1. Introduction

Despite the development of steelmaking technology, the integrated steelmaking process (BF-BOF) will remain the leading steelmaking process and in the next dozen or so years [

1,

2,

3]. Therefore, the production of coke, which is an essential and necessary raw material for this process, is also of key importance. Currently, coke oven technologies are being developed all over the world to improve the economy and ecology of coke production. The industrial implementation of the coke production process consists of high-temperature degassing of the coal charge without air access in the coke oven batteries. Coke-making technology utilises two systems for charging the coke oven chambers with coal: a stamp-charged system (stamp-charging) and a gravity charged system (top charging). In the top charged system, the coke chambers are filled with the coal blend through gravity. Coal in the tanks located on the charging car is poured into the coking chamber through special openings (charging holes) located in the roof of the battery. In the case of the stamp-charged method, the coal charge (coal cake) is formed in the steel box of the stamping-charging-pushing (SCP) car via a set of stampers and introduced into the coking chamber through a door opening on the machine side of the battery. Due to the increased density of the coal charge in relation to the top charging system (increase by approx. 30–35%), the use of this method enables coke production with enhanced quality of parameters from lower-quality coal blend or obtaining the same quality with an increased amount of inferior coals (sometimes not even coking coals). Additionally, it is vital, due to shortage of the best coking coals on the world market. Therefore, the European Union included coking coal on the list of critical raw materials, due to its importance in the functioning and economic development of the European Union [

4].

Hence, effective management of this scarce raw material with the need to maintain the highest possible economic and ecological efficiency of coke production is very important. Therefore, the technological development of the coke-making industry in recent years has been focused on processes that increase the density of the coal charge, including stamp charging technology [

5]. Japan, whose coke-making industry is considered to be the most modern in the world, has only recently announced the construction of the first stamp-charged coke oven battery, which will be implemented by JFE Steel Corporation 2025 [

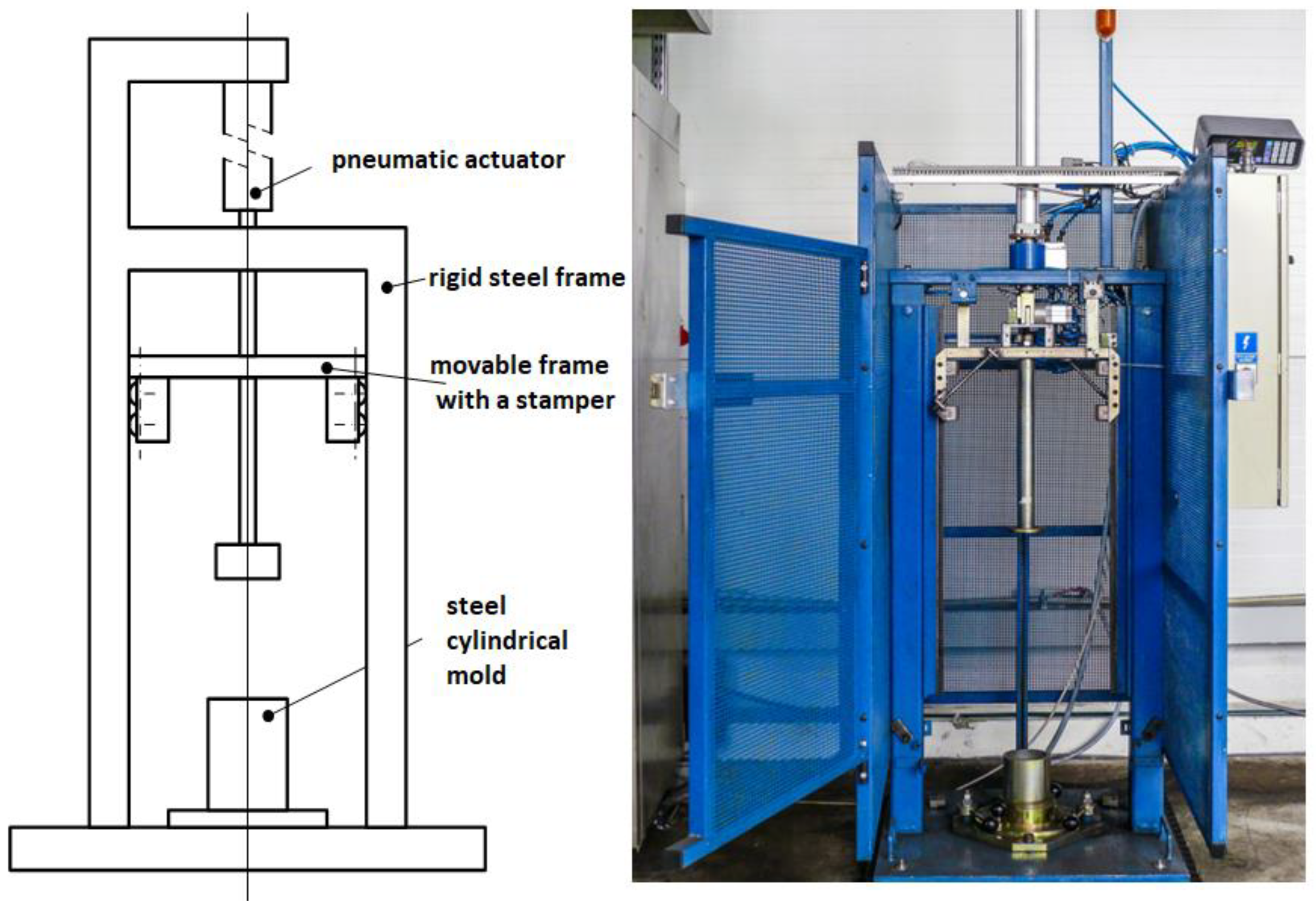

6]. A general view of the stamp-charged coke battery is shown in

Figure 1.

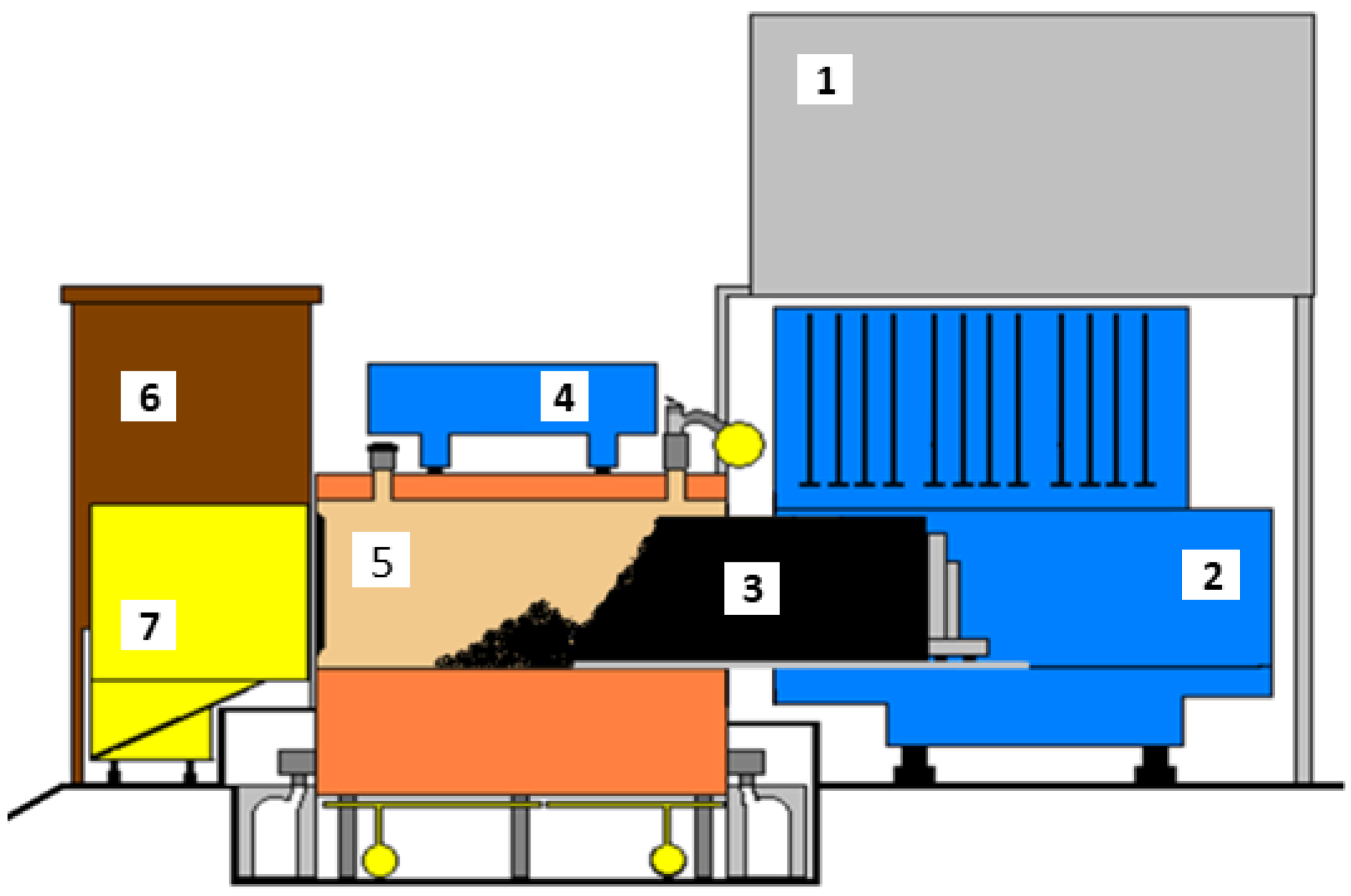

The main goal in the industrial process of preparation of stamped coal charges is to obtain the appropriate density of the charge, ensuring its trouble-free loading into the coking chamber. This guarantees the proper productivity of the chamber and obtaining coke of uniform, assumed quality. The necessary condition for the use of the stamped charge method is the appropriate compactness and mechanical strength of the charge (coal cake), preventing it from falling apart while filling the chamber (

Figure 2). Damage to the coal cake during filling causes considerable operational and environmental difficulties (fugitive emission) and reduces the productivity of the coking chamber. The weight of damaged coal cake usually ranges from several dozen kilograms to several tons. The stamped coal cake should withstand the loads resulting from its own weight; therefore, its maximum height is closely related to its mechanical strength. This is particularly important in the case of batteries with large-capacity chambers (only such types of batteries have been built in recent years), due to the greater height of the compacted charge, and thus its greater weight. Across the literature, there are several reports that examine the influence of certain factors on the obtained density of the coal cake. The final density of coal cake is primarily determined by the cumulative stamping energy and the properties of the coal blend used (crushing fineness, moisture content, properties of coal raw material). Research on the preparation of stamped charge has been conducted in India, Germany, Turkey and Poland. [

7,

8,

9,

10,

11,

12]. This work led to the identification of relevant factors influencing the density of the coal charge. Kuyumcu and Sander [

7] proposed an equation that describes the dependence of the charge density on the cumulative stamping energy, the initial density of the coal sample before stamping and its stampability index K. The introduced K index characterizes coal susceptibility to stamping (compaction). An empirical model of the influence of selected factors on the value of the stampability index K was also proposed (including HGI; parameters of the RRSB (Rosin–Rammler–Sperling–Bennett) equation d‘ and n; moisture content). According to the authors, depending on the properties of stamped coal, under the same conditions of the stamping process, different coal cake density and mechanical strength were obtained. Its strength increases linearly with its density. The authors concluded that there is an optimal moisture content (W

opt) for which the stamped coal cake achieves maximum density.

In work described in ref. [

10], it was stated that the moisture content in the coal charge in the range of 6.2–12.6% increased, which increased its density by 5.8% in wet basis and by 3.2% in dry basis. When the crushing fineness of the charge was increased (expressed by the content of the grain class <3.2 mm from 80% to 90%), a decrease in charge density from 1195 to 1145 kg/m

3 occurred. As the content of the dust fraction <0.5 mm increased from 20% to 70%, a reduction in charge density by 70 kg/m

3—from 1190 to 1120 kg/m

3 was observed. At a certain stamping energy, a coal cake with a density varying depending on the properties of the coal was achieved. The obtained results allowed the authors to determine seven regression equations that described the dependence of the density of the coal cake on such properties of coal, including volatile matter, ash content, true density and HGI. The coefficients of determination R

2 of the individual equations were within the range of 0.71–0.77. According to the authors, an increase in the specific gravity and ash content caused an increase in the density of the coal cake, while an increase in volatile matter and HGI (Hardgrove Grindability Index) resulted in reduced density.

In work described by ref. [

11], the influence of selected parameters (i.e., stamping energy, coal type, moisture content and crushing fineness) on coal cake density and mechanical strength was evaluated. It was observed that an increase in the moisture content positively influenced both the wet and dry bulk density of the coal cake. Additionally, for higher rank coals, greater coal cake density was obtained at constant stamping energy. The level of moisture content in coal charge, which provided the maximum strength of cake, was within the range of 8.5–10%. An increase in the density of the stamped coal cake with an increase in moisture content and a decrease in crushing fineness was also noted in work [

13]. A positive effect of increased crushing fineness on shear strength was also noted, with the highest shear strength observed for 11% moisture content (regardless of crushing fineness level).

Knowledge about the achieved coal cake density is crucial for the industrial production of coke in stamp-charged coke oven batteries. The importance of this parameter is also evidenced by attempts to measure the achieved density on an industrial scale with the use of various techniques, such as GPR (Ground Penetrating Radar), ultrasound or force sensors [

13,

14,

15,

16]. However, they have yet to be implemented on an industrial scale. Currently, drilling rigs are used for measurement, where a specific volume of coal (cylindrical sample) is cut out (from different places of the compacted charge). A coal sample can also be taken by inserting (punching) a cylindrical steel mould with a calibrated volume [

13]. The quotient of the mass of the cut coal and the volume of the drilling rig allows to estimate the density. Another approach is to measure the mass of the total compacted coal cake and the volume of the cartridge. Currently, industrial control of the stamped cake is carried out relatively rarely due to its labour-intensive and time-consuming nature.

To the best of our knowledge, there is minimal information in the literature regarding stamped coal cake preparation that would allow the estimation of the impact of the most frequently assessed parameters of the coal blends (by technologists at the coking plant) on coal cake density with relatively good accuracy.

This is particularly important nowadays, due to frequent changes in the composition of coal blends for the production of coke (global coal imports of varying parameters), caused by the limited availability of the best coals. In industrial practice of coal cake preparation, the most frequently assessed parameters of coking blends directed to stamping operation are volatile matter, ash, moisture content and crushing fineness. An appropriate mathematical model taking into account the abovementioned factors would help the technological staff of the coking plant in predicting the influence of the aforementioned parameters of coal on the density, as well as selecting the correct stamping energy depending on the coal blend used. The aim of the presented study was to develop an empirical model in order to predict the final density of the stamped coal cake depending on the properties of the coals used for the production of coke in the stamp-charged coke oven batteries.

3. Results and Discussion

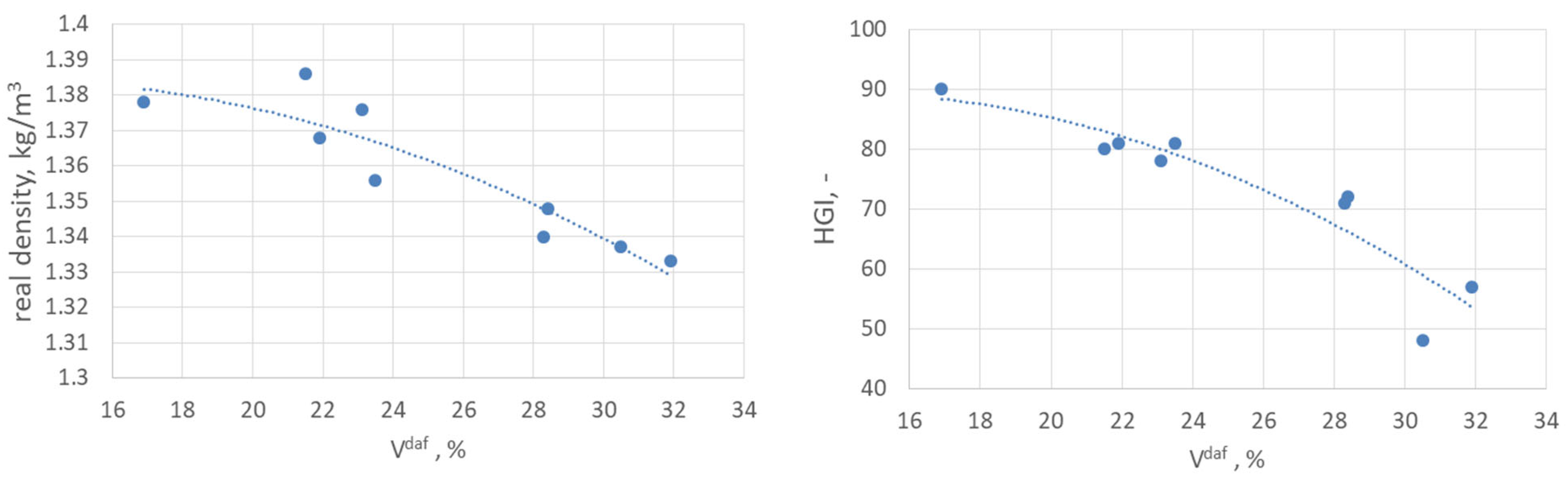

The properties of selected coals are presented in

Table 1. The selected coals reflected the types of coals used in the coke-making industry and were characterised by a wide range of volatile matter content, i.e., from 16.9% for coal no. 1 to 31.9% for coal no. 5. The ash content ranged from 4.9% (for coal no. 7) to 9.9% (for coal no. 3). The real density of coals was within a relatively narrow range, but it was well correlated with the volatile matter content in coal (

Figure 4). A similar correlation was observed for HGI value. The higher the volatile matter content, the lower the grindability (higher structural hardness), which was expressed by the HGI value. These observations were generally consistent with the literature data [

17,

18,

19,

20,

21,

22].

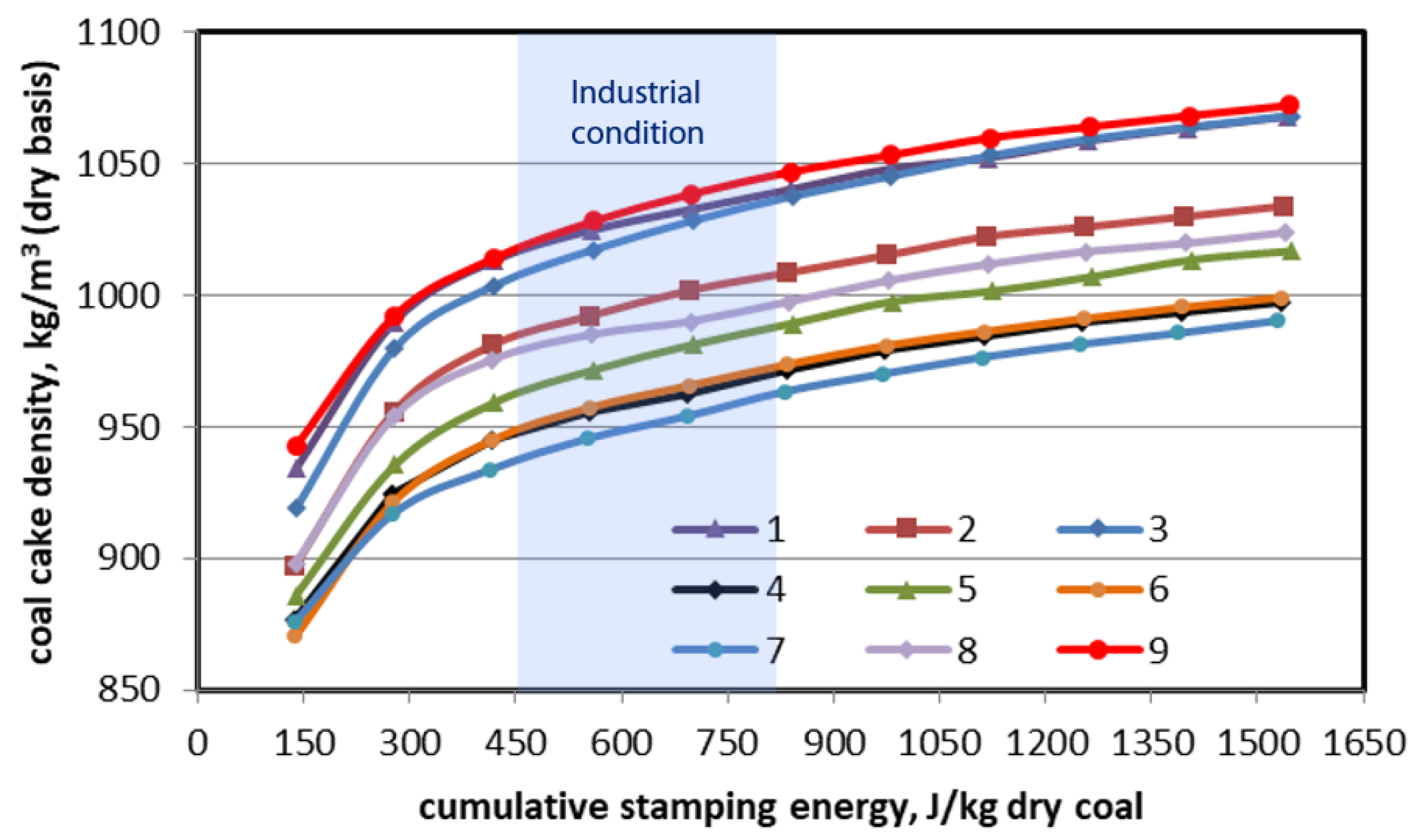

Examples of the results of the influence of the cumulative stamping energy on the obtained coal cake density (dry basis) are presented in

Figure 5. In industrial practice, it is assumed that the coal cake density at the level of 1000 kg/m

3 (dry basis), in the absence of other operational disturbances (incorrect operation of battery machines, excessive vibrations, etc.), is sufficient to ensure efficient and trouble-free loading of the coking chambers. In the case of Indian coking plants, the coal cake density is usually higher, as these use coal with a high ash content (mineral matter).

In terms of the established technological parameters of the process (moisture content and grain size), the main factor determining the mechanical strength of the coal cake is the stamping energy (the accumulated energy transferred to the coal cake in the stamping operation). Under operational conditions, the change in the stamping energy is primarily associated with the change in the time of the stamping operation, and the function of the increase in density depending on the stamping energy performed is logarithmic. The logarithmic nature of the effect of stamping energy is consistent with the results obtained in other studies [

7,

10,

11].

Coal grains under the influence of energy transmitted by the stamper at the moment of impact moved in relation to each other, successively filling the inter-grain spaces, creating a tightly packed bed. The movement of grains between themselves was facilitated by surface moisture, which minimised the forces of friction between particles. At the beginning of the stamping operation, the observed increase in density was more intense. As the density increased, and hence the degree of filling of the coal bed increased (defined as the ratio of the charge density to the actual coal density), the force (energy) necessary for further reorganization of the coal grain increased, causing a reduction in the intensity of the density growth.

The results showed that depending on the coal used, the achieved coal cake density at a specific level of the stamping energy performed differed significantly. The data on the chart clearly showed that, for some coals, the density at the level of 1000 kg/m3 was achieved at the energy of 350–400 J/kg, whereas in some cases the energy level of 1500 J/kg is insufficient. In practice, this would mean a significant extension of the stamping time and the associated increased energy consumption. In addition, a sufficiently short stamping time is necessary to ensure the proper schedule of servicing the coking chambers. For nominal battery operation, the handling time of a single oven chamber usually does not exceed 20 min (including opening the oven door, operating the ascension pipes of collecting main, pushing out the coke, cleaning the door frames, closing the door or driveway to the coal tower in order to load the coking blend). In industrial applications, single-component coals are rarely used for the production of coke. As a rule, multi-component coal blends are used; therefore, the situation described above would be an extremely rarely event. Nevertheless, the recipes for the production of different types of coke differ significantly. Foundry coke blends are characterised by a higher proportion of coals with a low volatile matters content than blends intended for blast furnace coke. In turn, blends for the production of industrial and heating coke contain a lot of coals with a high content of volatile matters. As a result, in practice, at a certain level of stamping energy, the final density of the coal cake may be different.

Based on the statistical analysis, an empirical model was developed, which facilitated the presentation of the impact of individual factors (parameters of the charge) on the density of the charcoal cake. The developed model is presented in Equation (2).

where:

ρd—stamped coal cake density, kg/m3 (dry basis)

E—cumulative stamping energy, J/kg (dry coal)

Vdaf—volatile matter content (dry ash free basis), %

Ad—ash content (dry basis), %

d′—specific diameter of coal particle (RRSB), mm

n—distribution parameter RRSB, -

—total moisture content, %.

The statistical significance of the obtained model was verified by the Fisher–Snedecor method. The significance of individual coefficients of the model was verified using the student’s

t-test. Detailed data for both analyses are presented in

Table 2. The value of the F test of the developed model was F = 670.7, with the critical value of the test F

CR (0.05; 6; 378) = 2.12, which proved the statistical significance of the obtained equation at the significance level α = 0.05 (95% confidence level). The statistical significance of individual model coefficients is evidenced by

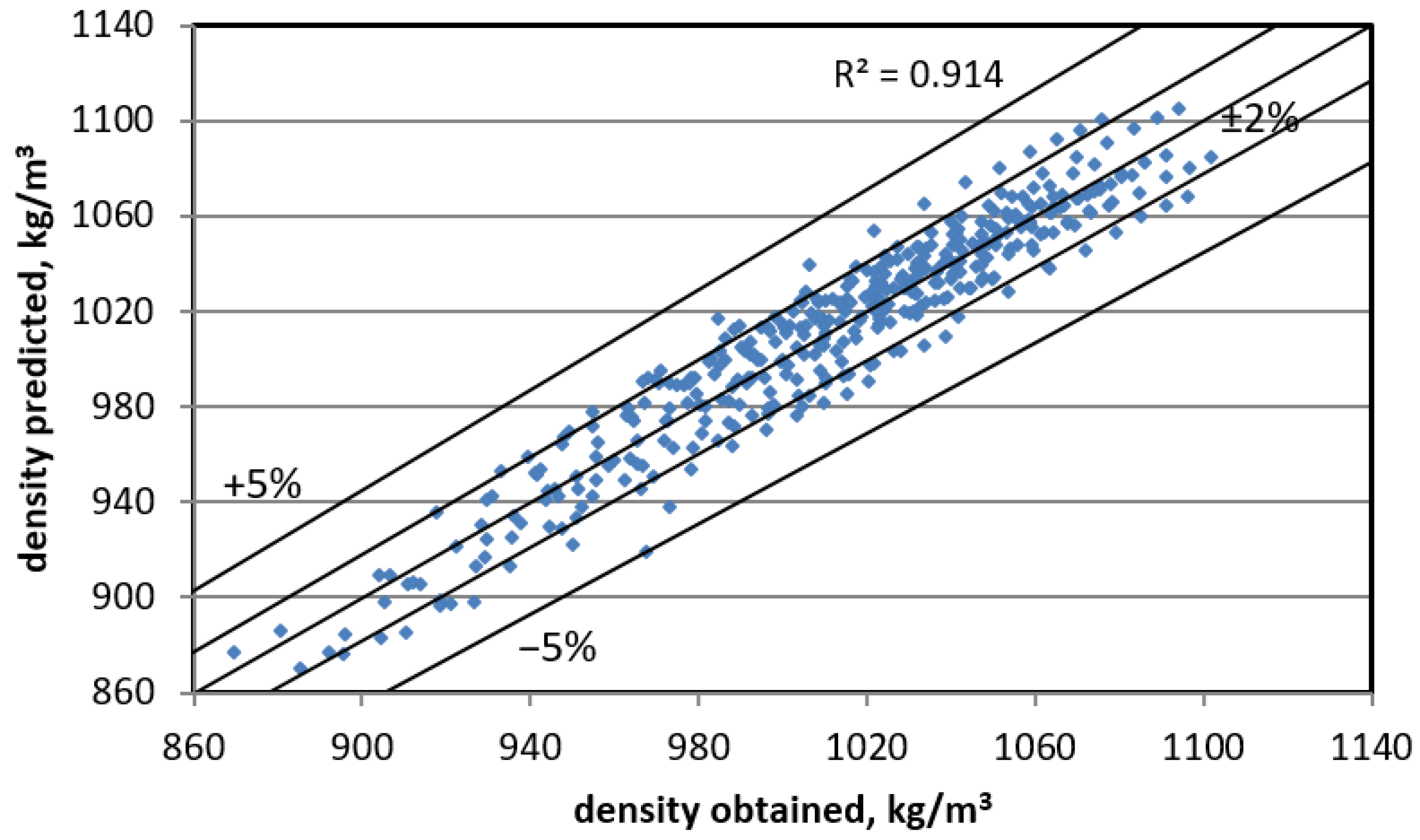

p values significantly below 0.05 (the assumed significance level). The coefficient of correlation and determination of the obtained equation were R = 0.956 and R

2 = 0.914, respectively, and the average standard error of density forecasting based on the model was 14.2 kg/m

3, which was approx. 1.4% (at a density of 1000 kg/m

3). This confirmed that the model was a very good fit. The comparison of the predicted and experimental values is presented in

Figure 6.

The developed model was utilised for easier interpretation of the influence of individual variables (parameters of the coal charge) on the density of the stamped coal cake due to the possibility of assuming a specific level of other variables (fixed values) that also influence the density where their mutual interactions could impact each other. Therefore, the data calculated by the model (2) were used to graphically present the impact of individual variables.

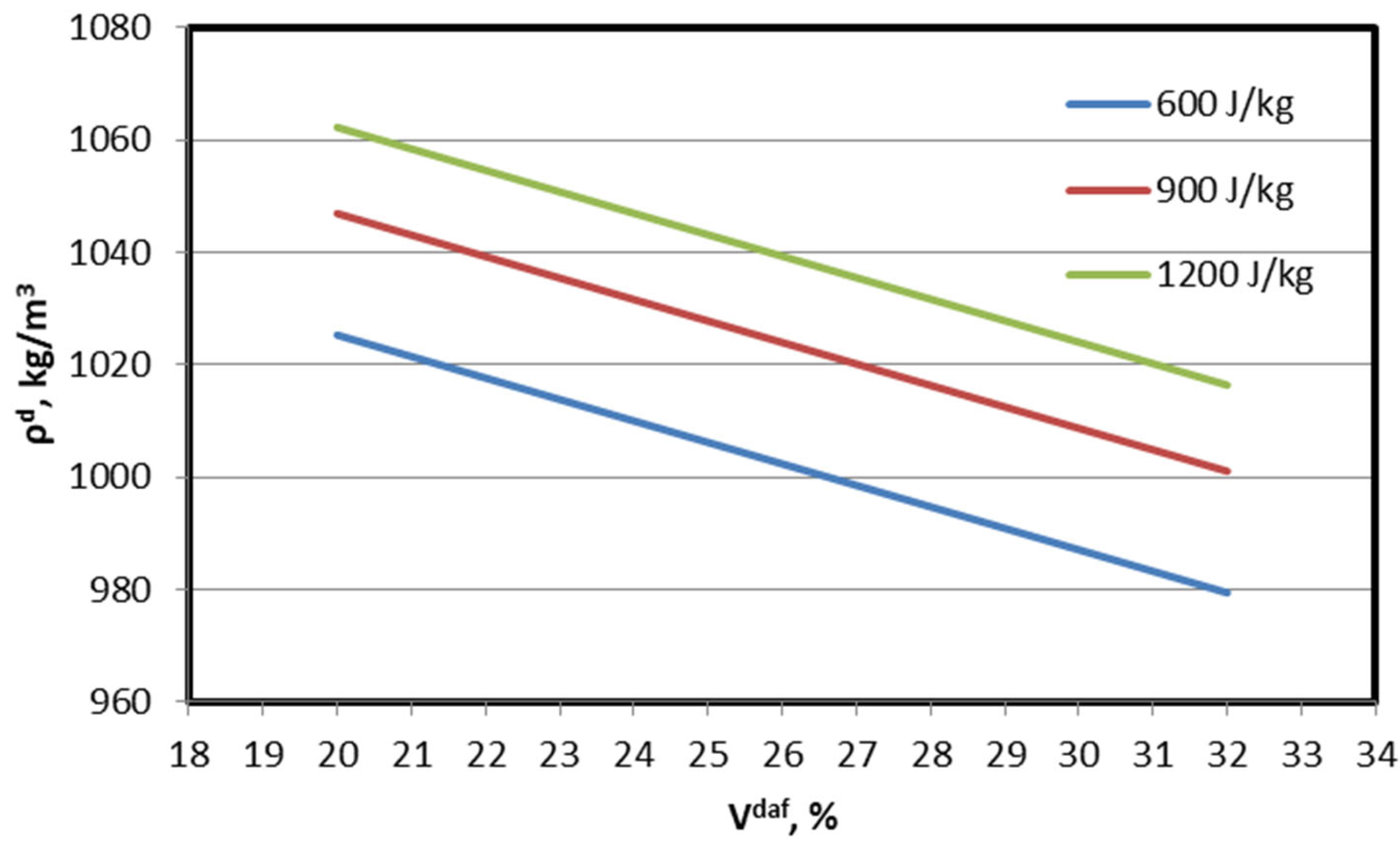

Figure 7 shows the effect of the volatile matter content on the density of the stamped coal charge at different stamping energy. A decrease in the density of the stamped coal cake was observed with increasing volatile matter content, for a given value of the stamping energy. In general, the discussed relationship was consistent with that described in the literature, in which, for coals differing in the volatile matter, higher density was achieved for coals with a lower content [

7,

10,

11]. Moreover, due to the specific feature of the coefficient of the regression equation, it is possible that for each 1% point of increase in the volatile matter content in coal (coal blend) there was a 3.82 kg/m

3 decrease in the density of the compacted charge. In addition, the obtained results show that an increase in the natural logarithm value (of the stamping energy) of 1, resulted in an increase in density by approx. 53.3 kg/m

3.

The decrease in density with an increase in the content of volatile parts may be caused by several factors, i.a., a decrease in the actual density of coal grains with increasing volatile parts (confirmed by the data shown in

Figure 4), and changes in the mechanical properties of coals expressed, for example, by their lower grinding susceptibility and by surface properties. The effect of the real density was most obvious, where a higher density of the coal particles automatically resulted in a higher density of the coal cake made of these particles. As the degree of coalification increased (decrease in volatile matters), the aromatisation of the carbon structure increased and the number of oxygen and aliphatic cross-linking bonds decreased. The aforementioned phenomenon has an impact on the mechanical properties of the carbonaceous substance (structure flexibility, susceptibility to deformation). Coking coals with a lower degree of coalification (higher volatile matters content) are usually characterised by a lower grindability (HGI), which is related to the aforementioned changes in their structure [

16]. The mechanical properties are also influenced by the content and chemical composition of the mineral matter and the petrographic composition [

18,

23]. Comparable to the grinding process, during the stamping operation, the coal grains are subjected to mechanical impact. At the moment of impact, the coal grains undergo elastoplastic deformation [

7]. In the case of coals with greater susceptibility to deformation (coals with lower volatile matter content), the grains of the coal may crumble, thereby gradually filling the inter-grain voids, leading to elevated density of the coal cake. This phenomenon in the case of coals with a lower degree of coalification (higher content of volatile matter) may occur to a lesser extent, resulting in lower density. As a result of a higher content of oxygen groups in coals with a higher content of volatile parts, their wettability is greater [

24,

25], which may also affect the strength of inter-grain interactions (liquid bridges, capillary forces), and in turn affect the coal grains’ reorganization process.

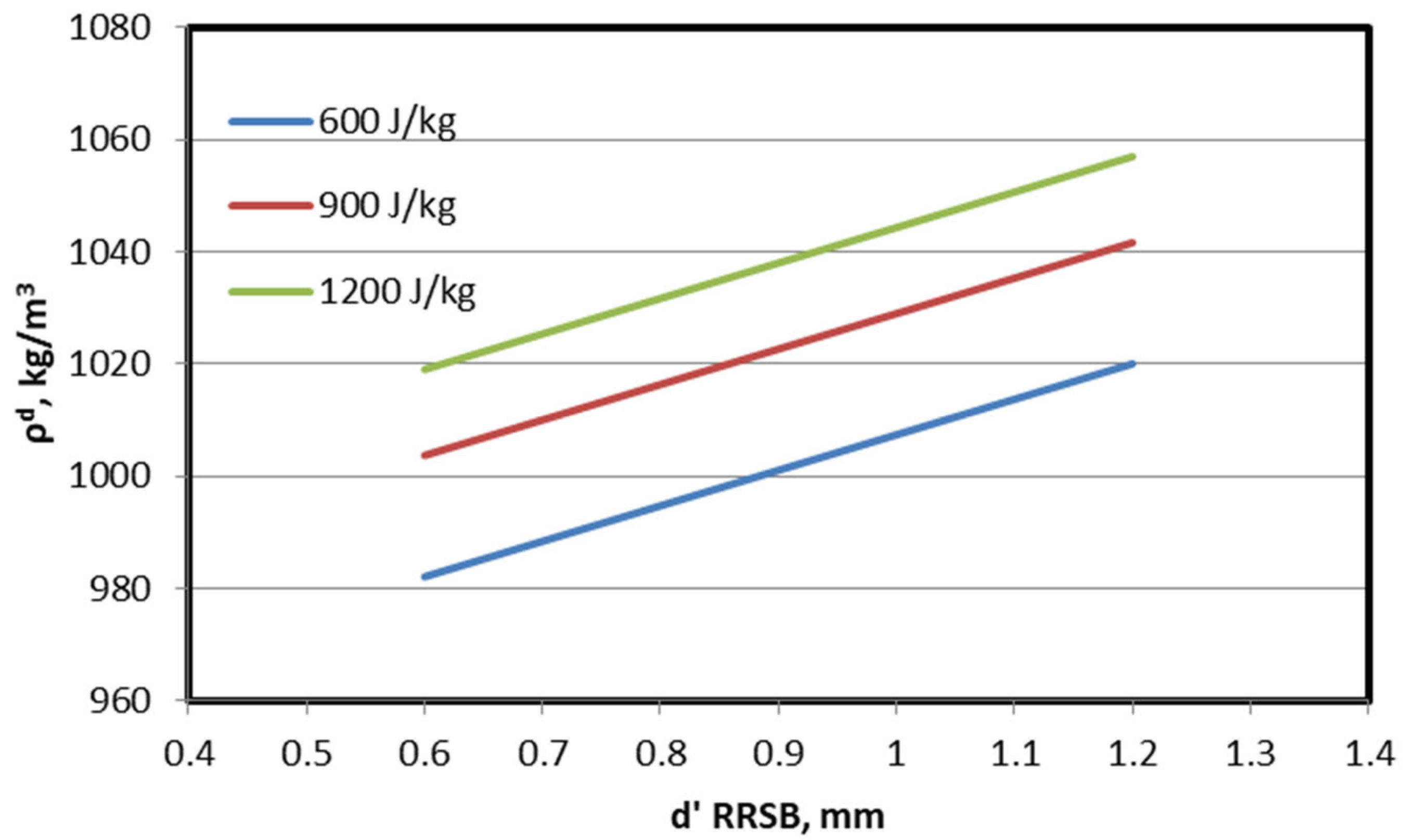

It should be noted that with the fixed moisture content of the charge and fixed stamping energy, the density of the coal cake increased with an increasing in the specific diameter d′ value. i.e., with a decrease in the crushing fineness of coal (

Figure 8). This phenomenon was probably caused by a decrease in the outer surface of coal grains (with increasing d′), which consequently promoted a decrease in the number of inter-particle contacts, as well as in the resistance of grains to move between themselves. This resulted in easier reorganisation of the coal grains and in increased density. According to the results, for every 0.1 mm increase in the specific diameter d′ value, there was approx. 6.4 kg/m

3 increase in density.

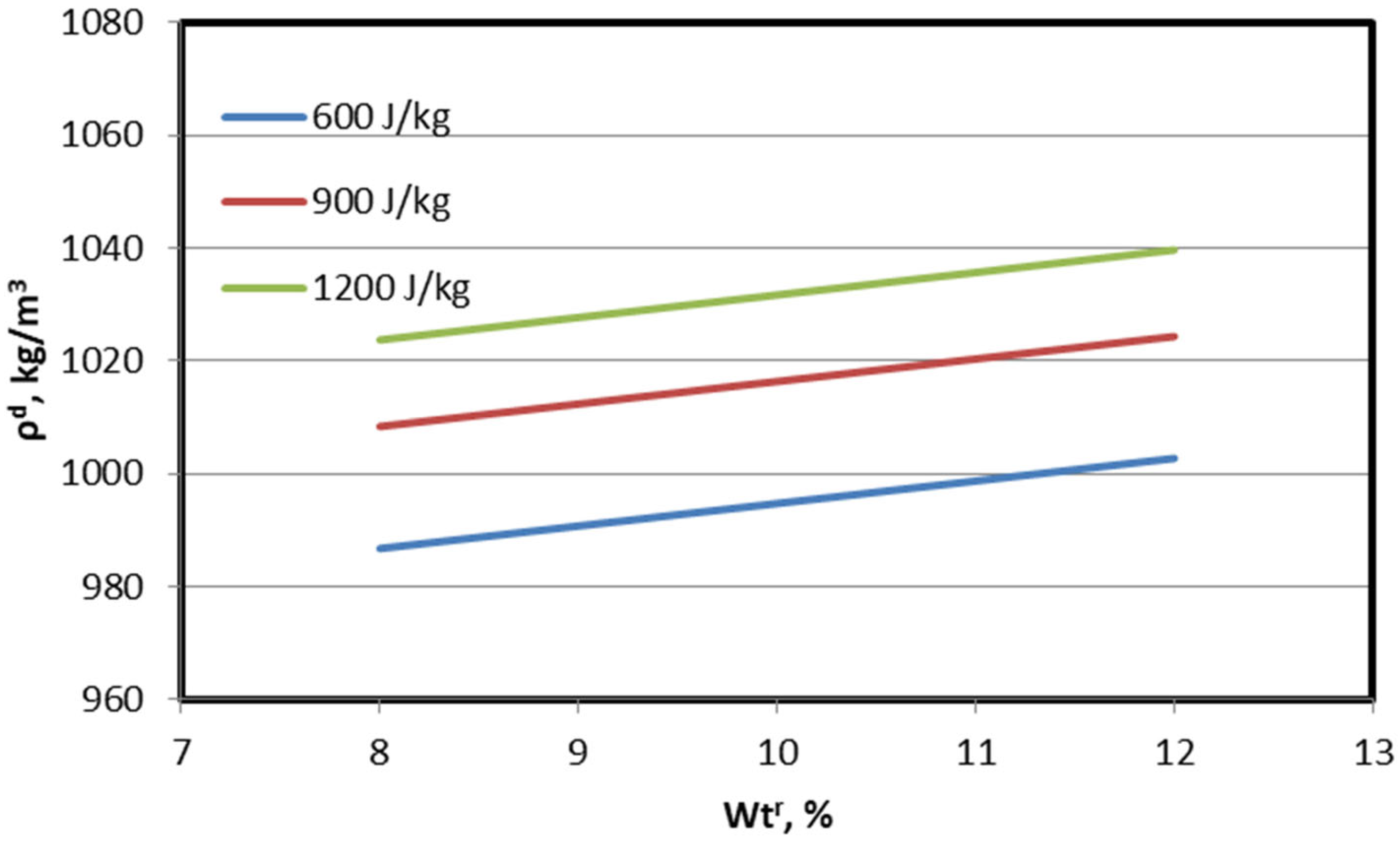

Figure 9 shows the effect of the total moisture content on the obtained density of the stamped coal cake. Water in the coal charge acts as a “lubricant” reducing the forces of friction between coal particles during the process of its densification process and the “binder”—i.e., it ensures adequate mechanical strength of the compacted coal cake [

7,

13,

22]. This is due to the occurrence of water bridges between the moistened grains of the coal cake. The increase in total moisture content in the studied range resulted in a slight increase in the density of the stamped coal cake (dry basis). For each 1% point of increase in moisture, an approx. 4 kg/m

3 increase in the density of the stamped cake was observed. However, excessive addition of moisture should not be a viable method of increasing the density due to its negative impact on the thermal balance of the process, which requires greater energy consumption for the evaporation of moisture. Additionally, excess moisture could negatively affect the refractory lining of coke oven battery chambers, causing their excessive cooling in the first phase of the coking cycle, directly after loading the coking chamber with coal blend. This could result in the formation of cracks and micro-cracks, which could lead to premature wear of the battery’s refractory lining, generation of additional operating costs (repairs) and, consequently, a shortened lifetime of the coke oven battery. From a practical point of view, an appropriate moisture content level should be kept to ensure the proper mechanical strength of the stamped coal cake. The optimal level depends on the recipe of the coal blends used, but in general it is considered that the value of 8–10% is sufficient [

11,

12].

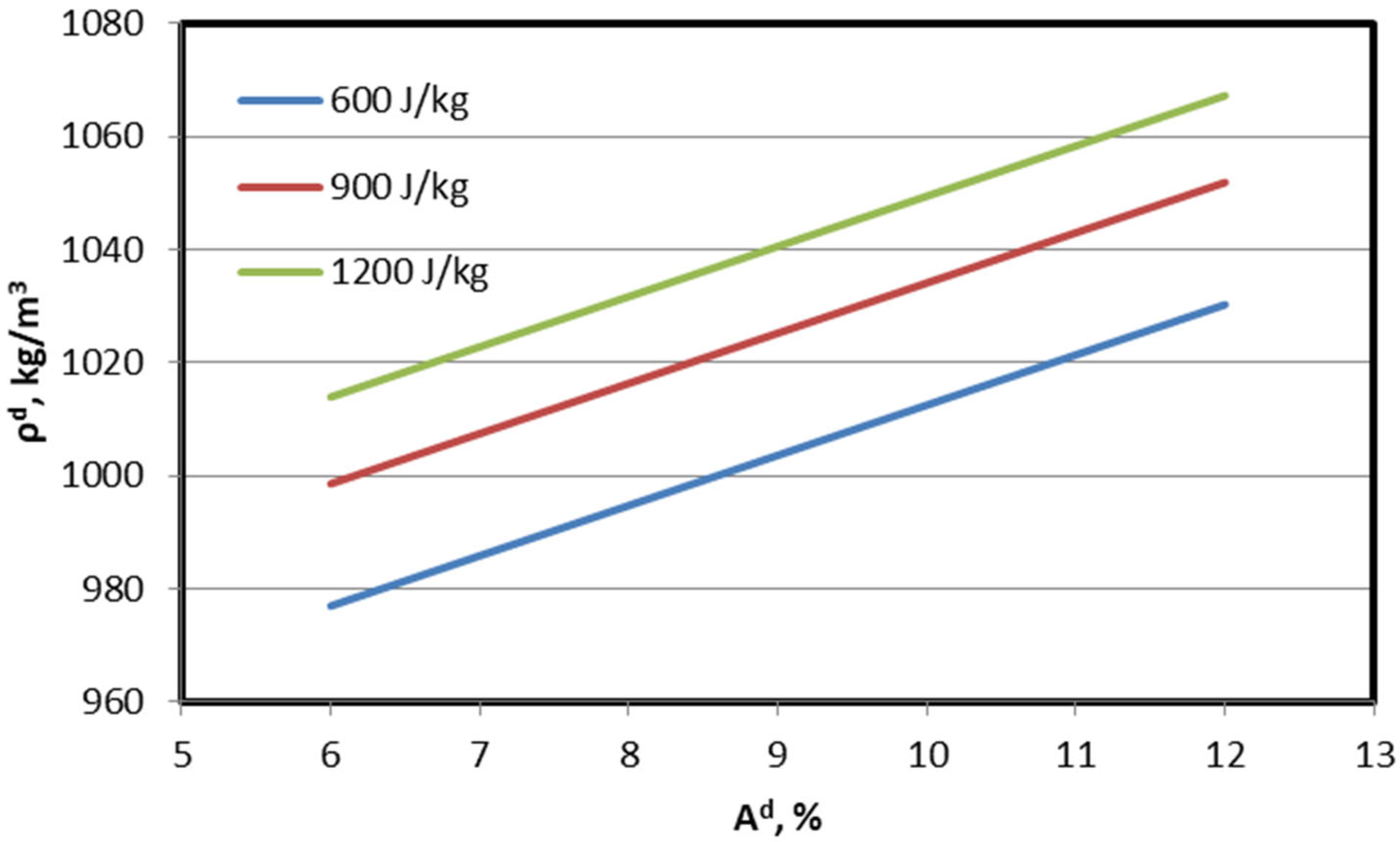

Figure 10 presents the effect of ash content on the stamped coal cake density at various cumulative stamping energy levels. In general, the ash content of the coal is some kind of reflection of the mineral matter content. However, the values of both parameters are not similar, as some components of the mineral substance (e.g., sulphides and carbonates) undergo thermal decomposition or transformations. However, as a rule, a higher ash yield means a higher mineral matter content. According to the data presented in

Figure 10, for constant stamping energy, the higher ash yield was associated with the obtainment of higher density of the compacted coal cake. For each 1% point of increase in ash content, there was an approx. 8.9 kg/m

3 increase in the density of the stamped cake. Hence, the procurement of the desired batch density (e.g., 1000 kg/m

3—dry state) using an industrial SCP machine requires less energy, i.e., a shorter amount of time. This resulted mainly from the much higher density of the components of the mineral substance rather than from the organic matter of coal. The final effect on the achieved density of the compacted charge could depend not only on the amount of the mineral substance, but also on its composition, where different components could be characterized by different densities. For example, the real density of calcite is approx. 2.6–2.8 g/cm

3, quartz’s is approx. 2.65 g/cm

3, pyrite’s approx. 5–5.2 g/cm

3, hematite’s approx. 5.2–5.3 g/cm

3 and dolomite’s approx. 3.7–3.9 g/cm

3 [

22]. The real density of the organic matter of coal is approx. 1.3 g/cm

3, which is a value several times lower. Optimisation of the density of the compacted charge (and thus the coke yield) through adjustment of the ash content in the coke blend can carry a considerable risk. Some of mineral matter compounds (mainly alkaline) exhibit a catalytic effect on the Boudouard reactions [

26,

27,

28], which may result in an increase in the reactivity of coke towards carbon dioxide (CRI) and a decrease in its CSR strength. Moreover, the higher density of the stamped coal cake due to the higher ash content does not always mean a higher degree of compaction of the stamped cake (relative density, RD), defined as the ratio of the obtained density to the real density. Consequently, it may also affect both the mechanical strength of the compacted charge and the quality of the coke. In the work described in ref. [

29], despite the increase in density caused by a higher ash content, reduction in the relative density occurred; hence, the mineral substance was harder to compress than pure coal. In our case, however, an inverse relationship was observed (

Figure 11), which proved a higher degree of packing of coal grains.

The difference in results may stem from variation in the composition of the mineral substance of the coals compared to the coals tested in ref. [

29], which may be related to their different compression susceptibility and the resistance of the coal to mechanical impact, expressed, for example, by the HGI value. Reported studies on the effect of ash content revealed positive [

23,

30], negative [

31] and neutral impact [

18] of its content on the HGI value. This proved that depending on the tested coal population, which differs in the content and composition of the mineral substance (ash), its impact on the mechanical properties may be different.

Summing up, the developed model is a helpful tool for the technological staff of coking plants to forecast the impact of the basic, most frequently assessed coal properties on the density of the compacted charge. On its basis, the energy necessary to achieve the desired density of the coal cake can be determined, and determination of technical parameters of the stamping devices (weight and number of stampers, drop height) allows the exact stamping time to be assessed. In order for the model to be used, for example, as an element of the algorithm controlling the operation of the stamping device, the model must be properly scaled to industrial conditions because the density obtained under laboratory conditions may differ from that obtained under industrial conditions. Differences in the density of the coal cake obtained under both conditions may result primarily from a physical and mechanical nature, i.e., different propagation of mechanical stresses (arising during the stamping operation) in the full volume of the coal cake, and lower rigidity of the industrial stamping steel box compared to the steel laboratory mould, causing its deformation and, consequently, a change in volume. It would also be beneficial to validate the model for the coals used in a given coking plant.

Industrial optimisation of coking blend preparation is a complex process. On the one hand, it is necessary to ensure the proper coal cake density, its mechanical strength and quality of the coke obtained. On the other hand, it is also necessary to ensure effective and trouble-free operation of all technological nodes of the coking plant. Therefore, during optimisation works related to coal coking blend parameters, all the aforementioned factors should be taken into account.