1.1. Background and Literature Review

Today, the earth faces a significant environmental problem, which is global warming. Renewable energy is one of the best ways to solve this problem. After the Great East Japan Earthquake, the share of nuclear electricity in Japan has decreased significantly [

1]. This is because the public’s concern about nuclear power plants has risen due to the nuclear accident. As a result, the dependence on thermal power generation has increased. However, Japan lacks energy resources; its energy self-sufficiency rate is meager compared to that of other OECD countries [

2,

3].

In 2013, the Japanese government promoted an initiative (3E + S) to achieve energy security, economic efficiency, and environmental compatibility, with safety as a priority [

2]. According to this plan, the desirable future energy mix in 2030 is as represented in

Figure 1.

As shown in

Figure 1, renewable energy is an effective countermeasure to increase energy resilience in Japan. For the current electricity market in Japan, renewable energy sources (RES) utilization mostly focuses on individual power sources, including solar photovoltaic systems, wind turbines, micro-hydropower, etc. However, the big concern with RES is their intermittency due to dependence on uncertain climate conditions [

4]. Consequently, reliance on an individual power system can result in over-sizing of the system and also a significant rise in the total cost of the system. The hybridization of variable renewables can allow for smooth, durable, and reliable output to power grids to improve the safety, reliability, and stability of dispatched power, which is cheaper than investing in single renewable technologies [

5,

6,

7]. Numerous scholars have focused on optimal designing and planning of the hybrid renewable energy systems (HRES) in Japan. Yoshida and Farzaneh applied the particle swarm optimization (PSO) method to find the optimal configuration of a stand-alone microgrid (Photovoltaic (PV)/wind/battery/diesel) used in providing the required electricity for the residential area in Fukuoka [

8]. Takatsu and Farzaneh proposed a hybrid hydrogen-based microgrid, consisting of a biomass supercritical gasifier and a solar water electrolyzer to provide the residential demand load requirement in Shinchi-machi, Fukushima Prefecture [

9]. Shaqour et al. proposed an efficient control scheme and design for a hybrid renewable energy system consisting of PV, wind turbine generator, lead-acid battery, inverter, and control unit installed in a typical Japanese house located in Kasuga City, Fukuoka Prefecture [

10]. Guohong Wu et al. designed a hybrid microgrid energy system consisting of PV, wind, battery storage, and an electrical double-layered capacitor as secondary battery storage implemented at the Tagajo campus Tohoku Gakuin University, Japan [

11]. Sugimura et al. developed a hybrid energy microgrid system consisting of a PV, wind generator, and diesel generator as the primary power sources, with battery energy storage for Aguni Island, located in Okinawa, Japan. They investigated the operation schedule of both the battery system and diesel generator and the optimal system configuration in terms of capacity under the application of demand response programs [

12].

The output power of the proposed HRES varies on environmental variables such as solar irradiance, wind, and operating temperature. The maximum power point tracking (MPPT) control technique is mainly used to extract the maximum capable power of the HRES with respective solar irradiance, wind speed, and temperature at a particular instant of time point.

The MPPT controller will make use of nearly 100% of the available power. In recent years, there has been great interest in the study, improvement, and implementation of MPPT algorithms [

13]. MPPT aims to regulate the actual operating voltage of solar panels to the voltage at the MPP. For this purpose, MPPT adjusts the output power of the inverter or DC converter. If the PV output voltage is higher than the maximum power point voltage, then transferred power to the load or network is increased; otherwise, it is decreased. The MPPT methods can be classified into indirect and direct methods. The indirect methods, such as short-circuit and open-circuit methods, need a prior evaluation of the PV panel, or they are based on mathematical relationships or a database not valid for all operating meteorological conditions. Therefore, they cannot obtain exactly the maximum power of a PV panel at any irradiance and cell temperature. Conversely, the direct methods operate at any meteorological condition and act in real time on the voltage reference variable, corresponding to the maximum power provided by the PV system. MPPT can be realized in the wind power generation control by adjusting the power or torque command. The input of the control block is the rotor speed. The optimum power corresponding to this speed will be generated and will be passed to the outer power control block as the power command. Even though a few improvement methods have just been utilized for MPPT, different and new methods may prompt better outcomes and are suggested for future research. Many algorithms have been developed to efficiently track the maximum power point, such as incremental conductance (INC), hill climbing, or perturbation and observation (P&O) [

14]. Zhang et al. proposed a hybrid MPPT algorithm that combines an iterative learning controler (ILC) and P&O to extract maximum power from PV systems. In their research, the ILC was proposed to obtain the maximum power point (MPP) in steady-state operation under periodic long-term variations in irradiance and temperature, where the working power point oscillates near the MPP. A high-frequency P&O was proposed to overcome the ILC’s shortcomings under highly changing irradiance, improving the dynamic response under such conditions [

15]. Messalti et al. proposed and tested two new artificial neural network (ANN) MPPT controllers based on fixed and variable step size. The neural network was trained based on data collected, using the P&O algorithm for the offline phase of training, configuring the neural network, and using the ANN in a PV system [

16]. Ahmed and Salam introduced a modified P&O MPPT algorithm in order to reduce steady-state oscillations and decrease the occurrence of tracking direction errors for the P&O-based MPPT controller. They introduced a modified scheme that dynamically alters the perturbation size coupled with introducing a dynamic boundary condition to prevent divergence from the tracking locus, indicating about 1.1% improvement over the traditional P&O when there is a slow change in irradiance levels and about 12% increase in efficiency under fast irradiance changes [

17]. Mei et al. implemented a novel incremental-resistance MPPT with variable step size, addressing the advantages of the ILC-based MPPT. They reported a significant improvement in MPPT response speed and accuracy at the steady-state condition, with an extensive operating range [

18]. Sher et al. presented a hybrid MPPT algorithm that combines the fractional short circuit current (FSCC) measurement and the P&O algorithm. The two-stage algorithm proposed increases performance under changing weather conditions, and the reliability of the model under environmental scenarios was satisfactory with both software and experimental validation [

19].

Table 1 shows the recent MPPT techniques for PV and wind renewable energy systems.

As mentioned above, although there is substantial research concerning the different MPPT algorithms, there are two challenges with the application of them in HRES:

Most of them suffer from the drawback of being slow tracking, due to which the utilization efficiency is reduced.

Furthermore, intermittency, rapid irradiation, and temperature changes may cause the MPPT to be oscillating around one of the multiple local peaks of power.

1.2. What Will Be Elucidated in this Research

Based on the above discussion, this study aims to introduce a hybrid renewable energy system (HRES) equipped with an advanced MPPT, which is envisioned to be installed at Kyushu University’s Chikushi Campus in Kasuga, Japan (

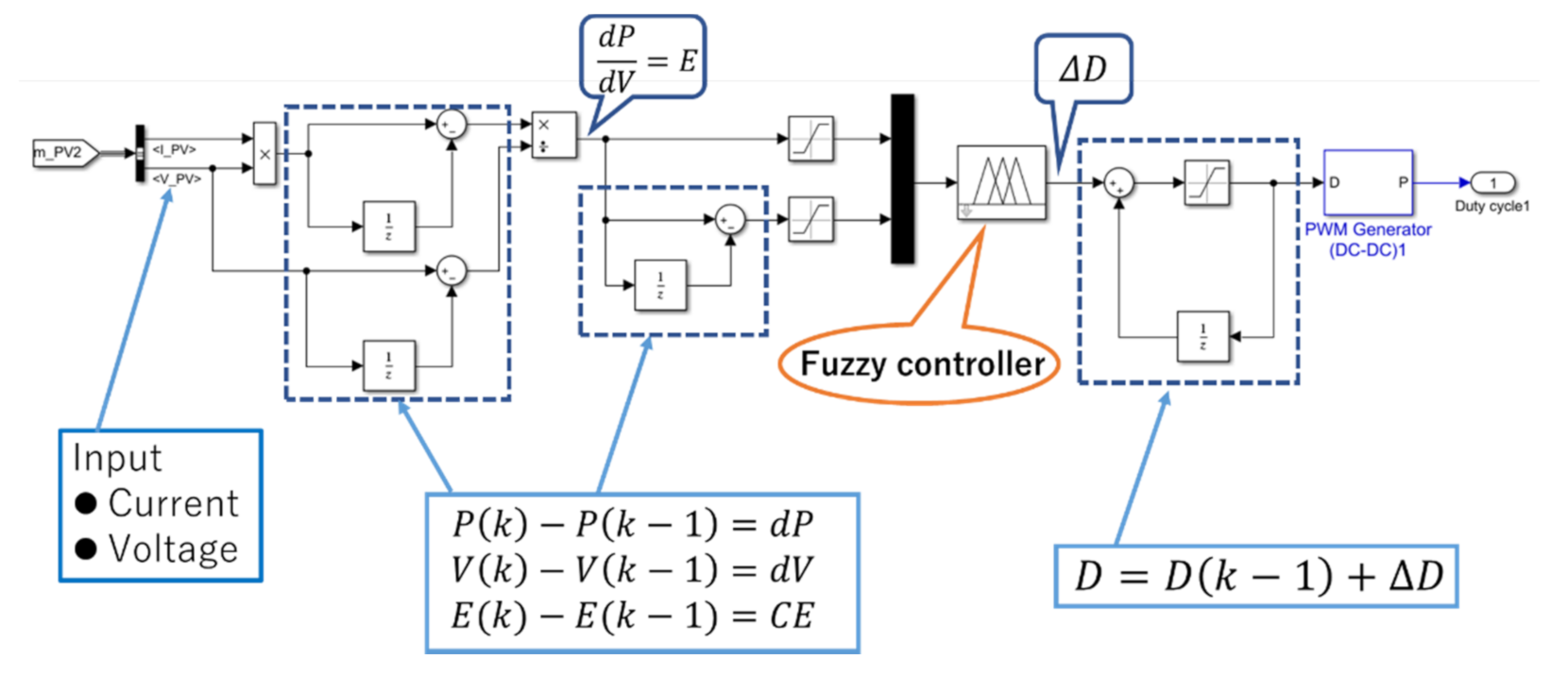

Figure 2). To overcome the drawbacks mentioned on the existing tracking systems, such as the P&O method, this study aims at introducing a MPPT system based on fuzzy logic control (FLC), which provides rapid control, and small oscillations once it reaches the MPP, under varying weather conditions. The proposed FLC-based MPPT controls the DC–DC converter, which is connected to the solar panel and wind turbine. The determination of input and output magnitude is the most notable feature of the FLC-based MPPT. The FLC determines the numerical input as a linguistic magnitude based on its own rules. It then selects the linguistic output corresponding to the linguistic information and finally converts it into an output value as a number. Thus, the FLC-based MPPT is faster and more accurate than other MPPT controllers, such as P&O, because it has the flexibility to change the magnitude of the output values depending on the position of the points, resulting in more power output from the HRES.

The research flow diagram in this paper is shown in

Figure 3. The first part of this research includes developing a detailed dynamic simulation performed in MATLAB Simulink to simulate the technical performance of the PV arrays and wind turbine, which are equipped with the FLC-based MPPT. The Simulink is used to evaluate the effectiveness of the FLC-based MPPT in rapid tracking of the MPP and extracting surplus power from the HRES, compared with a conventional P&O-based MPPT. The detailed meteorological data used in this study are collected from the Japan Meteorological Agency for Fukuoka City.

The second part of the study discusses a detailed techno-economic analysis (TEA) of the proposed HRES, including the hydrogen production and storage components. TEA is used to find the optimal configuration of the HRES and verify the balance of electricity and hydrogen generation for securing the operation feasibly during the system’s lifetime. Furthermore, it addresses the role of the FLC-based MPPT in reducing the levelized cost of electricity (LCOE) of the proposed HRES and, finally, the impact of the future costs of each component (solar, wind, fuel Cell) on the LCOE in 2030 will be evaluated.