1. Introduction

With the fast development of technology, the energy demand of society is increasing greatly. In 2019, the global primary energy consumption reached 581.51 EJ, of which oil, coal and natural gas accounted for 191.89 EJ, 157.64 EJ and 140.54 EJ, respectively [

1]. Although the global primary energy demand is still increasing, with the world’s attention on carbon emission the development of renewable energy has also been very rapid in recent years. In 2019, the global installed capacity of renewable energy was 2,536,853 MW. Solar energy is representative of renewable energy, with most of the energy on Earth coming from solar energy, and the global installed capacity of solar power was about 586,434 MW in 2019, which was increased by about 20% compared to that in 2018. Therefore, with the rapid development of solar technology, the utilization of solar energy-based renewable energy has been paid more attention [

2].

Within the world’s largest sources of energy consumption, space heating and cooling of buildings account for 1/4 of the total energy consumption [

3,

4]. In the context of promoting the utilization of renewable energy and the development of a distributed energy system, the solar system is being widely applied to space-heating systems. Solar technology is mainly divided into photovoltaic (PV), solar collector and photovoltaic/thermal (PV/T). Frattolillo et al. [

5] focused on integrating the solar collector on buildings by replacing traditional roofing or facade materials to achieve a domestic hot water supply and meet the heating demand, and the feasibility of the system was proved. However, both a PV and solar collector only utilize a wavelength range of solar irradiation to produce a single product, which means the limited comprehensive utilization efficiency of solar energy from two devices. PV/T which was proposed by Kern et al. [

6]. integrates PV and a solar collector. First, part of the wavelength range of solar irradiation is absorbed by a PV cell in PV/T to generate electricity while the remaining infrared wavelength irradiation is transformed into heat. Thus, the medium in the cooling channel below the PV cell absorbs the heat from the cell [

7,

8].

PV cells have the ability to convert solar irradiation into electricity. However, the high cost of photovoltaic cells restricts the application of a PV system. Using a concentrator and simultaneous exploitation of heat and electrical power are two effective measures to reduce the cost [

9]. Furthermore, combining a concentrator and PV/T can improve the received solar irradiation of a PV cell and quality of heat generated by PV/T [

10]. Solar concentrator technology is divided into low concentration (2–10 times concentration), medium concentration (10–100 times concentration) and high concentration (100–2000 times concentration), besides, a low concentration system has the potential to reduce the cost of producing electricity compared to conventional PV [

11,

12]. There are five solar concentrators: linear Fresnel reflector [

13] compound parabolic concentrator (CPC) [

14], parabolic trough collector [

15], solar power tower [

16] and parabolic dish systems [

17]. Reza et al. [

18] analyzed the performance of concentration photovoltaic/thermal (CPV/T) with different configurations. The result showed that for parabolic trough CPV/T, the thermal efficiency was 70% and the electrical efficiency was 25%. Chen et al. [

19] proposed a novel low-concentrating photovoltaic/thermal system (LCPV/T) and its electrical efficiency reached three times that of flat-plate PV/T, and the solar irradiation fluctuation had little effect on the electrical efficiency.

The cooling medium of PV/T which is widely used is water and air. PVT/WATER systems are more efficient than a PVT/AIR system due to the high thermophysical properties of water compared to those of air, which generally is low. However, a PVT/AIR system is utilized in many practical applications due to low construction (minimal use of material) and operating costs among other factors [

20]. Besides, PV/T with water has the risk of frost cracking while PV/T with air has better applicability in the cold region.

An air source heat pump is an environmentally friendly, efficient and energy-saving system. However, an air source heat pump is greatly affected by environmental and climatic conditions. With the decrease of ambient temperature, the coefficient of performance (COP) of an air source heat pump declines, and the heating capacity is also limited [

21]. In order to improve the performance of air source heat pumps in a cold region, many researchers have designed the framework of the heat pump. Saleh et al. [

22] studied the properties effect of different refrigerants on the vapor compression refrigeration cycle and provided a method for the selection of refrigerant. Ibrahim [

21] et al. set up a dynamic model of an air source heat pump water heater to research the impact of environmental factors on an air source heat pump water heater. In addition, solar energy technology and an air source heat pump coupling system are also widely researched. Cai et al. [

23] proposed a solar–air dual source heat pump, which combined a solar evaporator with an air source heat pump. Comparison between different heat source configurations was made, and the best working conditions of each system were determined. The result showed that COP of the heat pump in all configurations was in the range of 4.33 to 4.58. Liu et al. [

24] designed a composite heat exchanger which integrated a fin-tube and tube heat exchanger and designed a solar–air composite heat pump system to study the performance under different operation modes. The result showed that the dual heat-source mode increased 62% in heat capacity and 59% in COP compared to the single air-source heat pump mode.

In conclusion, the above measures and arrangements have effectively improved the performance of the air source heat pump in cold regions. However, the optimal design of a heat pump has strict technical requirements and the frost problem has not yet been completely overcome. So far, it remains still difficult to operate air source heat pumps in high efficiency in cold regions. Based on the conventional air-source heat pump system, this paper proposes a system of coupling PV/T with an air-source heat pump. By combining PV/T and an air-source heat pump, PV/T used air as a cooling medium to solve the frost cracking problem of PV/T in winter when water was used as a cooling medium. Furthermore, the air heated by PV/T can improve the performance of an air-source heat pump.

In this paper, a low-concentration photovoltaic/thermal (LCPV/T) coupled with an air source heat pump system (AHP) is investigated. The contributions of this work include: (1) the novel LCPV/T-AHP system is proposed for realizing comprehensive utilization of solar energy and improving the performance of an air-source heat pump during the heating season. (2) The building model is established to evaluate the feasibility of the system. (3) The energetic and exergetic performance of the system is investigated. (4) A comparison between the LCPV/T-AHP system and the AHP only system is made from the perspective of energy and exergy. (5) The impacts of key parameters on system performance in variable conditions are researched. In summary, this study provides a new idea for the coupling and application of PV/T technology and an air-source heat pump in building heating.

4. Result and Discussion

In this chapter, the simulation performance of the LCPV/T-AHP system was researched. The system operated in heating season (1 January to 31 March and 1 October to 31 December). Based on the composition of the system, the feasibility of the system was proved according to the indoor temperature. In addition, the energetic and exergetic performance of the LCPV/T and AHP were discussed. Furthermore, by changing the key parameters, the variable condition research was studied.

Figure 4 shows the inlet and outlet temperature of the LCPV/T on 15 January, which was the coldest day in this year. When the radiation was low, due to the effect of convective heat transfer, the outlet temperature was lower than inlet temperature. The beam radiation intensity reached maximum value at 13:00 which signified the maximum outlet temperature at 5.99 °C, corresponding to the temperature rise of 7.64 °C.

Figure 5 showed the power and thermal performance of the LCPV/T on 15 January, the figure indicated that the electrical efficiency was stable at 10%. During the day, the electrical efficiency appeared a trend of decreasing first and then increasing, since the highest electrical efficiency was 10.7% at 9:00 while the lowest electrical efficiency was 10% at 13:00. Although the increase of radiation improved the electrical efficiency of the PV cell, the inlet temperature also increased with increasing of radiation, which caused the temperature of PV cell was higher than that with reference condition under the joint action of two factors. The thermal efficiency increased with the increase of solar radiation which reached 31.88% at 13:00 and the maximum overall efficiency of the LCPV/T was 41.88%.

Figure 6 shows the operation performance of the AHP. To maintain indoor temperature at set temperature, the AHP kept operating all day. As is shown in this figure, the load side outlet temperature of the AHP remained stable at 44 °C while the inlet temperature was 40 °C corresponding to the temperature rise of 4 °C. The heat source inlet temperature of the AHP was equal to the outlet temperature of the LCPV/T. It can be seen that from the beginning of 11:00, the LCPV/T received radiation to heat the air. With the rising of outlet temperature of the LCPV/T, that was, the inlet temperature of the heat pump side, it had a positive effect on the COP of the AHP. When the heat source inlet temperature of AHP was from −10 °C to 5 °C, the COP of the AHP rose from 2.6 to 3.3. Then, with the decrease of heat source inlet temperature of the AHP, the COP changed back to 2.6.

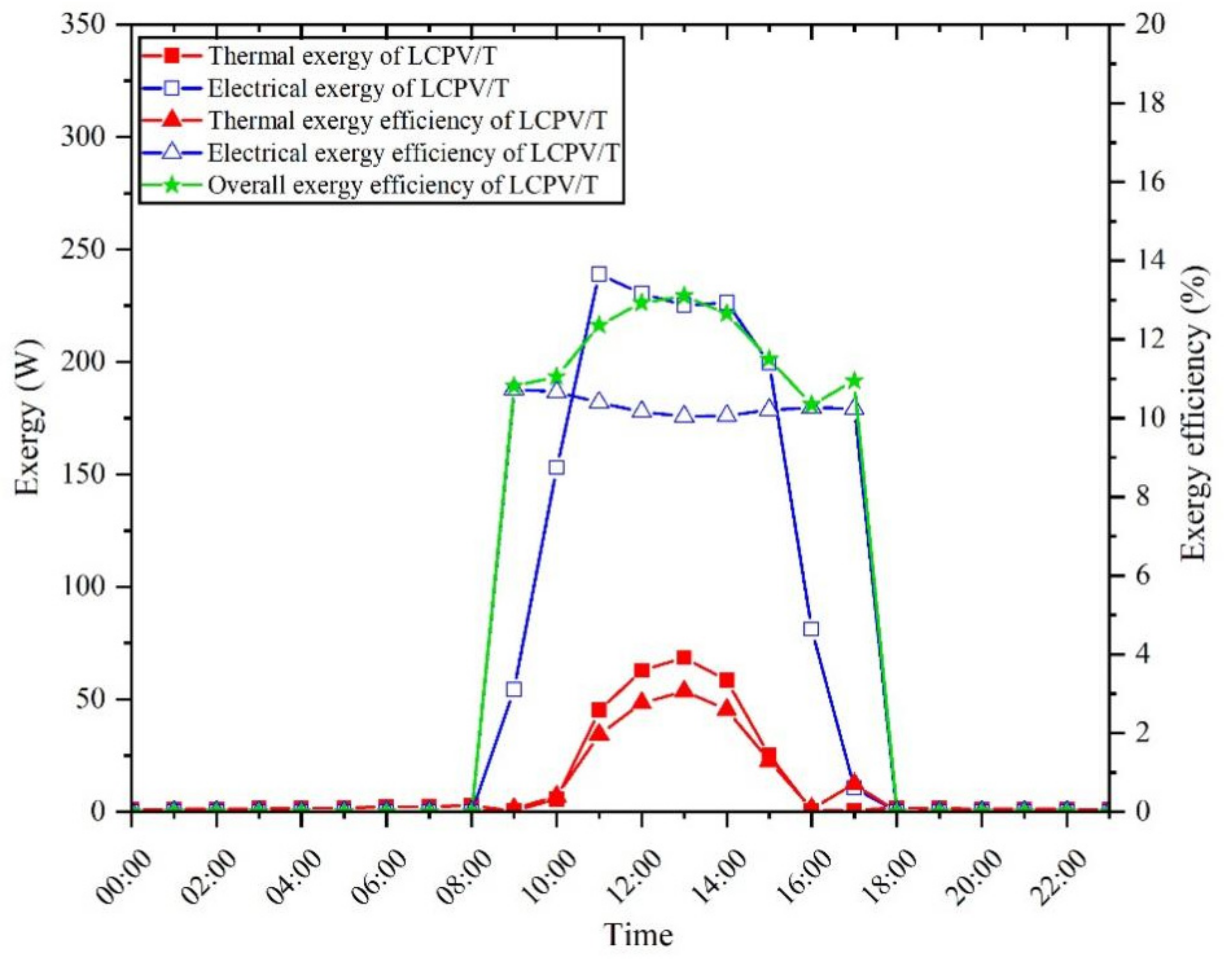

Figure 7 shows the exergy performance of the LCPV/T on 15 January, it was indicated that thermal exergy rate was far less than thermal capacity which thermal exergy was only 62 W while thermal capacity was 2281 W. The thermal energy produced by the LCPV/T was low grade energy which contributed to the low thermal exergy efficiency up to 2.7%. The electrical exergy efficiency was the same as that of electrical efficiency. The overall exergy efficiency of the LCPV/T was 13.1%. Therefore, in order to get more high-quality energy, the LCPV/T should operate on the premise of maximum electrical efficiency.

Figure 8 shows the electrical exergy rate, thermal exergy rate and exergy efficiency of the AHP on 15 January. The electrical exergy rate of the AHP was the same as power consumption of it. When the radiation reached max value, electrical exergy rate and thermal exergy rate increased simultaneously. The thermal exergy rate reached 500 W at noon and the thermal exergy efficiency also improved which was 47%. The weekly power consumption and generation of the LCPV/T-AHP was shown in

Figure 9, the power consumption of pump and fan in the system was not considered. When the radiation value reaches the maximum value, the power consumption of the AHP was compensated by LCPV/T about half of power consumption.

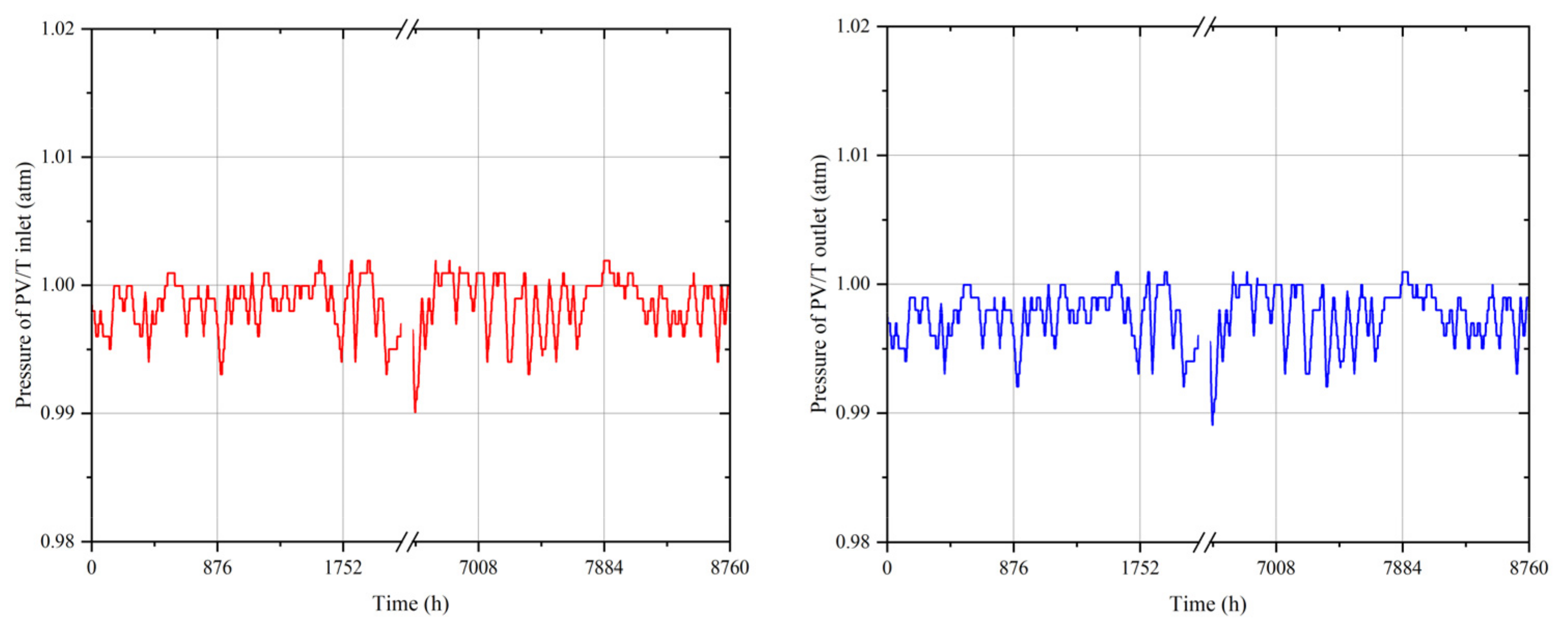

The pressure change of the fan is shown in

Figure 10. The outlet pressure of the fan was mainly influenced by the variation of inlet pressure, that was, the environmental pressure.

Figure 11 shows the variation of the air pressure change in the LCPV/T. According to this figure, the pressure drop of air in cooling channel was small which was about 100 Pa. Based on the pressure change in fan and the LCPV/T, the entropy change of the fan and LCPV/T can be obtained. As shown in

Figure 12, the entropy change of fan was small and the entropy change was relatively large in winter.

Figure 13 showed the entropy change of air in the LCPV/T. It can be seen that the entropy change was small in winter and enhanced with the increase of ambient temperature. The two factors influenced entropy change were

and

. With the increase of ambient temperature,

increased greatly while

changed slightly due to the low pressure drop. Thus entropy change was lower in winter.

The indoor temperature comparison between experimental room and reference room which was no space heating was shown in

Figure 14. It can be seen from the indoor temperature variation trend that with the effect of the LCPV/T-AHP system, the indoor temperature was basically maintained within the set value to meet the indoor temperature requirements in winter. Thus, the system can meet the heating demand of the experimental room.

Figure 15 shows the power consumption and power generation of the LCPV/T-AHP system in whole year.

To verify the improvement of the LCPV/T-AHP system when the LCPV/T was adopted, the comparison between the LCPV/T-AHP coupled system and the AHP only system on 15 January was studied which is shown in

Figure 16. Under the effect of LCPV/T, the COP of the AHP increased to a certain extent. When solar radiation was received by the LCPV/T, the COP of the AHP also raised with the increase of the LCPV/T outlet temperature, furthermore, the COP of the AHP with the LCPV/T was higher than that without the LCPV/T. The power consumption of the AHP with the LCPV/T was slightly lower than that of the AHP without the LCPV/T, and the heating capacity increased more when the outlet temperature of the LCPV/T was higher.

Figure 17 shows the comparison between the net power consumption of the LCPV/T-AHP system and the net power consumption of the AHP only system in heating season. In this study, the power consumption of the pump and fan was neglected, and the power consumption of the AHP was analyzed. It can be seen that because of the lower ambient temperature in January and December, the AHP was needed to operate longer to keep indoor temperature stable that the AHP power consumption was reached 720 kWh. With the increase of ambient temperature, the heat load gradually decreases, therefore, the operation time of the AHP and power consumption gradually reduced. The power generation of the LCPV/T compensated for part of power consumption, so the power consumption of the whole system was smaller than that of the AHP only. In March, the power generation of the LCPV/T can meet most of power consumption. Even in October, the system can generate excess power. However, it is worth mentioning that due to the change of radiation and sunlight time, the condition in winter was not conducive to the operation of the LCPV/T which was compared with that in spring or autumn. Therefore, the influence of the LCPV/T on the system in winter was smaller than that in spring, which was contrary to the variation trend of power consumption. The power generation trend of the LCPV/T cannot fully match the power consumption trend of the AHP in heating season.

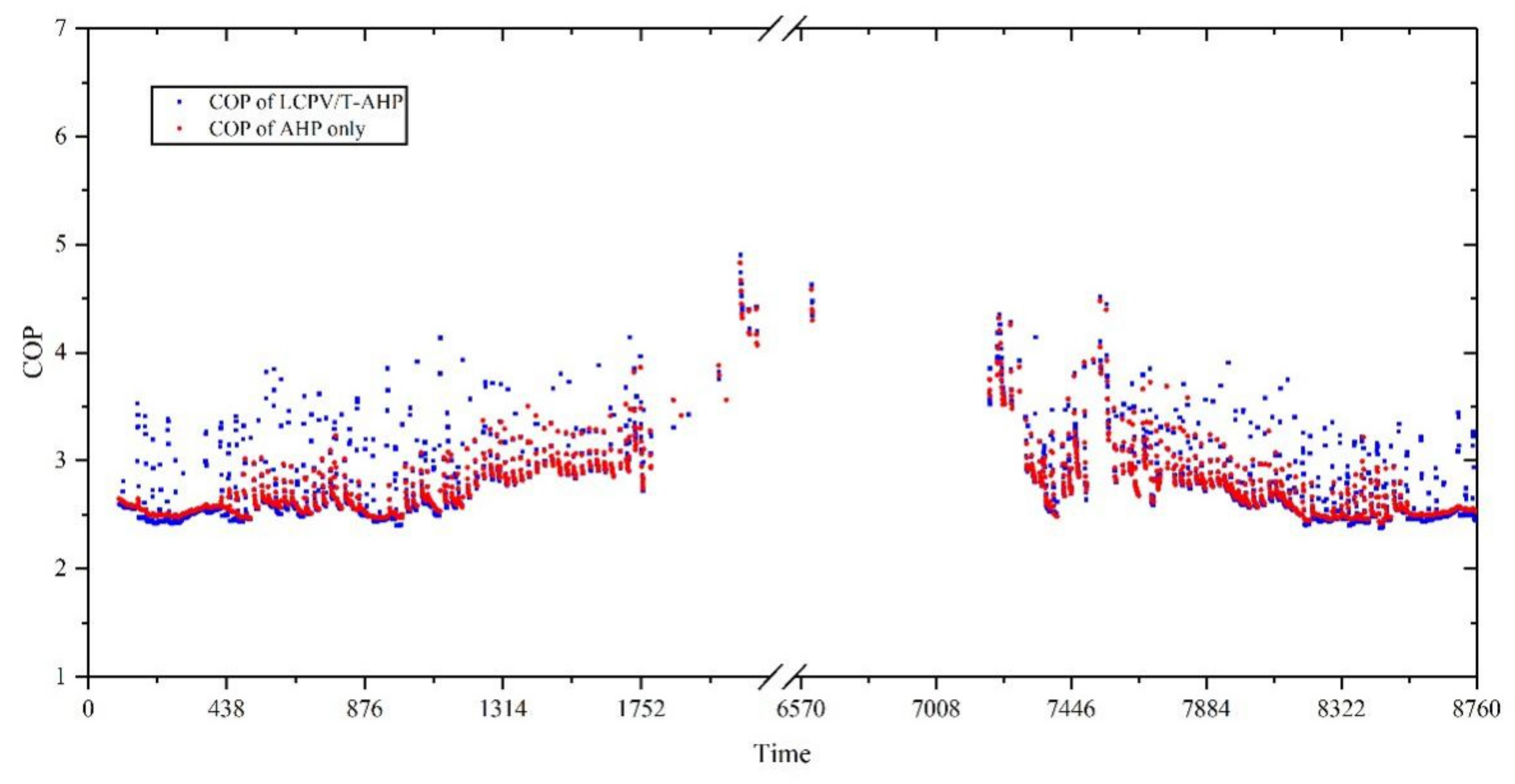

Figure 18 shows the COP comparison between the LCPV/T-AHP system and the AHP only system in heating season. It can be seen from the figure that the COP of the AHP only system changed relatively small and maintained within 2.5–3. In the LCPV/T-AHP system, air was heated by LCPV/T, therefore, the COP of the AHP in the LCPV/T-AHP system had higher COP with a maximum value of 4 compared to the AHP only system. In summary, the coupling of the LCPV/T and the AHP can effectively improve the performance of the AHP.

Figure 19 shows the AHP exergy efficiency comparison between the LCPV/T-AHP system and the AHP only system in the annual heating season. The variation trend of the COP of the two systems was similar. The exergy efficiency of the AHP only system showed a relatively stable variation trend in the annual heating season, and the exergy efficiency was maintained in the range of 35–45%. For the LCPV/T-AHP system, air heated by the LCPV/T was not only conducive to the promotion of heat pump COP, but also the increase of the inlet and outlet temperature of the heat pump side was conducive to improving the efficiency of the AHP. With the effect of LCPV/T, the maximum exergy efficiency of the AHP was raised to 55%.

Since the parameters of the experimental room remained unchanged, the rated parameter of the AHP remained the same. Thus, the main parameter that impacted the performance of the system was the area of the PV cell and the air flow rate of the LCPV/T. By changing the key parameter, the influence of different parameters on the system performance was studied. First, the influence of changing air flow rate on the system performance was studied. The flow rates were set at 500 kg/h, 1000 kg/h, 1500 kg/h and 2000 kg/h respectively.

Figure 20 shows the variation of the electrical efficiency and thermal efficiency of the LCPV/T at different air flow rates. It can be concluded that with the increase of flow rate, the thermal efficiency and electrical efficiency of the LCPV/T raised. The important factor was that the increase of air flow rate augmented the heat transfer capability of working medium. For the LCPV/T, the good cooling effect effectively reduced the temperature rise of the PV cell, thereby improving the efficiency of the PV cell. The increase of flow rate was also in favor of absorbing more heat, so the thermal efficiency also improved. When the air flow rate was increased from 500 kg/h to 2000 kg/h, the electrical efficiency increased from 9.45% to 9.57%, and the thermal efficiency was increased from 21% to 29%. From the variation of curve slope, when the air flow rate was increased from 500 kg/h to 1000 kg/h, the improvement effect of electrical efficiency and thermal efficiency of the LCPV/T was more obvious than that at higher flow rate.

Figure 21 revealed the variation of electrical exergy efficiency and thermal exergy efficiency of the LCPV/T under variable air flow rate. For the thermal exergy efficiency, it can be seen from the Equation (14) that the thermal exergy efficiency was mainly related to

and

. Since the radiation received by the LCPV/T determined the heat absorption of the LCPV/T only changed within limited range. Thus, the main factor affecting the thermal exergy efficiency of the LCPV/T was the air outlet temperature

of the LCPV/T, with the increase of air flow rate, the decrease of

led to the reduction of thermal efficiency.

Figure 22 shows the COP and exergy efficiency of the AHP under different air flow rate. The result showed that with the increase of air flow rate, the COP of the AHP gradually decreases from 2.82 of 500 kg/h to 2.73 of 2000 kg/h which was related to the decrease of inlet air temperature of the AHP. The exergy efficiency of the AHP decreases from 39.7% to 38.8% that was also related to the reduction of inlet air temperature of the AHP.

Figure 23 shows the power consumption of the AHP and the power production of LCPV/T in the system under different air flow rates. It was revealed that the increase of the flow rate caused the raise of power production of LCPV/T because of the efficient cooling of PV cell. On the other hand, the increased power consumption of the AHP was attributed to the decrease of the COP caused by the decrease of inlet air temperature of the AHP. In summary, the increase of the flow rate had little impact on the power consumption.

The above contents focused on the research of system performance under variable flow rate. The two main factors that influenced the system operation were flow rate and PV cell area. Next, the impact of the variable PV cell area on the system performance was evaluated.

Figure 24 shows the variation of the electoral efficiency and thermal efficiency of the LCPV/T in different PV cell area. It should be mentioned that the change of the area of the PV cell was realized by changing the way of connection between each PV cell. The air flow rate was kept constant at 1000 kg/h, and the result showed that with the increase of PV cell area, due to the limited cooling effect of air, the surface temperature of the PV cell increased, resulting in the reduction of electrical efficiency which was reduced from 9.50% to 9.22%. Moreover, although the increase of the radiation receiving area of the PV cell enhanced heat production, the restriction of air flow rate could not take away all the heat production, and the thermal efficiency decreased apparently from 28% to 11%.

Figure 25 shows the variation of electrical exergy efficiency and thermal exergy efficiency of the LCPV/T under different PV cell areas. As mentioned above, the electrical efficiency was the same as the electrical exergy efficiency. With the increase of area, the electrical efficiency decreased while the electrical exergy efficiency also decreased. The reduction of thermal exergy efficiency was caused by the limited cooling capacity of air and the increased trend of heat absorption of air was slower than the increase trend of received solar exergy. Therefore, the thermal exergy efficiency decreased with the increase of the PV cell area from 4% to 1%.

Figure 26 showed the variation of the COP and exergy efficiency of the AHP under different PV cell area. The increase of air temperature caused by the increase of the PV cell area was beneficial to the operation of the AHP while the COP and exergy efficiency of the AHP were improved to a certain extent. With the increase of the PV cell area, the COP increased from 2.76 to 2.79, and exergy efficiency increased from 38.6% to 39.9%.

Figure 27 shows the power generation of LCPV/T and consumption of the system under different PV cell area. First, the power consumption of the AHP did not change significantly with the increase of PV cell area, which corroborated the view that increasing the inlet air temperature of the AHP did not have an obvious effect on changing the power consumption of the AHP, which was only related to the indoor temperature of the experimental room, With the increase of the area of the PV cell, the power generation varied clearly, so it directly affected the overall power consumption of the system.

In the above research, the influence of changing air flow rate and PV cell area on the system was studied. The essence of changing two factors was to change the outlet temperature and the power generation of the LCPV/T. The cooling effect for a PV cell can be improved by raising the air flow rate which was more conducive to the operation of LCPV/T, instead, low air temperature had an adverse impact on the performance of the AHP. On the contrary, for the LCPV/T, although the PV cell area under limited air flow rate was not conducive to the operation of the PV cell, the improvement of air temperature helped to improve the efficiency of the AHP operation. In summary, whether changing air flow rate or PV cell area, improving the performance of one component always had a negative impact on another component.