Refractory All-Ceramic Thermal Emitter for High-Temperature Near-Field Thermophotovoltaics

Abstract

:1. Introduction

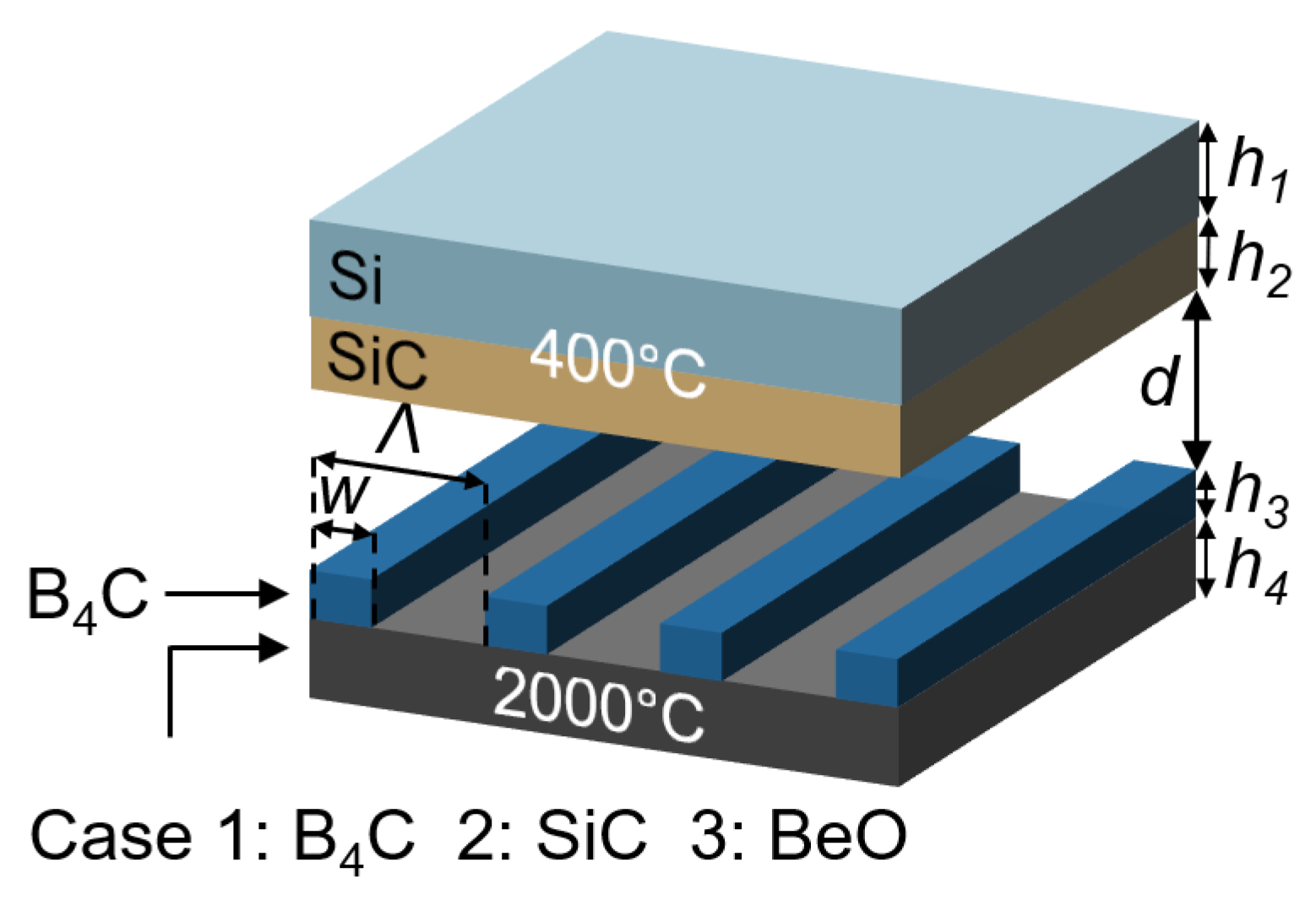

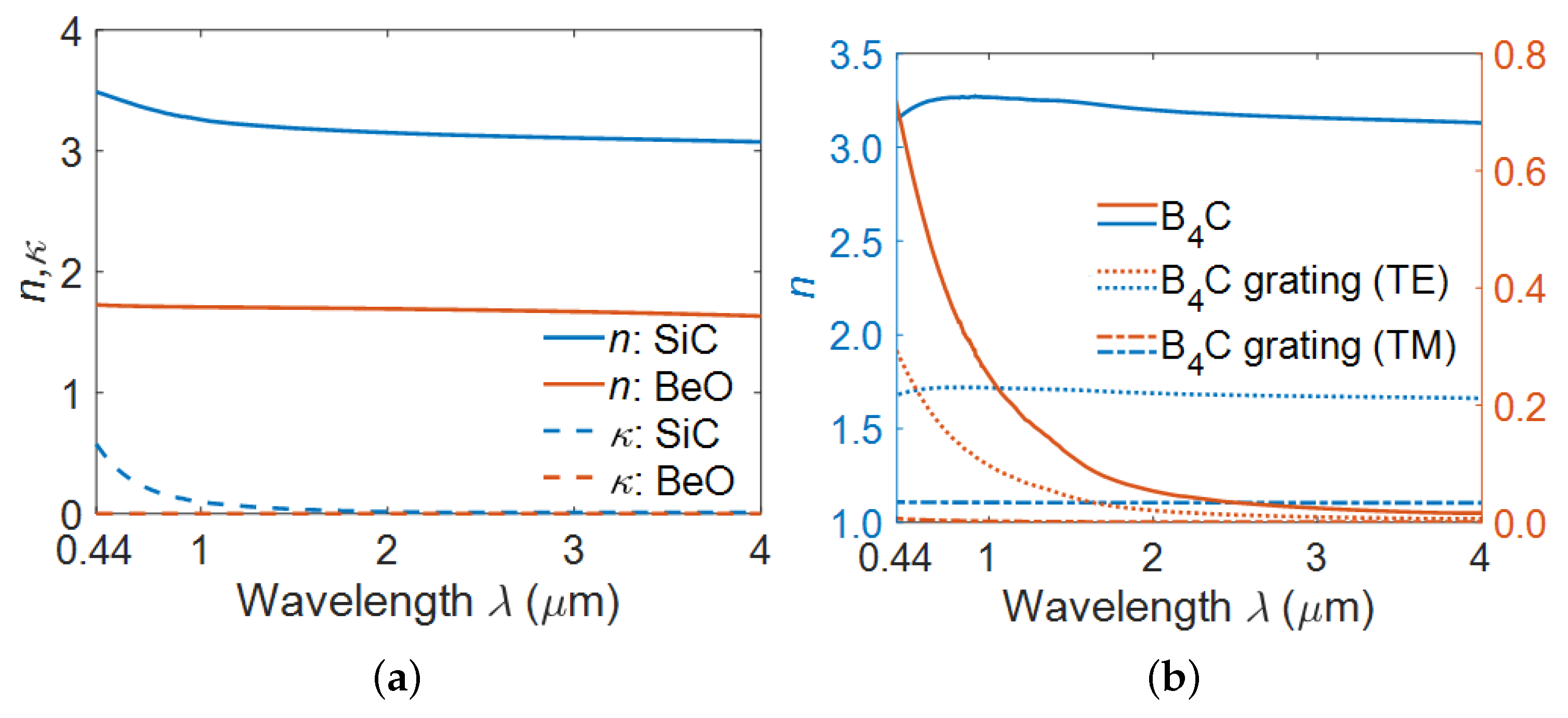

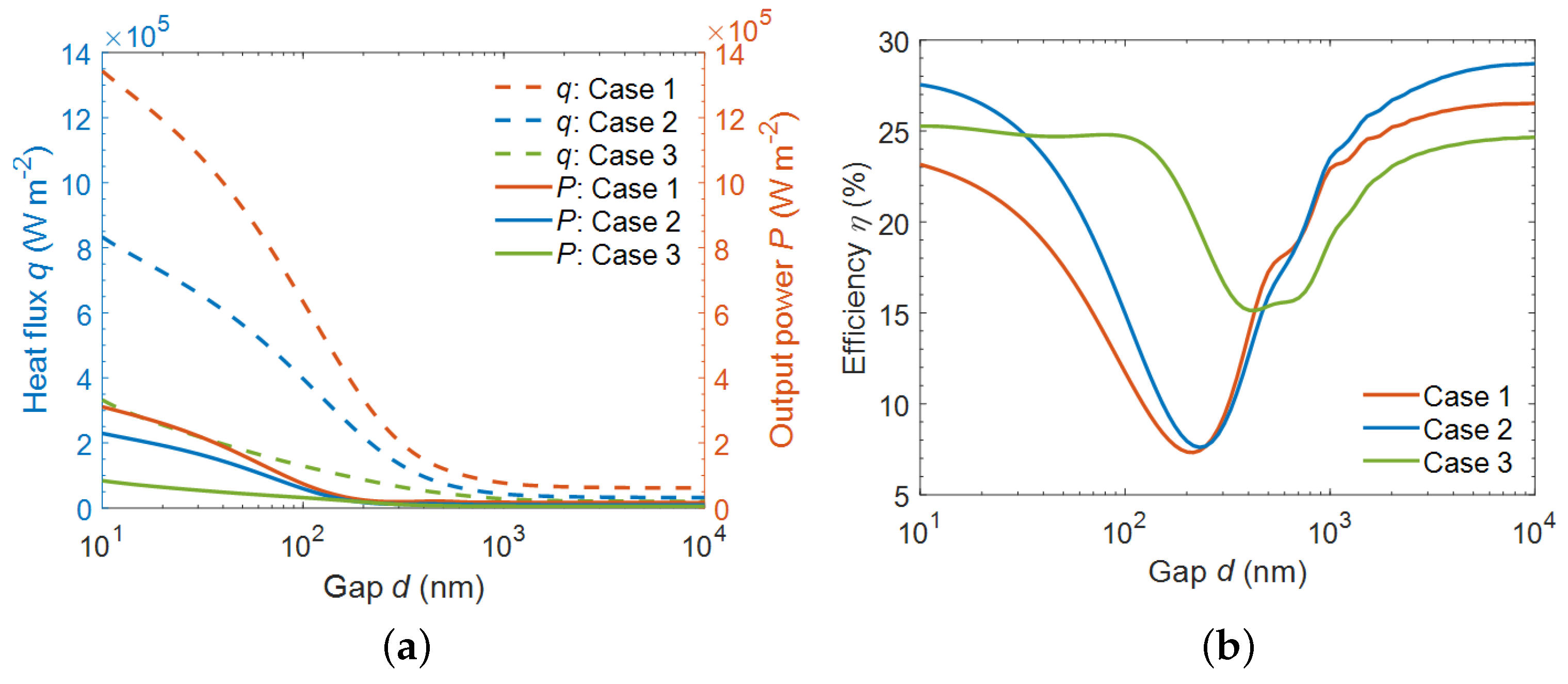

2. Theoretical Fundamentals for Analyzing Near-Field TPVs

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gamel, M.M.A.; Lee, H.J.; Rashid, W.E.S.W.A.; Ker, P.J.; Yau, L.K.; Hannan, M.A.; Jamaludin, M. A Review on Thermophotovoltaic Cell and Its Applications in Energy Conversion: Issues and Recommendations. Materials 2021, 14, 4944. [Google Scholar] [CrossRef] [PubMed]

- Ghanekar, A.; Lin, L.; Zheng, Y. Novel and efficient Mie-metamaterial thermal emitter for thermophotovoltaic systems. Optics Express 2016, 24, A868–A877. [Google Scholar] [CrossRef] [PubMed]

- Basu, S.; Chen, Y.B.; Zhang, Z. Microscale radiation in thermophotovoltaic devices—A review. Int. J. Energy Res. 2007, 31, 689–716. [Google Scholar] [CrossRef]

- Bauer, T. Thermophotovoltaics: Basic Principles and Critical Aspects of System Design; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Chen, Z.; Adair, P.L.; Rose, M. Investigation of energy conversion in TPV power generation prototype using blackbody/selective emitters. In Proceedings of the IECEC-97 Proceedings of the Thirty-Second Intersociety Energy Conversion Engineering Conference, Honolulu, HI, USA, 27 July–1 August 1997; Volume 2, pp. 1097–1100. [Google Scholar]

- Ferrari, C.; Melino, F.; Pinelli, M.; Spina, P.R.; Venturini, M. Overview and status of thermophotovoltaic systems. Energy Procedia 2014, 45, 160–169. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Z.; Sakr, E.; Sun, Y.; Bermel, P. Solar thermophotovoltaics: Reshaping the solar spectrum. Nanophotonics 2016, 5, 1–21. [Google Scholar] [CrossRef]

- Xuan, Y.; Chen, X.; Han, Y. Design and analysis of solar thermophotovoltaic systems. Renew. Energy 2011, 36, 374–387. [Google Scholar] [CrossRef]

- De Pascale, A.; Ferrari, C.; Melino, F.; Morini, M.; Pinelli, M. Integration between a thermophotovoltaic generator and an Organic Rankine Cycle. Appl. Energy 2012, 97, 695–703. [Google Scholar] [CrossRef]

- Chan, W.R.; Stelmakh, V.; Waits, C.M.; Soljacic, M.; Joannopoulos, J.D.; Celanovic, I. Photonic Crystal Enabled Thermophotovoltaics for a Portable Microgenerator. J. Phys. Conf. Ser. 2015, 660, 012069. [Google Scholar] [CrossRef] [Green Version]

- Utlu, Z.; Parali, U. Investigation of the potential of thermophotovoltaic heat recovery for the Turkish industrial sector. Energy Convers. Manag. 2013, 74, 308–322. [Google Scholar] [CrossRef]

- Bauer, T.; Forbes, I.; Pearsall, N. The potential of thermophotovoltaic heat recovery for the UK industry. Int. J. Ambient. Energy 2004, 25, 19–25. [Google Scholar] [CrossRef]

- Datas, A.; Martí, A. Thermophotovoltaic energy in space applications: Review and future potential. Solar Energy Mater. Sol. Cells 2017, 161, 285–296. [Google Scholar] [CrossRef]

- Wang, X.; Liang, R.; Fisher, P.; Chan, W.; Xu, J. Radioisotope thermophotovoltaic generator design methods and performance estimates for space missions. J. Propuls. Power 2020, 36, 593–603. [Google Scholar] [CrossRef]

- Datas, A.; Ramos, A.; Martí, A.; del Cañizo, C.; Luque, A. Ultra high temperature latent heat energy storage and thermophotovoltaic energy conversion. Energy 2016, 107, 542–549. [Google Scholar] [CrossRef] [Green Version]

- Amy, C.; Seyf, H.R.; Steiner, M.A.; Friedman, D.J.; Henry, A. Thermal energy grid storage using multi-junction photovoltaics. Energy Environ. Sci. 2019, 12, 334–343. [Google Scholar] [CrossRef] [Green Version]

- Chubb, D. Fundamentals of Thermophotovoltaic Energy Conversion; Elsevier: Amsterdam, The Netherlands, 2007. [Google Scholar]

- DeMeo, D.F.; Licht, A.S.; Shemelya, C.M.; Downs, C.M.; Vandervelde, T.E. Thermophotovoltaics: An alternative to and potential partner with rectenna energy harvesters. In Rectenna Solar Cells; Springer: Berlin/Heidelberg, Germany, 2013; pp. 371–390. [Google Scholar]

- Tian, Y.; Ghanekar, A.; Ricci, M.; Hyde, M.; Gregory, O.; Zheng, Y. A review of tunable wavelength selectivity of metamaterials in near-field and far-field radiative thermal transport. Materials 2018, 11, 862. [Google Scholar] [CrossRef] [Green Version]

- Sakakibara, R.; Stelmakh, V.; Chan, W.R.; Ghebrebrhan, M.; Joannopoulos, J.D.; Soljacic, M.; Čelanović, I. Practical emitters for thermophotovoltaics: A review. J. Photonics Energy 2019, 9, 032713. [Google Scholar] [CrossRef] [Green Version]

- Nielsen, O.M.; Arana, L.R.; Baertsch, C.D.; Jensen, K.F.; Schmidt, M.A. A thermophotovoltaic micro-generator for portable power applications. In Proceedings of the 12th International Conference on Solid-State Sensors, Actuators and Microsystems, Boston, MA, USA, 9–12 June 2003; Volume 1, pp. 714–717. [Google Scholar]

- Fraas, L.; Samaras, J.; Avery, J.; Minkin, L. Antireflection coated refractory metal matched emitters for use with GaSb thermophotovoltaic generators. In Proceedings of the Conference Record of the Twenty-Eighth IEEE Photovoltaic Specialists Conference-2000, Anchorage, AK, USA, 15–22 September 2000; pp. 1020–1023. [Google Scholar]

- Bitnar, B.; Durisch, W.; Mayor, J.C.; Sigg, H.; Tschudi, H. Characterisation of rare earth selective emitters for thermophotovoltaic applications. Sol. Energy Mater. Sol. Cells 2002, 73, 221–234. [Google Scholar] [CrossRef]

- Bierman, D.M.; Lenert, A.; Chan, W.R.; Bhatia, B.; Celanović, I.; Soljačić, M.; Wang, E.N. Enhanced photovoltaic energy conversion using thermally based spectral shaping. Nat. Energy 2016, 1, 16068. [Google Scholar] [CrossRef]

- Lenert, A.; Bierman, D.M.; Nam, Y.; Chan, W.R.; Celanović, I.; Soljačić, M.; Wang, E.N. A nanophotonic solar thermophotovoltaic device. Nat. Nanotechnol. 2014, 9, 126–130. [Google Scholar] [CrossRef]

- Chan, W.R.; Stelmakh, V.; Ghebrebrhan, M.; Soljačić, M.; Joannopoulos, J.D.; Čelanović, I. Enabling efficient heat-to-electricity generation at the mesoscale. Energy Environ. Sci. 2017, 10, 1367–1371. [Google Scholar] [CrossRef]

- Rinnerbauer, V.; Lenert, A.; Bierman, D.M.; Yeng, Y.X.; Chan, W.R.; Geil, R.D.; Senkevich, J.J.; Joannopoulos, J.D.; Wang, E.N.; Soljačić, M.; et al. Metallic photonic crystal absorber-emitter for efficient spectral control in high-temperature solar thermophotovoltaics. Adv. Energy Mater. 2014, 4, 1400334. [Google Scholar] [CrossRef]

- Kohiyama, A.; Shimizu, M.; Yugami, H. Unidirectional radiative heat transfer with a spectrally selective planar absorber/emitter for high-efficiency solar thermophotovoltaic systems. Appl. Phys. Express 2016, 9, 112302. [Google Scholar] [CrossRef] [Green Version]

- Shimizu, M.; Kohiyama, A.; Yugami, H. High-efficiency solar-thermophotovoltaic system equipped with a monolithic planar selective absorber/emitter. J. Photonics Energy 2015, 5, 053099. [Google Scholar] [CrossRef]

- Heidarzadeh, H.; Baghban, H.; Rasooli, H.; Dolatyari, M.; Rostami, A. A new proposal for Si tandem solar cell: Significant efficiency enhancement in 3C–SiC/Si. Optik 2014, 125, 1292–1296. [Google Scholar] [CrossRef]

- Foisal, A.R.M.; Nguyen, T.; Dinh, T.; Nguyen, T.K.; Tanner, P.; Streed, E.W.; Dao, D.V. 3C-SiC/Si heterostructure: An excellent platform for position-sensitive detectors based on photovoltaic effect. ACS Appl. Mater. Interfaces 2019, 11, 40980–40987. [Google Scholar] [CrossRef]

- Foisal, A.R.M.; Dinh, T.; Tanner, P.; Phan, H.P.; Nguyen, T.K.; Streed, E.W.; Dao, D.V. Photoresponse of a highly-rectifying 3C-SiC/Si heterostructure under UV and visible illuminations. IEEE Electron Device Lett. 2018, 39, 1219–1222. [Google Scholar] [CrossRef]

- Narayanaswamy, A.; Zheng, Y. A Green’s function formalism of energy and momentum transfer in fluctuational electrodynamics. J. Quant. Spectrosc. Radiat. Transf. 2014, 132, 12–21. [Google Scholar] [CrossRef] [Green Version]

- Raguin, D.H.; Morris, G.M. Antireflection structured surfaces for the infrared spectral region. Appl. Opt. 1993, 32, 1154–1167. [Google Scholar] [CrossRef]

- Chen, Y.B.; Zhang, Z.; Timans, P. Radiative Properties of Patterned Wafers with Nanoscale Linewidth. J. Heat Transf. 2007, 129, 79–90. [Google Scholar] [CrossRef]

- Park, K.; Basu, S.; King, W.; Zhang, Z. Performance analysis of near-field thermophotovoltaic devices considering absorption distribution. J. Quant. Spectrosc. Radiat. Transf. 2008, 2, 305–316. [Google Scholar] [CrossRef]

- Foisal, A.R.M.; Dinh, T.; Nguyen, V.T.; Tanner, P.; Phan, H.P.; Nguyen, T.K.; Haylock, B.; Streed, E.W.; Lobino, M.; Dao, D.V. Self-powered broadband (UV-NIR) photodetector based on 3C-SiC/Si heterojunction. IEEE Trans. Electron Devices 2019, 66, 1804–1809. [Google Scholar] [CrossRef]

- Singh, P.; Ravindra, N.M. Temperature dependence of solar cell performance—an analysis. Sol. Energy Mater. Sol. Cells 2012, 101, 36–45. [Google Scholar] [CrossRef]

- Kabe, M.D.; Lare, Y.; Ottaviani, L.; Pasquinelli, M.; Barakel, D.; Portail, M. Simulation and optimization of the nSiC layer’ s thickness in a nSiC/pSi photovoltaic cell. OAJ Mater. Devices 2019, 4, 1. [Google Scholar] [CrossRef]

- Tong, J.K.; Hsu, W.C.; Huang, Y.; Boriskina, S.V.; Chen, G. Thin-film ‘thermal well’emitters and absorbers for high-efficiency thermophotovoltaics. Sci. Rep. 2015, 5, 10661. [Google Scholar] [CrossRef] [PubMed]

| Emitter | (V) | FF (%) | q | P | (%) | |

|---|---|---|---|---|---|---|

| (A m, ) | (W m, ) | (W m, ) | ||||

| Case 1 (BC/BC) | 7.74 | 1.19 | 81.08 | 6.34 | 7.45 | 11.74 |

| Case 2 (BC/SiC) | 6.26 | 1.17 | 80.94 | 3.97 | 5.95 | 14.96 |

| Case 3 (BC/BeO) | 3.47 | 1.14 | 80.54 | 1.29 | 3.19 | 24.69 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, F.; Liu, X.; Tian, Y.; Goldsby, J.; Zheng, Y. Refractory All-Ceramic Thermal Emitter for High-Temperature Near-Field Thermophotovoltaics. Energies 2022, 15, 1830. https://doi.org/10.3390/en15051830

Chen F, Liu X, Tian Y, Goldsby J, Zheng Y. Refractory All-Ceramic Thermal Emitter for High-Temperature Near-Field Thermophotovoltaics. Energies. 2022; 15(5):1830. https://doi.org/10.3390/en15051830

Chicago/Turabian StyleChen, Fangqi, Xiaojie Liu, Yanpei Tian, Jon Goldsby, and Yi Zheng. 2022. "Refractory All-Ceramic Thermal Emitter for High-Temperature Near-Field Thermophotovoltaics" Energies 15, no. 5: 1830. https://doi.org/10.3390/en15051830

APA StyleChen, F., Liu, X., Tian, Y., Goldsby, J., & Zheng, Y. (2022). Refractory All-Ceramic Thermal Emitter for High-Temperature Near-Field Thermophotovoltaics. Energies, 15(5), 1830. https://doi.org/10.3390/en15051830