S. A comprehensive review on performance, combustion and emission characteristics of biodiesel fuelled diesel engines. Renew. Sustain. Energy Rev. 2017, 79, 1134–1159. [Google Scholar] [CrossRef]

- Shameer, P.M.; Ramesh, K.; Sakthivel, R.; Purnachandran, R. Effects of fuel injection parameters on emission characteristics of diesel engines operating on various biodiesel: A review. Renew. Sustain. Energy Rev. 2017, 67, 1267–1281. [Google Scholar] [CrossRef]

| Measured Parameter | Unit | Value |

|---|---|---|

| Efficiency per cycle | dm3 | 50 |

| Production time per cycle | h | 1.5 |

| Supply voltage | V | 230 |

| Rated power | kWh | 5.15 |

| Type of catalyst | - | basic/acidic |

| Rated power | kWh | 5.15 |

| Supply voltage | V | 230 |

| Process | - | periodic or semi-continuous |

| Type of process | - | single-stage or two-stage |

| Property | Standard | BBuE | RME | DF |

|---|---|---|---|---|

| Content of fatty acid methyl esters, % (w/w) | PN-EN 14103 [54] | 99.11 | 99.20 | - |

| Density at 15 °C, g/cm3 | PN-EN ISO 3675 [55] | 0.884 | 0.872 | 0.839 |

| Dynamic viscosity 40 °C, mPa·s | EN ISO 3104 [62] | 3.8 | 4.1 | 2.8 |

| Cetane number | PN-EN ISO 5165 [60] | 57.4 | 56.1 | 51.8 |

| Flashpoint, °C | PN-EN ISO 3679 [58] | 102 | 105 | 58 |

| Higher heating value, MJ/kg | PN-C-04375 [61] | 43.41 | 42.23 | 46.32 |

| Lower heating value, MJ/kg | PN-C-04375 [61] | 39.45 | 38.27 | 43.07 |

| Acid number, mg KOH/g | PN-EN 14104 [57] | 0.42 | 0.40 | - |

| Iodine number, g iodine/100 g | PN-EN14111 [56] | 12.4 | 103 | - |

| Water content, mg/kg | PN-EN ISO 12937 [63] | 206 | 221 | 132 |

| Sulphur content, mg/kg | EN ISO 8754 [64] | 1 | 3 | 7 |

| Oleic acid ester content C18:1, % (w/w) | PN-EN 14103 [54] | 12.26 | 60.91 | - |

| Linoleic acid ester contentC18:2, % (w/w) | PN-EN 14103 [54] | 2.19 | 19.25 | - |

| Alcohol content, % (w/w) | PN-EN 14110 [65] | 0.18 | 0.19 | - |

| Monoacylglycerol content, % (w/w) | PN-EN 14105 [66] | 0.5 | 0.6 | - |

| Diacylglycerol content, % (w/w) | PN-EN 14105 [66] | 0.13 | 0.11 | - |

| Glycerol content, % (w/w) | PN-EN 14105 [66] | 0.22 | 0.20 | - |

| Distillation Process Parameters | BBuE | RME | DF | BBuE-DF | RME-DF |

|---|---|---|---|---|---|

| Distillation start temperatureT0, °C | 243 | 285 | 160 | 83 | 125 |

| Distillation temperature of 10% by volume of fuel T10, °C | 270 | 299 | 191 | 79 | 108 |

| Distillation temperature of 50% by volume of fuel T50, °C | 318 | 321 | 286 | 32 | 35 |

| Distillation temperature of 90% of the fuel volume T90,°C | 340 | 342 | 329 | 11 | 13 |

| Distillation temperature of 95% of the fuel volume T95, °C | 345 | 350 | 338 | 7 | 12 |

| Distillation end temperature T | 351 | 357 | 347 | 4 | 10 |

| Volume of the fuel sample distilled to a temperature of 250 °C,% (v/v) | 4 | 0 | 27 | −23 | −27 |

| The volumeof the fuel sample distilled to a temperature of 350 °C,% (v/v) | 96 | 94 | 100 | −4 | −6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurczyński, D.; Wcisło, G.; Łagowski, P.; Leśniak, A.; Kozak, M.; Pracuch, B. Determination of the Effect of the Addition of Second-Generation Biodiesel BBuE to Diesel Fuel on Selected Parameters of “B” Fuels. Energies 2023, 16, 6999. https://doi.org/10.3390/en16196999

Kurczyński D, Wcisło G, Łagowski P, Leśniak A, Kozak M, Pracuch B. Determination of the Effect of the Addition of Second-Generation Biodiesel BBuE to Diesel Fuel on Selected Parameters of “B” Fuels. Energies. 2023; 16(19):6999. https://doi.org/10.3390/en16196999

Chicago/Turabian StyleKurczyński, Dariusz, Grzegorz Wcisło, Piotr Łagowski, Agnieszka Leśniak, Miłosław Kozak, and Bolesław Pracuch. 2023. "Determination of the Effect of the Addition of Second-Generation Biodiesel BBuE to Diesel Fuel on Selected Parameters of “B” Fuels" Energies 16, no. 19: 6999. https://doi.org/10.3390/en16196999

APA StyleKurczyński, D., Wcisło, G., Łagowski, P., Leśniak, A., Kozak, M., & Pracuch, B. (2023). Determination of the Effect of the Addition of Second-Generation Biodiesel BBuE to Diesel Fuel on Selected Parameters of “B” Fuels. Energies, 16(19), 6999. https://doi.org/10.3390/en16196999